MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 651 of 1273

21-1

CLUTCH

CONTENTS

CLUTCH CONTROL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . .10SPECIFICATIONS. . . . . . . . . . . . . . . ..*...........................2

CLUTCHMASTER CYLINDER. . . . . . . . . . . . . . . . . . . . . . . .12GeneralSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CLUTCH PEDALLubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .\

. . . . . . . . . . . . . . . . . . . . . . .3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. . . . . . . . . .7

ServiceSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CLUTCHRELEASECYLINDER. . . . . . . . . . . . . . . . . . . . . . .13Torque Specifications . . . . . . . . . .._.......................3

SERVICE ADJUSTMENT PROCEDURES . . . . . . . 5TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . \

. .4

Bleeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6Clutch chatters

Clutch Pedal Inspection and Adjustment . . . .

5Clutch noise

Clutch pedal feels “heavy”

Clutch slips

Gear shift malfunction

CAUTION When

servicing clutch assemblies or com-

ponents for vehicles with SOHC engine

(Up to 1991 models), do NOT create dust

by sanding or by cleaning clutch parts

with a dry brush or with compressed air.

(A water dampened cloth should be used).

The clutch disc contains “Asbestos Fibers”

which can become airborne if dust is

created during service operations. Breath-

ing dust containing “Asbestos Fibers”

may cause serious bodily harm.

Page 652 of 1273

21-2CLUTCH - Specifications

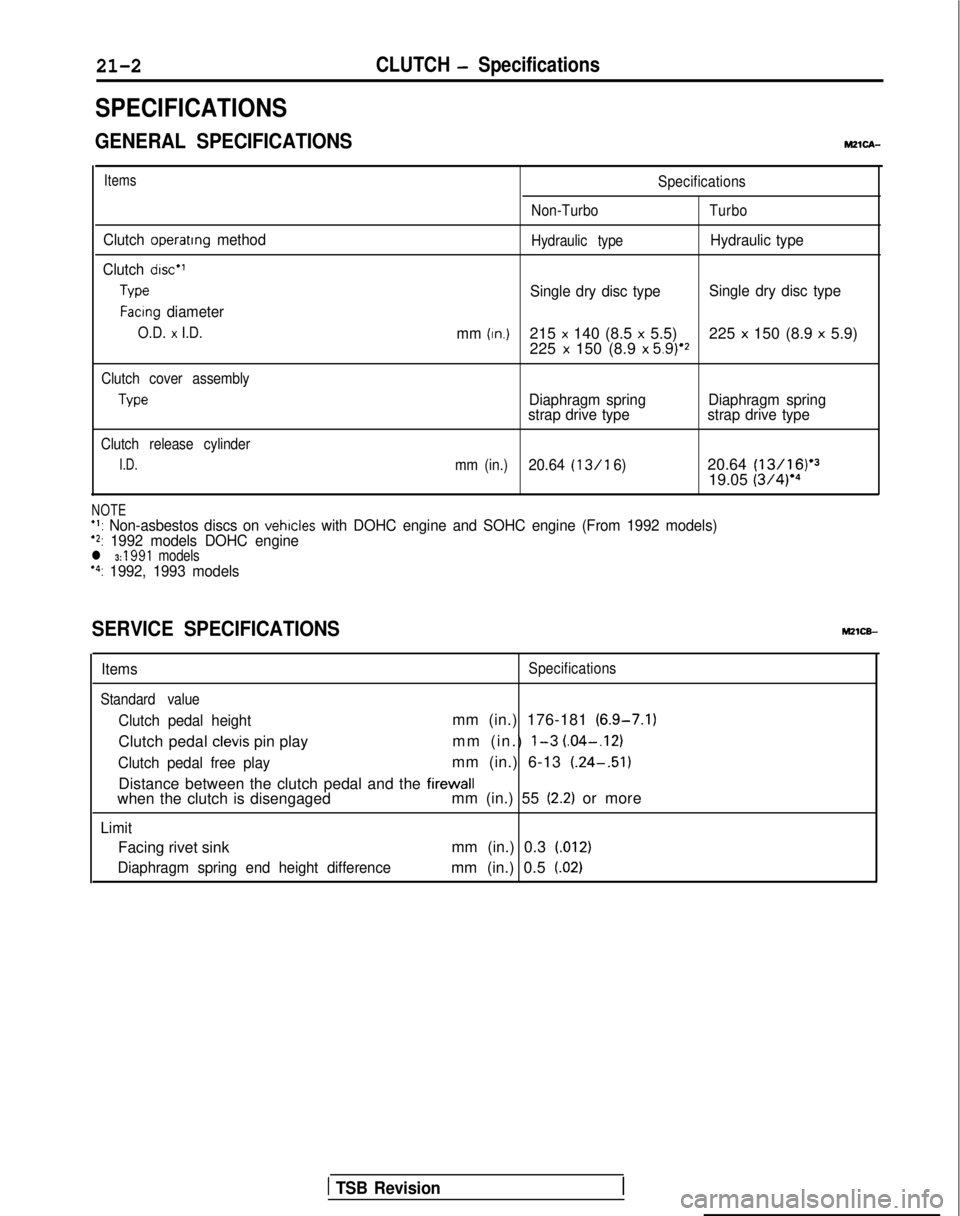

SPECIFICATIONS

GENERAL SPECIFICATIONSMZlCA-

Items

Clutch operattng method

Clutch disc”

Type

Facing diameter

O.D. x I.D.

Specifications

Non-Turbo Turbo

Hydraulic type

Hydraulic type

Single dry disc type Single dry disc type

mm

(In.)215 x 140 (8.5 x 5.5) 225 x 150 (8.9 x 5.9)

225 x 150 (8.9 x 5.9)‘2

Clutch cover assembly

Type

Clutch release cylinder

I.D.

Diaphragm spring Diaphragm spring

strap drive type strap drive type

mm (in.)20.64 (13/l 6)20.64 (13/16)‘3

19.05 (3/4)‘4

NOTE+l: Non-asbestos discs on vehicles with DOHC engine and SOHC engine (From 1992 models)‘2: 1992 models DOHC enginel 3: 1991 models“: 1992, 1993 models

SERVICE SPECIFICATIONS

ItemsSpecifications

Standard value

Clutch pedal heightmm (in.) 176-181 (6.9-7.1)

Clutch pedal

clevis pin play mm (in.) l-3 (.04-.I21

Clutch pedal free playmm (in.) 6-13

(.24-.51)

Distance between the clutch pedal and the

firewallwhen the clutch is disengaged mm (in.) 55 (2.2) or more

Limit

Facing rivet sinkmm (in.) 0.3 1.012)

Diaphragm spring end height differencemm (in.) 0.5 f.02)

1 TSB Revision

Page 653 of 1273

CLUTCH - Specifications21-3

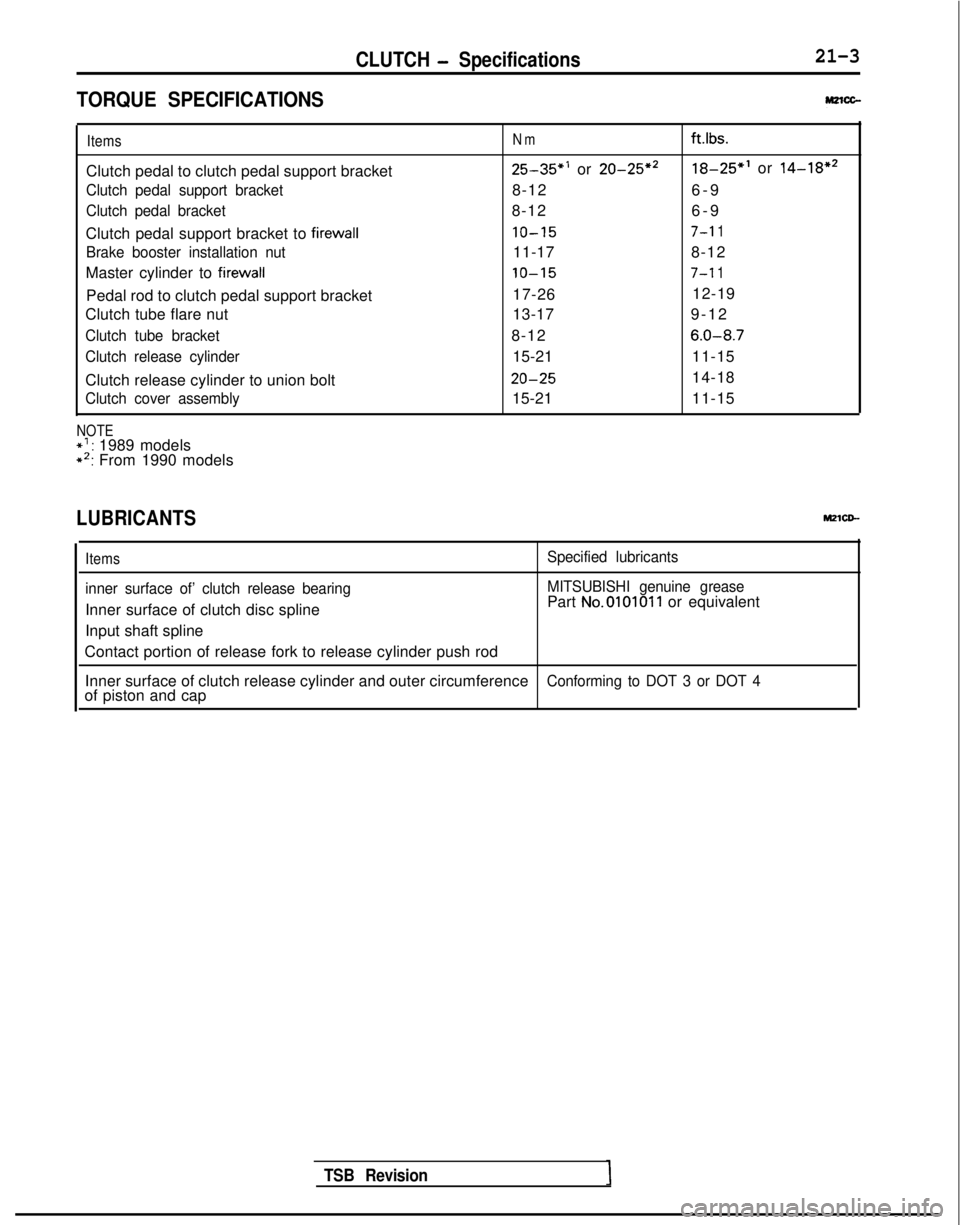

TORQUE SPECIFICATIONSM2lcc-

ItemsNmft.lbs.

Clutch pedal to clutch pedal support bracket25-35”’ or 20-25*218-25”’ or 14-18*2

Clutch pedal support bracket8-12

6-

9

Clutch pedal bracket8-12

6-

9

Clutch pedal support bracket to

firewall10-157-l 1

Brake booster installation nut11-17 8-12

Master cylinder to

firewall10-157-l 1

Pedal rod to clutch pedal support bracket 17-26

12-19

Clutch tube flare nut 13-179-1

2

Clutch tube bracket8-126.0-8.7

Clutch release cylinder15-21

11-15

Clutch release cylinder to union bolt

20-2514-18

Clutch cover assembly15-21 11-15

NOTE*’ : 1989 models*‘: From 1990 models

LUBRICANTSMZlCD-

Items

inner surface of’ clutch release bearing

Inner surface of clutch disc spline

Input shaft spline

Specified lubricants

MITSUBISHI genuine grease

Part No.010101 1 or equivalent

Contact portion of release fork to release cylinder push rod Inner surface of clutch release cylinder and outer circumference

Conforming to DOT 3 or DOT 4of piston and cap

TSB Revision

Page 654 of 1273

CLUTCH - Troubleshootinn

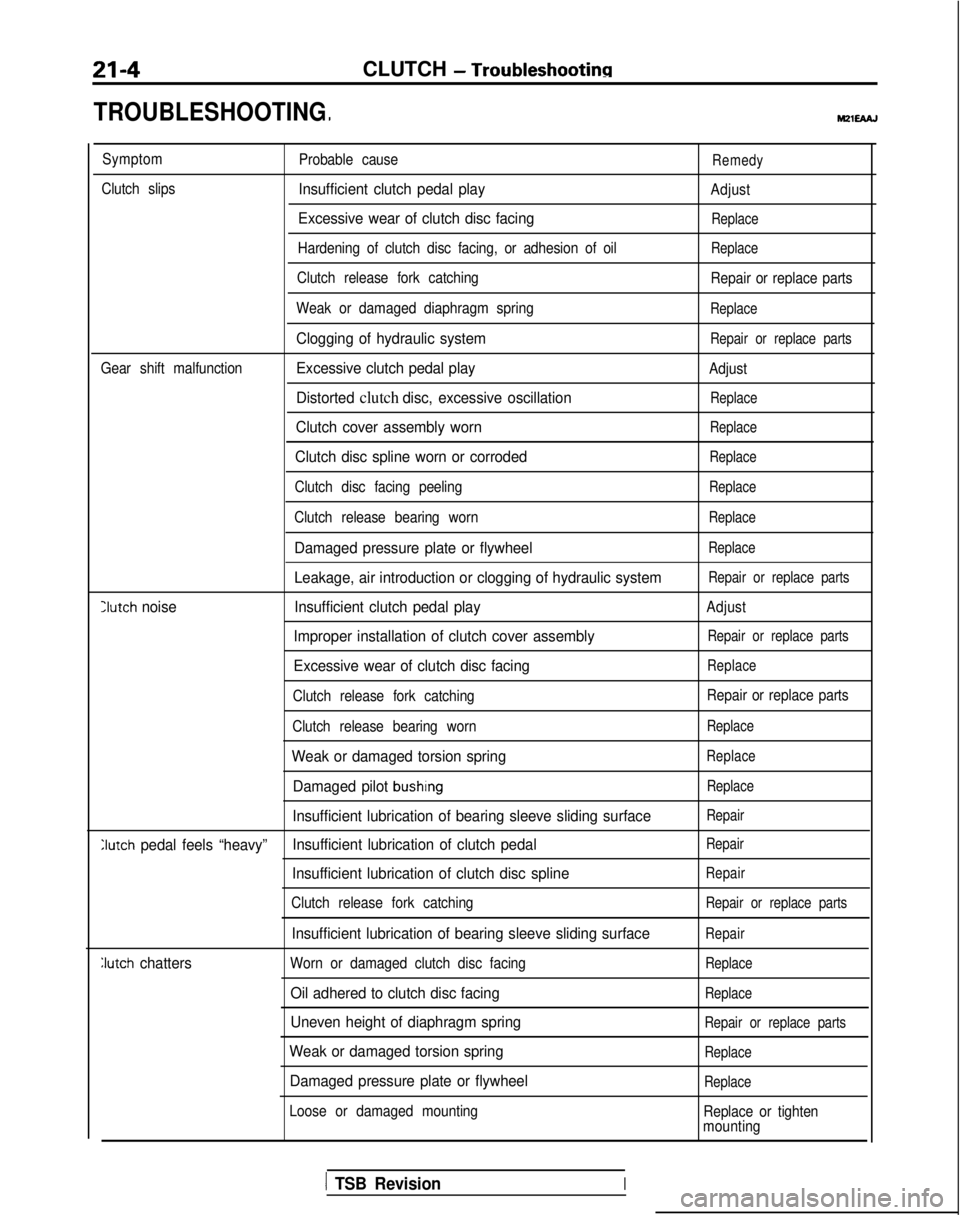

TROUBLESHOOTING

Symptom

Probable causeRemedy

Clutch slipsInsufficient clutch pedal playAdjust

Excessive wear of clutch disc facingReplace

Hardening of clutch disc facing, or adhesion of oilReplace

Clutch release fork catching Repair or replace parts

Weak or damaged diaphragm spring

Replace

Clogging of hydraulic systemRepair or replace parts

Gear shift malfunctionExcessive clutch pedal playAdjust

Distorted clutch disc, excessive oscillationReplace

Clutch cover assembly wornReplace

Clutch disc spline worn or corrodedReplace

Clutch disc facing peelingReplace

Clutch release bearing wornReplace

Damaged pressure plate or flywheelReplace

Leakage, air introduction or clogging of hydraulic systemRepair or replace parts

Iutch noise Insufficient clutch pedal playAdjust

Improper installation of clutch cover assemblyRepair or replace parts

Excessive wear of clutch disc facingReplace

Clutch release fork catching Repair or replace parts

Clutch release bearing worn

Replace

Weak or damaged torsion springReplace

Damaged pilot bushingReplace

Insufficient lubrication of bearing sleeve sliding surfaceRepair

Clutch pedal feels “heavy” Insufficient lubrication of clutch pedalRepair

Insufficient lubrication of clutch disc splineRepair

Clutch release fork catchingRepair or replace parts

Insufficient lubrication of bearing sleeve sliding surfaceRepair

Iutch

chattersWorn or damaged clutch disc facingReplace

Oil adhered to clutch disc facingReplace

Uneven height of diaphragm springRepair or replace parts

Weak or damaged torsion springReplace

Damaged pressure plate or flywheelReplace

Loose or damaged mounting

Replace or tighten

mounting

1 TSB RevisionI

Page 655 of 1273

CLUTCH - Service Adiustment Procedures21-5

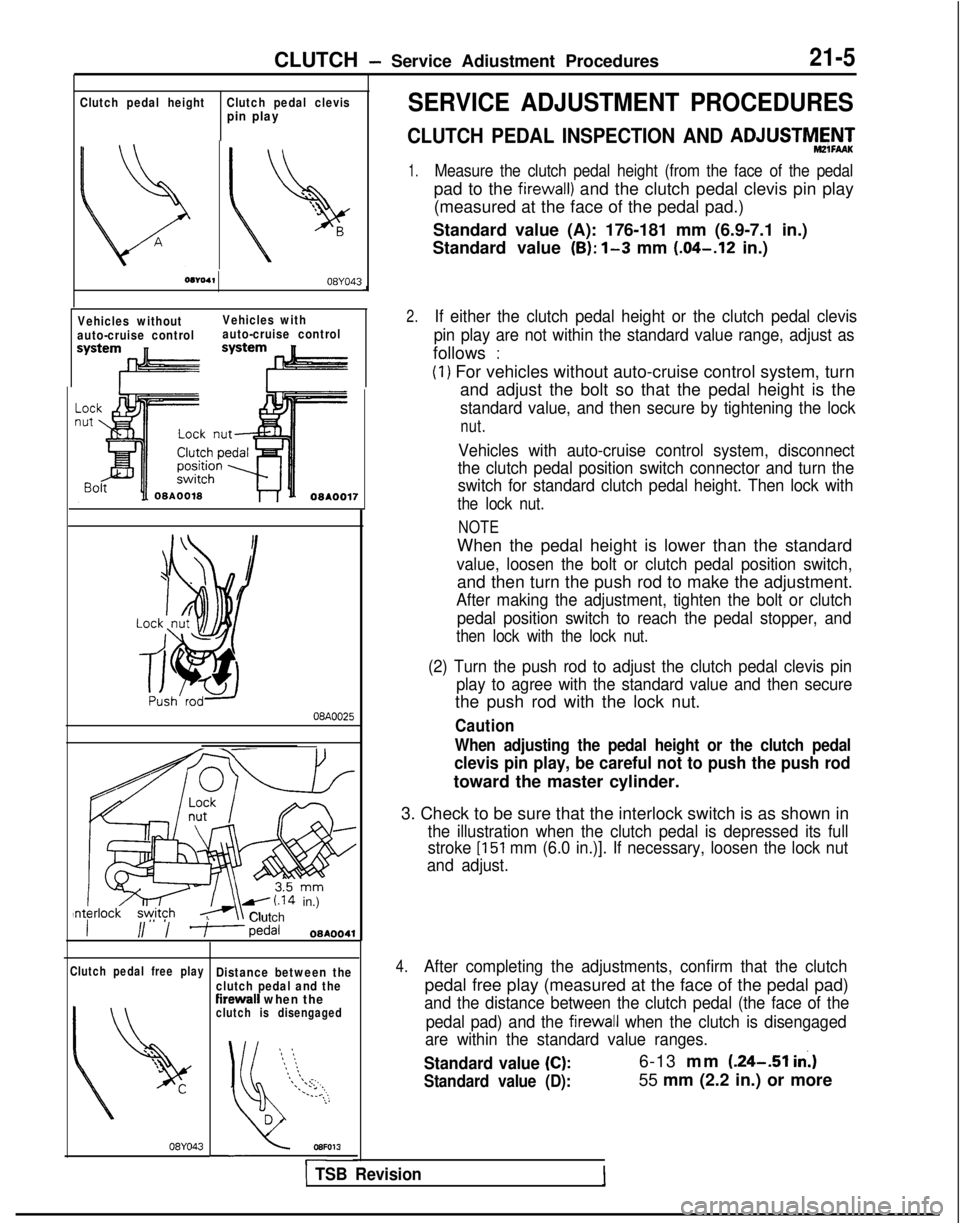

Clutch pedal height

Clutch pedal clevispin play

08104,08YO43

Vehicles without

auto-cruise control Vehicles with

auto-cruise control

08A0025

IL\\A- i.14

in.)Nnt,erlock s.y,ityh ,

Clutch

II/ / ?--pedal08AOO41

Clutch pedal free play

08YO43

Distance between the

clutch pedal and the

firewall when theclutch is disengaged

‘5 :: :

*\\\ ;.,

\.

.-‘.* ..,.--. . .:,

eir-

.;

D

l3sFO13

SERVICE ADJUSTMENT PROCEDURES

CLUTCH PEDAL INSPECTION AND ADJUSTM&‘+d+d

1.Measure the clutch pedal height (from the face of the pedal

pad to the firewall) and the clutch pedal clevis pin play

(measured at the face of the pedal pad.)

Standard value (A): 176-181 mm (6.9-7.1 in.)

Standard value

(B): l-3 mm (.04-.12

in.)

2.If either the clutch pedal height or the clutch pedal clevis

pin play are not within the standard value range, adjust as

follows :

(1) For vehicles without auto-cruise control system, turn and adjust the bolt so that the pedal height is the

standard value, and then secure by tightening the lock

nut.

Vehicles with auto-cruise control system, disconnect

the clutch pedal position switch connector and turn the

switch for standard clutch pedal height. Then lock with

the lock nut.

NOTE

When the pedal height is lower than the standard

value, loosen the bolt or clutch pedal position switch,

and then turn the push rod to make the adjustment.

After making the adjustment, tighten the bolt or clutch

pedal position switch to reach the pedal stopper, and

then lock with the lock nut.

(2) Turn the push rod to adjust the clutch pedal clevis pin play to agree with the standard value and then secure

the push rod with the lock nut.

Caution

When adjusting the pedal height or the clutch pedal

clevis pin play, be careful not to push the push rod

toward the master cylinder.

3. Check to be sure that the interlock switch is as shown in

the illustration when the clutch pedal is depressed its full

stroke

[I51 mm (6.0 in.)]. If necessary, loosen the lock nut

and adjust.

4.After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of the

pedal pad) and the

firewall when the clutch is disengaged

are within the standard value ranges.

Standard value (C):6-13 mm (.24--51 in.)

Standard value (D):55 mm (2.2 in.) or more

1 TSB Revision

Page 656 of 1273

21-6CLUTCH - Service Adjustment Procedures

5.If the clutch pedal free play and the distance between the

clutch pedal and the firewall when the clutch is disengaged

do not agree with the standard values, it is probably the

result of either air in the hydraulic system or a faulty master

cylinder or clutch. Bleed the air, or disassemble and inspect

the master cylinder or clutch.

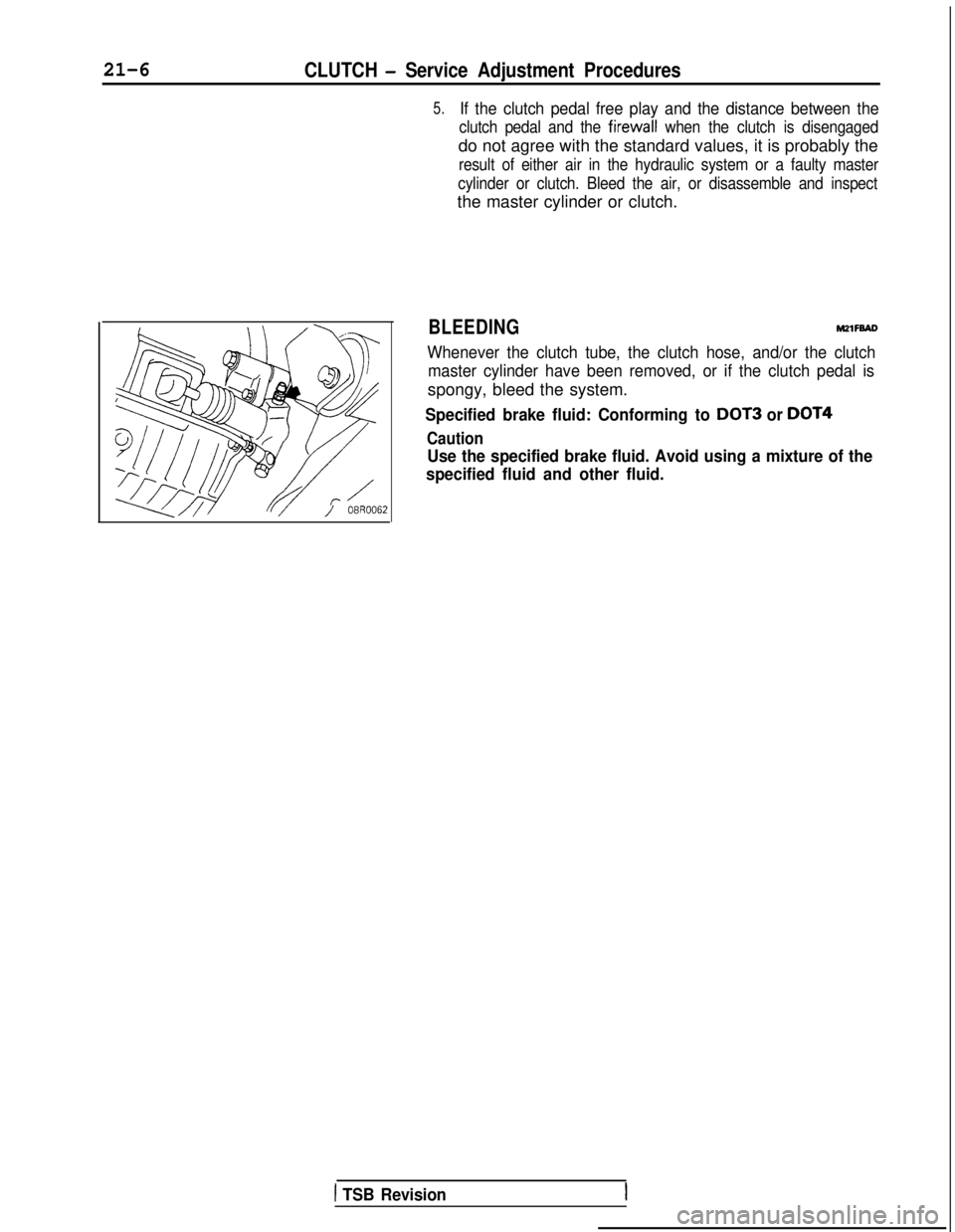

BLEEDINGM2lFBAD

Whenever the clutch tube, the clutch hose, and/or the clutch master cylinder have been removed, or if the clutch pedal is

spongy, bleed the system.

Specified brake fluid: Conforming to DOT3 or DOT4

Caution

Use the specified brake fluid. Avoid using a mixture of the

specified fluid and other fluid.

1 TSB Revision

Page 657 of 1273

CLUTCH - Clutch Pedalm-7

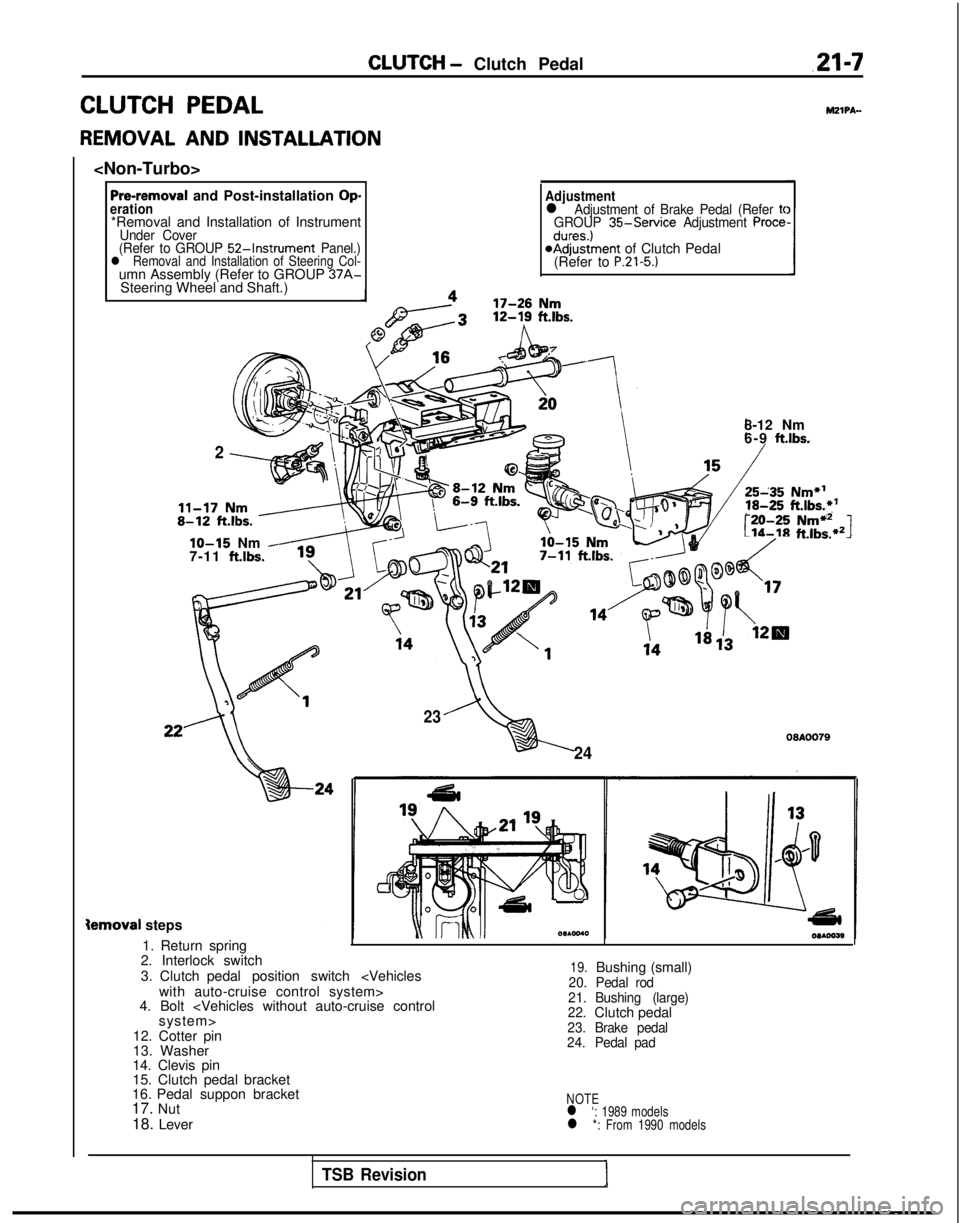

CLUTCH PEDAL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation*Removal and Installation of InstrumentUnder Cover

(Refer to GROUP 52-Instrument Panel.)l Removal and Installation of Steering Col-umn Assembly (Refer to GROUP 37A-Steering Wheel and Shaft.)

Adjustmentl Adjustment of Brake Pedal (Refer tcGROUP 35-Service Adjustment Procedures.)@Adjustment of Clutch Pedal

(Refer to P.21-5.)

MZIPA-

2

8-12 Nm

6-9 ft.lbs.

r:-20-25Nmi12Lib-18ft.lbs.*21lo-15 Nm -7-11 ftlbs.

23

24

09AOO79

Semoval steps

1. Return spring

2. Interlock switch

3. Clutch pedal position switch

4. Bolt

12. Cotter pin

13. Washer

14. Clevis pin

15. Clutch pedal bracket

16. Pedal suppon bracket

17. Nut

18. Lever

19.Bushing (small)20. Pedal rod

21.

22. Bushing (large)

Clutch pedal23.

Brake pedal

24. Pedal pad

NOTEl ‘: 1989 modelsl *: From 1990 models

TSB Revision

Page 658 of 1273

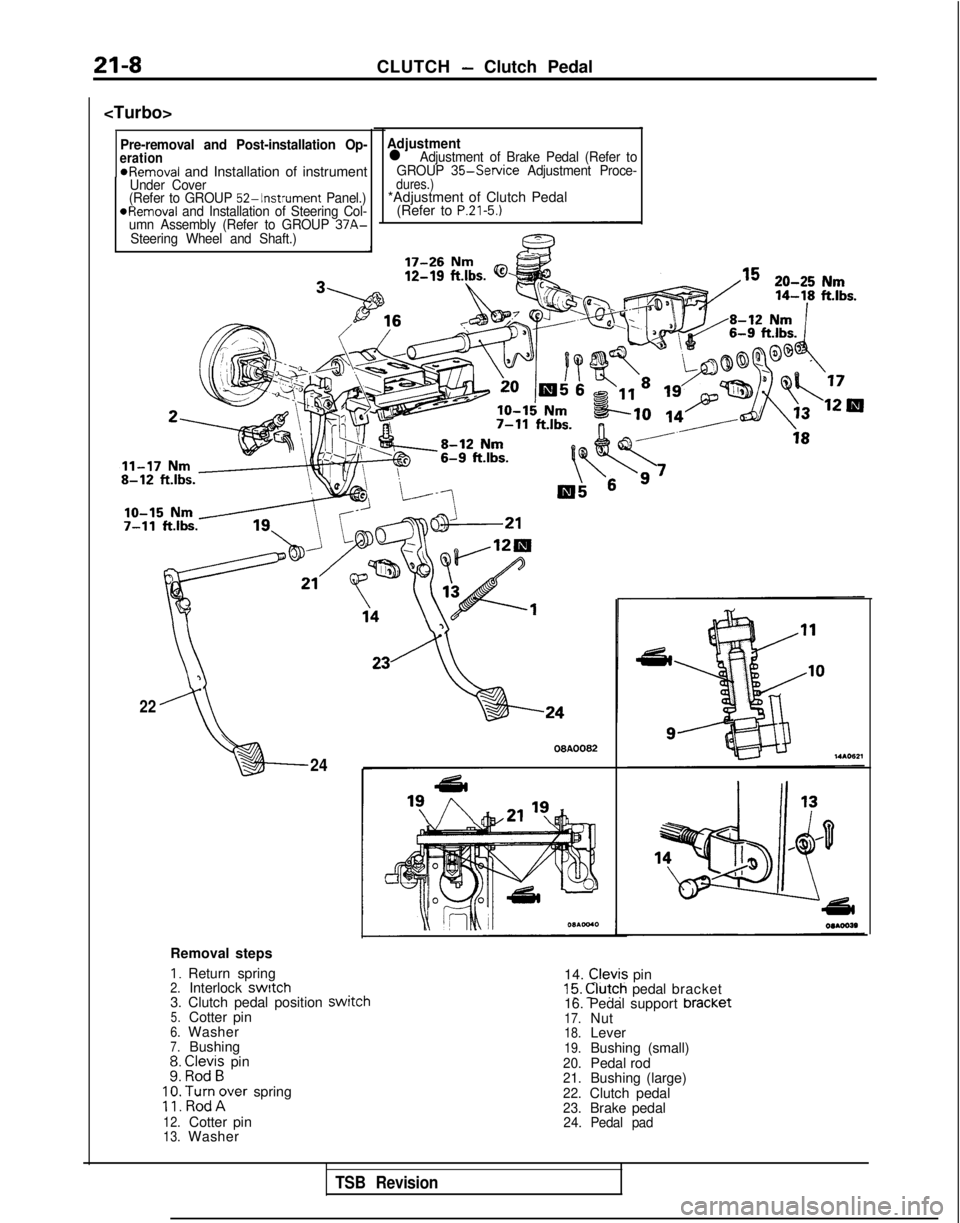

21-8CLUTCH- Clutch Pedal

Pre-removal and Post-installation Op-eration*Removal and Installation of instrumentUnder Cover

(Refer to GROUP 52-Instrument Panel.)*Removal and Installation of Steering Col-

umn Assembly (Refer to GROUP 37A-

Steering Wheel and Shaft.)

Adjustmentl Adjustment of Brake Pedal (Refer to

GROUP 35-Service Adjustment Proce-dures.)*Adjustment of Clutch Pedal

(Refer to P.21-5.1

3

22

“,24 00AOO82

Removal steps

I. Return spring 14. Clevis pin15. @fch pedal bracket2.Interlock switch3. Clutch pedal position switcn5.Cotter pin6.Washer7.Bushing;: E;;i; pin

;

;: poTrer spring

12.Cotter pin13.Washer 16. Pedal support bracket

17.Nut18.Lever19.Bushing (small)20.Pedal rod21.Bushing (large)22.Clutch pedal23.Brake pedal24.

Pedal pad

TSB Revision

Page 659 of 1273

CLUTCH - Clutch Pedal21-9

INSPECTIONM!ZlPCAG

l Check the pedal shaft and bushing for wear.

l Check the clutch pedal for bend or torsion.

l Check the return spring for damage or deterioration.

l Check the pedal pad for damage or wear.

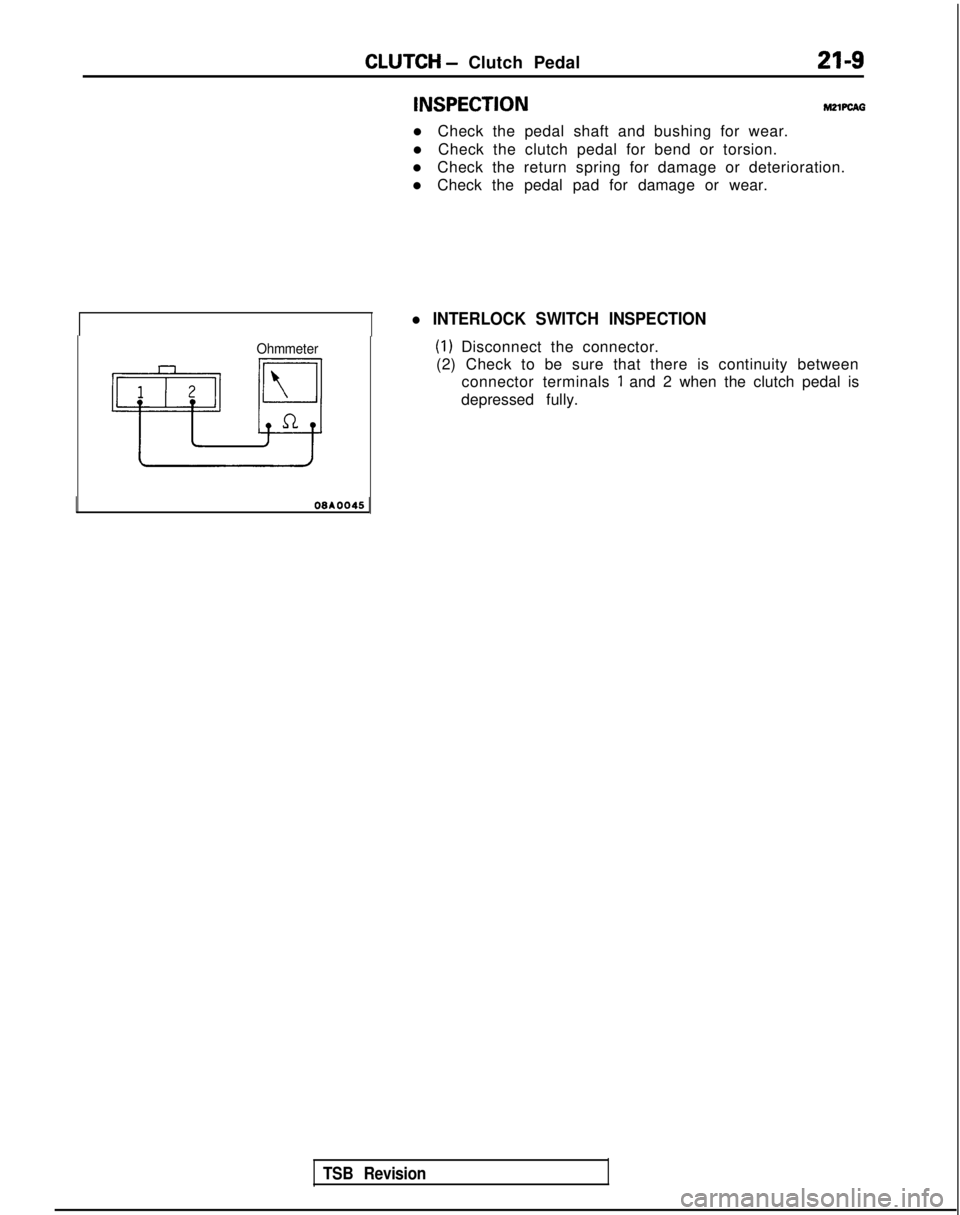

l INTERLOCK SWITCH INSPECTION

Ohmmeter(1) Disconnect the connector.

(2) Check to be sure that there is continuity between connector terminals

1 and 2 when the clutch pedal is

depressed fully.

OGAOO45

TSB Revision

Page 660 of 1273

21-10CLUTCH - Clutch Control

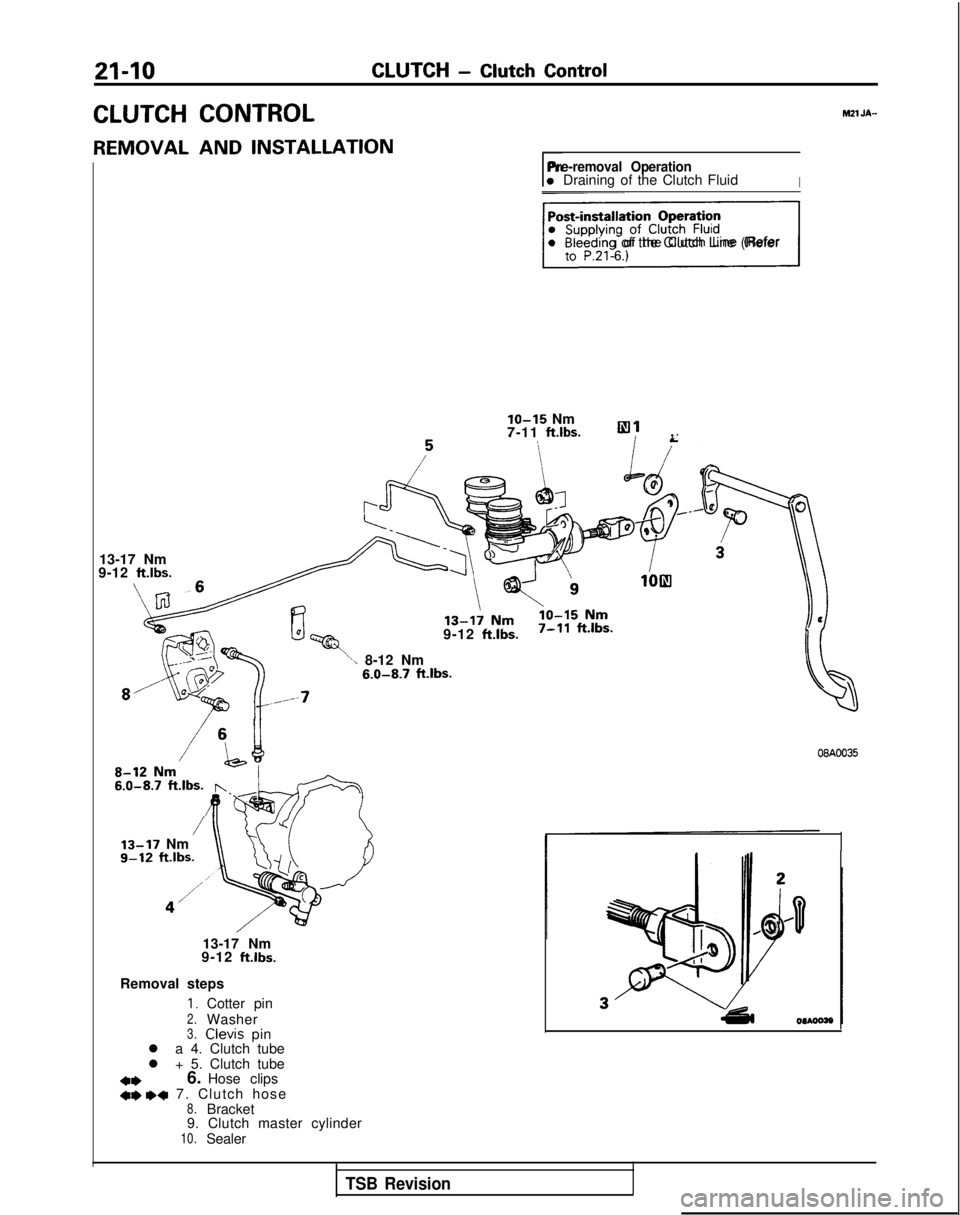

CLUTCH CONTROLh121 JA-

REMOVAL AND INSTALLATION

rPre-removal Operationl Draining of the Clutch FluidI

piigsql Bleeding of the Clutch Line (Refer

lo-15 Nm

7-11 ft.lbs.,

13-17 Nm

9-12

ft.lbs.

9-12 ft.lbs.

\-\ 8-12 Nm 6.0-8.7

ft.lbs.

/ 13-17

Nm

9-12 ftlbs.

13-17 Nm

9-12

ft.lbs.

Removal steps

I. Cotter pin2.Washer3. Clevis

pin

l a 4. Clutch tube

l + 5. Clutch tube

a*6. Hose clips*I) wq 7. Clutch hose8.Bracket

9. Clutch master cylinder

10.Sealer

08A0035

TSB Revision