MITSUBISHI GALANT 1989 Service Repair Manual

GALANT 1989

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57312/w960_57312-0.png

MITSUBISHI GALANT 1989 Service Repair Manual

Trending: lock, warning lights, brakes, diagram, width, set clock, fuel pump

Page 631 of 1273

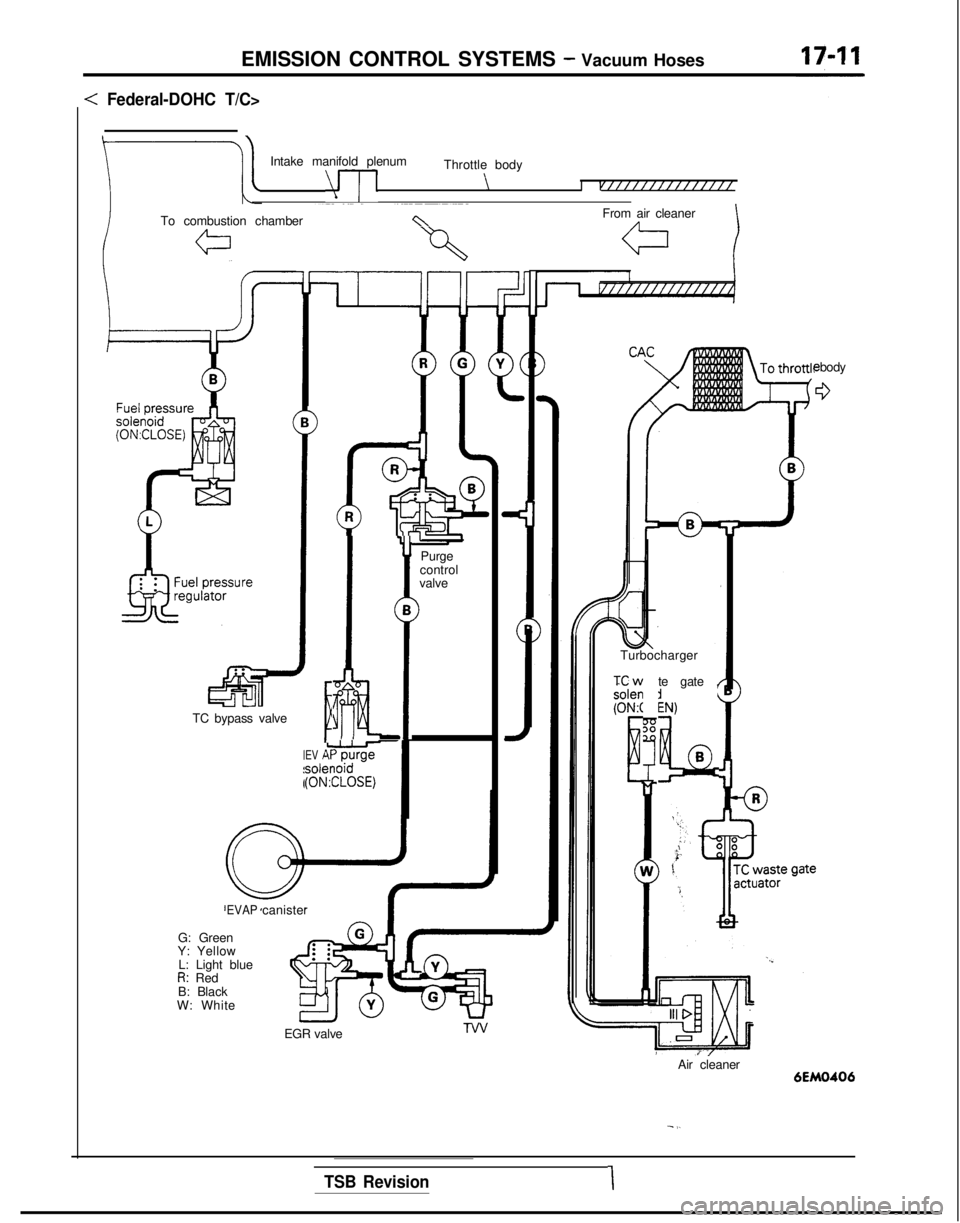

EMISSION CONTROL SYSTEMS - Vacuum Hoses

: Federal-DOHC T/C>

Intake manifold plenum

\--p

Throttle body

\I vff/ffffffffffff

ITo combustion chamberc\From air cleaner

a

e body

0

l5Bii-TC bypass valve

Y

Purge

control

valve B

>

1.fi. .

EV ALi1;o?psoler(ON3ZLOSEi)

EVAPcanister

Turbocharger

ixw solen

(ONA

E

te gate ,

:N,

!4Q

B

G: Green

Y: Yellow

L: Light blue

R: Red

B: Black

W: White

EGR valve

Air cleaner

6EM0406

- I.

TSB Revision1

Page 632 of 1273

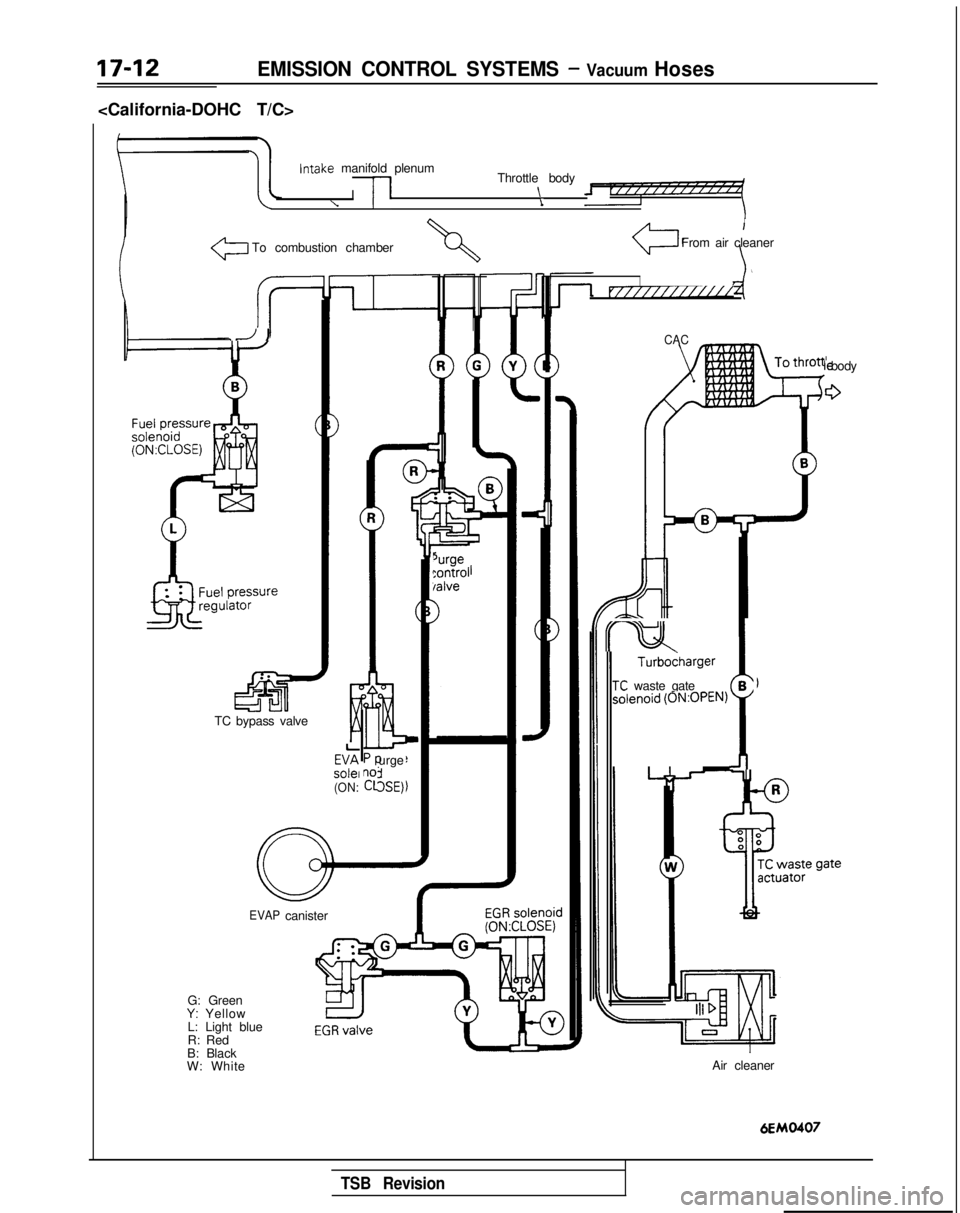

EMISSION CONTROL SYSTEMS - Vacuum Hoses

Intake

manifold plenum

I

/I

Throttle body \

\i

To combustion chamber

I

From air cleaner

IVI////////////

.J JCAC

le body

G

Turbodharger

TC waste gateB

- ;

Sl

slenoid

(0N:OPEN)

urge

:SE)

‘urge:ontrol /alve

TC bypass valve EV?

solei

(ON:

EVAP

canister

G: Green

Y: Yellow

L: Light blue

R: Red

B: Black

W: White Air cleaner

6EMO407

TSB Revision

Page 633 of 1273

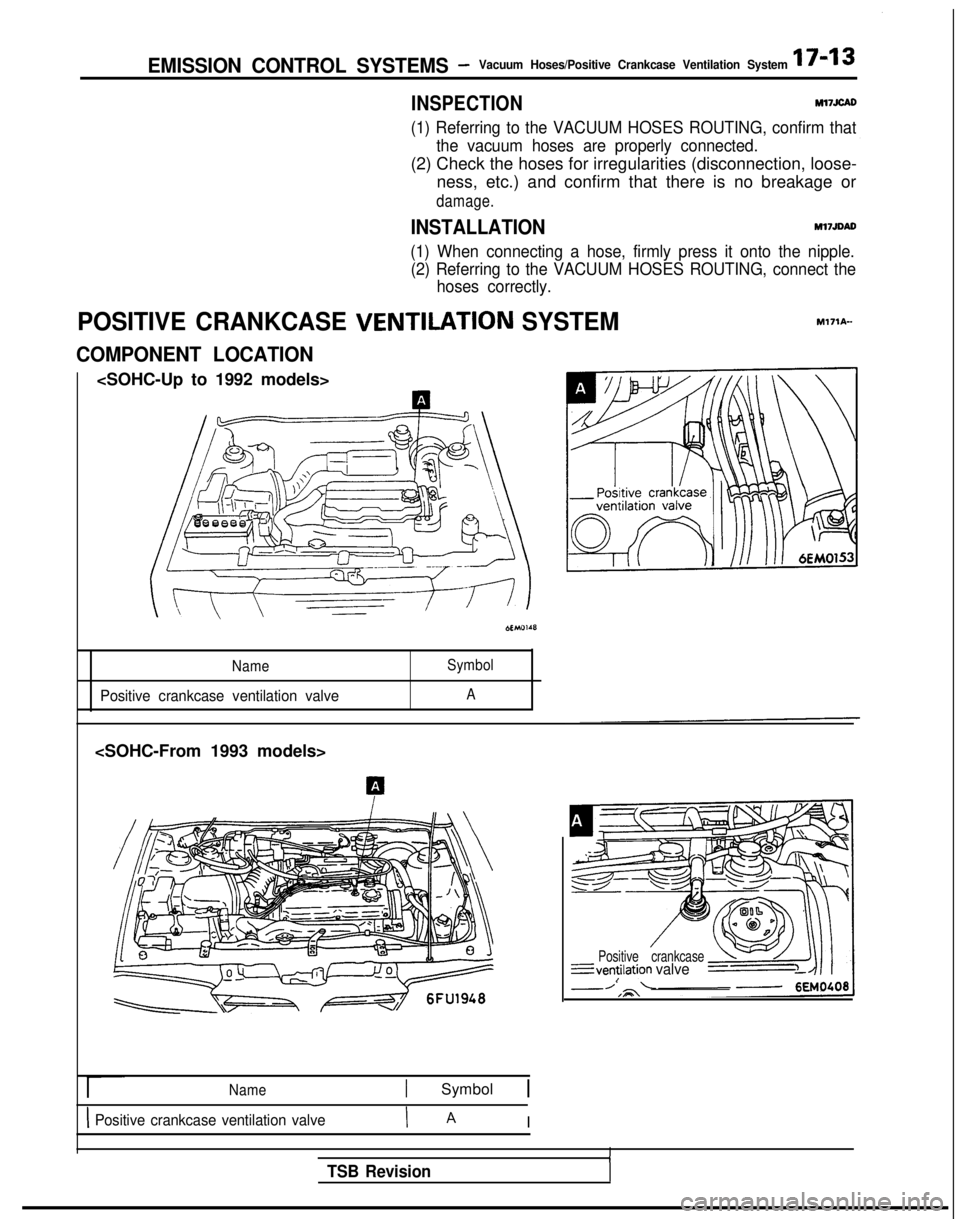

EMISSION CONTROL SYSTEMS -Vacuum Hoses/Positive Crankcase Ventilation System17-13

INSPECTIONMl7JcAo

(1) Referring to the VACUUM HOSES ROUTING, confirm thatthe vacuum hoses are properly connected.

(2) Check the hoses for irregularities (disconnection, loose-ness, etc.) and confirm that there is no breakage or

damage.

INSTALLATION Ml7JDAD

(1) When connecting a hose, firmly press it onto the nipple.

(2) Referring to the VACUUM HOSES ROUTING, connect the hoses correctly.

POSITIVE CRANKCASE VENTILATION SYSTEMM171A-

COMPONENT LOCATION

Name Symbol

Positive crankcase ventilation valveA

Name1 Symbol 1

1 Positive crankcase ventilation valveI A I

Positive crankcase---ventilation

valveI

ITSB Revision

Page 634 of 1273

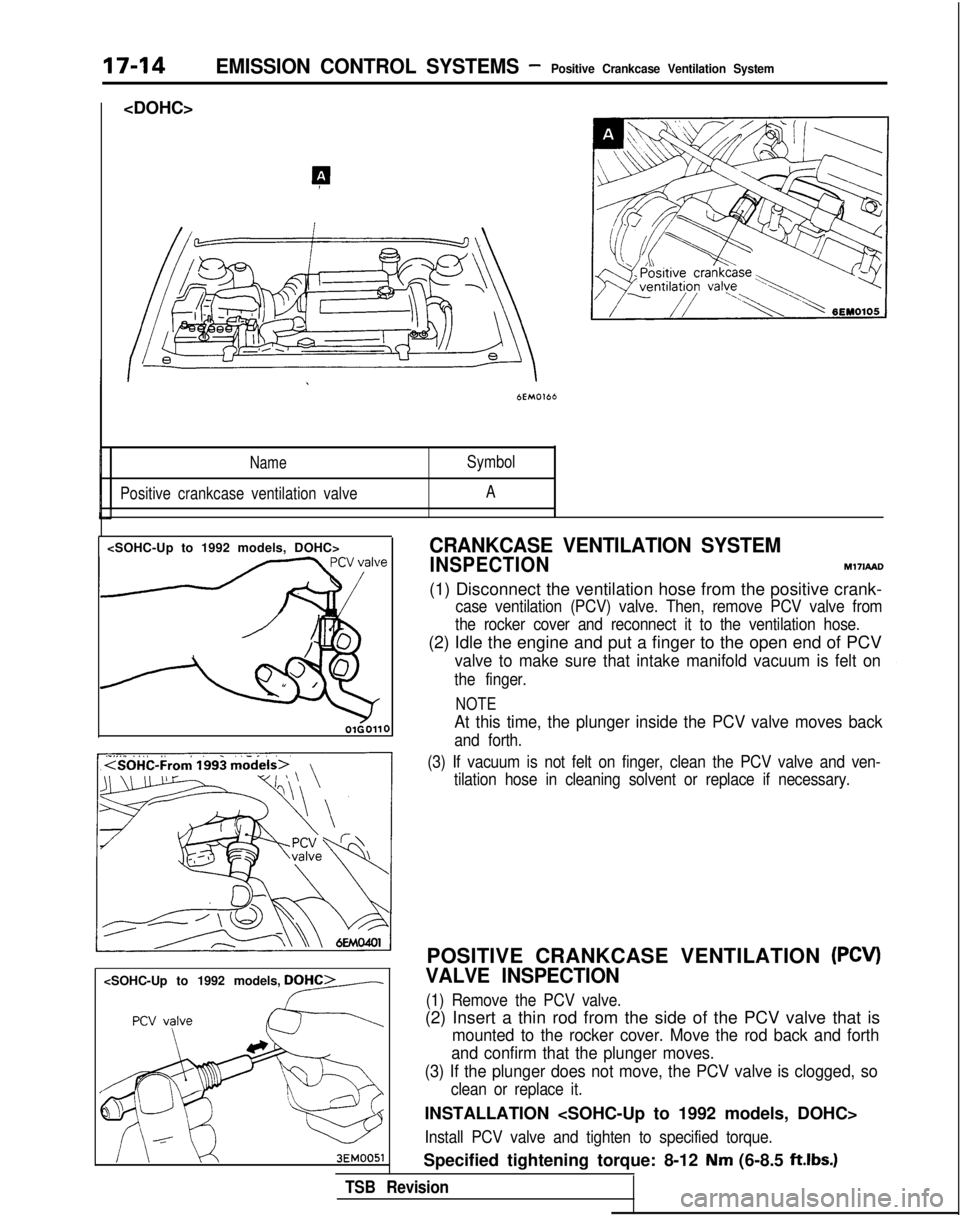

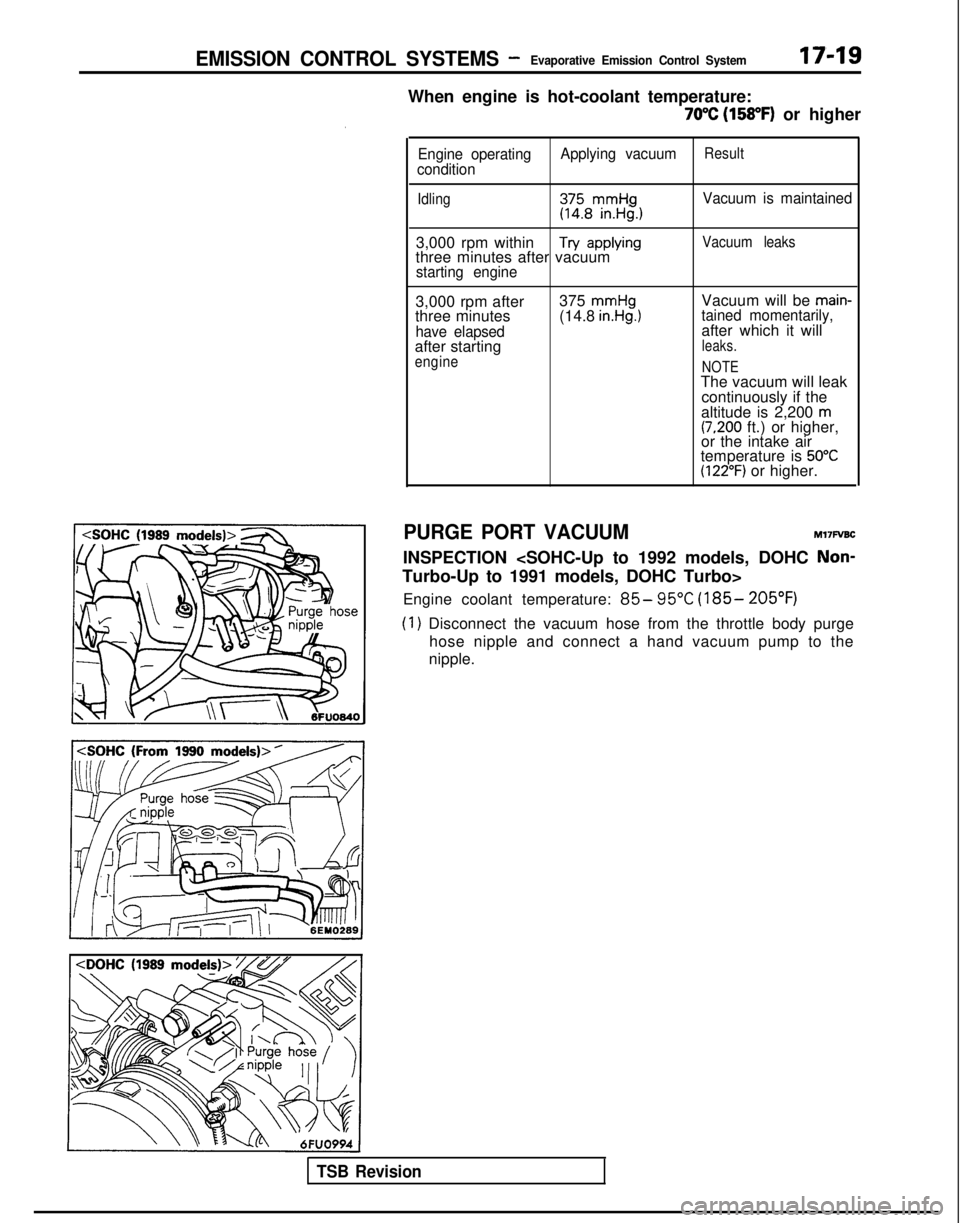

17-14EMISSION CONTROL SYSTEMS -Positive Crankcase Ventilation System

NameSymbol

Positive crankcase ventilation valve A

OlGOllO

CRANKCASE VENTILATION SYSTEM

INSPECTIONM17IAAO

(1) Disconnect the ventilation hose from the positive crank-

case ventilation (PCV) valve. Then, remove PCV valve from

the rocker cover and reconnect it to the ventilation hose.

(2) Idle the engine and put a finger to the open end of PCV

valve to make sure that intake manifold vacuum is felt on

the finger.

NOTE

At this time, the plunger inside the PCV valve moves back

and forth.

(3) If vacuum is not felt on finger, clean the PCV valve and ven- tilation hose in cleaning solvent or replace if necessary.

POSITIVE CRANKCASE VENTILATION (PCV)

VALVE INSPECTION

(1) Remove the PCV valve.

(2) Insert a thin rod from the side of the PCV valve that is

mounted to the rocker cover. Move the rod back and forth

and confirm that the plunger moves.

(3) If the plunger does not move, the PCV valve is clogged, so

clean or replace it.

INSTALLATION

Install PCV valve and tighten to specified torque.

Specified tightening torque: 8-12 Nm (6-8.5 ftlbs.)

TSB Revision

Page 635 of 1273

EMISSION CONTROL SYSTEMS -Positive Crankcase Ventilation System/

Evaporative emission Control System17-15

_

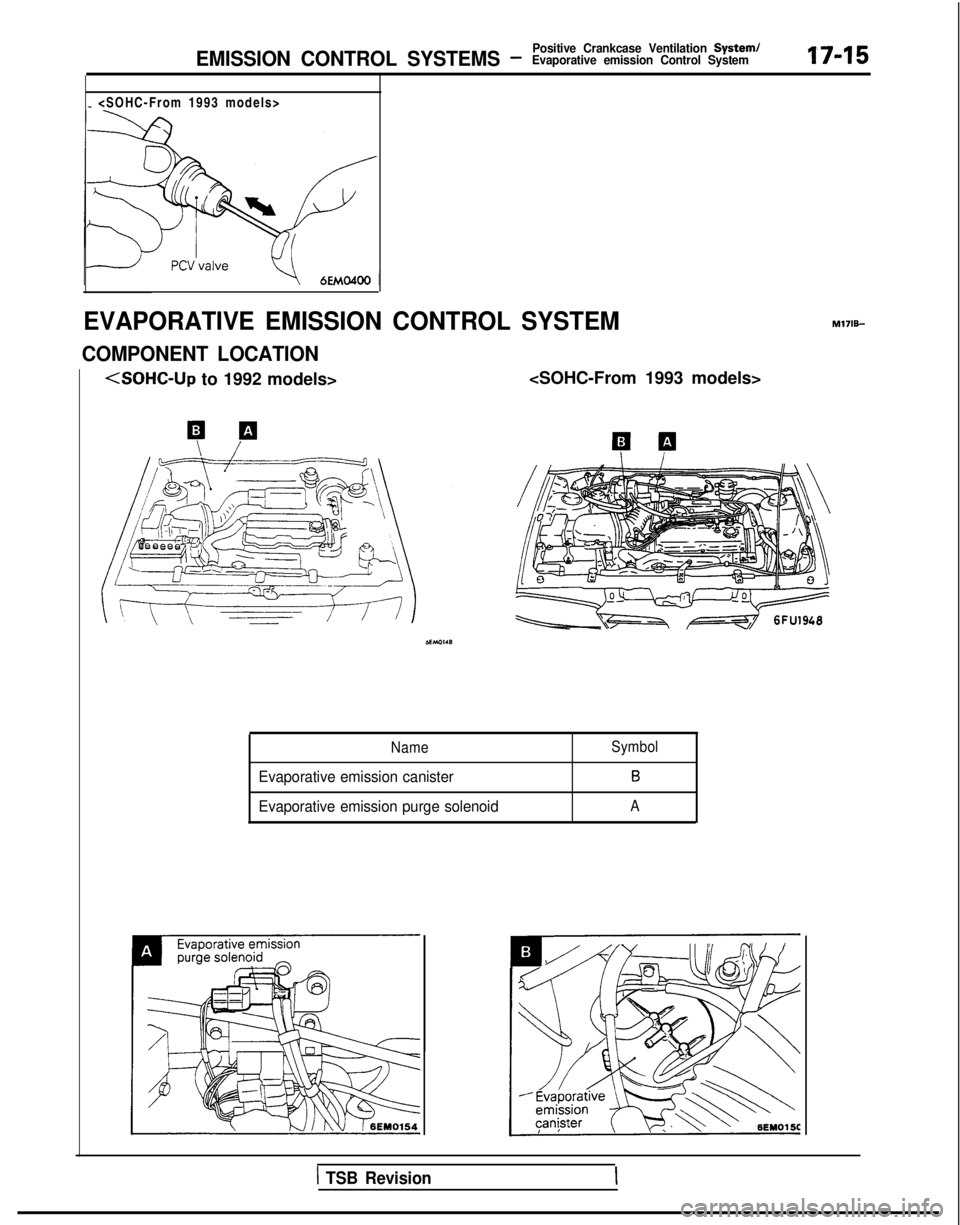

EVAPORATIVE EMISSION CONTROL SYSTEM

COMPONENT LOCATION M171B-

to 1992 models>

Name

Evaporative emission canister

Evaporative emission purge solenoid

Symbol

B

A

1 TSB Revision

Page 636 of 1273

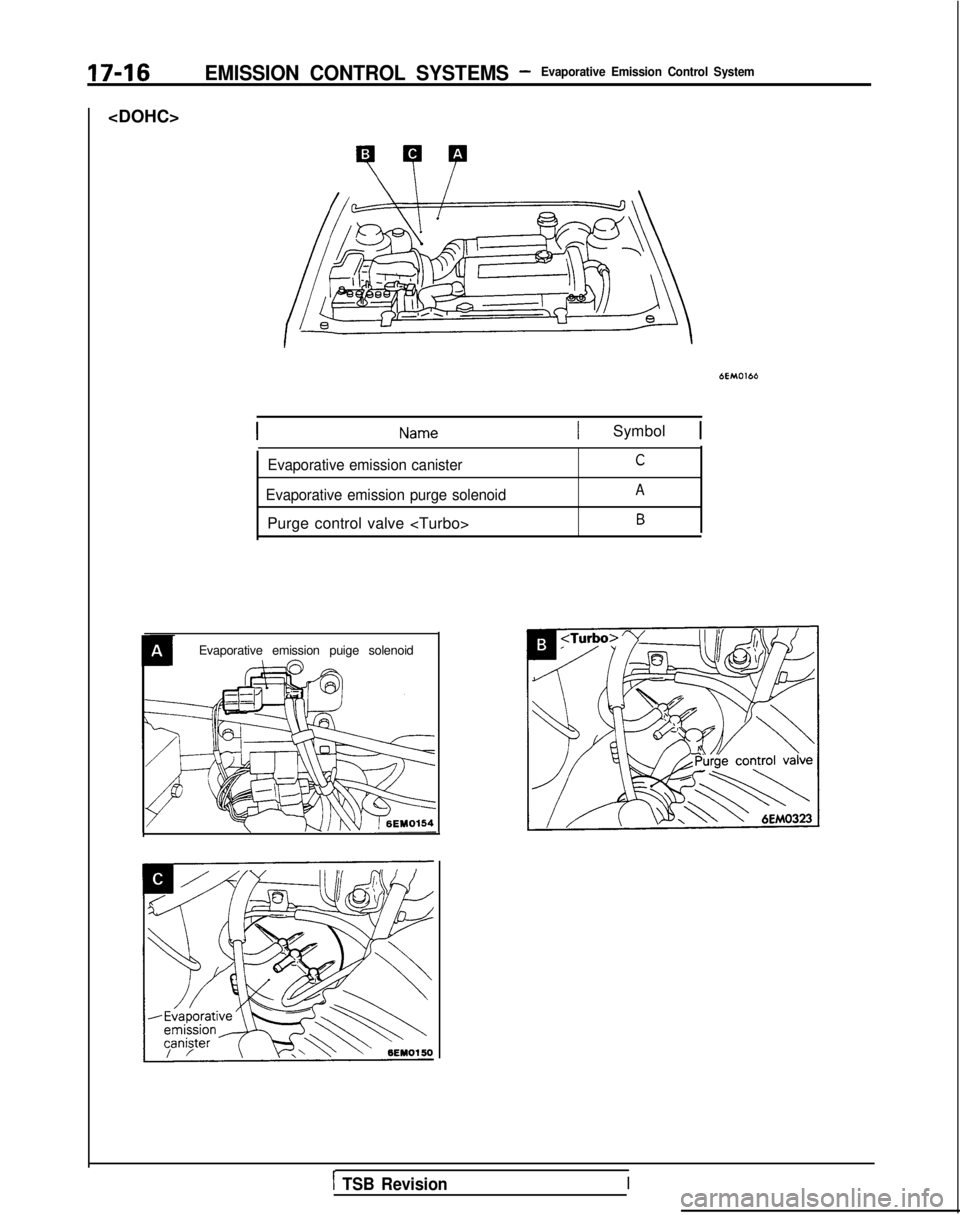

17-16EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

6EM0166

1 Symbol 1

Evaporative emission canisterC

Evaporative emission purge solenoidA

Purge control valve B

Evaporative emission puige solenoid

1 TSB RevisionI

Page 637 of 1273

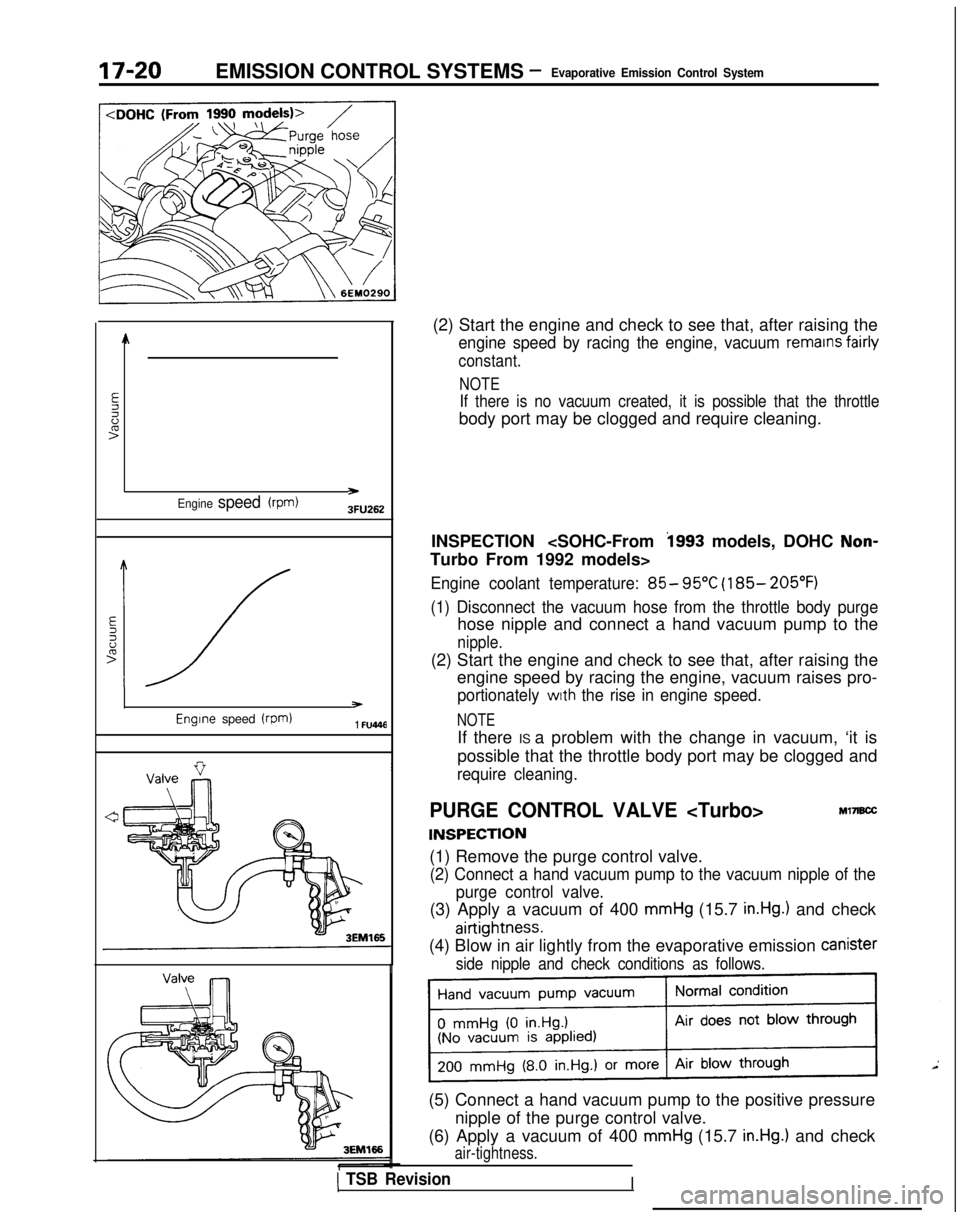

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System17-17

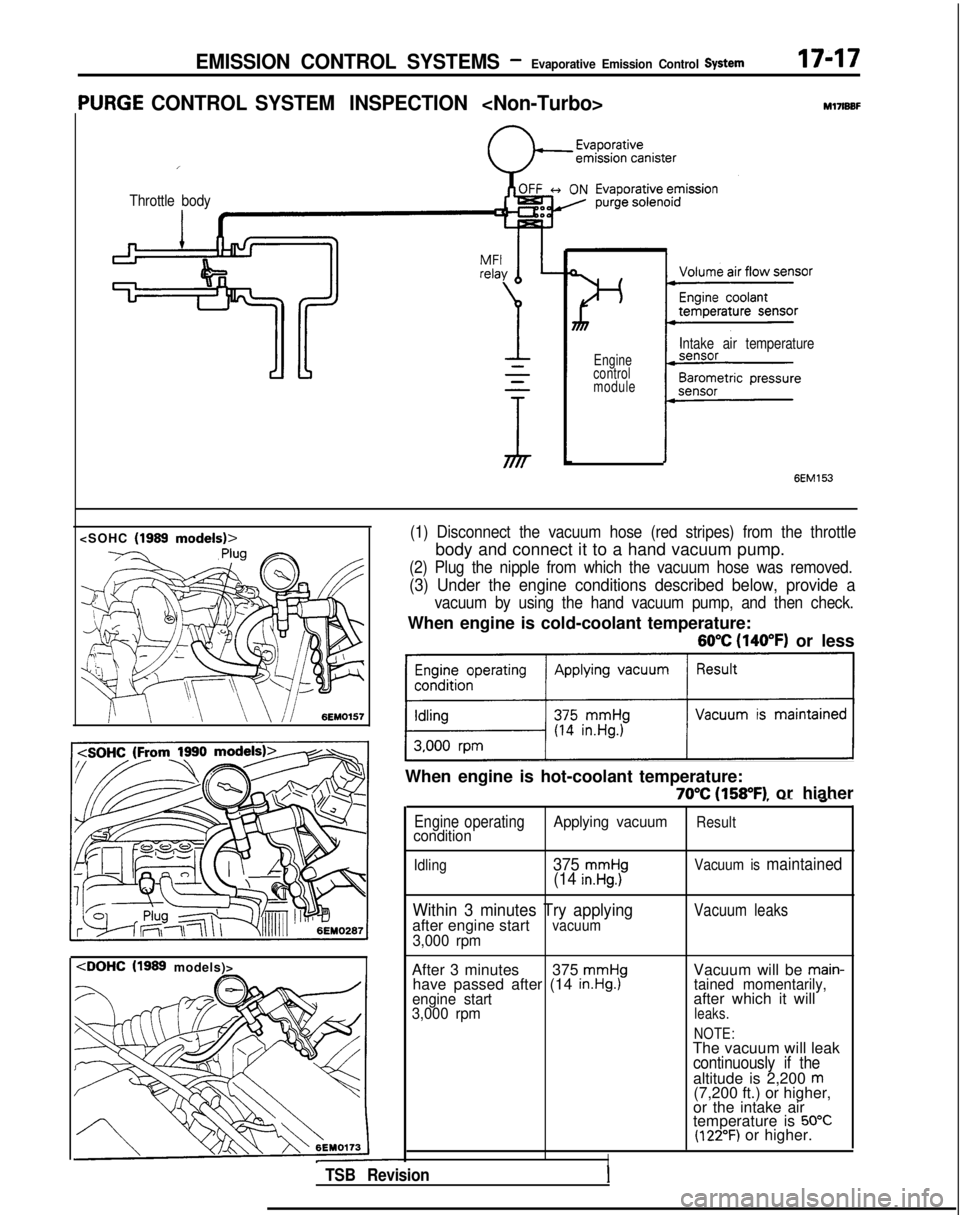

‘URGE CONTROL SYSTEM INSPECTION

I

Throttle body

M17lBBF

Engine

control

module

Intake air temperature

(1999

models)>

6EM153

(1) Disconnect the vacuum hose (red stripes) from the throttle

body and connect it to a hand vacuum pump.

(2) Plug the nipple from which the vacuum hose was removed.

(3) Under the engine conditions described below, provide a

vacuum by using the hand vacuum pump, and then check.

When engine is cold-coolant temperature:

60°C (140°F) or less

~1

When engine is hot-coolant temperature:

70°C (158°F) or hiaher, -- ---~“----

Engine operatingApplying vacuumResultcondition

Idling375 mmHg(14 in.Hg.)Vacuum is maintained

Within 3 minutes Try applyingafter engine startvacuum3,000 rpm

Vacuum leaks

After 3 minutes 375 mmHghave passed after (14 in.Hg.)engine start

3,000 rpm

Vacuum will be main-tained momentarily,after which it willleaks.

NOTE:

The vacuum will leakcontinuously if thealtitude is 2,200 m(7,200 ft.) or higher,

or the intake air

temperature is

50°C(122°F) or higher.

ITSB RevisionI

Page 638 of 1273

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

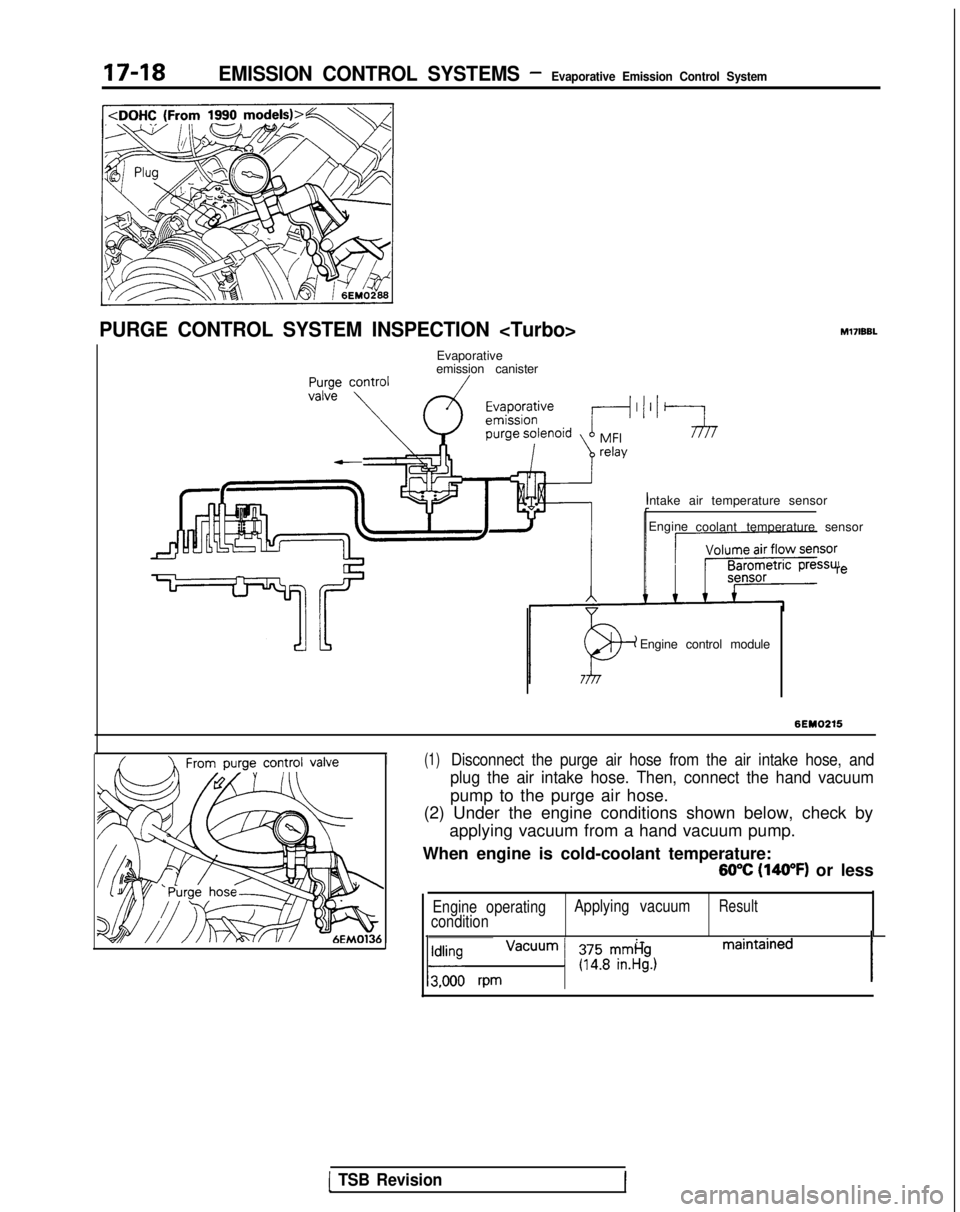

PURGE CONTROL SYSTEM INSPECTION M17lBBL

Evaporative

emission canister

Intake air temperature sensorEngine coolant temperature sensor re

Engine control module

I(1)Disconnect the purge air hose from the air intake hose, and

plug the air intake hose. Then, connect the hand vacuum

pump to the purge air hose.

(2) Under the engine conditions shown below, check by

applying vacuum from a hand vacuum pump.

When engine is cold-coolant temperature:

60°C (140°F) or less

Engine operating Applying vacuumResultcondition

1 vacuum is maintained 1ldldl rpm1 gy?r$y)

[ TSB Revision

Page 639 of 1273

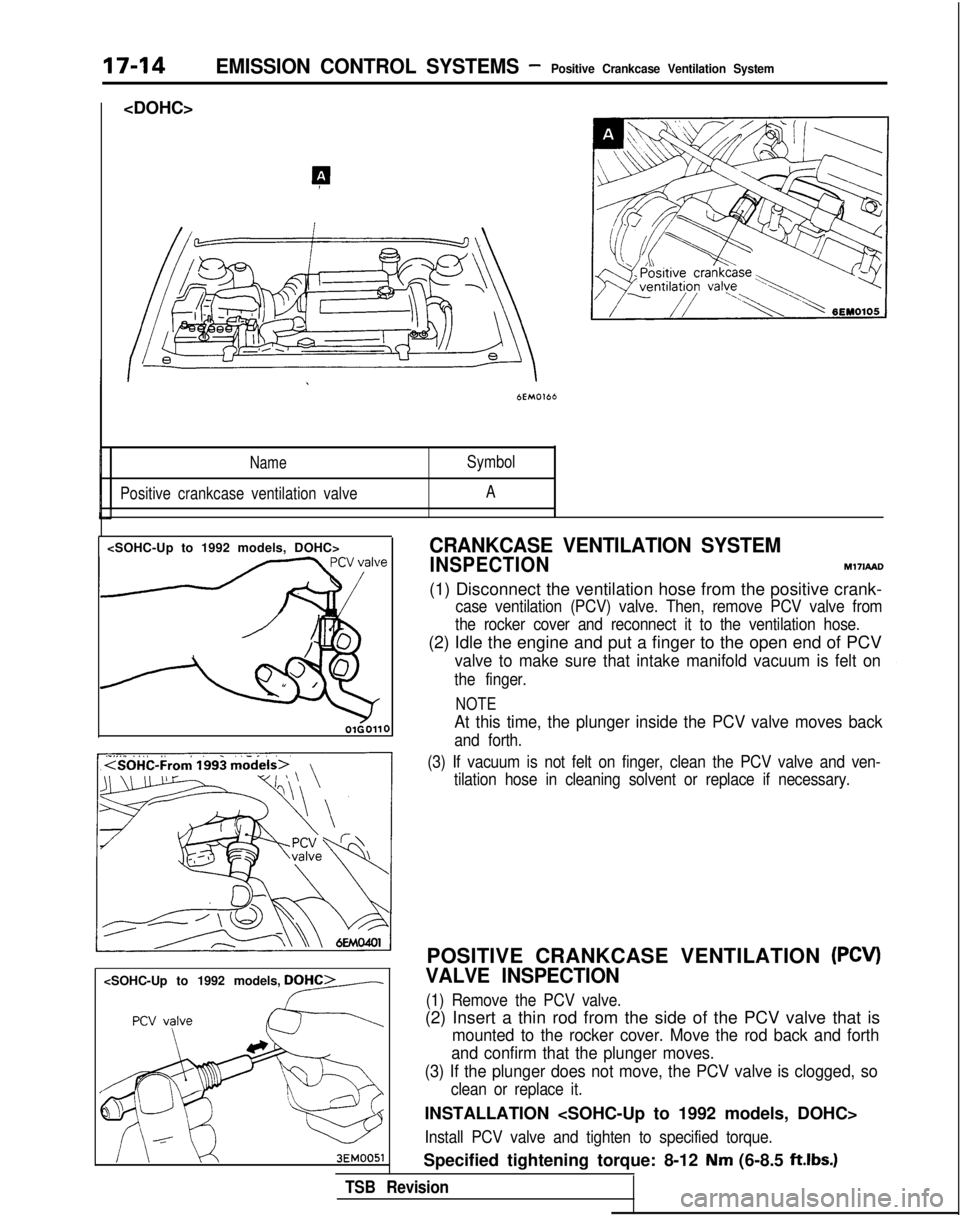

EMISSION CONTROL SYSTEMS -Evaporative Emission Control System17-19

When engine is hot-coolant temperature:

70% (158°F) or higher

Engine operating

condition Applying vacuumResult

Idling

Vacuum is maintained

3,000 rpm withinTry applyingthree minutes after vacuumstarting engine

Vacuum leaks

3,000 rpm after

three minutes

have elapsedafter startingengine

375 mmHg(14.8 in.Hg.1Vacuum will be main-tained momentarily,after which it willleaks.

NOTE

The vacuum will leak

continuously if the

altitude is 2,200

m(7,200 ft.) or higher,

or the intake air

temperature is

50°C(122°F) or higher.

PURGE PORT VACUUM MITFVBC

INSPECTION

Non-

Turbo-Up to 1991 models, DOHC Turbo> Engine coolant temperature:

85- 95°C (185- 205°F)

(1) Disconnect the vacuum hose from the throttle body purge hose nipple and connect a hand vacuum pump to the

nipple.

TSB Revision

Page 640 of 1273

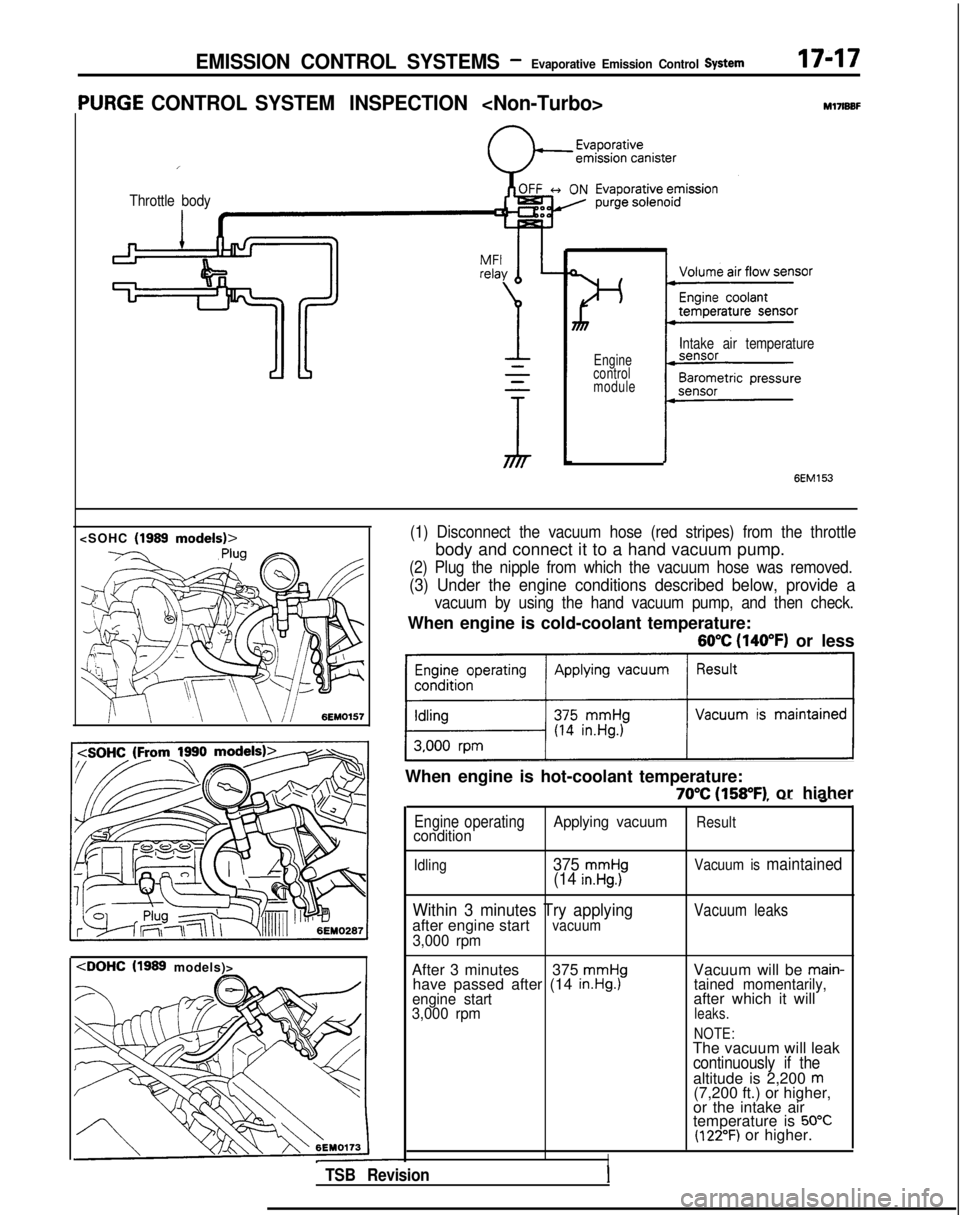

17-20EMISSION CONTROL SYSTEMS -Evaporative Emission Control System

Engine speed (rpm)>

3FU262

E2id>

‘_/- )Engine

speed

(rpm)1 FU446

1 TSB Revision

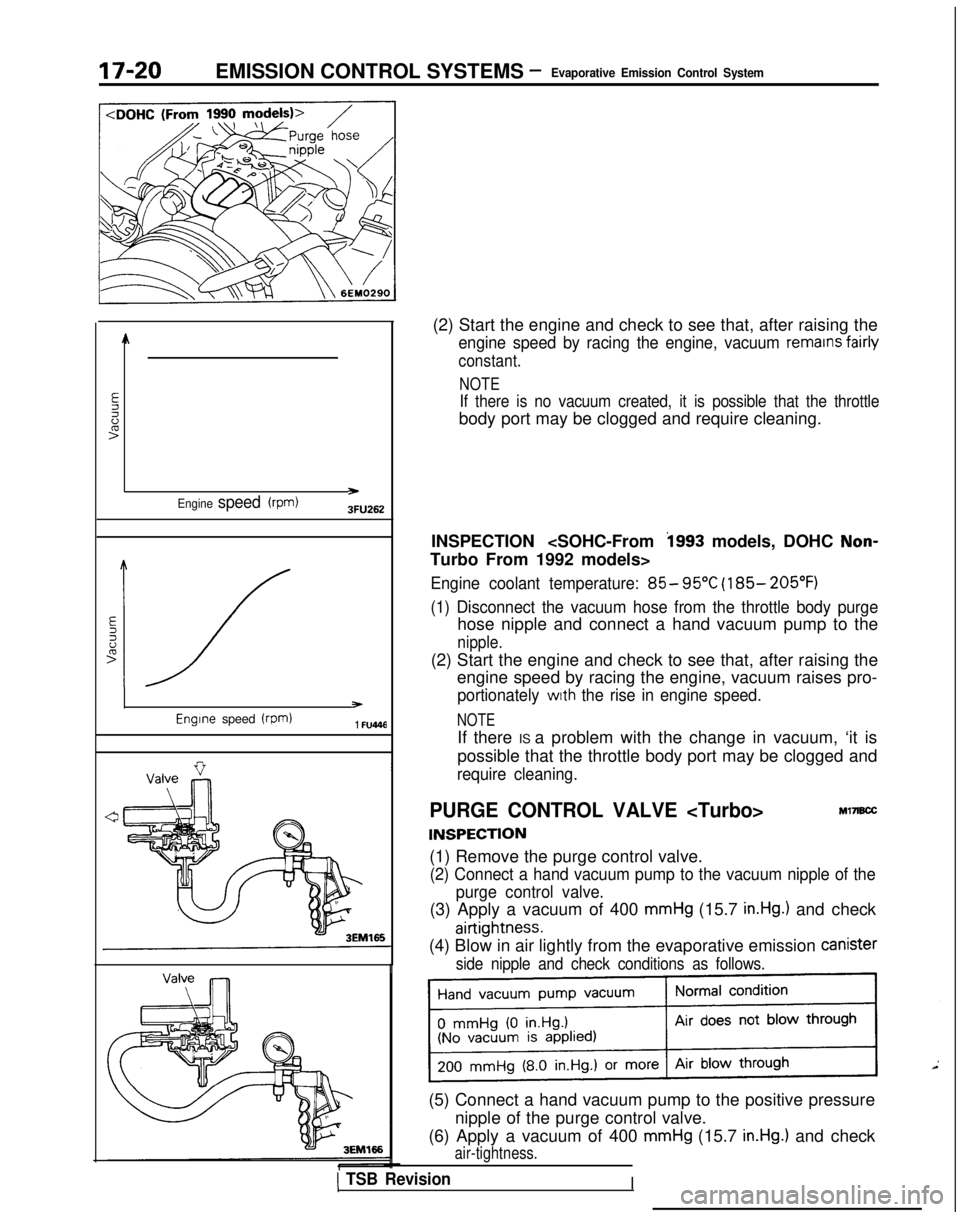

(2) Start the engine and check to see that, after raising the

engine speed by racing the engine, vacuum remains fairly

constant.

NOTE

If there is no vacuum created, it is possible that the throttle

body port may be clogged and require cleaning.

INSPECTION

i993 models, DOHC Non-

Turbo From 1992 models>

Engine coolant temperature: 85- 95°C (185- 205°F)

(1) Disconnect the vacuum hose from the throttle body purge

hose nipple and connect a hand vacuum pump to the

nipple.

(2) Start the engine and check to see that, after raising the engine speed by racing the engine, vacuum raises pro-

portionately with the rise in engine speed.

NOTE

If there IS a problem with the change in vacuum, ‘it is

possible that the throttle body port may be clogged and

require cleaning.

PURGE CONTROL VALVE

INSPECTION

Ml7B.X

(1) Remove the purge control valve.

(2) Connect a hand vacuum pump to the vacuum nipple of the

purge control valve.

(3) Apply a vacuum of 400 mmHg (15.7 in.Hg.) and check

airtightness.

(4) Blow in air lightly from the evaporative emission Canister

side nipple and check conditions as follows.

(5) Connect a hand vacuum pump to the positive pressure

nipple of the purge control valve.

(6) Apply a vacuum of 400

mmHg (15.7 in.Hg.) and check

air-tightness.

I

Trending: jack points, gas type, timing belt, rims, check engine light, set clock, spark plugs