MITSUBISHI L200 2015 Owner's Manual (in English)

Manufacturer: MITSUBISHI, Model Year: 2015, Model line: L200, Model: MITSUBISHI L200 2015Pages: 418, PDF Size: 25.8 MB

Page 321 of 418

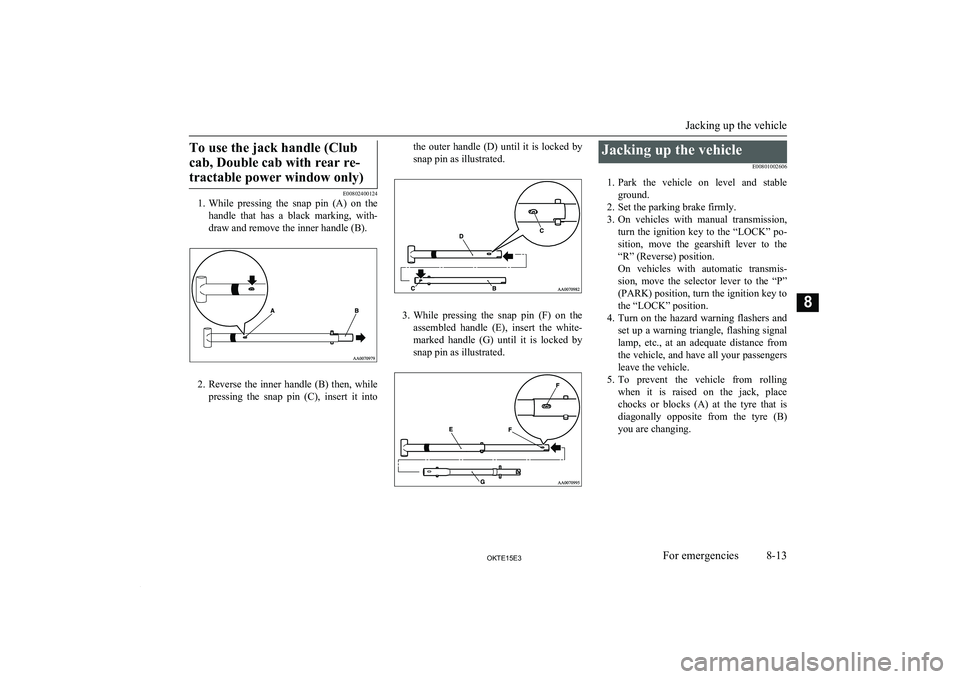

To use the jack handle (Clubcab, Double cab with rear re-tractable power window only)

E00802400124

1. While pressing the snap pin (A) on the

handle that has a black marking, with-draw and remove the inner handle (B).

2. Reverse the inner handle (B) then, while

pressing the snap pin (C), insert it into

the outer handle (D) until it is locked by

snap pin as illustrated.

3. While pressing the snap pin (F) on the

assembled handle (E), insert the white-

marked handle (G) until it is locked by snap pin as illustrated.

Jacking up the vehicle

E00801002606

1. Park the vehicle on level and stable

ground.

2. Set the parking brake firmly.

3. On vehicles with manual transmission,

turn the ignition key to the “LOCK” po-

sition, move the gearshift lever to the “R” (Reverse) position.

On vehicles with automatic transmis- sion, move the selector lever to the “P” (PARK) position, turn the ignition key tothe “LOCK” position.

4. Turn on the hazard warning flashers and

set up a warning triangle, flashing signal lamp, etc., at an adequate distance from

the vehicle, and have all your passengers

leave the vehicle.

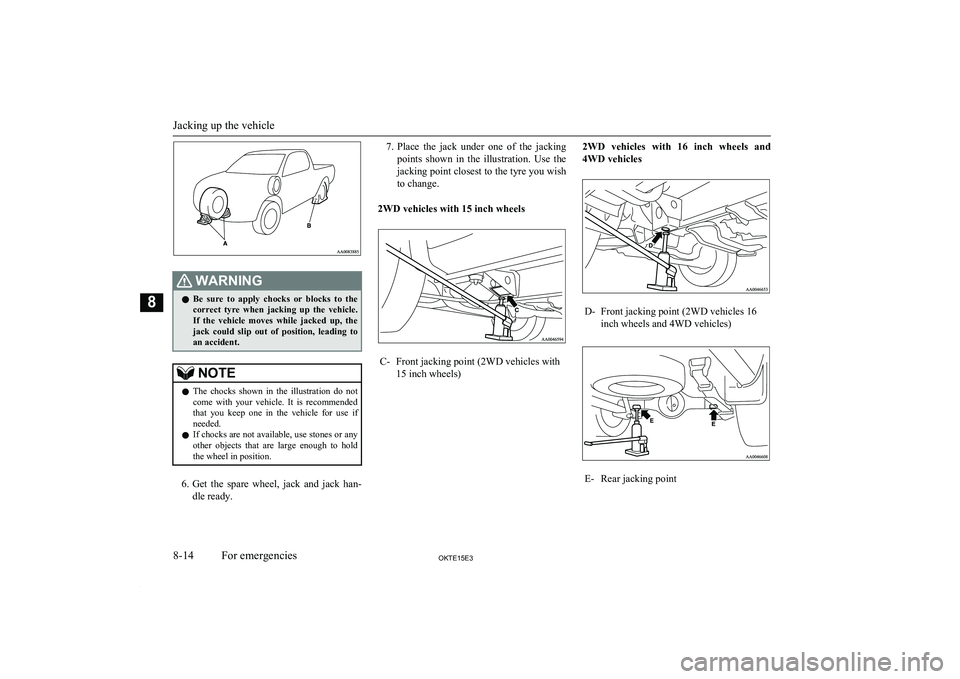

5. To prevent the vehicle from rolling

when it is raised on the jack, place

chocks or blocks (A) at the tyre that is diagonally opposite from the tyre (B)

you are changing.

Jacking up the vehicle

8-13OKTE15E3For emergencies8

Page 322 of 418

WARNINGlBe sure to apply chocks or blocks to the

correct tyre when jacking up the vehicle.If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.NOTEl The chocks shown in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if needed.

l If chocks are not available, use stones or any

other objects that are large enough to hold the wheel in position.

6. Get the spare wheel, jack and jack han-

dle ready.

7. Place the jack under one of the jacking

points shown in the illustration. Use the jacking point closest to the tyre you wish

to change.

2WD vehicles with 15 inch wheelsC-Front jacking point (2WD vehicles with

15 inch wheels)2WD vehicles with 16 inch wheels and

4WD vehiclesD-Front jacking point (2WD vehicles 16

inch wheels and 4WD vehicles)E-Rear jacking point

Jacking up the vehicle

8-14OKTE15E3For emergencies8

Page 323 of 418

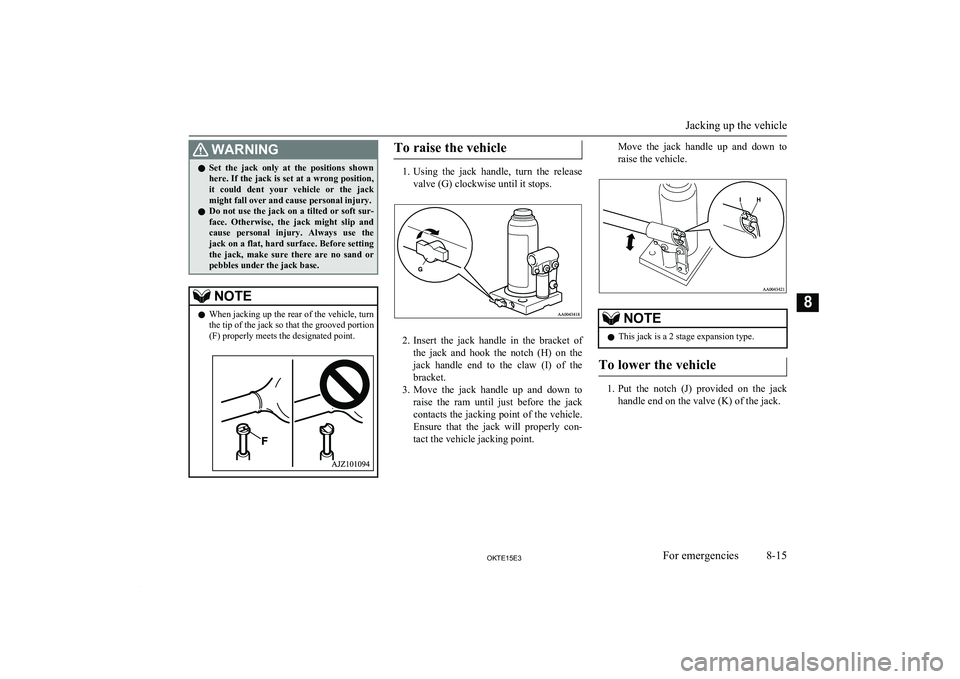

WARNINGlSet the jack only at the positions shown

here. If the jack is set at a wrong position, it could dent your vehicle or the jack

might fall over and cause personal injury.

l Do not use the jack on a tilted or soft sur-

face. Otherwise, the jack might slip and cause personal injury. Always use the jack on a flat, hard surface. Before setting

the jack, make sure there are no sand or pebbles under the jack base.NOTEl When jacking up the rear of the vehicle, turn

the tip of the jack so that the grooved portion

(F) properly meets the designated point.To raise the vehicle

1. Using the jack handle, turn the release

valve (G) clockwise until it stops.

2. Insert the jack handle in the bracket of

the jack and hook the notch (H) on the jack handle end to the claw (I) of thebracket.

3. Move the jack handle up and down to

raise the ram until just before the jack contacts the jacking point of the vehicle.

Ensure that the jack will properly con-

tact the vehicle jacking point.

Move the jack handle up and down to raise the vehicle.NOTEl This jack is a 2 stage expansion type.

To lower the vehicle

1.

Put the notch (J) provided on the jack

handle end on the valve (K) of the jack.

Jacking up the vehicle

8-15OKTE15E3For emergencies8

Page 324 of 418

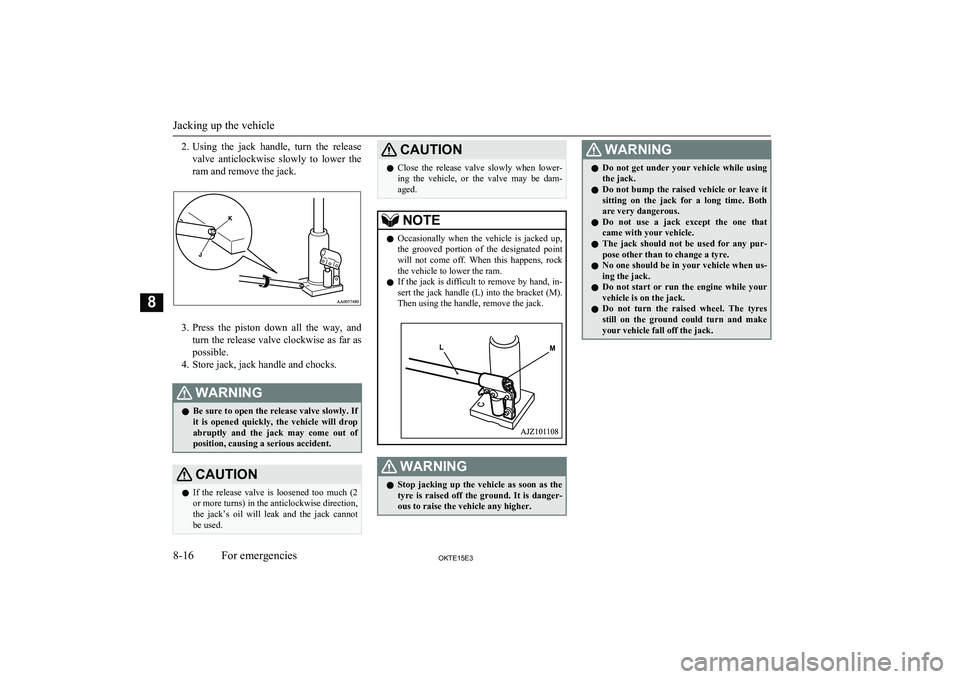

2.Using the jack handle, turn the release

valve anticlockwise slowly to lower theram and remove the jack.

3. Press the piston down all the way, and

turn the release valve clockwise as far as possible.

4. Store jack, jack handle and chocks.

WARNINGl Be sure to open the release valve slowly. If

it is opened quickly, the vehicle will drop

abruptly and the jack may come out of position, causing a serious accident.CAUTIONl If the release valve is loosened too much (2

or more turns) in the anticlockwise direction, the jack’s oil will leak and the jack cannot

be used.CAUTIONl Close the release valve slowly when lower-

ing the vehicle, or the valve may be dam-

aged.NOTEl Occasionally when the vehicle is jacked up,

the grooved portion of the designated pointwill not come off. When this happens, rock

the vehicle to lower the ram.

l If the jack is difficult to remove by hand, in-

sert the jack handle (L) into the bracket (M).

Then using the handle, remove the jack.WARNINGl Stop jacking up the vehicle as soon as the

tyre is raised off the ground. It is danger-

ous to raise the vehicle any higher.WARNINGl Do not get under your vehicle while using

the jack.

l Do not bump the raised vehicle or leave it

sitting on the jack for a long time. Both

are very dangerous.

l Do not use a jack except the one that

came with your vehicle.

l The jack should not be used for any pur-

pose other than to change a tyre.

l No one should be in your vehicle when us-

ing the jack.

l Do not start or run the engine while your

vehicle is on the jack.

l Do not turn the raised wheel. The tyres

still on the ground could turn and make your vehicle fall off the jack.

Jacking up the vehicle

8-16OKTE15E3For emergencies8

Page 325 of 418

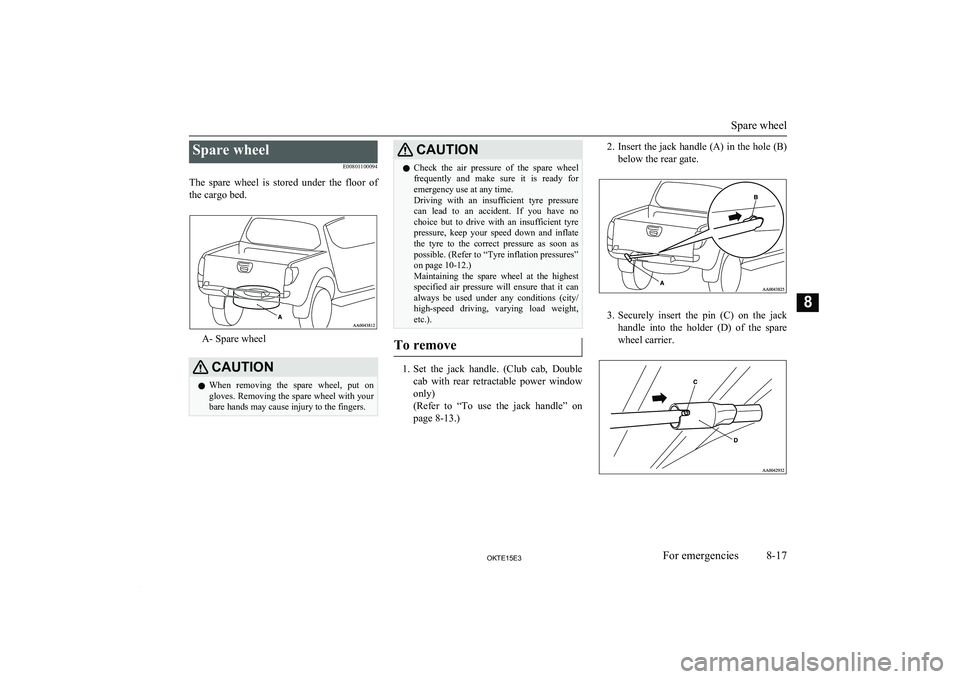

Spare wheelE00801100094

The spare wheel is stored under the floor of the cargo bed.

A- Spare wheel

CAUTIONl When removing the spare wheel, put on

gloves. Removing the spare wheel with your

bare hands may cause injury to the fingers.CAUTIONl Check the air pressure of the spare wheel

frequently and make sure it is ready for

emergency use at any time.

Driving with an insufficient tyre pressure

can lead to an accident. If you have no choice but to drive with an insufficient tyre

pressure, keep your speed down and inflate the tyre to the correct pressure as soon as possible. (Refer to “Tyre inflation pressures”

on page 10-12.)

Maintaining the spare wheel at the highest

specified air pressure will ensure that it can always be used under any conditions (city/

high-speed driving, varying load weight,

etc.).

To remove

1. Set the jack handle. (Club cab, Double

cab with rear retractable power window

only)

(Refer to “To use the jack handle” on page 8-13.)

2. Insert the jack handle (A) in the hole (B)

below the rear gate.

3. Securely insert the pin (C) on the jack

handle into the holder (D) of the spare

wheel carrier.

Spare wheel

8-17OKTE15E3For emergencies8

Page 326 of 418

4.Insert the wheel nut wrench (E) through

the end of the jack handle hole (F), and

then turn it anticlockwise to lower the spare wheel completely to the ground

and to slack the chain.

5. Remove the hanger disc (G) from the

spare wheel.

To install

1. Install the hanger disc (A) in the wheel

disc hole.

2. Turn the wheel nut wrench (B) clock-

wise to wind up the chain.

NOTEl Confirm that the hanger disc is securely fit-

ted in the wheel disc hole when the wheel isjust lifted off the ground.

3. After winding up the spare wheel suffi-

ciently, make sure it is not loose (the tightening torque should be approxi-

mately 40 Nm) then withdraw the jack

handle, taking care not to turn it in the

reverse direction.

CAUTIONl The spare wheel should always be securely

in position.

If a flat tyre is changed, put the flat tyre in

the spare wheel mounting position with the wheel outer surface upward, and use the wheel nut wrench to secure it firmly.How to change a tyre

E00801202653

Before changing a tyre, first stop your vehi-cle in a safe, flat location. 1. Park the vehicle on level and stable

ground.

2. Set the parking brake firmly.

How to change a tyre

8-18OKTE15E3For emergencies8

Page 327 of 418

3.On vehicles with manual transmission,

turn the ignition key to the “LOCK” po-

sition, move the gearshift lever to the “R” (Reverse) position.

On vehicles with automatic transmis- sion, move the selector lever to the “P” (PARK) position, turn the ignition key to

the “LOCK” position.

4. Turn on the hazard warning flashers and

set up a warning triangle, flashing signal lamp, etc., at an adequate distance from

the vehicle, and have all your passengers

leave the vehicle.

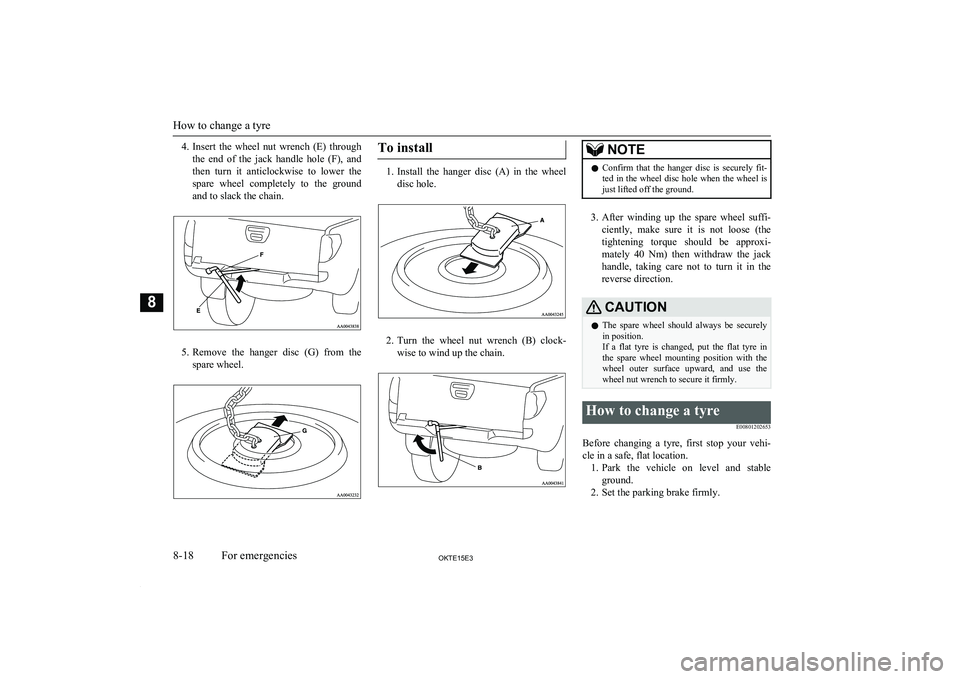

5. To prevent the vehicle from rolling

when it is raised on the jack, place

chocks or blocks (A) at the tyre that is diagonally opposite from the tyre (B)

you are changing.WARNINGl Be sure to apply chocks or blocks to the

correct tyre when jacking up the vehicle.If the vehicle moves while jacked up, the

jack could slip out of position, leading to

an accident.NOTEl The chocks shown in the illustration do not

come with your vehicle. It is recommended

that you keep one in the vehicle for use if needed.

l If chocks are not available, use stones or any

other objects that are large enough to hold the wheel in position.

6. Get the spare wheel, jack, jack handle

and wheel nut wrench ready.

NOTEl Put the spare wheel under the vehicle body

near the flat tyre. This makes it safer if the jack slips out of position.

7. Loosen the wheel nuts with the wheel

nut wrench. Do not remove the wheel nuts yet.

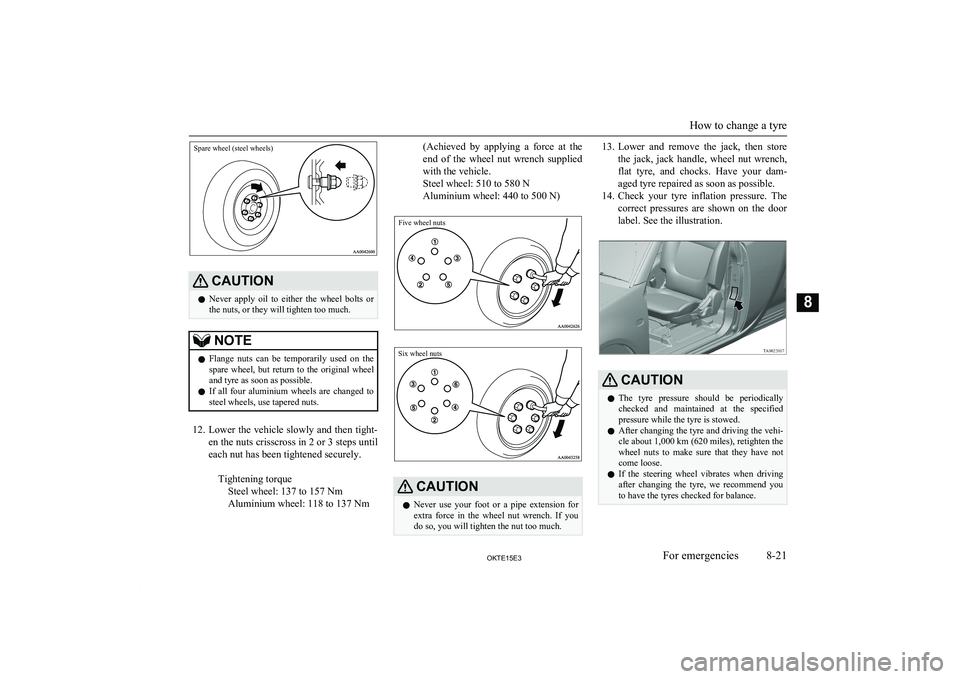

Five wheel nutsSix wheel nuts

How to change a tyre

8-19OKTE15E3For emergencies8

Page 328 of 418

8.Find the closest jacking point to the flat

tyre (refer to “Jacking up the vehicle” on page 8-13). Then position the jack and

raise the vehicle until the tyre is slightly off the ground.

9. Remove the wheel nuts with the wheel

nut wrench, then take the wheel off.CAUTIONl Handle the wheel carefully when changing

the tyre, to avoid scratching the wheel sur- face.

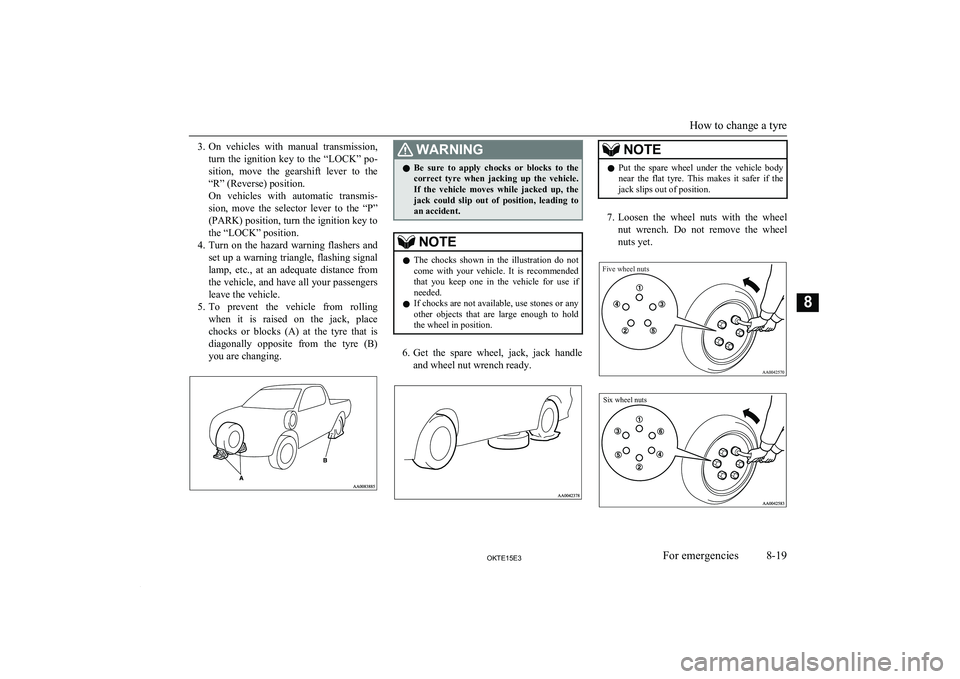

10. Clean out any mud, etc. on the hub sur-

face (C), hub bolts (D) or in the installa- tion holes (E) in the wheel, and then

mount the spare wheel.

WARNINGl Mount the spare wheel with the valve

stem (F) facing outboard. If you cannot see the valve stem (F), you have installed

the wheel backwards.

Operating the vehicle with the spare wheel installed backwards can cause vehi-

cle damage and result in an accident.

11. Finger-tighten the wheel nuts. (Turn

them clockwise.)

Vehicles with steel wheels

Tighten the wheel nuts (tapered nuts)

until the tapered parts of the wheel nuts make light contact with the seats of the wheel holes and the wheel is not loose.

With a spare wheel, tighten the wheel

nuts in the same way.

Vehicles with aluminium wheels

Tighten the wheel nuts (flange nuts) un-

til the flanges of the wheel nuts touch the wheel and the wheel is not loose.

Normal wheels and spare wheel

(aluminium wheels)

With a spare wheel, tighten the wheel

nuts until the tapered parts of the wheel nuts make light contact with the seats of the wheel holes and the wheel is not

loose.

How to change a tyre

8-20OKTE15E3For emergencies8

Page 329 of 418

Spare wheel (steel wheels)

CAUTIONlNever apply oil to either the wheel bolts or

the nuts, or they will tighten too much.NOTEl Flange nuts can be temporarily used on the

spare wheel, but return to the original wheel and tyre as soon as possible.

l If all four aluminium wheels are changed to

steel wheels, use tapered nuts.

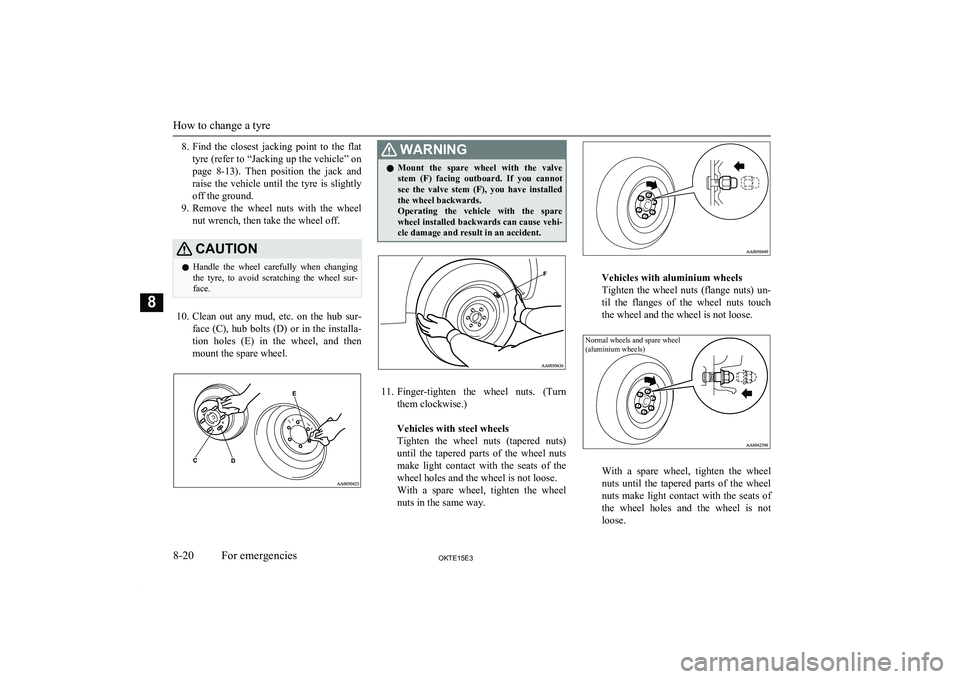

12. Lower the vehicle slowly and then tight-

en the nuts crisscross in 2 or 3 steps until

each nut has been tightened securely.

Tightening torqueSteel wheel: 137 to 157 Nm

Aluminium wheel: 118 to 137 Nm

(Achieved by applying a force at the

end of the wheel nut wrench supplied with the vehicle.

Steel wheel: 510 to 580 N

Aluminium wheel: 440 to 500 N)Five wheel nutsSix wheel nuts

CAUTIONl Never use your foot or a pipe extension for

extra force in the wheel nut wrench. If you

do so, you will tighten the nut too much.13. Lower and remove the jack, then store

the jack, jack handle, wheel nut wrench, flat tyre, and chocks. Have your dam-

aged tyre repaired as soon as possible.

14. Check your tyre inflation pressure. The

correct pressures are shown on the door label. See the illustration.CAUTIONl The tyre pressure should be periodically

checked and maintained at the specified pressure while the tyre is stowed.

l After changing the tyre and driving the vehi-

cle about 1,000 km (620 miles), retighten the

wheel nuts to make sure that they have not come loose.

l If the steering wheel vibrates when driving

after changing the tyre, we recommend you to have the tyres checked for balance.

How to change a tyre

8-21OKTE15E3For emergencies8

Page 330 of 418

CAUTIONlDo not mix one type of tyre with another or

use a different size from the one listed. This

would cause early wear and poor handling.Towing

E00801505107

If your vehicle needs to be tow-

ed

If towing is necessary, we recommend you to have it done by your MITSUBISHI

MOTORS Authorized Service Point or a

commercial tow truck service.

In the following cases, transport the vehicle

using a tow truck.

l The engine runs but the vehicle does not

move or abnormal noise is produced.

l Inspection of the vehicle’s underside re-

veals that oil or some other fluid is leak- ing.

If a wheel gets stuck in a ditch, do not try to tow the vehicle. Please contact your

MITSUBISHI MOTORS Authorized Service

Point or a commercial tow truck service for assistance.

Only when you cannot receive a towing serv-

ice from a MITSUBISHI MOTORS Author-

ized Service Point or commercial tow truck

service, tow your vehicle carefully in accord- ance with the instructions given in “Emer-gency towing” in this part.

The regulations concerning towing may dif-

fer from country to country. It is recommen-

ded that you obey the regulations of the area where you are driving your vehicle.Towing the vehicle by a tow

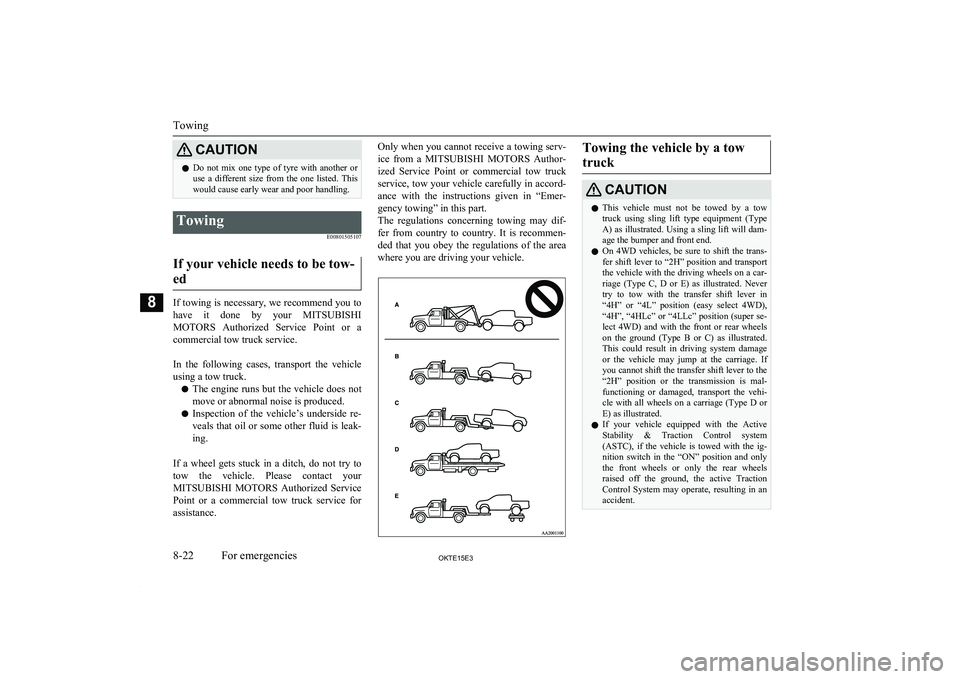

truckCAUTIONl This vehicle must not be towed by a tow

truck using sling lift type equipment (Type A) as illustrated. Using a sling lift will dam-age the bumper and front end.

l On 4WD vehicles, be sure to shift the trans-

fer shift lever to “2H” position and transport

the vehicle with the driving wheels on a car- riage (Type C, D or E) as illustrated. Never

try to tow with the transfer shift lever in

“4H” or “4L” position (easy select 4WD),

“4H”, “4HLc” or “4LLc” position (super se- lect 4WD) and with the front or rear wheels

on the ground (Type B or C) as illustrated.

This could result in driving system damage or the vehicle may jump at the carriage. If you cannot shift the transfer shift lever to the “2H” position or the transmission is mal-

functioning or damaged, transport the vehi- cle with all wheels on a carriage (Type D or E) as illustrated.

l If your vehicle equipped with the Active

Stability & Traction Control system

(ASTC), if the vehicle is towed with the ig-

nition switch in the “ON” position and only the front wheels or only the rear wheels

raised off the ground, the active Traction Control System may operate, resulting in an

accident.

Towing

8-22OKTE15E3For emergencies8