oil MITSUBISHI LANCER 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 146 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-14

DRIVE SHAFT ASSEMBLY

REMOVAL AND INSTALLATIONM1261003500399

CAUTION

•Do not strike the ABS rotors installed to the BJ outer race of drive shaft against other parts when

removing or installing the drive shaft. Otherwise the ABS rotors will be damaged.

•Be careful not to strike the pole piece at the tip of the front ABS sensor with tools during servicing

work.

Pre-installation Operation

•Transmission Fluid Draining (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

•Front Exhaust Pipe Removal (Refer to GROUP

15, Exhaust Pipe and Muffler P.15-11).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to

GROUP 15, Exhaust Pipe and Muffler

P.15-11).

•Check the Ball Joint Dust Cover for cracks or

damage by pushing it with your finger.

•Transmission Fluid Filling (Refer to GROUP

22A, On-vehicle Service − Transmission Oil

Replacement P.22A-8).

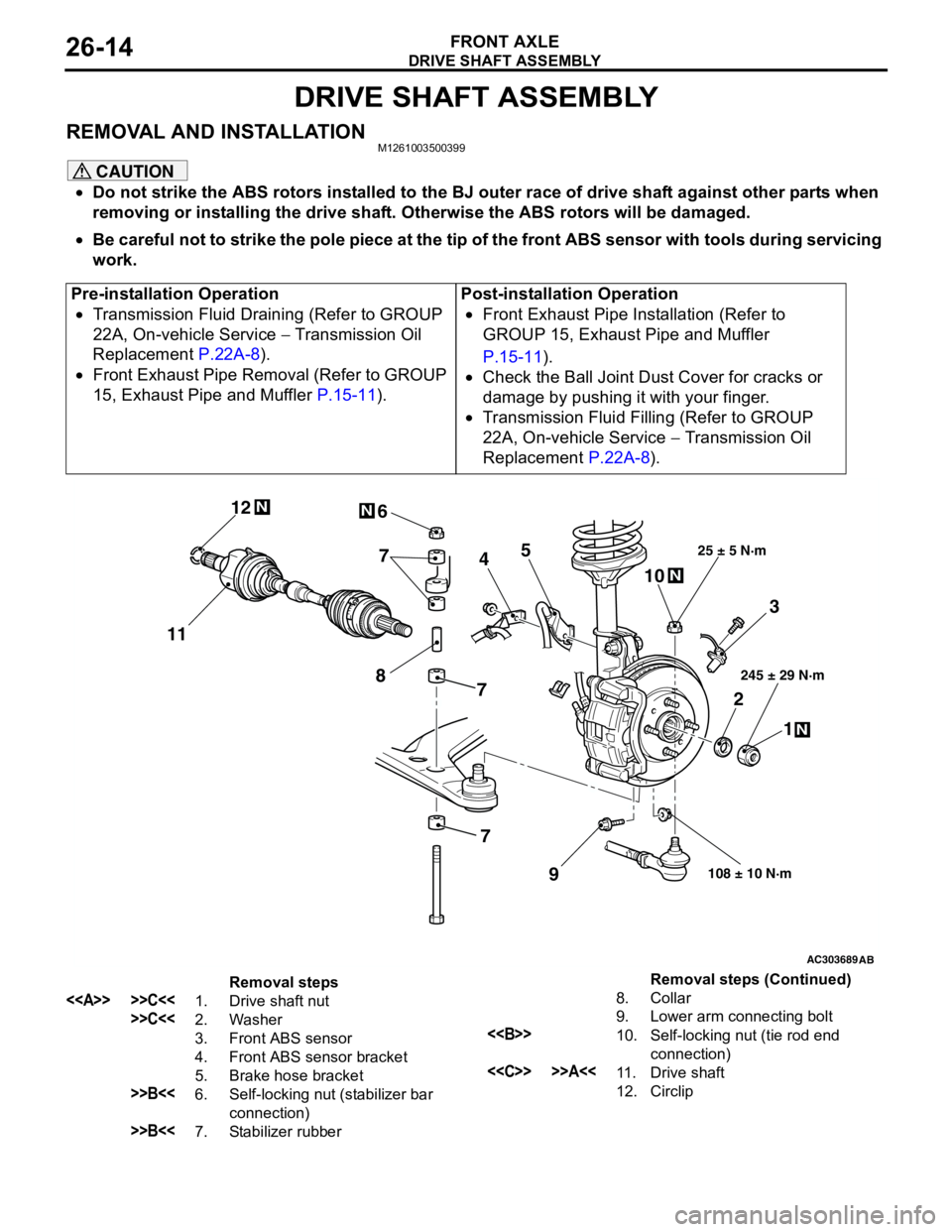

AC303689AB

9

N

N

NN

10 7

4

3

2

1

25 ± 5 N·m

245 ± 29 N·m

108 ± 10 N·m

8

5 6

1112

7

7

Removal steps

<> >>C<<1. Drive shaft nut

>>C<<2. Washer

3. Front ABS sensor

4. Front ABS sensor bracket

5. Brake hose bracket

>>B<<6. Self-locking nut (stabilizer bar

connection)

>>B<<7. Stabilizer rubber8. Collar

9. Lower arm connecting bolt

<>10. Self-locking nut (tie rod end

connection)

<

12. CirclipRemoval steps (Continued)

Page 148 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-16

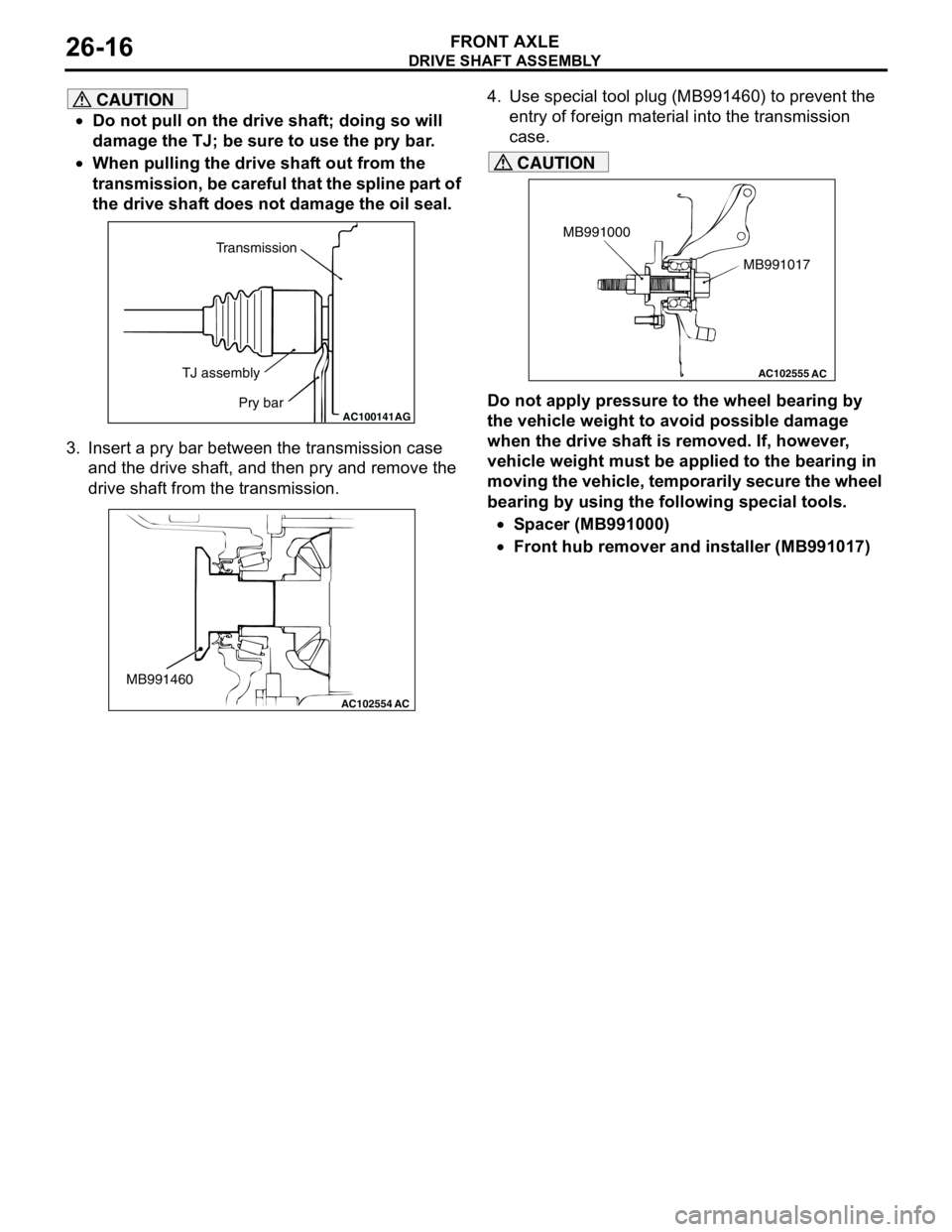

CAUTION

•Do not pull on the drive shaft; doing so will

damage the TJ; be sure to use the pry bar.

•When pulling the drive shaft out from the

transmission, be careful that the spline part of

the drive shaft does not damage the oil seal.

3. Insert a pry bar between the transmission case

and the drive shaft, and then pry and remove the

drive shaft from the transmission.4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the drive shaft is removed. If, however,

vehicle weight must be applied to the bearing in

moving the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)AC100141

Transmission

TJ assembly

Pry bar

AG

AC102554

MB991460

AC

AC102555

AC

MB991017 MB991000

Page 149 of 788

DRIVE SHAFT ASSEMBLY

FRONT AXLE26-17

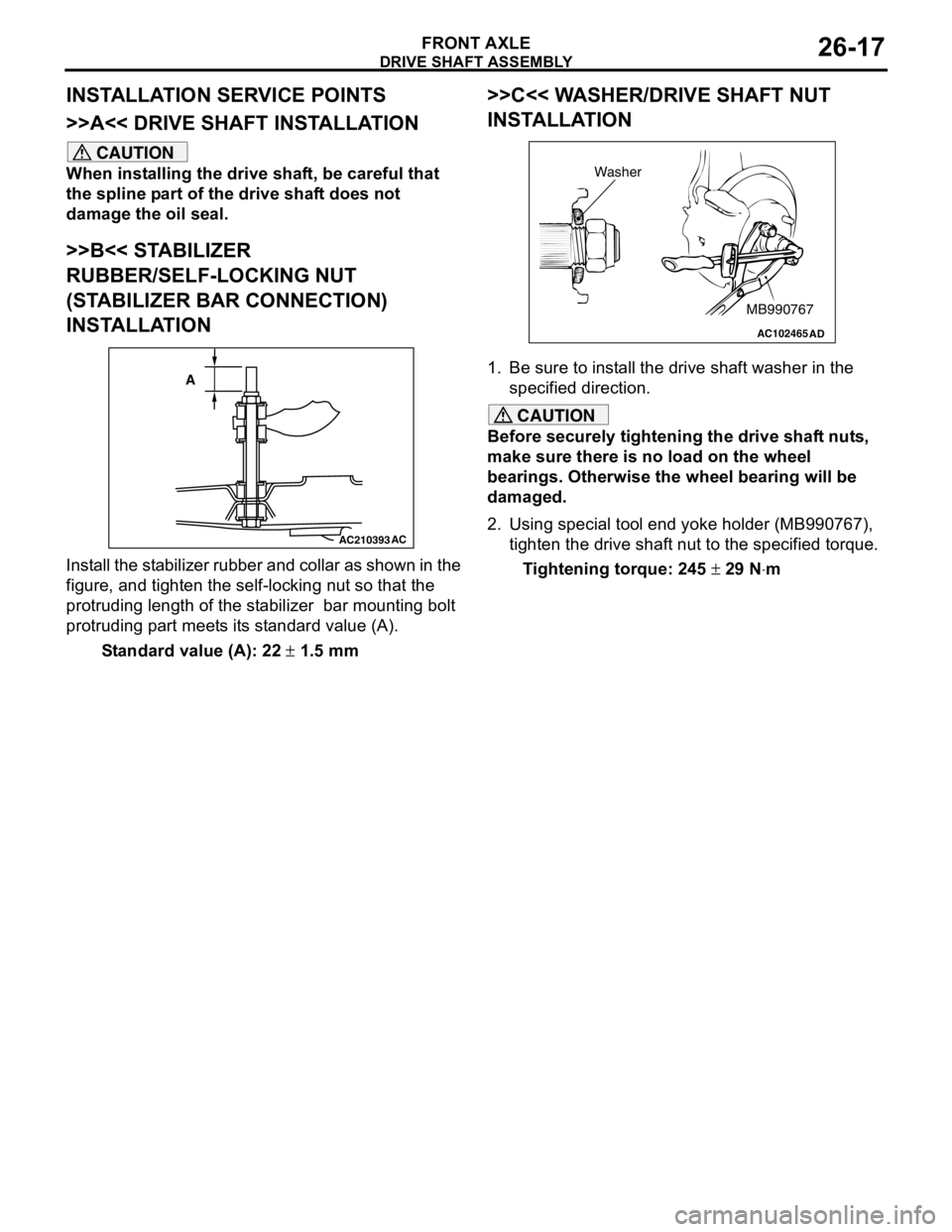

INSTALLATION SERVICE POINTS

>>A<< DRIVE SHAFT INSTALLATION

CAUTION

When installing the drive shaft, be careful that

the spline part of the drive shaft does not

damage the oil seal.

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

>>C<< WASHER/DRIVE SHAFT NUT

INSTALLATION

1. Be sure to install the drive shaft washer in the

specified direction.

CAUTION

Before securely tightening the drive shaft nuts,

make sure there is no load on the wheel

bearings. Otherwise the wheel bearing will be

damaged.

2. Using special tool end yoke holder (MB990767),

tighten the drive shaft nut to the specified torque.

Tightening torque: 245 ± 29 N⋅m

AC210393AC

A

AC102465AD

MB990767 Washer

Page 158 of 788

GENERAL INFORMATION

REAR AXLE27-2

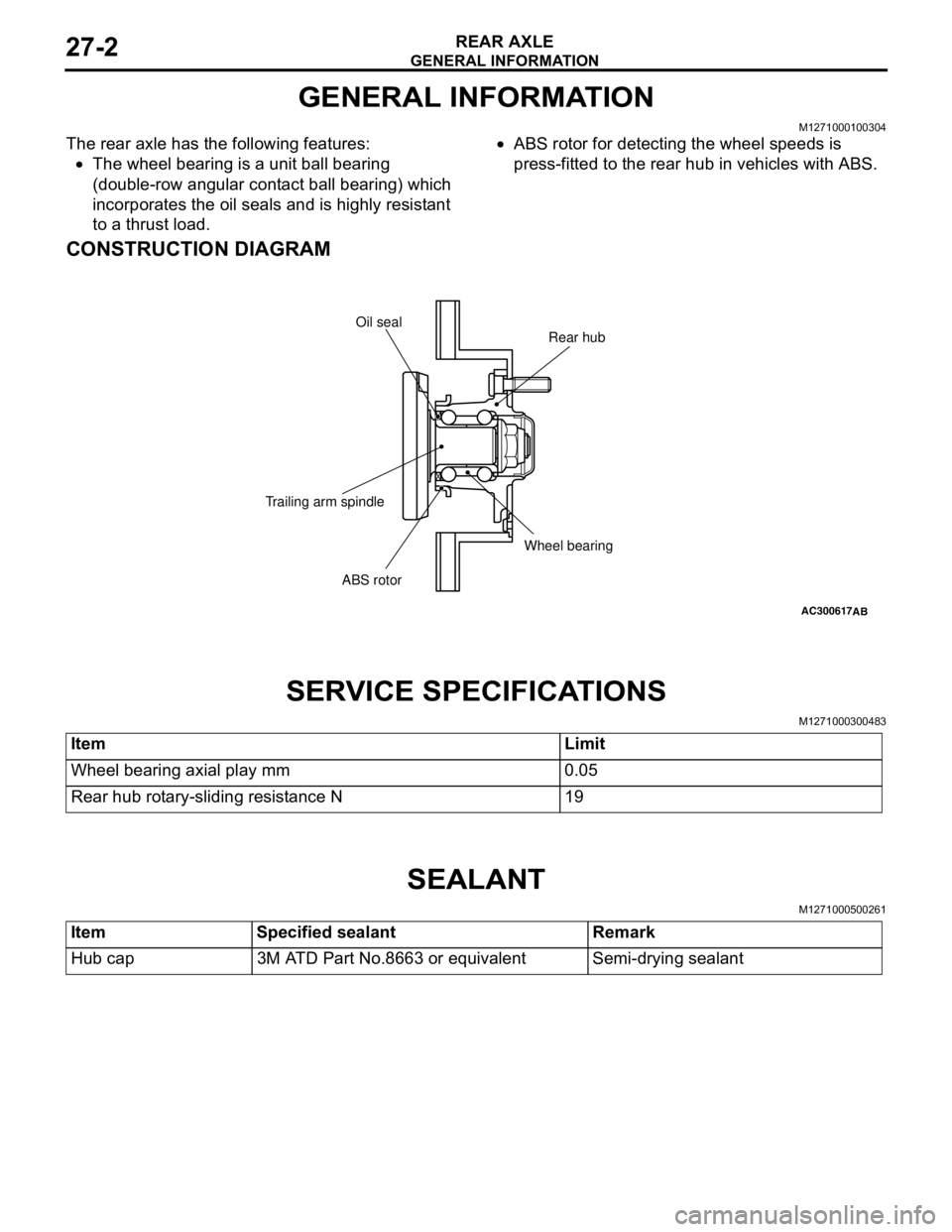

GENERAL INFORMATION

M1271000100304

The rear axle has the following features:

•The wheel bearing is a unit ball bearing

(double-row angular contact ball bearing) which

incorporates the oil seals and is highly resistant

to a thrust load.•ABS rotor for detecting the wheel speeds is

press-fitted to the rear hub in vehicles with ABS.

CONSTRUCTION DIAGRAM

SERVICE SPECIFICATIONS

M1271000300483

SEALANT

M1271000500261

AC300617AB

Rear hub Oil seal

Wheel bearing

ABS rotor Trailing arm spindle

Item Limit

Wheel bearing axial play mm 0.05

Rear hub rotary-sliding resistance N 19

Item Specified sealant Remark

Hub cap 3M ATD Part No.8663 or equivalent Semi-drying sealant

Page 161 of 788

REAR AXLE HUB ASSEMBLY

REAR AXLE27-5

REAR AXLE HUB ASSEMBLY

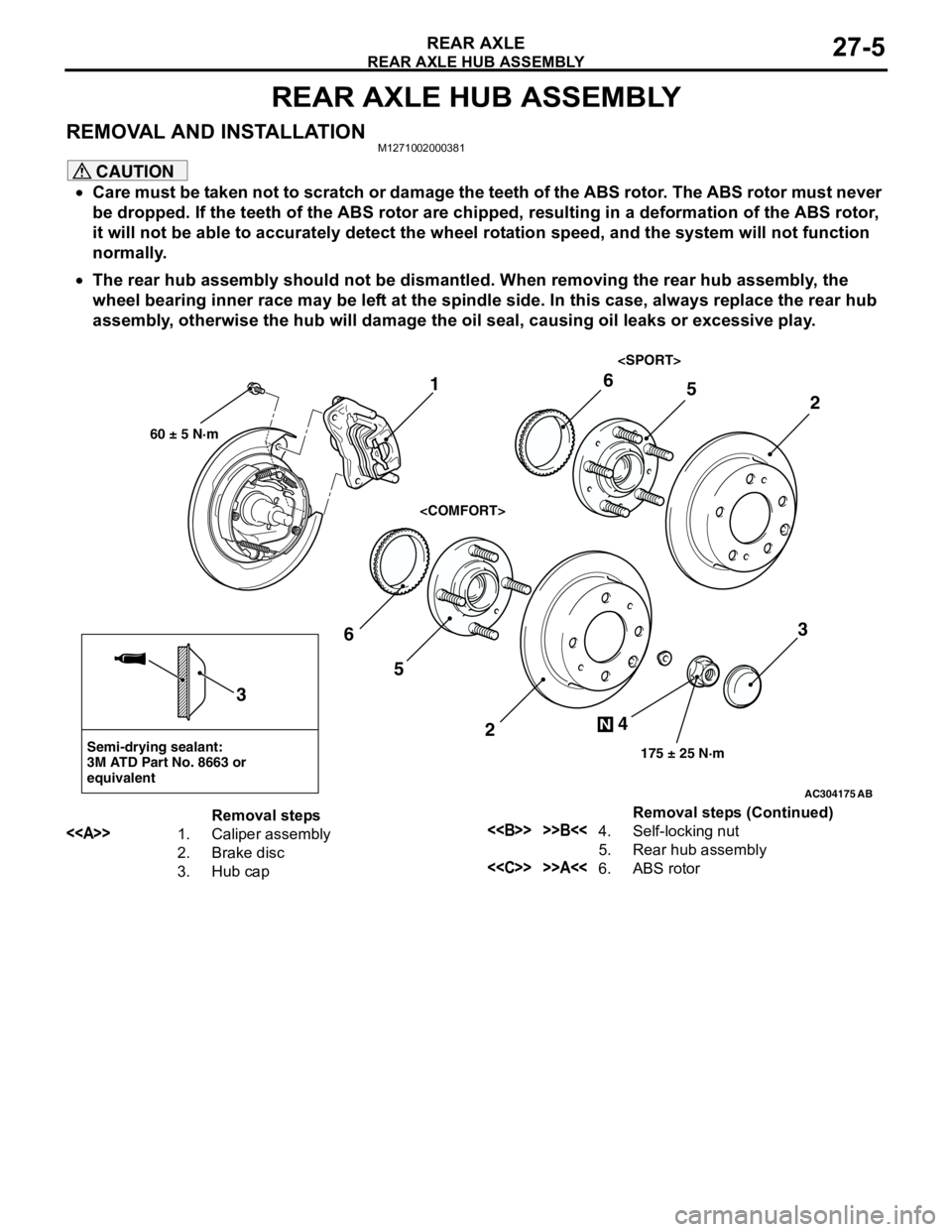

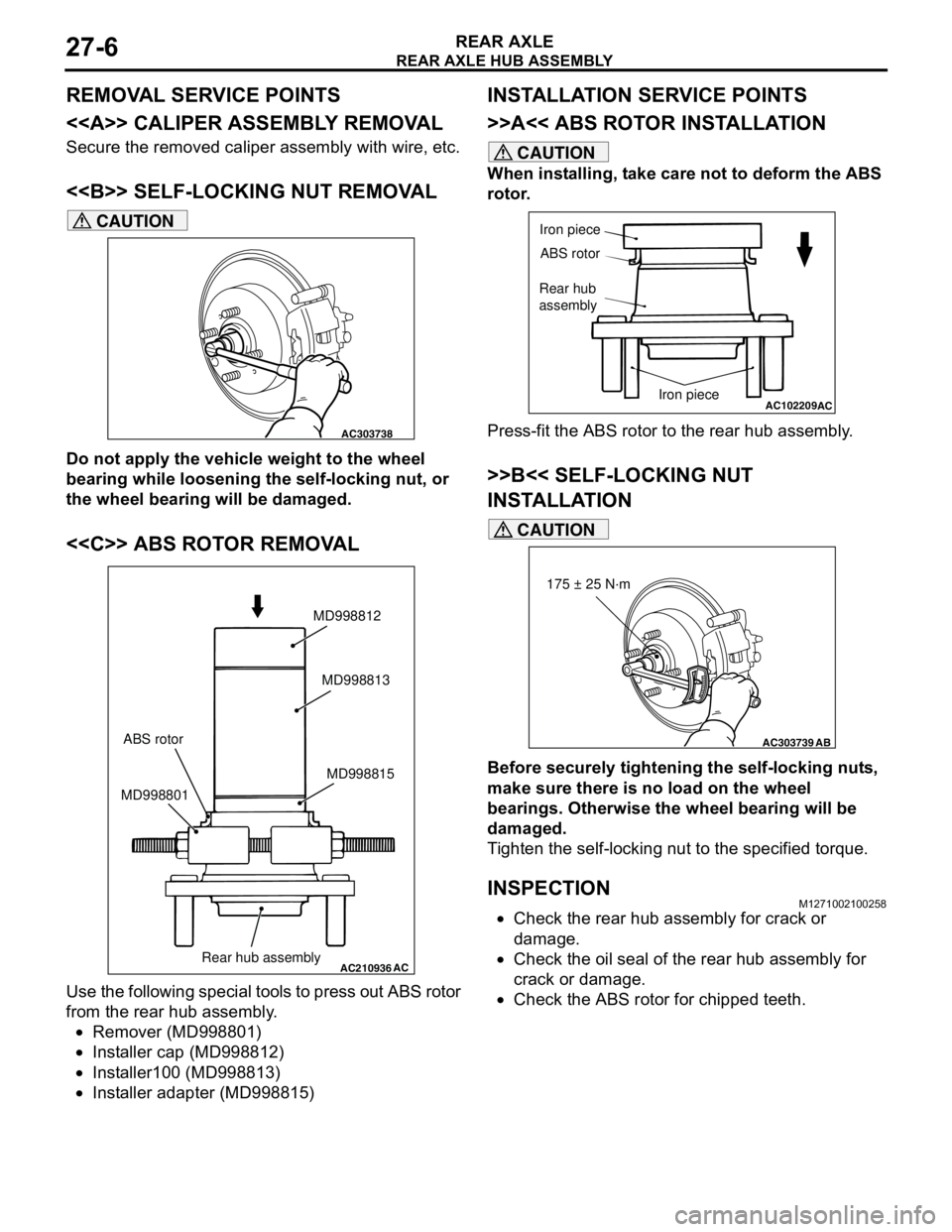

REMOVAL AND INSTALLATIONM1271002000381

CAUTION

•Care must be taken not to scratch or damage the teeth of the ABS rotor. The ABS rotor must never

be dropped. If the teeth of the ABS rotor are chipped, resulting in a deformation of the ABS rotor,

it will not be able to accurately detect the wheel rotation speed, and the system will not function

normally.

•The rear hub assembly should not be dismantled. When removing the rear hub assembly, the

wheel bearing inner race may be left at the spindle side. In this case, always replace the rear hub

assembly, otherwise the hub will damage the oil seal, causing oil leaks or excessive play.

AC304175

Semi-drying sealant:

3M ATD Part No. 8663 or

equivalent

2

3

5 6

4

N

175 ± 25 N·m

3

AB

1

60 ± 5 N·m

2

56

Removal steps

<>1. Caliper assembly

2. Brake disc

3. Hub cap<> >>B<<4. Self-locking nut

5. Rear hub assembly

<

Page 162 of 788

Page 184 of 788

GENERAL INFORMATION

FRONT SUSPENSION33-2

GENERAL INFORMATION

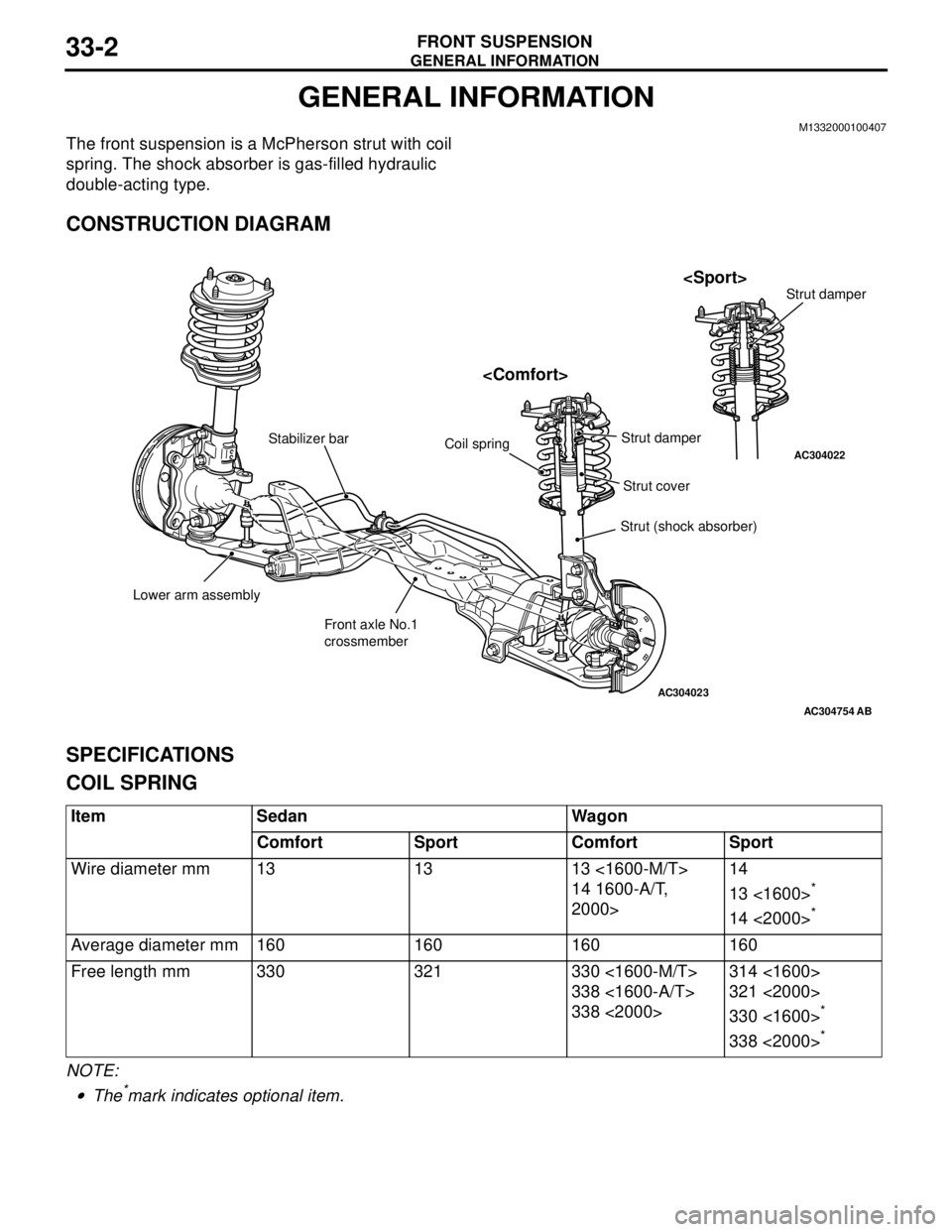

M1332000100407

The front suspension is a McPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

SPECIFICATIONS

COIL SPRING

NOTE: .

•The*mark indicates optional item.

AC304023

AC304022

AC304754

Lower arm assembly

Front axle No.1

crossmember Stabilizer bar

Strut (shock absorber) Coil spring

AB

Strut cover Strut damper

Item Sedan Wagon

Comfort Sport Comfort Sport

Wire diameter mm 13 13 13 <1600-M/T>

14 1600-A/T,

2000>14

13 <1600>

*

14 <2000>*

Average diameter mm 160 160 160 160

Free length mm 330 321 330 <1600-M/T>

338 <1600-A/T>

338 <2000>314 <1600>

321 <2000>

330 <1600>

*

338 <2000>*

Page 186 of 788

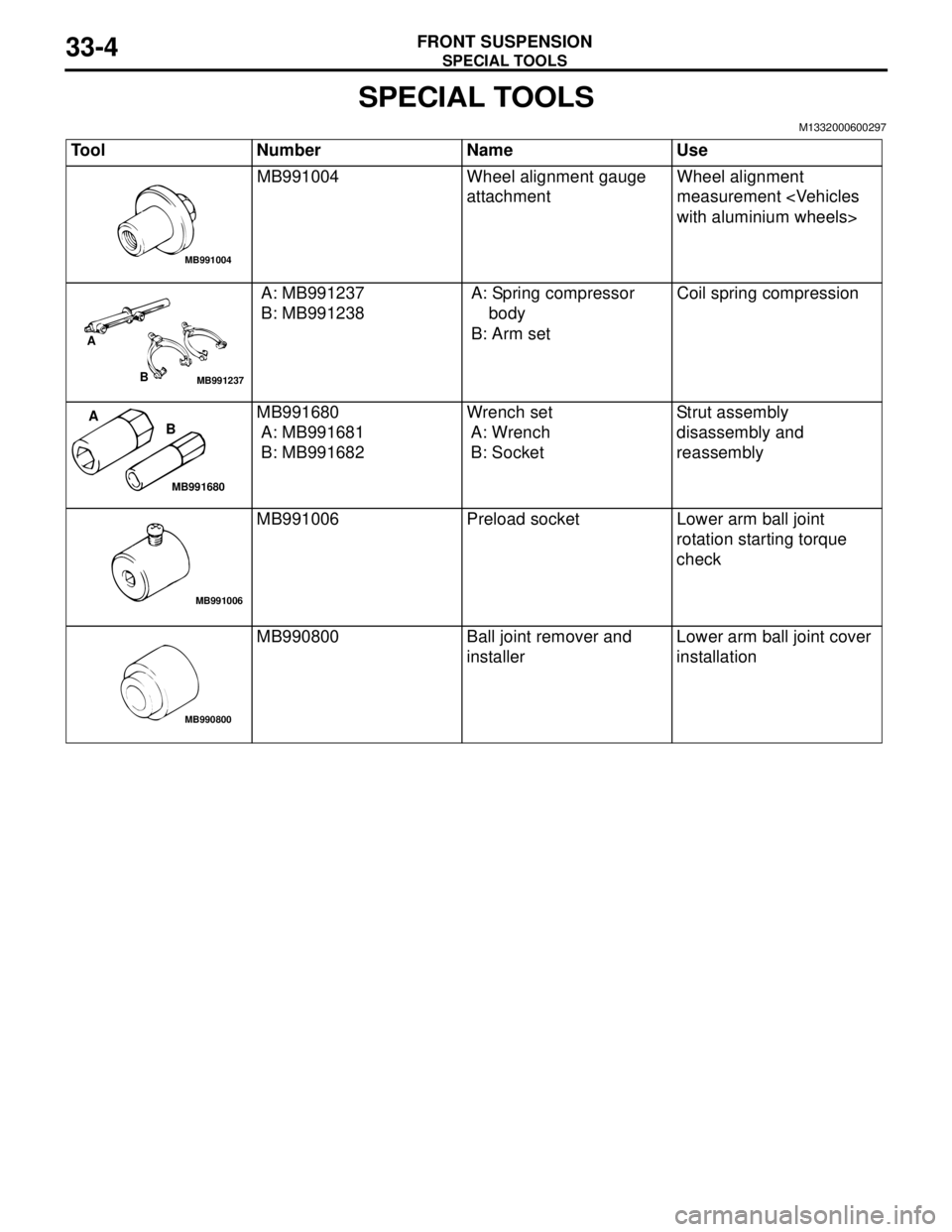

SPECIAL TOOLS

FRONT SUSPENSION33-4

SPECIAL TOOLS

M1332000600297

Tool Number Name Use

MB991004 Wheel alignment gauge

attachmentWheel alignment

measurement

A: MB991237

B: MB991238A: Spring compressor

body

B: Arm setCoil spring compression

MB991680

A: MB991681

B: MB991682Wrench set

A: Wrench

B: SocketStrut assembly

disassembly and

reassembly

MB991006 Preload socket Lower arm ball joint

rotation starting torque

check

MB990800 Ball joint remover and

installerLower arm ball joint cover

installation

MB991004

MB991237

A

B

MB991680

A

B

MB991006

MB990800

Page 189 of 788

STRUT ASSEMBLY

FRONT SUSPENSION33-7

STRUT ASSEMBLY

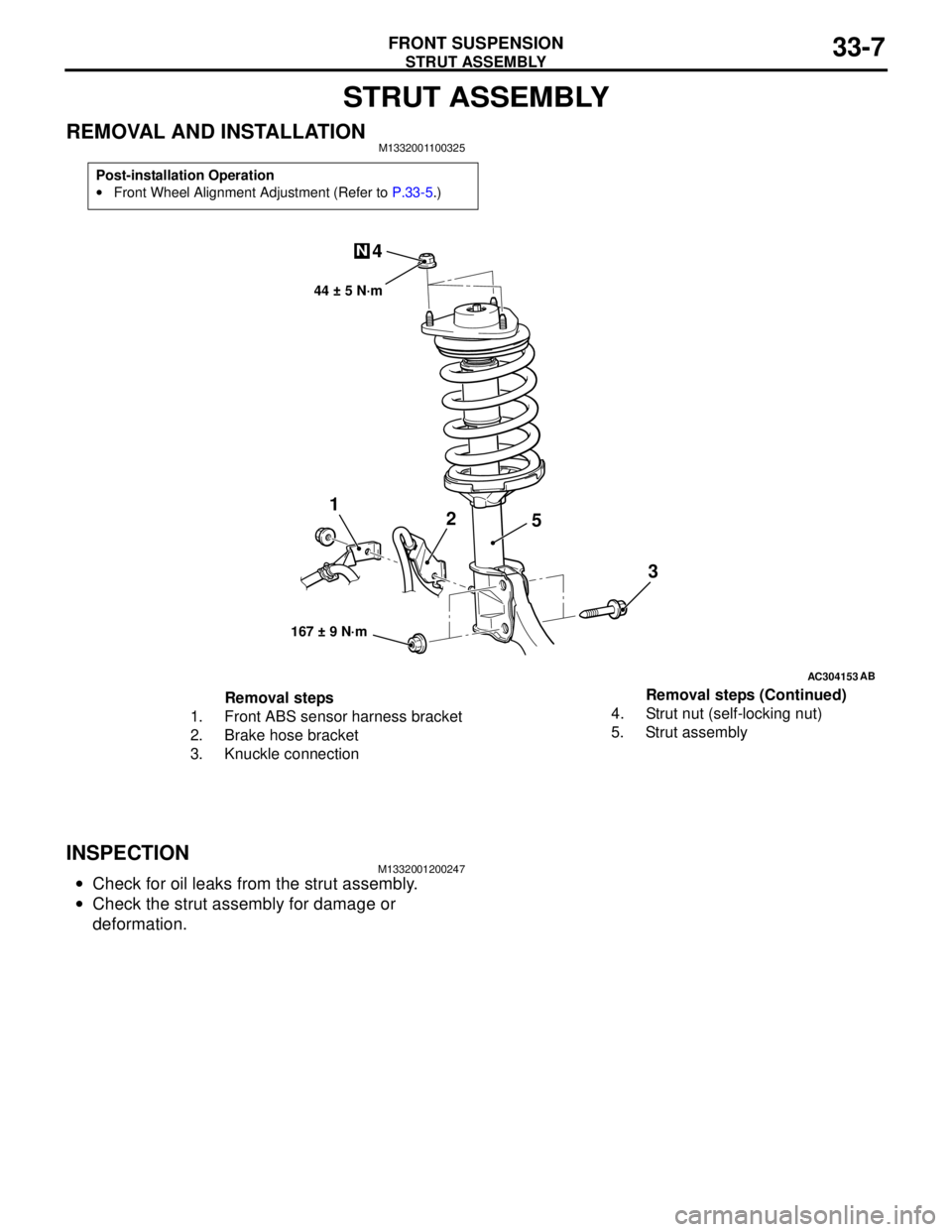

REMOVAL AND INSTALLATIONM1332001100325

INSPECTIONM1332001200247

•Check for oil leaks from the strut assembly.

•Check the strut assembly for damage or

deformation.

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-5.)

AC304153

44 ± 5 N·m

1

2

3 4

N

AB

167 ± 9 N·m

5

Removal steps

1. Front ABS sensor harness bracket

2. Brake hose bracket

3. Knuckle connection4. Strut nut (self-locking nut)

5. Strut assemblyRemoval steps (Continued)

Page 190 of 788

STRUT ASSEMBLY

FRONT SUSPENSION33-8

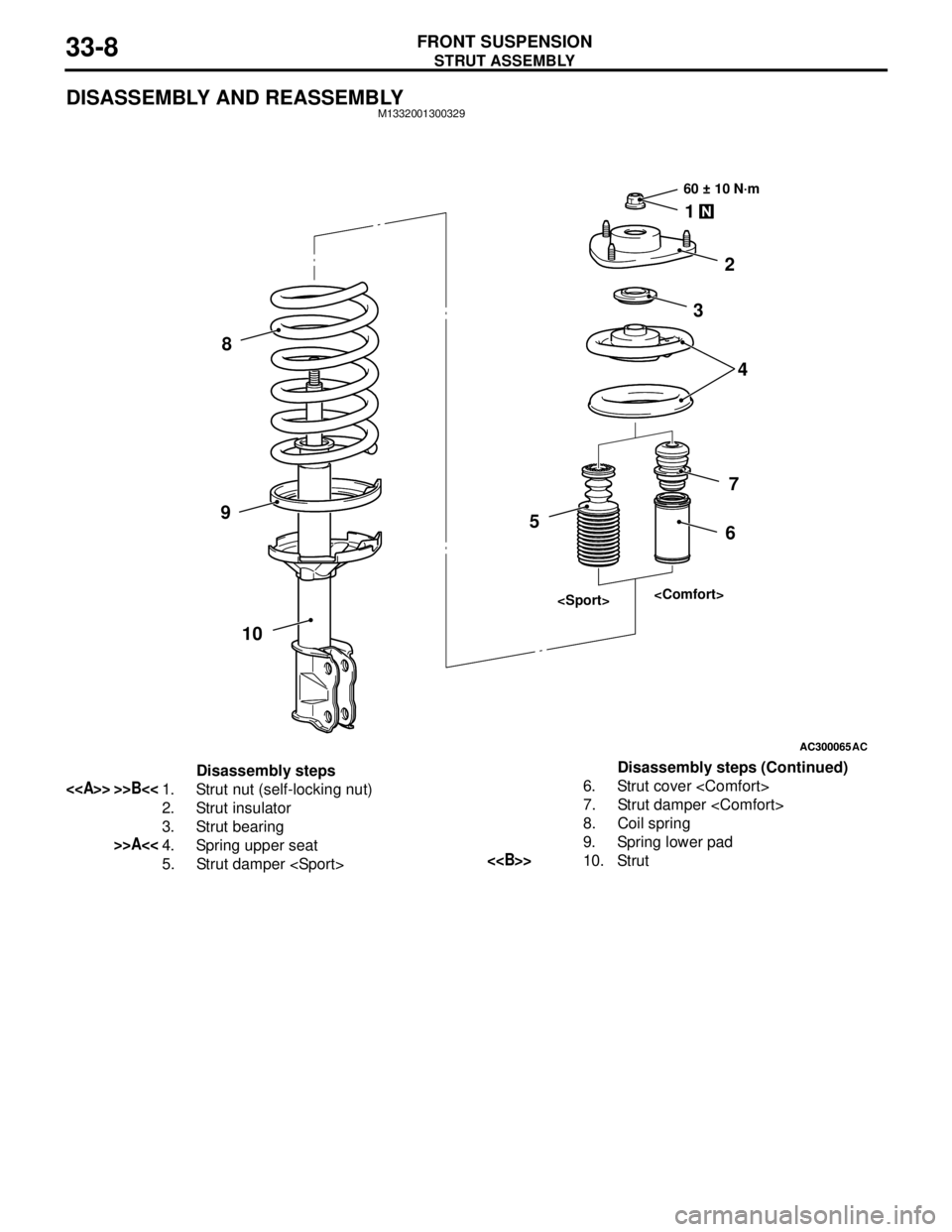

DISASSEMBLY AND REASSEMBLYM1332001300329

AC300065AC300065

9

101

2

3

4

5

6

60 ± 10 N·m

AC

8

7

Disassembly steps

<> >>B<<1. Strut nut (self-locking nut)

2. Strut insulator

3. Strut bearing

>>A<<4. Spring upper seat

5. Strut damper

7. Strut damper

8. Coil spring

9. Spring lower pad<>10. StrutDisassembly steps (Continued)