front MITSUBISHI LANCER 2005 Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 213 of 788

Page 228 of 788

ON-VEHICLE SERVICE

PARKING BRAKES36-4

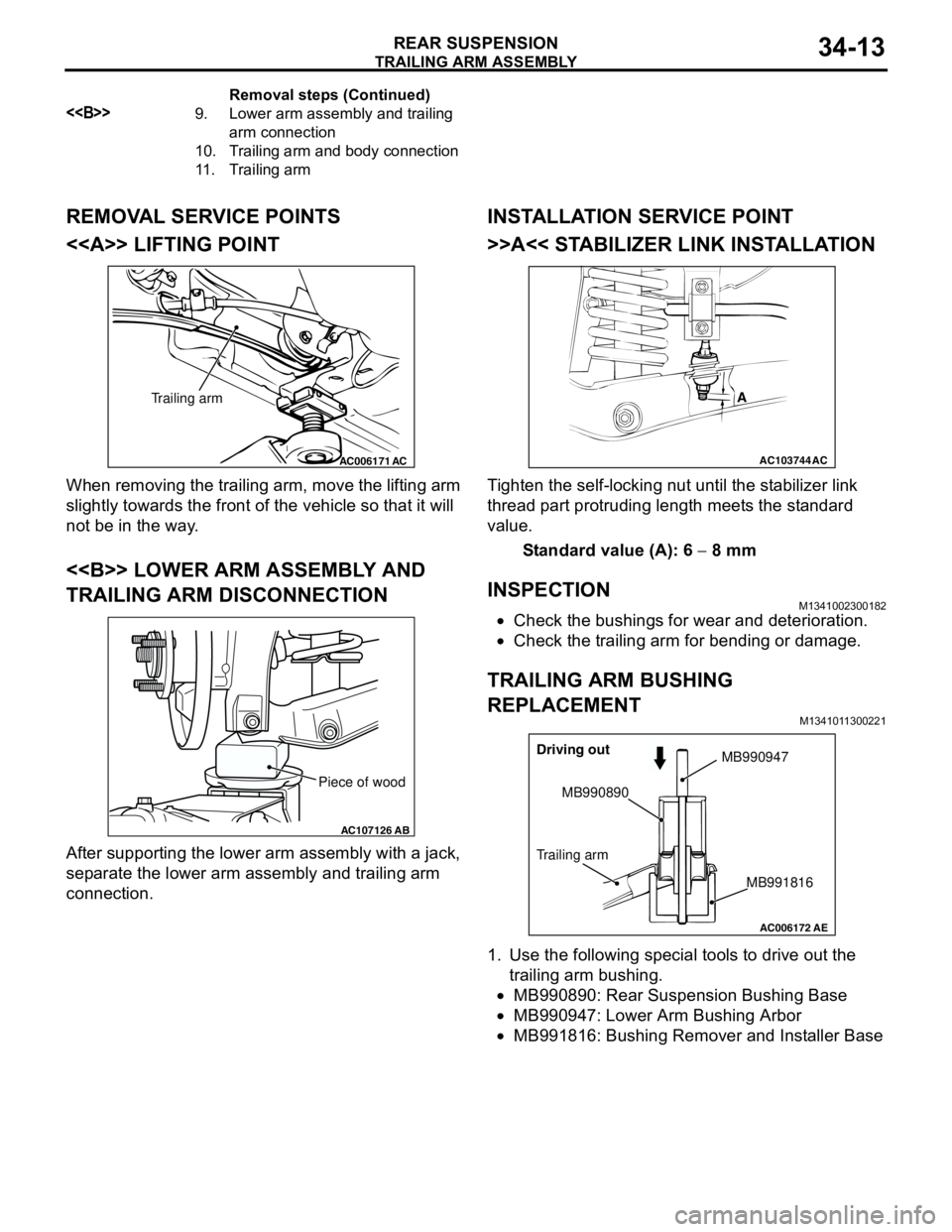

2. Hook a spring balance onto the centre of the

parking brake lever grip and pull it with a force of

100 − 150 N in a direction perpendicular to the

handle.

3. Drive the vehicle at a constant speed of 35 − 50

km/h for 100 metres.

4. Release the parking brake and let the brakes cool

for 5 − 10 minutes.

5. Repeat the procedure in steps 2 to 4, four or five

times.

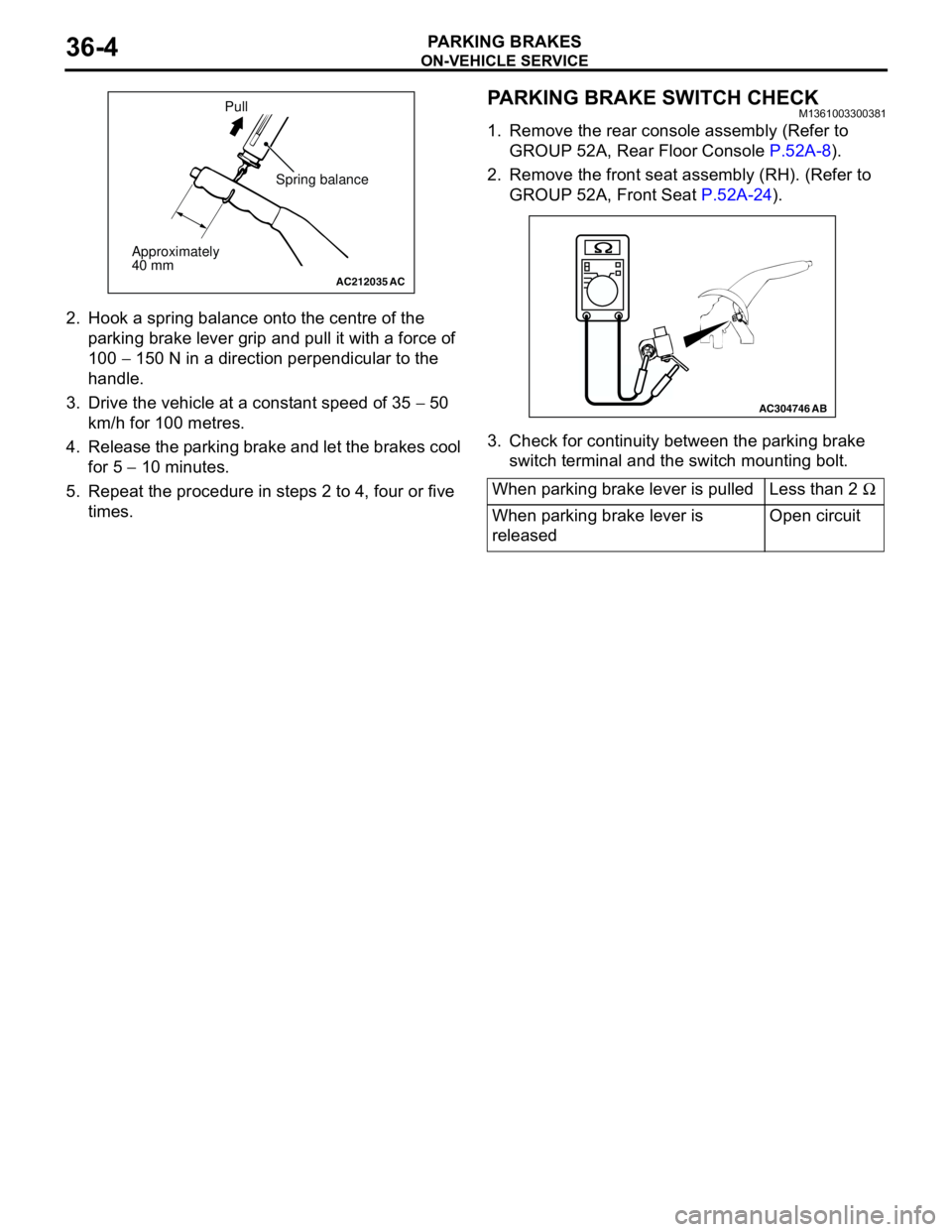

PARKING BRAKE SWITCH CHECKM1361003300381

1. Remove the rear console assembly (Refer to

GROUP 52A, Rear Floor Console P.52A-8).

2. Remove the front seat assembly (RH). (Refer to

GROUP 52A, Front Seat P.52A-24).

3. Check for continuity between the parking brake

switch terminal and the switch mounting bolt.

AC212035AC

Spring balance

Approximately

40 mmPull

When parking brake lever is pulled Less than 2 Ω

When parking brake lever is

releasedOpen circuit

AC304746AB

Page 232 of 788

Page 233 of 788

PARKING BRAKE LINING AND DRUM

PARKING BRAKES36-9

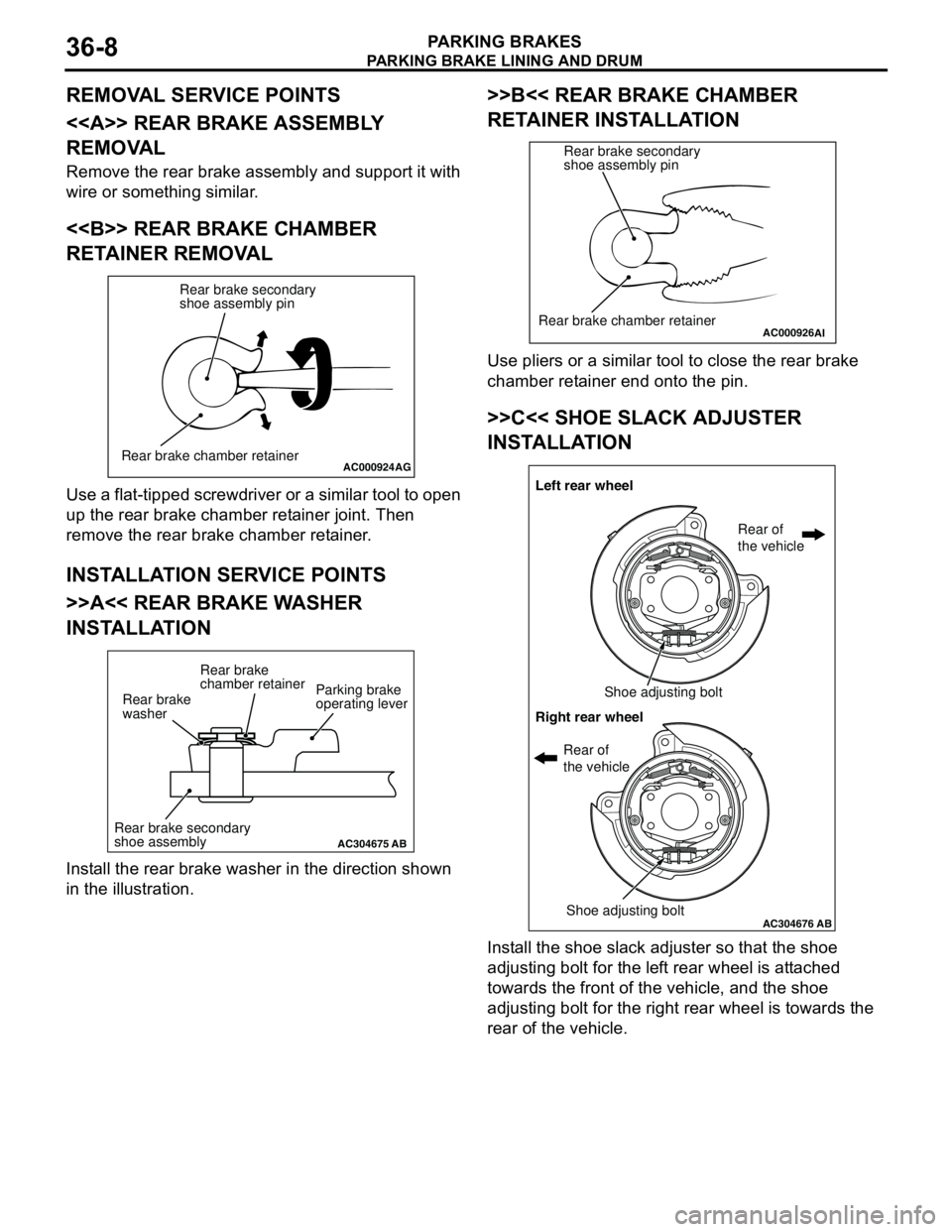

>>D<< SHOE RETURN SPRINGS

INSTALLATION

The shoe return springs are not interchangeable as

their constants are different. The one with blue paint

mark should be install at the front of the vehicle, and

the other with yellow paint at the rear of the vehicle,

respectively.

NOTE: The illustration shows the left rear wheel. The

right rear wheel is symmetrical to that.

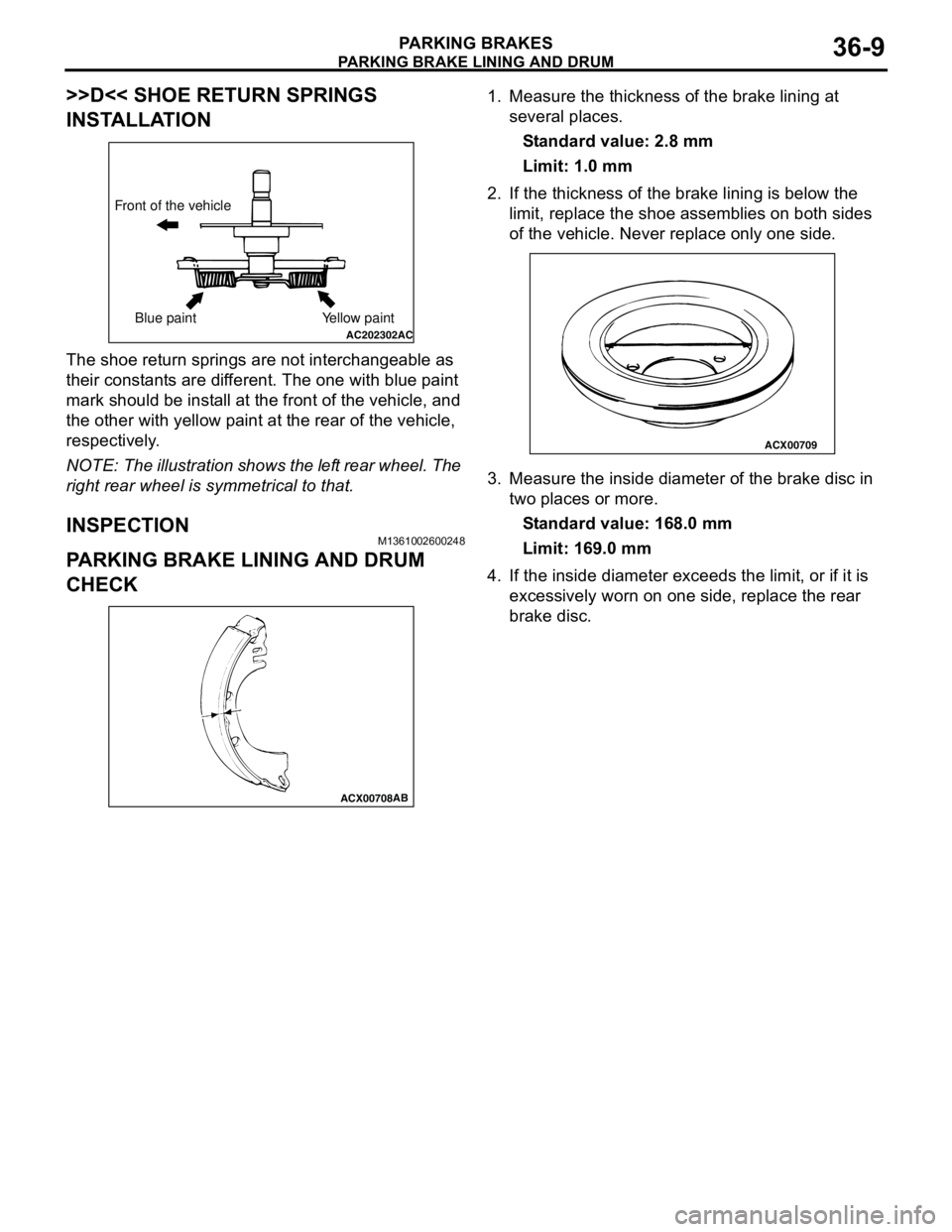

INSPECTIONM1361002600248

PARKING BRAKE LINING AND DRUM

CHECK

1. Measure the thickness of the brake lining at

several places.

Standard value: 2.8 mm

Limit: 1.0 mm

2. If the thickness of the brake lining is below the

limit, replace the shoe assemblies on both sides

of the vehicle. Never replace only one side.

3. Measure the inside diameter of the brake disc in

two places or more.

Standard value: 168.0 mm

Limit: 169.0 mm

4. If the inside diameter exceeds the limit, or if it is

excessively worn on one side, replace the rear

brake disc.

AC202302AC

Front of the vehicle

Blue paint Yellow paint

ACX00708AB

ACX00709

Page 235 of 788

37-1

GROUP 37

POWER STEERING

CONTENTS

GENERAL INFORMATION . . . . . . . .37-3

SERVICE SPECIFICATIONS . . . . . . .37-6

LUBRICANTS . . . . . . . . . . . . . . . . . .37-7

SEALANTS . . . . . . . . . . . . . . . . . . . .37-7

SPECIAL TOOLS . . . . . . . . . . . . . . . .37-8

ON-VEHICLE SERVICE . . . . . . . . . . .37-11

STEERING WHEEL FREE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-11

STEERING ANGLE CHECK . . . . . . . . . . . . 37-11

TIE ROD END BALL JOINT TURNING

TORQUE CHECK . . . . . . . . . . . . . . . . . . . . 37-12

STATIONARY STEERING EFFORT

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-12

STEERING WHEEL RETURN TO

CENTRE CHECK . . . . . . . . . . . . . . . . . . . . 37-13DRIVE BELT TENSION CHECK . . . . . . . . . 37-13

FLUID LEVEL CHECK . . . . . . . . . . . . . . . . 37-13

FLUID REPLACEMENT . . . . . . . . . . . . . . . 37-13

POWER STEERING SYSTEM AIR

BLEEDING . . . . . . . . . . . . . . . . . . . . . . . . . 37-13

OIL PUMP PRESSURE TEST . . . . . . . . . . 37-14

POWER STEERING PRESSURE

SWITCH CHECK . . . . . . . . . . . . . . . . . . . . . 37-15

TIE ROD END BALL JOINT DUST COVER

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37-15

STEERING COLUMN SHAFT

ASSEMBLY SHOCK ABSORBING

MECHANISM CHECK . . . . . . . . . . . . . . . . . 37-15

STEERING WHEEL* . . . . . . . . . . . . . .37-17

REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

Continued on next page

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING

•Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to

personal injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and

paassenger (from rendering the SRS inoperative).

•Service or maintenance of any SRS component or SRS-related component must be performed only at an

authorized MITSUBISHI dealer.

•MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any

SRS-related component.

NOTE

The SRS includes the following components: SRS air bag control unit, SRS warning light, front impact sensors, air bag module,

clock spring, and interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection

with SRS service or maintenance) are indicated in the table of contents by an asterisk (*).

Page 244 of 788

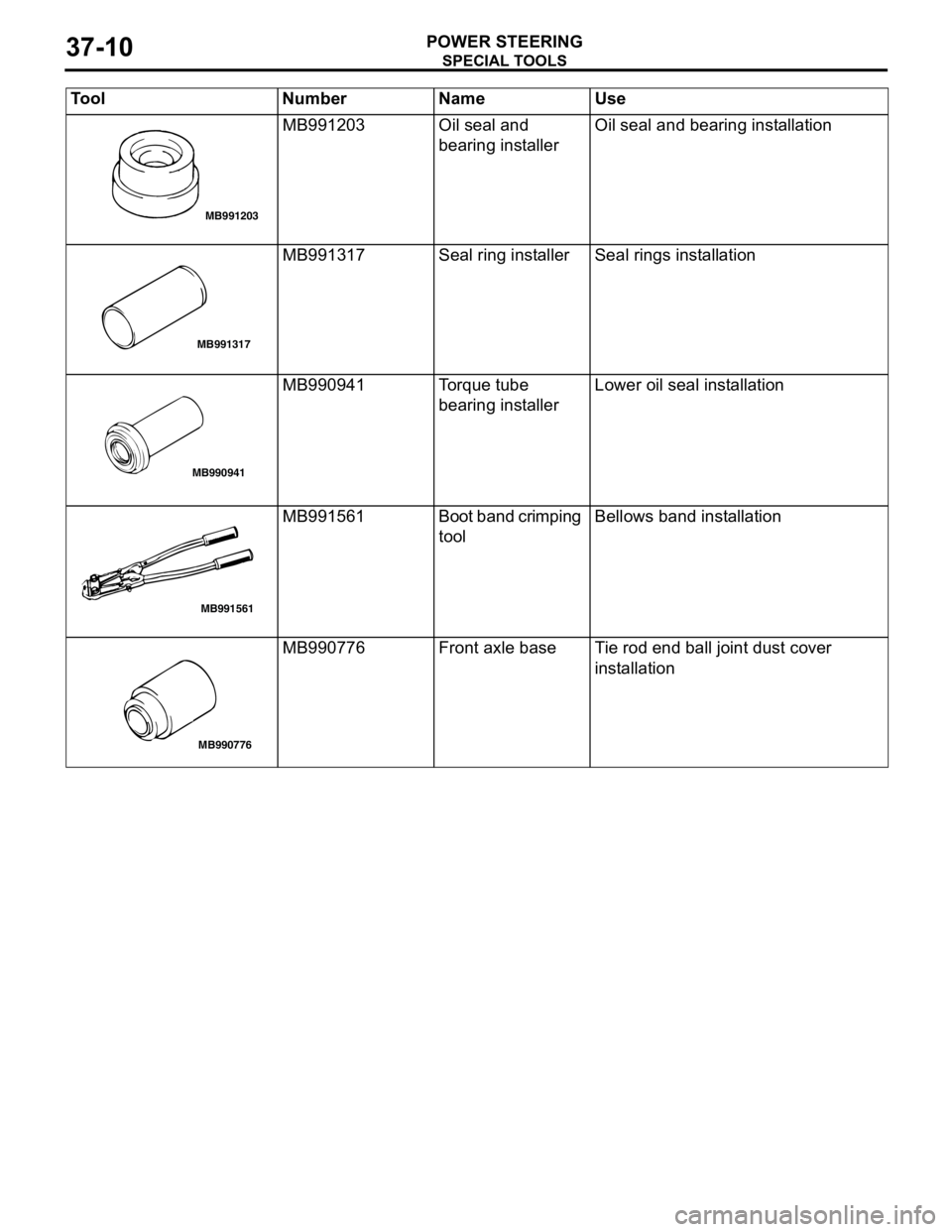

SPECIAL TOOLS

POWER STEERING37-10

MB991203 Oil seal and

bearing installerOil seal and bearing installation

MB991317 Seal ring installer Seal rings installation

MB990941 Torque tube

bearing installerLower oil seal installation

MB991561 Boot band crimping

toolBellows band installation

MB990776 Front axle base Tie rod end ball joint dust cover

installation Tool Number Name Use

MB991203

MB991317

MB990941

MB991561

MB990776

Page 245 of 788

ON-VEHICLE SERVICE

POWER STEERING37-11

ON-VEHICLE SERVICE

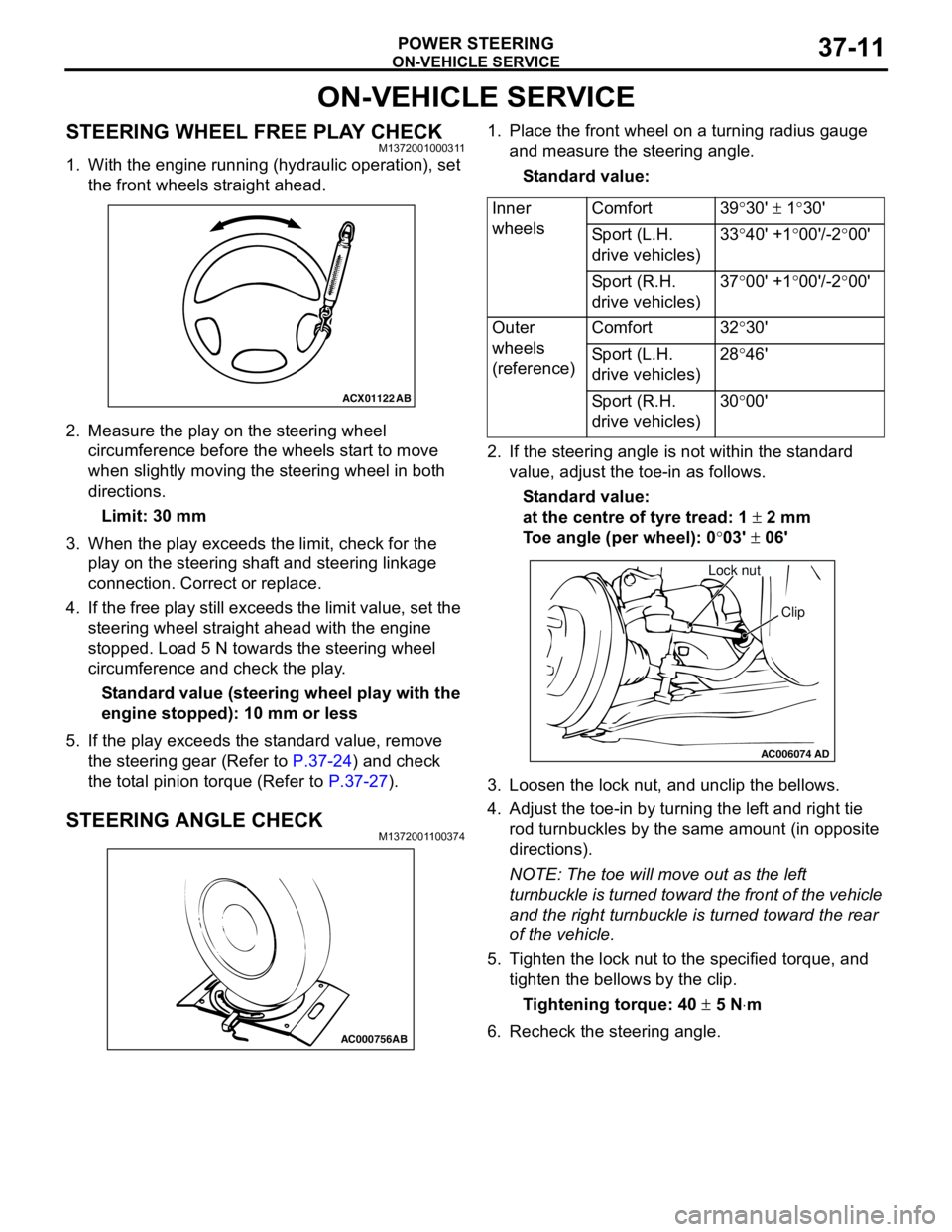

STEERING WHEEL FREE PLAY CHECKM1372001000311

1. With the engine running (hydraulic operation), set

the front wheels straight ahead.

2. Measure the play on the steering wheel

circumference before the wheels start to move

when slightly moving the steering wheel in both

directions.

Limit: 30 mm

3. When the play exceeds the limit, check for the

play on the steering shaft and steering linkage

connection. Correct or replace.

4. If the free play still exceeds the limit value, set the

steering wheel straight ahead with the engine

stopped. Load 5 N towards the steering wheel

circumference and check the play.

Standard value (steering wheel play with the

engine stopped): 10 mm or less

5. If the play exceeds the standard value, remove

the steering gear (Refer to P.37-24) and check

the total pinion torque (Refer to P.37-27).

STEERING ANGLE CHECKM1372001100374

1. Place the front wheel on a turning radius gauge

and measure the steering angle.

Standard value:

2. If the steering angle is not within the standard

value, adjust the toe-in as follows.

Standard value:

at the centre of tyre tread: 1 ± 2 mm

Toe angle (per wheel): 0°03' ± 06'

3. Loosen the lock nut, and unclip the bellows.

4. Adjust the toe-in by turning the left and right tie

rod turnbuckles by the same amount (in opposite

directions).

NOTE: The toe will move out as the left

turnbuckle is turned toward the front of the vehicle

and the right turnbuckle is turned toward the rear

of the vehicle.

5. Tighten the lock nut to the specified torque, and

tighten the bellows by the clip.

Tightening torque: 40 ± 5 N⋅m

6. Recheck the steering angle.

ACX01122

AB

AC000756AB

Inner

wheelsComfort 39°30' ± 1°30'

Sport (L.H.

drive vehicles)33°40' +1°00'/-2°00'

Sport (R.H.

drive vehicles)37°00' +1°00'/-2°00'

Outer

wheels

(reference)Comfort 32°30'

Sport (L.H.

drive vehicles)28°46'

Sport (R.H.

drive vehicles)30°00'

AC006074AD

Lock nut

Clip

Page 247 of 788

ON-VEHICLE SERVICE

POWER STEERING37-13

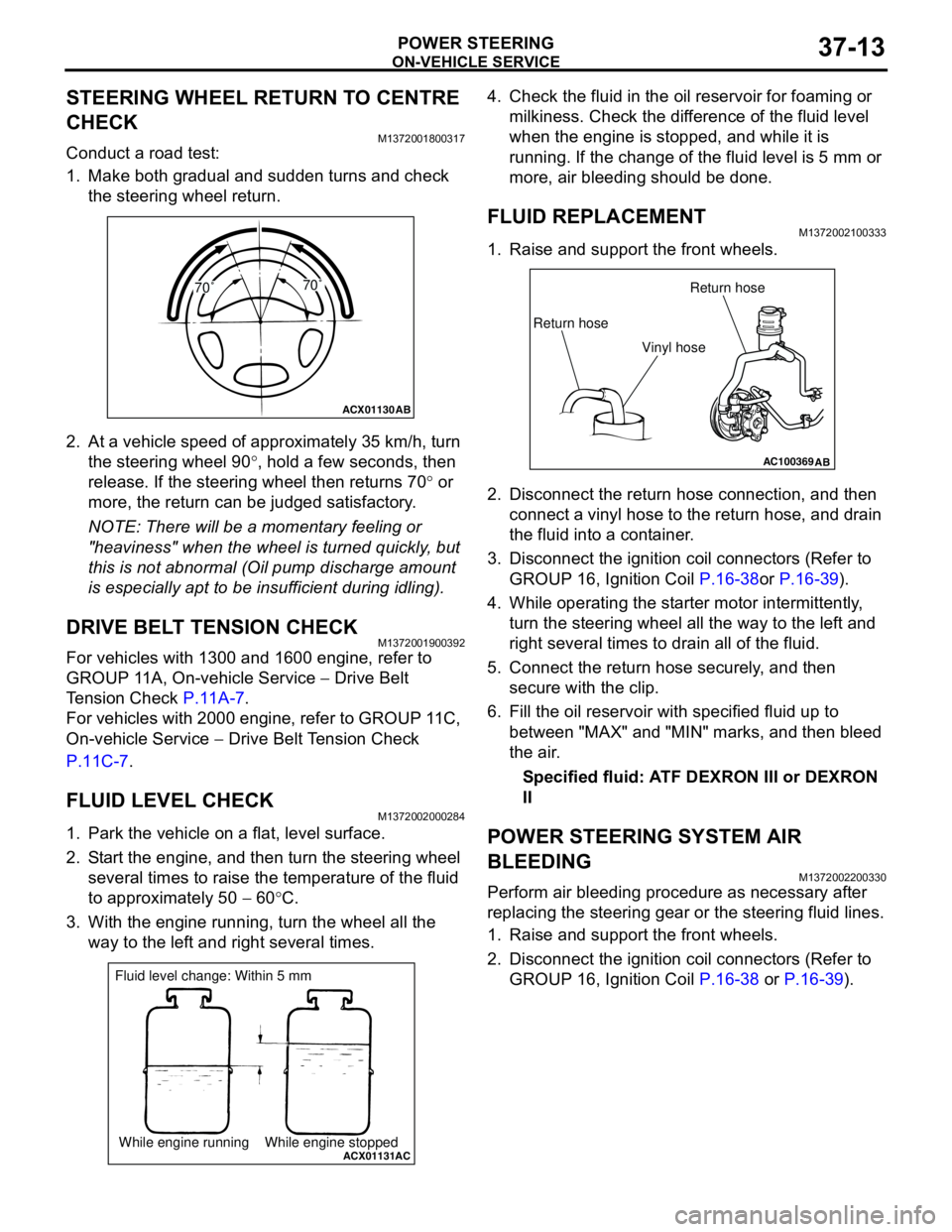

STEERING WHEEL RETURN TO CENTRE

CHECK

M1372001800317

Conduct a road test:

1. Make both gradual and sudden turns and check

the steering wheel return.

2. At a vehicle speed of approximately 35 km/h, turn

the steering wheel 90°, hold a few seconds, then

release. If the steering wheel then returns 70° or

more, the return can be judged satisfactory.

NOTE: There will be a momentary feeling or

"heaviness" when the wheel is turned quickly, but

this is not abnormal (Oil pump discharge amount

is especially apt to be insufficient during idling).

DRIVE BELT TENSION CHECKM1372001900392

For vehicles with 1300 and 1600 engine, refer to

GROUP 11A, On-vehicle Service − Drive Belt

Tension Check P.11A-7.

For vehicles with 2000 engine, refer to GROUP 11C,

On-vehicle Service − Drive Belt Tension Check

P.11C-7.

FLUID LEVEL CHECKM1372002000284

1. Park the vehicle on a flat, level surface.

2. Start the engine, and then turn the steering wheel

several times to raise the temperature of the fluid

to approximately 50 − 60°C.

3. With the engine running, turn the wheel all the

way to the left and right several times.4. Check the fluid in the oil reservoir for foaming or

milkiness. Check the difference of the fluid level

when the engine is stopped, and while it is

running. If the change of the fluid level is 5 mm or

more, air bleeding should be done.

FLUID REPLACEMENTM1372002100333

1. Raise and support the front wheels.

2. Disconnect the return hose connection, and then

connect a vinyl hose to the return hose, and drain

the fluid into a container.

3. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38or P.16-39).

4. While operating the starter motor intermittently,

turn the steering wheel all the way to the left and

right several times to drain all of the fluid.

5. Connect the return hose securely, and then

secure with the clip.

6. Fill the oil reservoir with specified fluid up to

between "MAX" and "MIN" marks, and then bleed

the air.

Specified fluid: ATF DEXRON III or DEXRON

II

POWER STEERING SYSTEM AIR

BLEEDING

M1372002200330

Perform air bleeding procedure as necessary after

replacing the steering gear or the steering fluid lines.

1. Raise and support the front wheels.

2. Disconnect the ignition coil connectors (Refer to

GROUP 16, Ignition Coil P.16-38 or P.16-39).

ACX01130

AB

70˚70˚

ACX01131While engine running While engine stoppedAC

Fluid level change: Within 5 mm

AC100369AB

Return hoseReturn hose

Vinyl hose

Page 258 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-24

POWER STEERING GEAR BOX AND LINKAGE

REMOVAL AND INSTALLATIONM1372010900237

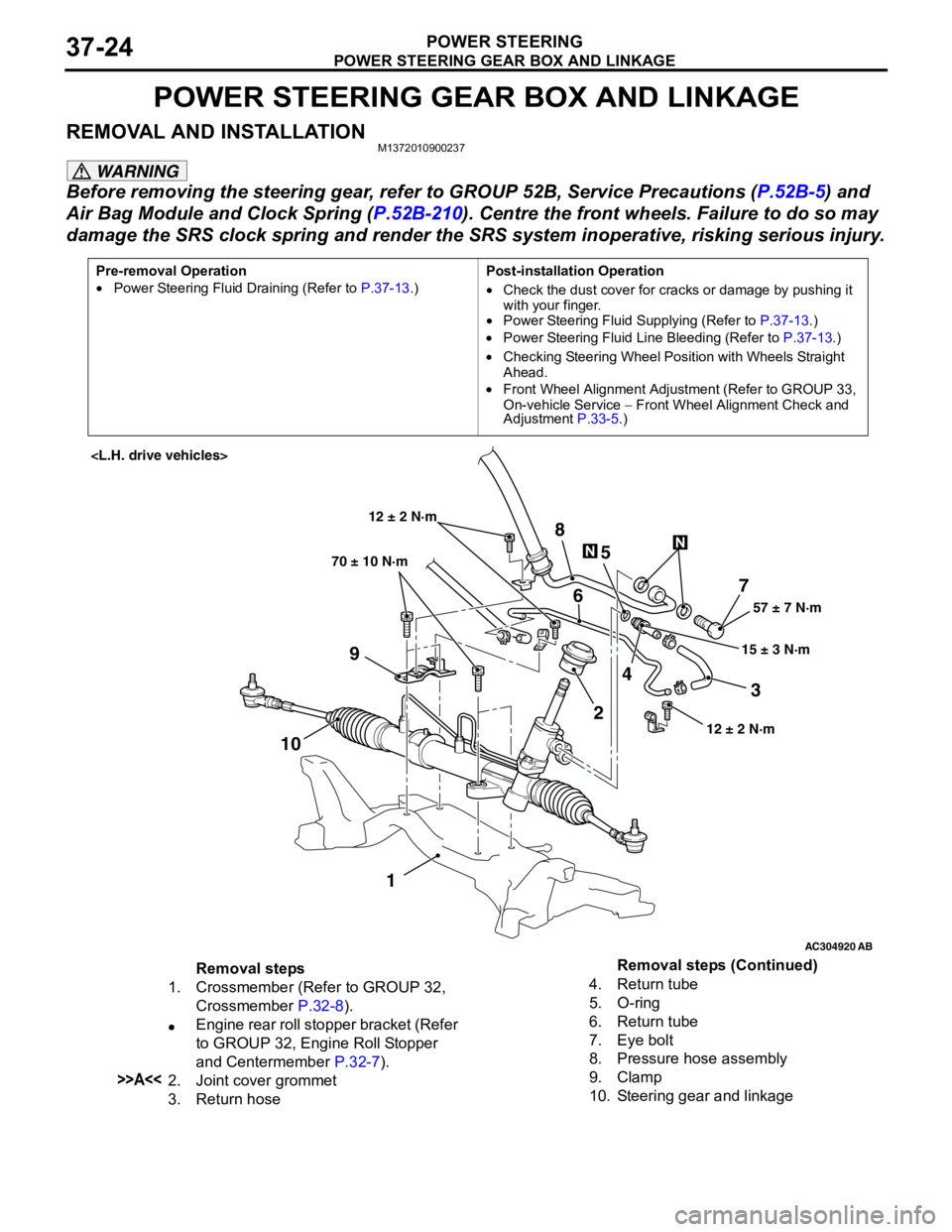

WARNING

Before removing the steering gear, refer to GROUP 52B, Service Precautions (P.52B-5) and

Air Bag Module and Clock Spring (P.52B-210). Centre the front wheels. Failure to do so may

damage the SRS clock spring and render the SRS system inoperative, risking serious injury.

Pre-removal Operation

•Power Steering Fluid Draining (Refer to P.37-13.)Post-installation Operation

•Check the dust cover for cracks or damage by pushing it

with your finger.

•Power Steering Fluid Supplying (Refer to P.37-13.)

•Power Steering Fluid Line Bleeding (Refer to P.37-13.)

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Adjustment (Refer to GROUP 33,

On-vehicle Service − Front Wheel Alignment Check and

Adjustment P.33-5.)

AC304920

AB

57 ± 7 N·m

15 ± 3 N·m 70 ± 10 N·m

7

3 8

5

6

9

1024

1

12 ± 2 N·m

12 ± 2 N·m

Removal steps

1. Crossmember (Refer to GROUP 32,

Crossmember P.32-8).

•Engine rear roll stopper bracket (Refer

to GROUP 32, Engine Roll Stopper

and Centermember P.32-7).

>>A<<2. Joint cover grommet

3. Return hose4. Return tube

5. O-ring

6. Return tube

7. Eye bolt

8. Pressure hose assembly

9. Clamp

10. Steering gear and linkageRemoval steps (Continued)

Page 270 of 788

POWER STEERING GEAR BOX AND LINKAGE

POWER STEERING37-36

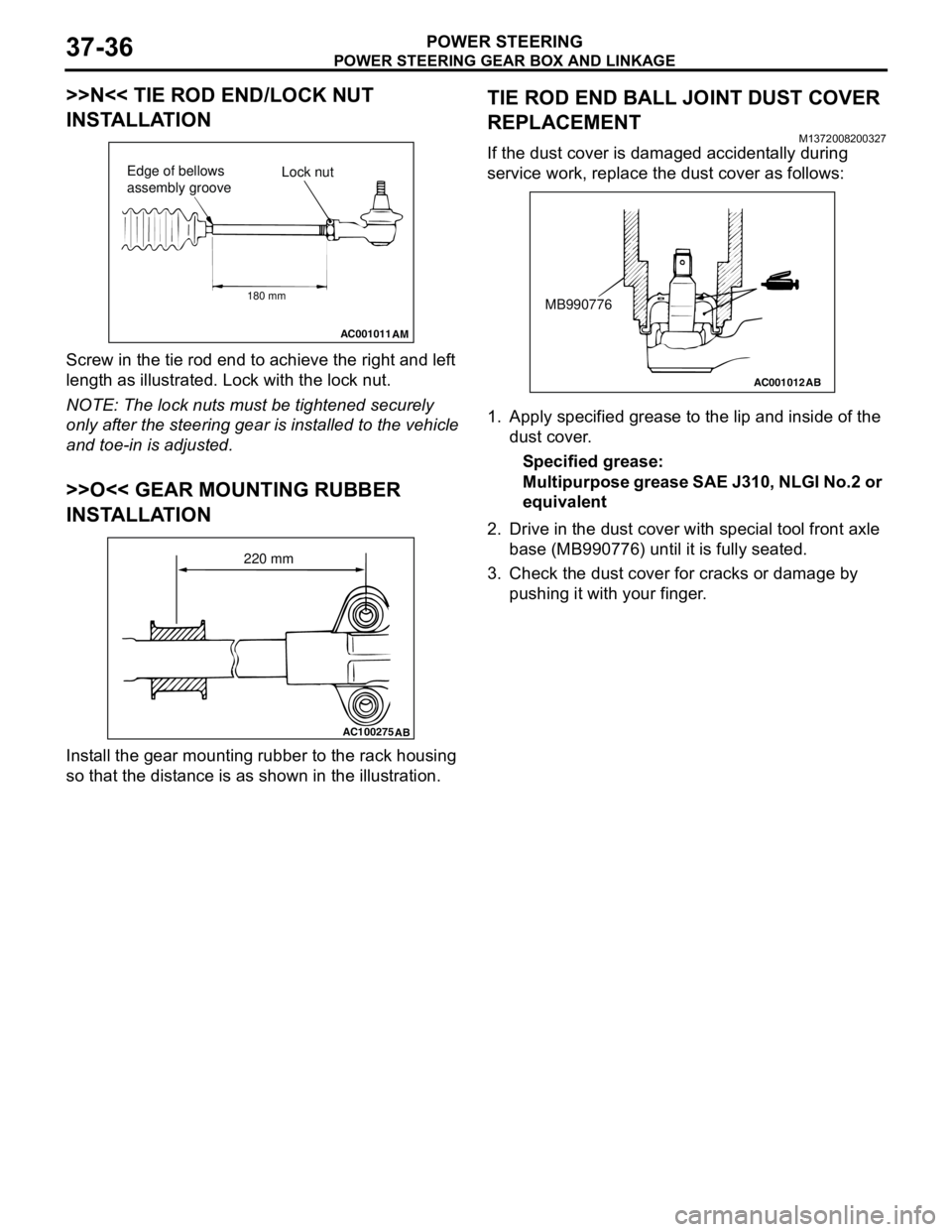

>>N<< TIE ROD END/LOCK NUT

INSTALLATION

Screw in the tie rod end to achieve the right and left

length as illustrated. Lock with the lock nut.

NOTE: The lock nuts must be tightened securely

only after the steering gear is installed to the vehicle

and toe-in is adjusted.

>>O<< GEAR MOUNTING RUBBER

INSTALLATION

Install the gear mounting rubber to the rack housing

so that the distance is as shown in the illustration.

TIE ROD END BALL JOINT DUST COVER

REPLACEMENT

M1372008200327

If the dust cover is damaged accidentally during

service work, replace the dust cover as follows:

1. Apply specified grease to the lip and inside of the

dust cover.

Specified grease:

Multipurpose grease SAE J310, NLGI No.2 or

equivalent

2. Drive in the dust cover with special tool front axle

base (MB990776) until it is fully seated.

3. Check the dust cover for cracks or damage by

pushing it with your finger.

AC001011

AM

Lock nut Edge of bellows

assembly groove

180 mm

AC100275

AB

220 mm

AC001012

AB

MB990776