MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 681 of 1273

MANUAL TRANSAXLE

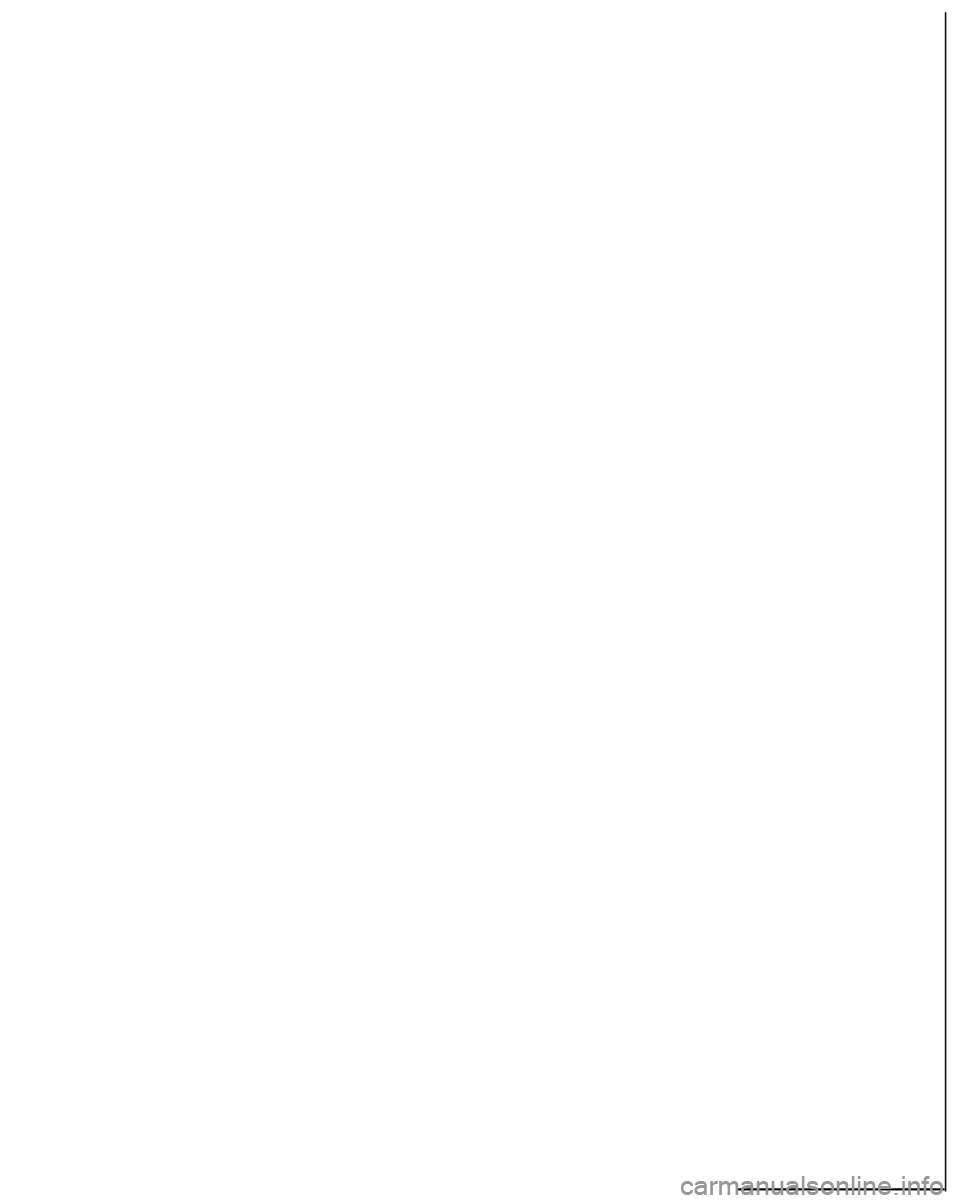

SPECIAL TOOLSMZSDA-

ToolNumberNameI Use

w

MB99

1193

r

PlugPrevention of entry of foreign objects into

the transaxle and transfer

L

MD998803Differential 011 sealInstallation of differential oil seal

t&-

installer

MD998304-0 1Oil seal installer Installation of front output shaft bearing and

transfer extention

housing oil seal

TROUBLESHOOTING

Refer to P.22-3.

M22EAAE

SERVICE ADJUSTMENT PROCEDURES

TRANSAXLE OIL LEVEL INSPECTIONm

Refer to GROUP 00-Maintenance Service.

\ //’ 09AOO24

Page 682 of 1273

22-18 MANUAL TRANSAXLE

I I09K567

09K56f

For L.H.For R.H.

Dust

5

-

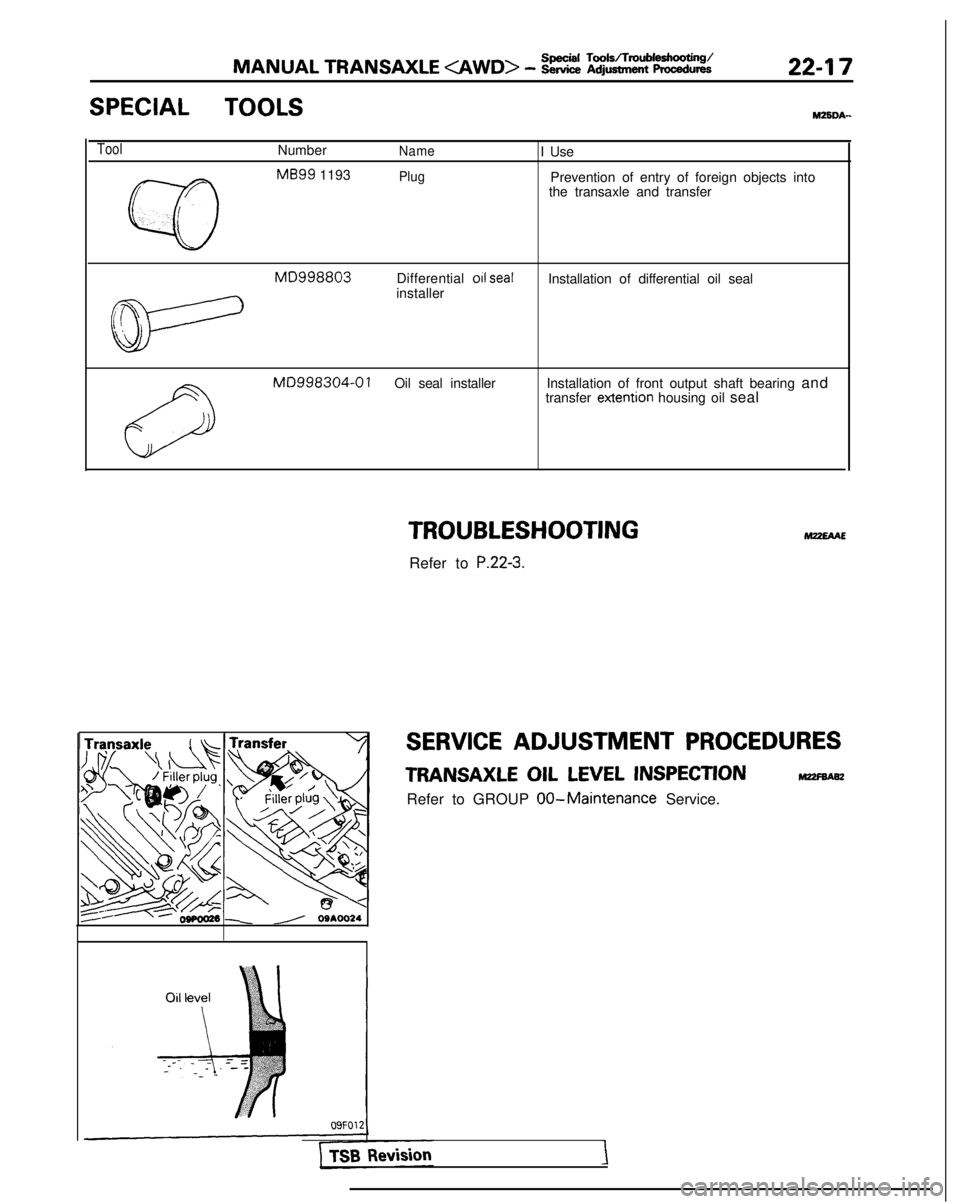

TRANSAXLE OIL REPLACEMENTM22FC.AH

(1) Position vehicle on a flat level and remove filler and drain

plugs to drain transaxle oil.

(2) Pour in fresh transaxle oil through filler port until it reaches the bottom of filler port.

Transaxle oil:Hypoid gear oil SAE 75W-85W conform-

ing to API classification GL-4 or higher

Transaxle: 2.3

dm3 (2.4 qts.)

Transfer: 0.6 dm3 (.6 qt.)

DRIVE SHAFT OIL SEALS REPLACEMENT MZZFDAH

(1) Disconnect the drive shaft from the transaxle. (Refer to GROUP

26-Drive Shaft.)

(2) Remove the transfer assembly.

(3) Using a flat-tip (-)

screwdriver, remove the oil seal.

(4) Install the oil seals using the following procedure:

Using the special tool, tap the oil seal into the transaxle.

Note that there are two types of oil seals, one for R.H. and

the other for L.H., and the shape of each type is different,

as shown.

1 TSB Revision

Page 683 of 1273

MANUAL TRANSAXLE

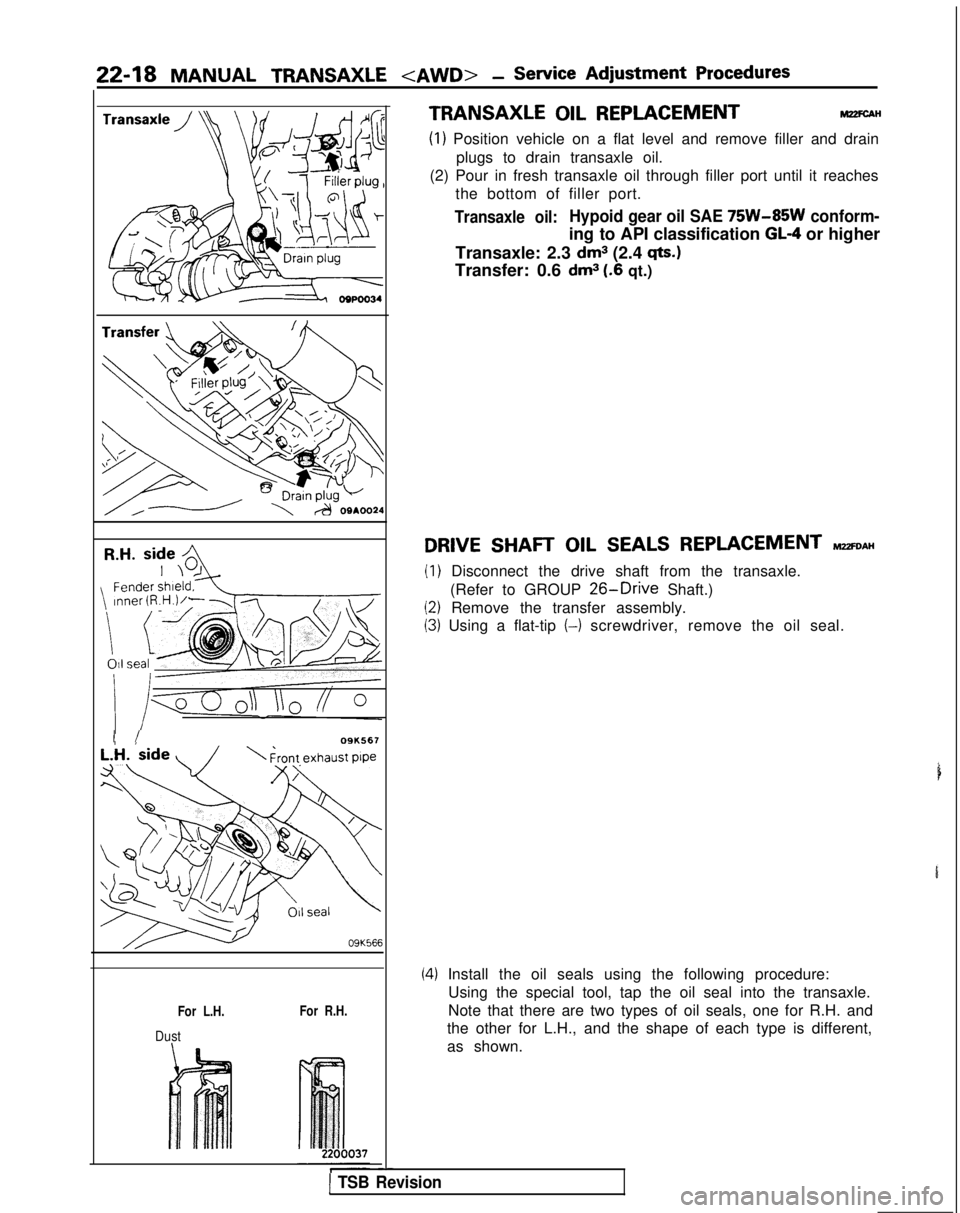

IL.H. side _

MC;998~3 / ()

TRANSFER OIL SEAL REPLACEMENThl22FGAF

(1) Pull out the propeller shaft from the transaxle. (Refer toGROUP

25-Propeller Shaft.)

(2) Using a fiat-tip (-) screwdriver, remove the oil seal.

(3) Using the special tool, tap the drive shaft oil seal into the transaxle.

(4) Apply a coating of the transaxle.

Transaxle oil:Hypoid gear oil SAE 75W-85W conform-

ing to API classification GL-4 or higher

SPEEDOMETER CABLE REPLACEMENT ~22~

Refer to P.22-5.

TRANSAXLE CONTROL

M22JA.B

Refer to

P.22-6.

SHIFT LEVER ASSEMBLYMZZGE-8

Refer to P.22-9.

TSB Revision

Page 684 of 1273

22-20MANUAL TRANSAXLE

TRANSAXLE

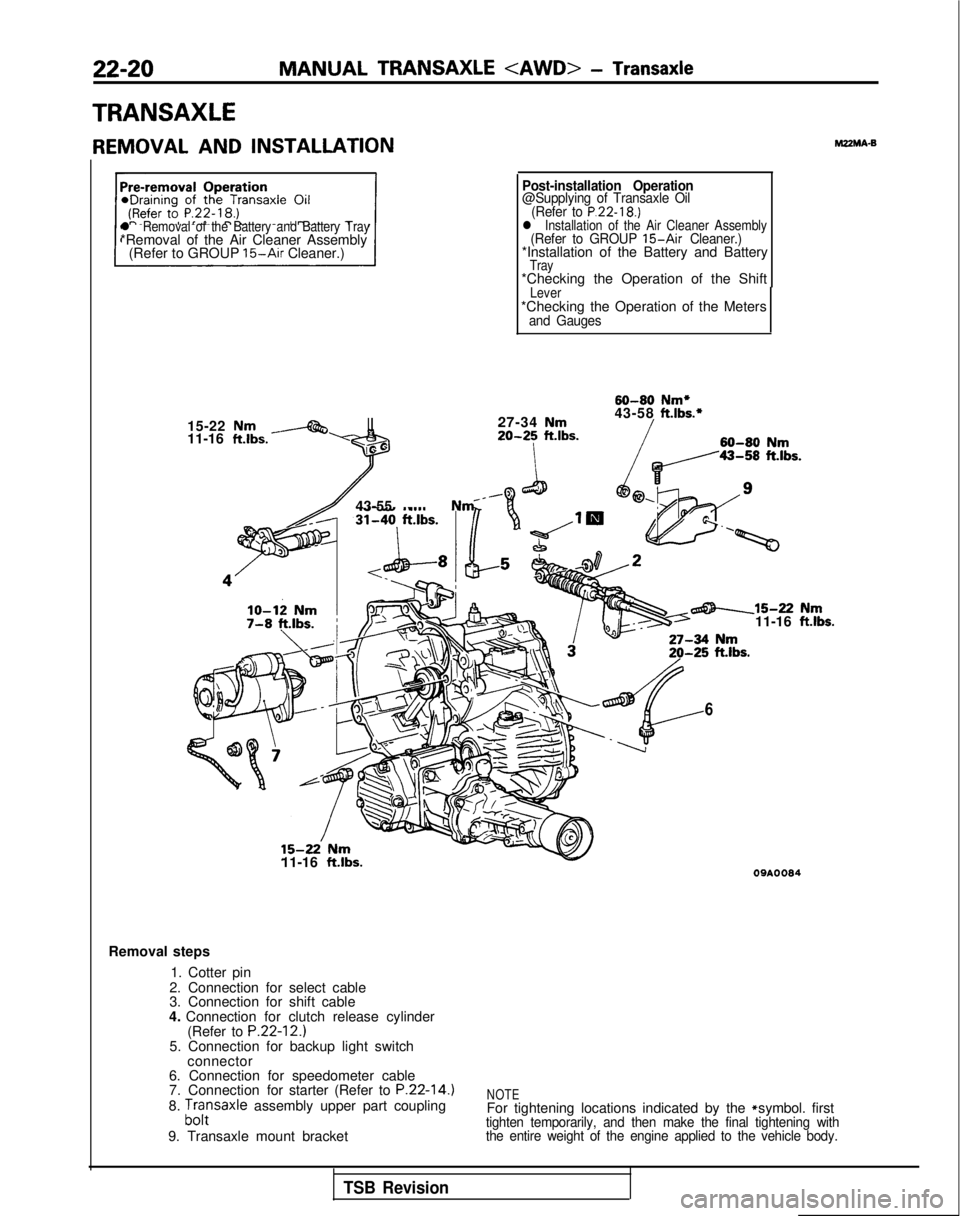

REMOVAL AND INSTALLATIONMZMA-B

l Removal of the Battery and Battery Tray*Removal of the Air Cleaner Assembly

(Refer to GROUP 15-Air Cleaner.)

15-22

Nm11-16 ft.lbs.-

lo-12 Nm7-8 ft.lbs.;

Post-installation Operation@Supplying of Transaxle Oil (Refer to P.22-18.)l Installation of the Air Cleaner Assembly(Refer to GROUP 15-Air Cleaner.)*Installation of the Battery and BatteryTray*Checking the Operation of the ShiftLever*Checking the Operation of the Metersand Gauges

60-80

Nm*

27-34

Nm43-58ft.lbs.*

20-25ft.lbs.60-80Nm

43-55 Nm _

15-22’ Nm11-16 ft.lbs.

6

-15-22 Nm11-16 ftlbs.

09AOOS4

Removal steps

1. Cotter pin

2. Connection for select cable

3. Connection for shift cable

4. Connection for clutch release cylinder (Refer to

P.22-12.)5. Connection for backup light switchconnector

6. Connection for speedometer cable

7. Connection for starter (Refer to

P.22-14.)8. ;,,:saxle assembly upper part coupling

9. Transaxle mount bracketNOTEFor tightening locations indicated by the * symbol. firsttighten temporarily, and then make the final tightening with

the entire weight of the engine applied to the vehicle body.

TSB Revision

Page 685 of 1273

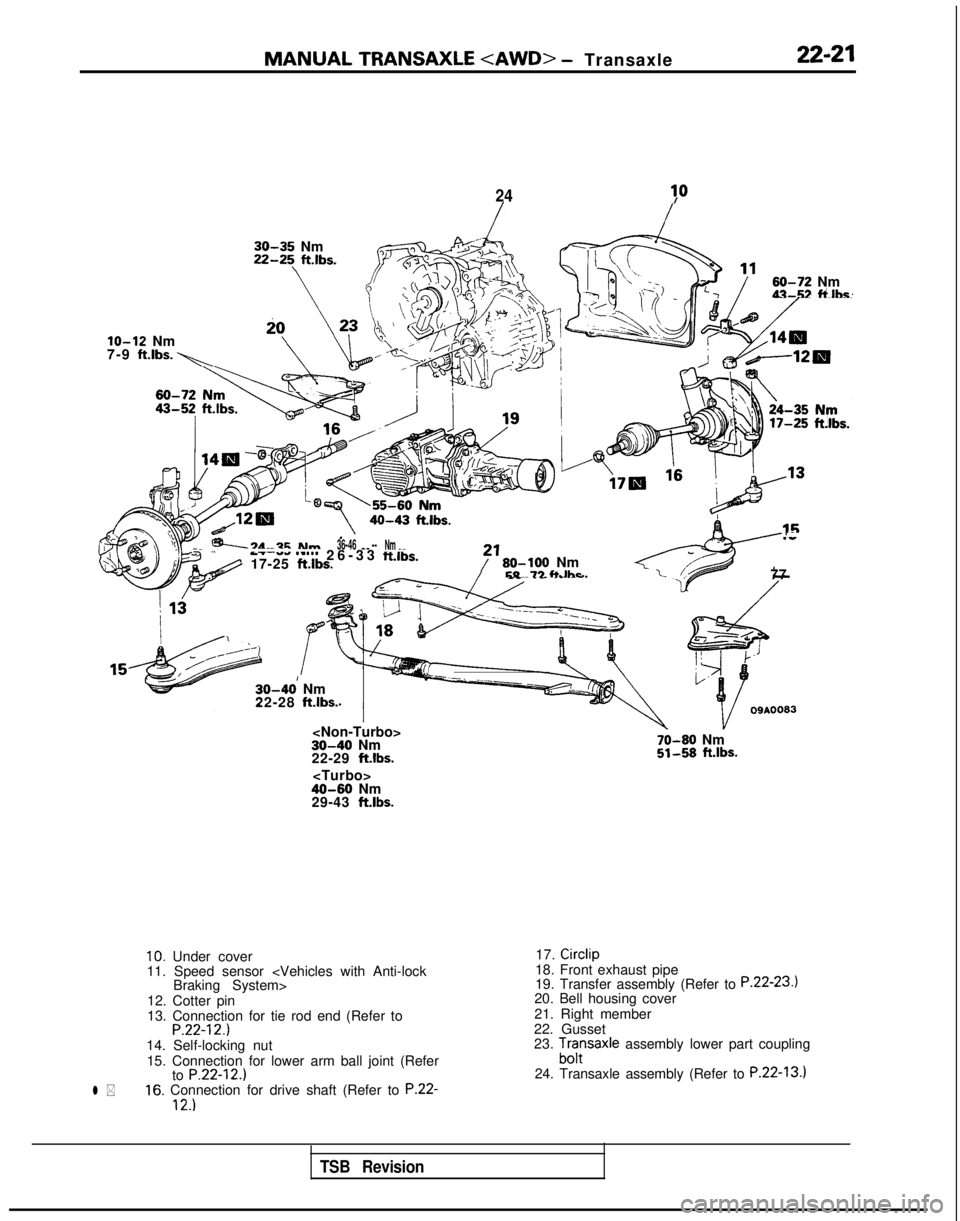

MANUAL TRANSAXLE

- Transaxle22-21

2430

30-35 Nm 22-25\

ftlbs.

-.

60-72 Nm\‘I..-\)43-52 ti.lhe~

lo-12 Nm

7-9 ft.lbs. 1

40-43 ftlbs..-3d-2FNm

--A 17-25 ft.lbs.

36-46 -_ --Nm _ _.-7.--.--l ‘-“’ 26-33

ftlbs.,f ’

80-106

NmEQ-73 fi Ihr77

30-40’ Nm

22-28 ft.lbs.

22-29 ftlbs.

70-80 Nm51-58 ft.lbs.

29-43 ft.lbs.

l *

10. Under cover

11. Speed sensor

12. Cotter pin

13. Connection for tie rod end (Refer to

P.22-12.)14. Self-locking nut 15. Connection for lower arm ball joint (Refer to

P.22-12.)16. Connection for drive shaft (Refer to P.22-12.)

17. Circlip

18. Front exhaust pipe

19. Transfer assembly (Refer to

P.22-23.120. Bell housing cover

21. Right member

22. Gusset

23.

;f;saxle assembly lower part coupling

24. Transaxle assembly (Refer to

P.22-13.1

TSB Revision

Page 686 of 1273

MANUAL TRANSAXLE

“\

)I

wb

I 1

\

I

1

M#

\\11Aoooo

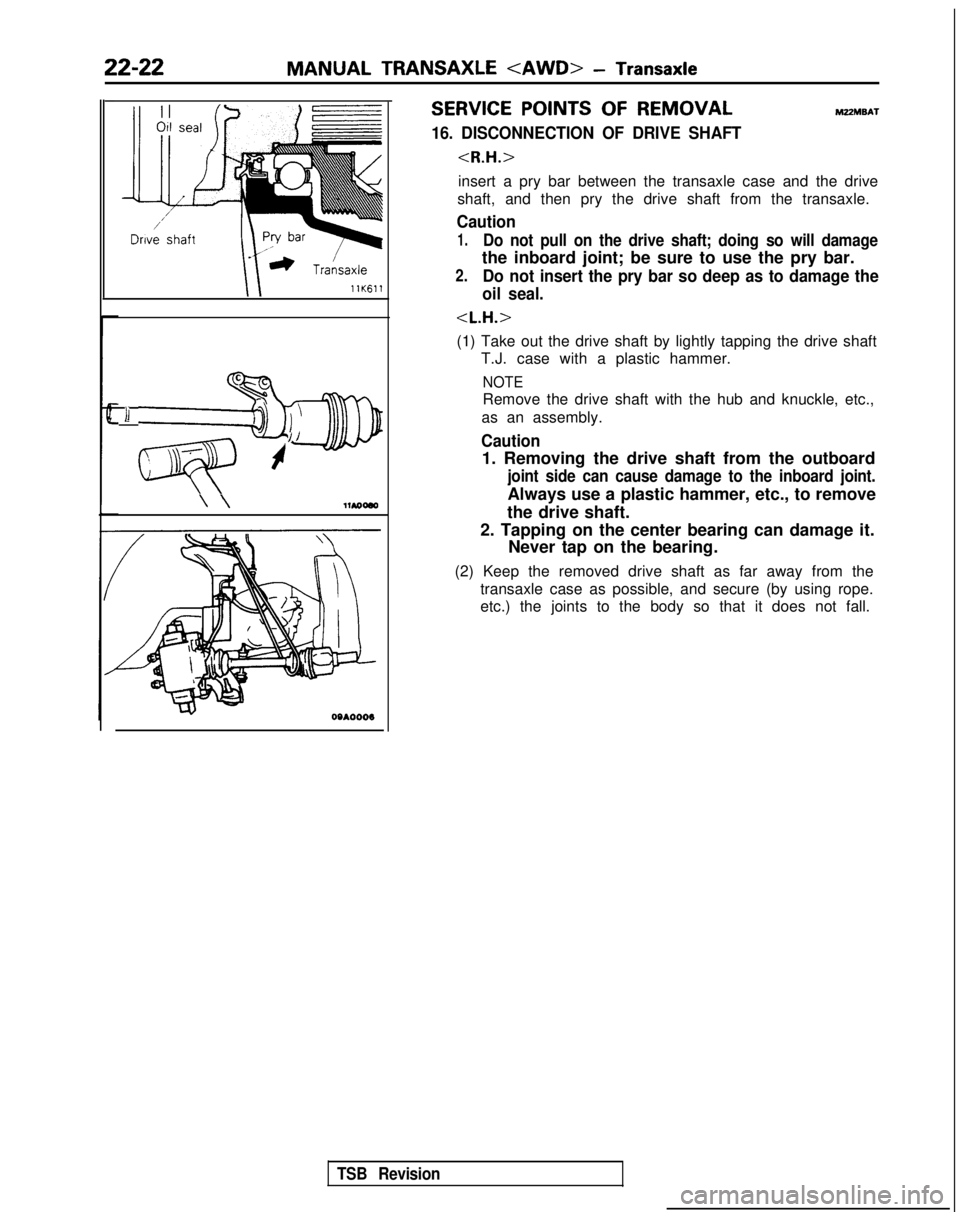

SERVICE POINTS OF REMOVALM22MBAT

16. DISCONNECTION OF DRIVE SHAFT

insert a pry bar between the transaxle case and the drive

shaft, and then pry the drive shaft from the transaxle.

Caution

1.Do not pull on the drive shaft; doing so will damage

the inboard joint; be sure to use the pry bar.

2.Do not insert the pry bar so deep as to damage the

oil seal.

(1) Take out the drive shaft by lightly tapping the drive shaft T.J. case with a plastic hammer.

NOTE

Remove the drive shaft with the hub and knuckle, etc.,

as an assembly.

Caution

1. Removing the drive shaft from the outboard

joint side can cause damage to the inboard joint.

Always use a plastic hammer, etc., to remove

the drive shaft.

2. Tapping on the center bearing can damage it. Never tap on the bearing.

(2) Keep the removed drive shaft as far away from the transaxle case as possible, and secure (by using rope.

etc.) the joints to the body so that it does not fall.

TSB Revision

Page 687 of 1273

MANUAL TRANSAXLE

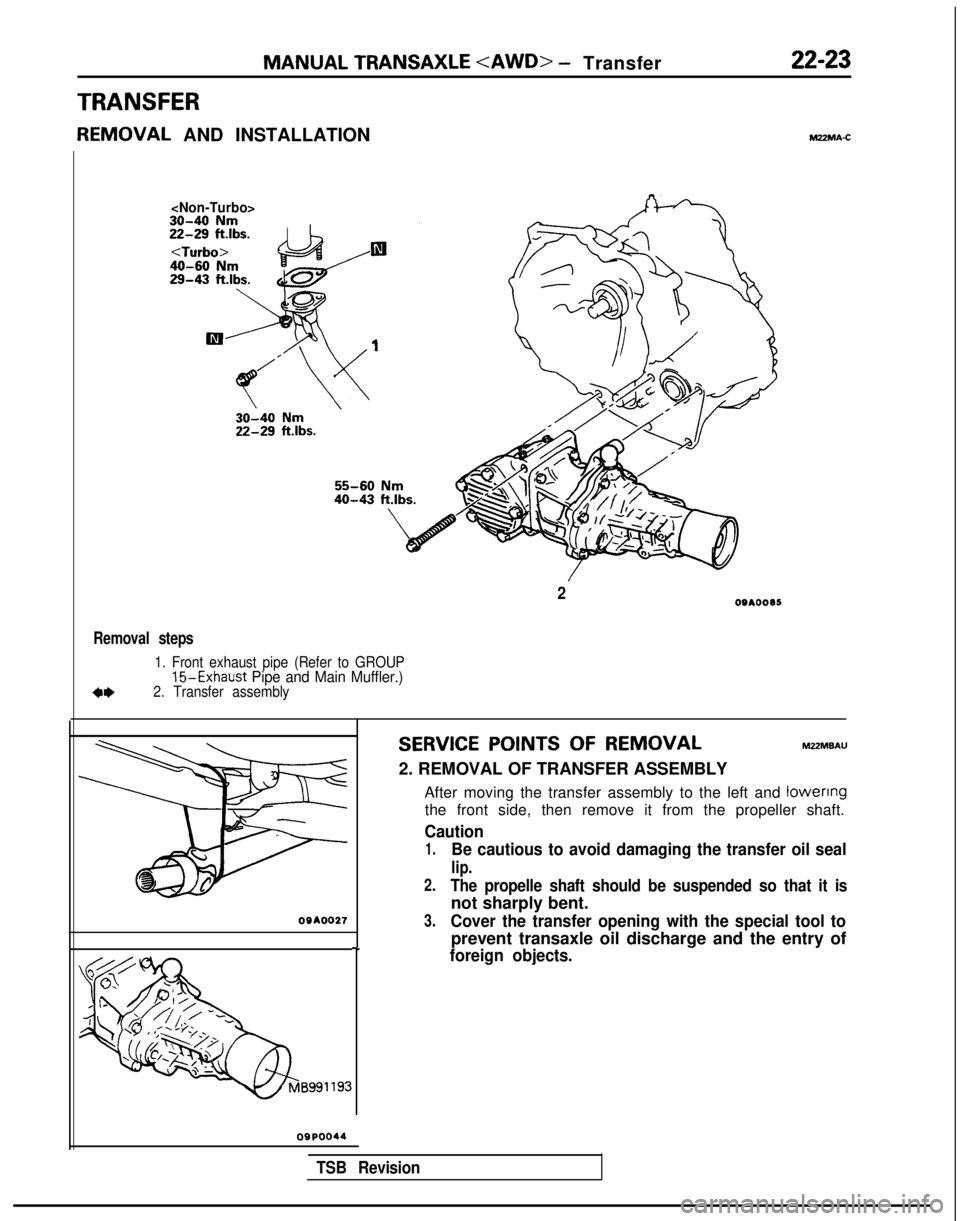

TRANSFER

REMOVAL AND INSTALLATION

22-23M22MA.C

Removal steps

1. Front exhaust pipe (Refer to GROUP15-Exhaust

Pipe and Main Muffler.)2. Transfer assembly

SERVICE POINTS OF REMOVAL MZZMBAU

2. REMOVAL OF TRANSFER ASSEMBLY After moving the transfer assembly to the left and lowenng

the front side, then remove it from the propeller shaft.

Caution

1.Be cautious to avoid damaging the transfer oil seal

lip.

2.The propelle shaft should be suspended so that it is

not sharply bent.09AOO273.Cover the transfer opening with the special tool to

prevent transaxle oil discharge and the entry of-Iforeign objects.

20910095

OQPOO44

TSB Revision

Page 688 of 1273

NOTES

Page 689 of 1273

23-1

AUTOMATIC

TRANSAXLE

CONTENTShl23AA-

GENERALINFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICEADJUSTMENTPROCEDURES.....

Drive Shaft OilSealsReplacement...........

KeyInterlockMechanismCheck............... Kickdown

ServoAdjustment ......................

Line Pressure Adjustment .........................

Park/Neutral Position Switch

Adjustment

............................................................

ReducingPressure Adjustment .................

Selector LeverOperation

Check...............

Shift

LockMechanismCheck....................

Speedometer

CableReplacement .............

Throttle-position Sensor Adjustment ..........

TransaxleFluidLevelInspection ...........i...

TransaxleFluidReplacement .....................

Transfer

Oil LevelInspection .....................

Transfer

OilReplacement ..........................

SPECIAL

TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . .21

SPECIFICATIONS ...........................................19

General Specifications

................................19

Lubricants....................................................20

Torque Specifications .................................20

2TRANSAXLEASSEMBLY

82

92

83

86

88

84

91

83

84

93

92

82

82

82

82

TRANSAXLEASSEMBLY

TRANSAXLE CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

TRANSAXLE OIL

COOLERHOSES . . . . . . . . . . . . .100

TRANSFER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . . . . . . . . .108

TROUBLESHOOTING

....................................

CircuitDiagram...........................................

Converter Stall Test ...................................

Datalink

andTest................................................

E.L.C. 4-speed Automatic Transaxle

ControlComponents

Layout

......................

Element in Use at Each Position

of Selector Lever .......................................

Fail-safe Item ..............................................

Fault Code Description ...............................

OilPressure Tests

.....................................

Shift Patterns ..............................................

Transaxle

Control........................................

22

60

59

26

80

37

32

28

52

37 59

Page 690 of 1273