oil MITSUBISHI LANCER 2005 Owner's Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 99 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-35

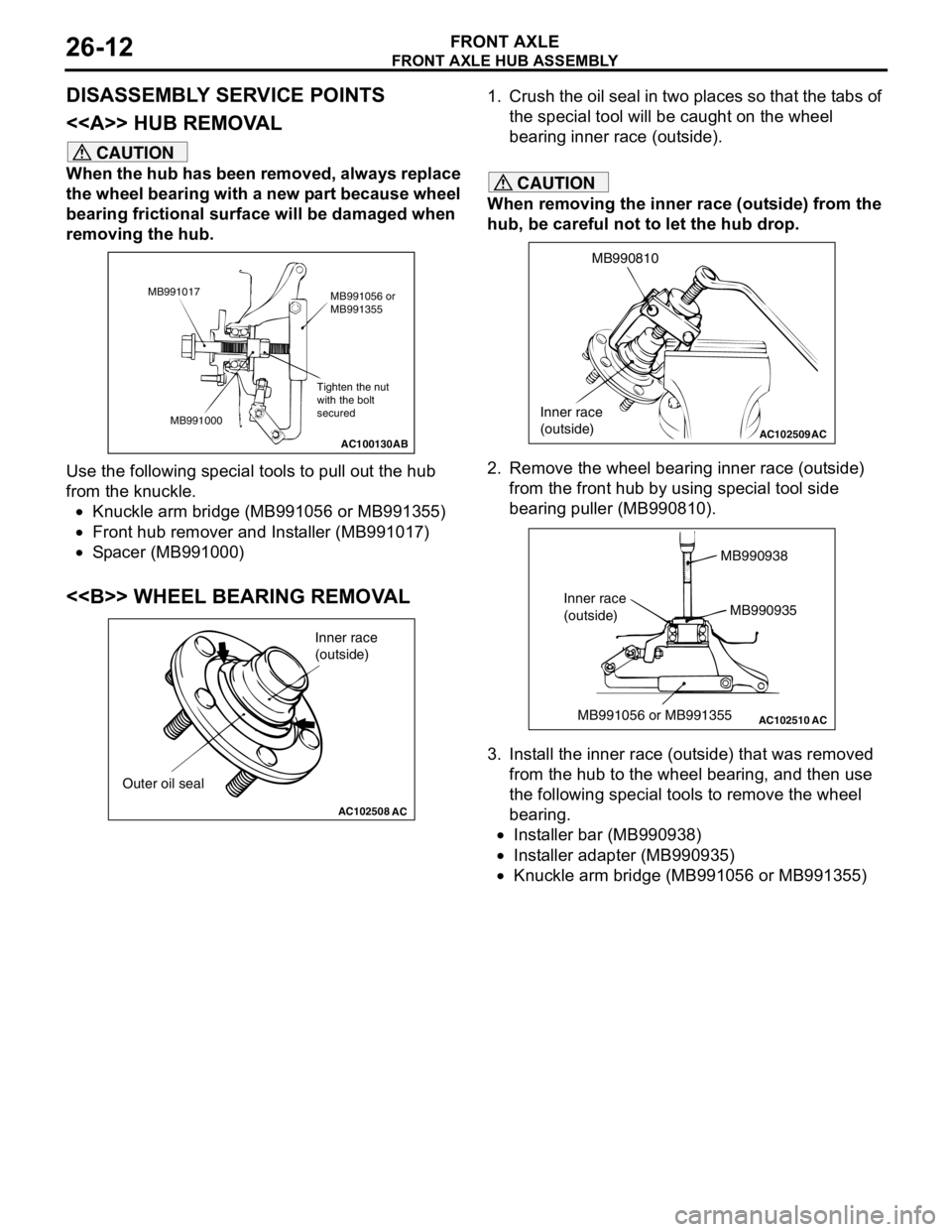

WAVEFORM OBSERVATION POINTS

Point A: The height, length and slope of the spark line show the following trends (Refer to abnormal

waveform examples, 1, 2, 3 and 4).

Point B: Number of vibration in reduction vibration section (Refer to abnormal waveform example 5)

Point C: Number of vibrations at beginning of dwell section (Refer to abnormal waveform example 5)

Point D: Ignition voltage height (distribution per each cylinder) shows the following trends.

AKX01275

kV

Secondary ignition

voltage wave pattern

0

2NO. 1 cylinder

NO. 3 cylinder

ignition noise

Newtral sectionNO. 4 cylinderNO. 2 cylinder

ignition noise

Time

AC

Spark line Plug gap Condition of

electrodeCompression

force Concentration

of air mixtureIgnition

timingSpark plug

cable

Length Long Small Normal Low Rich Advanced Leak

Short Large Large wear High Lean Retarded High

resistance

Height High Large Large wear High Lean Retarded High

resistance

Low Small Normal Low Rich Advanced Leak

Slope Large Plug is fouled

−− −−

Number of vibrations Coil and condenser

3 or more Normal

Except above Abnormal

Number of vibrations Coil

5 − 6 or higher Normal

Except above Abnormal

Ignition

voltagePlug gap Condition of

electrodeCompression

forceConcentration

of air mixtureIgnition

timingSpark plug

cable

High Large Large wear High Lean Retarded High

resistance

Low Small Normal Low Rich Advanced Leak

Page 100 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-36

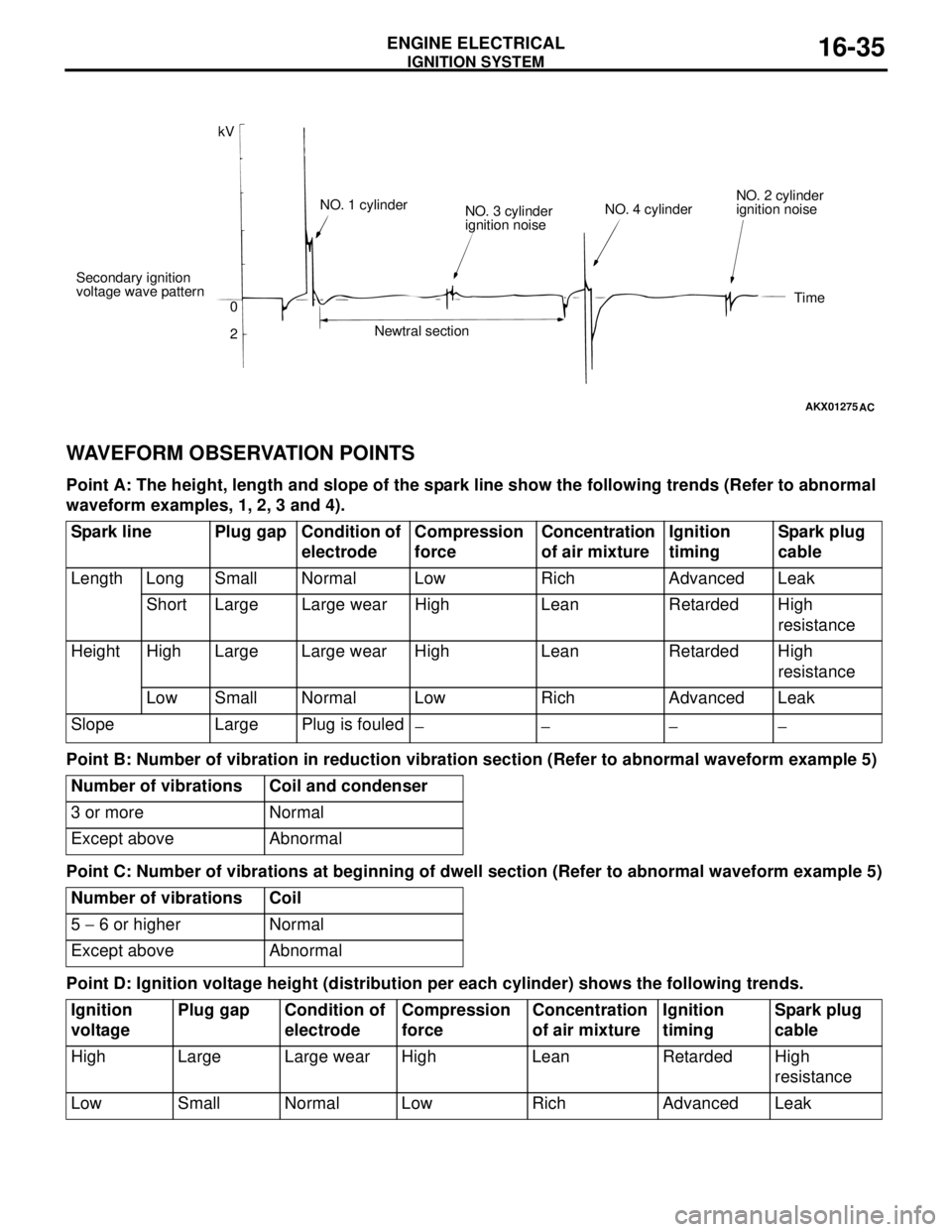

EXAMPLES OF ABNORMAL

WAV E F O R M S

Example 1

•Wave characteristics

Spark line is high and short.

•Cause of problem

Spark plug gap is too large.

Example 2

•Wave characteristics

Spark line is low and long, and is sloping.

Also, the second half of the spark line is distorted.

This could be a result of misfiring.

•Cause of problem

Spark plug gap is too small.Example 3

•Wave characteristics

Spark line is low and long, and is sloping.

However, there is almost no spark line

distortion.

•Cause of problem

Spark plug gap is fouled.

Example 4

•Wave characteristics

Spark line is high and short.

Difficult to distinguish between this and abnormal

waveform example 1.

•Cause of problem

Spark plug cable is nearly falling off (Causing a

dual ignition).

Example 5

•Wave characteristics

No waves in wave damping section.

•Cause of problem

Layer short in ignition coil.

AKX00280

AKX00281

AKX00282

AKX00283

AKX00284

Page 101 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-37

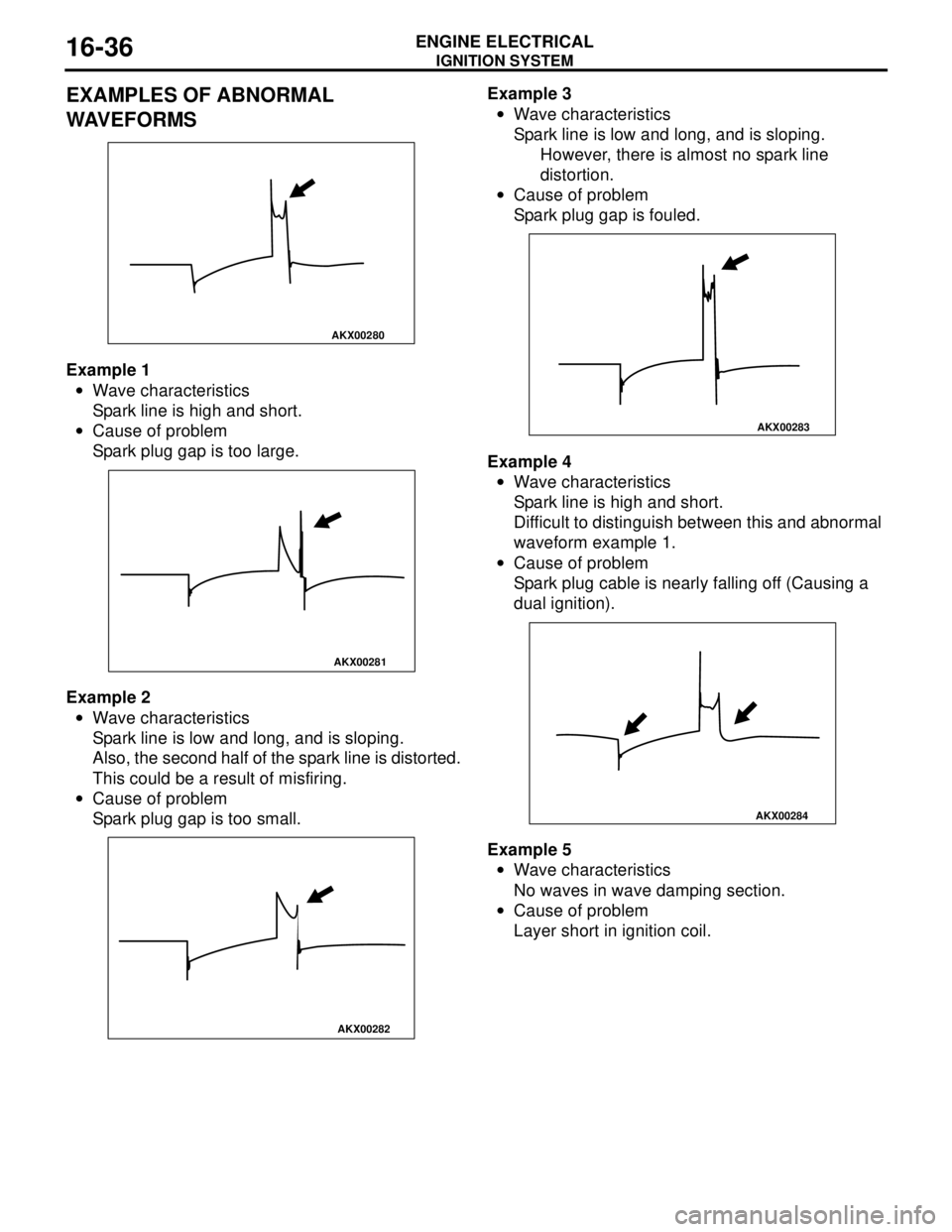

IGNITION COIL RELAY CHECKM1163006500018

AC301727

2 1

3 4

AC304311AB

Battery

Ignition coil relay

Battery

voltageTerminal No.to

be connected to

testerContinuity test

results

Not applied 1 − 4 Open circuit

Connect

terminal

No.2 and

battery (+)

terminal.

Connect

terminal

No.3 and

battery (−)

terminal.1 − 4 Less than 2 ohms

Page 102 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-38

IGNITION COIL

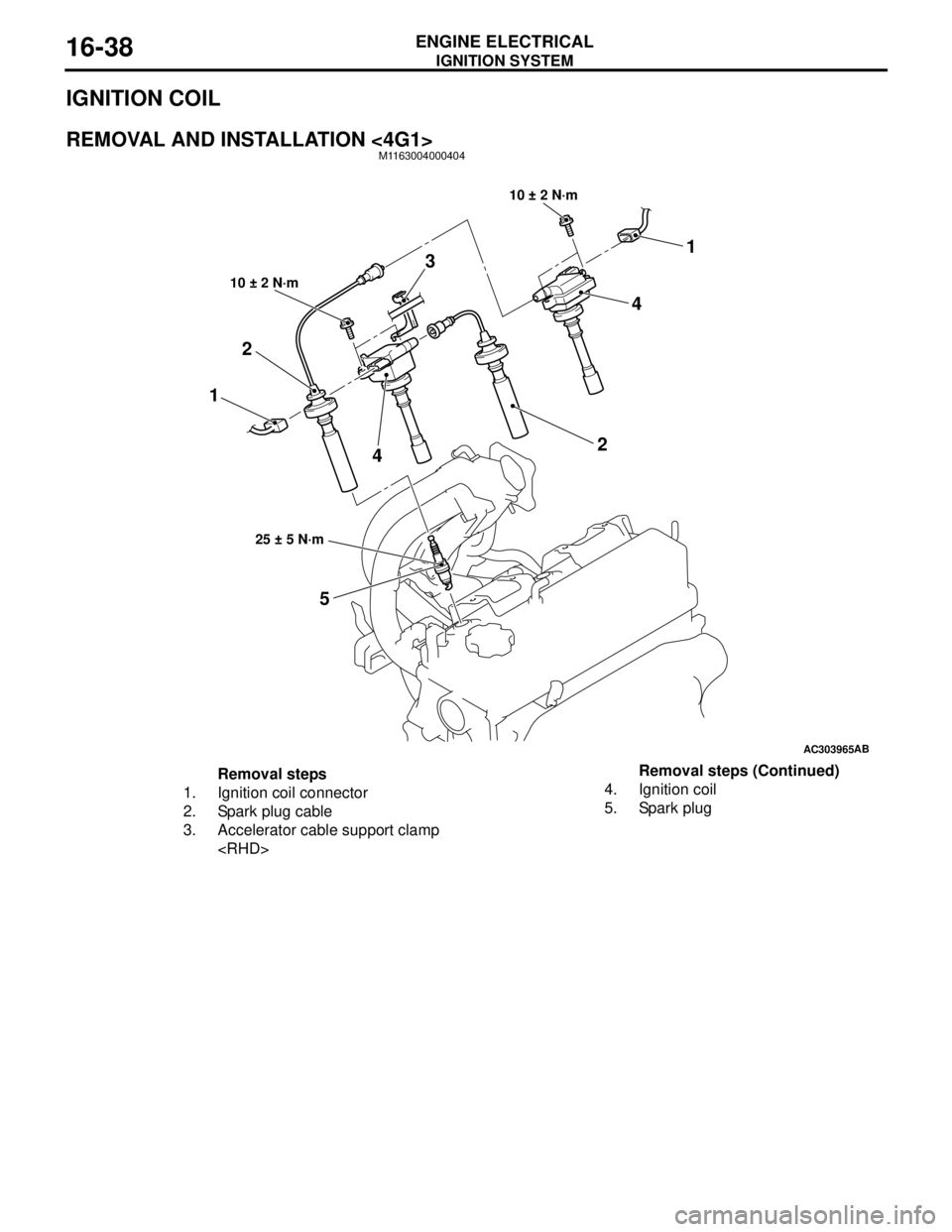

REMOVAL AND INSTALLATION <4G1>M1163004000404

AC303965AB

11

5 2

2

10 ± 2 N·m

10 ± 2 N·m

25 ± 5 N·m

3

4

4

Removal steps

1. Ignition coil connector

2. Spark plug cable

3. Accelerator cable support clamp

5. Spark plugRemoval steps (Continued)

Page 103 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-39

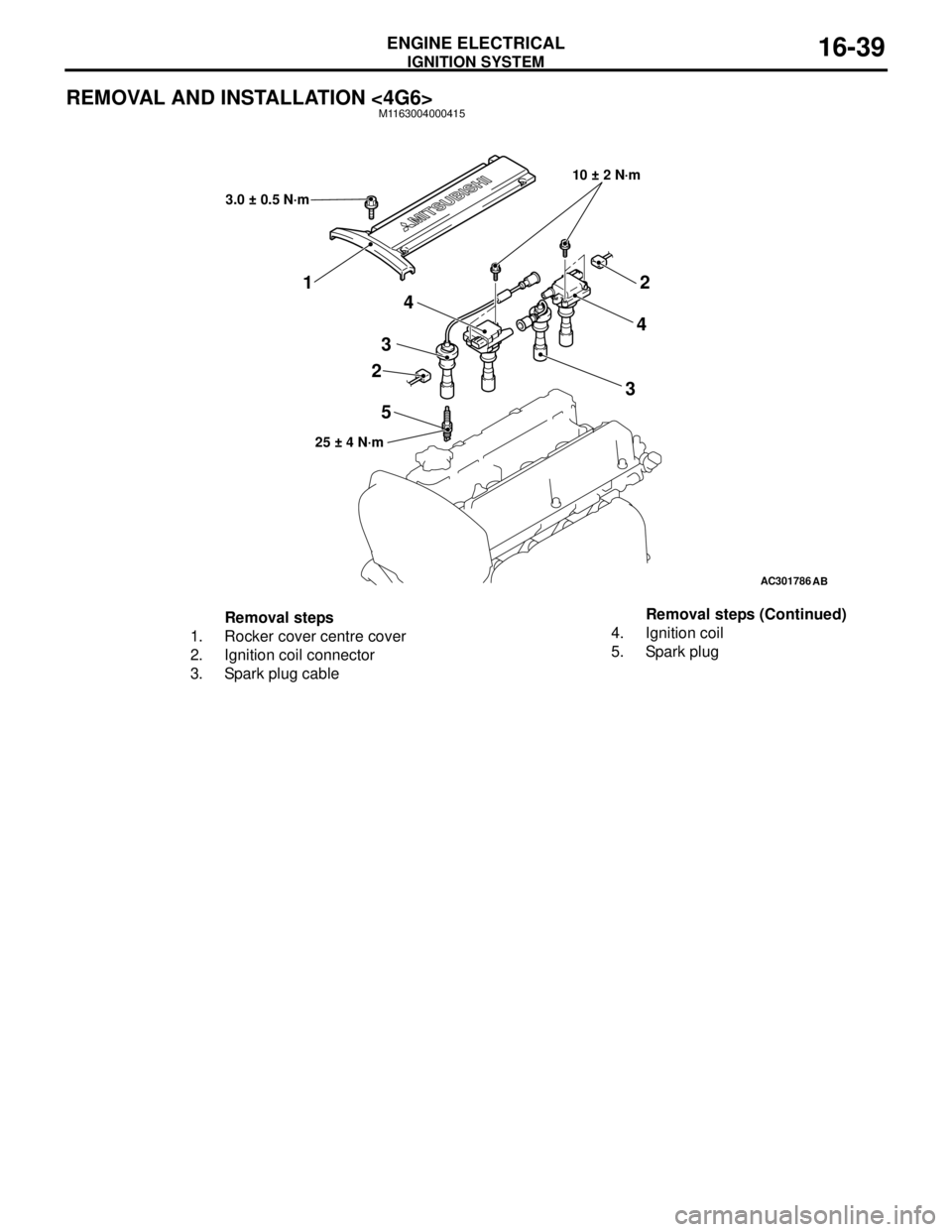

REMOVAL AND INSTALLATION <4G6>M1163004000415

AC301786

10 ± 2 N·m

25 ± 4 N·m

54

22

3 34

AB

1

3.0 ± 0.5 N·m

Removal steps

1. Rocker cover centre cover

2. Ignition coil connector

3. Spark plug cable4. Ignition coil

5. Spark plugRemoval steps (Continued)

Page 106 of 788

IGNITION SYSTEM

ENGINE ELECTRICAL16-42

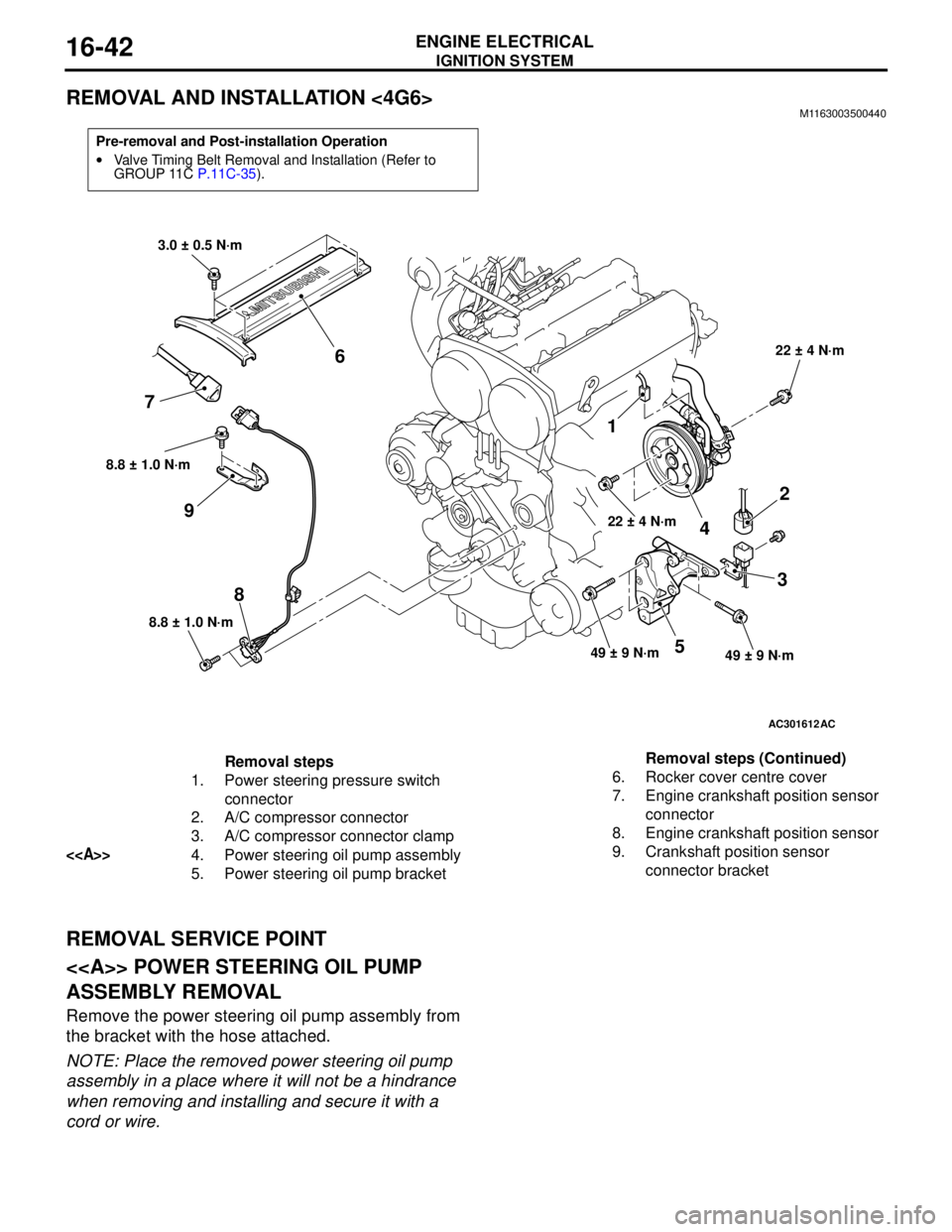

REMOVAL AND INSTALLATION <4G6>M1163003500440

REMOVAL SERVICE POINT

<> POWER STEERING OIL PUMP

ASSEMBLY REMOVAL

Remove the power steering oil pump assembly from

the bracket with the hose attached.

NOTE: Place the removed power steering oil pump

assembly in a place where it will not be a hindrance

when removing and installing and secure it with a

cord or wire.

Pre-removal and Post-installation Operation

•Valve Timing Belt Removal and Installation (Refer to

GROUP 11C P.11C-35).

AC301612

8.8 ± 1.0 N·m

8

8.8 ± 1.0 N·m

9

1

22 ± 4 N·m

4

2

3

49 ± 9 N·m49 ± 9 N·m5

22 ± 4 N·m

3.0 ± 0.5 N·m

6

7

AC

Removal steps

1. Power steering pressure switch

connector

2. A/C compressor connector

3. A/C compressor connector clamp

<>4. Power steering oil pump assembly

5. Power steering oil pump bracket6. Rocker cover centre cover

7. Engine crankshaft position sensor

connector

8. Engine crankshaft position sensor

9. Crankshaft position sensor

connector bracket Removal steps (Continued)

Page 113 of 788

EMISSION CONTROL

ENGINE AND EMISSION CONTROL17-5

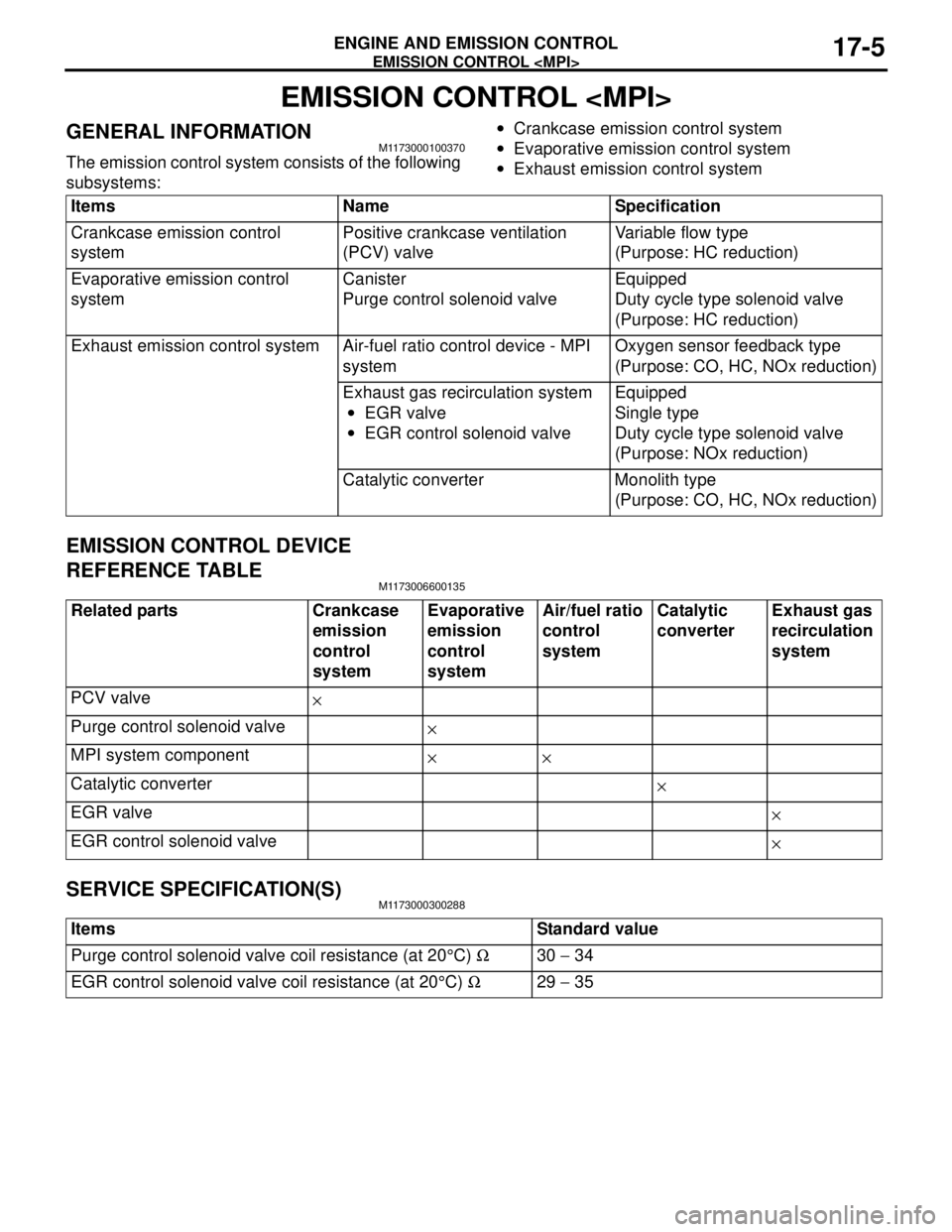

EMISSION CONTROL

GENERAL INFORMATIONM1173000100370

The emission control system consists of the following

subsystems:•Crankcase emission control system

•Evaporative emission control system

•Exhaust emission control system

EMISSION CONTROL DEVICE

REFERENCE TABLE

M1173006600135

SERVICE SPECIFICATION(S)M1173000300288

Items Name Specification

Crankcase emission control

systemPositive crankcase ventilation

(PCV) valveVariable flow type

(Purpose: HC reduction)

Evaporative emission control

systemCanister

Purge control solenoid valveEquipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

Exhaust emission control system Air-fuel ratio control device - MPI

systemOxygen sensor feedback type

(Purpose: CO, HC, NOx reduction)

Exhaust gas recirculation system

•EGR valve

•EGR control solenoid valveEquipped

Single type

Duty cycle type solenoid valve

(Purpose: NOx reduction)

Catalytic converter Monolith type

(Purpose: CO, HC, NOx reduction)

Related parts Crankcase

emission

control

systemEvaporative

emission

control

systemAir/fuel ratio

control

systemCatalytic

converterExhaust gas

recirculation

system

PCV valve

×

Purge control solenoid valve

×

MPI system component

××

Catalytic converter

×

EGR valve

×

EGR control solenoid valve

×

Items Standard value

Purge control solenoid valve coil resistance (at 20°C) Ω30 − 34

EGR control solenoid valve coil resistance (at 20°C) Ω29 − 35

Page 134 of 788

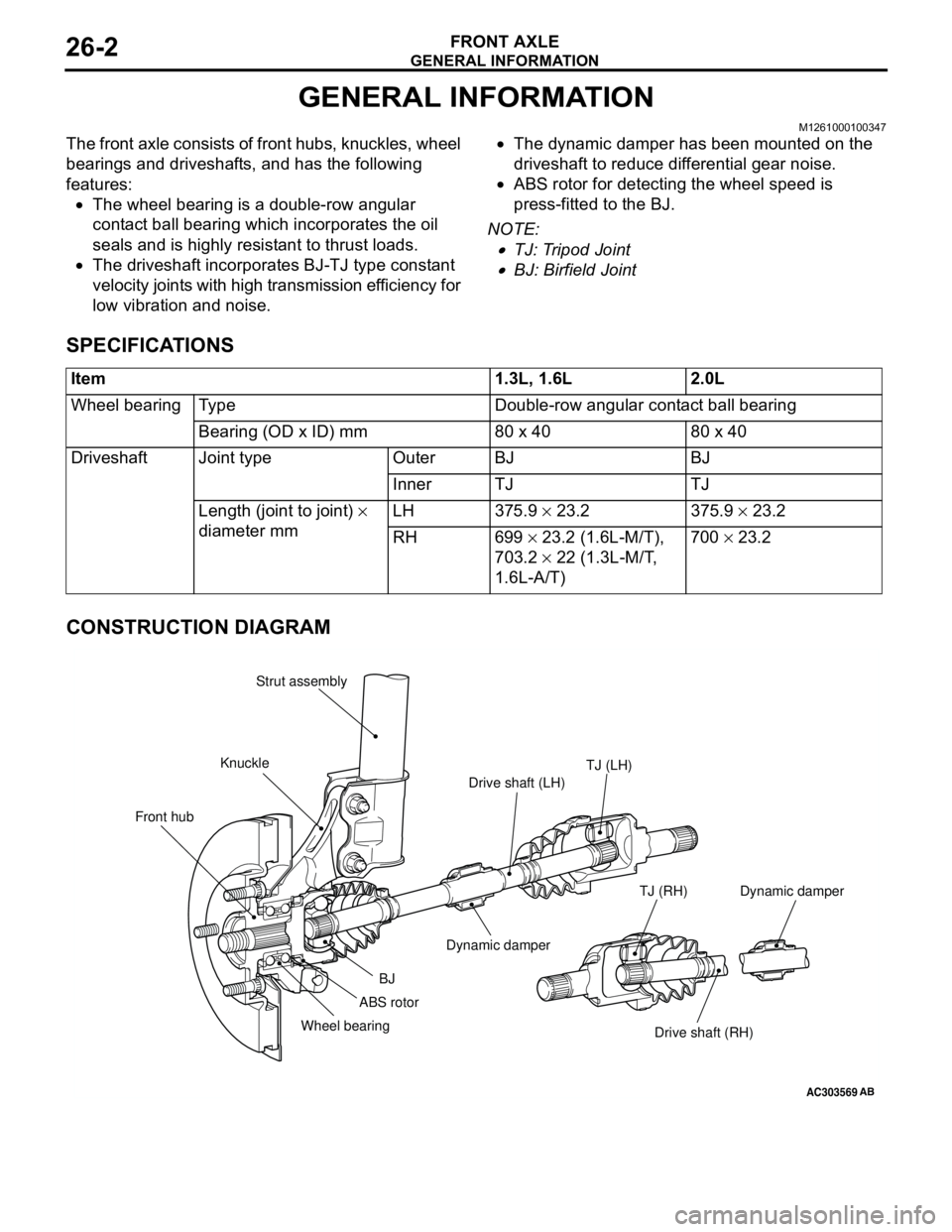

GENERAL INFORMATION

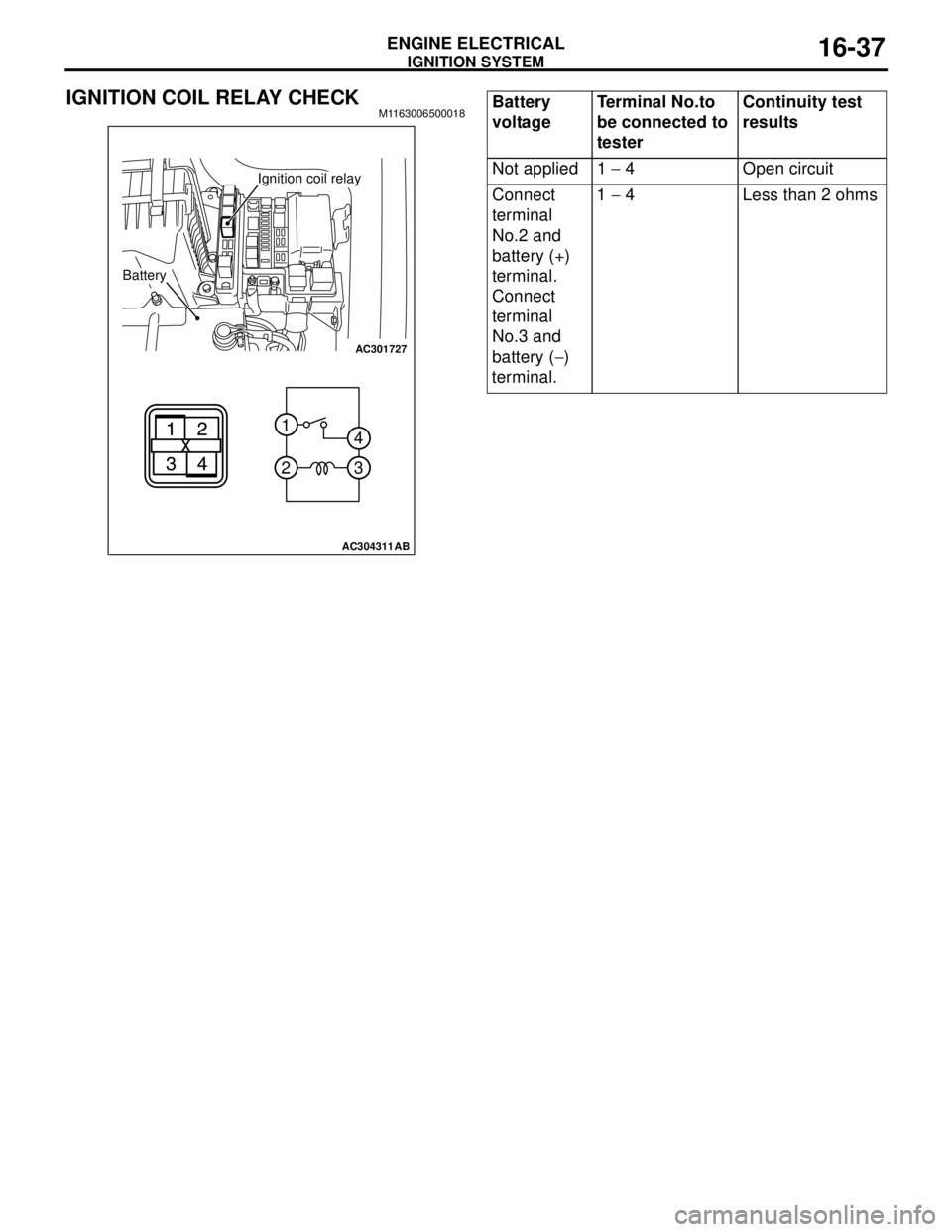

FRONT AXLE26-2

GENERAL INFORMATION

M1261000100347

The front axle consists of front hubs, knuckles, wheel

bearings and driveshafts, and has the following

features:

•The wheel bearing is a double-row angular

contact ball bearing which incorporates the oil

seals and is highly resistant to thrust loads.

•The driveshaft incorporates BJ-TJ type constant

velocity joints with high transmission efficiency for

low vibration and noise.•The dynamic damper has been mounted on the

driveshaft to reduce differential gear noise.

•ABS rotor for detecting the wheel speed is

press-fitted to the BJ.

NOTE: .

•TJ: Tripod Joint

•BJ: Birfield Joint

SPECIFICATIONS

CONSTRUCTION DIAGRAM

Item 1.3L, 1.6L 2.0L

Wheel bearing Type Double-row angular contact ball bearing

Bearing (OD x ID) mm 80 x 40 80 x 40

Driveshaft Joint type Outer BJ BJ

Inner TJ TJ

Length (joint to joint) ×

diameter mm LH 375.9 × 23.2 375.9 × 23.2

RH 699 × 23.2 (1.6L-M/T),

703.2 × 22 (1.3L-M/T,

1.6L-A/T)700 × 23.2

AC303569

Front hubKnuckleStrut assembly

TJ (LH)

Drive shaft (LH)

Dynamic damper

BJ

Wheel bearing

Drive shaft (RH) TJ (RH)

AB

ABS rotorDynamic damper

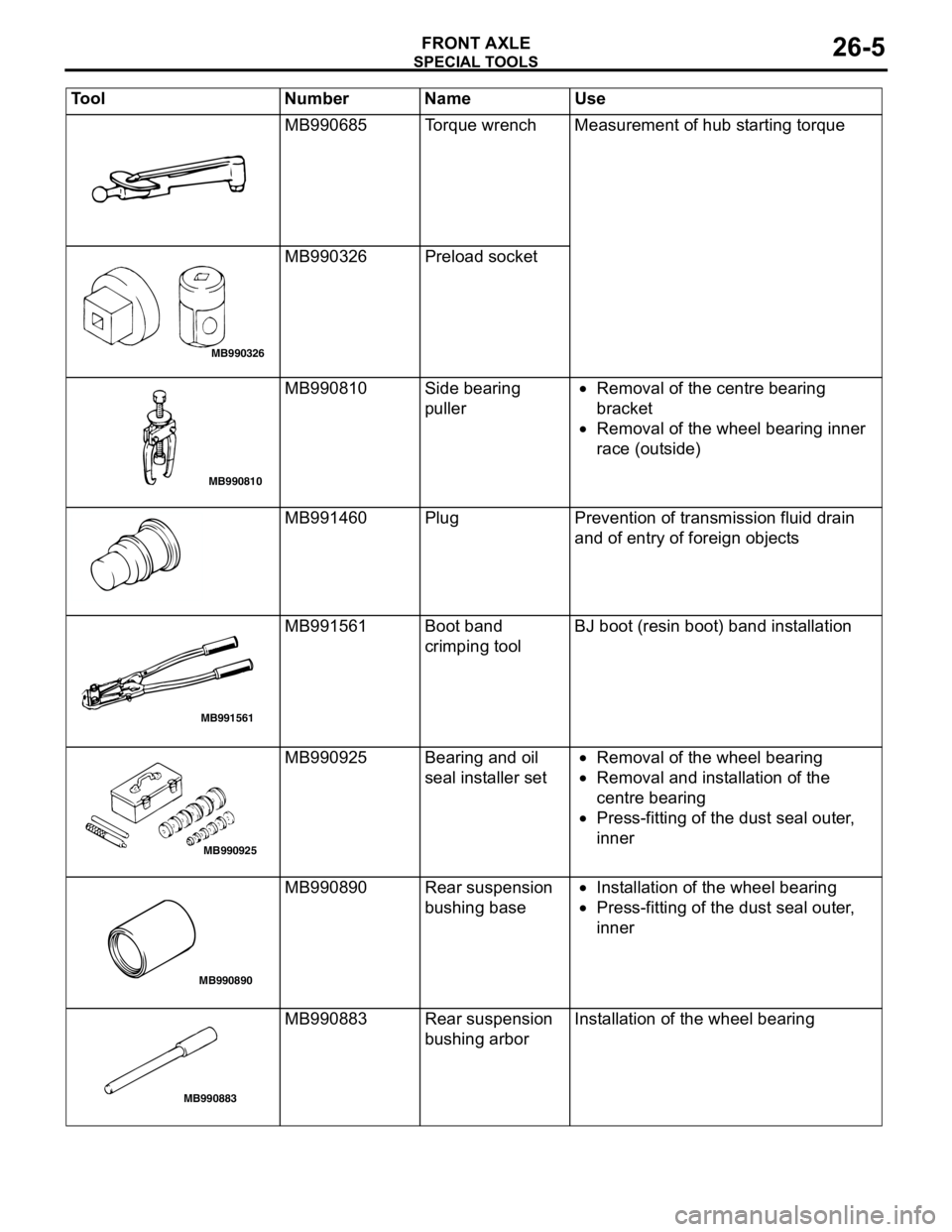

Page 137 of 788

SPECIAL TOOLS

FRONT AXLE26-5

MB990685 Torque wrench Measurement of hub starting torque

MB990326 Preload socket

MB990810 Side bearing

puller•Removal of the centre bearing

bracket

•Removal of the wheel bearing inner

race (outside)

MB991460 Plug Prevention of transmission fluid drain

and of entry of foreign objects

MB991561 Boot band

crimping toolBJ boot (resin boot) band installation

MB990925 Bearing and oil

seal installer set•Removal of the wheel bearing

•Removal and installation of the

centre bearing

•Press-fitting of the dust seal outer,

inner

MB990890 Rear suspension

bushing base•Installation of the wheel bearing

•Press-fitting of the dust seal outer,

inner

MB990883 Rear suspension

bushing arborInstallation of the wheel bearing Tool Number Name Use

MB990326

MB990810

MB991561

MB990925

MB990890

MB990883

Page 144 of 788