front MITSUBISHI LANCER 2005 Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 178 of 788

CROSSMEMBER

POWER PLANT MOUNT32-8

INSTALLATION SERVICE POINTS

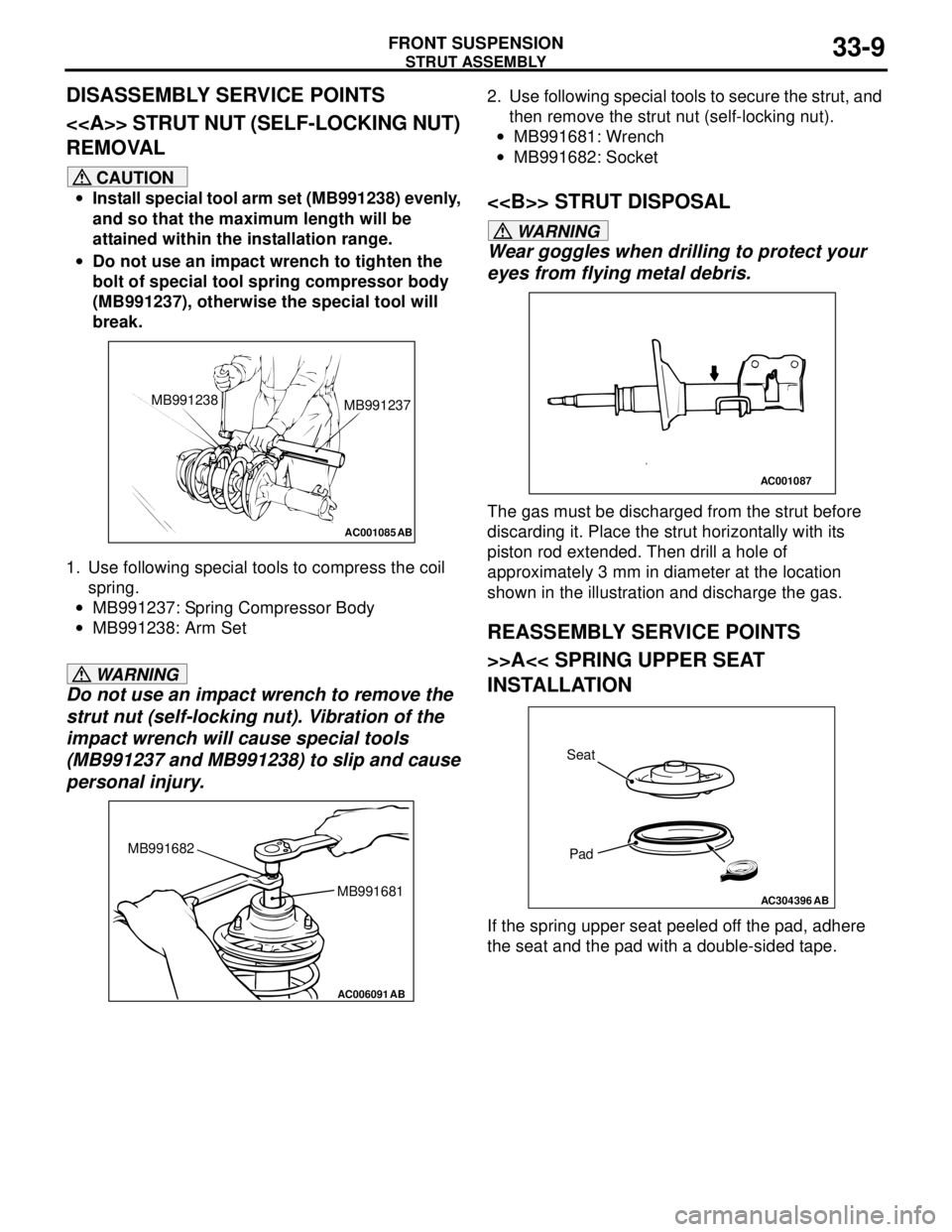

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200368

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*

1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•*

2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

AC005918Front of vehicleHoleACAC304315ABFront of vehicle

HoleEngine mounting

cushion stopper

Pre-removal Operation

•Centermember Removal (Refer to P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 183 of 788

33-1

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . .33-2

SERVICE SPECIFICATIONS . . . . . . .33-3

LUBRICANT . . . . . . . . . . . . . . . . . . . .33-3

SPECIAL TOOLS . . . . . . . . . . . . . . . .33-4

ON-VEHICLE SERVICE . . . . . . . . . . .33-5

FRONT WHEEL ALIGNMENT CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . . . . 33-5

LOWER ARM BALL JOINT AXIAL PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-6

LOWER ARM BALL JOINT COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33-6

STRUT ASSEMBLY . . . . . . . . . . . . . .33-7

REMOVAL AND INSTALLATION . . . . . . . . 33-7

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-7

DISASSEMBLY AND REASSEMBLY . . . . . 33-8

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-10

LOWER ARM . . . . . . . . . . . . . . . . . . .33-11

REMOVAL AND INSTALLATION . . . . . . . . 33-11

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BALL JOINT COVER

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-12

LOWER ARM BUSHING (REAR)

REPLACEMENT . . . . . . . . . . . . . . . . . . . . . 33-13

STABILIZER BAR* . . . . . . . . . . . . . . .33-14

REMOVAL AND INSTALLATION . . . . . . . . 33-14

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . 33-17

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 184 of 788

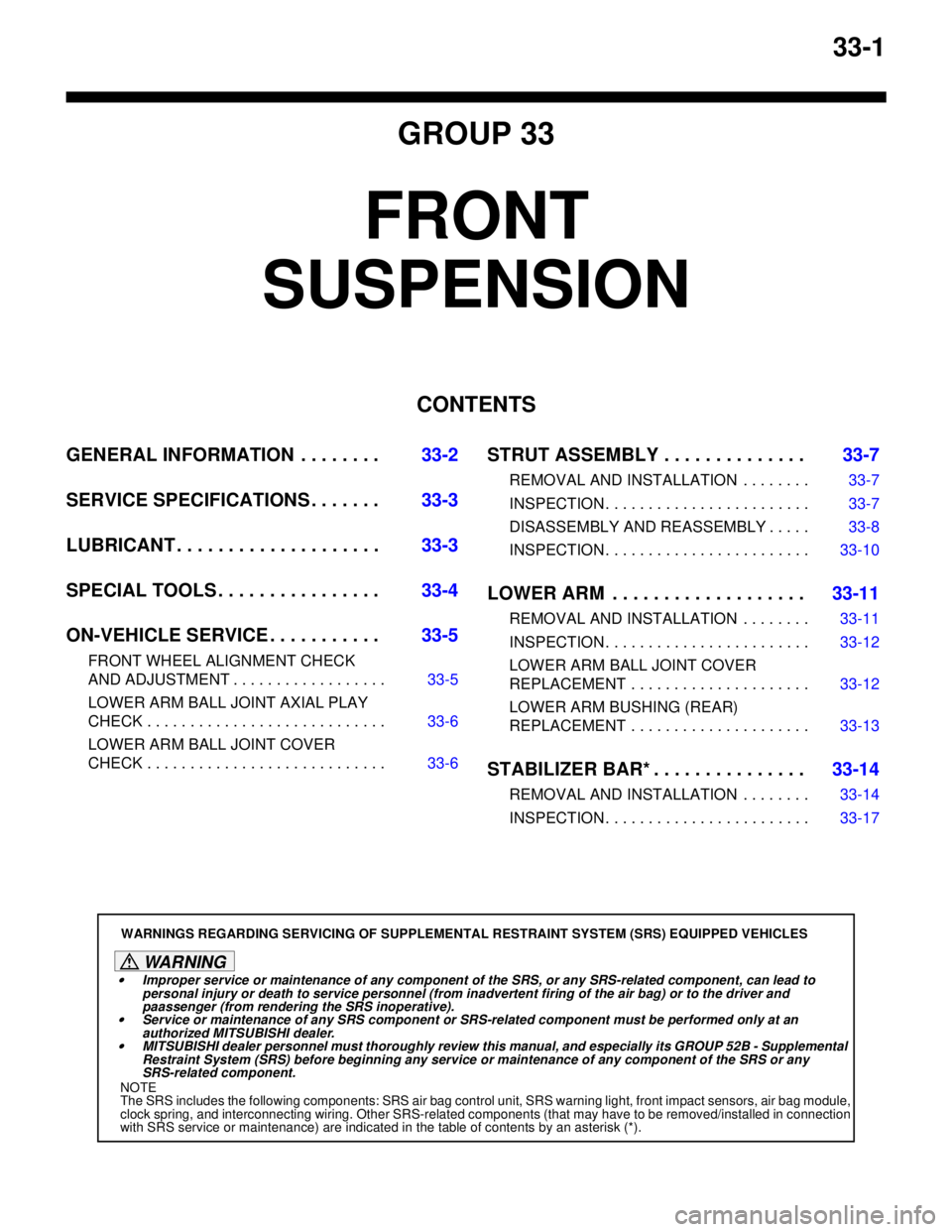

GENERAL INFORMATION

FRONT SUSPENSION33-2

GENERAL INFORMATION

M1332000100407

The front suspension is a McPherson strut with coil

spring. The shock absorber is gas-filled hydraulic

double-acting type.

CONSTRUCTION DIAGRAM

SPECIFICATIONS

COIL SPRING

NOTE: .

•The*mark indicates optional item.

AC304023

AC304022

AC304754

Lower arm assembly

Front axle No.1

crossmember Stabilizer bar

Strut (shock absorber) Coil spring

AB

Strut cover Strut damper

Item Sedan Wagon

Comfort Sport Comfort Sport

Wire diameter mm 13 13 13 <1600-M/T>

14 1600-A/T,

2000>14

13 <1600>

*

14 <2000>*

Average diameter mm 160 160 160 160

Free length mm 330 321 330 <1600-M/T>

338 <1600-A/T>

338 <2000>314 <1600>

321 <2000>

330 <1600>

*

338 <2000>*

Page 185 of 788

SERVICE SPECIFICATIONS

FRONT SUSPENSION33-3

SERVICE SPECIFICATIONS

M1332000300586

NOTE: *: difference between right and left wheels must be less than 30'

LUBRICANT

M1332000400152

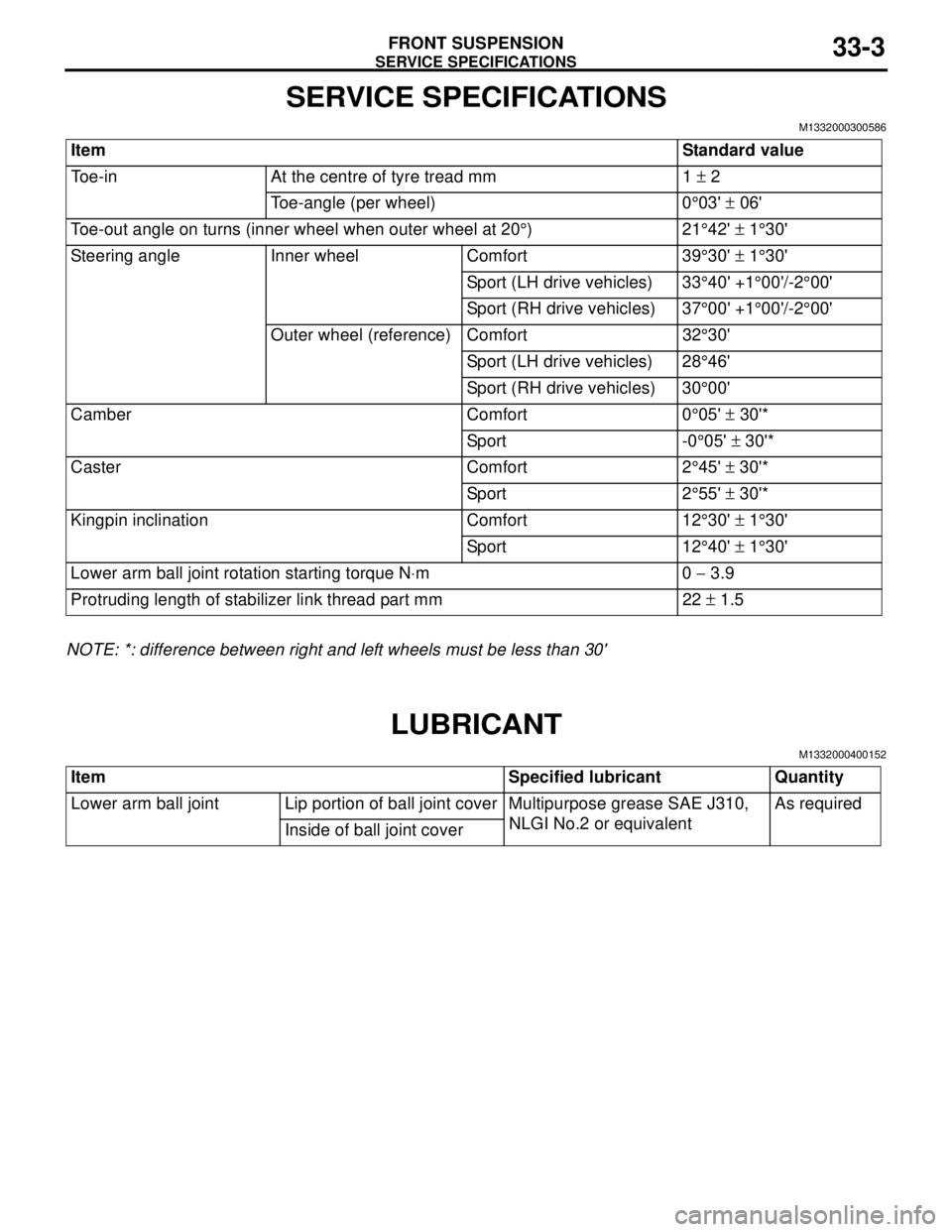

ItemStandard value

Toe-in At the centre of tyre tread mm 1 ± 2

Toe-angle (per wheel) 0°03' ± 06'

Toe-out angle on turns (inner wheel when outer wheel at 20°)21°42' ± 1°30'

Steering angle Inner wheel Comfort 39°30' ± 1°30'

Sport (LH drive vehicles) 33°40' +1°00'/-2°00'

Sport (RH drive vehicles) 37°00' +1°00'/-2°00'

Outer wheel (reference) Comfort 32°30'

Sport (LH drive vehicles) 28°46'

Sport (RH drive vehicles) 30°00'

Camber Comfort 0°05' ± 30'*

Sport -0°05' ± 30'*

Caster Comfort 2°45' ± 30'*

Sport 2°55' ± 30'*

Kingpin inclination Comfort 12°30' ± 1°30'

Sport 12°40' ± 1°30'

Lower arm ball joint rotation starting torque N⋅m0 − 3.9

Protruding length of stabilizer link thread part mm 22 ± 1.5

Item Specified lubricant Quantity

Lower arm ball joint Lip portion of ball joint cover Multipurpose grease SAE J310,

NLGI No.2 or equivalentAs required

Inside of ball joint cover

Page 186 of 788

SPECIAL TOOLS

FRONT SUSPENSION33-4

SPECIAL TOOLS

M1332000600297

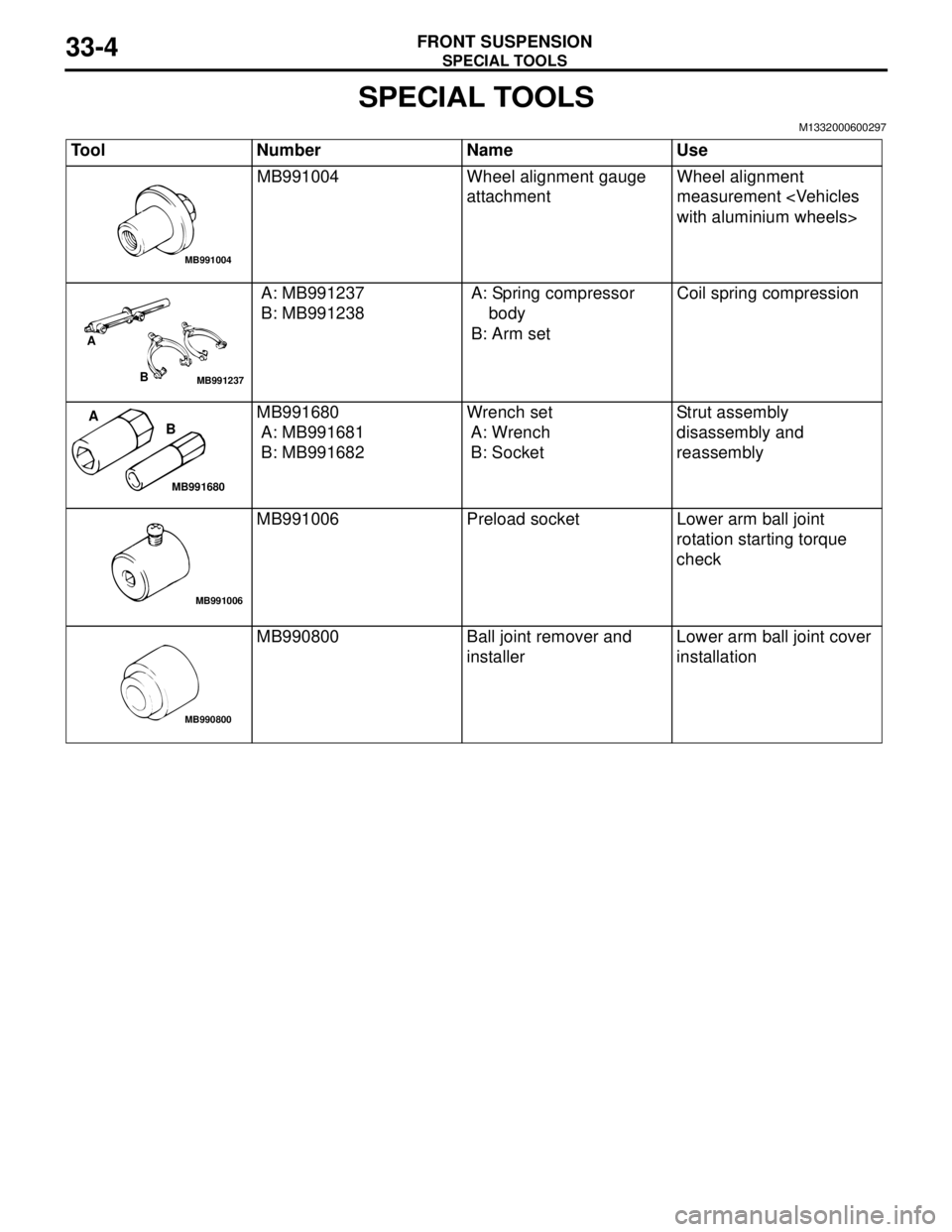

Tool Number Name Use

MB991004 Wheel alignment gauge

attachmentWheel alignment

measurement

A: MB991237

B: MB991238A: Spring compressor

body

B: Arm setCoil spring compression

MB991680

A: MB991681

B: MB991682Wrench set

A: Wrench

B: SocketStrut assembly

disassembly and

reassembly

MB991006 Preload socket Lower arm ball joint

rotation starting torque

check

MB990800 Ball joint remover and

installerLower arm ball joint cover

installation

MB991004

MB991237

A

B

MB991680

A

B

MB991006

MB990800

Page 187 of 788

ON-VEHICLE SERVICE

FRONT SUSPENSION33-5

ON-VEHICLE SERVICE

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

M1331000900682

Measure wheel alignment with alignment equipment

on a level surface. The front suspension, steering

system, wheels, and tyres should be serviced to

normal condition before measuring wheel alignment.

TOE-IN

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

1. Adjust the toe-in by undoing the clip and lock nut,

and turning the left and right tie rod turnbuckles by

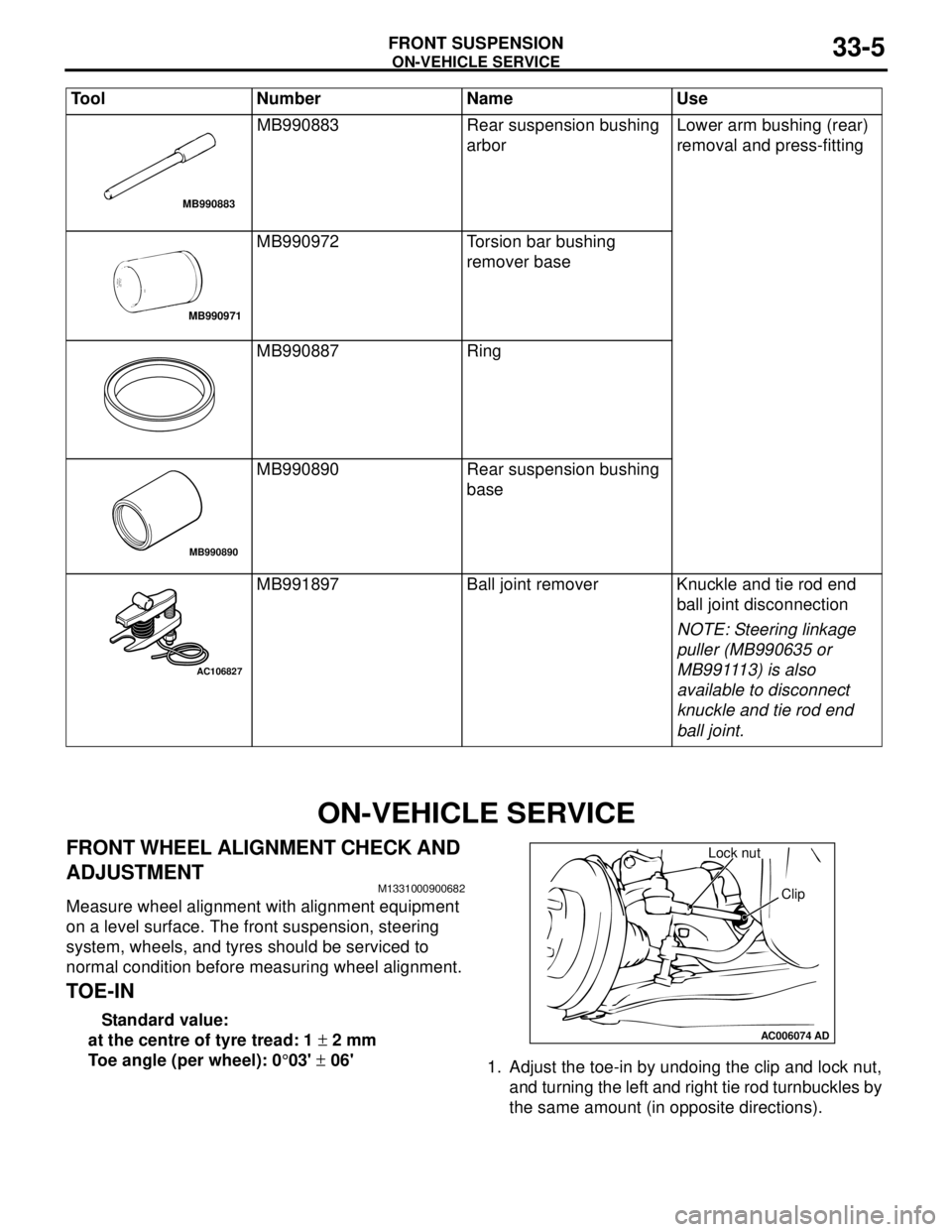

the same amount (in opposite directions). MB990883 Rear suspension bushing

arborLower arm bushing (rear)

removal and press-fitting

MB990972 Torsion bar bushing

remover base

MB990887 Ring

MB990890 Rear suspension bushing

base

MB991897 Ball joint remover Knuckle and tie rod end

ball joint disconnection

NOTE: Steering linkage

puller (MB990635 or

MB991113) is also

available to disconnect

knuckle and tie rod end

ball joint. Tool Number Name Use

MB990883

MB990971

MB990890

AC106827

AC006074AD

Lock nut

Clip

Page 188 of 788

ON-VEHICLE SERVICE

FRONT SUSPENSION33-6

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

2. Install the clip and tighten the lock nut to the

specified torque.

Tightening torque: 40 ± 5 N⋅m

3. Confirm that the toe-in is at the standard value.

4. Use a turning radius gauge to check that the

steering angle is at the standard value.

STEERING ANGLE

Standard value:

TOE-OUT ANGLE ON TURNS

To check the steering linkage, especially after the

vehicle has been involved in an accident or if an

accident is presumed, it is advisable to check the

toe-out angle on turns in addition to the wheel

alignment.

Conduct this test on the left turn as well as on the

right turn.

Standard value:

CAMBER, CASTER AND KINGPIN

INCLINATION

Standard value:NOTE: *: difference between right and left wheels

must be less than 30'

NOTE: Camber and caster are preset at the factory

and cannot be adjusted.

CAUTION

Never subject the wheel bearings to the vehicle

load when the driveshaft nuts are loosened.

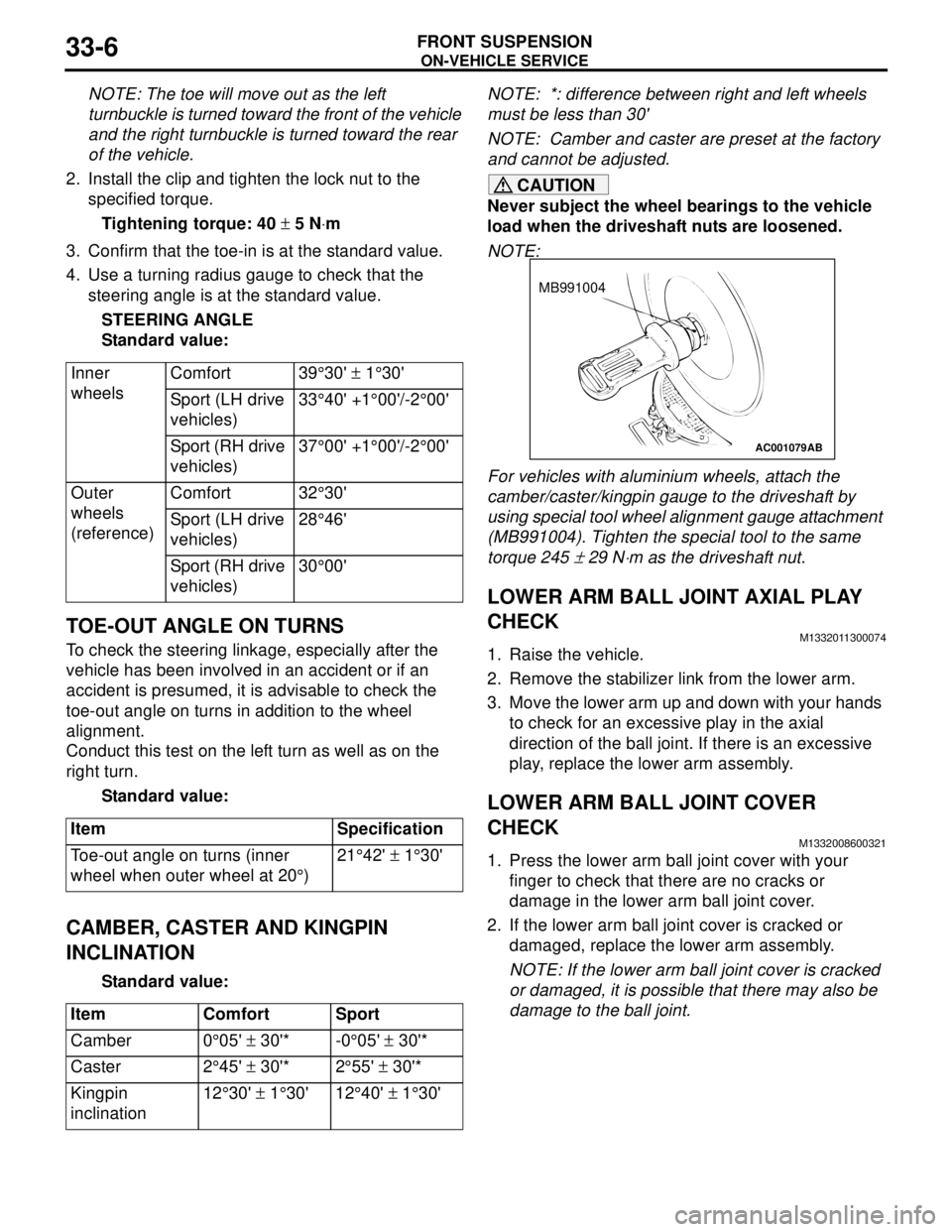

NOTE:

For vehicles with aluminium wheels, attach the

camber/caster/kingpin gauge to the driveshaft by

using special tool wheel alignment gauge attachment

(MB991004). Tighten the special tool to the same

torque 245

± 29 N⋅m as the driveshaft nut.

LOWER ARM BALL JOINT AXIAL PLAY

CHECK

M1332011300074

1. Raise the vehicle.

2. Remove the stabilizer link from the lower arm.

3. Move the lower arm up and down with your hands

to check for an excessive play in the axial

direction of the ball joint. If there is an excessive

play, replace the lower arm assembly.

LOWER ARM BALL JOINT COVER

CHECK

M1332008600321

1. Press the lower arm ball joint cover with your

finger to check that there are no cracks or

damage in the lower arm ball joint cover.

2. If the lower arm ball joint cover is cracked or

damaged, replace the lower arm assembly.

NOTE: If the lower arm ball joint cover is cracked

or damaged, it is possible that there may also be

damage to the ball joint. Inner

wheelsComfort 39°30' ± 1°30'

Sport (LH drive

vehicles)33°40' +1°00'/-2°00'

Sport (RH drive

vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (LH drive

vehicles)28°46'

Sport (RH drive

vehicles)30°00'

Item Specification

Toe-out angle on turns (inner

wheel when outer wheel at 20°)21°42' ± 1°30'

Item Comfort Sport

Camber 0°05' ± 30'* -0°05' ± 30'*

Caster 2°45' ± 30'* 2°55' ± 30'*

Kingpin

inclination12°30' ± 1°30' 12°40' ± 1°30'

AC001079

MB991004

AB

Page 189 of 788

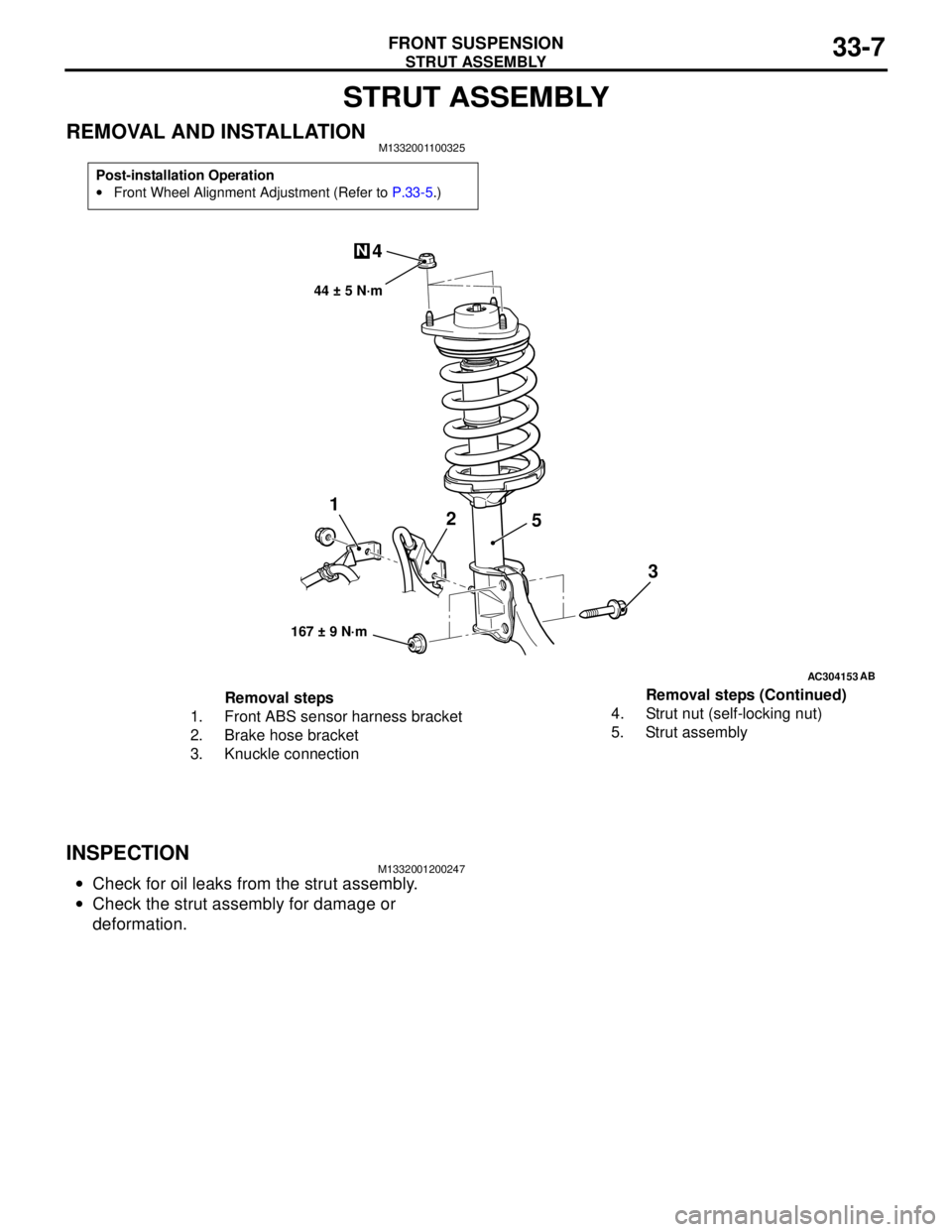

STRUT ASSEMBLY

FRONT SUSPENSION33-7

STRUT ASSEMBLY

REMOVAL AND INSTALLATIONM1332001100325

INSPECTIONM1332001200247

•Check for oil leaks from the strut assembly.

•Check the strut assembly for damage or

deformation.

Post-installation Operation

•Front Wheel Alignment Adjustment (Refer to P.33-5.)

AC304153

44 ± 5 N·m

1

2

3 4

N

AB

167 ± 9 N·m

5

Removal steps

1. Front ABS sensor harness bracket

2. Brake hose bracket

3. Knuckle connection4. Strut nut (self-locking nut)

5. Strut assemblyRemoval steps (Continued)

Page 190 of 788

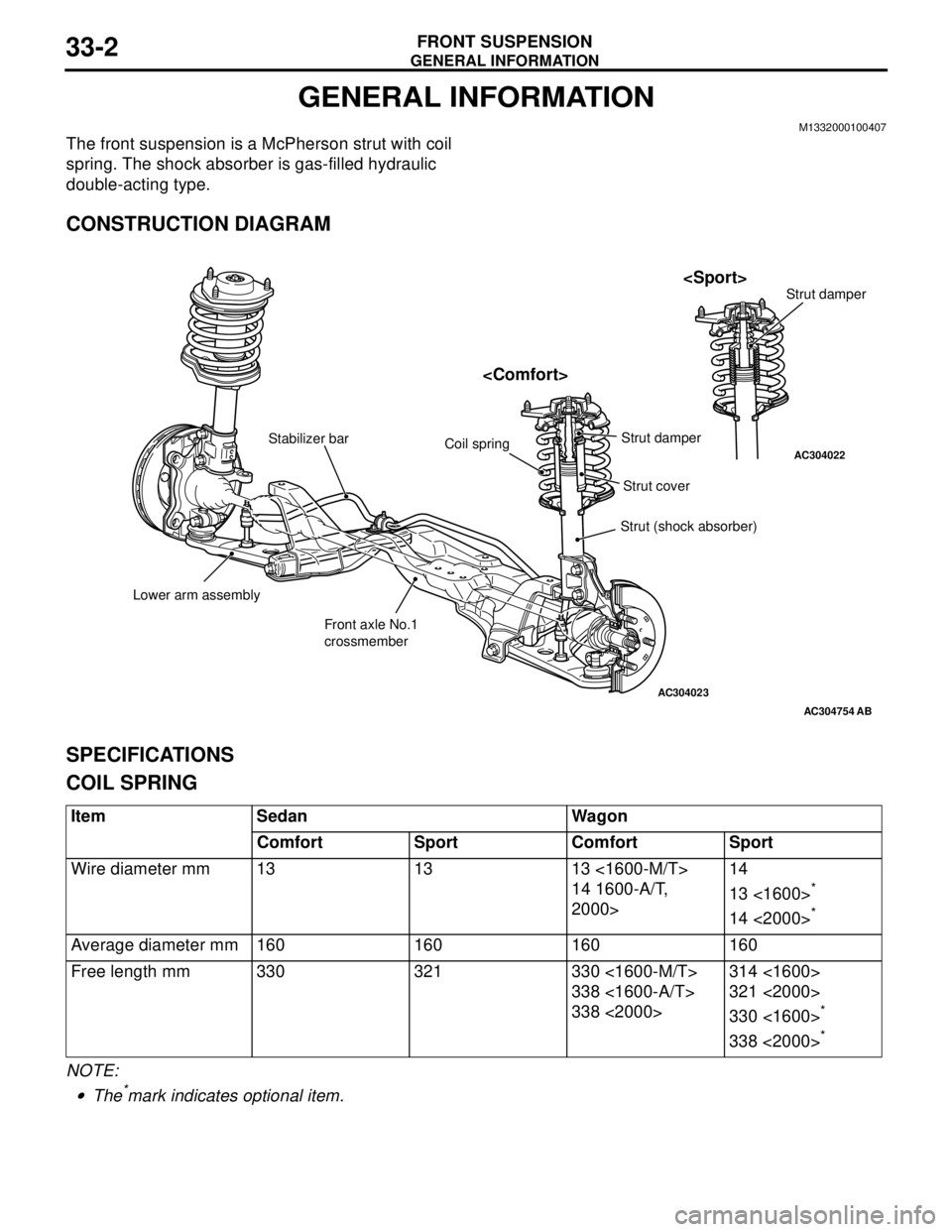

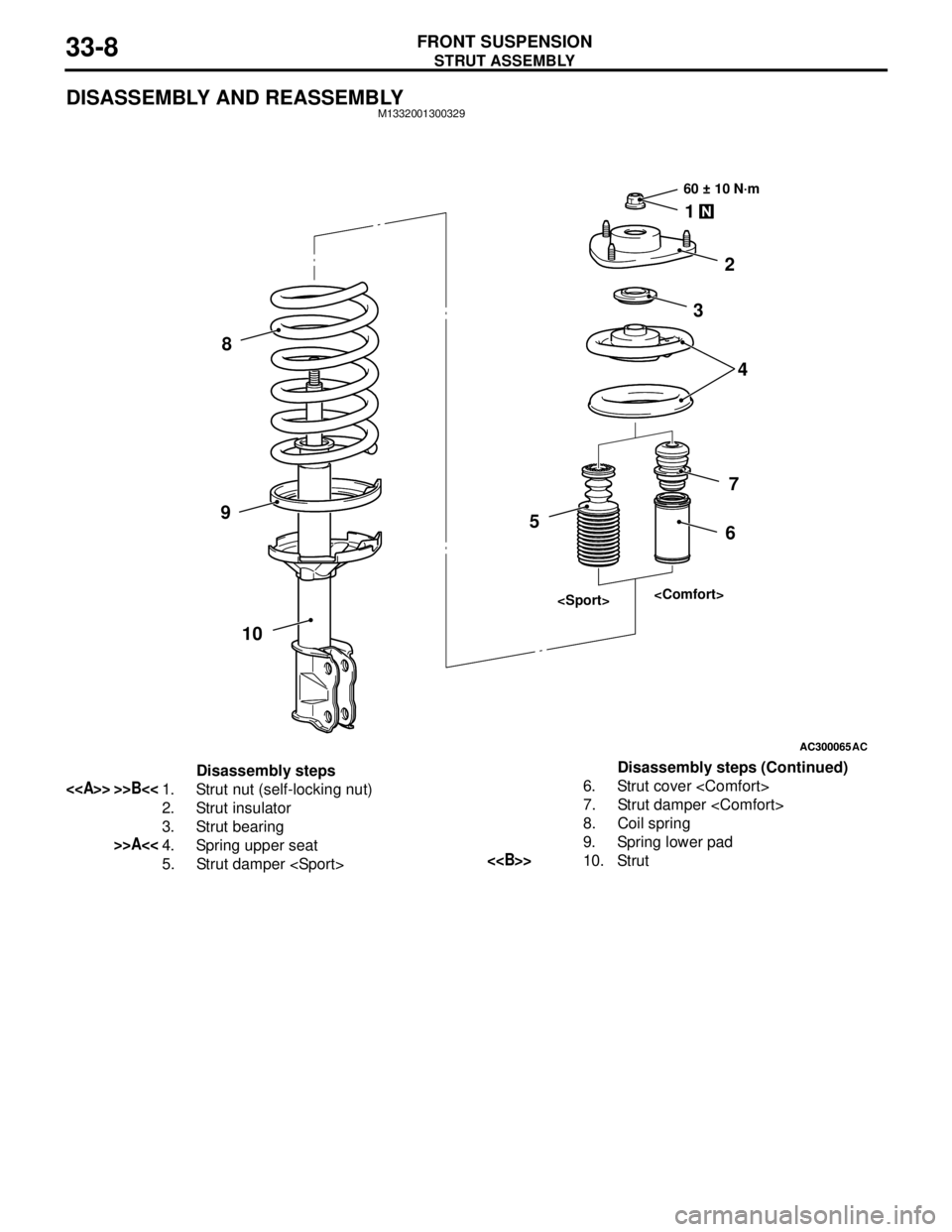

STRUT ASSEMBLY

FRONT SUSPENSION33-8

DISASSEMBLY AND REASSEMBLYM1332001300329

AC300065AC300065

9

101

2

3

4

5

6

60 ± 10 N·m

AC

8

7

Disassembly steps

<> >>B<<1. Strut nut (self-locking nut)

2. Strut insulator

3. Strut bearing

>>A<<4. Spring upper seat

5. Strut damper

7. Strut damper

8. Coil spring

9. Spring lower pad<>10. StrutDisassembly steps (Continued)

Page 191 of 788