MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 751 of 1273

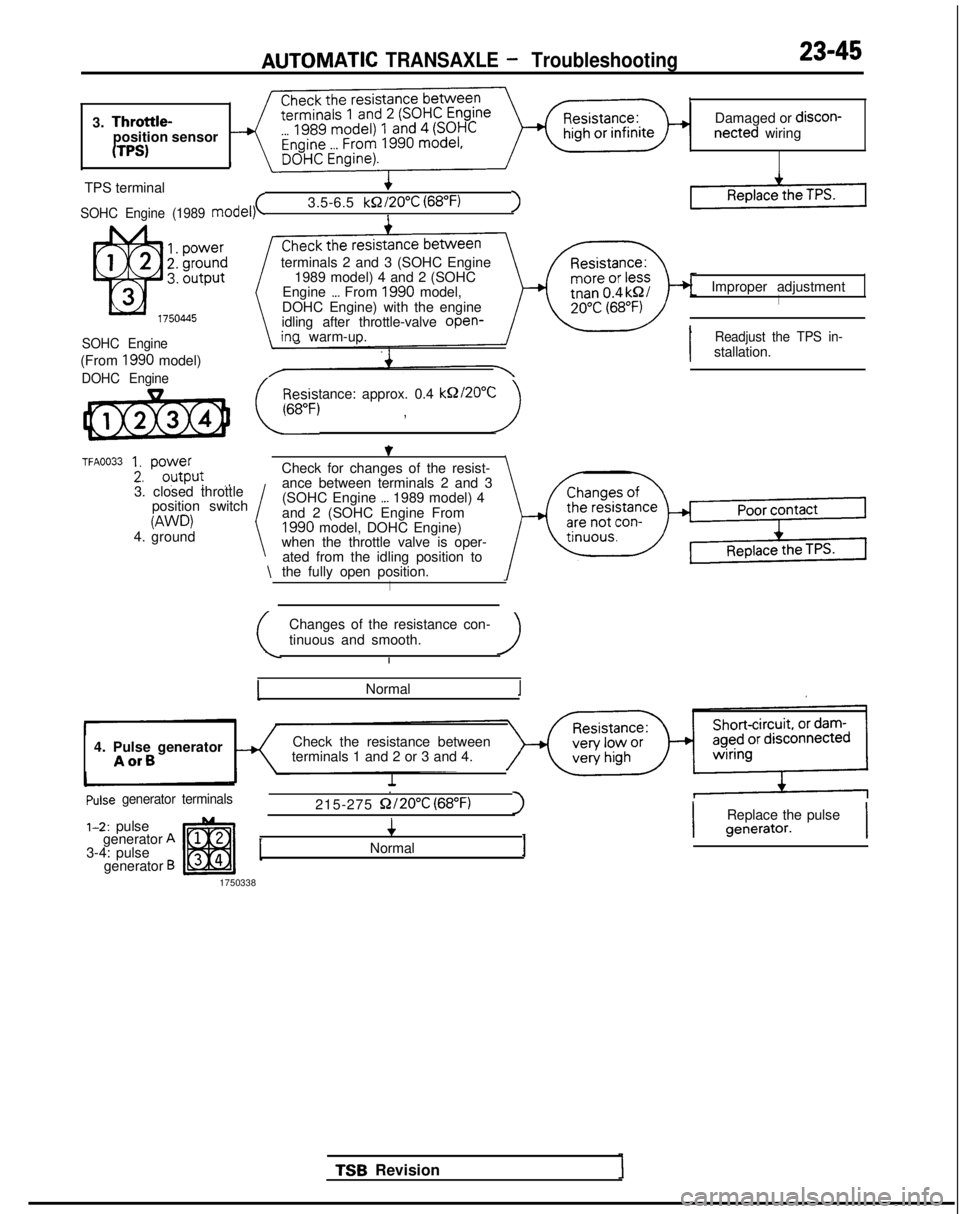

AlJTCMVlATlC TRANSAXLE - Troubleshooting23-45

3. Throttle-position sensor

UPS)

Damaged or discon-netted wiring

TPS terminal

SOHC Engine (1989 model)(3.5-6.5 kQ/20”C

(68°F)1I

SOHC Engine

(From 1990 model)

DOHC Engine

TFA0033 1. power

2. outpur.,

terminals 2 and 3 (SOHC Engine

1989 model) 4 and 2 (SOHC

Engine

_._ From 1990 model,

DOHC Engine) with the engine

idling after throttle-valve open-

ina warm-up.

Resistance: approx. 0.4

kQZ20”C

(,6,, , )

3. closed throttle position switch

W’D)4. ground \

Check for changes of the resist-

ance between terminals 2 and 3

(SOHC Engine

,._ 1989 model) 4

and 2 (SOHC Engine From

1990 model, DOHC Engine)

when the throttle valve is oper-

ated from the idling position to

the fully open position.

I

Changes of the resistance con-

tinuous and smooth.

Normal

4. Pulse generator

AorB

Check the resistance between

terminals 1 and 2 or 3 and 4.

Pulse generator terminals.

215-275

Q/20% (68°F)I

1-2: pulse

generator A3-4: pulse

generator B

4

Normal1

1750338 Improper adjustment

I

I

Readjust the TPS in-stallation.

TSB Revision

I

Replace the pulsegenerator.I

Page 752 of 1273

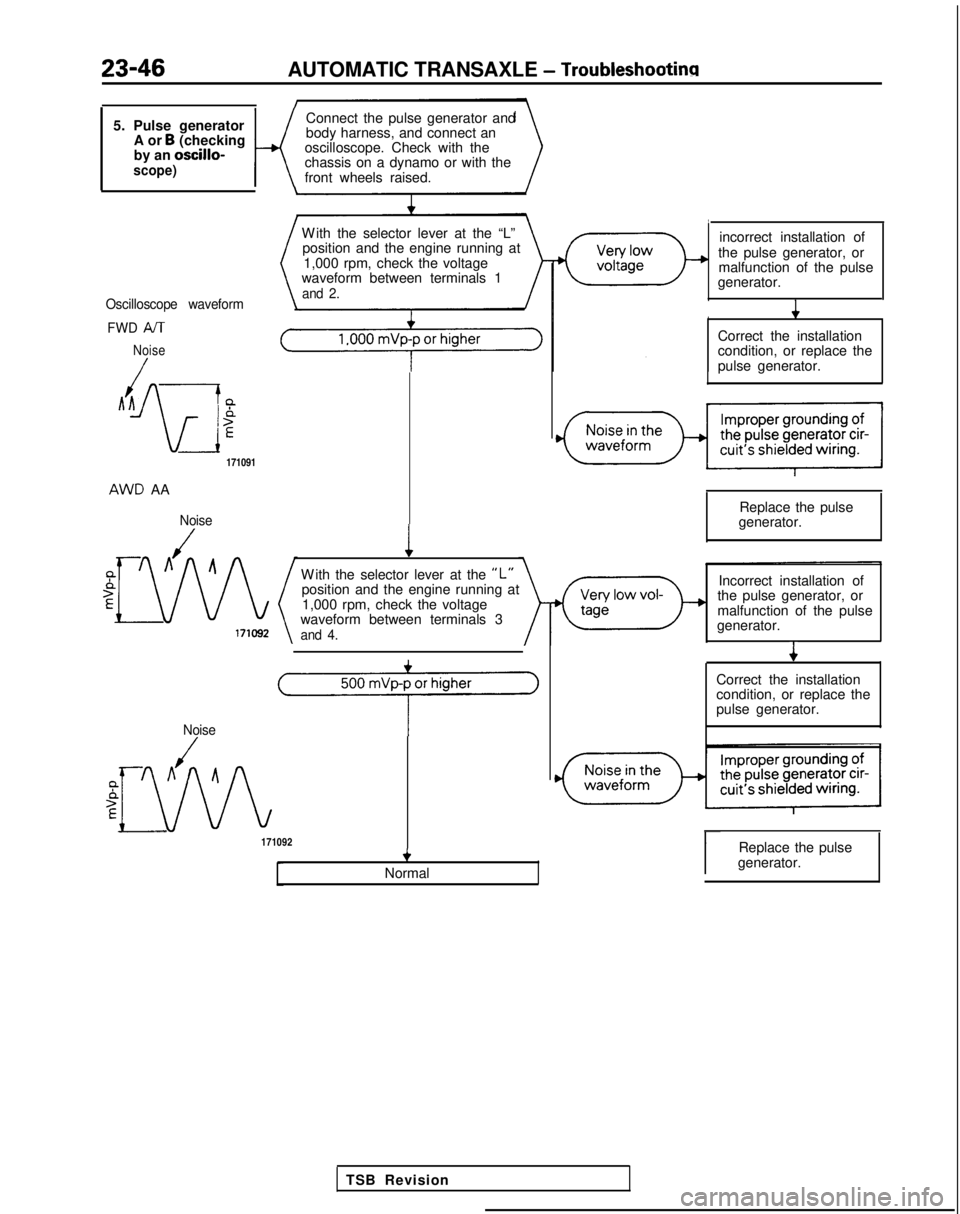

23-46AUTOMATIC TRANSAXLE - Troubleshootincl

5. Pulse generatorA or B (checking

by an oscillo-

scope)K

Connect the pulse generator and

body harness, and connect an

oscilloscope. Check with the

chassis on a dynamo or with the

front wheels raised.

Oscilloscope waveform

FWD

/VT

Noise

/Ah --L

Ar

IP

-iE

171091 AWD

AA

Noise

W

ith the selector lever at the “L”

position and the engine running at

1,000 rpm, check the voltage

waveform between terminals 1

and 2.

1

W

ith the selector lever at the

“L”position and the engine running at

1,000 rpm, check the voltage

waveform between terminals 3

and 4.

Noise

A

(6

171092+

Normal incorrect installation of

the pulse generator, or malfunction of the pulse

generator. 4

Correct the installation

condition, or replace the

pulse generator.

Replace the pulse

generator.

Incorrect installation of

the pulse generator, or

malfunction of the pulse

generator. 4

Correct the installation

condition, or replace the

pulse generator.r

Replace the pulse

generator.

TSB Revision

Page 753 of 1273

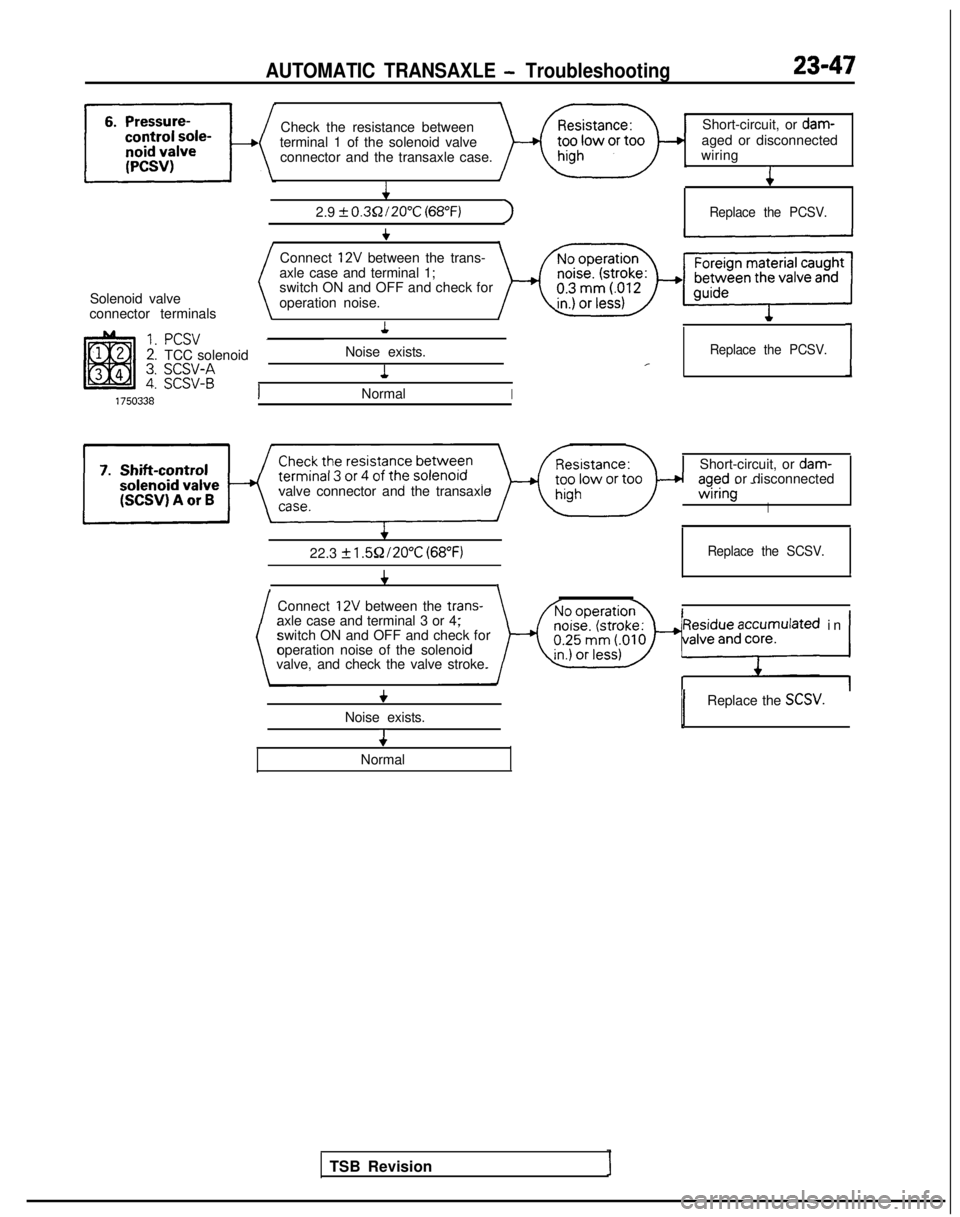

AUTOMATIC TRANSAXLE - Troubleshooting23-47

Check the resistance betweenShort-circuit, or dam-

terminal 1 of the solenoid valve aged or disconnected

connector and the transaxle case. wiring4 4

2.9

+ 0.3Q/20°C (68°F)1Replace the PCSV.

t

Solenoid valve

connector terminals

PCSVTCC solenoid

;g;:;

Connect 12V between the trans-

axle case and terminal 1;

switch ON and OFF and check for

operation noise.

1

Noise exists. 1Replace the PCSV.1J

NormalI

valve connector and the transaxleAlShort-circuit, or

dam-aoed or disconnected-=!-- -’ -.

wrringI

I

f

22.3 k l.5Q/20°C (68°F)Replace the SCSV.

4II,1 I \

Connect

12V between the trans-

axle case and terminal 3 or 4; switch ON and OFF and check for

operation noise of the solenoid

valve, and check the valve stroke.

TSB Revision

yF$$;za;:pulated in /

+

Noise exists. 4

Normal

1Replace the SCSV.]

Page 754 of 1273

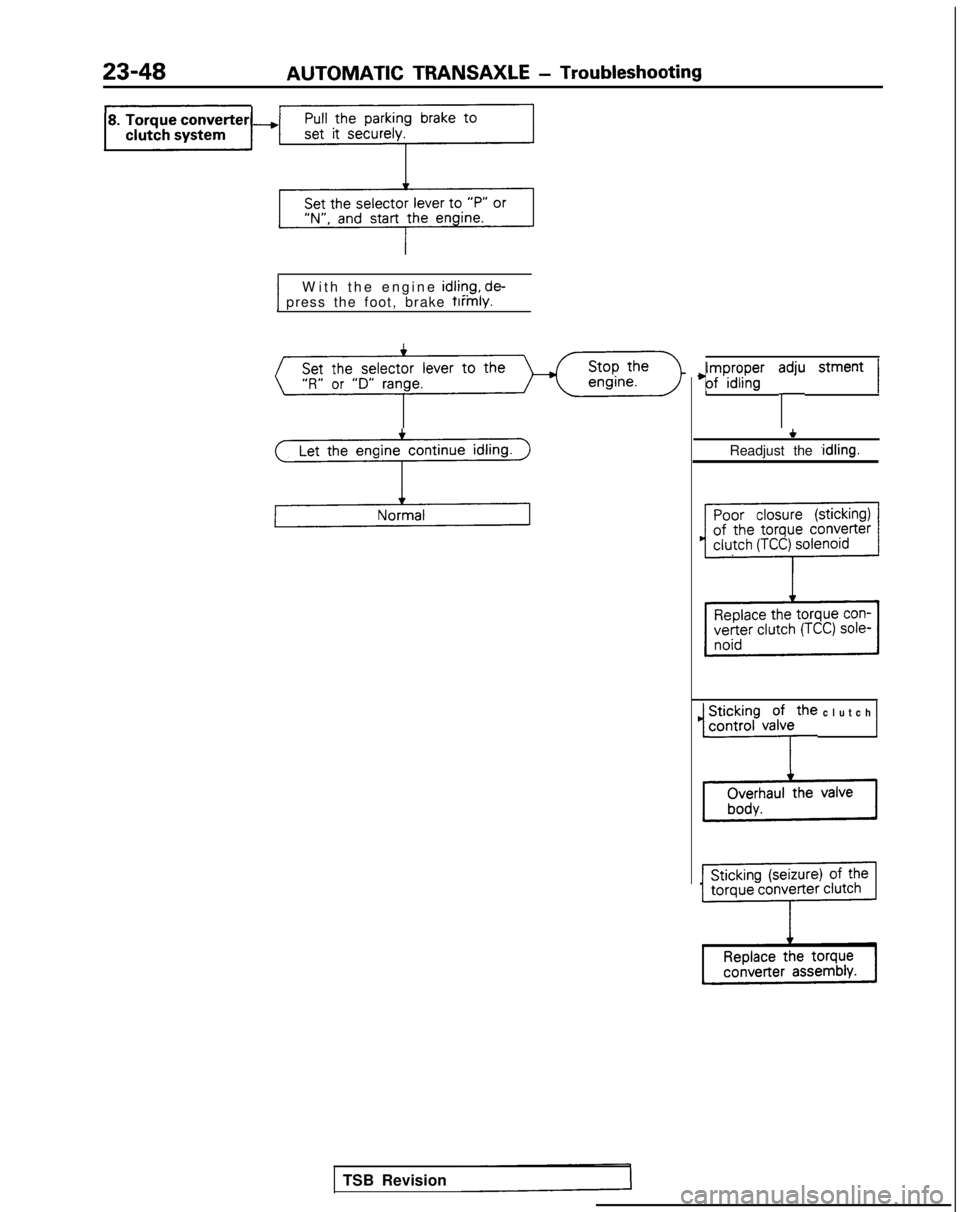

23-48AUTOMATIC TRANSAXLE

- Troubleshooting

1 press the foot, brake firmly.1W

ith the engine

idliqg, de-

Let the engine continue idling.

3

TSB Revision

4;ry;pn”g’ y stment 1

+

Readjust the ,idling.

1 ~i$.;h~,~~~e clutch 1

Page 755 of 1273

AUTOMATIC TRANSAXLE - Troubleshootinn

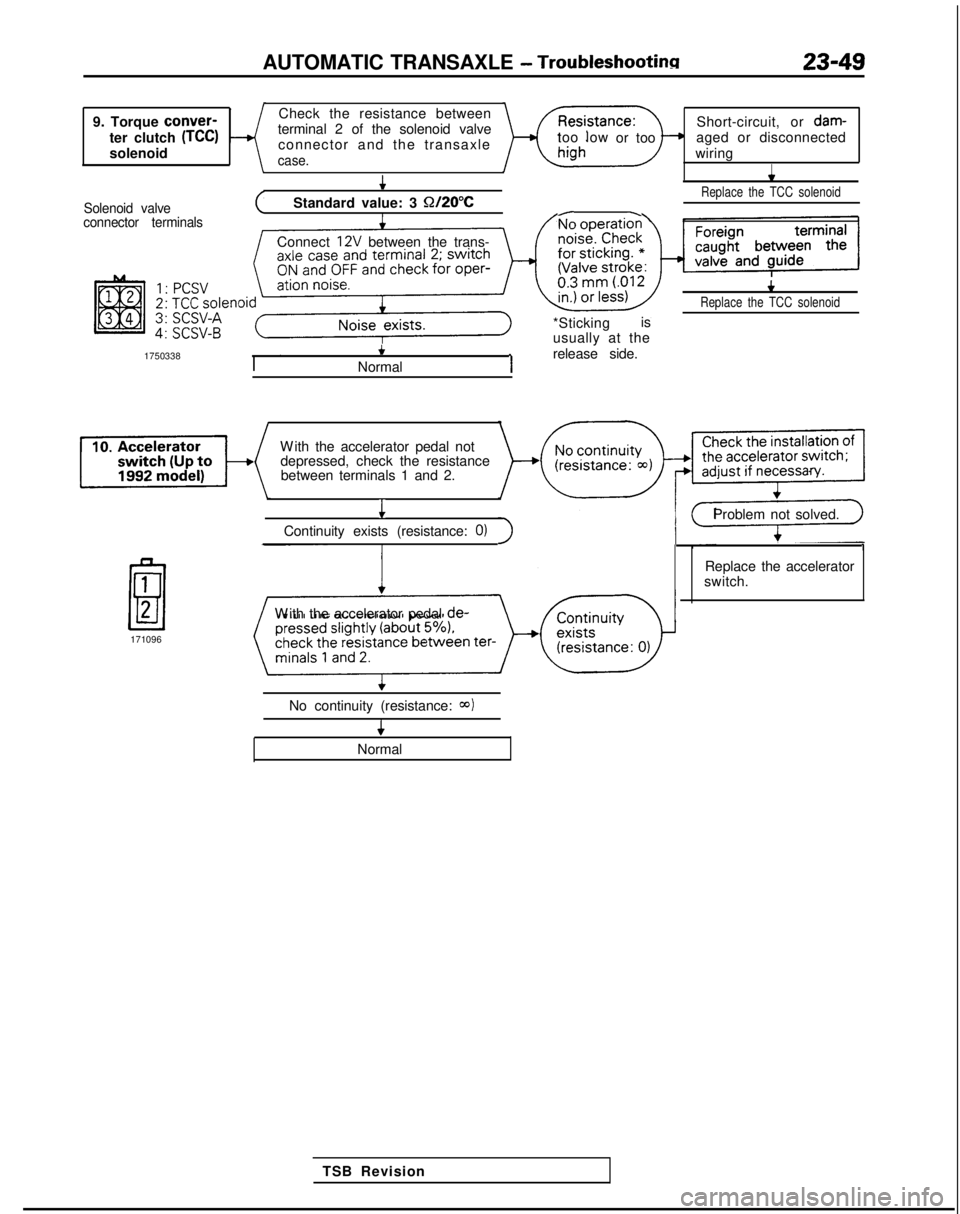

9. Torque

conver-

ter clutch

(TCC)solenoid Check the resistance between

terminal 2 of the solenoid valve connector and the transaxlecase.

Short-circuit, or dam-

too low

or too aged or disconnected

wiring

I

Solenoid valve

4*

(Standard value: 3 Q/2O”CReplace the TCC solenoid

/-connector terminals

Connect 12V between the trans-

*Stickingis

usually at the

1750338

4

Normal1release side.

4

Replace the TCC solenoid

W

ith the accelerator pedal not

depressed, check the resistance between terminals 1 and 2.

1

Continuity exists (resistance: 0)

Problem not solved.

1

1

E/l2

171096 Replace the accelerator

switch.

W

ith the accelerator pedal de-

No continuity (resistance:

CQ)I

TSB Revision

+

Normal

Page 756 of 1273

23-50AUTOMATICTRANSAXLE-Troubleshooting

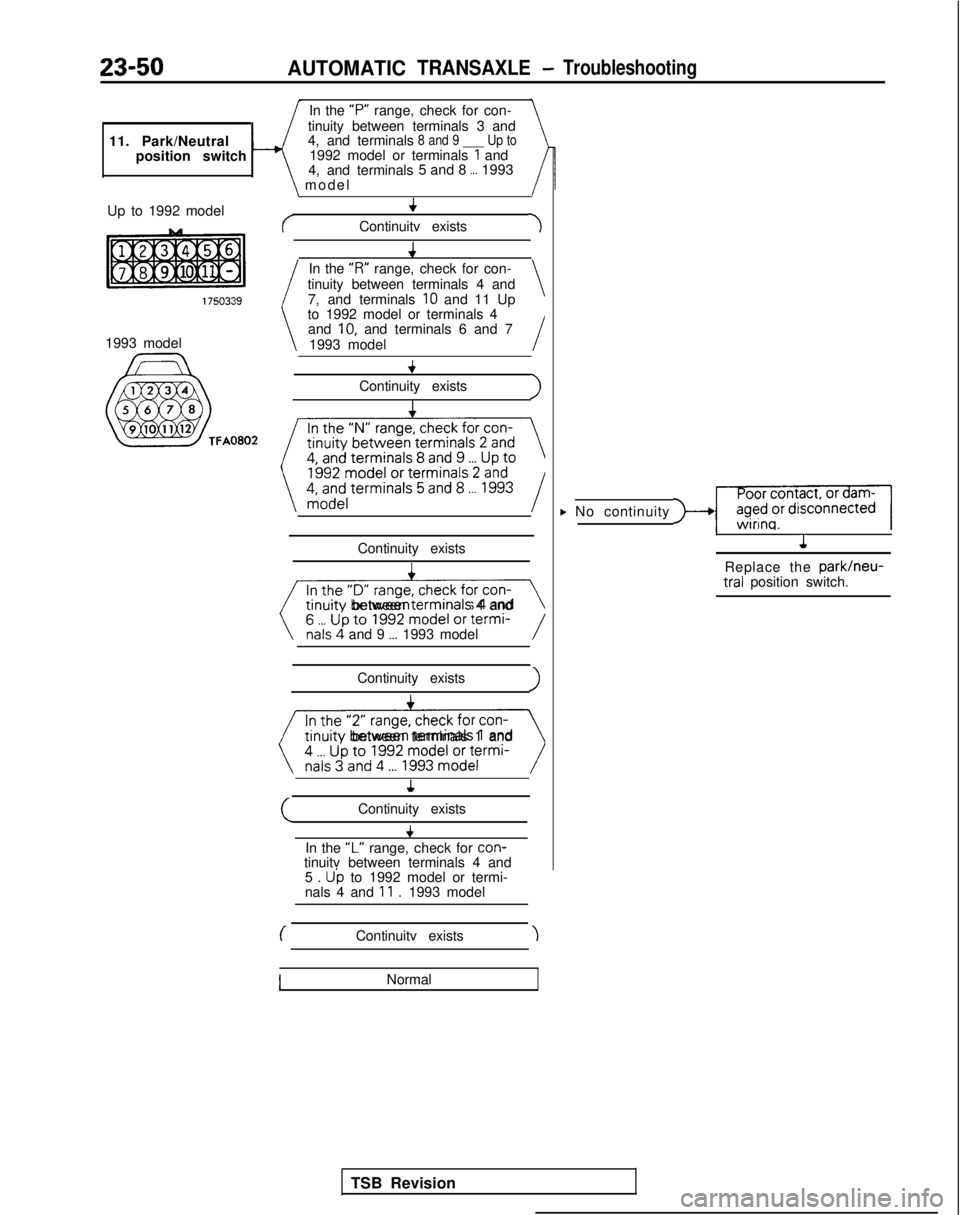

11. Park/Neutralposition switch In the “P”

range, check for con-

tinuity between terminals 3 and

4, and terminals8 and 9 ___ Up to1992 model or terminals 1 and

4, and terminals 5 and 8 _._ 1993

Up to 1992 model

1993 model

‘FA0802

\ mode

l

\I

4

cContinuitv exists-I

In the

“R”

range, check for con-

tinuity between terminals 4 and 7, and terminals

10 and 11 Up\

to 1992 model or terminals 4and IO, and terminals 6 and 7

1993 model

I

+

Continuity exists>I

tinuity between’terminals 2 and

~~

Continuity existsI

iv- trnurty

between termrnals

4 and

\nals4 and 9 __. 1993 model/

Continuity existsI

(() trnurty

between terminals 1 and

(Continuity exists

In the

“L” range, check for con-

tinuitv between terminals 4 and

5 .

Up to 1992 model or termi-

nals 4 and 11 . 1993 model

(Continuitv exists

Normal

F No continuity-)+I1

,1

Replace the park/neu- tral

position switch.

TSB Revision

Page 757 of 1273

AUTOMATIC TRANSAXLE - Troubleshooting23-51

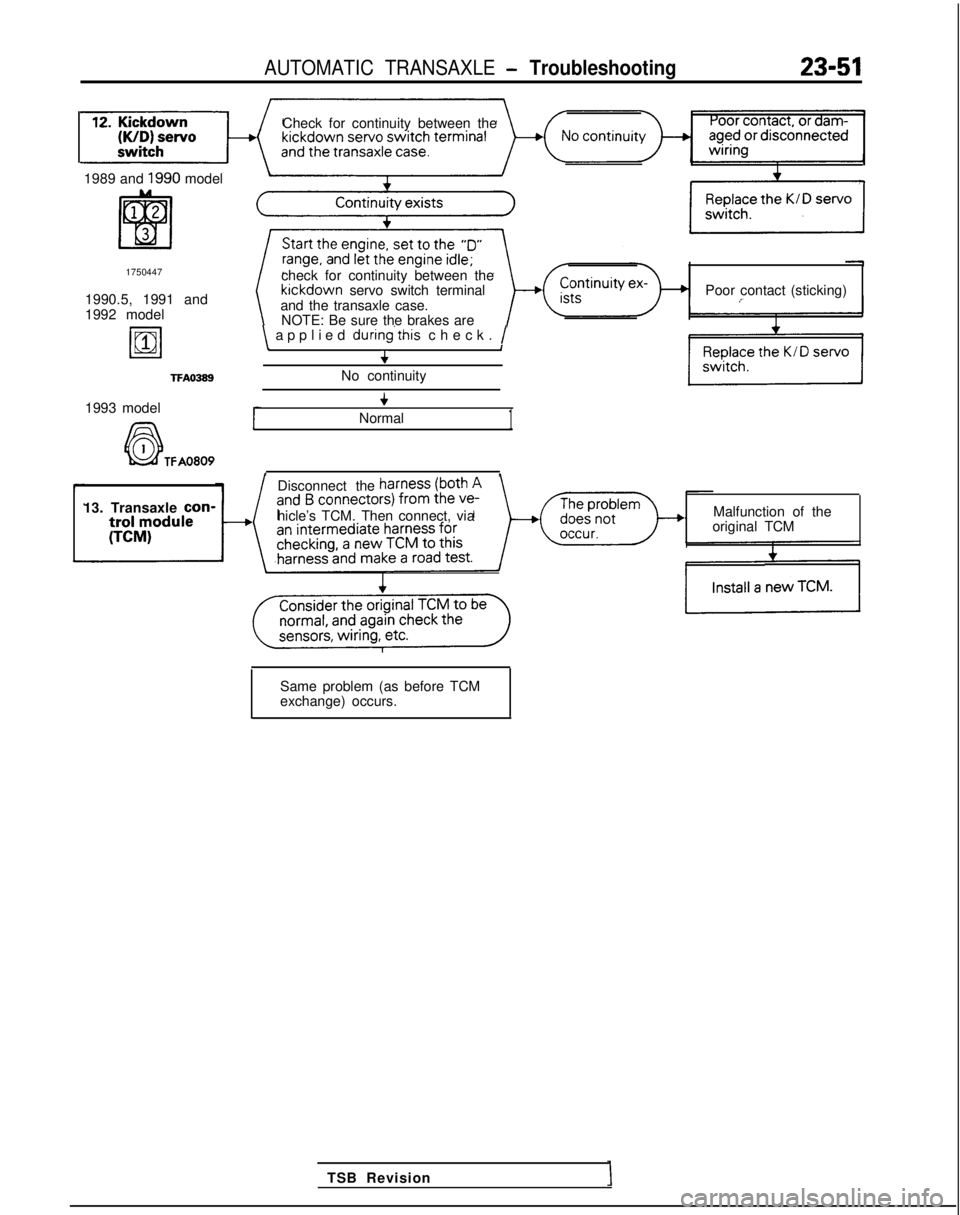

Check for continuity between the

1989 and

1990 model

1750447

1990.5, 1991 and

1992 model

19811

TFAO389

check for continuity between the kickdown

servo switch terminal

and the transaxle case. Poor contact (sticking)

NOTE: Be sure the brakes are

\ applied during’this

check. /\I+

No continuity

1993 model

A6-l

+

Normal1

k&f TFA0809, ,

Disconnect the

13. Transaxle con-

hicle’s TCM. Then connect, via Malfunction of the

original TCM

TSB Revision

Same problem (as before TCM

exchange) occurs.

Page 758 of 1273

23-52AUTOMATIC TRANSAXLE - Troubleshooting

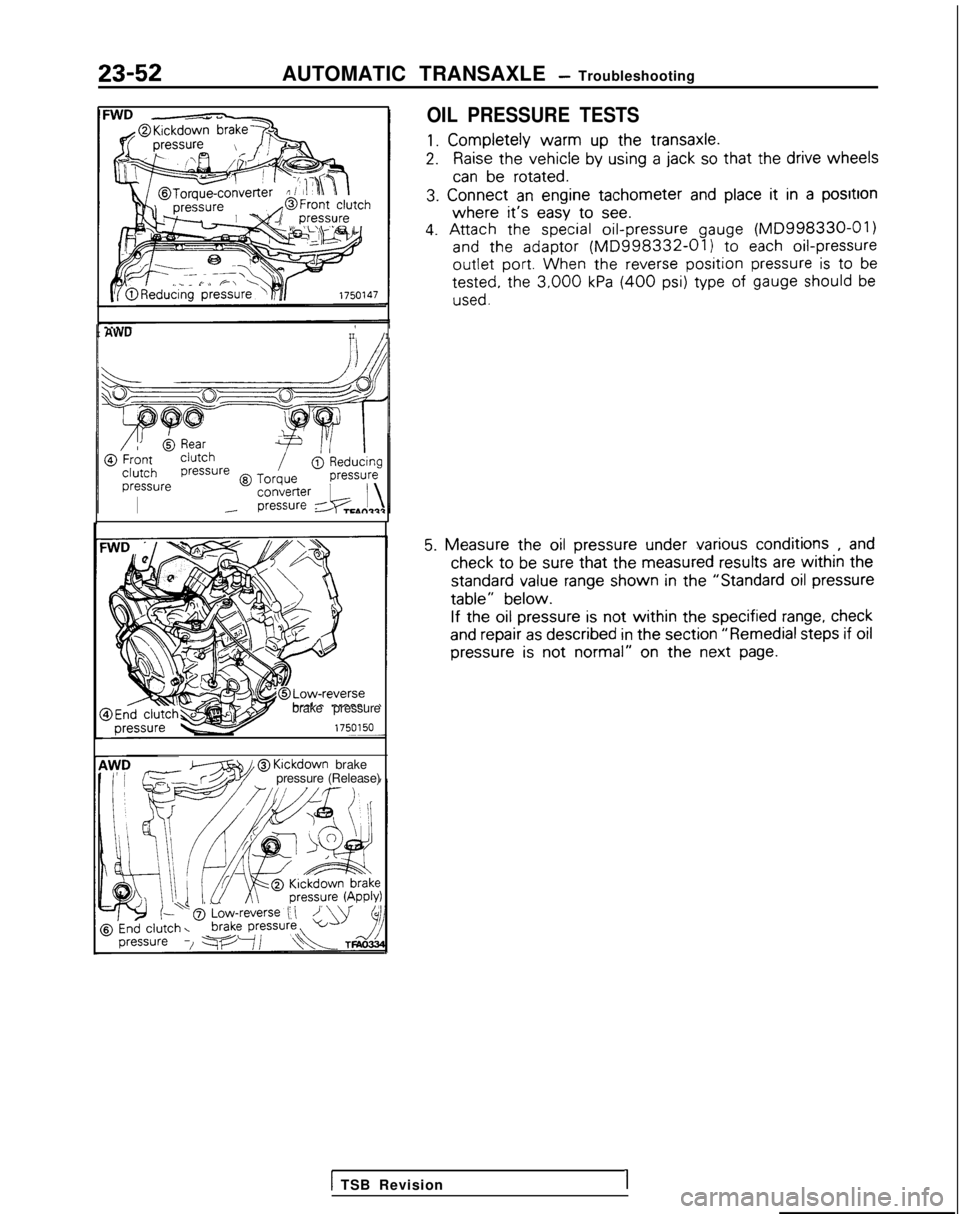

OIL PRESSURE TESTS

1. Completely

warm

up the

transaxle.

2.Raise the

vehicle

by

using

a jack so that the

drive

wheels

can be

rotated.

3.

Connect

an engine

tachometer

and place it

in a positron

where it’s easy

to

see.

4. Attach

the

special oil-pressure

gauge (MD998330-01)

and

the

adaptor

(MD998332-01) to

each oil-pressure

outlet

port. When

the

reverse position pressure is to

be tested,

the

3,000 kPa (400 psi) type

of gauge should be

used.

I AWUII/I

brake pressure

zT?ziw@

Klckdown

brake

pressure (Release)

5. Measure

the

oil pressure

under

various

conditions

, and check

to be sure that the

measured

results

are within the

standard

value

range shown

in the

“Standard

oil pressure

table”

below.

If the

oil pressure

is not

within the

specified

range, check

and repair

as described

in the

section

“Remedial

steps

if oil

pressure

is not

normal”

on the next

page.

1 TSB Revision1

Page 759 of 1273

AUTOMATIC TRANSAXLE - Troubleshooting23-53

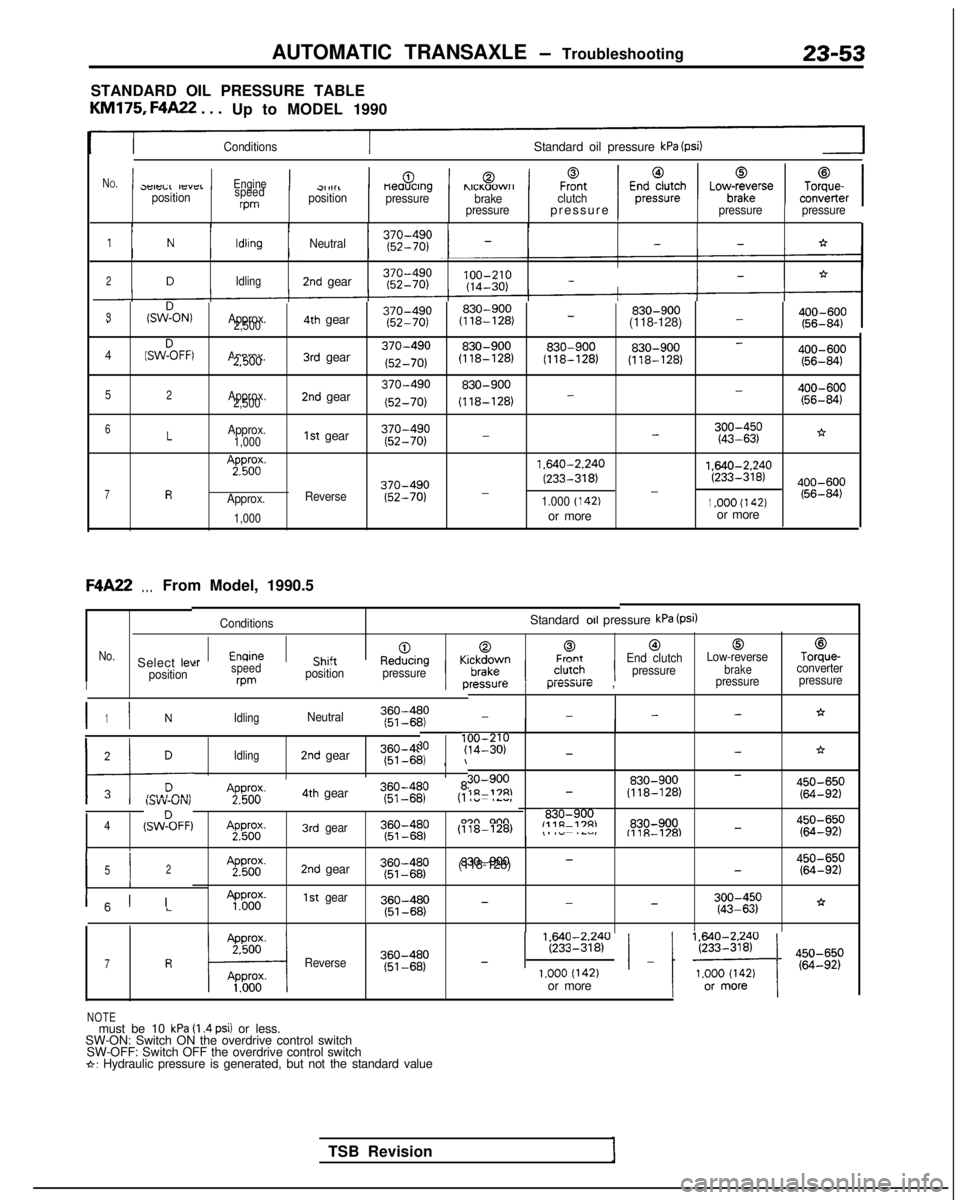

STANDARD OIL PRESSURE TABLE

KM175,

F4A22

. . .

Up to MODEL 1990

ConditionsStandard oil pressure kPa (psi)

N

O.1p -,-,..,-,,-_1Engine1Ch;J+1-0.1,,._,?...-1F%tclutch1E;;;;;;h1Lov$rse1To;;er13eleLL IfsYCIpositionspeedrpm

cl,1111positionneaucrng

pressurehlCI(aOWrIbrake

pressurepressure )Ipressure pressure

1NldlrngNeutral--*

2DIdling2nd gear 100-210

(14-30)

-

3(SWDON,Approx.830-900 830-900

400-600

--2,5004th gear

(118-128)

(118-128) (56-84)

(SWZFFI

Approx.3rd gear370-490830-900830-900 830-900

400-600-42.500

(52-70) (118-128)

(118-128)

(118-128)

(56-84)

52Approx.

2,5002nd gear370-490830-900 400-600-

(52-70) (118-128)

- (56-84)

-*6LApprox.1st gear370-4901,000

(52-70)-;g:gp

7R

A;pp56od(.

Approx.

1,000

Reverse370-490

(52-70) 1.640-2.240

1.640-2.240

(233-318)(233-318)--1.000 (142)1.OOO (I 42)or more

or moreF4A22

. . .From Model, 1990.5

ConditionsStandard 011 pressure kPa (Psi)

[email protected]“__l__^:__KrlrA,vrrnFrontEnd clutch

Low-reverseTorque-Select leve

brakeconverter

position pressure

‘ressurep-“cxm”1~ ,pressure

pressure

:rspeedcl,,,i;ne”“l;lily wmposition

pressureII

I I360-4801NIdlingNeutral(51~6P’2,--*--

TSB Revision

171 DIdling2nd gear360-4f (51-6b,

, \I

30?y;I;;p-*->i

30-900830-900450-650-1n-17RI- (118-128)(64-92)A2pPg4th gear360-480I I,.lY”-“Iv,(51-681

830-9004(SWZFF)A2pWg.3rdgear

(118-128)

,- .~,,,,“~.--,~.-lL”l,E%830-900-fllR-l='4g::;p

I I52

II

A2pg;.2nd gear~~~~~~p830-900-(118-128)-$g:;p

300-450

-*--”LApP&y.1stgear

(43-63)

1

ICI I

1 EEi2840 / _ 1 ‘~o~$~ ) 4iiIi;p7RReverse360-480

(51-68)

-1.000 (142)or more

NOTEmust be 10 kPa (I .4 psi) or less.

SW-ON: Switch ON the overdrive control switch SW-OFF: Switch OFF the overdrive control switch

*: Hydraulic pressure is generated, but not the standard value

Page 760 of 1273

23-54AUTOMATIC TRANSAXLE - Troubleshooting

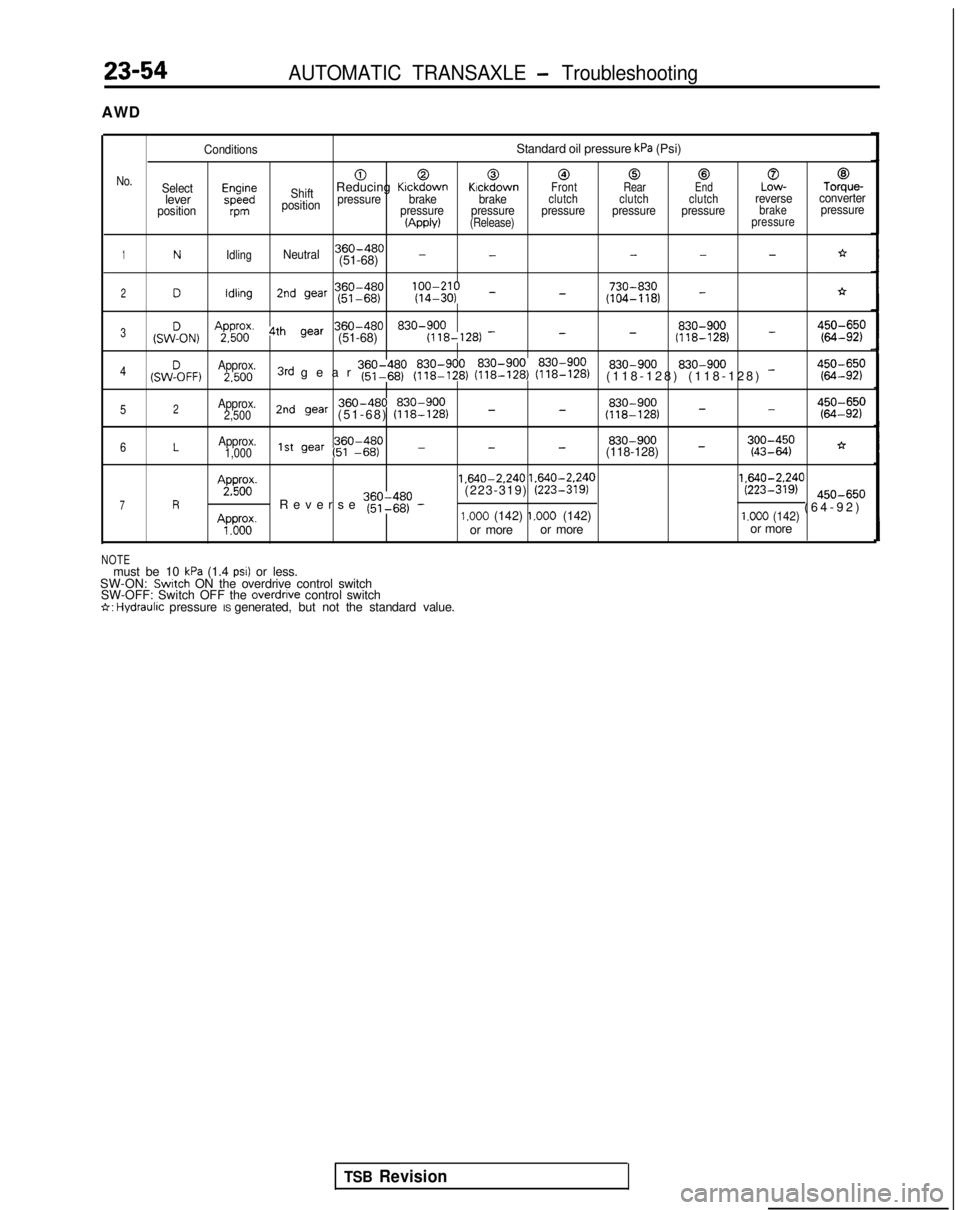

AWD

ConditionsStandard oil pressure kPa (Psi)

000@0@0@

No.Selectm;;ShiftReducing KickdownKickdownFront RearEndLow-Torque-leverpressurebrake brakeclutch clutch clutchreverseconverter

positionvmposition pressure pressure pressure pressure pressurebrakepressure(Apply)(Release)

pressure

1NIdlingNeutral360-480---*(51-68) --

360-480 lfyfI;;; _ 730-8302Dldlrng2nd war (51-68)

(104-118) -*-

(sw!oN)

AgFil’ 4th gear360-480 830-900 830-900

_3--(51-68)

(118-128)

-(118-128)g:gp 830-900

4(SW%FF)Approx. 830-9002.5003rd gear ~~~I$p (y$$zr (~$$EJ (??i??$)(118-128) (118-128) -g::;p

Approx.2nd gear 360-480 830-900

830-900450-650-52(51-68)

(118-128) _-2,500

(118-128) - (64-92)

6LApprox.360-480

830-9001,0001st gear (51 -66)---(118-128) -;:;I$;*

Ap&;.

1.640-2.240

1.640-2.240 1.640-2.240

7R ’Reverse ~~~$~p -(223-319)

(223-319)(223-319) @O-65,,

(64-92

)

Ap”do”o”.1.000 (142) 1.000 (142)1.000 (142)or more

or more or more

NOTEmust be 10 kPa (1.4 PSI) or less.

SW-ON: Switch ON the overdrive control switch

SW-OFF: Switch OFF the overdrrve control switch6: Hydraulrc pressure IS generated, but not the standard value.

TSB Revision