MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 661 of 1273

CLUTCH- Clutch Control

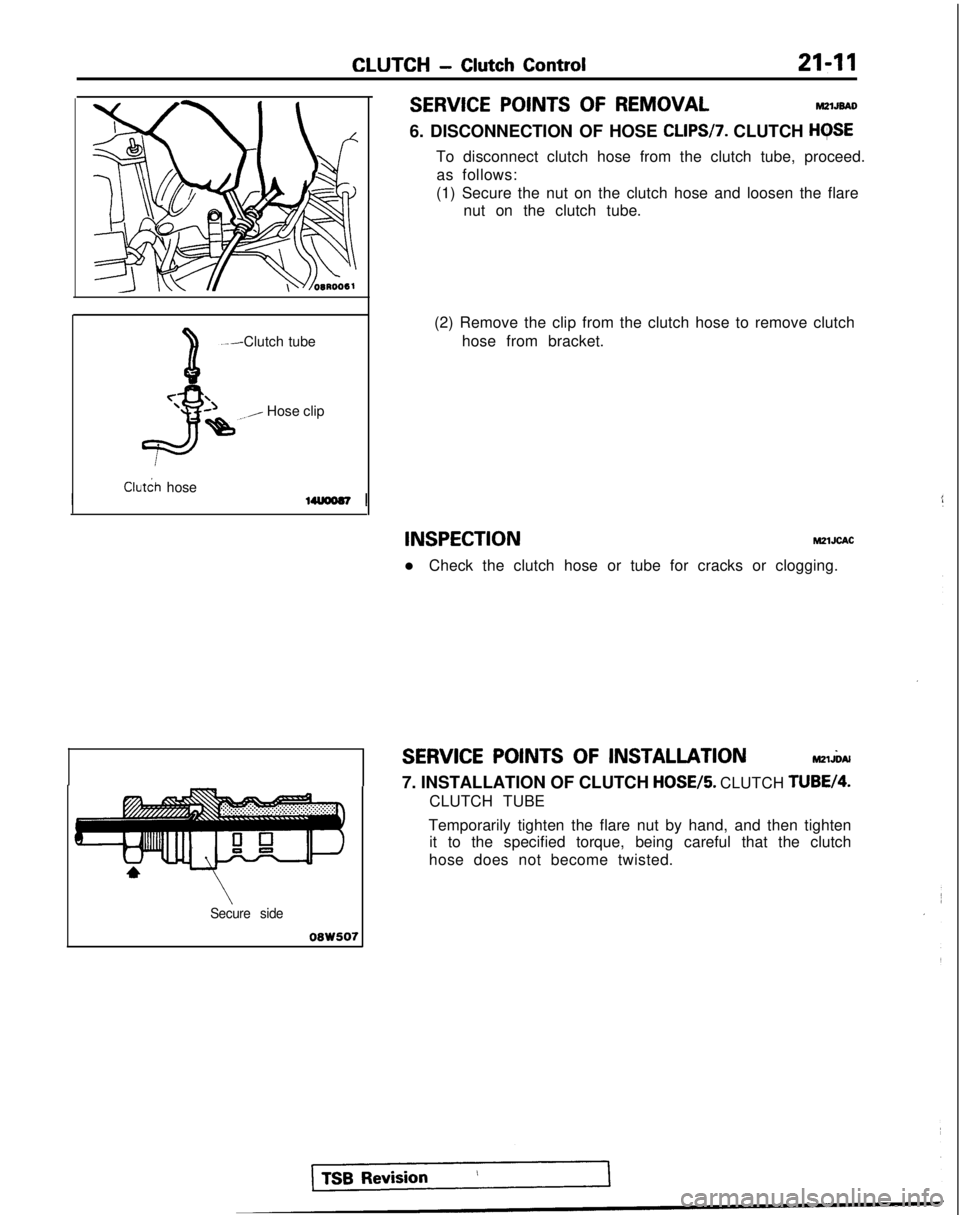

Clutdh hose-Clutch tube

.., Hose clip

Secure side

08W507

SERVICE POINTS OF REMOVALM2lJBAD

6. DISCONNECTION OF HOSE CLIPSI7. CLUTCH HOSE

To disconnect clutch hose from the clutch tube, proceed.

as follows:

(1) Secure the nut on the clutch hose and loosen the flare nut on the clutch tube.

(2) Remove the clip from the clutch hose to remove clutch hose from bracket.

INSPECTION M21JCAC

l Check the clutch hose or tube for cracks or clogging.

SERVICE POINTS OF INSTALLATIONhl21JiW

7. INSTALLATION OF CLUTCH HOSE/S. CLUTCH TUBE/4.

CLUTCH TUBE

Temporarily tighten the flare nut by hand, and then tighten it to the specified torque, being careful that the clutch

hose does not become twisted.

Page 662 of 1273

21-12CLUTCH - Clutch Master Cylinder

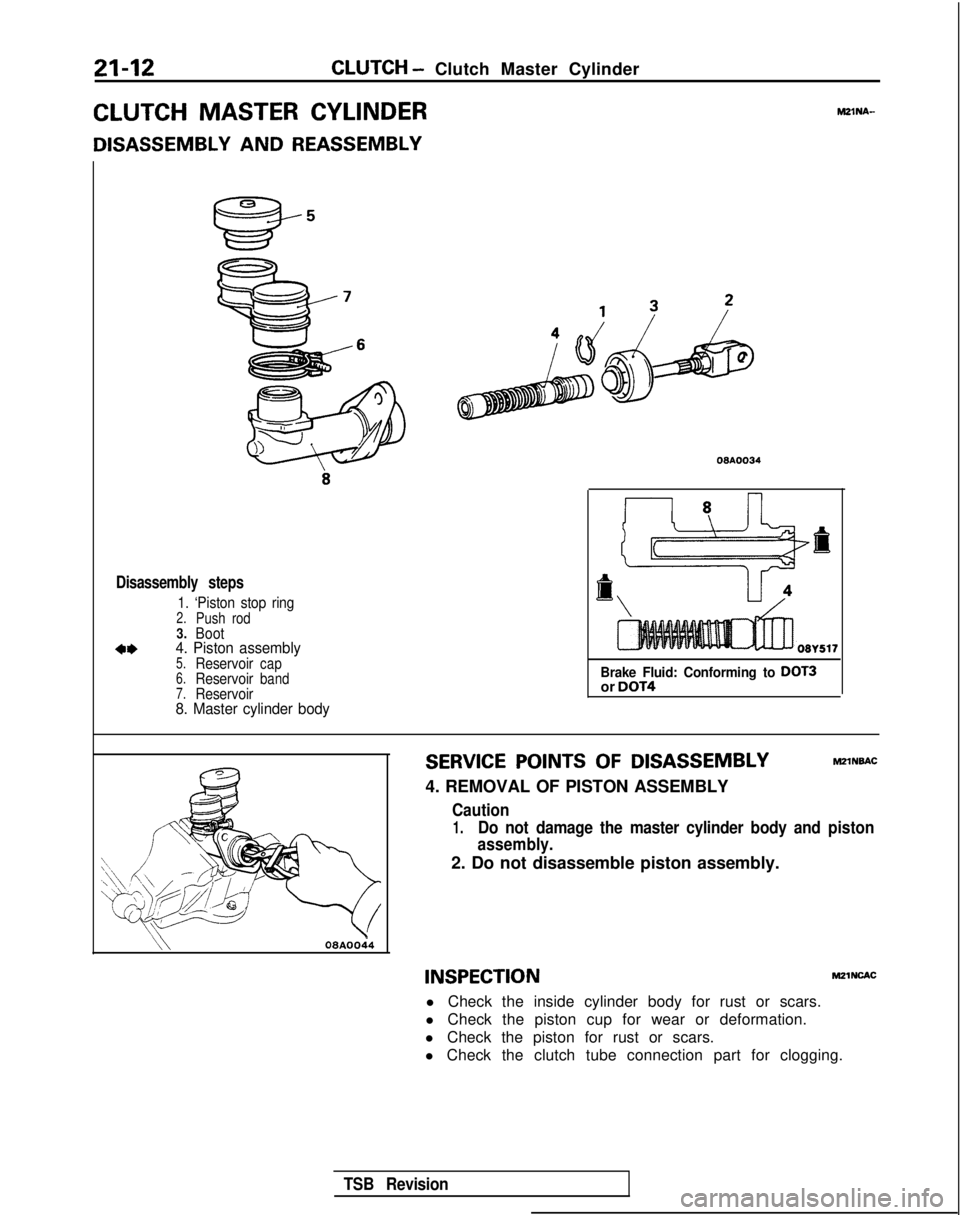

CLUTCH MASTER CYLINDER

DISASSEMBLY AND REASSEMBLY

MZlNA-

Disassembly steps

1. ‘Piston stop ring2.Push rod3.Boot

*I)4. Piston assembly5.Reservoircap6.Reservoirband7.Reservoir8. Master cylinder body

08AOO34

Brake Fluid: Conforming to DOT3or DOT4

SERVICE POINTS OF DISASSEMBLYMZlNBAC

4. REMOVAL OF PISTON ASSEMBLY

Caution

1.Do not damage the master cylinder body and piston

assembly.

2. Do not disassemble piston assembly.

\\08AOOi4

INSPECTIONM21NcAc

l Check the inside cylinder body for rust or scars.

l Check the piston cup for wear or deformation.

l Check the piston for rust or scars.

l Check the clutch tube connection part for clogging.

TSB Revision

Page 663 of 1273

CLUTCH - Clutch Release Cylinder

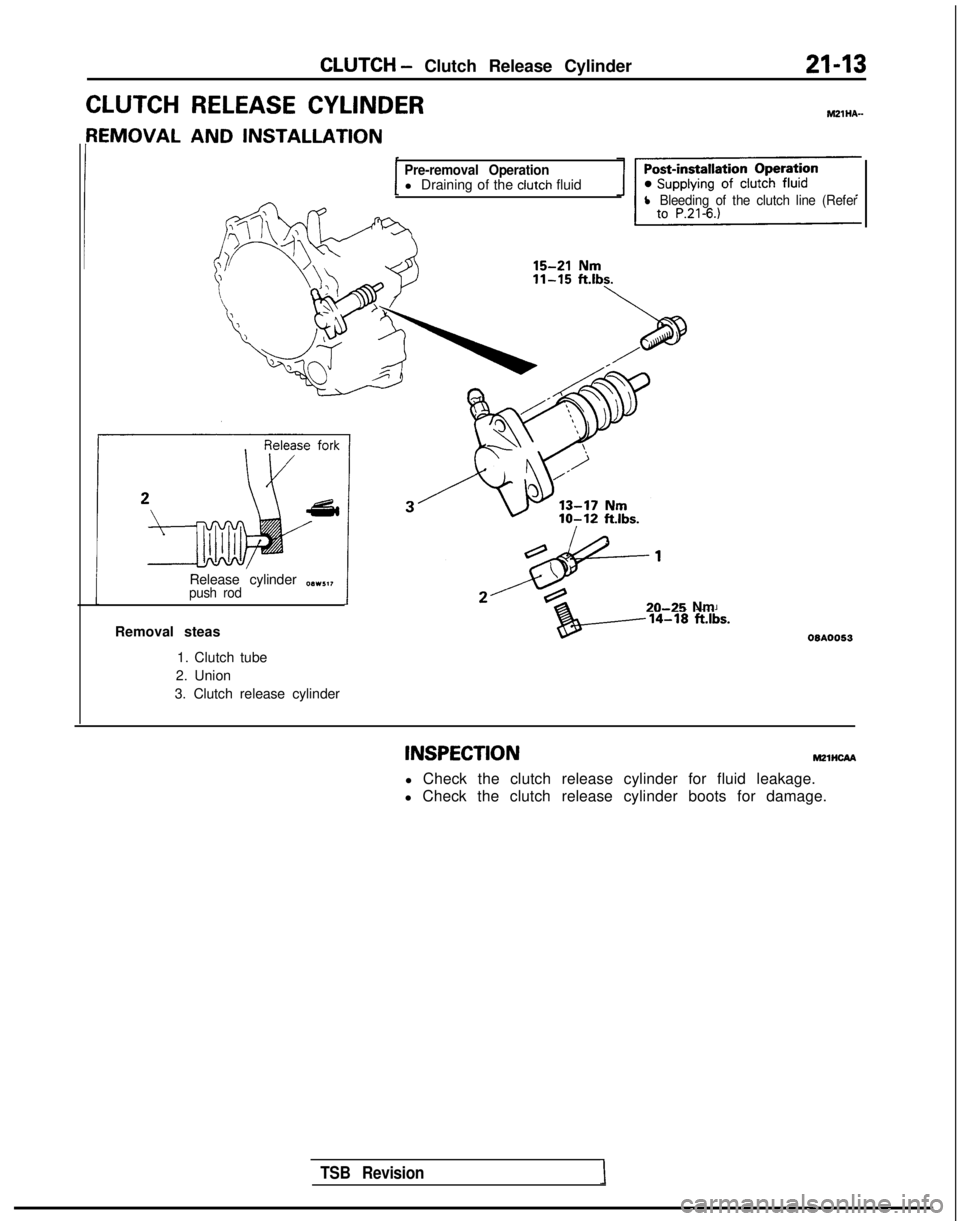

CLUTCH RELEASE CYLINDER

{EMOVAL AND INSTALLATION

Pre-removal Operationl Draining of the clutch fluidl Bleeding of the clutch line (Refer

Release cylinder O(Ivl,,push rod

TSB Revision1

20-25 Nm

Removal steas

1. Clutch tube

2. Union

3. Clutch release cylinder

INSPECTIONm21ncAA

l Check the clutch release cylinder for fluid leakage.

l Check the clutch release cylinder boots for damage.

Page 664 of 1273

NOTES

Page 665 of 1273

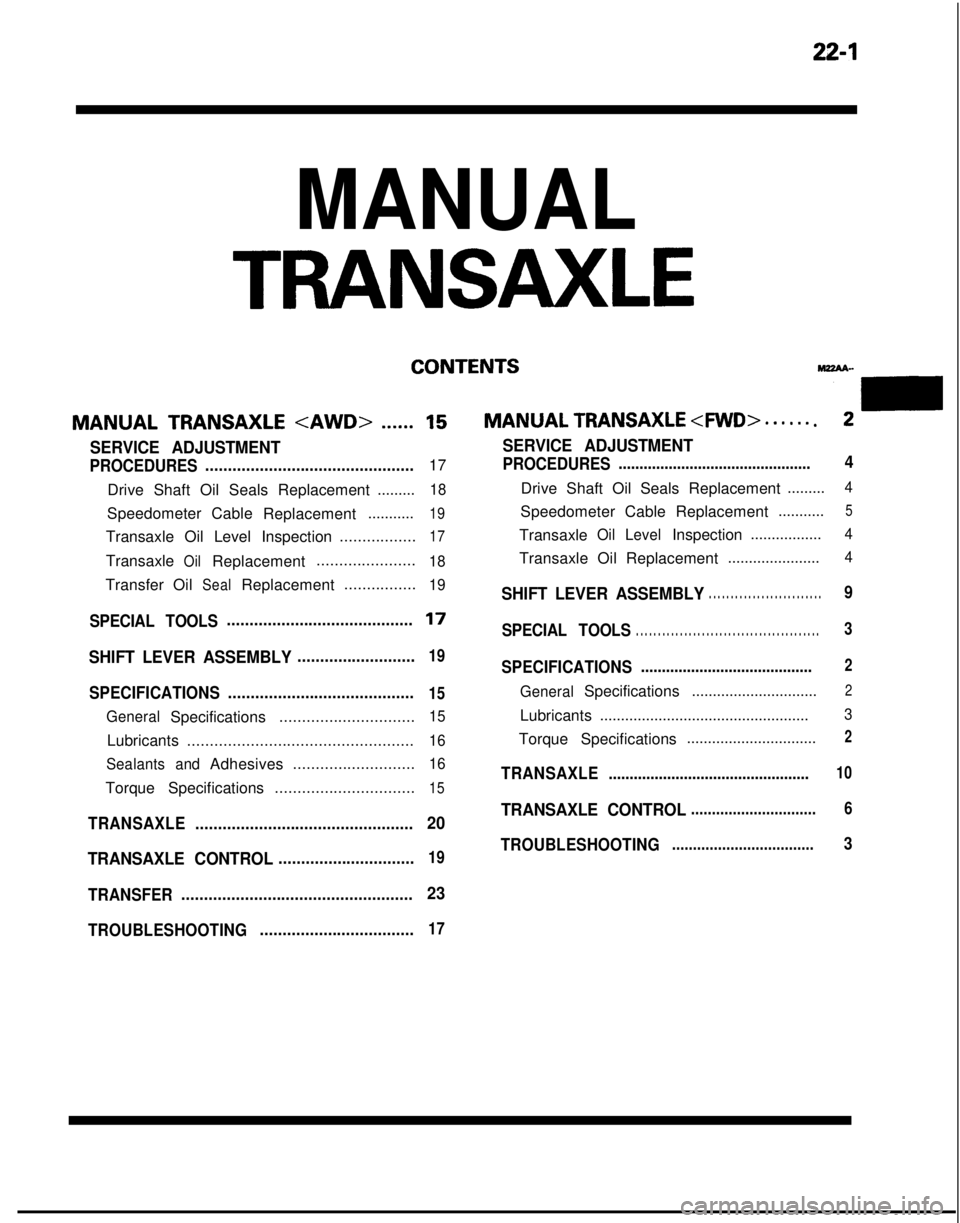

22-1

MANUAL

TRANSAXLE

CONTENTS

--m

MANUAL TRANSAXLE

SERVICE ADJUSTMENT

PROCEDURES..............................................17

Drive Shaft Oil Seals Replacement .........

18

Speedometer Cable

Replacement...........19

Transaxle Oil Level Inspection

.................17

TransaxleOilReplacement......................18

Transfer OilSealReplacement

................19

SERVICE ADJUSTMENT

PROCEDURES ..............................................4

Drive Shaft Oil Seals Replacement .........4

Speedometer Cable Replacement...........5

TransaxleOil

LevelInspection .................4

Transaxle Oil Replacement ......................4

SHIFT LEVER ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . .9

SPECIAL TOOLS ......................................... 17

SHIFT LEVER ASSEMBLY..........................19

SPECIFICATIONS

.........................................15

GeneralSpecifications..............................15

Lubricants

..................................................16

Sealants and

Adhesives ...........................16

Torque Specifications ...............................15

TRANSAXLE

................................................20

TRANSAXLE CONTROL

..............................19

TRANSFER ...................................................23

TROUBLESHOOTING ..................................17

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . .3

SPECIFICATIONS.........................................2

GeneralSpecifications

..............................2

Lubricants..................................................3

Torque Specifications ...............................2

TRANSAXLE

................................................10

TRANSAXLE CONTROL.............................. 6

TROUBLESHOOTING..................................3

Page 666 of 1273

22-2MANUAL TRANSAXLE

- Specifications

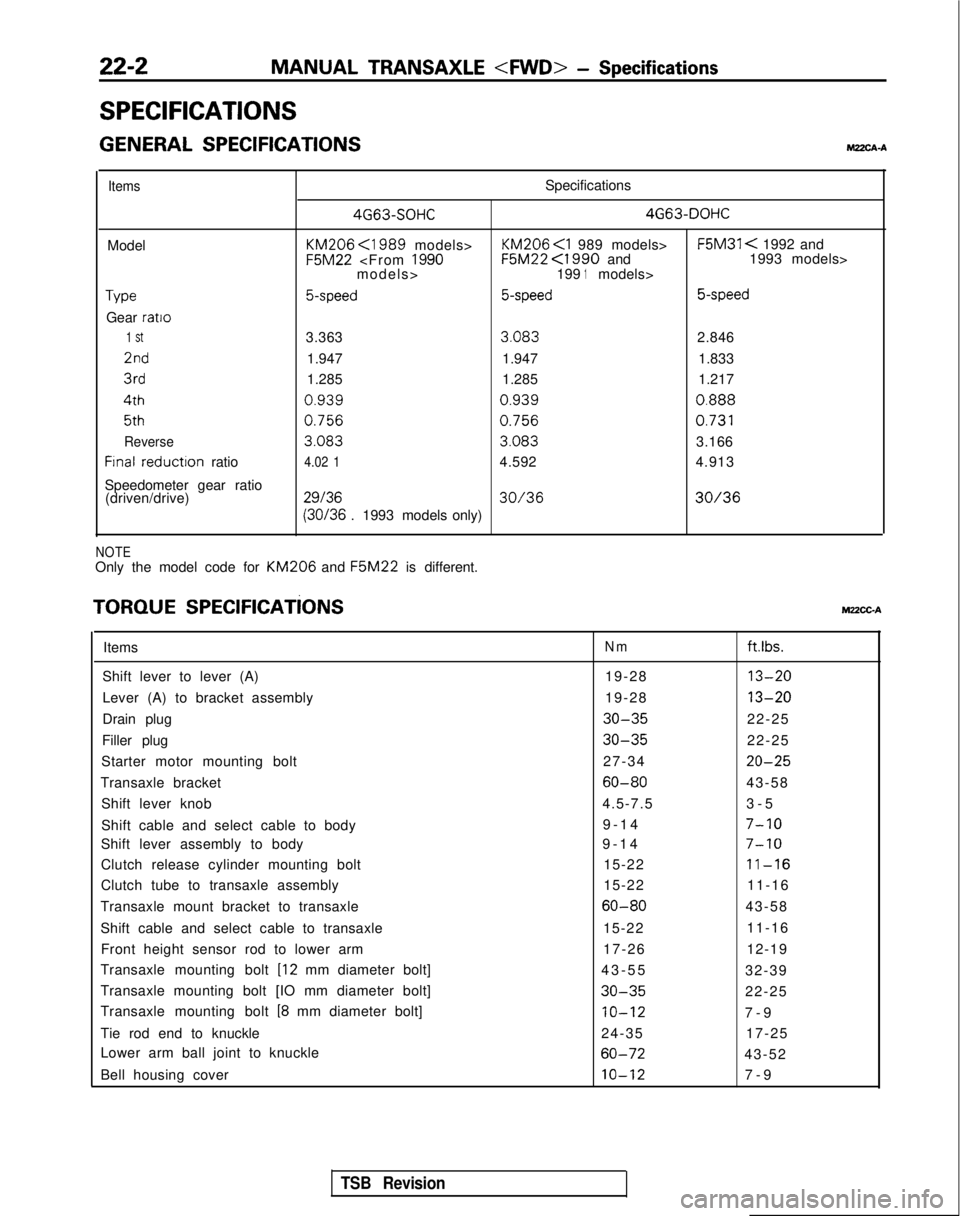

SPECIFICATIONS

GENERAL SPECIFICATIONSMZXA-A

ItemsSpecifications 4G63-SOHC 4G63-DOHC

Model KM206

<1989 models> KM206

F5M31 < 1992 and F5M22

models> 1991models>

Type5-speed5-speed 5-speed

Gear ratio

1 St3.363

3.083

2.8462nd

1.947 1.947 1.8333rd

1.285 1.285 1.2174th

0.9390.9390.888

5th0.7560.756

0.731

Reverse

3.083 3.083

3.166

Frnal reductron

ratio4.02 14.592 4.913

Speedometer gear ratio (driven/drive)

2913630/3630/36 (30/36

. 1993 models only)

NOTEOnly the model code for KM206 and F5M22

is different.

TORQUE SPEClFlCATiONSMUCC-A

ItemsNmftlbs.

Shift lever to lever (A) 19-2813-20

Lever (A) to bracket assembly19-2813-20

Drain plug30-3522-25

Filler plug

30-3522-25

Starter motor mounting bolt 27-34

20-25

Transaxle bracket60-8043-58

Shift lever knob 4.5-7.53-

5

Shift cable and select cable to body 9-14

7-10

Shift lever assembly to body

9-1

4

7-10

Clutch release cylinder mounting bolt

15-2211-16

Clutch tube to transaxle assembly15-2211-16

Transaxle mount bracket to transaxle

60-8043-58

Shift cable and select cable to transaxle 15-2211-16

Front height sensor rod to lower arm 17-2612-19

Transaxle mounting bolt

[I2 mm diameter bolt] 43-5

5

32-39

Transaxle mounting bolt [IO mm diameter bolt]

30-3522-25

Transaxle mounting bolt

[8 mm diameter bolt]IO-127-

9

Tie rod end to knuckle 24-3517-25

Lower arm ball joint to knuckle

60-7243-52

Bell housing cover

10-127-

9

TSB Revision

Page 667 of 1273

MANUAL TRANSAXLE

- Soec~cations/SpeciI

Tools/Troubleshooting 22-3

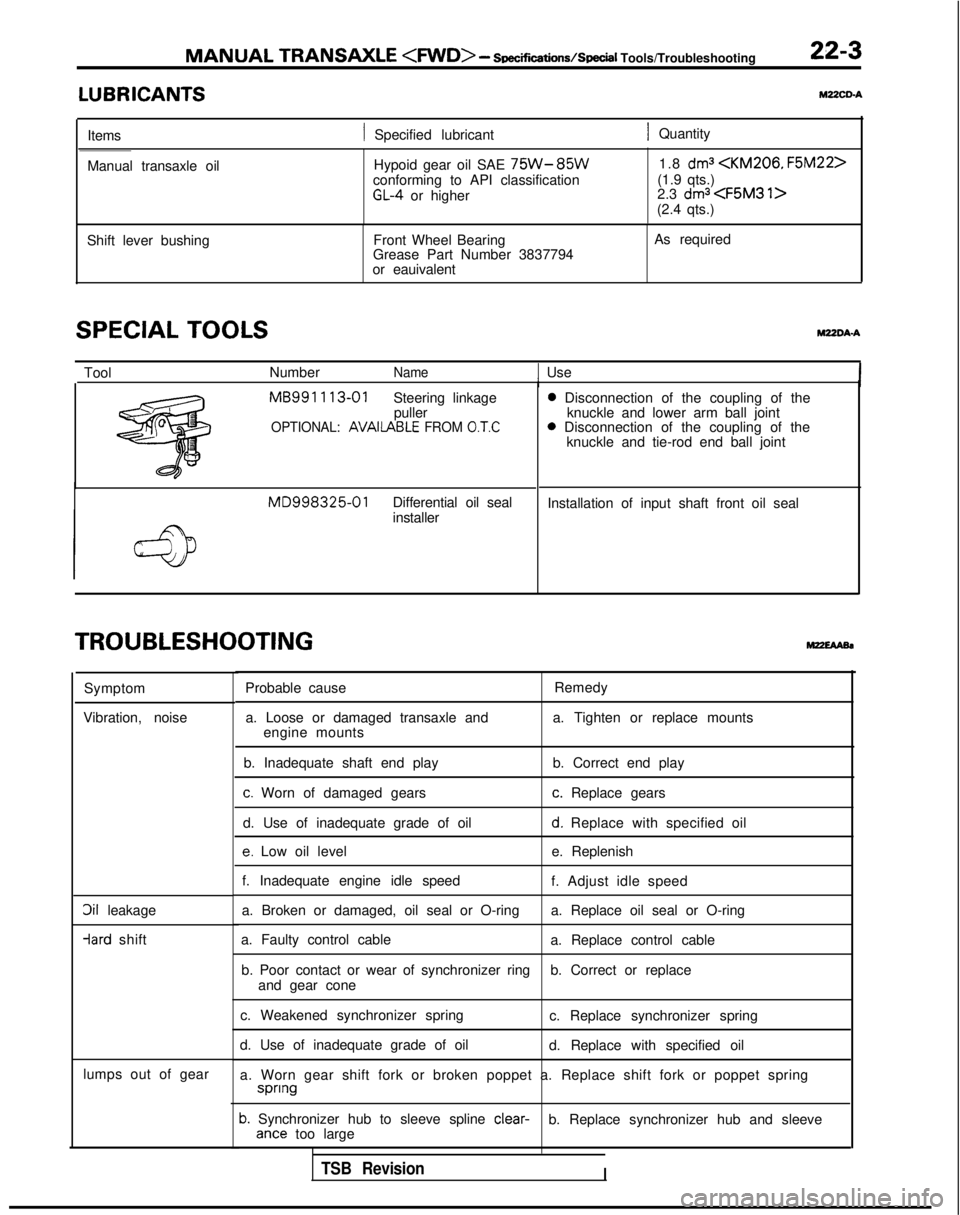

LUBRICANTSYZZCD-A

Items1 Specified lubricant1 Quantity

Manual transaxle oil Hypoid gear oil SAE

75W-85Wconforming to API classificationGL-4 or higher1.8

dma

(1.9 qts.)

2.3 dma

Shift lever bushing Front Wheel Bearing

Grease Part Number 3837794

or eauivalent As required

SPECIAL TOOLSWDA-A

Tool

NumberName1 UseI MB991

113-01

Steering linkage

puller

OPTIONAL: AVAIlABLE FROM 0.T.C

MD998325-01Differential oil seal

installer 0

Disconnection of the coupling of the

knuckle and lower arm ball joint 0

Disconnection of the coupling of the

knuckle and tie-rod end ball joint

Installation of input shaft front oil seal

TROUBLESHOOTING

Symptom

Vibration, noise

3il leakage -lard

shift

lumps out of gear Probable cause

Remedy

a. Loose or damaged transaxle and a. Tighten or replace mounts

engine mounts

b. Inadequate shaft end play b. Correct end play

c. Worn of damaged gearsc. Replace gears

d. Use of inadequate grade of oil

d. Replace with specified oil

e. Low oil level e. Replenish

f. Inadequate engine idle speed f. Adjust idle speed

a. Broken or damaged, oil seal or O-ring a. Replace oil seal or O-ring

a. Faulty control cable a. Replace control cable

b. Poor contact or wear of synchronizer ring b. Correct or replace

and gear cone

c. Weakened synchronizer spring c. Replace synchronizer spring

d. Use of inadequate grade of oil d. Replace with specified oil

a. Worn gear shift fork or broken poppet a. Replace shift fork or poppet\

spring spnng

b. Synchronizer hub to sleeve spline

clear-

b. Replace synchronizer hub and sleeveante too large

TSB RevisionI

Page 668 of 1273

22-4MANUAL TRANSAXLE

09”011009FO12

R.H. side

x

I I09K567I

Front exhaust pipe

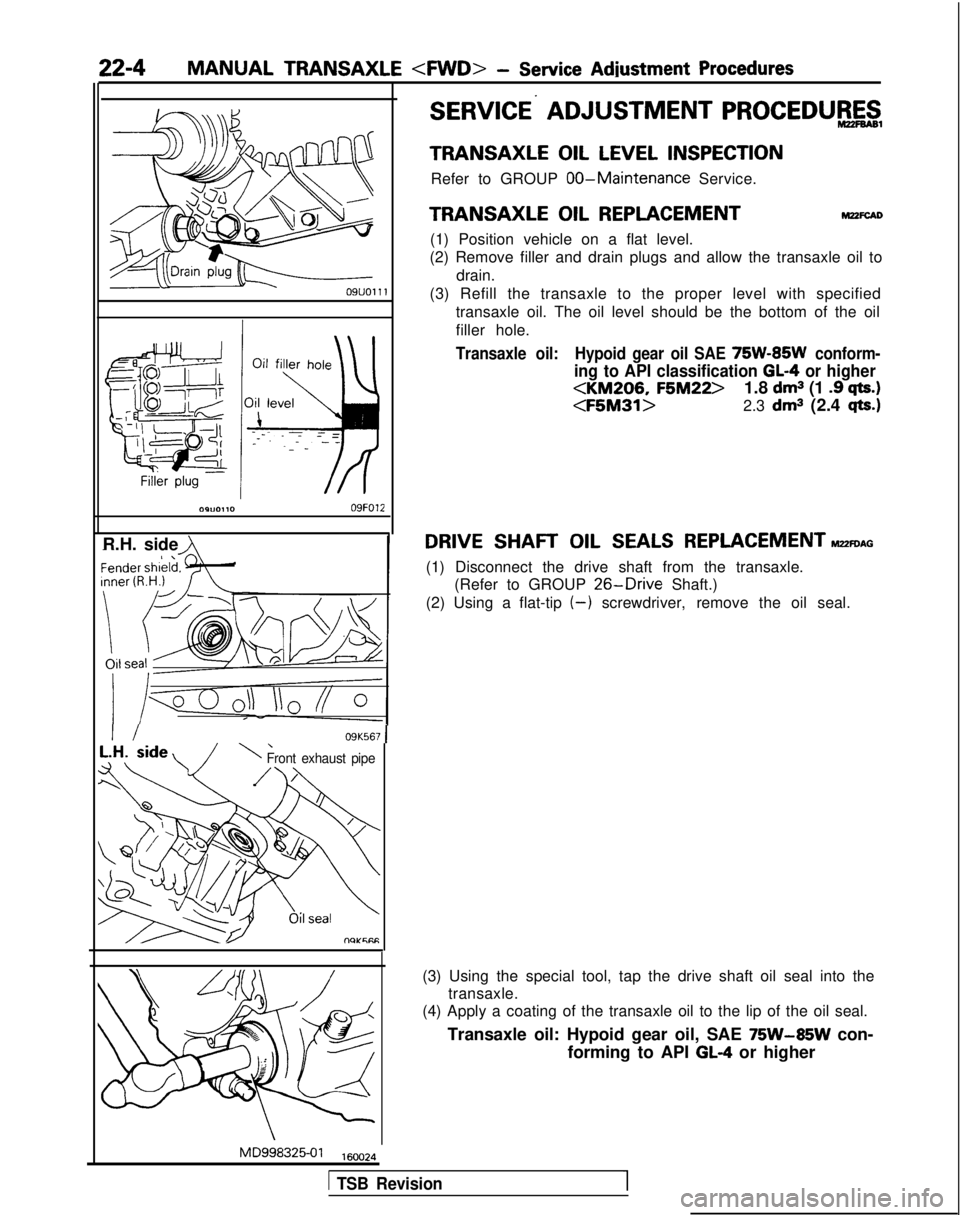

SERVICE’ ADJUSTMENT PROCEDURAF

TRANSAXLE OIL LEVEL INSPECTION

Refer to GROUP 00-Maintenance Service.

TRANSAXLE OIL REPLACEMENTMZZFCAD

(1) Position vehicle on a flat level.

(2) Remove filler and drain plugs and allow the transaxle oil to

drain.

(3) Refill the transaxle to the proper level with specified transaxle oil. The oil level should be the bottom of the oil

filler hole.

Transaxle oil: Hypoid gear oil SAE 75W-85W conform-

ing to API classification GL-4 or higher

DRIVE SHAFT OIL SEALS REPLACEMENT MYSDAG

(1) Disconnect the drive shaft from the transaxle. (Refer to GROUP

26-Drive Shaft.)

(2) Using a flat-tip

(-) screwdriver, remove the oil seal.

(3) Using the special tool, tap the drive shaft oil seal into the transaxle.

(4) Apply a coating of the transaxle oil to the lip of the oil seal.

Transaxle oil: Hypoid gear oil, SAE

75W-85W con-

forming to API

GL-4 or higher

MD998325-01160024

1 TSB Revision

Page 669 of 1273

MANUAL TRANSAXLE

Adapter09A0058

TSB Revision

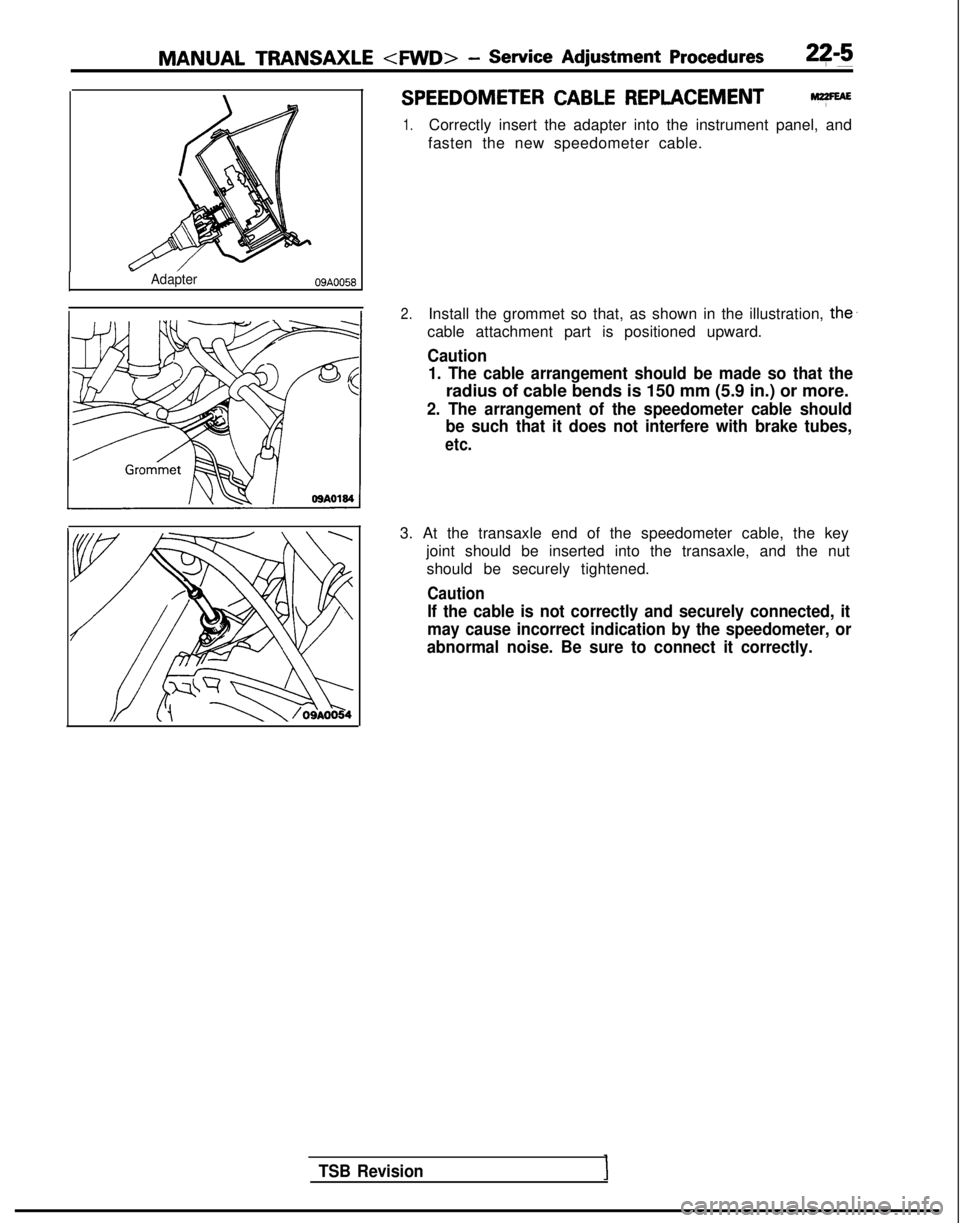

SPEEDOMETER CABLE REPLACEMENT~~FEIE

1.Correctly insert the adapter into the instrument panel, and

fasten the new speedometer cable.

2.Install the grommet so that, as shown in the illustration, the’

cable attachment part is positioned upward.

Caution 1. The cable arrangement should be made so that the

radius of cable bends is 150 mm (5.9 in.) or more.

2. The arrangement of the speedometer cable should be such that it does not interfere with brake tubes,

etc.

3. At the transaxle end of the speedometer cable, the key

joint should be inserted into the transaxle, and the nutshould be securely tightened.

Caution

If the cable is not correctly and securely connected, it

may cause incorrect indication by the speedometer, or

abnormal noise. Be sure to connect it correctly.

Page 670 of 1273

22-6MANUAL TRANSAXLE

- Transaxle Control

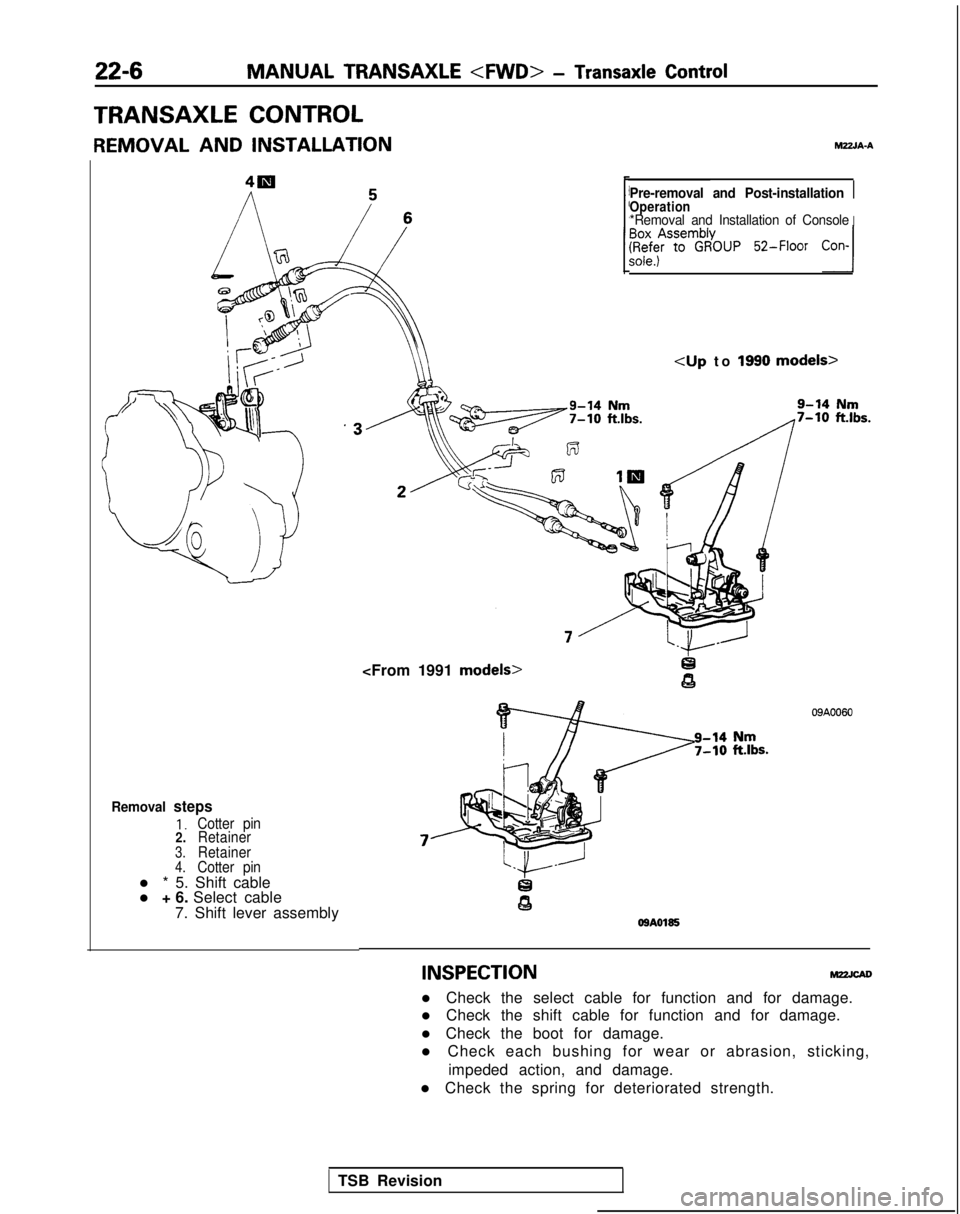

TRANSAXLE CONTROL

REMOVAL AND INSTALLATION hl22JA-A

Removal steps

1.Cotter pin

2. Retainer

3.Retainer4.Cotter pinl * 5. Shift cable

l + 6. Select cable

7. Shift lever assembly

Pre-removal and Post-installation 1Operation*Removal and Installation of ConsoleI

~$%!m$$NP Z-Floor

Con-l

9-14 Nm7-10 ftlbs.

09A0060

OSAO185

INSPECTION

l Check the select cable for function and for damage.

l Check the shift cable for function and for damage.

l Check the boot for damage.

l Check each bushing for wear or abrasion, sticking,

impeded action, and damage.

l Check the spring for deteriorated strength.

TSB Revision