Transmission control system MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 1 of 788

GROUP INDEX

00General . . . . . . . . . . . . . . . . . . . . . . . .

11Engine. . . . . . . . . . . . . . . . . . . . . . . . .

12Engine Lubrication . . . . . . . . . . . . . .

13Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . .

14Engine Cooling . . . . . . . . . . . . . . . . .

15Intake and Exhaust . . . . . . . . . . . . . .

16Engine Electrical . . . . . . . . . . . . . . . .

17Engine and Emission Control . . . . .

21Clutch . . . . . . . . . . . . . . . . . . . . . . . . .

22Manual Transmission . . . . . . . . . . . .

23Automatic Transmission. . . . . . . . . .

26Front Axle . . . . . . . . . . . . . . . . . . . . . .

27Rear Axle . . . . . . . . . . . . . . . . . . . . . .

31Wheel and Tyre . . . . . . . . . . . . . . . . .

32Power Plant Mount . . . . . . . . . . . . . .

33Front Suspension . . . . . . . . . . . . . . .

34Rear Suspension . . . . . . . . . . . . . . . .

35Service Brakes . . . . . . . . . . . . . . . . . .

36Parking Brakes . . . . . . . . . . . . . . . . .

37Power Steering . . . . . . . . . . . . . . . . .

42Body . . . . . . . . . . . . . . . . . . . . . . . . . .

51Exterior . . . . . . . . . . . . . . . . . . . . . . . .

52 . . . . . . . . . .

54Chassis Electrical . . . . . . . . . . . . . . .

55 . . . . . . .

70Component Locations. . . . . . . . . . . .

80Configration Diagrams . . . . . . . . . . .

90Circuit Diagrams . . . . . . . . . . . . . . . .

LANCER /

LANCER WAGON

WORKSHOP MANUAL

FOREWORD

This Workshop manual contains procedures for

service mechanics, including removal, disassembly,

inspection, adjustment, reassembly and installation.

Use the following manuals in combination with this

manual as required.

TECHNICAL INFORMATION MANUAL

PYME0302

PYME0302-A

WORKSHOP MANUAL

CHASSIS GROUP PWME0302

BODY REPAIR MANUAL

PBME0302

PBME0302-A

PARTS CATALOGUE

B606K005A_

All information, illustrations and product descriptions

contained in this manual are current as at the time of

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

Mitsubishi Motors Corporation May 2004

Heater, Air Conditioner and

Ventilation Interior and Supplemental

Restraint System (SRS)

Page 94 of 788

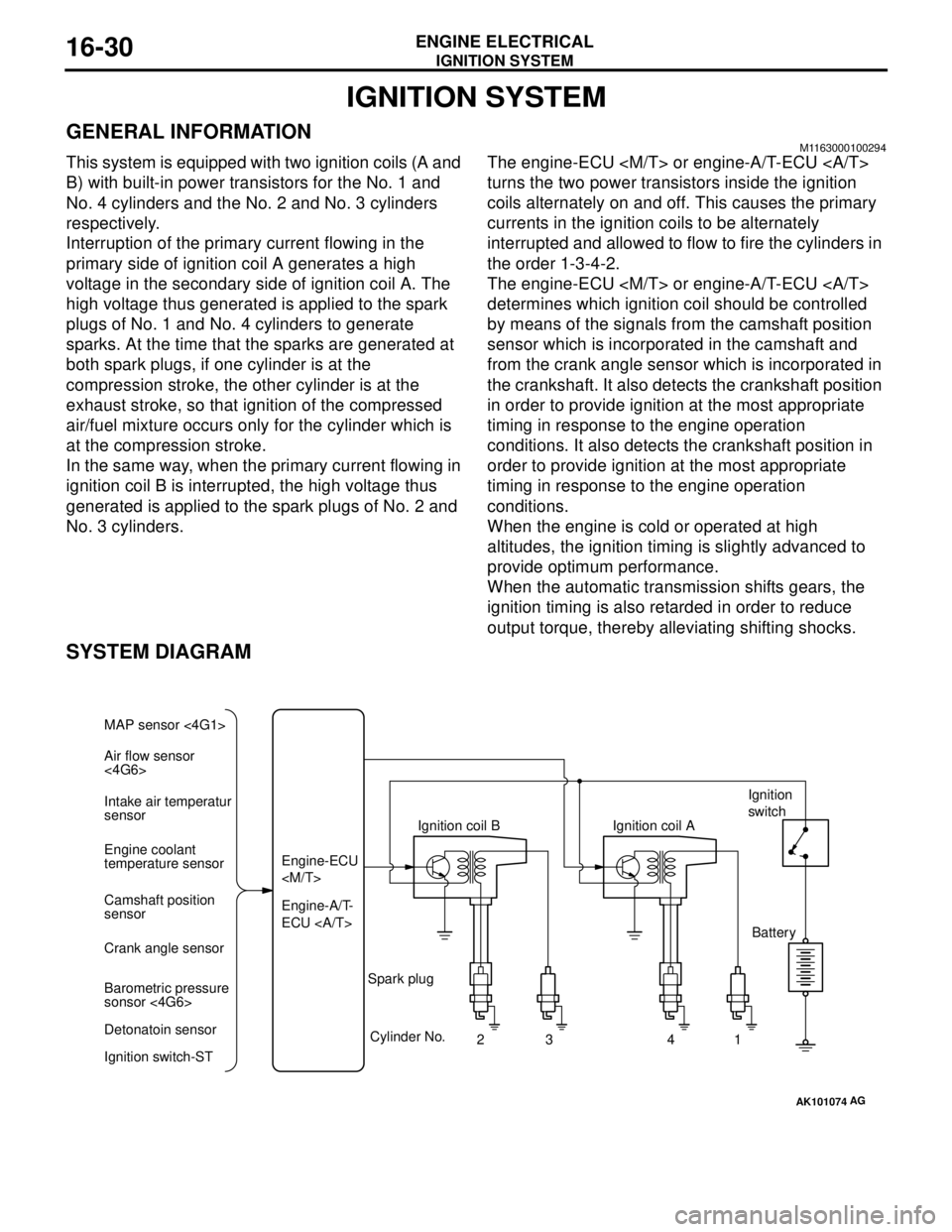

IGNITION SYSTEM

ENGINE ELECTRICAL16-30

IGNITION SYSTEM

GENERAL INFORMATIONM1163000100294

This system is equipped with two ignition coils (A and

B) with built-in power transistors for the No. 1 and

No. 4 cylinders and the No. 2 and No. 3 cylinders

respectively.

Interruption of the primary current flowing in the

primary side of ignition coil A generates a high

voltage in the secondary side of ignition coil A. The

high voltage thus generated is applied to the spark

plugs of No. 1 and No. 4 cylinders to generate

sparks. At the time that the sparks are generated at

both spark plugs, if one cylinder is at the

compression stroke, the other cylinder is at the

exhaust stroke, so that ignition of the compressed

air/fuel mixture occurs only for the cylinder which is

at the compression stroke.

In the same way, when the primary current flowing in

ignition coil B is interrupted, the high voltage thus

generated is applied to the spark plugs of No. 2 and

No. 3 cylinders.The engine-ECU

turns the two power transistors inside the ignition

coils alternately on and off. This causes the primary

currents in the ignition coils to be alternately

interrupted and allowed to flow to fire the cylinders in

the order 1-3-4-2.

The engine-ECU

determines which ignition coil should be controlled

by means of the signals from the camshaft position

sensor which is incorporated in the camshaft and

from the crank angle sensor which is incorporated in

the crankshaft. It also detects the crankshaft position

in order to provide ignition at the most appropriate

timing in response to the engine operation

conditions. It also detects the crankshaft position in

order to provide ignition at the most appropriate

timing in response to the engine operation

conditions.

When the engine is cold or operated at high

altitudes, the ignition timing is slightly advanced to

provide optimum performance.

When the automatic transmission shifts gears, the

ignition timing is also retarded in order to reduce

output torque, thereby alleviating shifting shocks.

SYSTEM DIAGRAM

AK101074

Air flow sensor

<4G6> MAP sensor <4G1>

Intake air temperatur

sensor

Engine coolant

temperature sensor

Camshaft position

sensor

Crank angle sensor

Barometric pressure

sonsor <4G6>

Detonatoin sensor

Ignition switch-STEngine-A/T-

ECU Engine-ECU

Cylinder No.

23 4

AG

1 Spark plugIgnition coil AIgnition

switch

Battery

Page 560 of 788

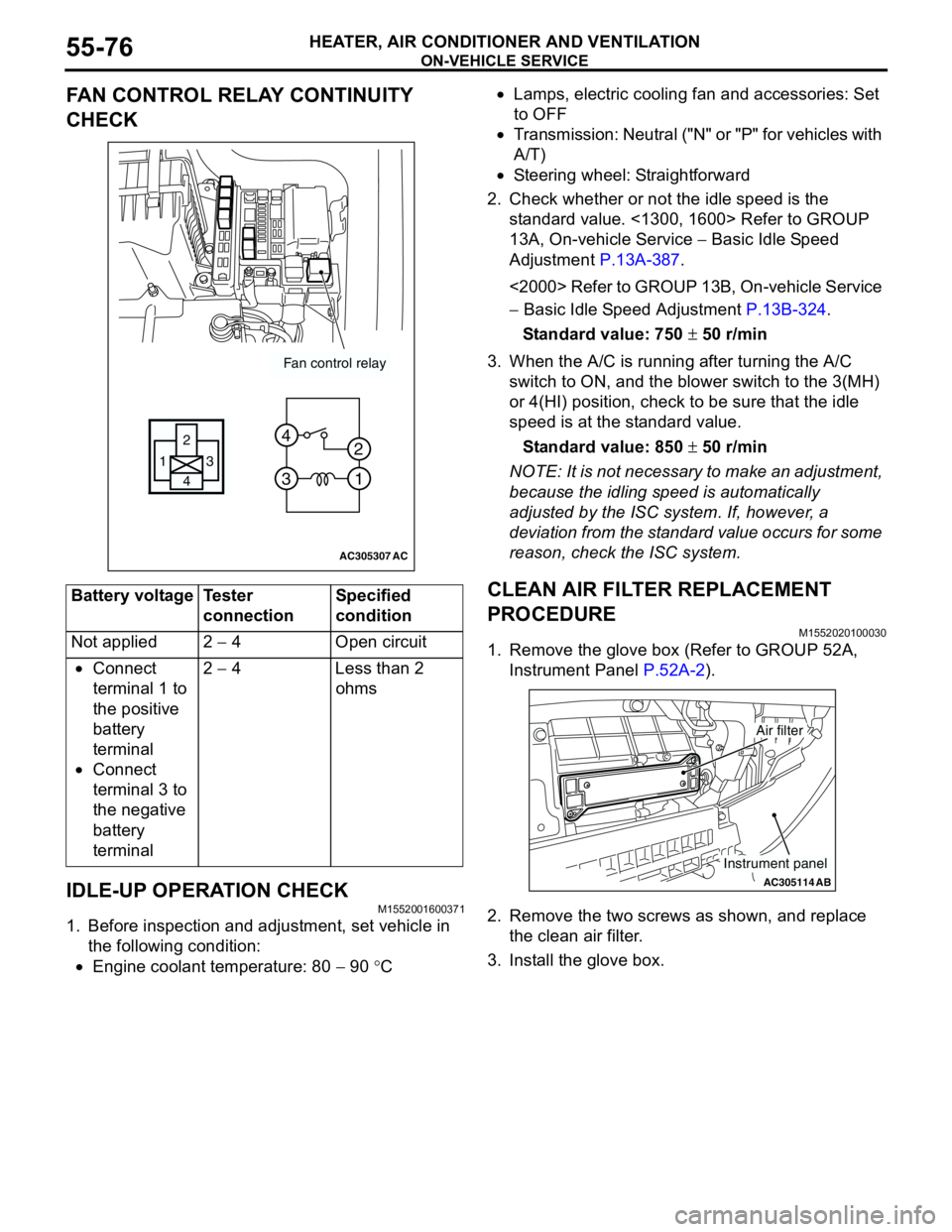

ON-VEHICLE SERVICE

HEATER, AIR CONDITIONER AND VENTILATION55-76

FAN CONTROL RELAY CONTINUITY

CHECK

IDLE-UP OPERATION CHECK

M1552001600371

1. Before inspection and adjustment, set vehicle in

the following condition:

•Engine coolant temperature: 80 − 90 °C•Lamps, electric cooling fan and accessories: Set

to OFF

•Transmission: Neutral ("N" or "P" for vehicles with

A/T)

•Steering wheel: Straightforward

2. Check whether or not the idle speed is the

standard value. <1300, 1600> Refer to GROUP

13A, On-vehicle Service − Basic Idle Speed

Adjustment P.13A-387.

<2000> Refer to GROUP 13B, On-vehicle Service

− Basic Idle Speed Adjustment P.13B-324.

Standard value: 750 ± 50 r/min

3. When the A/C is running after turning the A/C

switch to ON, and the blower switch to the 3(MH)

or 4(HI) position, check to be sure that the idle

speed is at the standard value.

Standard value: 850 ± 50 r/min

NOTE: It is not necessary to make an adjustment,

because the idling speed is automatically

adjusted by the ISC system. If, however, a

deviation from the standard value occurs for some

reason, check the ISC system.

CLEAN AIR FILTER REPLACEMENT

PROCEDURE

M1552020100030

1. Remove the glove box (Refer to GROUP 52A,

Instrument Panel P.52A-2).

2. Remove the two screws as shown, and replace

the clean air filter.

3. Install the glove box. Battery voltage Tester

connectionSpecified

condition

Not applied 2 − 4 Open circuit

•Connect

terminal 1 to

the positive

battery

terminal

•Connect

terminal 3 to

the negative

battery

terminal2 − 4 Less than 2

ohms

AC305307

Fan control relay

13

4 2

3 4

1 2

AC

AC305114AB

Air filter

Instrument panel

Page 615 of 788

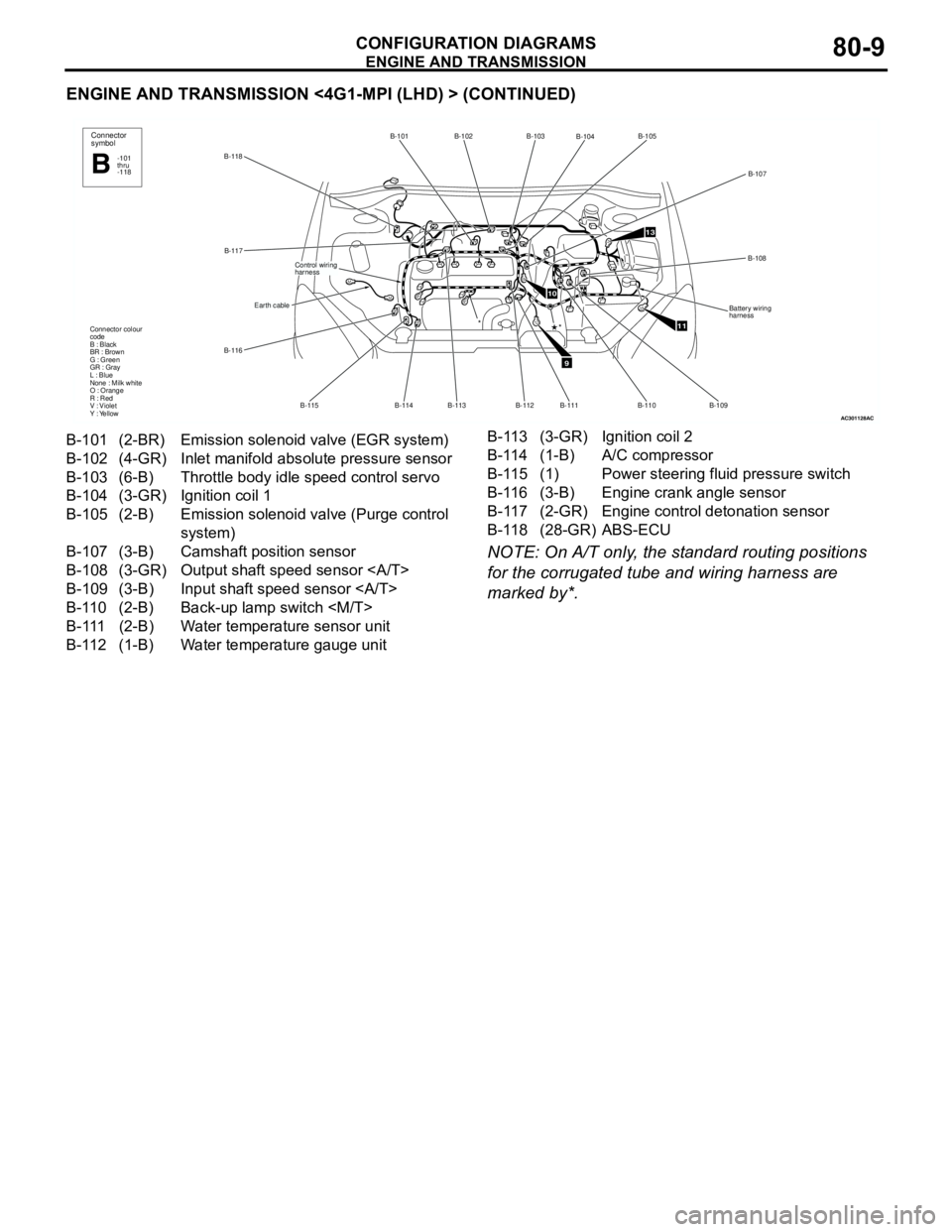

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-9

ENGINE AND TRANSMISSION <4G1-MPI (LHD) > (CONTINUED)

NOTE: On A/T only, the standard routing positions

for the corrugated tube and wiring harness are

marked by*.

AC301128

B-118B-101 B-102

B-113

B-114 B-115 B-116B-117

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118B

*

AC

9

10

11

13

B-103

B-104B-105

B-107

B-108

Battery wiring

harness

B-109

B-110 B-111

*

B-112

B-101 (2-BR) Emission solenoid valve (EGR system)

B-102 (4-GR) Inlet manifold absolute pressure sensor

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-107 (3-B) Camshaft position sensor

B-108 (3-GR) Output shaft speed sensor

B-109 (3-B) Input shaft speed sensor

B-110 (2-B) Back-up lamp switch

B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unitB-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

Page 617 of 788

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-11

ENGINE AND TRANSMISSION <4G1-MPI (RHD) > (CONTINUED)

NOTE: On A/T only, the standard routing positions

for the corrugated tube and wiring harness are

marked by*.

AC301131

B-117B-101 B-102

B-113 B-114 B-115 B-116

Earth cable

Control wiring

harness

Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118B

*

AC

9

10

11

13

B-103

B-104B-105

B-107

B-108

Battery wiring

harness

B-109 B-110 B-111

*

B-112

B-118

B-101 (2-BR) Emission solenoid valve (EGR system)

B-102 (4-GR) Inlet manifold absolute pressure sensor

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-107 (3-B) Camshaft position sensor

B-108 (3-GR) Output shaft speed sensor

B-109 (3-B) Input shaft speed sensor

B-110 (2-B) Back-up lamp switch

B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unitB-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

Page 619 of 788

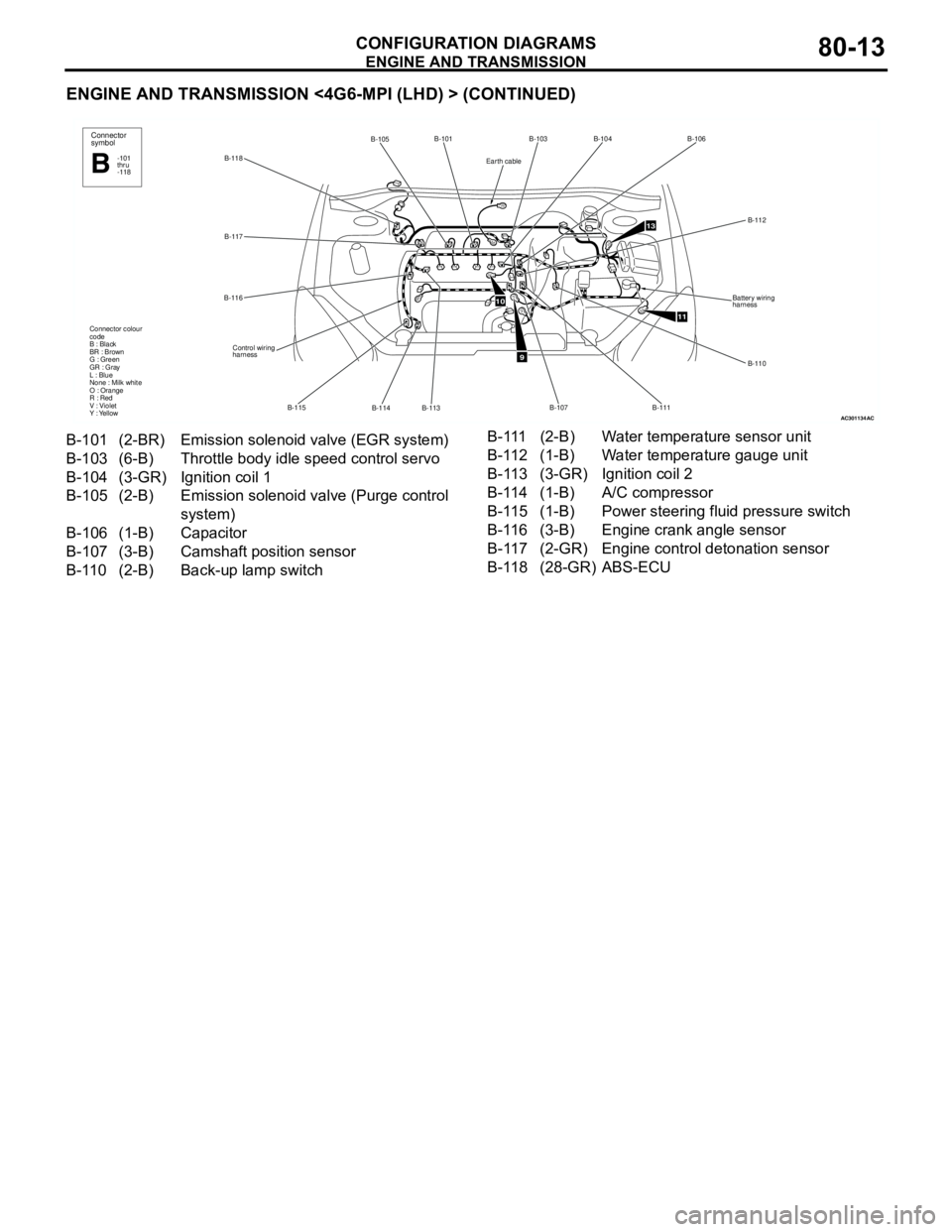

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-13

ENGINE AND TRANSMISSION <4G6-MPI (LHD) > (CONTINUED)

AC301134

B-118B-101

B-114 B-115 B-116B-117

Control wiring

harness Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

B-113

B-105Connector

symbol

-101

thru

-118B

AC

9

10

11

13

B-103B-104B-106

B-112

B-110 Battery wiring

harness

B-111

B-107

Earth cable

B-101 (2-BR) Emission solenoid valve (EGR system)

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-106 (1-B) Capacitor

B-107 (3-B) Camshaft position sensor

B-110 (2-B) Back-up lamp switch B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unit

B-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1-B) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU

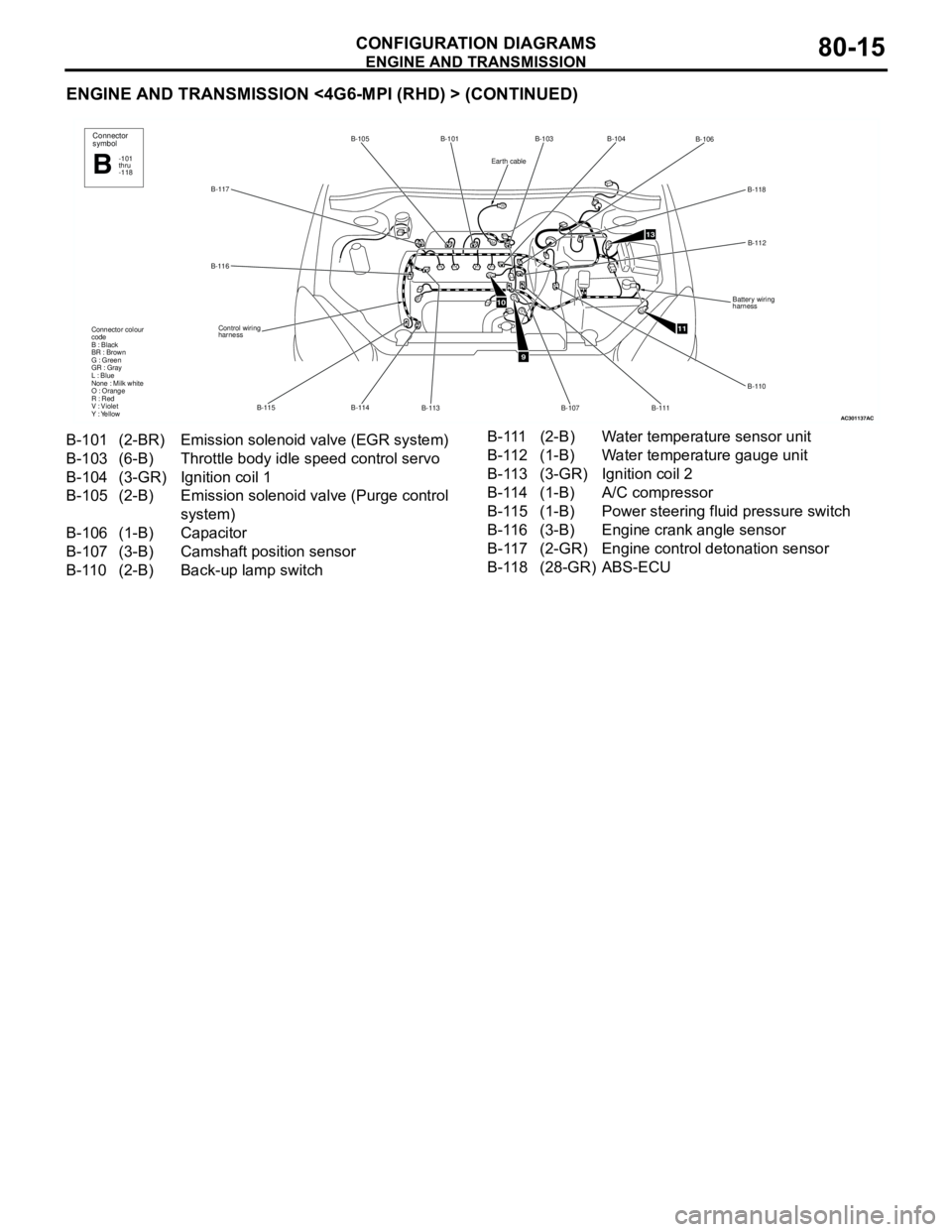

Page 621 of 788

ENGINE AND TRANSMISSION

CONFIGURATION DIAGRAMS80-15

ENGINE AND TRANSMISSION <4G6-MPI (RHD) > (CONTINUED)

AC301137

B-117B-105 B-101

B-113 B-114 B-115 B-116

Control wiring

harness Connector colour

code

B : Black

BR : Brown

G : Green

GR : Gray

L : Blue

None : Milk white

O : Orange

R : Red

V : Violet

Y : Yellow

Connector

symbol

-101

thru

-118B

AC

9

11

13

B-103

B-106

B-118

B-112

Battery wiring

harness

B-110

B-111

B-107

B-104

10

Earth cable

B-101 (2-BR) Emission solenoid valve (EGR system)

B-103 (6-B) Throttle body idle speed control servo

B-104 (3-GR) Ignition coil 1

B-105 (2-B) Emission solenoid valve (Purge control

system)

B-106 (1-B) Capacitor

B-107 (3-B) Camshaft position sensor

B-110 (2-B) Back-up lamp switch B-111 (2-B) Water temperature sensor unit

B-112 (1-B) Water temperature gauge unit

B-113 (3-GR) Ignition coil 2

B-114 (1-B) A/C compressor

B-115 (1-B) Power steering fluid pressure switch

B-116 (3-B) Engine crank angle sensor

B-117 (2-GR) Engine control detonation sensor

B-118 (28-GR) ABS-ECU