MITSUBISHI L200 2004 Owner's Manual (in English)

Manufacturer: MITSUBISHI, Model Year: 2004, Model line: L200, Model: MITSUBISHI L200 2004Pages: 264, PDF Size: 4.14 MB

Page 181 of 264

FOR EMERGENCIES

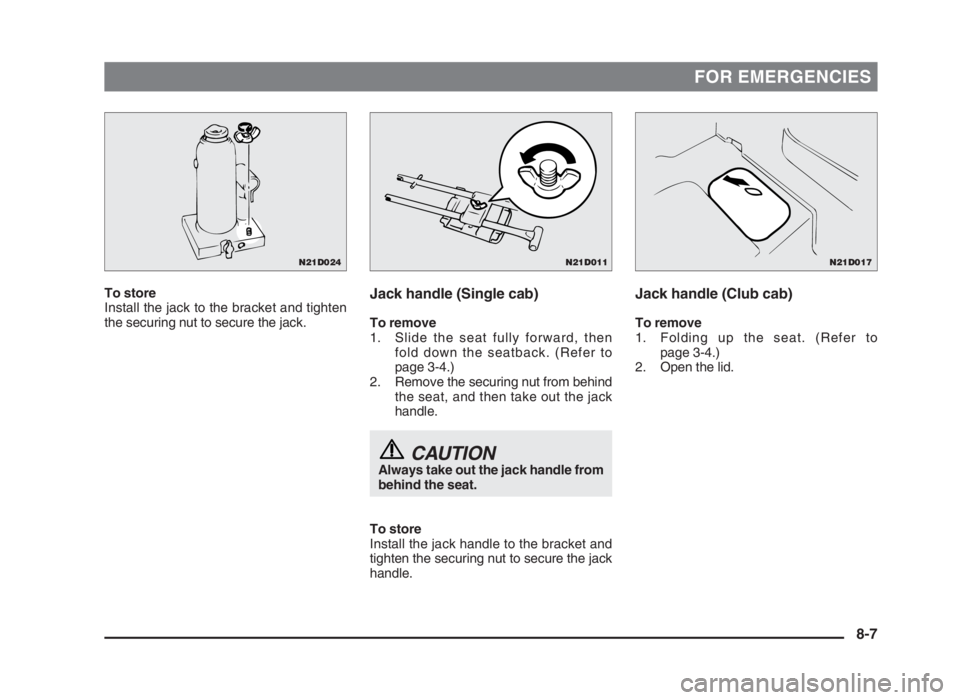

To store

Install the jack to the bracket and tighten

the securing nut to secure the jack.Jack handle (Club cab)

To remove

1. Folding up the seat. (Refer to

page 3-4.)

2. Open the lid.

Jack handle (Single cab)

To remove

1. Slide the seat fully forward, then

fold down the seatback. (Refer to

page 3-4.)

2. Remove the securing nut from behind

the seat, and then take out the jack

handle.

CAUTION Always take out the jack handle from

behind the seat.

To store

Install the jack handle to the bracket and

tighten the securing nut to secure the jack

handle.

8-7

N21D011N21D017N21D024

08engL2_240082_4 22-01-2004 13:10 Page 8-7

Page 182 of 264

FOR EMERGENCIES

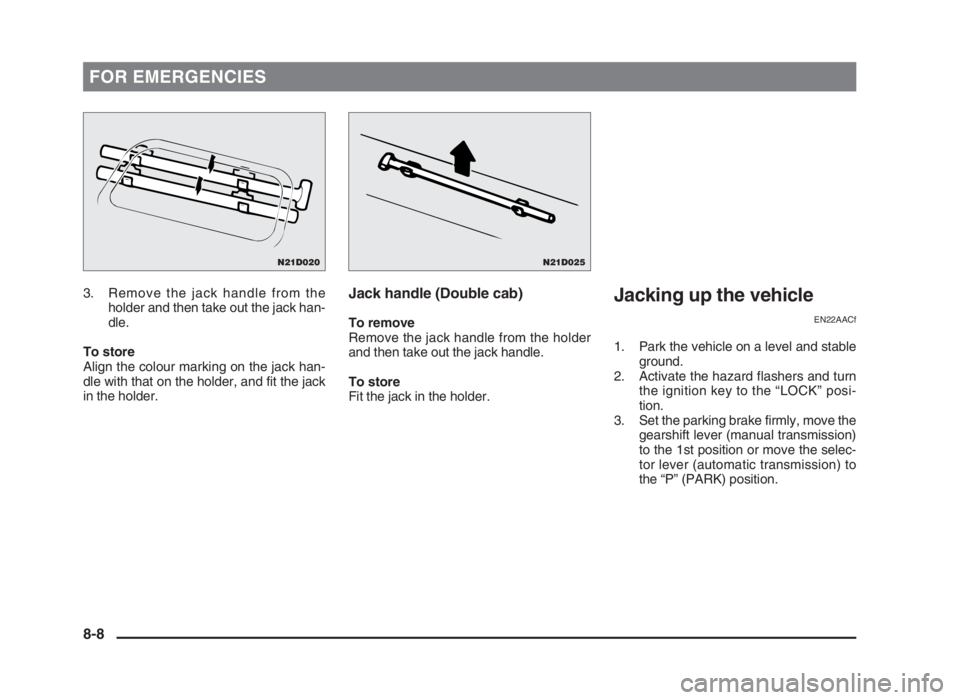

3. Remove the jack handle from the

holder and then take out the jack han-

dle.

To store

Align the colour marking on the jack han-

dle with that on the holder, and fit the jack

in the holder.Jack handle (Double cab)

To remove

Remove the jack handle from the holder

and then take out the jack handle.

To store

Fit the jack in the holder.

Jacking up the vehicle

EN22AACf

1. Park the vehicle on a level and stable

ground.

2. Activate the hazard flashers and turn

the ignition key to the “LOCK” posi-

tion.

3. Set the parking brake firmly, move the

gearshift lever (manual transmission)

to the 1st position or move the selec-

tor lever (automatic transmission) to

the “P” (PARK) position.

8-8

N21D025N21D020

08engL2_240082_4 22-01-2004 13:10 Page 8-8

Page 183 of 264

FOR EMERGENCIES

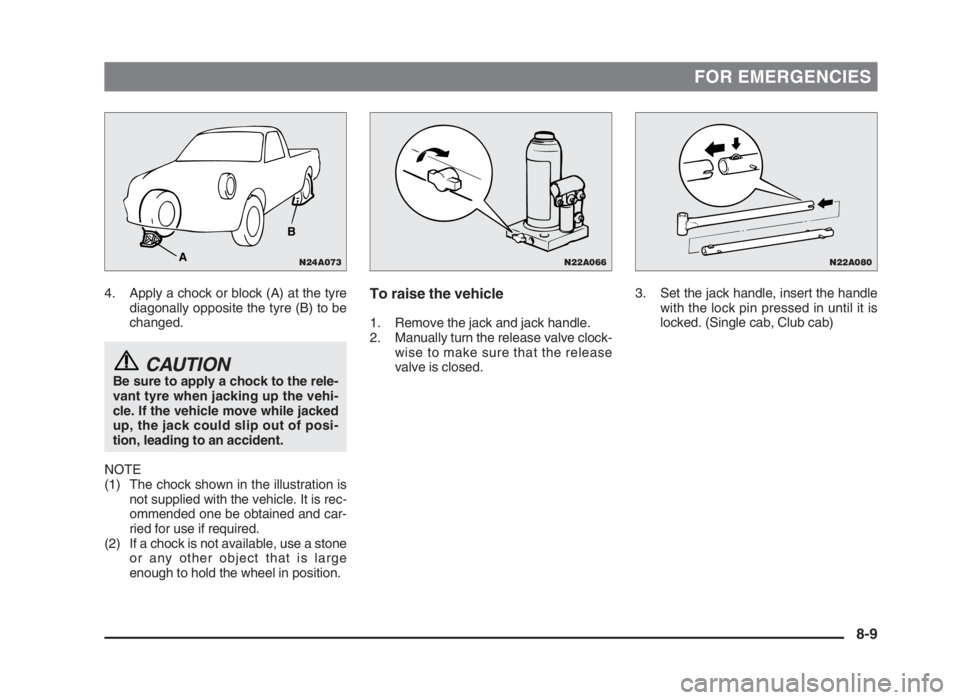

4. Apply a chock or block (A) at the tyre

diagonally opposite the tyre (B) to be

changed.

CAUTIONBe sure to apply a chock to the rele-

vant tyre when jacking up the vehi-

cle. If the vehicle move while jacked

up, the jack could slip out of posi-

tion, leading to an accident.

NOTE

(1) The chock shown in the illustration is

not supplied with the vehicle. It is rec-

ommended one be obtained and car-

ried for use if required.

(2) If a chock is not available, use a stone

or any other object that is large

enough to hold the wheel in position.

3. Set the jack handle, insert the handle

with the lock pin pressed in until it is

locked. (Single cab, Club cab)To raise the vehicle

1. Remove the jack and jack handle.

2. Manually turn the release valve clock-

wise to make sure that the release

valve is closed.

8-9

N22A066N22A080N24A073

B

A

08engL2_240082_4 22-01-2004 13:10 Page 8-9

Page 184 of 264

FOR EMERGENCIES

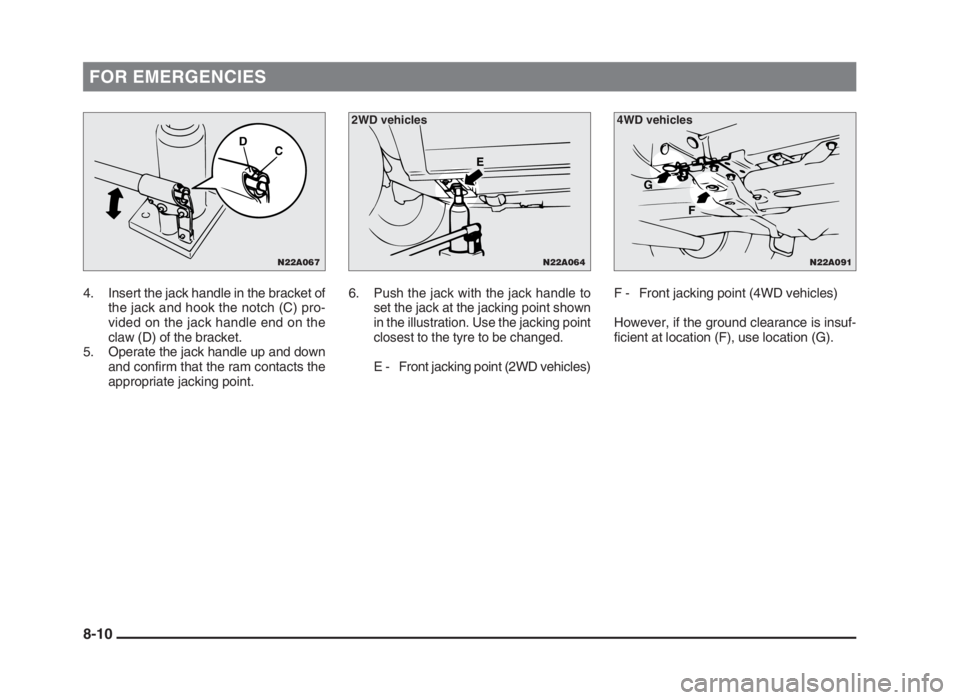

4. Insert the jack handle in the bracket of

the jack and hook the notch (C) pro-

vided on the jack handle end on the

claw (D) of the bracket.

5. Operate the jack handle up and down

and confirm that the ram contacts the

appropriate jacking point.6.Push the jack with the jack handle to

set the jack at the jacking point shown

in the illustration. Use the jacking point

closest to the tyre to be changed.

E - Front jacking point (2WD vehicles)F - Front jacking point (4WD vehicles)

However, if the ground clearance is insuf-

ficient at location (F), use location (G).

8-10

N22A064

E

N22A091

F G

4WD vehicles 2WD vehicles

N22A067

D

C

08engL2_240082_4 22-01-2004 13:10 Page 8-10

Page 185 of 264

FOR EMERGENCIES

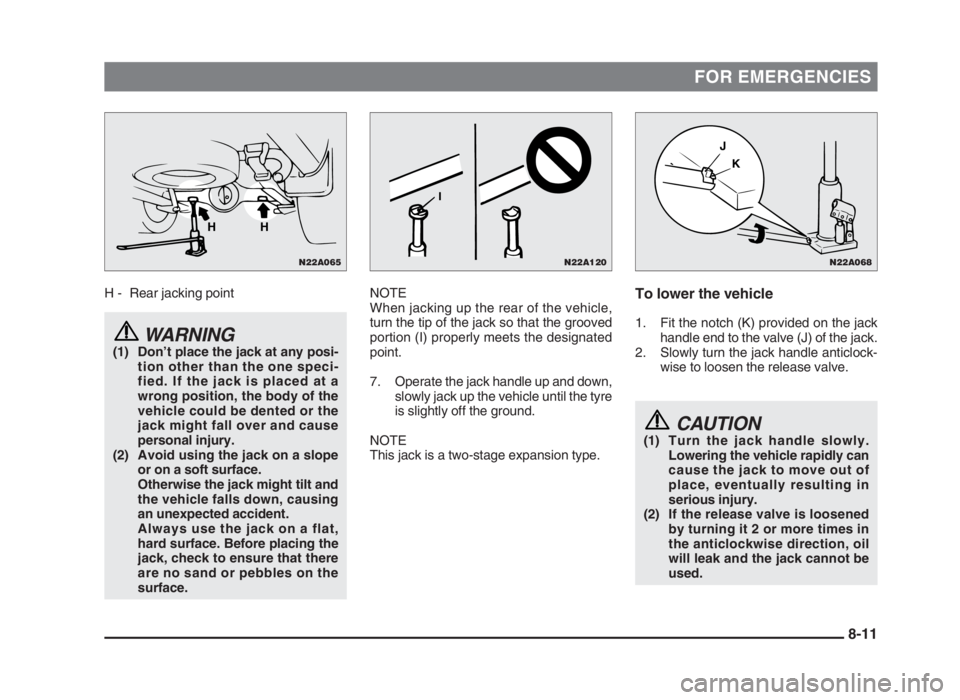

H - Rear jacking point

WARNING(1) Don’t place the jack at any posi-

tion other than the one speci-

fied. If the jack is placed at a

wrong position, the body of the

vehicle could be dented or the

jack might fall over and cause

personal injury.

(2) Avoid using the jack on a slope

or on a soft surface.

Otherwise the jack might tilt and

the vehicle falls down, causing

an unexpected accident.

Always use the jack on a flat,

hard surface. Before placing the

jack, check to ensure that there

are no sand or pebbles on the

surface.

To lower the vehicle

1. Fit the notch (K) provided on the jack

handle end to the valve (J) of the jack.

2. Slowly turn the jack handle anticlock-

wise to loosen the release valve.

CAUTION(1) Turn the jack handle slowly.

Lowering the vehicle rapidly can

cause the jack to move out of

place, eventually resulting in

serious injury.

(2) If the release valve is loosened

by turning it 2 or more times in

the anticlockwise direction, oil

will leak and the jack cannot be

used.

NOTE

When jacking up the rear of the vehicle,

turn the tip of the jack so that the grooved

portion (I) properly meets the designated

point.

7. Operate the jack handle up and down,

slowly jack up the vehicle until the tyre

is slightly off the ground.

NOTE

This jack is a two-stage expansion type.

8-11

N22A120

I

N22A068

K J

N22A065

HH

08engL2_240082_4 22-01-2004 13:10 Page 8-11

Page 186 of 264

FOR EMERGENCIES

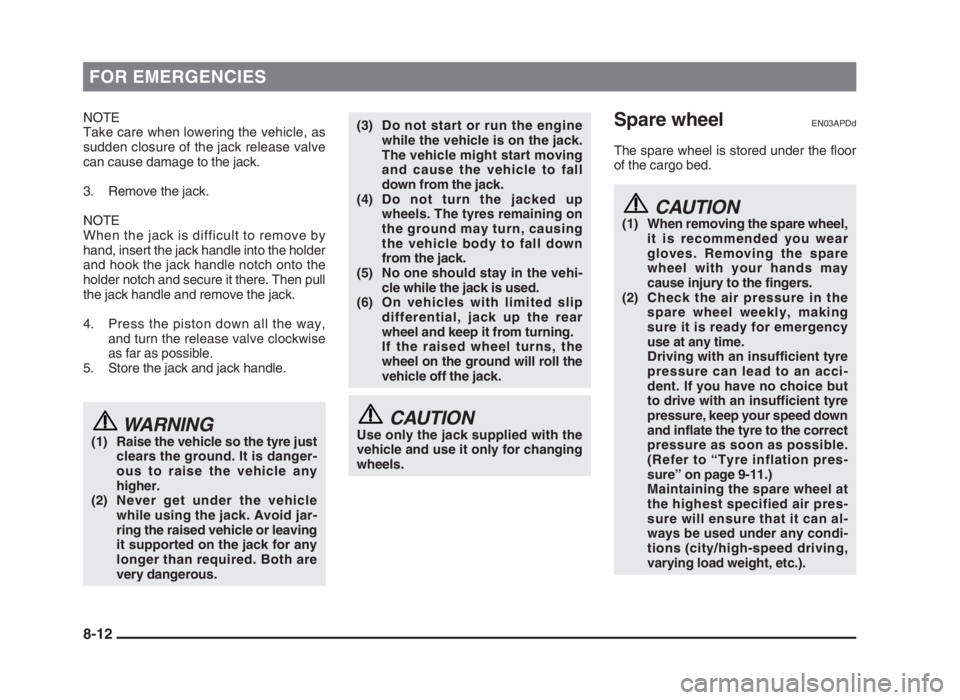

NOTE

Take care when lowering the vehicle, as

sudden closure of the jack release valve

can cause damage to the jack.

3. Remove the jack.

NOTE

When the jack is difficult to remove by

hand, insert the jack handle into the holder

and hook the jack handle notch onto the

holder notch and secure it there. Then pull

the jack handle and remove the jack.

4. Press the piston down all the way,

and turn the release valve clockwise

as far as possible.

5. Store the jack and jack handle.

WARNING(1) Raise the vehicle so the tyre just

clears the ground. It is danger-

ous to raise the vehicle any

higher.

(2) Never get under the vehicle

while using the jack. Avoid jar-

ring the raised vehicle or leaving

it supported on the jack for any

longer than required. Both are

very dangerous.

(3) Do not start or run the engine

while the vehicle is on the jack.

The vehicle might start moving

and cause the vehicle to fall

down from the jack.

(4) Do not turn the jacked up

wheels. The tyres remaining on

the ground may turn, causing

the vehicle body to fall down

from the jack.

(5) No one should stay in the vehi-

cle while the jack is used.

(6) On vehicles with limited slip

differential, jack up the rear

wheel and keep it from turning.

If the raised wheel turns, the

wheel on the ground will roll the

vehicle off the jack.

CAUTIONUse only the jack supplied with the

vehicle and use it only for changing

wheels.

Spare wheelEN03APDd

The spare wheel is stored under the floor

of the cargo bed.

CAUTION(1) When removing the spare wheel,

it is recommended you wear

gloves. Removing the spare

wheel with your hands may

cause injury to the fingers.

(2) Check the air pressure in the

spare wheel weekly, making

sure it is ready for emergency

use at any time.

Driving with an insufficient tyre

pressure can lead to an acci-

dent. If you have no choice but

to drive with an insufficient tyre

pressure, keep your speed down

and inflate the tyre to the correct

pressure as soon as possible.

(Refer to “Tyre inflation pres-

sure” on page 9-11.)

Maintaining the spare wheel at

the highest specified air pres-

sure will ensure that it can al-

ways be used under any condi-

tions (city/high-speed driving,

varying load weight, etc.).

8-12

08engL2_240082_4 22-01-2004 13:10 Page 8-12

Page 187 of 264

FOR EMERGENCIES

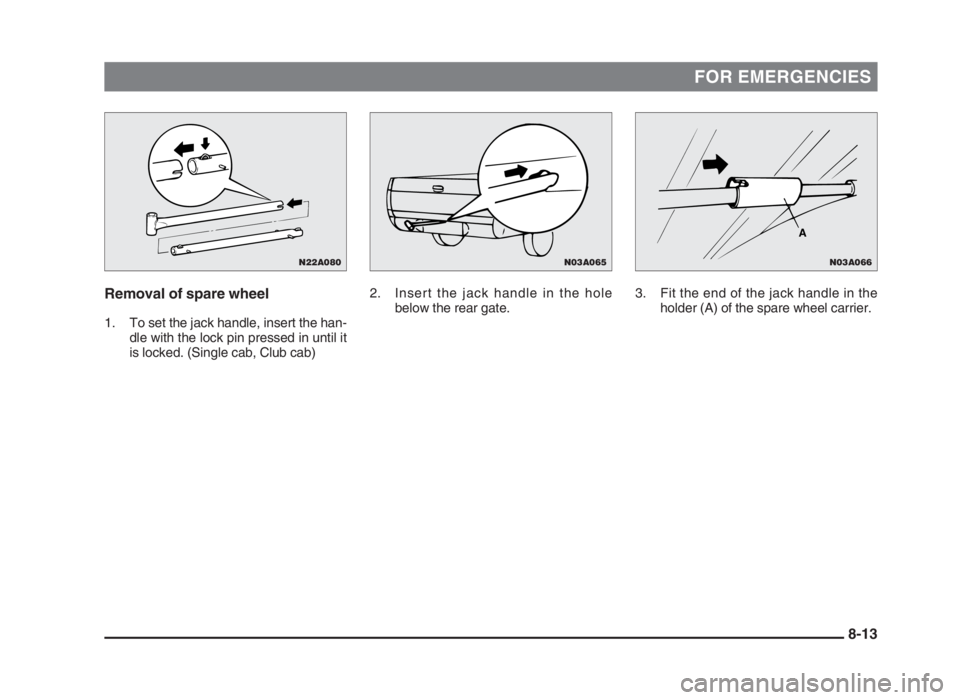

Removal of spare wheel

1. To set the jack handle, insert the han-

dle with the lock pin pressed in until it

is locked. (Single cab, Club cab)3. Fit the end of the jack handle in the

holder (A) of the spare wheel carrier. 2. Insert the jack handle in the hole

below the rear gate.

8-13

N03A066

A

N03A065N22A080

08engL2_240082_4 22-01-2004 13:10 Page 8-13

Page 188 of 264

FOR EMERGENCIES

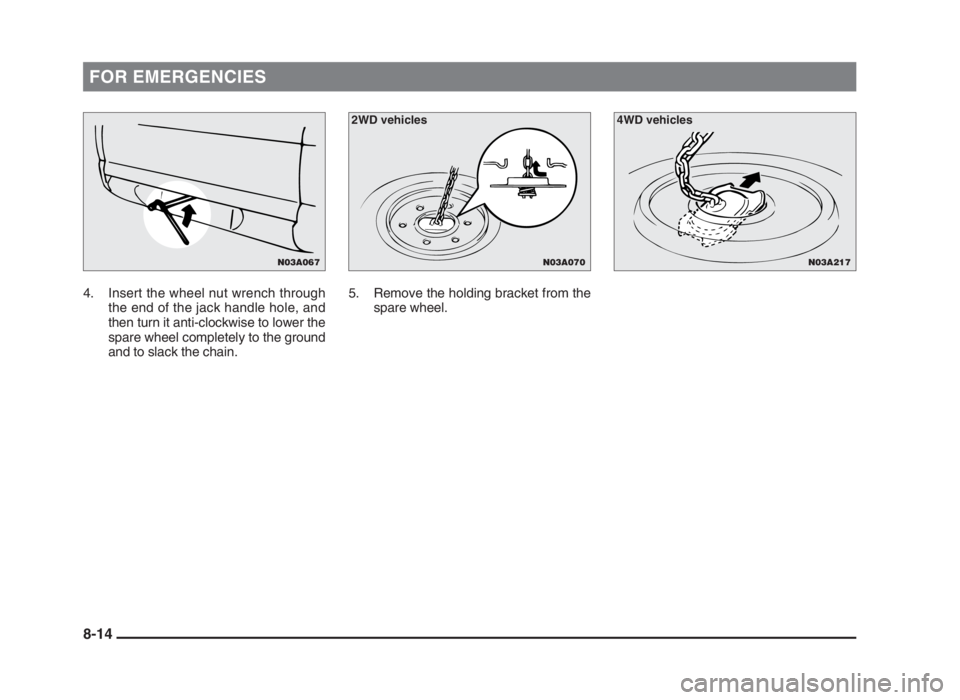

4. Insert the wheel nut wrench through

the end of the jack handle hole, and

then turn it anti-clockwise to lower the

spare wheel completely to the ground

and to slack the chain.5. Remove the holding bracket from the

spare wheel.

8-14

N03A217N03A070

2WD vehicles 4WD vehicles

N03A067

08engL2_240082_4 22-01-2004 13:10 Page 8-14

Page 189 of 264

FOR EMERGENCIES

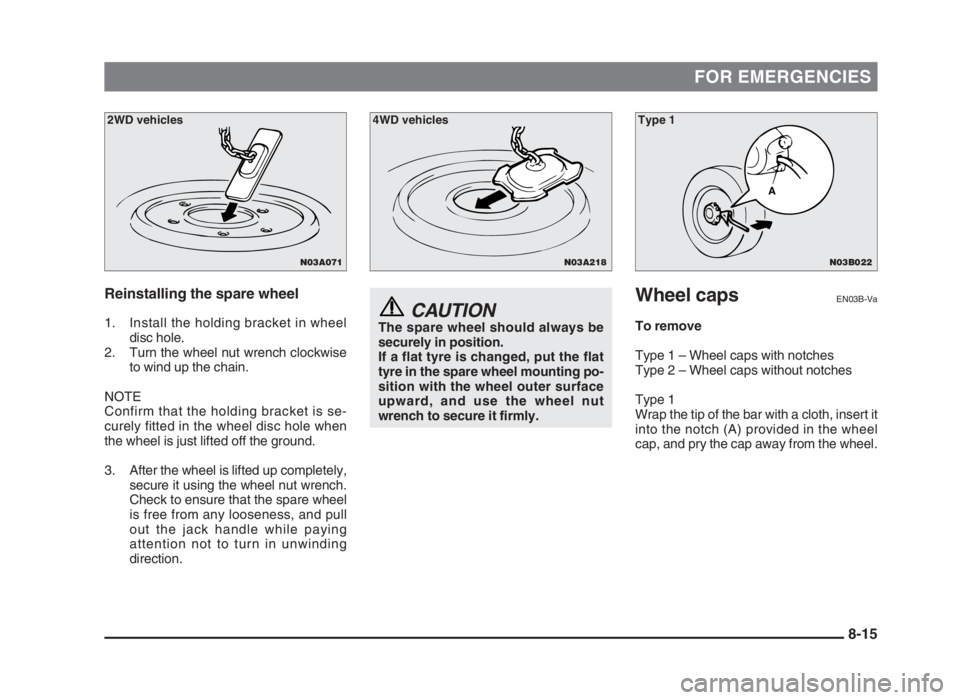

Reinstalling the spare wheel

1. Install the holding bracket in wheel

disc hole.

2. Turn the wheel nut wrench clockwise

to wind up the chain.

NOTE

Confirm that the holding bracket is se-

curely fitted in the wheel disc hole when

the wheel is just lifted off the ground.

3. After the wheel is lifted up completely,

secure it using the wheel nut wrench.

Check to ensure that the spare wheel

is free from any looseness, and pull

out the jack handle while paying

attention not to turn in unwinding

direction.

Wheel capsEN03B-Va

To remove

Type 1 – Wheel caps with notches

Type 2 – Wheel caps without notches

Type 1

Wrap the tip of the bar with a cloth, insert it

into the notch (A) provided in the wheel

cap, and pry the cap away from the wheel.CAUTIONThe spare wheel should always be

securely in position.

If a flat tyre is changed, put the flat

tyre in the spare wheel mounting po-

sition with the wheel outer surface

upward, and use the wheel nut

wrench to secure it firmly.

8-15

N03B022

A

N03A218

4WD vehicles Type 1

N03A071

2WD vehicles

08engL2_240082_4 22-01-2004 13:10 Page 8-15

Page 190 of 264

FOR EMERGENCIES

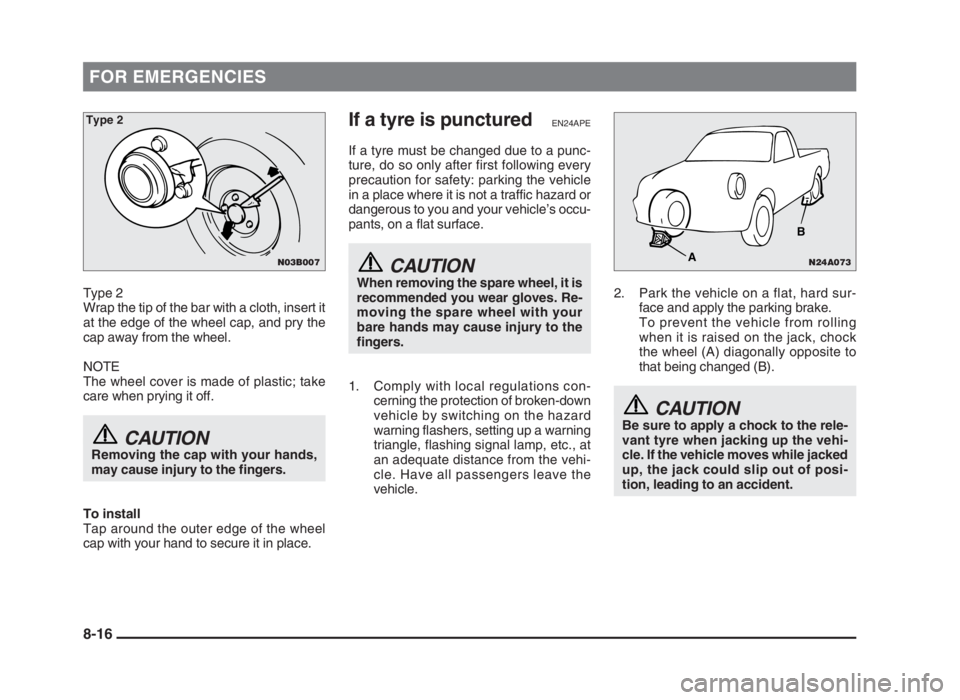

Type 2

Wrap the tip of the bar with a cloth, insert it

at the edge of the wheel cap, and pry the

cap away from the wheel.

NOTE

The wheel cover is made of plastic; take

care when prying it off.

CAUTIONRemoving the cap with your hands,

may cause injury to the fingers.

To install

Tap around the outer edge of the wheel

cap with your hand to secure it in place.

If a tyre is puncturedEN24APE

If a tyre must be changed due to a punc-

ture, do so only after first following every

precaution for safety: parking the vehicle

in a place where it is not a traffic hazard or

dangerous to you and your vehicle’s occu-

pants, on a flat surface.

CAUTIONWhen removing the spare wheel, it is

recommended you wear gloves. Re-

moving the spare wheel with your

bare hands may cause injury to the

fingers.

1. Comply with local regulations con-

cerning the protection of broken-down

vehicle by switching on the hazard

warning flashers, setting up a warning

triangle, flashing signal lamp, etc., at

an adequate distance from the vehi-

cle. Have all passengers leave the

vehicle.2. Park the vehicle on a flat, hard sur-

face and apply the parking brake.

To prevent the vehicle from rolling

when it is raised on the jack, chock

the wheel (A) diagonally opposite to

that being changed (B).

CAUTIONBe sure to apply a chock to the rele-

vant tyre when jacking up the vehi-

cle. If the vehicle moves while jacked

up, the jack could slip out of posi-

tion, leading to an accident.

8-16

N24A073

B

A

N03B007

Type 2

08engL2_240082_4 22-01-2004 13:10 Page 8-16