MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 781 of 1273

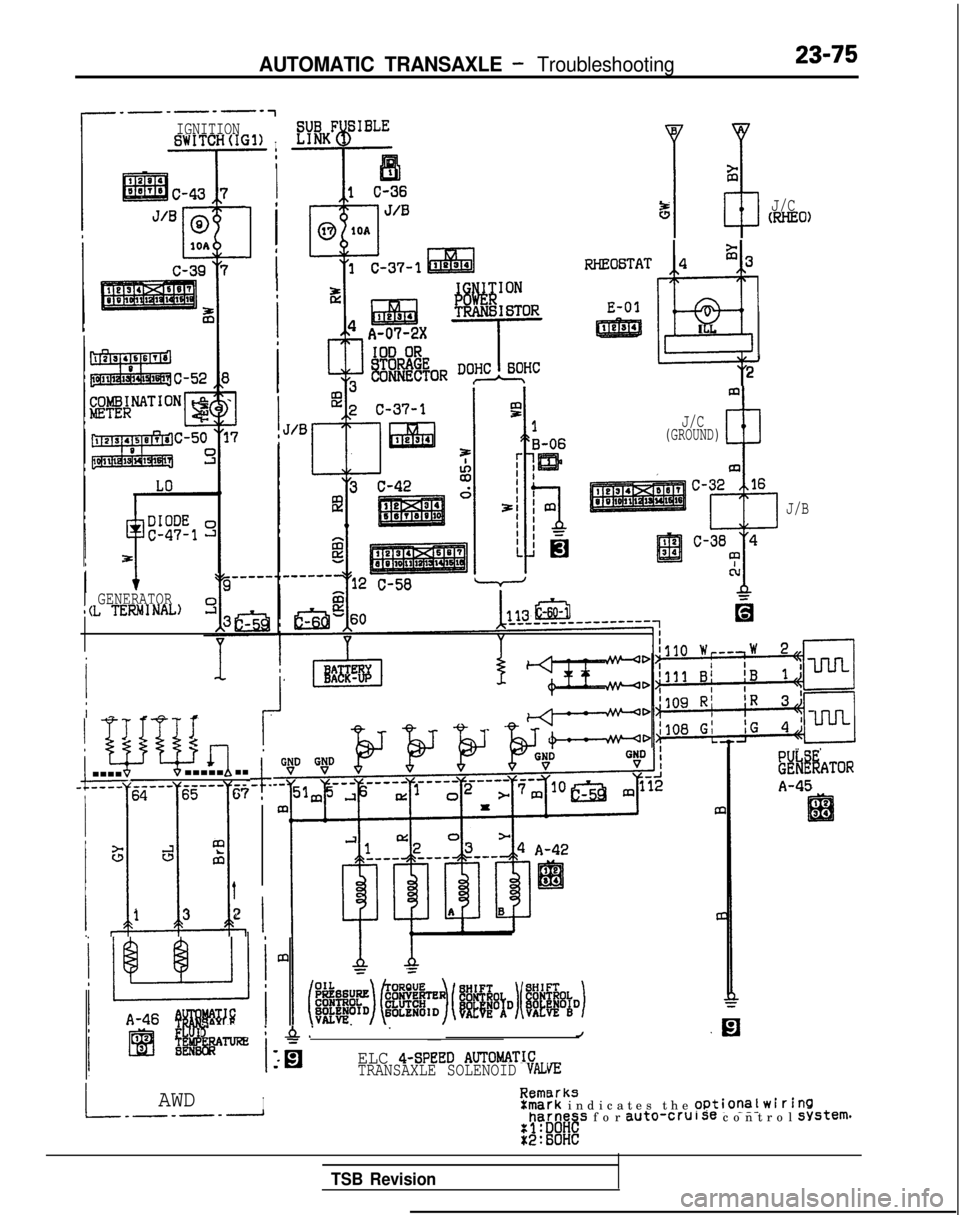

AUTOMATIC TRANSAXLE - Troubleshooting23-75

IGNITIONBWITCH(IG1)I

Ia

I

1 ’

iRHEO6TAT

E-01

5J/CmHE0)

GENERATORl(L TERMNAL)

4$3

@

I

L

2

I I-?i

wb&q-------.-.-.-------6567

I

Y

.l!.

GJal

t

13 2

$- .

I

J/C(GROUND)

J/B

s -iA.’ . .

~J

ELC 4-SPEED AUTOtdATICTRANSAXLE SOLENOID VALVIZ

8rksIAWDIE::-...-rk indicates the Optional WirinQharness for auto-cruise control system.

..a

.nnuL_-_-____1

8ki%ATOR

A-45

TSB Revision

Page 782 of 1273

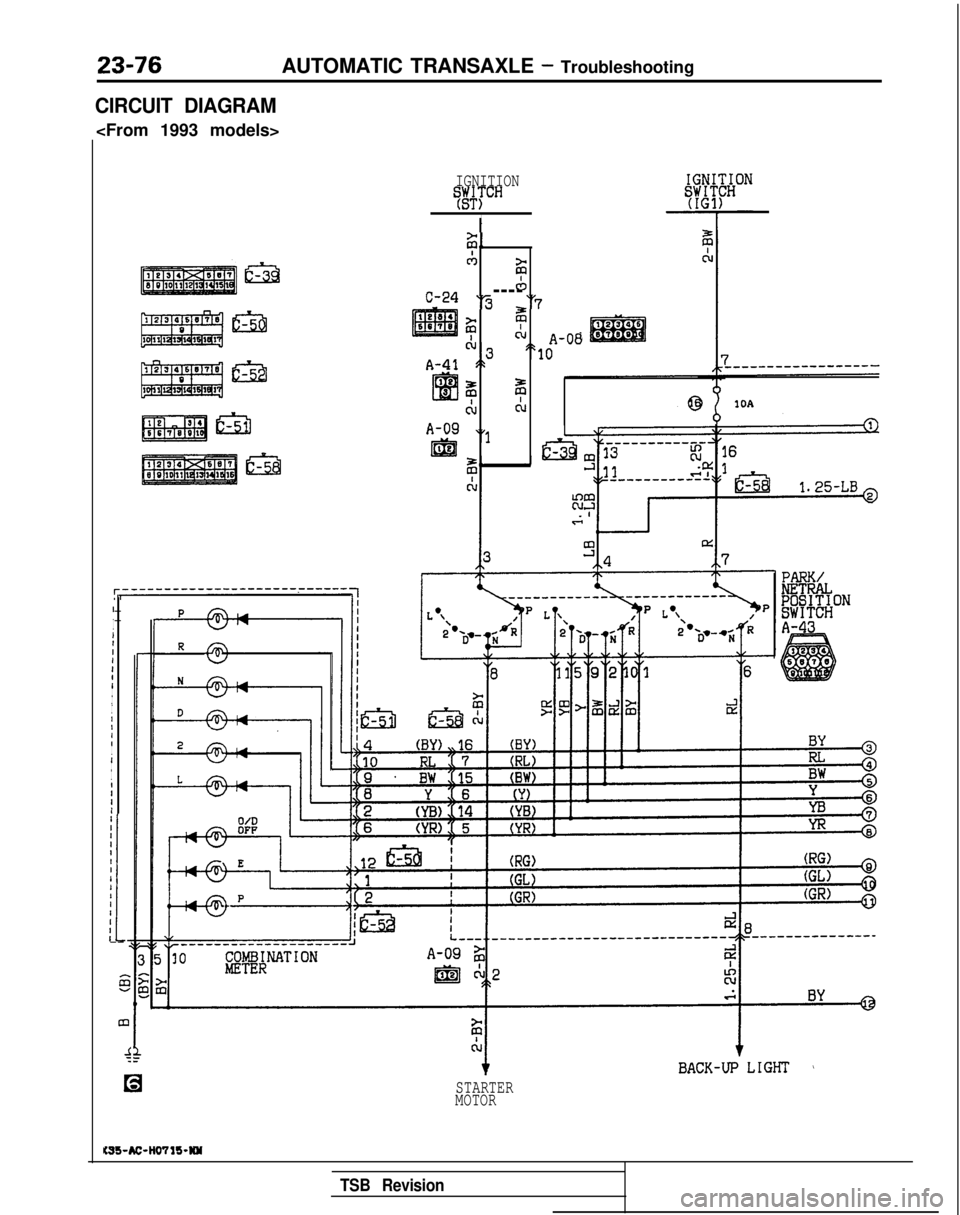

23-76AUTOMATIC TRANSAXLE - Troubleshooting

CIRCUIT DIAGRAM

IGNITIONT#TCH

I

IIIIIII

II

I

I

I

IIII

I

I

I

I

IIII

I

iII-- 5

m

4

C-24

A-41

A-09

I&

ii,,

CAzicb----‘3 “7

? zcl,\ A-08",e "10,.

z z

CL

&

“1

Gl)

I

10A

STARTER

MOTOR

PARK/

lg@&bN

A-43

KSS-AC-H0711-W

TSB Revision

Page 783 of 1273

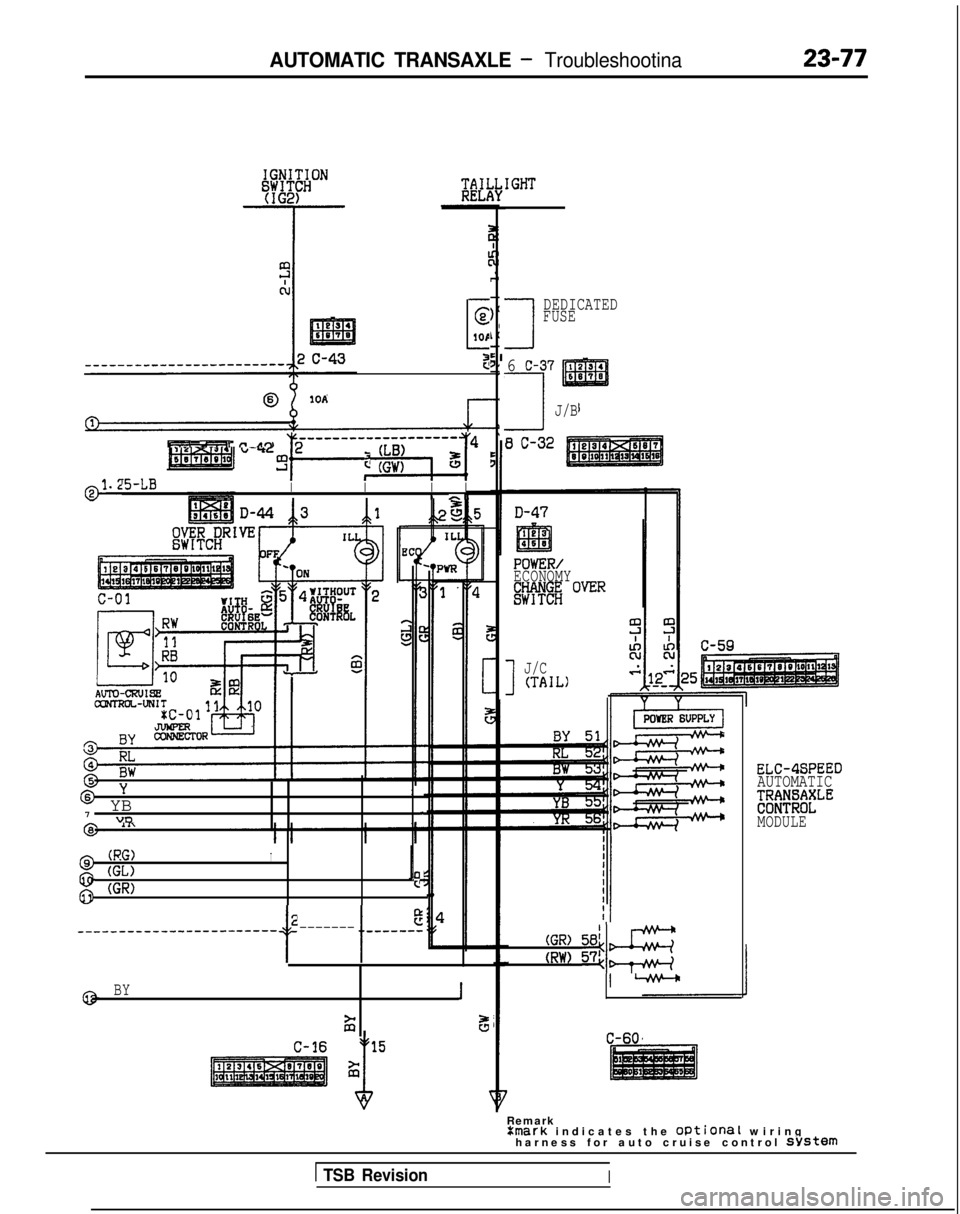

AUTOMATIC TRANSAXLE - Troubleshootina

-

E

1OP

3

@IOA

PT.-. L-_..il Tr-ltn

-

.-

-~-------y~-J4 ~

!kJ-LBII

I II rrl

6Y

* YB

I

7"DI.

(RG)

@ (GL)I

g (GR)Is

2

t I

e_-_-_----_~~__---~~~~~~~ -------w-v----

BY

1 2

s

1

DEDICATED

FUSE

6 C-37

7J/B

8 C-32

POWER/

ECONOMY

!RRi OVER

1

J/C(TAIL)

ELC-4SPEED

AUTOMATIC

;;;f?;;lfLE

MODULE

(GR) 58;&

(RW) 574~

C-60

Remark Xmark

indicates the Optional wirin

g

harness for auto cruise control

system

1 TSB RevisionI

Page 784 of 1273

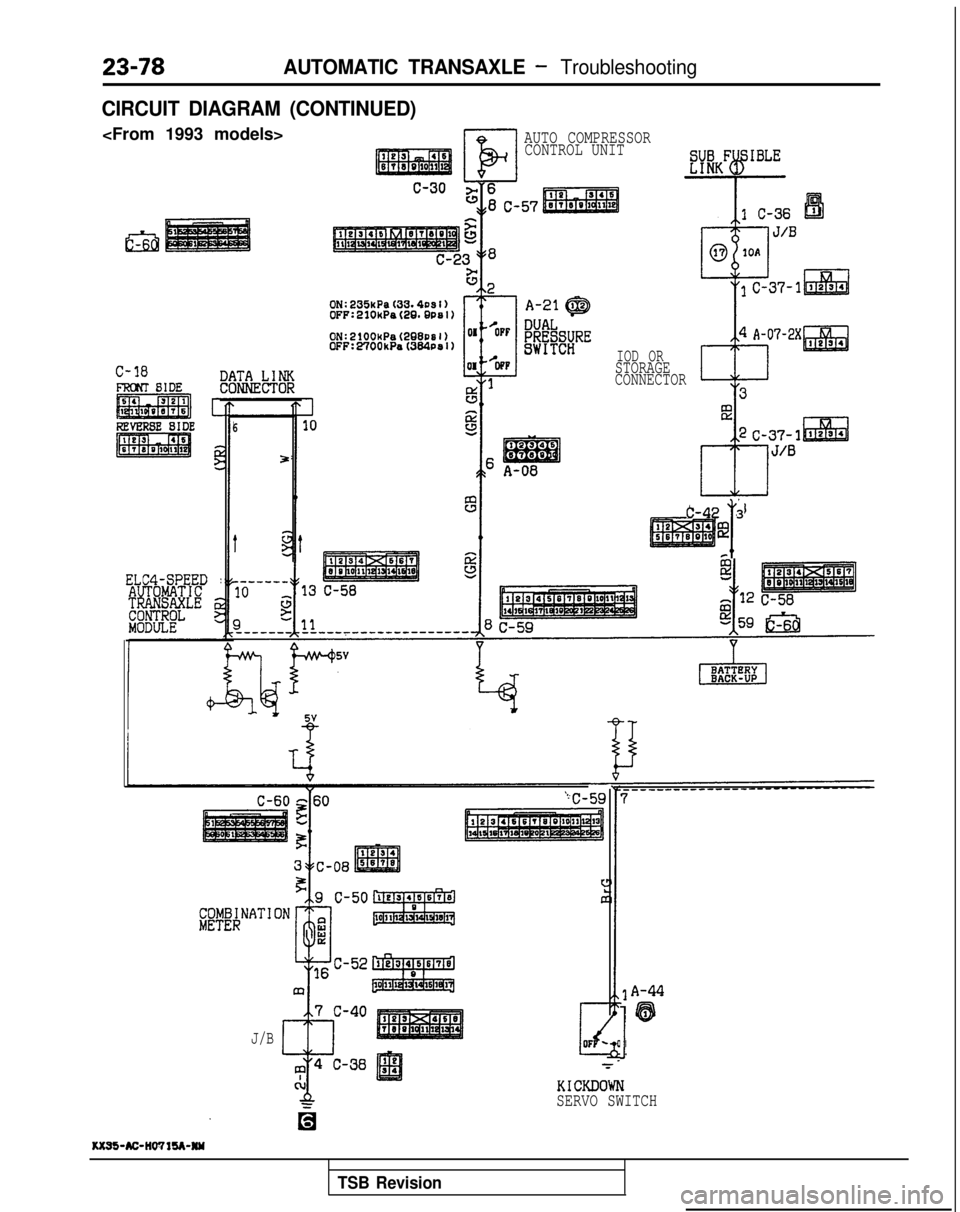

AUTOMATIC TRANSAXLE - Troubleshooting

CIRCUIT DIAGRAM (CONTINUED)

El

AUTO COMPRESSORCONTROL UNIT

C-18

ELC4-SPEED :

6

5

J/B IOD OR

STORAGE

CONNECTOR

T

C-42 3

@

I

A-44

'63

1

KICKDOWN

SERVO SWITCH

1(x95-AC-IlWlU-NW

TSB Revision

Page 785 of 1273

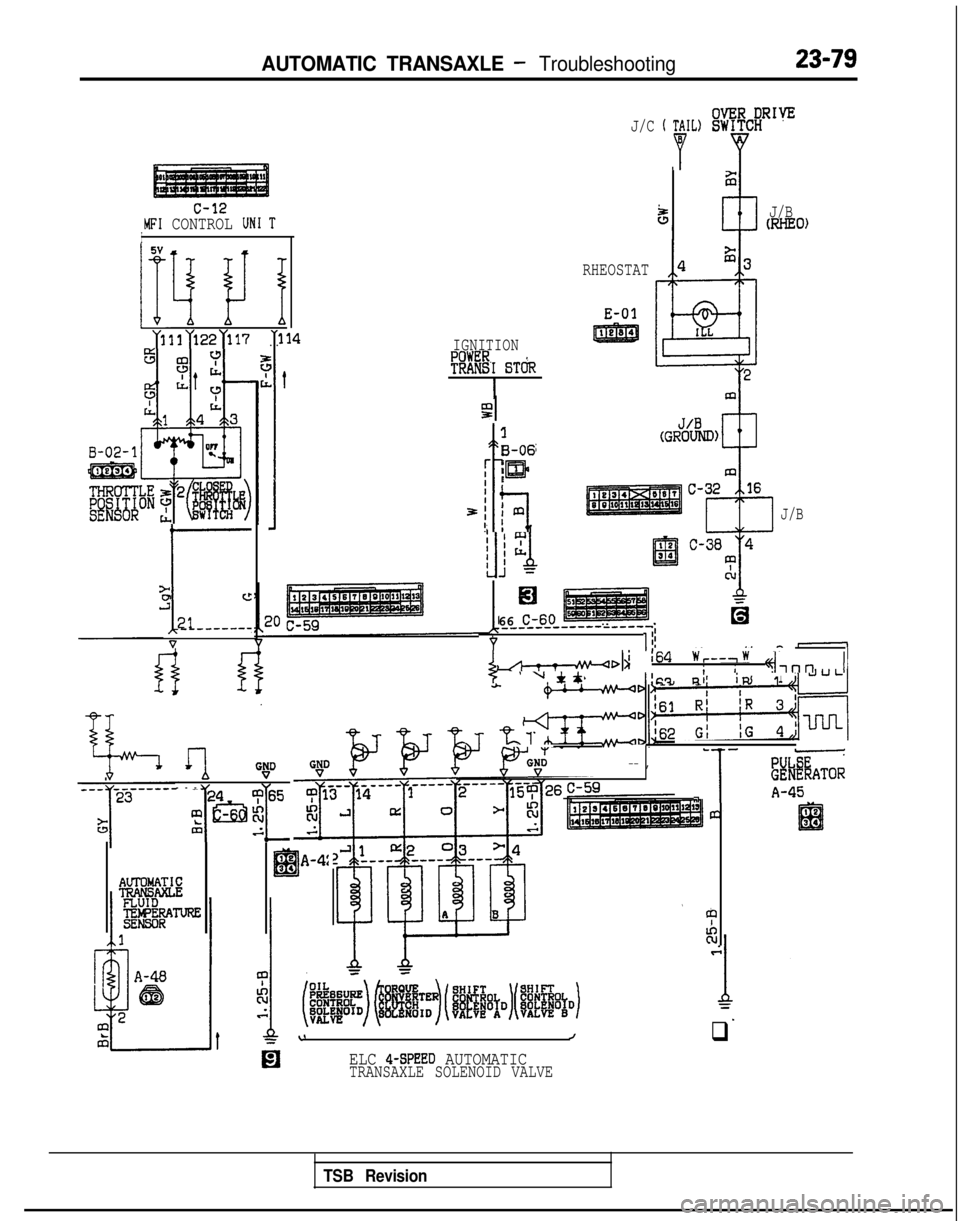

AUTOMATIC TRANSAXLE - Troubleshooting23-79

c-12MFI CONTROL UN1 TI5V

IFI I! I

m~131>22~117. .

I-

a

J”c

;It------

V

IGNITION

?!RE-I BT&

I

1

B-06

[ lm

3;

t7 fmI! 1

J/C ’ P’L)!%flg

5J/BWIEO)

RHEOSTAT

E-01

J/B

1.

El

66 C-60_____-_-m-w---v-v-

Yli

I-~I~i64w,--,w i!

’ u Jtt; i 4-l”” II!C? niiR1

.rllG!D

--

-

m2&jg”5

7 L&.z

’ eIEB34A-4:

twT&AAg

rGN:-- --- ,

- -

V

,,,1

-

ii#d%ATOR

A-45._I2IEil34

43

tc

\Jq

ELC 4-SPEED AUTOMATICTRANSAXLE SOLENOID VALVE

TSB Revision

Page 786 of 1273

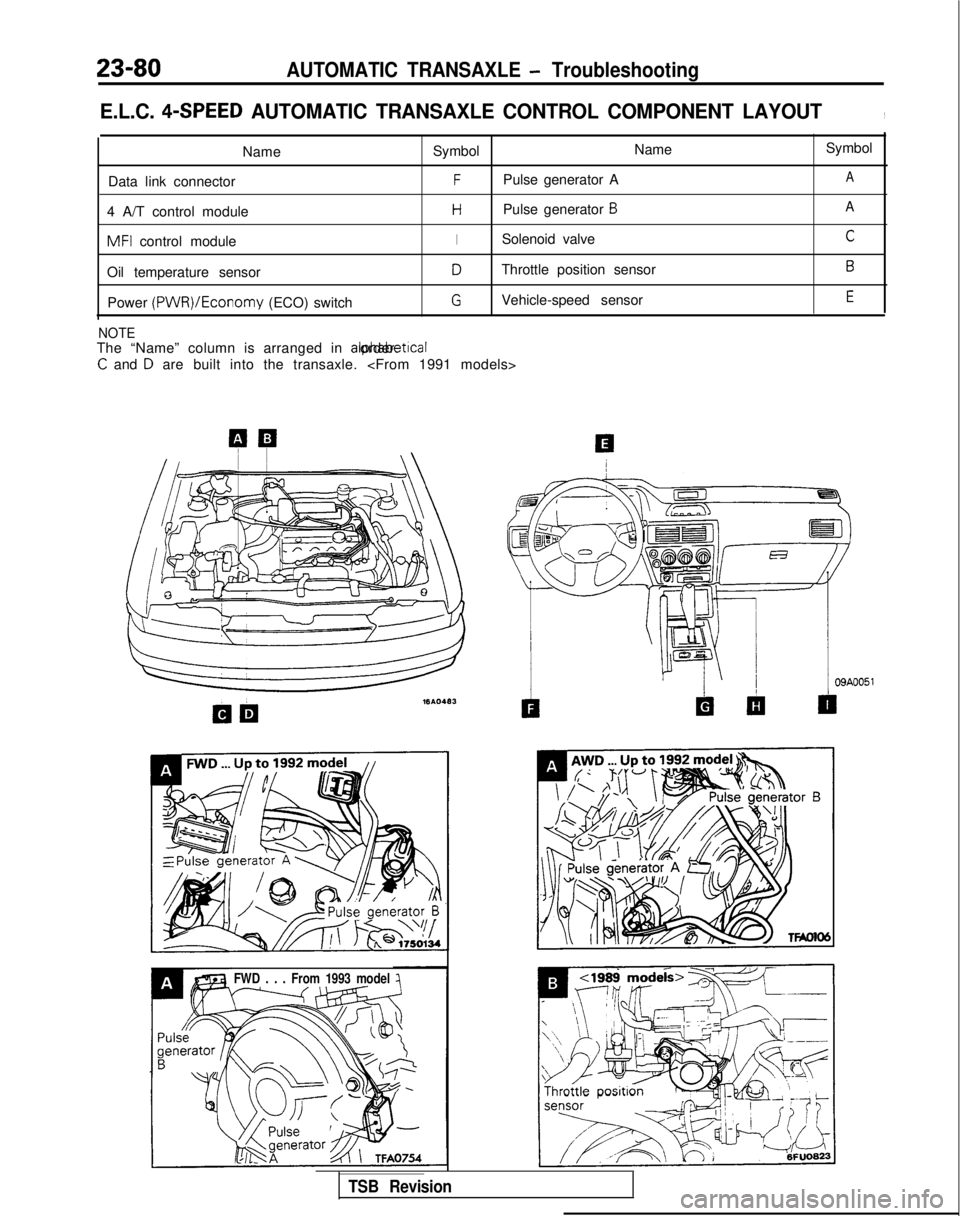

23-80AUTOMATIC TRANSAXLE - Troubleshooting

E.L.C. 4-SPEED AUTOMATIC TRANSAXLE CONTROL COMPONENT LAYOUT,

NameSymbol Name

Data link connector

FPulse generator A

4 A/T control module

HPulse generator 6

MFI control moduleISolenoid valve

Oil temperature sensor

DThrottle position sensor

Power (PWR)/Economy

(ECO) switch

GVehicle-speed sensor

NOTEThe “Name” column is arranged in alphabetrcal order.

C and D are built into the transaxle.

Symbol

A

A

C

B

E

FWD . . . From 1993 model

TSB Revision

Page 787 of 1273

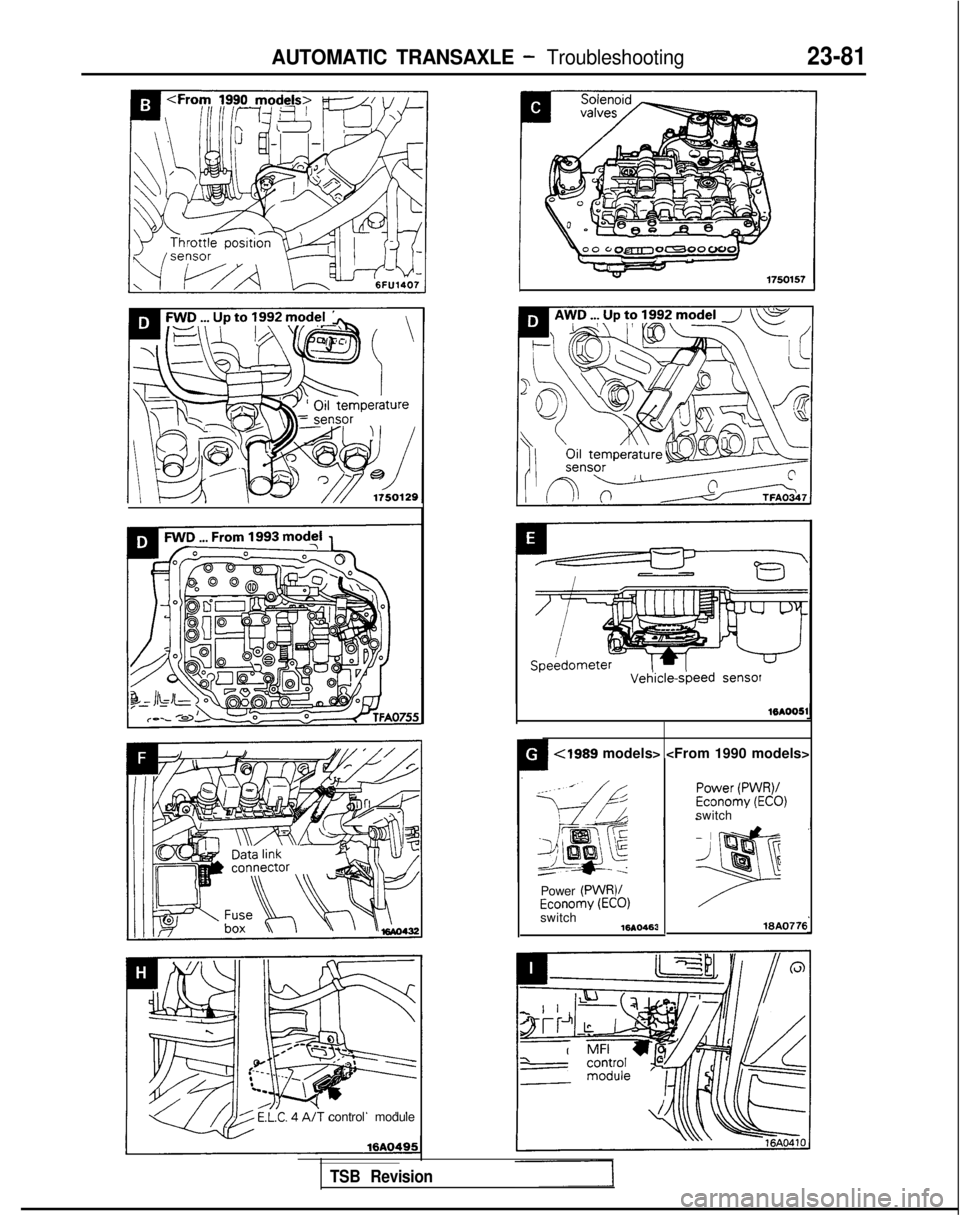

AUTOMATIC TRANSAXLE - Troubleshooting23-81

control module

Vet-kle-sbeed sensor

16AOOSl4

<1989 models>

Power

(PWR)/Economy (ECO)switch 16AO463

Power (PWR)/Economy (ECO)switch

WA0776

TSB Revision

Page 788 of 1273

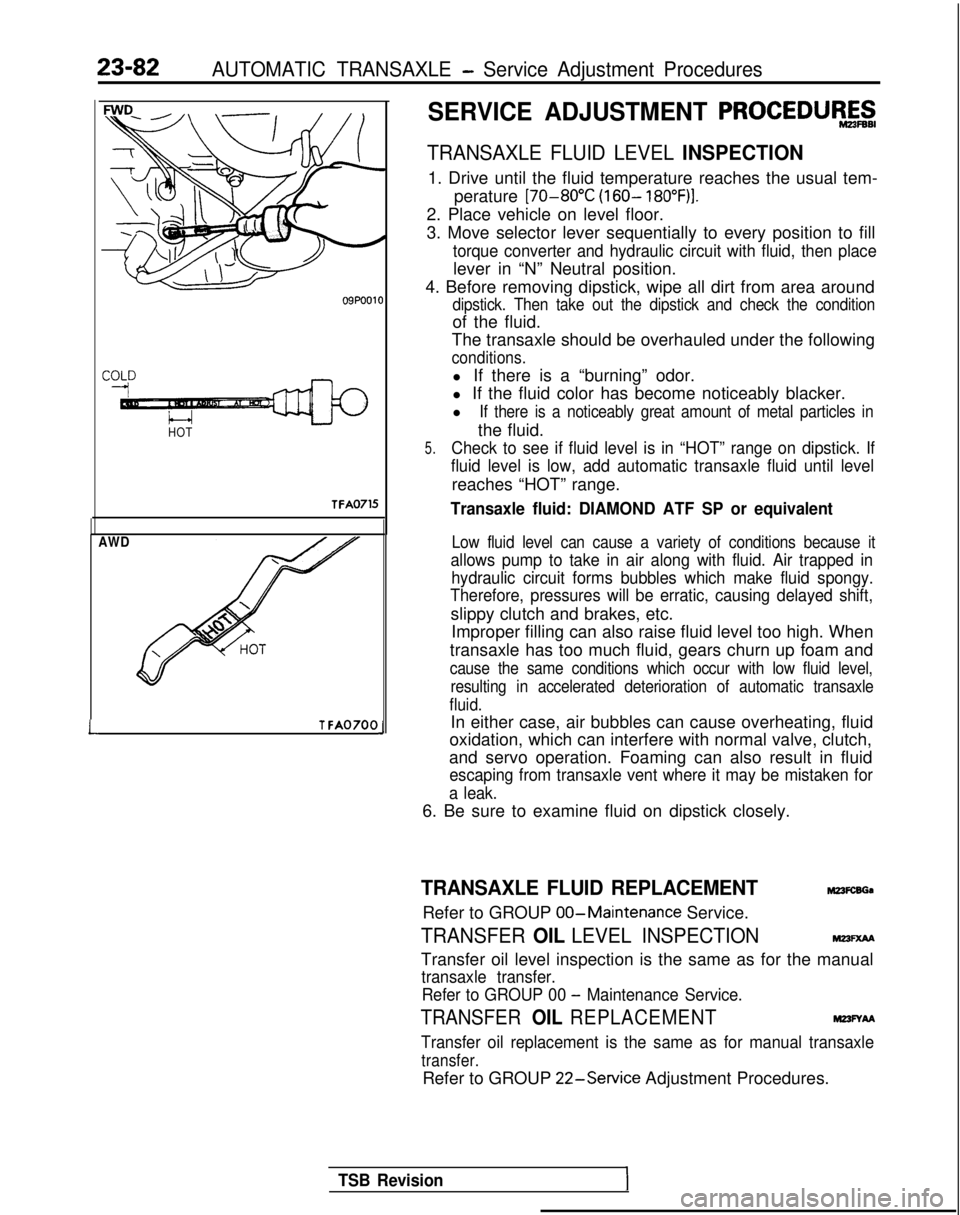

23-82AUTOMATIC TRANSAXLE - Service Adjustment Procedures

HOTTFA0715

AWD

LT FA0700J

SERVICE ADJUSTMENT PROCEDUR&g

TRANSAXLE FLUID LEVEL INSPECTION

1. Drive until the fluid temperature reaches the usual tem-

perature [70-80°C

(160- 18O”F)I.

2. Place vehicle on level floor.

3. Move selector lever sequentially to every position to fill

torque converter and hydraulic circuit with fluid, then place

lever in “N” Neutral position.

4. Before removing dipstick, wipe all dirt from area around

dipstick. Then take out the dipstick and check the condition

of the fluid.

The transaxle should be overhauled under the following

conditions.

l If there is a “burning” odor.

l If the fluid color has become noticeably blacker.

l

If there is a noticeably great amount of metal particles in

the fluid.

5.Check to see if fluid level is in “HOT” range on dipstick. If

fluid level is low, add automatic transaxle fluid until level

reaches “HOT” range.

Transaxle fluid: DIAMOND ATF SP or equivalent

Low fluid level can cause a variety of conditions because it

allows pump to take in air along with fluid. Air trapped in hydraulic circuit forms bubbles which make fluid spongy.

Therefore, pressures will be erratic, causing delayed shift,

slippy clutch and brakes, etc.

Improper filling can also raise fluid level too high. When

transaxle has too much fluid, gears churn up foam and

cause the same conditions which occur with low fluid level, resulting in accelerated deterioration of automatic transaxle

fluid.

In either case, air bubbles can cause overheating, fluid

oxidation, which can interfere with normal valve, clutch,

and servo operation. Foaming can also result in fluid

escaping from transaxle vent where it may be mistaken for

a leak.

6. Be sure to examine fluid on dipstick closely.

TRANSAXLE FLUID REPLACEMENTM23FcsGa

Refer to GROUP 00-Maintenance

Service.

TRANSFER OIL LEVEL INSPECTIONMm=xM

Transfer oil level inspection is the same as for the manual

transaxle transfer.

Refer to GROUP 00

- Maintenance Service.

TRANSFER OIL REPLACEMENTM23FYAA

Transfer oil replacement is the same as for manual transaxle

transfer.

Refer to GROUP 22-Service

Adjustment Procedures.

TSB Revision

Page 789 of 1273

AUTOMATIC TRANSAXLE - Service Adjustment Procedures23-83

I:

I’

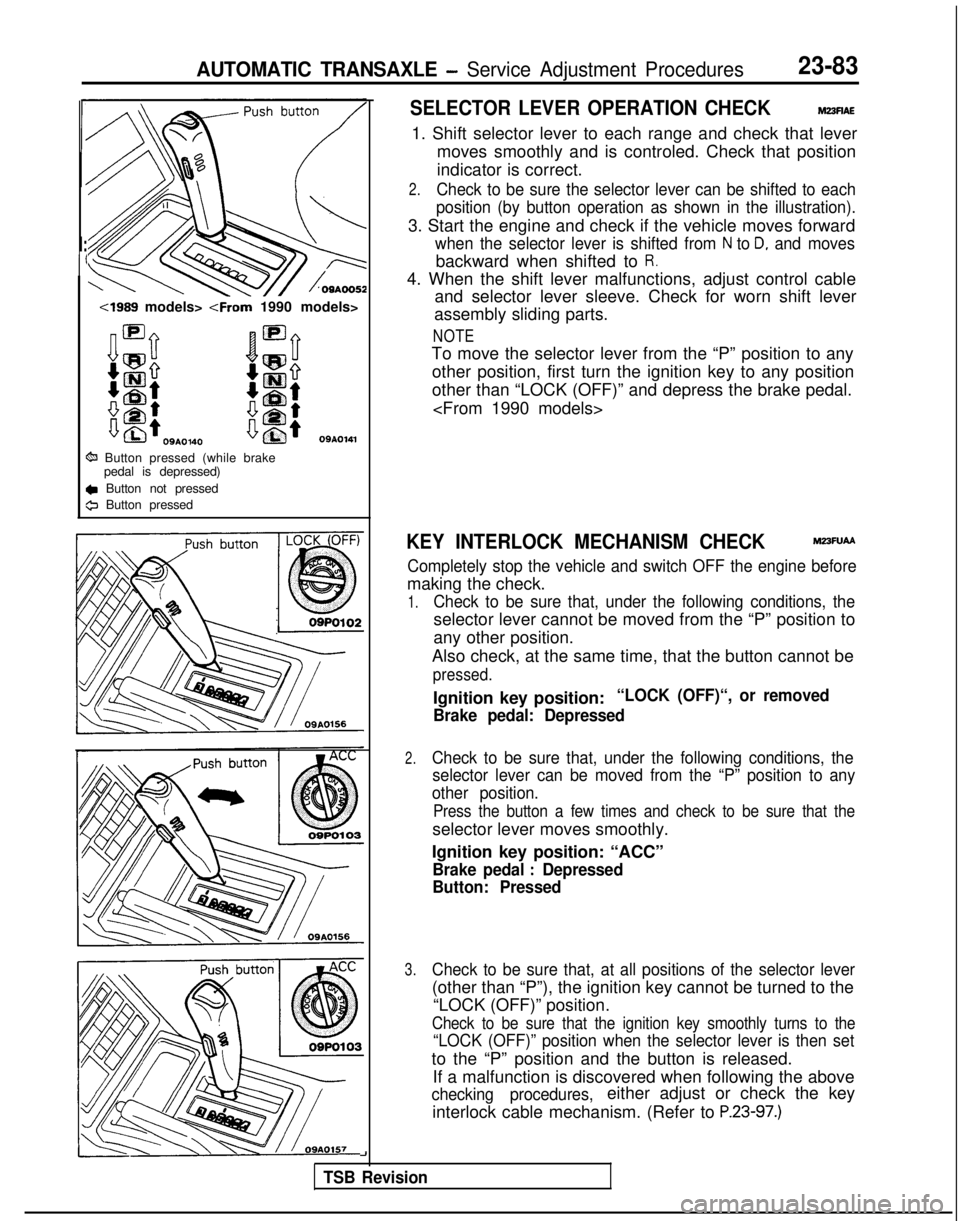

4989 models>

09A0140

6% Button pressed (while brakepedal is depressed)

c Button not pressed

0 Button pressed

SELECTOR LEVER OPERATION CHECKM23flAE

1. Shift selector lever to each range and check that lever

moves smoothly and is controled. Check that position

indicator is correct.

2.Check to be sure the selector lever can be shifted to each

position (by button operation as shown in the illustration).

3. Start the engine and check if the vehicle moves forward

when the selector lever is shifted from N to D, and moves

backward when shifted to R.

4. When the shift lever malfunctions, adjust control cable and selector lever sleeve. Check for worn shift lever

assembly sliding parts.

NOTE

To move the selector lever from the “P” position to any

other position, first turn the ignition key to any position

other than “LOCK (OFF)” and depress the brake pedal.

KEY INTERLOCK MECHANISM CHECKM23FUAA

Completely stop the vehicle and switch OFF the engine before

making the check.

1.Check to be sure that, under the following conditions, the

selector lever cannot be moved from the “P” position to

any other position.

Also check, at the same time, that the button cannot be

pressed.

Ignition key position:“LOCK (OFF)“, or removed

Brake pedal: Depressed

2.Check to be sure that, under the following conditions, the selector lever can be moved from the “P” position to any

other position.

Press the button a few times and check to be sure that the

selector lever moves smoothly.

Ignition key position: “ACC”

Brake pedal : Depressed

Button: Pressed

3.Check to be sure that, at all positions of the selector lever

(other than “P”), the ignition key cannot be turned to the

“LOCK (OFF)” position.

Check to be sure that the ignition key smoothly turns to the

“LOCK (OFF)” position when the selector lever is then set

to the “P” position and the button is released.

If a malfunction is discovered when following the above

checking procedures,either adjust or check the key

interlock cable mechanism. (Refer to

P.23-97.)

-I

TSB Revision

Page 790 of 1273

23-84AUTOMATIC TRANSAXLE - Service Adiustment Procedures

Brake

pedal

IOSM0045

A

iection A-A

Switch body

- 175133

12 mm (.47 in.)

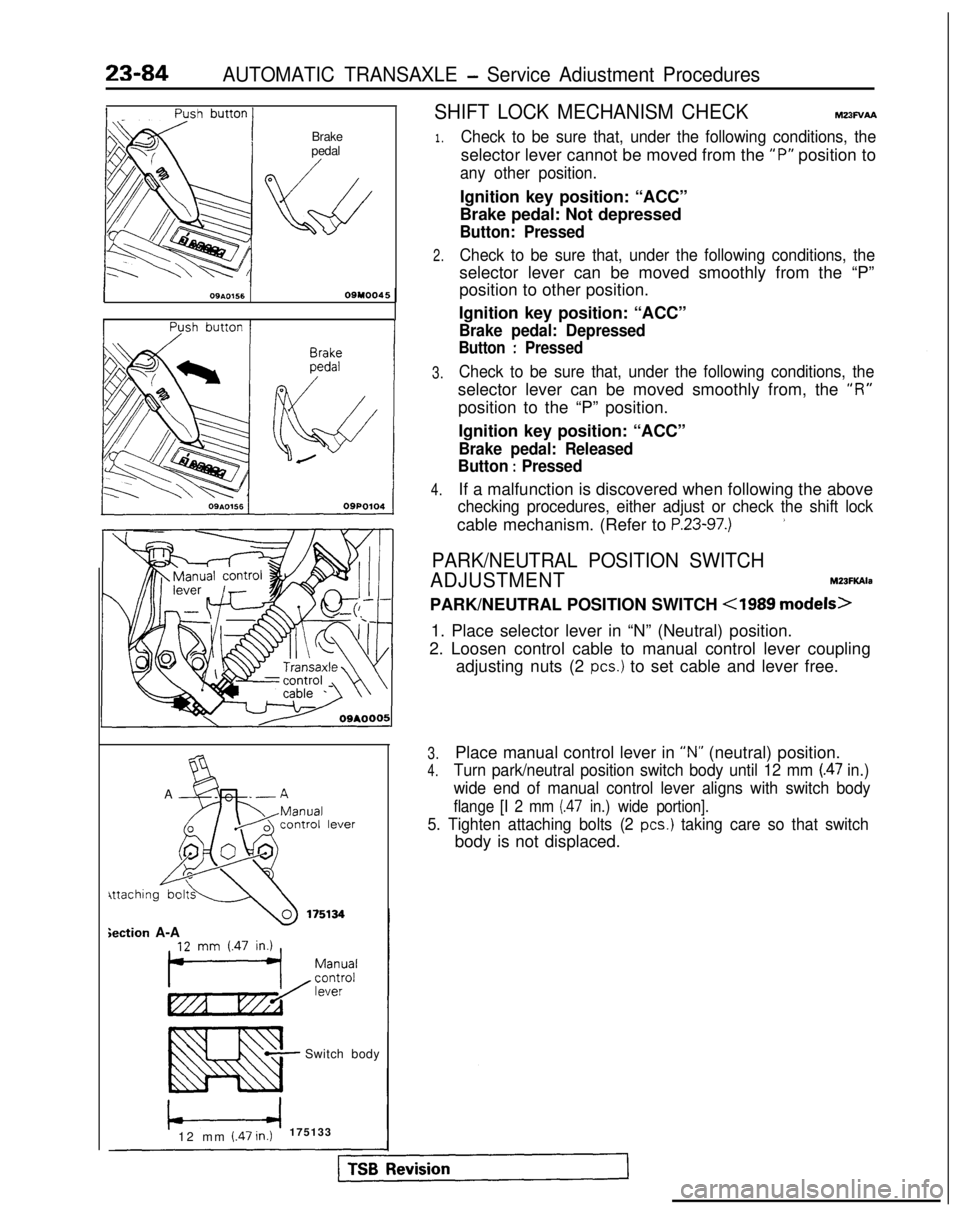

SHIFT LOCK MECHANISM CHECKMz3Fv~

1.

2.

3.

4.

Check to be sure that, under the following conditions, the

selector lever cannot be moved from the “P”

position to

any other position.

Ignition key position: “ACC”

Brake pedal: Not depressed

Button: Pressed

Check to be sure that, under the following conditions, the

selector lever can be moved smoothly from the “P”

position to other position.

Ignition key position: “ACC”

Brake pedal: Depressed

Button : Pressed

Check to be sure that, under the following conditions, the

selector lever can be moved smoothly from, the “I?”

position to the “P” position.

Ignition key position: “ACC”

Brake pedal: Released

Button

: Pressed

If a malfunction is discovered when following the above

checking procedures, either adjust or check the shift lock

cable mechanism. (Refer to P.23-97.)’

PARK/NEUTRAL POSITION SWITCH

ADJUSTMENT M23FKAla

PARK/NEUTRAL POSITION SWITCH

<1989 models>

1. Place selector lever in “N” (Neutral) position.

2. Loosen control cable to manual control lever coupling adjusting nuts (2

PCS.) to set cable and lever free.

3.Place manual control lever in “N” (neutral) position.

4.Turn park/neutral position switch body until 12 mm (.47 in.)

wide end of manual control lever aligns with switch body

flange [I 2 mm (.47 in.) wide portion].

5. Tighten attaching bolts (2 PCS.) taking care so that switch

body is not displaced.