MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 571 of 788

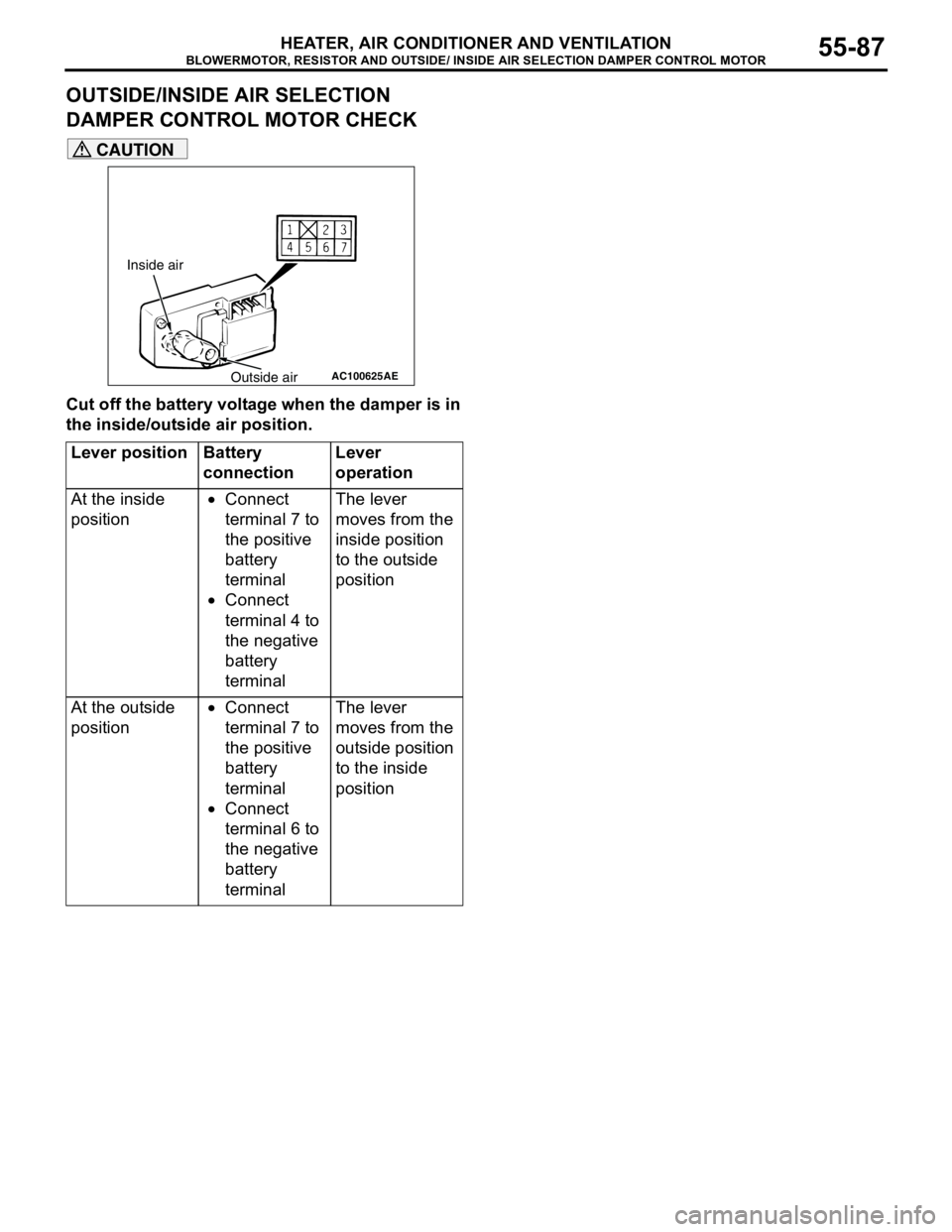

BLOWERMOTOR, RESISTOR AND OUTSIDE/ INSIDE AIR SELECTION DAMPER CONTROL MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-87

OUTSIDE/INSIDE AIR SELECTION

DAMPER CONTROL MOTOR CHECK

CAUTION

Cut off the battery voltage when the damper is in

the inside/outside air position.

Lever position Battery

connectionLever

operation

At the inside

position•Connect

terminal 7 to

the positive

battery

terminal

•Connect

terminal 4 to

the negative

battery

terminalThe lever

moves from the

inside position

to the outside

position

At the outside

position•Connect

terminal 7 to

the positive

battery

terminal

•Connect

terminal 6 to

the negative

battery

terminalThe lever

moves from the

outside position

to the inside

position

AC100625

Inside air

Outside air

AE

Page 572 of 788

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-88

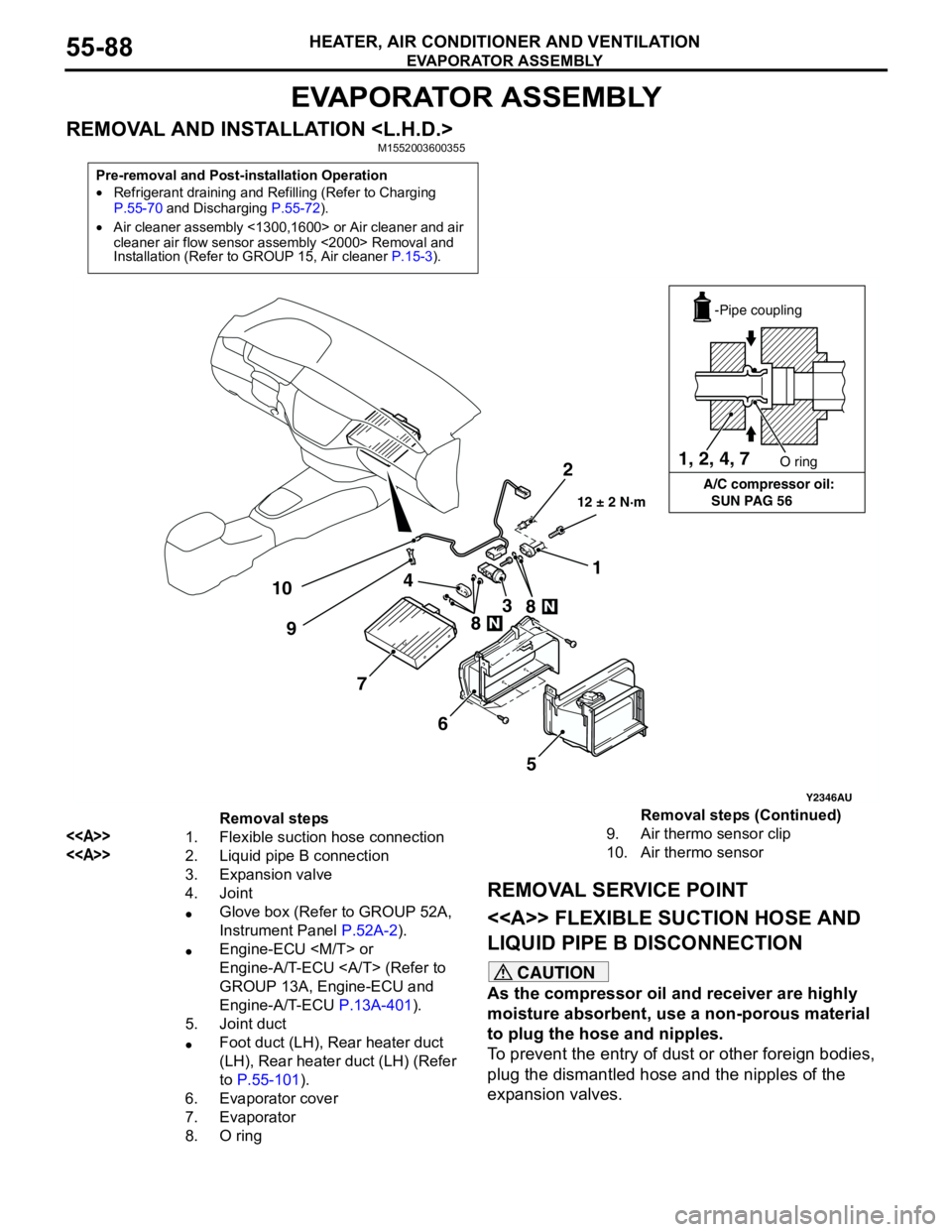

EVAPORATOR ASSEMBLY

REMOVAL AND INSTALLATION

REMOVAL SERVICE POINT

<> FLEXIBLE SUCTION HOSE AND

LIQUID PIPE B DISCONNECTION

CAUTION

As the compressor oil and receiver are highly

moisture absorbent, use a non-porous material

to plug the hose and nipples.

To prevent the entry of dust or other foreign bodies,

plug the dismantled hose and the nipples of the

expansion valves.

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

Y2346AU

1, 2, 4, 7

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

2

101

3 4

7

6

5 98

8

12 ± 2 N·m

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

4. Joint

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

5. Joint duct

•Foot duct (LH), Rear heater duct

(LH), Rear heater duct (LH) (Refer

to P.55-101).

6. Evaporator cover

7. Evaporator

8. O ring 9. Air thermo sensor clip

10. Air thermo sensorRemoval steps (Continued)

Page 573 of 788

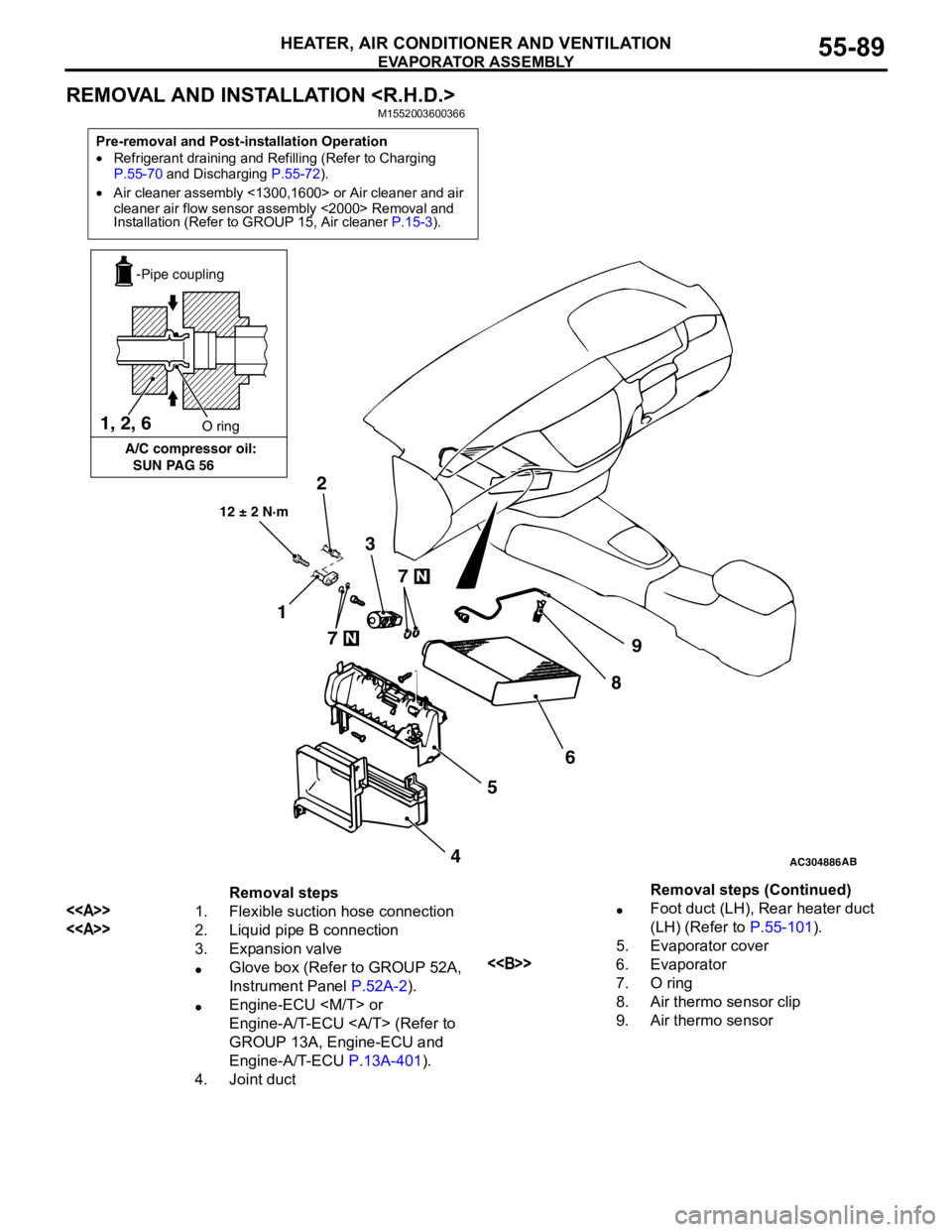

EVAPORATOR ASSEMBLY

HEATER, AIR CONDITIONER AND VENTILATION55-89

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner assembly <1300,1600> or Air cleaner and air

cleaner air flow sensor assembly <2000> Removal and

Installation (Refer to GROUP 15, Air cleaner P.15-3).

AC304886AB

12 ± 2 N·m

7

7

2

1

9

8

6

5

4 3 1, 2, 6

A/C compressor oil:

SUN PAG 56O ring

-Pipe coupling

Removal steps

<>1. Flexible suction hose connection

<>2. Liquid pipe B connection

3. Expansion valve

•Glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Engine-ECU

Engine-A/T-ECU (Refer to

GROUP 13A, Engine-ECU and

Engine-A/T-ECU P.13A-401).

4. Joint duct•Foot duct (LH), Rear heater duct

(LH) (Refer to P.55-101).

5. Evaporator cover

<>6. Evaporator

7. O ring

8. Air thermo sensor clip

9. Air thermo sensorRemoval steps (Continued)

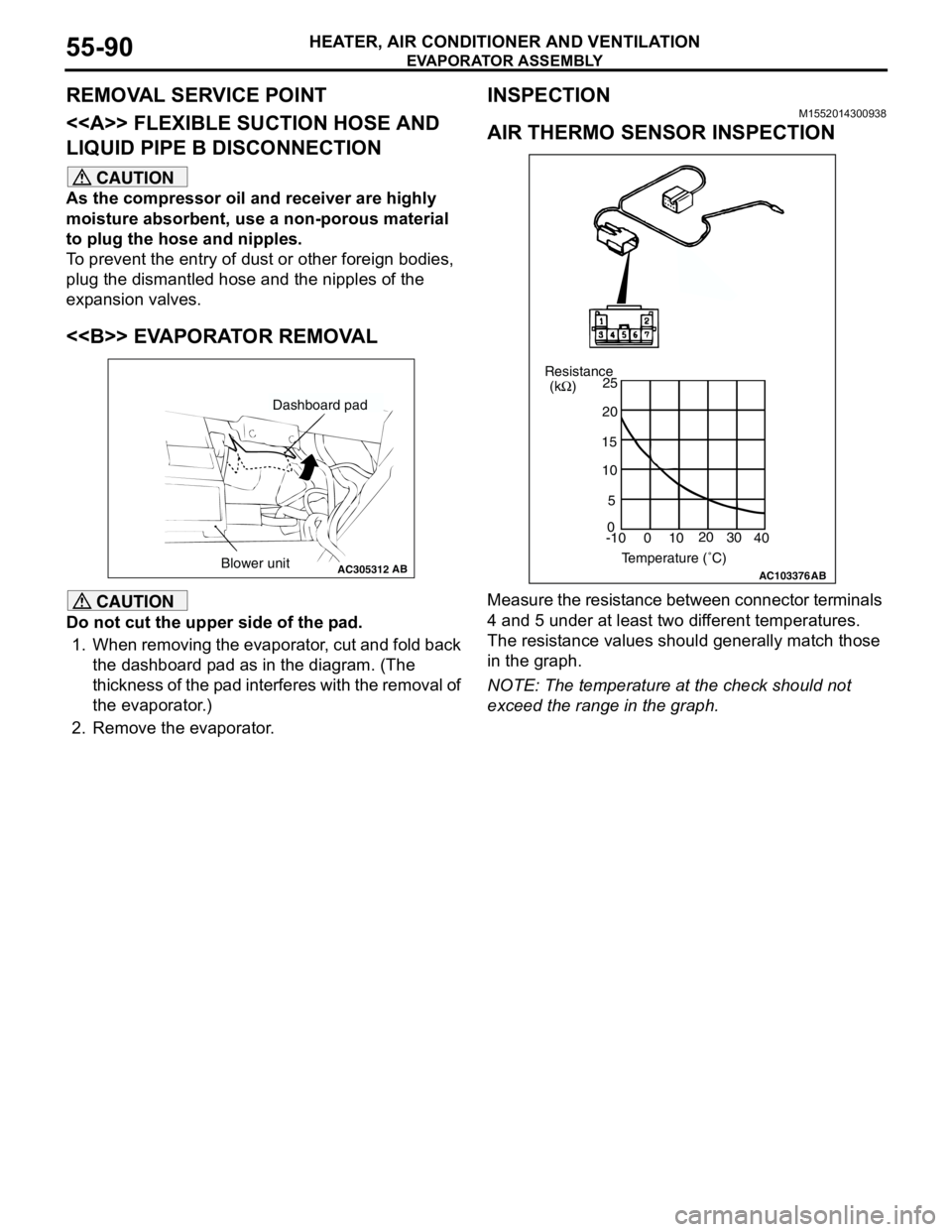

Page 574 of 788

Page 575 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-91

COMPRESSOR ASSEMBLY AND TENSION PULLEY

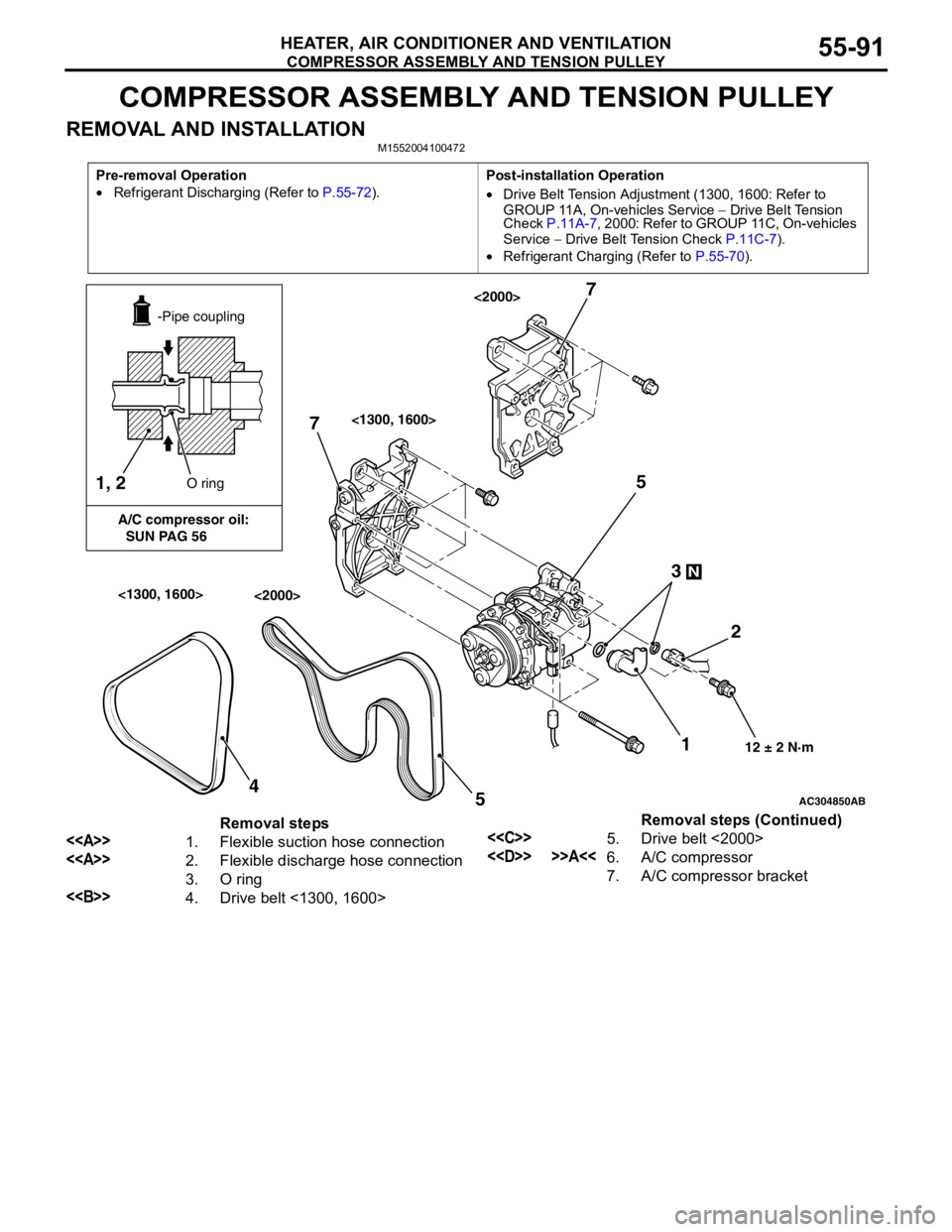

REMOVAL AND INSTALLATIONM1552004100472

Pre-removal Operation

•Refrigerant Discharging (Refer to P.55-72).Post-installation Operation

•Drive Belt Tension Adjustment (1300, 1600: Refer to

GROUP 11A, On-vehicles Service − Drive Belt Tension

Check P.11A-7, 2000: Refer to GROUP 11C, On-vehicles

Service − Drive Belt Tension Check P.11C-7).

•Refrigerant Charging (Refer to P.55-70).

AC304850

1, 2

A/C compressor oil:

SUN PAG 56-Pipe coupling

O ring

12 ± 2 N·m

N

12 3 5

AB

7

54

7

<1300, 1600>

<1300, 1600><2000>

<2000>

Removal steps

<>1. Flexible suction hose connection

<>2. Flexible discharge hose connection

3. O ring

<>4. Drive belt <1300, 1600>

<

<

7. A/C compressor bracketRemoval steps (Continued)

Page 576 of 788

Page 577 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-93

INSTALLATION SERVICE POINT

>>A<< A/C COMPRESSOR

INSTALLATION

If a new compressor is installed, first adjust the

amount of oil according to the procedures described

below, and then install the compressor.

1. Measure the amount (X mL) of oil within the

removed compressor.

2. Drain (from the new compressor) the amount of

oil calculated according to the following formula,

and then install the new compressor.

New compressor oil amount = 140mL <1300,

1600>, 120 mL <2000>

140 mL−X mL = Y mL <1300, 1600>

120 mL−X mL = Y mL <2000>

NOTE: Y mL indicates the amount of oil in the

refrigerant line, the condenser, the evaporator, etc.

NOTE: When replacing the following parts at the

same times as the compressor, subtract the rated oil

amount of the each part from Y mL and discharge

from the new compressor.

Quantity:

•Evaporator: 60 mL

•Condenser: 15 mL

•Suction hose: 10 mL

•Receiver: 10 mL

INSPECTIONM1552014300949

COMPRESSOR MAGNETIC CLUTCH

OPERATION CHECK

Connect the compressor connector terminal to the

battery positive (+) terminal and earth the battery’s

negative (−) terminal to the compressor unit. At that

time, the magnetic clutch should make a definite

operating sound.

AC005671

Magnetic clutch connector

AC

Page 578 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-94

DISASSEMBLY AND REASSEMBLYM1552004600660

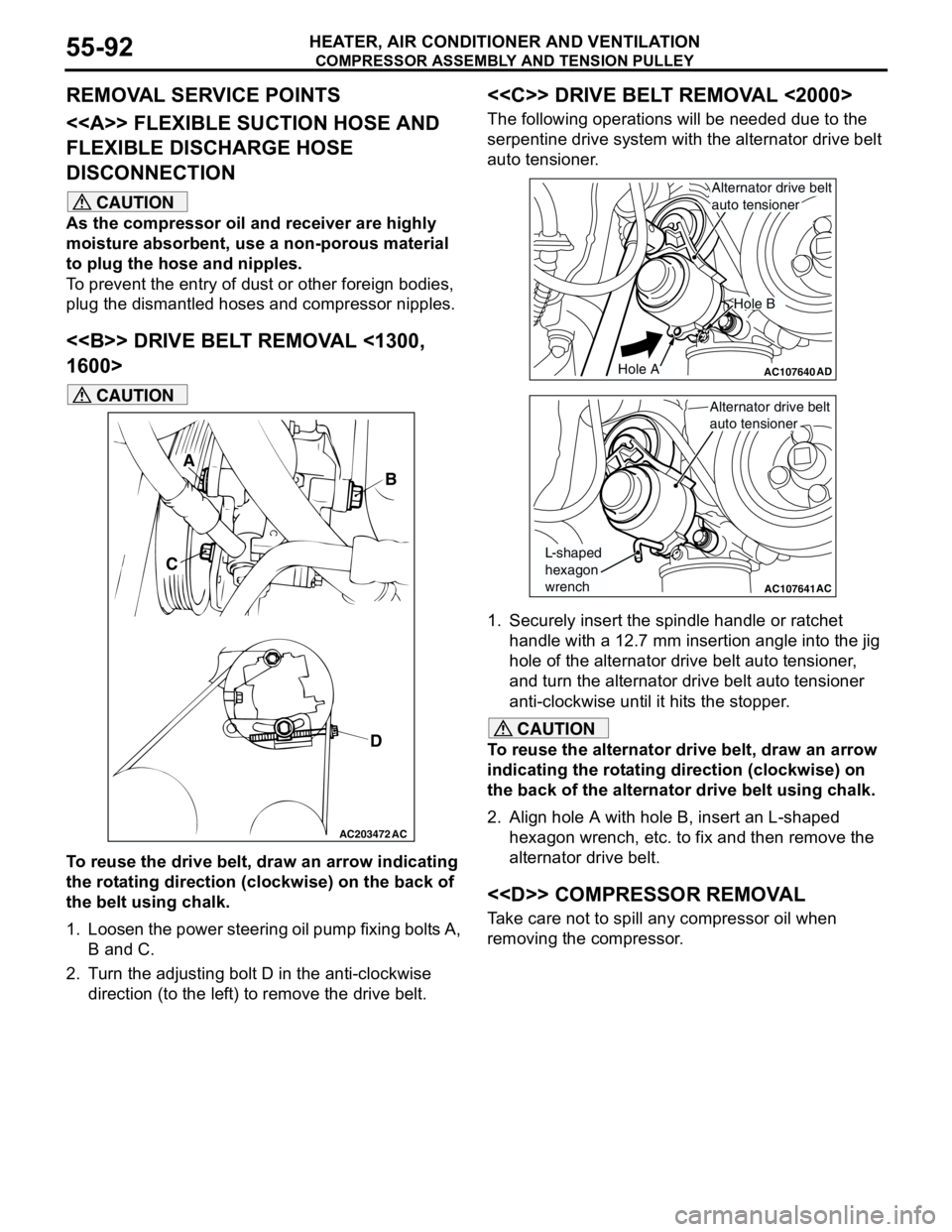

DISASSEMBLY SERVICE POINT

<> SELF-LOCKING NUT REMOVAL

Use the special tools to remove the self-locking nut.

•Special spanner (MB991367)

•Pin (MB991386)

REASSEMBLY SERVICE POINTS

>>A<< FIELD CORE ATTACHMENT

Line up the pin hole on the compressor unit with the

field core projection and attach.

AC100630

N

N

16 ± 1 N·m

10

46789

512

AB

3

11

Cooling temperature switch

disassembly steps

1. Snap ring

2. Refrigerant temperature switch

3. O ring

Magnetic clutch disassembly

>>D<<•Air gap adjustment

<> >>C<<4. Self-locking nut5. Armature

>>B<<6. Snap ring

7. Rotor

8. Snap ring

>>A<<9. Field core

10. Shim

11. A/C compressorMagnetic clutch disassembly

AC100633AB

MB991386

MB991367

AC100634AB

Field core projection

Compressor

unit pin hole

Page 579 of 788

COMPRESSOR ASSEMBLY AND TENSION PULLEY

HEATER, AIR CONDITIONER AND VENTILATION55-95

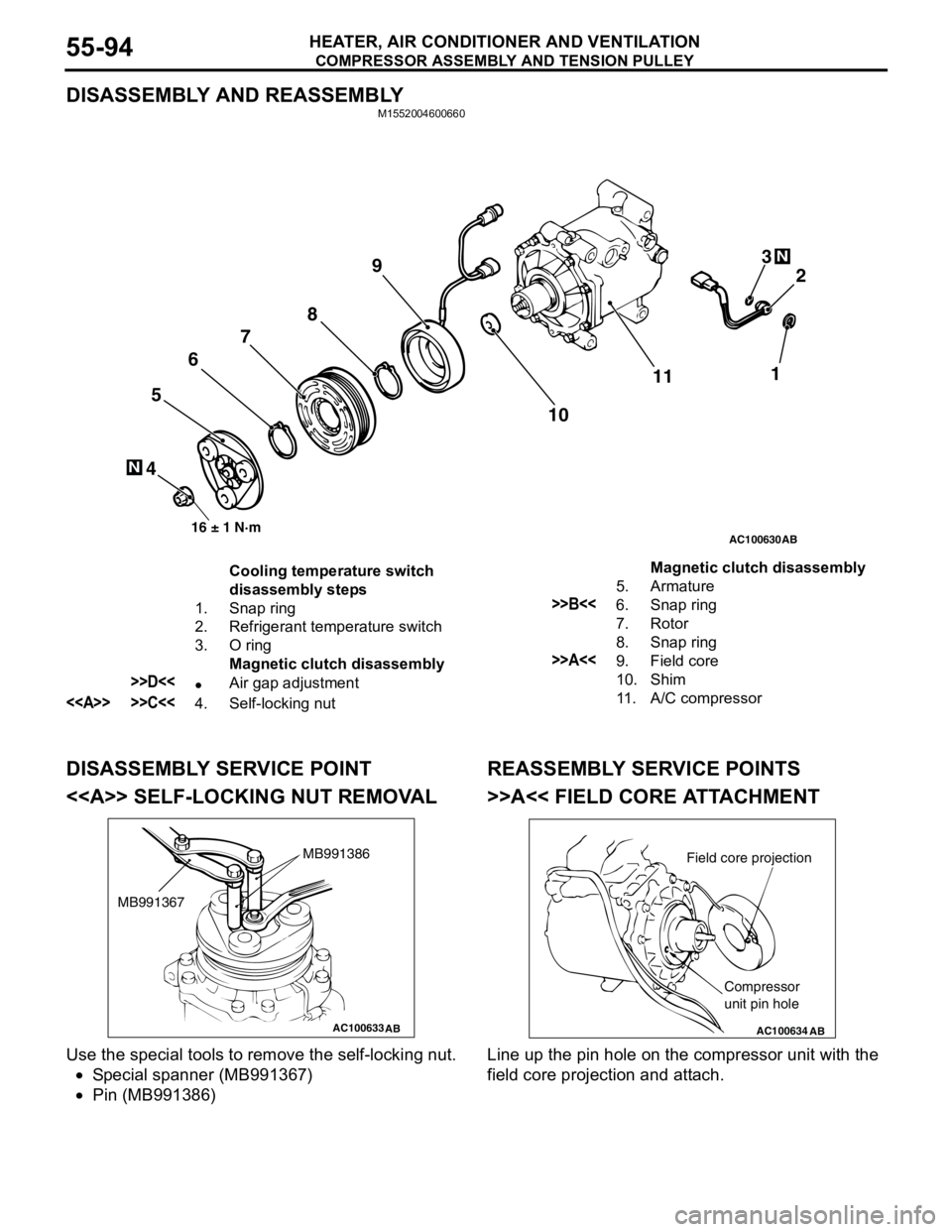

>>B<< SNAP RING INSTALLATION

Using snap ring pliers, fit the snap ring so that the

snap ring’s tapered part is on the outside.

>>C<< SELF-LOCKING NUT

INSTALLATION

Use the special tools to install the self-locking nut.

•Special spanner (MB991367)

•Pin (MB991386)

>>D<< AIR GAP ADJUSTMENT

Check that the clutch air gap is inside the standard

value. If outside the standard value, use a shim to

adjust the gap.

Standard value: 0.3 − 0.5 mm

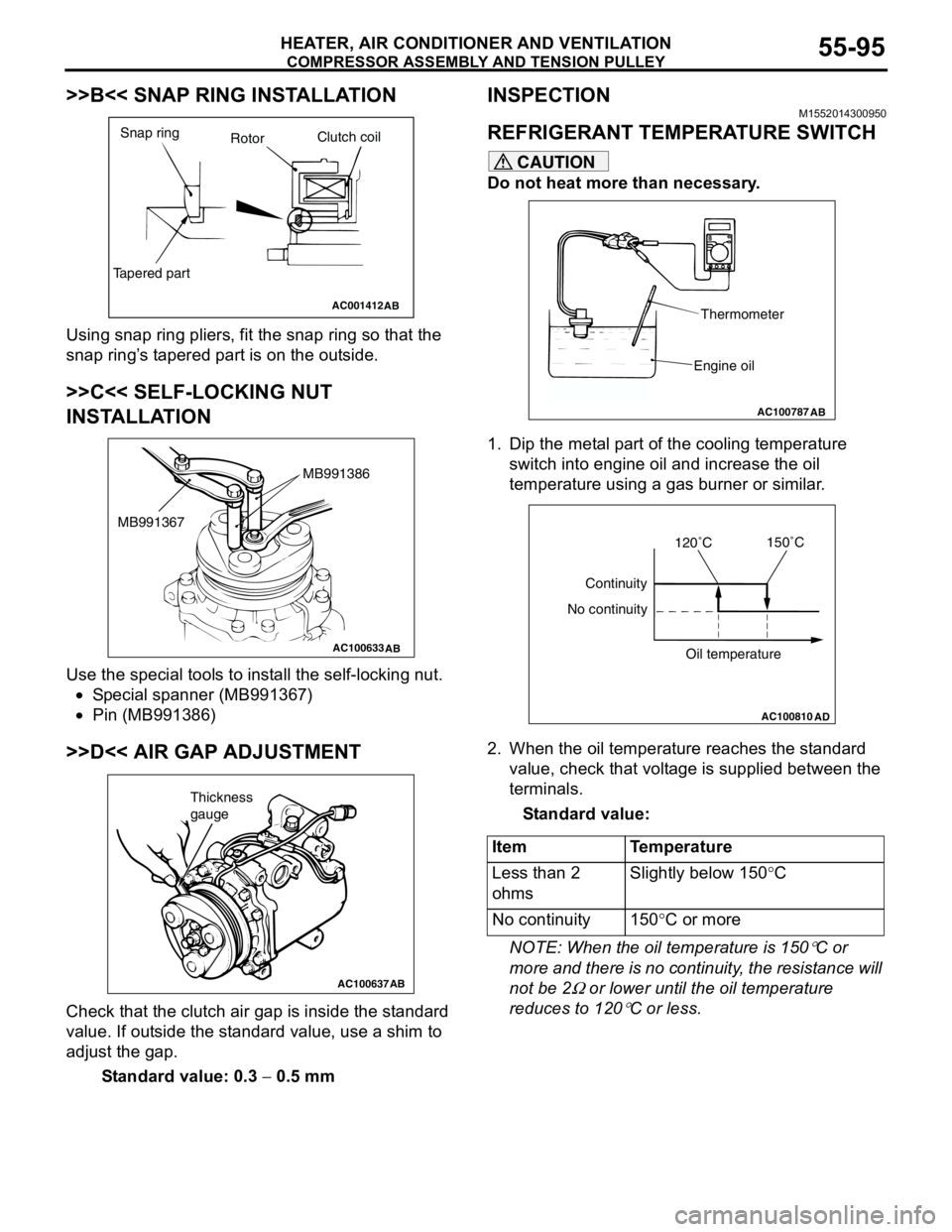

INSPECTIONM1552014300950

REFRIGERANT TEMPERATURE SWITCH

CAUTION

Do not heat more than necessary.

1. Dip the metal part of the cooling temperature

switch into engine oil and increase the oil

temperature using a gas burner or similar.

2. When the oil temperature reaches the standard

value, check that voltage is supplied between the

terminals.

Standard value:

NOTE: When the oil temperature is 150

°C or

more and there is no continuity, the resistance will

not be 2

Ω or lower until the oil temperature

reduces to 120

°C or less.

AC001412

Snap ring

RotorClutch coil

Tapered part

AB

AC100633AB

MB991386

MB991367

AC100637AB

Thickness

gauge

Item Temperature

Less than 2

ohmsSlightly below 150°C

No continuity 150°C or more

AC100787

Thermometer

Engine oil

AB

AC100810

Continuity

No continuity

Oil temperature

AD

120˚C150˚C

Page 580 of 788

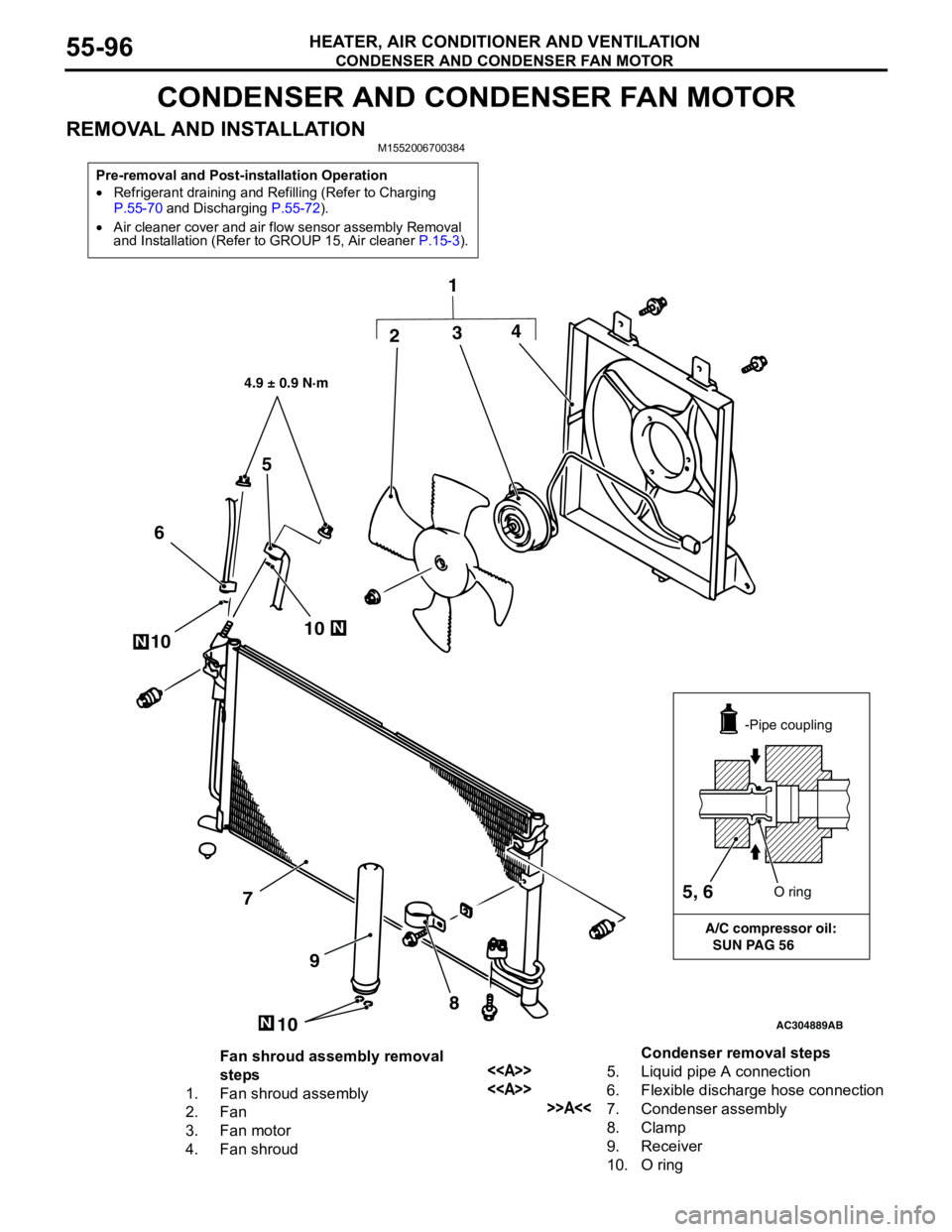

CONDENSER AND CONDENSER FAN MOTOR

HEATER, AIR CONDITIONER AND VENTILATION55-96

CONDENSER AND CONDENSER FAN MOTOR

REMOVAL AND INSTALLATIONM1552006700384

Pre-removal and Post-installation Operation

•Refrigerant draining and Refilling (Refer to Charging

P.55-70 and Discharging P.55-72).

•Air cleaner cover and air flow sensor assembly Removal

and Installation (Refer to GROUP 15, Air cleaner P.15-3).

AC304889

5, 6

A/C compressor oil:

SUN PAG 56-Pipe coupling

O ring

2

5

10

106

7

9

8

1034

1

NN

NAB

4.9 ± 0.9 N·m

Fan shroud assembly removal

steps

1. Fan shroud assembly

2. Fan

3. Fan motor

4. Fan shroudCondenser removal steps<>5. Liquid pipe A connection

<>6. Flexible discharge hose connection

>>A<<7. Condenser assembly

8. Clamp

9. Receiver

10. O ring