MITSUBISHI GALANT 1989 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1989, Model line: GALANT, Model: MITSUBISHI GALANT 1989Pages: 1273, PDF Size: 37.62 MB

Page 761 of 1273

AUTOMATIC TRANSAXLE - Troubleshooting23-55

Remedial Steps If Oil Pressure Is Not Normal

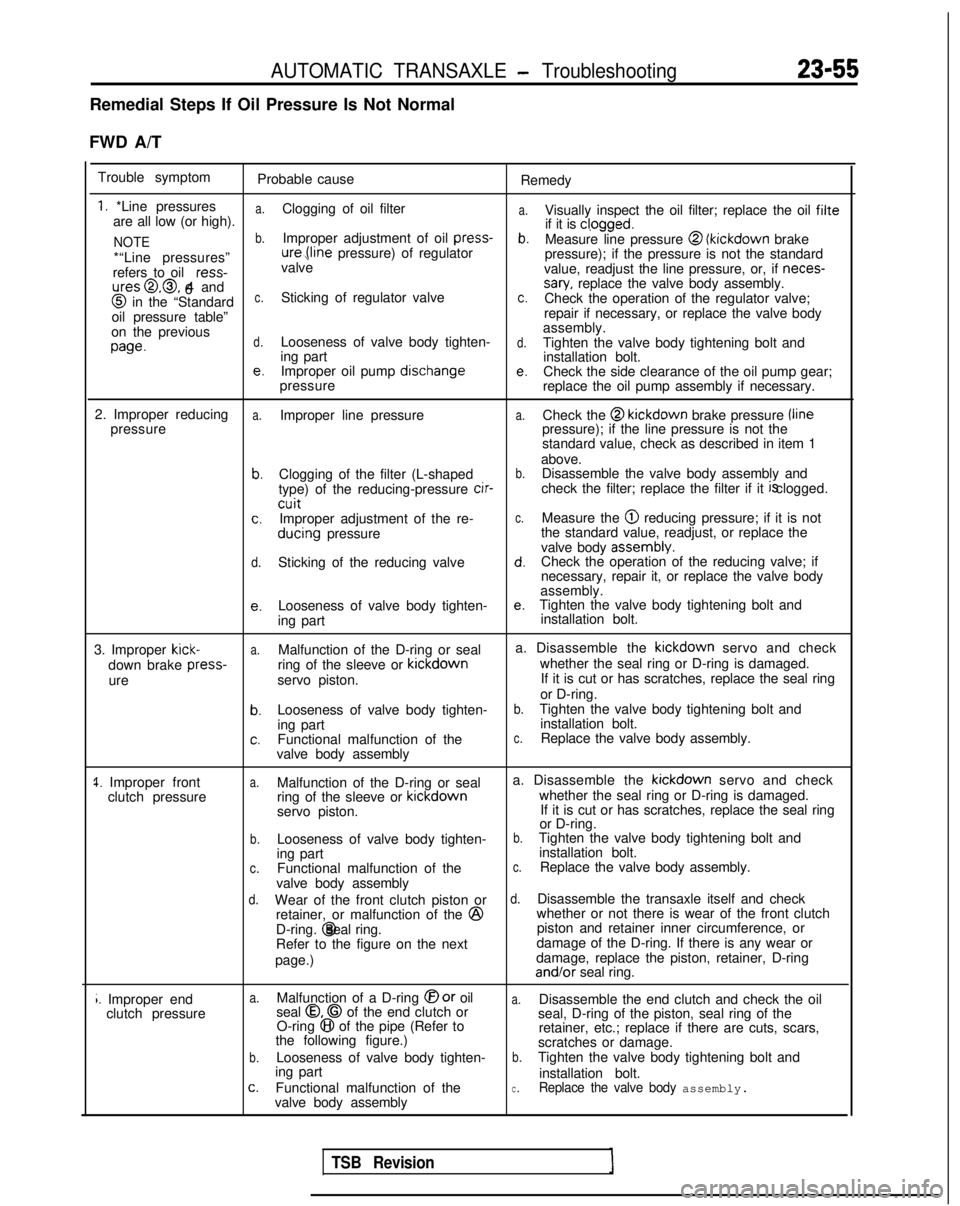

FWD A/T Trouble symptom Probable cause Remedy

1. *Line pressuresa.

a.are all low (or high).Clogging of oil filter

Visually inspect the oil filter; replace the oil filte

NOTEb.Improper adjustment of oil press-

if it is cl,ogged.b.Measure line pressure @ (kickdown

brake

*“Line pressures” ure,(line

pressure) of regulator

pressure); if the pressure is not the standard

refers to oil ress-

valve

value, readjust the line pressure, or, if neces-

ures@,@, 4 and

6sary, replace the valve body assembly. @

in the “Standardc.Sticking of regulator valvec.Check the operation of the regulator valve;

oil pressure table” repair if necessary, or replace the valve body

on the previous assembly.

wed.Looseness of valve body tighten-d.Tighten the valve body tightening bolt and

ing part installation bolt.

e.Improper oil pump dischangee.Check the side clearance of the oil pump gear;

pressure replace the oil pump assembly if necessary.

2. Improper reducing

a.Improper line pressurea.Check the @ kickdown

brake pressure /line

pressure pressure); if the line pressure is not the

standard value, check as described in item 1

above.

b.Clogging of the filter (L-shapedb.Disassemble the valve body assembly and

type) of the reducing-pressure cir-

check the filter; replace the filter if it is clogged.

cuitc.Improper adjustment of the re-c.Measure the @ reducing pressure; if it is not

ducing

pressure the standard value, readjust, or replace the

valve body assembly.

d.Sticking of the reducing valved.Check the operation of the reducing valve; if

necessary, repair it, or replace the valve body

assembly.

e.Looseness of valve body tighten-e.Tighten the valve body tightening bolt and

ing part installation bolt.

3. Improper

kick-a.Malfunction of the D-ring or seal a. Disassemble the kickdown

servo and check

down brake press-

ring of the sleeve or kickdown

whether the seal ring or D-ring is damaged.

ure servo piston. If it is cut or has scratches, replace the seal ring

or D-ring.

b.Looseness of valve body tighten-b.Tighten the valve body tightening bolt and

ing part installation bolt.

c.Functional malfunction of thec.Replace the valve body assembly.

valve body assembly

1. Improper front clutch pressurea.Malfunction of the D-ring or seal a. Disassemble the kickdown

servo and check

ring of the sleeve or kickdown

whether the seal ring or D-ring is damaged.

servo piston. If it is cut or has scratches, replace the seal ring

or D-ring.

b.Looseness of valve body tighten-b.Tighten the valve body tightening bolt and

ing part installation bolt.

c.Functional malfunction of thec.Replace the valve body assembly.

valve body assembly

d.Wear of the front clutch piston ord.Disassemble the transaxle itself and check

retainer, or malfunction of the @

whether or not there is wear of the front clutch

D-ring. @ seal ring.

piston and retainer inner circumference, or

Refer to the figure on the next damage of the D-ring. If there is any wear or

page.) damage, replace the piston, retainer, D-ring and/or

seal ring.

i. Improper end

clutch pressurea.Malfunction of a D-ring @or oila.Disassemble the end clutch and check the oil

seal 0.0 of the end clutch or

O-ring 8 of the pipe (Refer to seal, D-ring of the piston, seal ring of the

the following figure.) retainer, etc.; replace if there are cuts, scars,

scratches or damage.

b.Looseness of valve body tighten-b.Tighten the valve body tightening bolt and

ing part installation bolt.

c.Functional malfunction of thec.Replace the valve body assembly.valve body assembly

TSB Revision

Page 762 of 1273

23-56AUTOMATIC TRANSAXLE - Troubleshooting

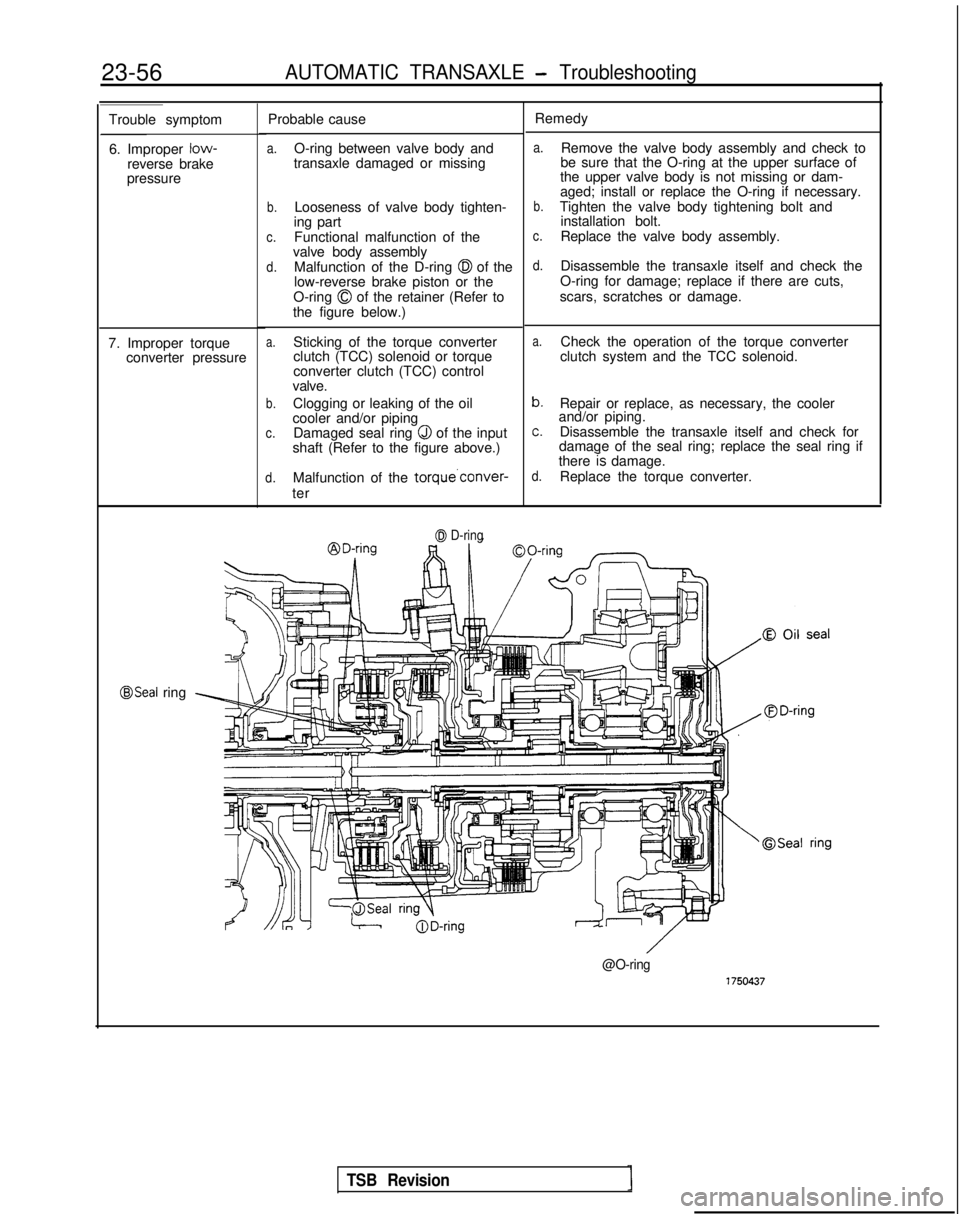

Trouble symptom

6. Improper low-

reverse brake

pressure Probable cause

a.O-ring between valve body and

transaxle damaged or missing

b.Looseness of valve body tighten-

ing part

c.Functional malfunction of the

valve body assembly

d.Malfunction of the D-ring 0 of the

low-reverse brake piston or the

O-ring

0 of the retainer (Refer to

the figure below.)

a.Sticking of the torque converter

clutch (TCC) solenoid or torque

converter clutch (TCC) control

valve.

b.Clogging or leaking of the oil

cooler and/or piping

c.Damaged seal ring Q of the input

shaft (Refer to the figure above.)

d.Malfunction of the torque’conver-

ter

7. Improper torque

converter pressure

0 D-ring

Remedy

a.Remove the valve body assembly and check to

be sure that the O-ring at the upper surface of

the upper valve body is not missing or dam-

aged; install or replace the O-ring if necessary.

b.Tighten the valve body tightening bolt and installation bolt.

c.Replace the valve body assembly.

d.Disassemble the transaxle itself and check the

O-ring for damage; replace if there are cuts,

scars, scratches or damage.

a.Check the operation of the torque converter

clutch system and the TCC solenoid.

b.Repair or replace, as necessary, the cooler

and/or piping.

c.Disassemble the transaxle itself and check for

damage of the seal ring; replace the seal ring if

there

7s damage.d.Replace the torque converter.

@Seal ring

@O-ring

TSB Revision

Page 763 of 1273

AUTOMATIC TRANSAXLE - Troubleshootinn

23-57

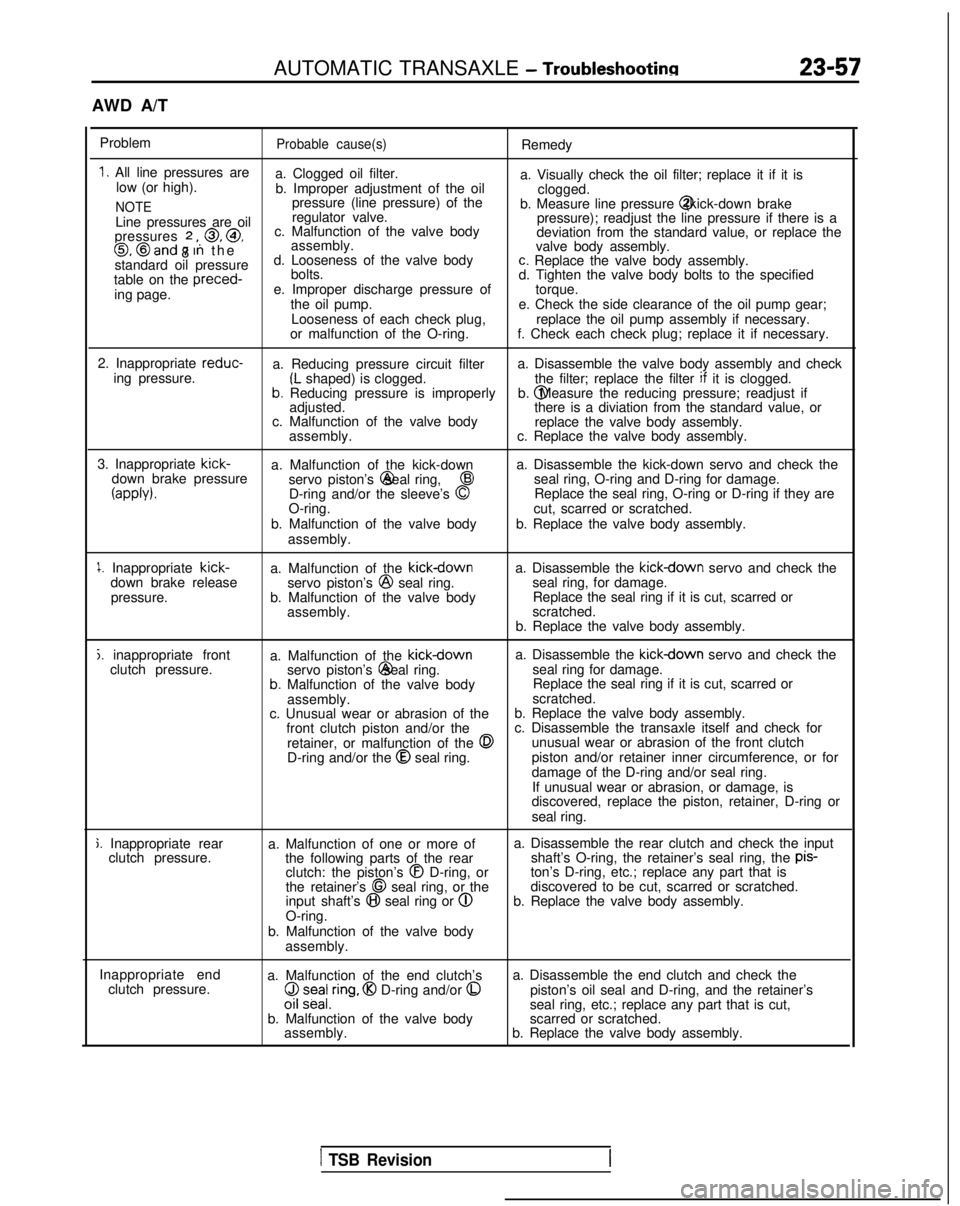

AWD A/T

Problem

Probable cause(s)Remedy

1. All line pressures are a. Clogged oil filter.

low (or high). a. Visually check the oil filter; replace it if it is

b. Improper adjustment of the oil clogged.

NOTEpressure (line pressure) of the

b. Measure line pressure @ (kick-down brake

Line pressures are oil regulator valve.

pressure); readjust the line pressure if there is a

pressures

2 ,, 0, @,

8 c. Malfunction of the valve body

deviation from the standard value, or replace the0, @and 7 In th

e

assembly.

valve body assembly.

standard oil pressure d. Looseness of the valve body

c. Replace the valve body assembly.

table on the preced-

bolts.

d. Tighten the valve body bolts to the specified

ing page. e. Improper discharge pressure of

torque.

the oil pump. e. Check the side clearance of the oil pump gear;

Looseness of each check plug, replace the oil pump assembly if necessary.

or malfunction of the O-ring. f. Check each check plug; replace it if necessary.

2. Inappropriate reduc-

a. Reducing pressure circuit filter a. Disassemble the valve body assembly and check

ing pressure.

(L shaped) is clogged. the filter; replace the filter if

it is clogged.b. Reducing pressure is improperly b. @ Measure the reducing pressure; readjust if

adjusted. there is a diviation from the standard value, or

c. Malfunction of the valve body replace the valve body assembly.

assembly. c. Replace the valve body assembly.

3. Inappropriate kick-

a. Malfunction of the kick-down a. Disassemble the kick-down servo and check the

down brake pressure servo piston’s @ seal ring,

43seal ring, O-ring and D-ring for damage.

(appb).D-ring and/or the sleeve’s 0Replace the seal ring, O-ring or D-ring if they are

O-ring. cut, scarred or scratched.

b. Malfunction of the valve body b. Replace the valve body assembly.

assembly.

1. Inappropriate kick-

down brake release

pressure. a. Malfunction of the kickdownservo piston’s @

seal ring.

b. Malfunction of the valve body assembly. a. Disassemble the kickdown servo and check the

seal ring, for damage. Replace the seal ring if it is cut, scarred or

scratched.

b. Replace the valve body assembly.

j. inappropriate front clutch pressure. a. Malfunction of the kickdowna. Disassemble the kickdown servo and check the

servo piston’s @ seal ring.

seal ring for damage.

b. Malfunction of the valve body Replace the seal ring if it is cut, scarred or

assembly. scratched.

c. Unusual wear or abrasion of the b. Replace the valve body assembly.

front clutch piston and/or the c. Disassemble the transaxle itself and check for

retainer, or malfunction of the

0unusual wear or abrasion of the front clutch

D-ring and/or the @

seal ring. piston and/or retainer inner circumference, or for

damage of the D-ring and/or seal ring.

If unusual wear or abrasion, or damage, is

discovered, replace the piston, retainer, D-ring or

seal ring.

j. Inappropriate rear clutch pressure. a. Malfunction of one or more of

the following parts of the rearclutch: the piston’s

@I D-ring, or

the retainer’s 68 seal ring, or the

input shaft’s @I seal ring or @

O-ring.

b. Malfunction of the valve body assembly. a. Disassemble the rear clutch and check the input

shaft’s O-ring, the retainer’s seal ring, the pis-

ton’s D-ring, etc.; replace any part that is

discovered to be cut, scarred or scratched.

b. Replace the valve body assembly.

Inappropriate end clutch pressure. a. Malfunction of the end clutch’s

($ z;ea/,ring, @I D-ring and/or 0

b. Malfunction of the valve body

assembly. a. Disassemble the end clutch and check the

piston’s oil seal and D-ring, and the retainer’s

seal ring, etc.; replace any part that is cut,

scarred or scratched.

b. Replace the valve body assembly.

1 TSB Revision

Page 764 of 1273

23-58AUTOMATIC TRANSAXLE - Troubleshooting

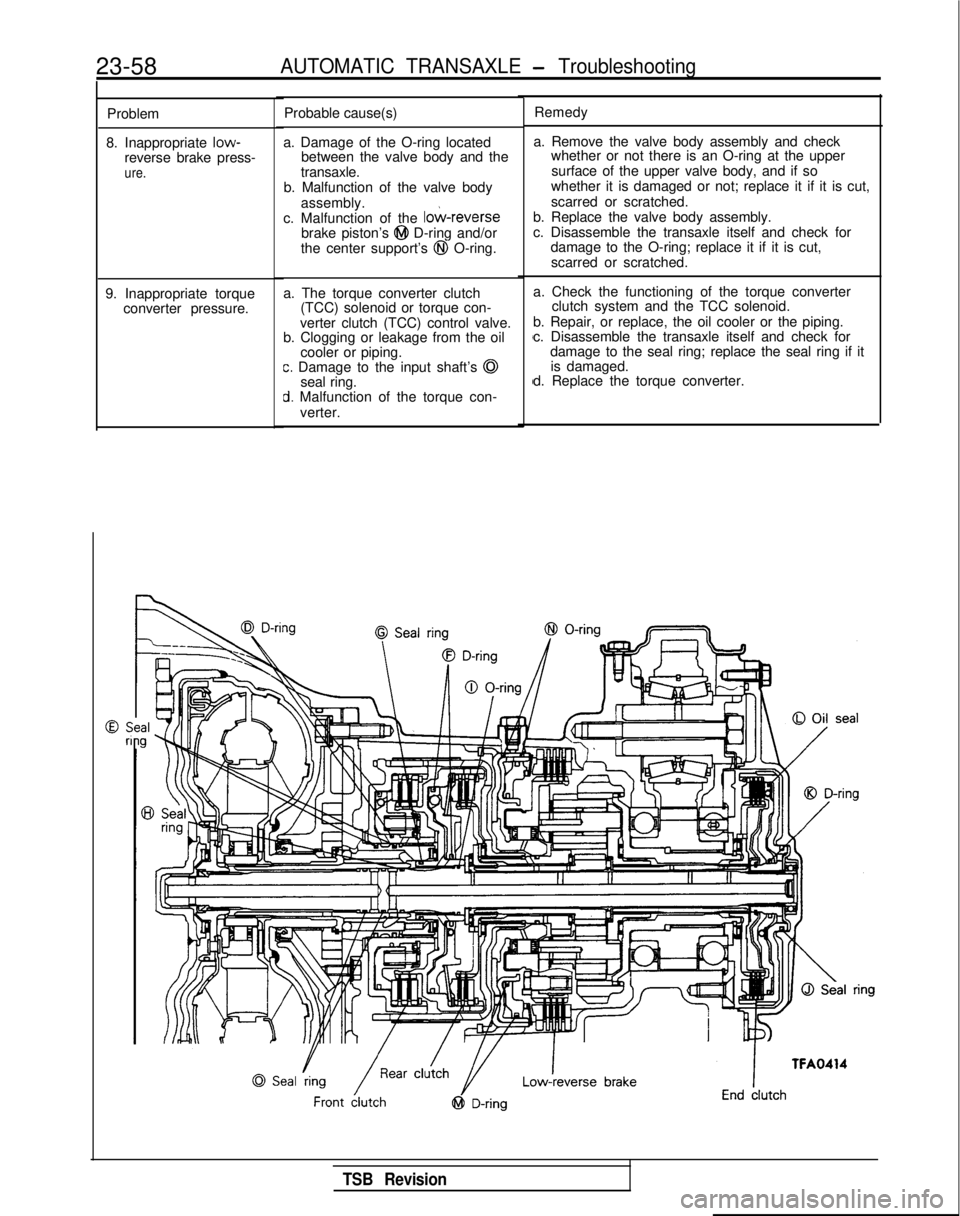

Problem

8. Inappropriate low-

reverse brake press-

ure.

9. Inappropriate torque converter pressure. Probable cause(s)

a. Damage of the O-ring located between the valve body and the

transaxle.

b. Malfunction of the valve body

assembly.

c. Malfunction of the

lo&reversebrake piston’s @I D-ring and/or

the center support’s @I O-ring.

a. The torque converter clutch (TCC) solenoid or torque con-

verter clutch (TCC) control valve.

b. Clogging or leakage from the oil

cooler or piping.

c. Damage to the input shaft’s @

seal ring.

d. Malfunction of the torque con-

verter. Remedy

a. Remove the valve body assembly and check whether or not there is an O-ring at the upper

surface of the upper valve body, and if so

whether it is damaged or not; replace it if it is cut,

scarred or scratched.

b. Replace the valve body assembly.

c. Disassemble the transaxle itself and check for damage to the O-ring; replace it if it is cut,

scarred or scratched.

a. Check the functioning of the torque converter clutch system and the TCC solenoid.

b. Repair, or replace, the oil cooler or the piping.

c. Disassemble the transaxle itself and check for damage to the seal ring; replace the seal ring if itis damaged.

d. Replace the torque converter.

TSB Revision

Page 765 of 1273

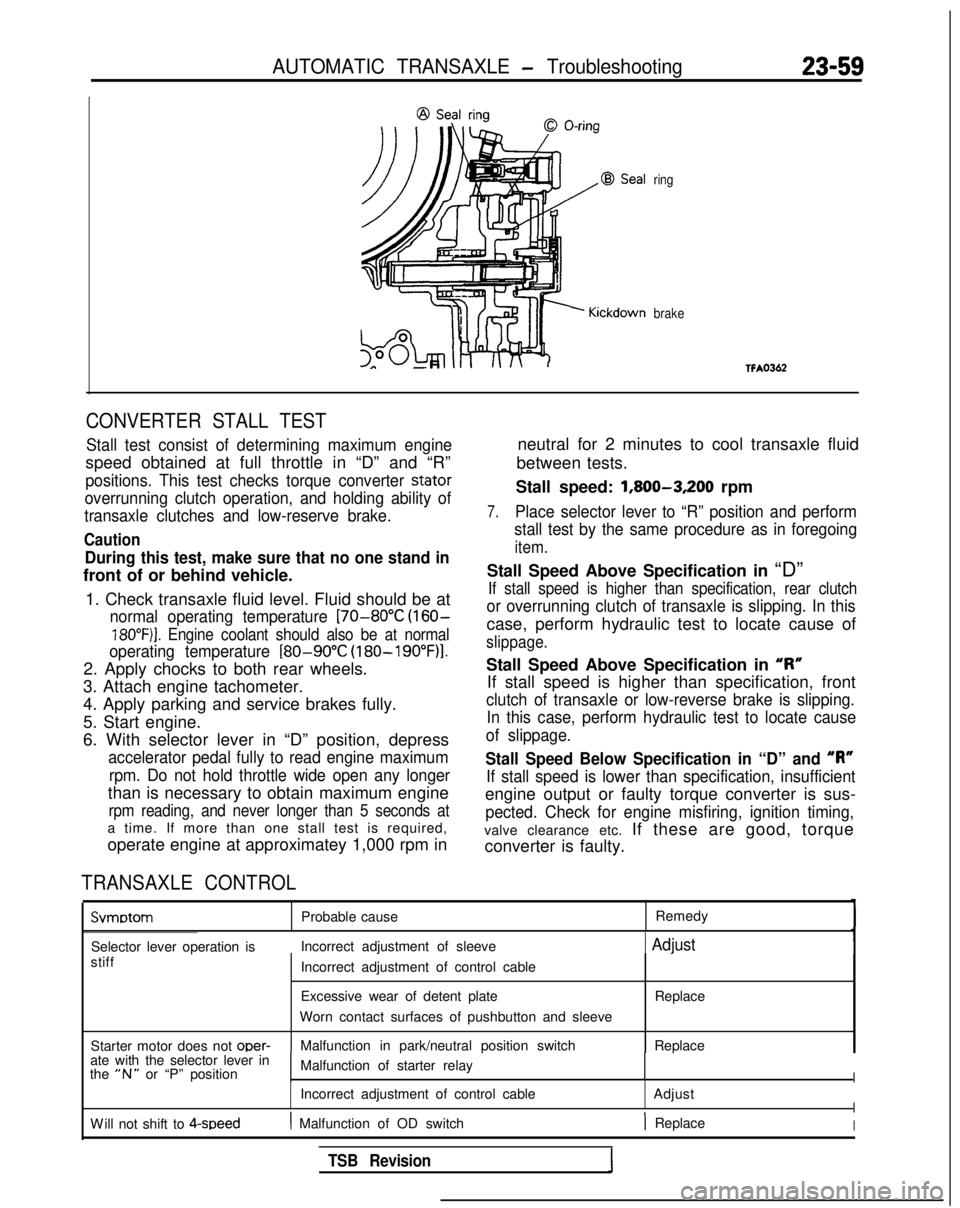

AUTOMATIC TRANSAXLE - Troubleshooting23-59

ring

brake

CONVERTER STALL TEST

Stall test consist of determining maximum engine

speed obtained at full throttle in “D” and “R”

positions. This test checks torque converter stator

overrunning clutch operation, and holding ability of

transaxle clutches and low-reserve brake.

Caution

During this test, make sure that no one stand in

front of or behind vehicle.

1. Check transaxle fluid level. Fluid should be at

normal operating temperature [70-80°C (160-

18O”F)j. Engine coolant should also be at normal

operating temperature

[80-90°C (180-19O”F)l.

2. Apply chocks to both rear wheels.

3. Attach engine tachometer.

4. Apply parking and service brakes fully.

5. Start engine.

6. With selector lever in “D” position, depress

accelerator pedal fully to read engine maximum

rpm. Do not hold throttle wide open any longer

than is necessary to obtain maximum engine

rpm reading, and never longer than 5 seconds at

a time. If more than one stall test is required,

operate engine at approximatey 1,000 rpm in

TRANSAXLE CONTROL

neutral for 2 minutes to cool transaxle fluid

between tests.

Stall speed: 1,800-3,200

rpm

7.Place selector lever to “R” position and perform

stall test by the same procedure as in foregoing

item.

Stall Speed Above Specification in “D”

If stall speed is higher than specification, rear clutch

or overrunning clutch of transaxle is slipping. In this

case, perform hydraulic test to locate cause of

slippage.

Stall Speed Above Specification in “I?”

If stall speed is higher than specification, front

clutch of transaxle or low-reverse brake is slipping. In this case, perform hydraulic test to locate cause

of slippage.

Stall Speed Below Specification in “D” and “R”

If stall speed is lower than specification, insufficient

engine output or faulty torque converter is sus-

pected. Check for engine misfiring, ignition timing,

valve clearance etc. If these are good, torque

converter is faulty. Svmotom

Probable cause

Remedy

Selector lever operation is Incorrect adjustment of sleeve

1 Adjust

stiff

Starter motor does not oper-

Incorrect adjustment of control cable

Excessive wear of detent plate

Worn contact surfaces of pushbutton and sleeve

Malfunction in park/neutral position switch Replace

Replace

ate with the selector lever in

the

“N” or “P” position Malfunction of starter relayI

Incorrect adjustment of control cable

AdjustI

W

ill not shift to 4-speed

( Malfunction of OD switch) ReplaceI

TSB Revision

Page 766 of 1273

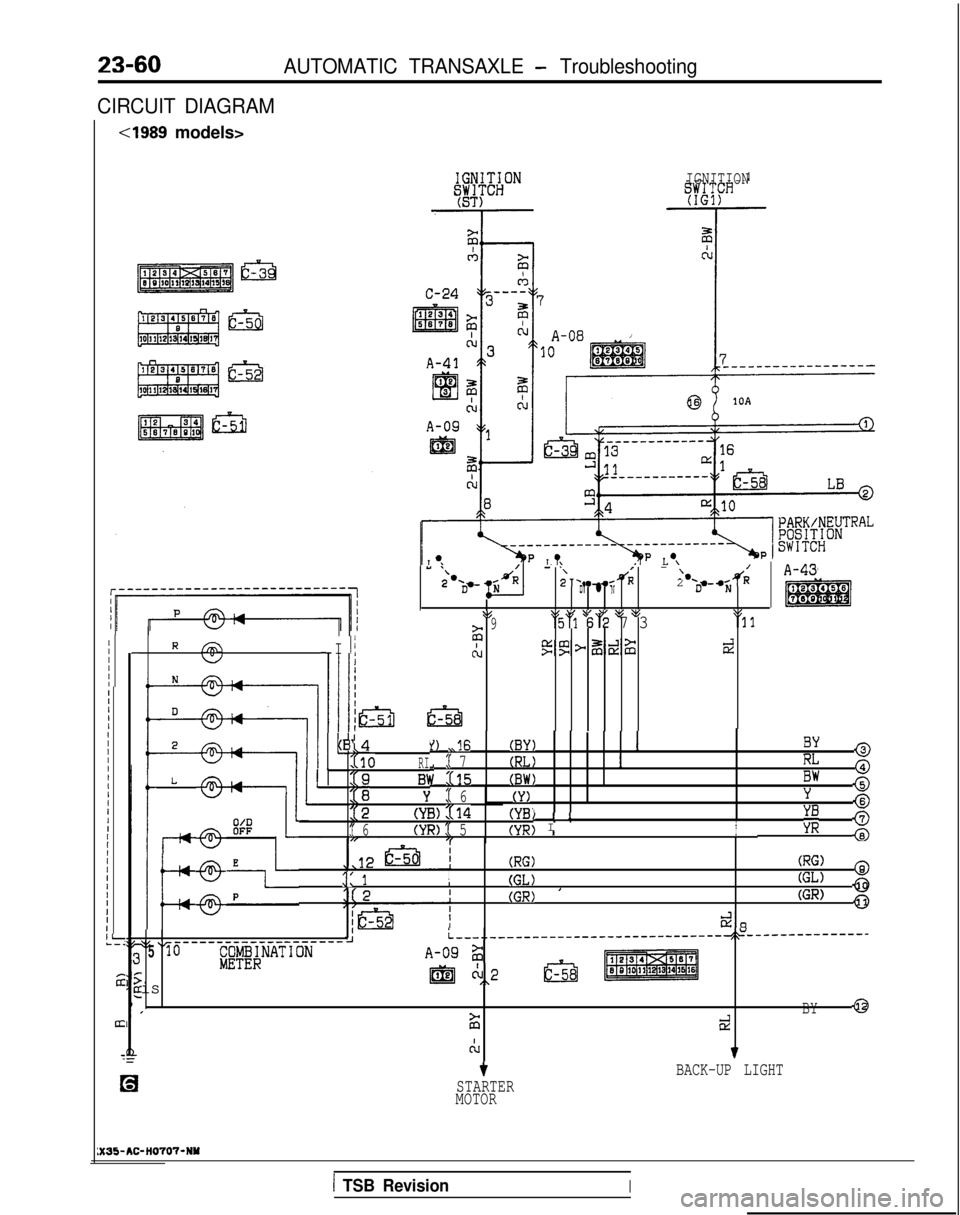

23-60AUTOMATIC TRANSAXLE - Troubleshooting

CIRCUIT DIAGRAM

cl989 models>

IGNITION

- ‘\- ‘\I-/.d2 -s/R‘*A-432.‘Da-2‘-- RD* l ND N

\$\I \I $6 >’ pg $5\I

- I 1:29‘ki 62 7 3'11

AJ5gp&%dII -IIIIIII1IIIIIIIIIIIIIIIIIIIIIIIIII-*-:

;2

III

:

R fiKJ

Ill,14(B'

1I10RI

1' 2i

B1I

Y:( 6

12(YB)114(YB'

:( 6(YR):( 5(YR;1I

0 ,16(BY)I

:( 7By @

; x15

(RL)IRL @(BW)BW @(Y)Y,"I2@I I1I\ II;;; 8

L

I--+

P

-@

@-

-@-

(RG)

:: 1I(GL)

(RG) @

I

(GR) '

(GL) a

(GR)0

&iL__-..___-------------------------~~---------------$5 ‘r-----_______________510;gyg;NATIONA-092

is

@jJA2,\

rBY43

2Et?

CL7

tBACK-UP LIGHT

STARTER

MOTOR

:X35-AC-H0707-NY

1 TSB RevisionI

Page 767 of 1273

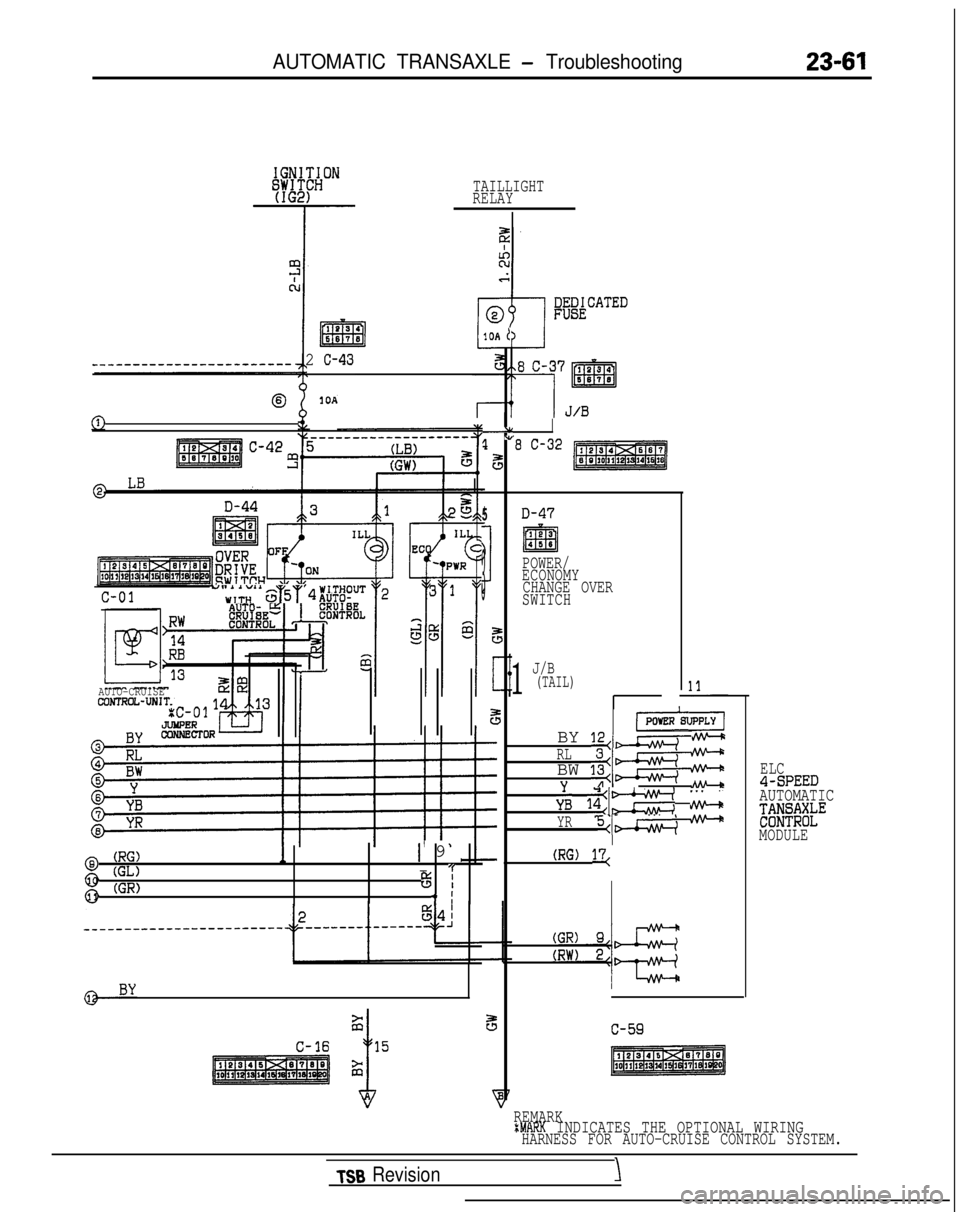

AUTOMATIC TRANSAXLE - Troubleshooting

TAILLIGHT

RELAY

I334m6678

____-__-_--__-----------2 c-43

01OA

@

c-01"'&,"'$,5‘r

AUTO-CRUISECDWROL-UNIT

(RG)@ (GL)

1 9

g (GR)I 'f% I

3 I

C-16

1OA 1

-1

!I ”

5

5

>

1

3

5

5

e

'8 C-32

D-47

POWER/

ECONOMY CHANGE OVER

SWITCH

1

J/B(TAIL)

IPOYER

BY 12,

RLBW 1::s"/I-

;B li:m ki

YR5

ELC4-SPEEDAUTOMATIC

FGEt;;kE

MODULE

REMARK

tMARK INDICATES THE OPTIONAL WIRINGHARNESS FOR AUTO-CRUISE CONTROL SYSTEM.

TSB Revision\

Page 768 of 1273

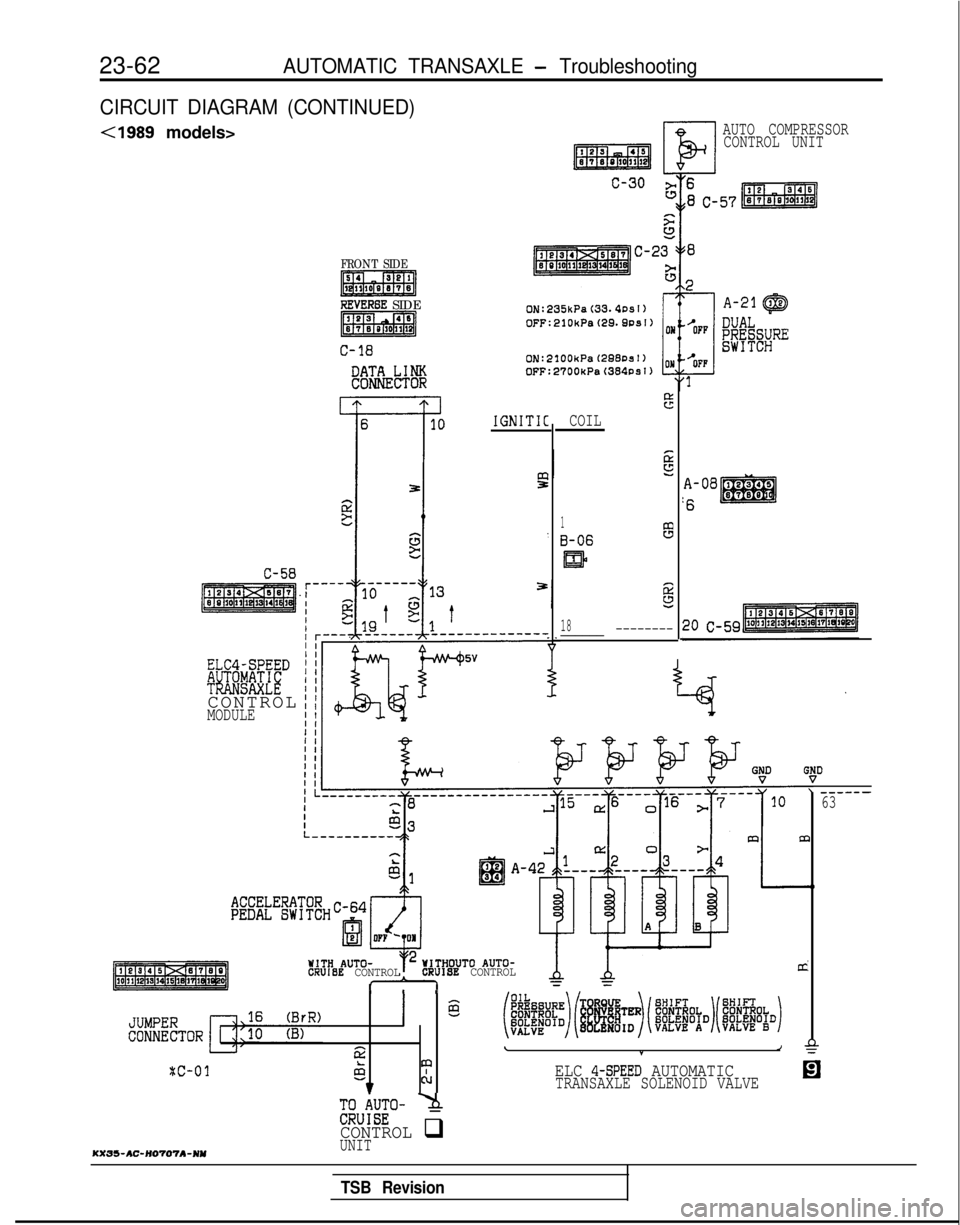

23-62AUTOMATIC TRANSAXLE - Troubleshooting

CIRCUIT DIAGRAM (CONTINUED)

<1989 models>

FRONT SIDE

REVERBE SIDE

C-18

e!T&Lcl%

C-58

ELC4-SPEED

!#i!.E%CECONTRO

L

MODULE

r'.I

AUTO COMPRESSOR

CONTROL UNIT

IIIIIIII1IIIIIII

I

IGNITIC

WITH AUTO-WITHOUT0 AUTO-CRUIBE CONTROLCRUIBE CONTROLI==I I I

( @ (~~~~)~~~~(~~~~)(~~~~~D)

\*ese343cd 7

puJJE'o- -5

CONTROL q

ELC 4-SPEED AUTOMATICTRANSAXLE SOLENOID VALVE

%

COIL

1

B-068

5

18______ --------

A-08

:6

1------63

KXs5-AC-n0707A-nnUNIT

TSB Revision

Page 769 of 1273

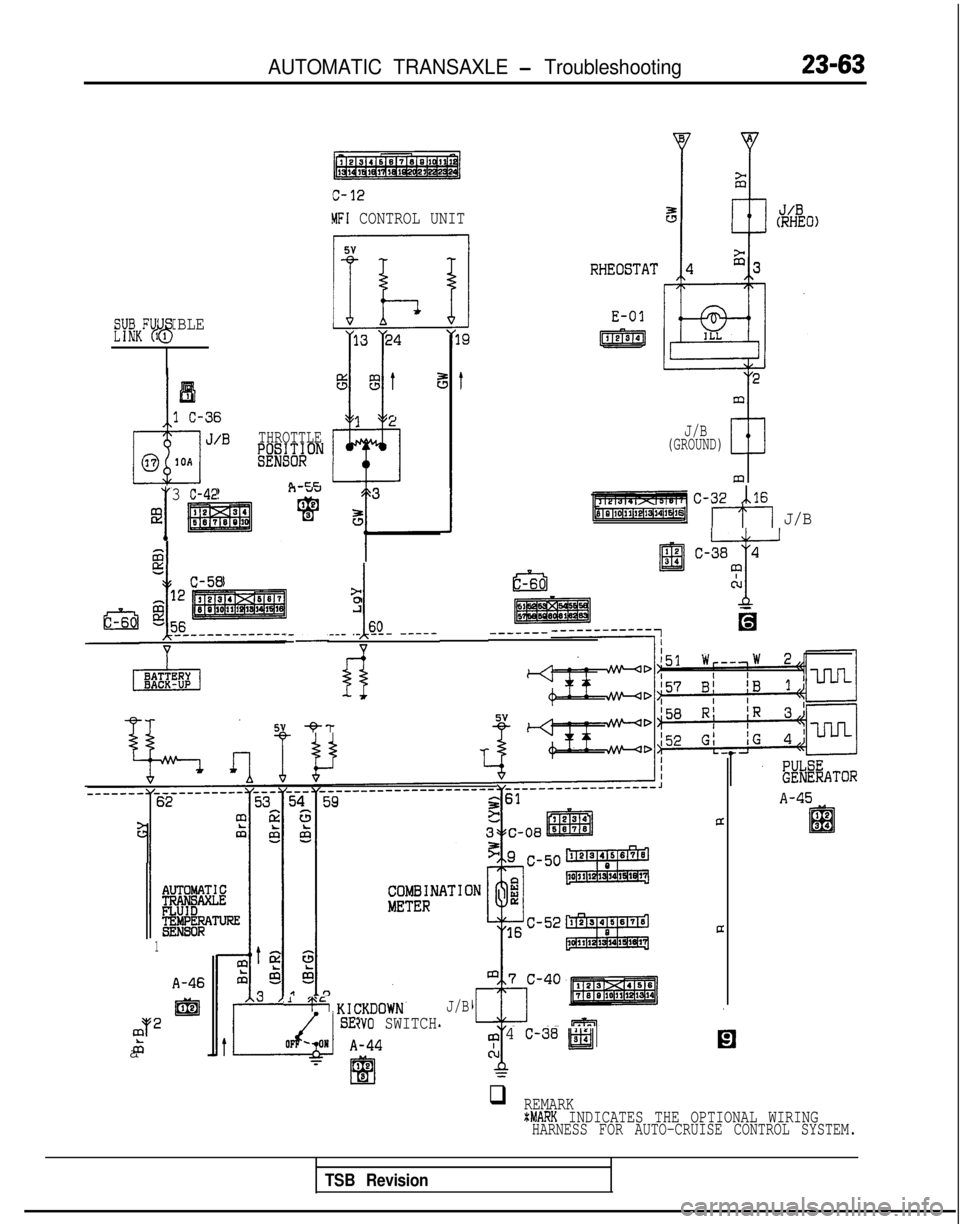

AUTOMATIC TRANSAXLE - Troubleshooting

MFI CONTROL UNIT

THROTTLEW#ON

n cc

E-01

mfY;KFU1 IBLE23

J/B(GROUND)

C-32 xi.16

I

3 C-42E

5 13 ~1~11~1Ef13(14l15#61117 J/B

c-38 4

T

41cu

-c-58>0

i

.___ -’s_Q- -----

fl

,---_-_---

5v 9-T

A-45

1

A-46

a

m

m2

65

+ KlCKDOWNJ/B

iv0 SWITCH4 c-38 wEl

qREMARKtMARK INDICATES THE OPTIONAL WIRINGHARNESS FOR AUTO-CRUISE CONTROL SYSTEM.

TSB Revision

Page 770 of 1273

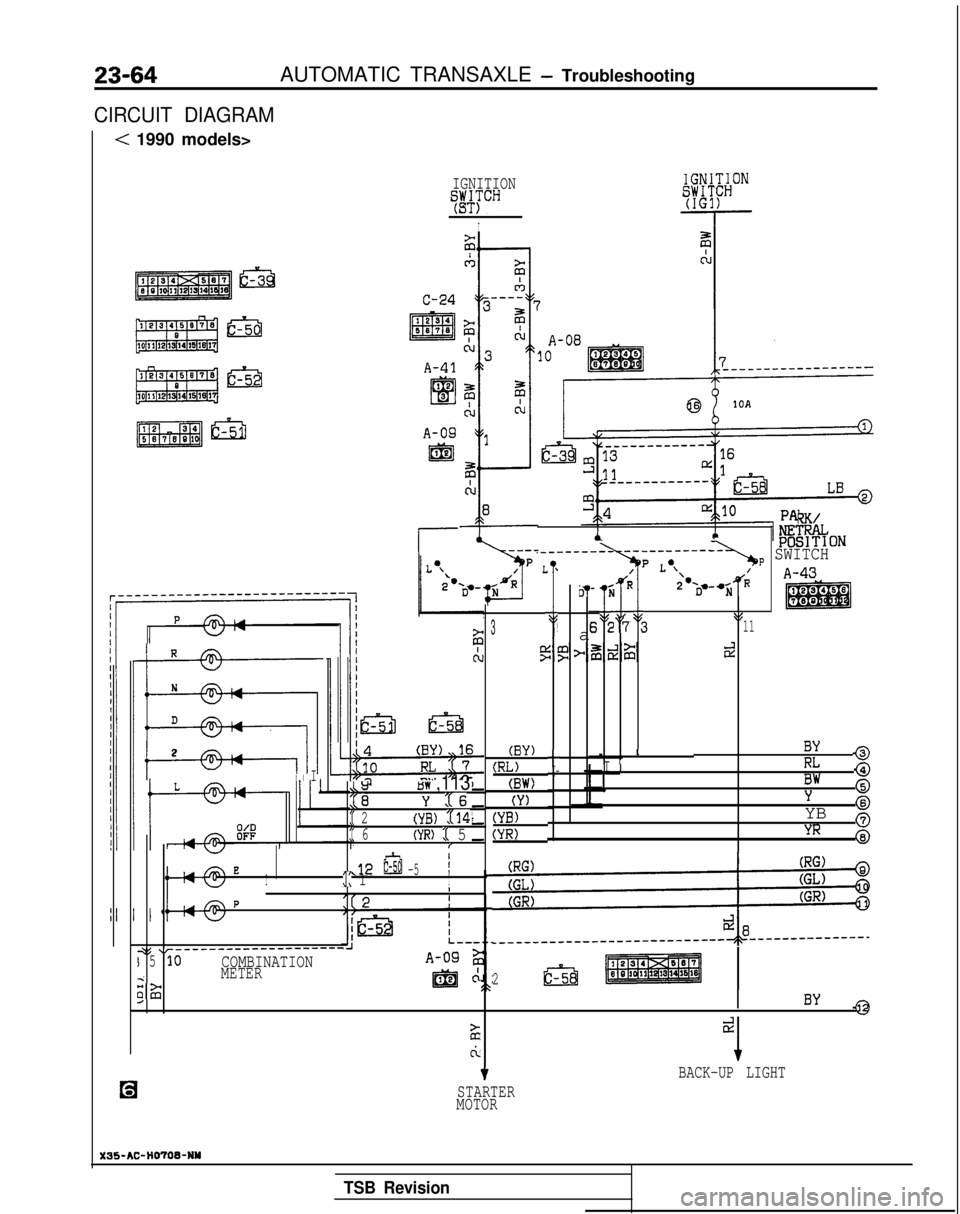

23-64AUTOMATIC TRANSAXLE - Troubleshooting

CIRCUIT DIAGRAM

< 1990 models>

IGNITION

WCH

I

A-09

@

RK/

,_________ -_----__----

L '/p Lo\

J ,"

-LB!f#kONp SWITCH

'*IA-43

a

il-'jR2 -o,-wdRN

Ej2'7 5 113

P

(BY)

(RL)

(BW)

(Y)

(YB)

(YR)

tI I II IBY @

I-I 1

!RL @

Bw @Y

YB $j

YR @

I

R

N

EEi

D

2

II

1 IIai

t5w ,113

Y :tS

:( 2',YB) 114:( 6(YR) J 5IIE.,12E -51I:: 1II

P4

+<

_____--_---__-------

I510COMBINATIONiMETER

;zi

mc:

4

4

L

2E3

I

ciI

t

STARTER

MOTOR BACK-UP LIGHT

X35-AC-HOTOWNY

TSB Revision