key MITSUBISHI LANCER 2005 Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 178 of 788

CROSSMEMBER

POWER PLANT MOUNT32-8

INSTALLATION SERVICE POINTS

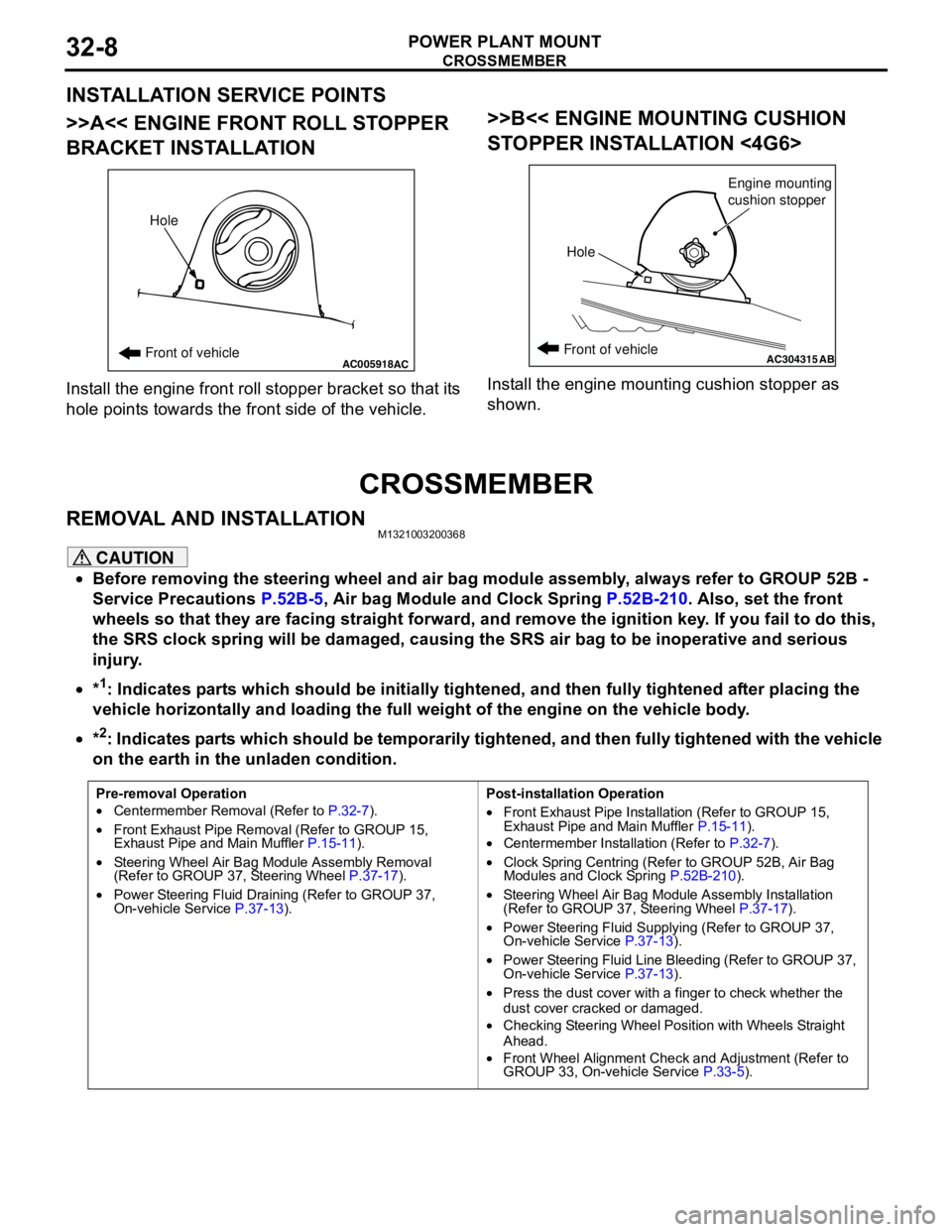

>>A<< ENGINE FRONT ROLL STOPPER

BRACKET INSTALLATION

Install the engine front roll stopper bracket so that its

hole points towards the front side of the vehicle.

>>B<< ENGINE MOUNTING CUSHION

STOPPER INSTALLATION <4G6>

Install the engine mounting cushion stopper as

shown.

CROSSMEMBER

REMOVAL AND INSTALLATIONM1321003200368

CAUTION

•Before removing the steering wheel and air bag module assembly, always refer to GROUP 52B -

Service Precautions P.52B-5, Air bag Module and Clock Spring P.52B-210. Also, set the front

wheels so that they are facing straight forward, and remove the ignition key. If you fail to do this,

the SRS clock spring will be damaged, causing the SRS air bag to be inoperative and serious

injury.

•*

1: Indicates parts which should be initially tightened, and then fully tightened after placing the

vehicle horizontally and loading the full weight of the engine on the vehicle body.

•*

2: Indicates parts which should be temporarily tightened, and then fully tightened with the vehicle

on the earth in the unladen condition.

AC005918Front of vehicleHoleACAC304315ABFront of vehicle

HoleEngine mounting

cushion stopper

Pre-removal Operation

•Centermember Removal (Refer to P.32-7).

•Front Exhaust Pipe Removal (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Steering Wheel Air Bag Module Assembly Removal

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Draining (Refer to GROUP 37,

On-vehicle Service P.37-13).Post-installation Operation

•Front Exhaust Pipe Installation (Refer to GROUP 15,

Exhaust Pipe and Main Muffler P.15-11).

•Centermember Installation (Refer to P.32-7).

•Clock Spring Centring (Refer to GROUP 52B, Air Bag

Modules and Clock Spring P.52B-210).

•Steering Wheel Air Bag Module Assembly Installation

(Refer to GROUP 37, Steering Wheel P.37-17).

•Power Steering Fluid Supplying (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Power Steering Fluid Line Bleeding (Refer to GROUP 37,

On-vehicle Service P.37-13).

•Press the dust cover with a finger to check whether the

dust cover cracked or damaged.

•Checking Steering Wheel Position with Wheels Straight

Ahead.

•Front Wheel Alignment Check and Adjustment (Refer to

GROUP 33, On-vehicle Service P.33-5).

Page 255 of 788

STEERING SHAFT

POWER STEERING37-21

STEERING SHAFT

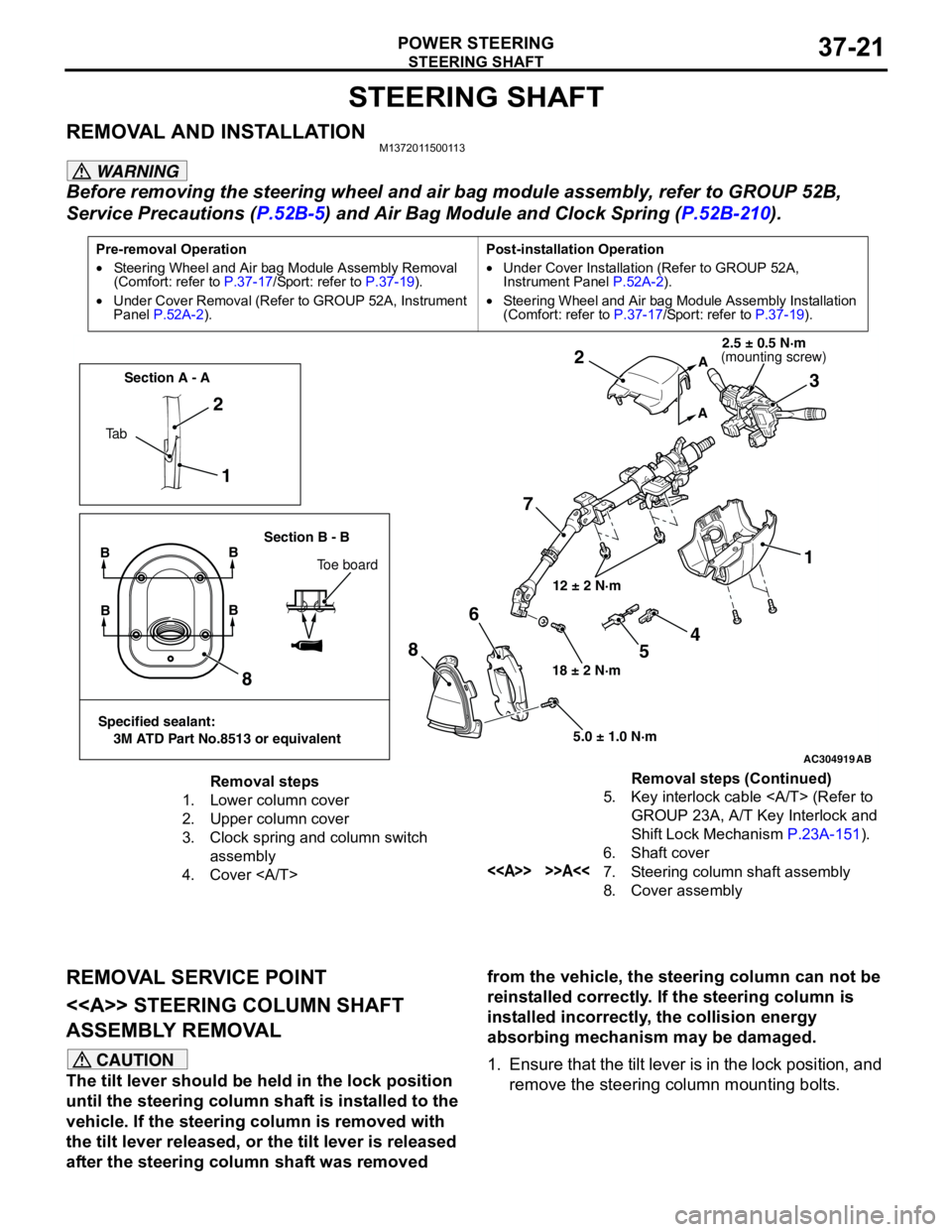

REMOVAL AND INSTALLATIONM1372011500113

WARNING

Before removing the steering wheel and air bag module assembly, refer to GROUP 52B,

Service Precautions (P.52B-5) and Air Bag Module and Clock Spring (P.52B-210).

REMOVAL SERVICE POINT

<> STEERING COLUMN SHAFT

ASSEMBLY REMOVAL

CAUTION

The tilt lever should be held in the lock position

until the steering column shaft is installed to the

vehicle. If the steering column is removed with

the tilt lever released, or the tilt lever is released

after the steering column shaft was removed from the vehicle, the steering column can not be

reinstalled correctly. If the steering column is

installed incorrectly, the collision energy

absorbing mechanism may be damaged.

1. Ensure that the tilt lever is in the lock position, and

remove the steering column mounting bolts.

Pre-removal Operation

•Steering Wheel and Air bag Module Assembly Removal

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

•Under Cover Removal (Refer to GROUP 52A, Instrument

Panel P.52A-2).Post-installation Operation

•Under Cover Installation (Refer to GROUP 52A,

Instrument Panel P.52A-2).

•Steering Wheel and Air bag Module Assembly Installation

(Comfort: refer to P.37-17/Sport: refer to P.37-19).

AC304919AB

12 ± 2 N·m

18 ± 2 N·m

5.0 ± 1.0 N·m

1 2

73 2

1

8

86

A

A

Ta bSection A - A

Section B - B

BB

Toe board

Specified sealant:

3M ATD Part No.8513 or equivalent

BB

4

5

(mounting screw)2.5 ± 0.5 N·m

Removal steps

1. Lower column cover

2. Upper column cover

3. Clock spring and column switch

assembly

4. Cover 5. Key interlock cable (Refer to

GROUP 23A, A/T Key Interlock and

Shift Lock Mechanism P.23A-151).

6. Shaft cover

<> >>A<<7. Steering column shaft assembly

8. Cover assemblyRemoval steps (Continued)

Page 280 of 788

42-2

TROUBLESHOOTING . . . . . . . . . .42-26

ON-VEHICLE SERVICE. . . . . . . . .42-27

DOOR FIT ADJUSTMENT. . . . . . . . . . . 42-27

DOOR WINDOW GLASS ADJUSTMENT42-28

GLASS SLIDING MECHANISM CHECK

AND ADJUSTMENT . . . . . . . . . . . . . . . 42-28

POWER WINDOW OPERATING

CURRENT CHECK . . . . . . . . . . . . . . . . 42-28

POWER WINDOW RELAY CHECK . . . 42-29

CIRCUIT BREAKER (INCORPORATED

IN THE POWER WINDOW MOTOR)

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

POWER WINDOW CHECK . . . . . . . . . . 42-29

CENTRAL DOOR LOCKING SYSTEM

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR OUTSIDE HANDLE PLAY

CHECK . . . . . . . . . . . . . . . . . . . . . . . . . 42-29

DOOR INSIDE HANDLE PLAY

ADJUSTMENT . . . . . . . . . . . . . . . . . . . . 42-30

DOOR ASSEMBLY . . . . . . . . . . . .42-31

REMOVAL AND INSTALLATION . . . . . 42-31

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-32

DOOR GLASS AND

REGULATOR . . . . . . . . . . . . . . . . .

42-32

REMOVAL AND INSTALLATION . . . . . 42-32

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-34

DOOR HANDLE AND LATCH . . . .42-36

REMOVAL AND INSTALLATION . . . . . 42-36

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-37

WINDOW GLASS RUNCHANNEL AND

DOOR OPENING

WEATHERSTRIP . . . . . . . . . . . . . .

42-39

REMOVAL AND INSTALLATION . . . . . 42-39

TRUNK LID . . . . . . . . . . . . . . . .42-41

SPECIAL TOOL . . . . . . . . . . . . . . .

42-41

ON-VEHICLE SERVICE. . . . . . . . .42-41

TRUNK LID ADJUSTMENT . . . . . . . . . . 42-41

ADJUSTMENT OF CLEARANCE

AROUND TRUNK LID . . . . . . . . . . . . . . 42-42

TRUNK LID STRIKER ADJUSTMENT . 42-42

TRUNK LID HEIGHT ADJUSTMENT . . 42-42

TRUNK LID . . . . . . . . . . . . . . . . . . .42-43

REMOVAL AND INSTALLATION . . . . . . 42-43

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-45

TAILGATE . . . . . . . . . . . . . . . . 42-46

SERVICE SPECIFICATIONS . . . . .

42-46

SEALANTS . . . . . . . . . . . . . . . . . . .42-46

SPECIAL TOOL . . . . . . . . . . . . . . .42-46

TROUBLESHOOTING . . . . . . . . . .42-46

ON-VEHICLE SERVICE . . . . . . . . .42-46

TAILGATE FIT ADJUSTMENT. . . . . . . . 42-46

TAILGATE HANDLE PLAY CHECK . . . . 42-47

TAILGATE . . . . . . . . . . . . . . . . . . .42-48

REMOVAL AND INSTALLATION . . . . . . 42-48

TAILGATE HANDLE AND

LATCH . . . . . . . . . . . . . . . . . . . . . .

42-50

REMOVAL AND INSTALLATION . . . . . . 42-50

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-51

KEYLESS ENTRY SYSTEM . . 42-51

SERVICE SPECIFICATIONS . . . . .

42-51

SPECIAL TOOLS . . . . . . . . . . . . . .42-52

TROUBLESHOOTING . . . . . . . . . .42-53

ON-VEHICLE SERVICE . . . . . . . . .42-53

KEYLESS ENTRY SYSTEM CHECK. . . 42-53

KEYLESS ENTRY SYSTEM TIMER

LOCK FUNCTION INSPECTION . . . . . . 42-53

ENABLING/DISABLING

THE ANSWERBACK FUNCTION . . . . . 42-53

HOW TO REGISTER SECRET CODE . 42-55

TRANSMITTER. . . . . . . . . . . . . . . .42-58

DISASSEMBLY AND REASSEMBLY . . 42-58

INSPECTION . . . . . . . . . . . . . . . . . . . . . 42-59

Page 307 of 788

DOOR

BODY42-29

3. If the operation current is outside the standard

value, refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

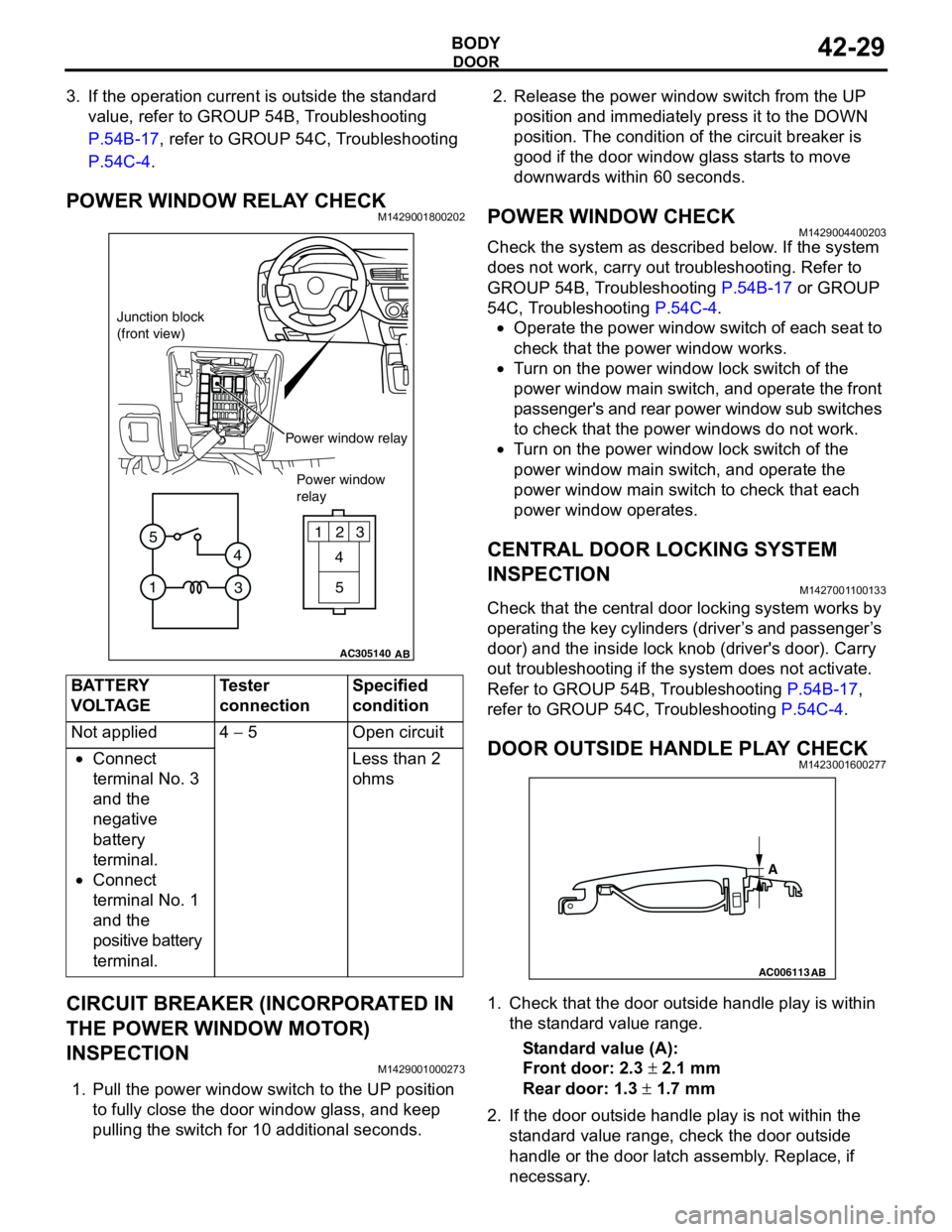

POWER WINDOW RELAY CHECKM1429001800202

CIRCUIT BREAKER (INCORPORATED IN

THE POWER WINDOW MOTOR)

INSPECTION

M1429001000273

1. Pull the power window switch to the UP position

to fully close the door window glass, and keep

pulling the switch for 10 additional seconds.2. Release the power window switch from the UP

position and immediately press it to the DOWN

position. The condition of the circuit breaker is

good if the door window glass starts to move

downwards within 60 seconds.

POWER WINDOW CHECKM1429004400203

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

•Operate the power window switch of each seat to

check that the power window works.

•Turn on the power window lock switch of the

power window main switch, and operate the front

passenger's and rear power window sub switches

to check that the power windows do not work.

•Turn on the power window lock switch of the

power window main switch, and operate the

power window main switch to check that each

power window operates.

CENTRAL DOOR LOCKING SYSTEM

INSPECTION

M1427001100133

Check that the central door locking system works by

operating the key cylinders (driver’s and passenger’s

door) and the inside lock knob (driver's door). Carry

out troubleshooting if the system does not activate.

Refer to GROUP 54B, Troubleshooting P.54B-17,

refer to GROUP 54C, Troubleshooting P.54C-4.

DOOR OUTSIDE HANDLE PLAY CHECKM1423001600277

1. Check that the door outside handle play is within

the standard value range.

Standard value (A):

Front door: 2.3 ± 2.1 mm

Rear door: 1.3 ± 1.7 mm

2. If the door outside handle play is not within the

standard value range, check the door outside

handle or the door latch assembly. Replace, if

necessary. BATTERY

VOLTAGETester

connectionSpecified

condition

Not applied 4 − 5 Open circuit

•Connect

terminal No. 3

and the

negative

battery

terminal.

•Connect

terminal No. 1

and the

positive battery

terminal.Less than 2

ohms

AC305140

123

4

5

1

3 4 5

AB

Junction block

(front view)

Power window relay

Power window

relay

AC006113

AB

A

Page 314 of 788

DOOR

BODY42-36

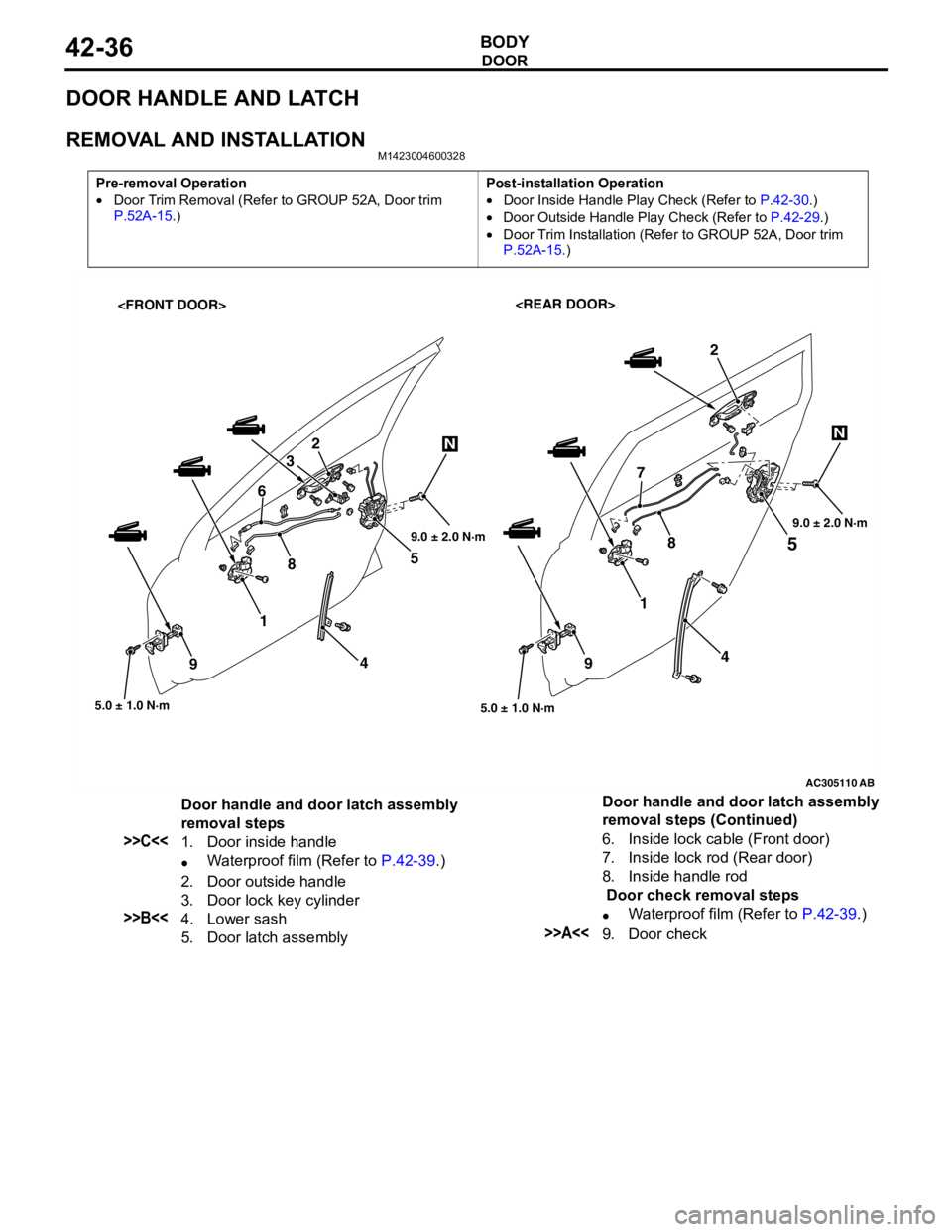

DOOR HANDLE AND LATCH

REMOVAL AND INSTALLATIONM1423004600328

Pre-removal Operation

•Door Trim Removal (Refer to GROUP 52A, Door trim

P.52A-15.)Post-installation Operation

•Door Inside Handle Play Check (Refer to P.42-30.)

•Door Outside Handle Play Check (Refer to P.42-29.)

•Door Trim Installation (Refer to GROUP 52A, Door trim

P.52A-15.)

AC305110

5

5.0 ± 1.0 N·m

1

4

9

2

AB

45 2

3

87

5.0 ± 1.0 N·m

1 6

9

NN

89.0 ± 2.0 N·m9.0 ± 2.0 N·m

Door handle and door latch assembly

removal steps

>>C<<1. Door inside handle

•Waterproof film (Refer to P.42-39.)

2. Door outside handle

3. Door lock key cylinder

>>B<<4. Lower sash

5. Door latch assembly6. Inside lock cable (Front door)

7. Inside lock rod (Rear door)

8. Inside handle rod

Door check removal steps

•Waterproof film (Refer to P.42-39.)>>A<<9. Door check Door handle and door latch assembly

removal steps (Continued)

Page 316 of 788

DOOR

BODY42-38

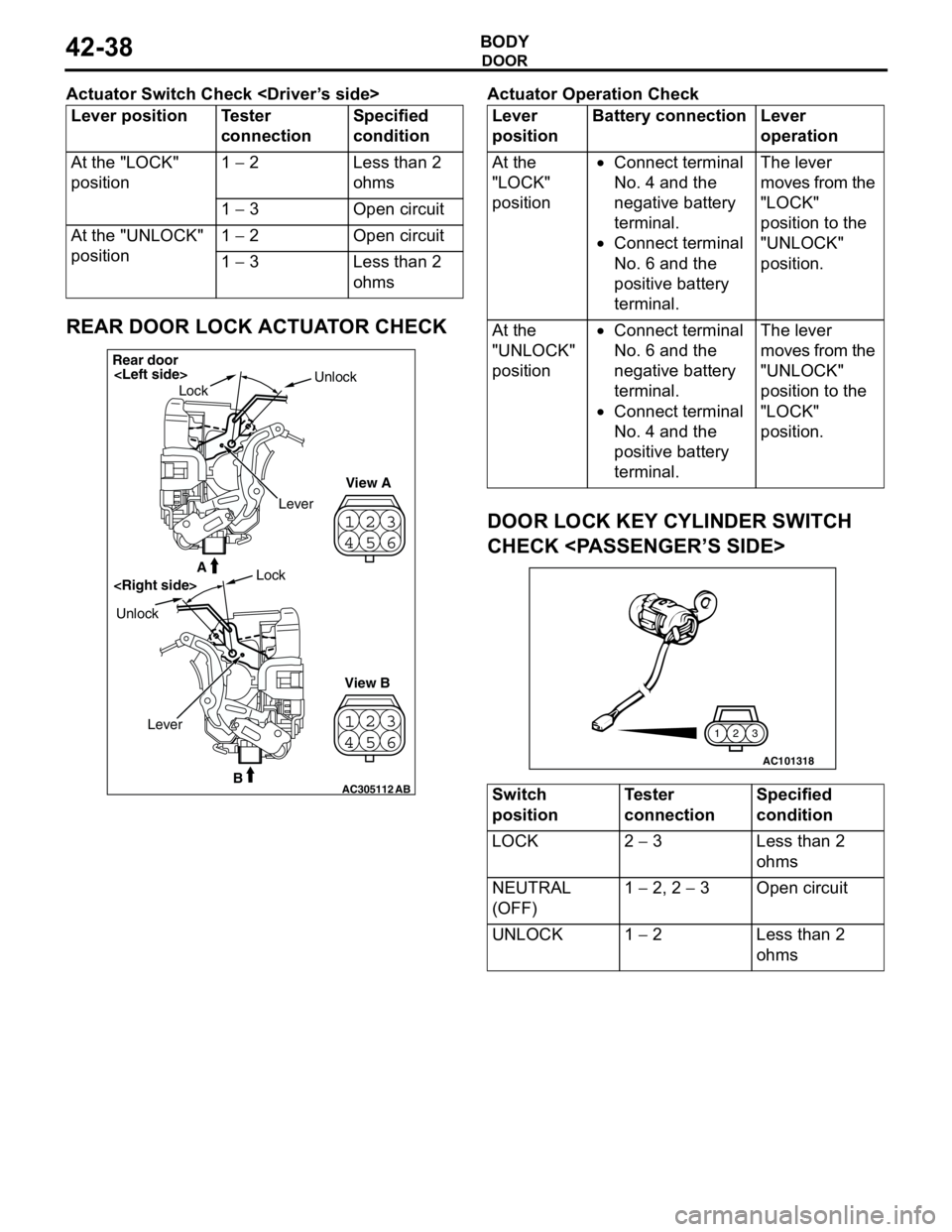

Actuator Switch Check

REAR DOOR LOCK ACTUATOR CHECK

Actuator Operation Check

DOOR LOCK KEY CYLINDER SWITCH

CHECK

Lever position Tester

connectionSpecified

condition

At the "LOCK"

position1 − 2 Less than 2

ohms

1 − 3 Open circuit

At the "UNLOCK"

position1 − 2 Open circuit

1 − 3 Less than 2

ohms

23

41

56

23

41

56

AC305112B

A

AB

Rear door

LockUnlock

View A

View B UnlockLock

Lever

Lever

positionBattery connection Lever

operation

At the

"LOCK"

position•Connect terminal

No. 4 and the

negative battery

terminal.

•Connect terminal

No. 6 and the

positive battery

terminal.The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No. 6 and the

negative battery

terminal.

•Connect terminal

No. 4 and the

positive battery

terminal.The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

Switch

positionTester

connectionSpecified

condition

LOCK 2 − 3 Less than 2

ohms

NEUTRAL

(OFF)1 − 2, 2 − 3 Open circuit

UNLOCK 1 − 2 Less than 2

ohms

AC101318

3 2 1

Page 328 of 788

TA I L G AT E

BODY42-50

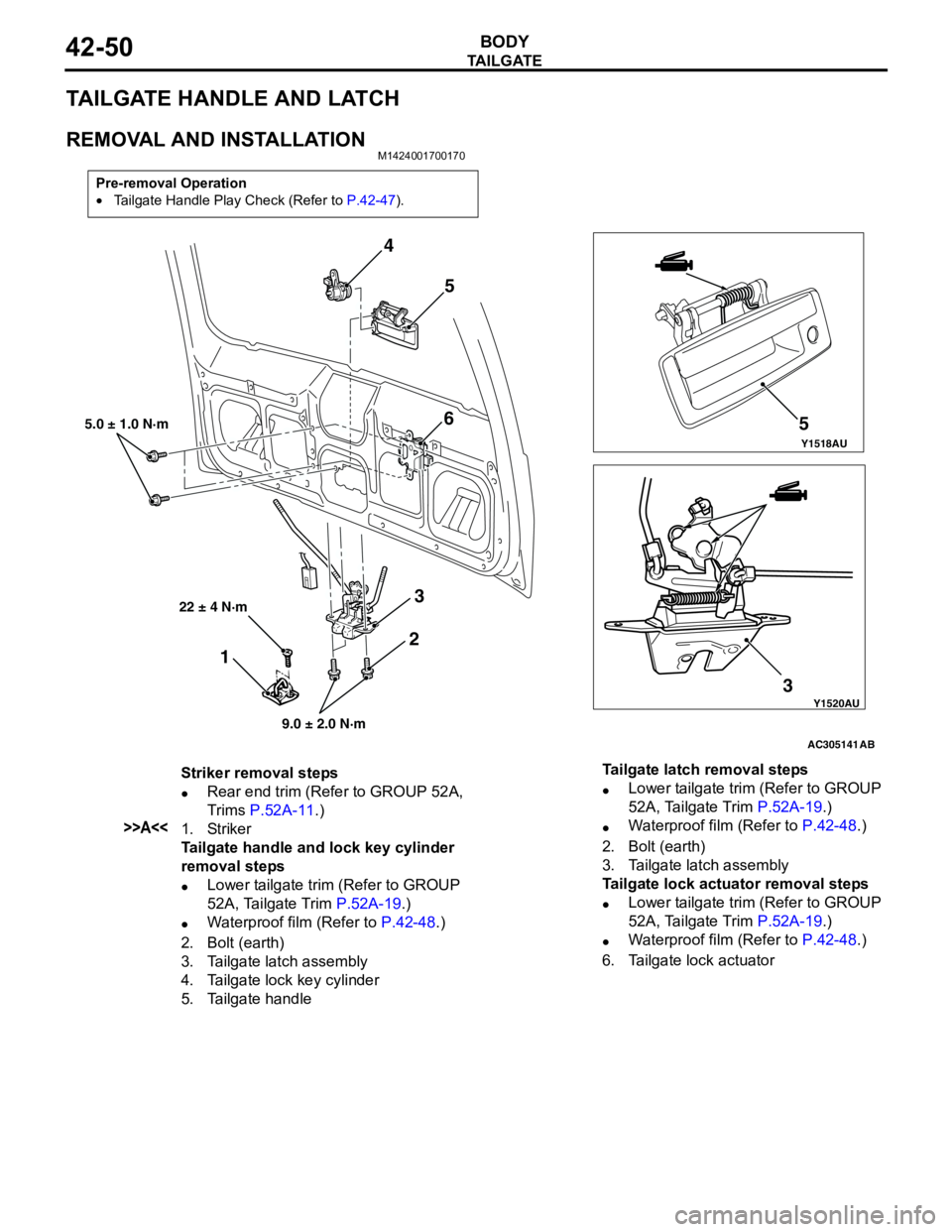

TAILGATE HANDLE AND LATCH

REMOVAL AND INSTALLATIONM1424001700170

Pre-removal Operation

•Tailgate Handle Play Check (Refer to P.42-47).

Y1518AU

Y1520AU

AC305141

4

5

6

3 35

5.0 ± 1.0 N·m

9.0 ± 2.0 N·m

AB

2

1

22 ± 4 N·m

Striker removal steps

•Rear end trim (Refer to GROUP 52A,

Trims P.52A-11.)

>>A<<1. Striker

Tailgate handle and lock key cylinder

removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim P.52A-19.)

•Waterproof film (Refer to P.42-48.)

2. Bolt (earth)

3. Tailgate latch assembly

4. Tailgate lock key cylinder

5. Tailgate handleTailgate latch removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim P.52A-19.)

•Waterproof film (Refer to P.42-48.)

2. Bolt (earth)

3. Tailgate latch assembly

Tailgate lock actuator removal steps

•Lower tailgate trim (Refer to GROUP

52A, Tailgate Trim P.52A-19.)

•Waterproof film (Refer to P.42-48.)

6. Tailgate lock actuator

Page 329 of 788

KEYLESS ENTRY SYSTEM

BODY42-51

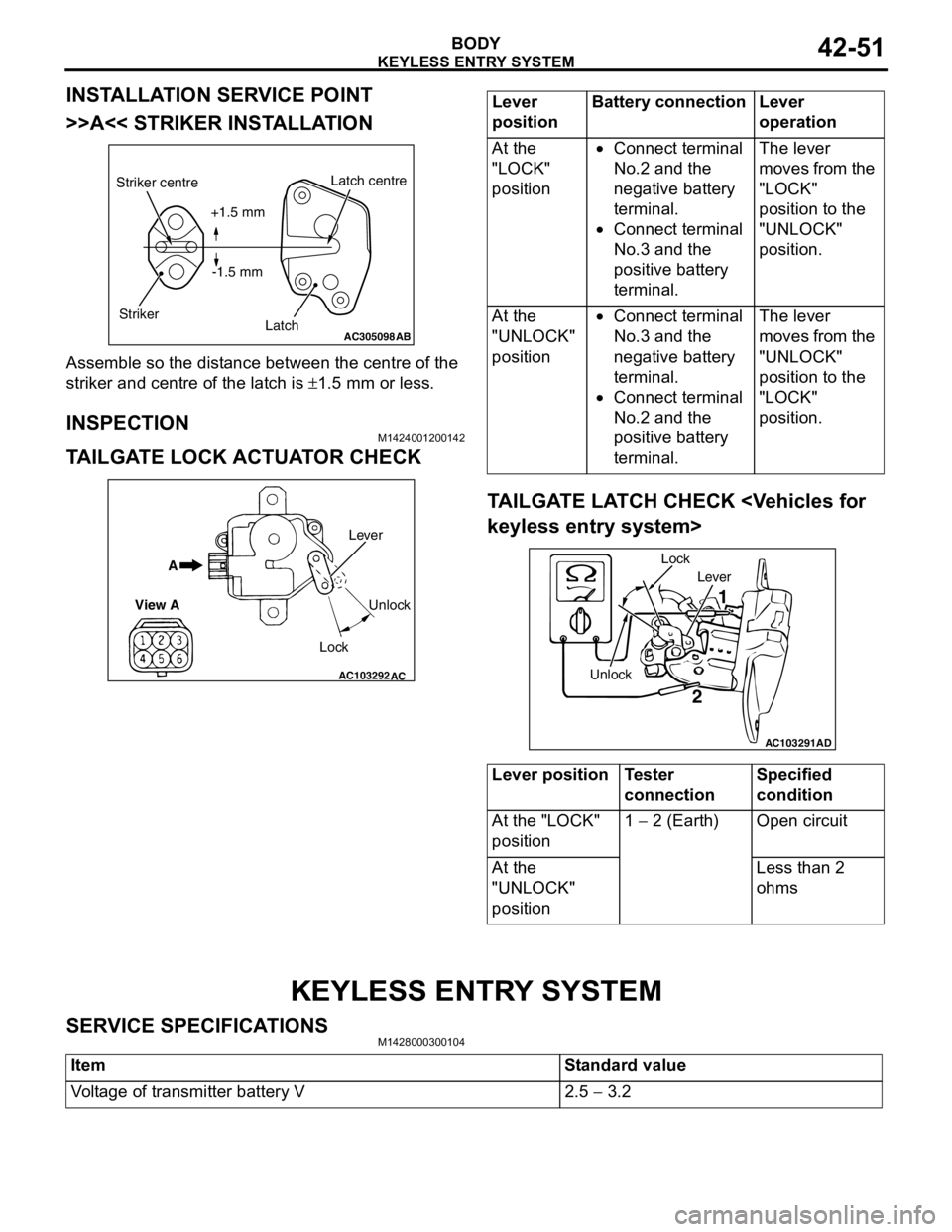

INSTALLATION SERVICE POINT

>>A<< STRIKER INSTALLATION

Assemble so the distance between the centre of the

striker and centre of the latch is ±1.5 mm or less.

INSPECTIONM1424001200142

TAILGATE LOCK ACTUATOR CHECK

TAILGATE LATCH CHECK

KEYLESS ENTRY SYSTEM

SERVICE SPECIFICATIONSM1428000300104

AC305098AB

Striker centre

StrikerLatch centre

Latch +1.5 mm

-1.5 mm

AC103292

A

View A

Unlock

Lock Lever

AC

Lever

positionBattery connection Lever

operation

At the

"LOCK"

position•Connect terminal

No.2 and the

negative battery

terminal.

•Connect terminal

No.3 and the

positive battery

terminal.The lever

moves from the

"LOCK"

position to the

"UNLOCK"

position.

At the

"UNLOCK"

position•Connect terminal

No.3 and the

negative battery

terminal.

•Connect terminal

No.2 and the

positive battery

terminal.The lever

moves from the

"UNLOCK"

position to the

"LOCK"

position.

Lever position Tester

connectionSpecified

condition

At the "LOCK"

position1 − 2 (Earth) Open circuit

At the

"UNLOCK"

positionLess than 2

ohms

AC103291

Lever

Unlock Lock

1

2

AD

Item Standard value

Voltage of transmitter battery V 2.5 − 3.2

Page 330 of 788

KEYLESS ENTRY SYSTEM

BODY42-52

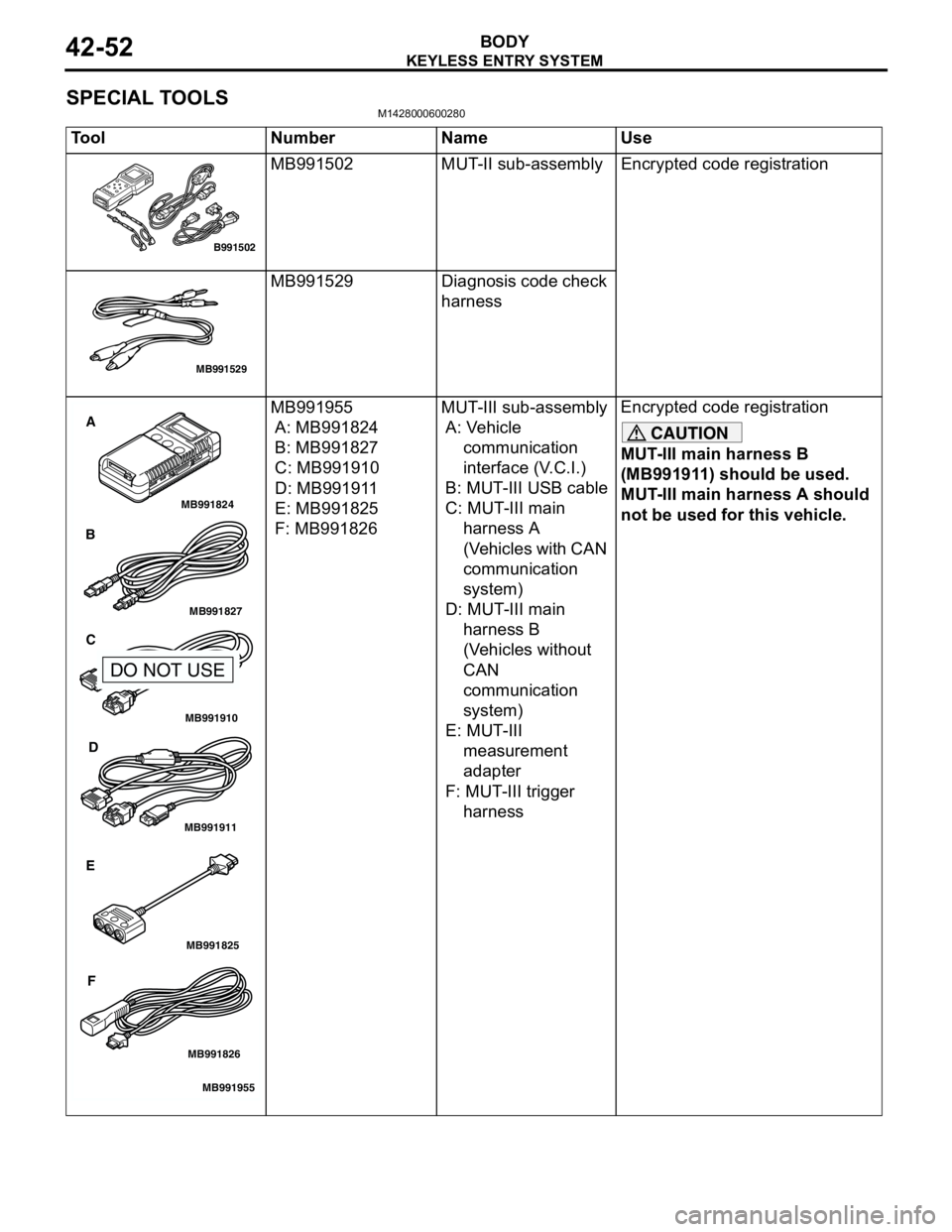

SPECIAL TOOLSM1428000600280

Tool Number Name Use

MB991502 MUT-II sub-assembly Encrypted code registration

MB991529 Diagnosis code check

harness

MB991955

A: MB991824

B: MB991827

C: MB991910

D: MB991911

E: MB991825

F: MB991826MUT-III sub-assembly

A: Vehicle

communication

interface (V.C.I.)

B: MUT-III USB cable

C: MUT-III main

harness A

(Vehicles with CAN

communication

system)

D: MUT-III main

harness B

(Vehicles without

CAN

communication

system)

E: MUT-III

measurement

adapter

F: MUT-III trigger

harnessEncrypted code registration

CAUTION

MUT-III main harness B

(MB991911) should be used.

MUT-III main harness A should

not be used for this vehicle.

B991502

MB991529

MB991910

MB991826

MB991955

MB991911

MB991824

MB991827

MB991825

A

B

C

D

E

F

DO NOT USE

Page 331 of 788

KEYLESS ENTRY SYSTEM

BODY42-53

TROUBLESHOOTINGM1428000700287

The keyless entry system is controlled by the Smart

Wiring System (SWS). For troubleshooting, refer to

GROUP 54B, Troubleshooting P.54B-17 or GROUP

54C, Troubleshooting P.54C-4.

ON-VEHICLE SERVICE

KEYLESS ENTRY SYSTEM CHECKM1428001400096

Check the system as described below. If the system

does not work, carry out troubleshooting. Refer to

GROUP 54B, Troubleshooting P.54B-17, refer to

GROUP 54C, Troubleshooting P.54C-4.

•Operate the transmitter to check that the doors

and tailgate can be locked and unlocked.

•Operate the transmitter to check that the

answerback function works in response to door

and tailgate

NOTE: The adjustment function allows you to

change the answerback setting as follows. Prior

to that check, confirm which setting is activated.

.

•The hazard warning lamps flash twice when

locked and once when unlocked. The room

lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

locked and flash once when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps flash twice when

locked and do not flash when unlocked. The

room lamp flashes twice when locked and

illuminates for 15 seconds when unlocked.

•The hazard warning lamps do not flash when

both locked and unlocked. The room lamp

flashes twice when locked and illuminates for

15 seconds when unlocked.

KEYLESS ENTRY SYSTEM TIMER LOCK

FUNCTION INSPECTION

M1428004000138

Push the transmitter unlock button and check to see

that the doors and tailgate

seconds. If it doesn't, then execute troubleshooting

remedies. Refer to GROUP 54B, Troubleshooting

P.54B-17, refer to GROUP 54C, Troubleshooting

P.54C-4.

ENABLING/DISABLING THE

ANSWERBACK FUNCTION

M1428003200214

If the keyless entry system locks or unlocks the

doors, the room lamp flashes or illuminates, the

hazard warning lamp flashes (hazard answerback

function). The hazard answerback function can be

enabled or disabled according to the following

procedure:

ENABLING/DISABLING THE HAZARD

ANSWERBACK FUNCTION

The hazard answerback function can be enabled or

disabled by one of the two following procedures.

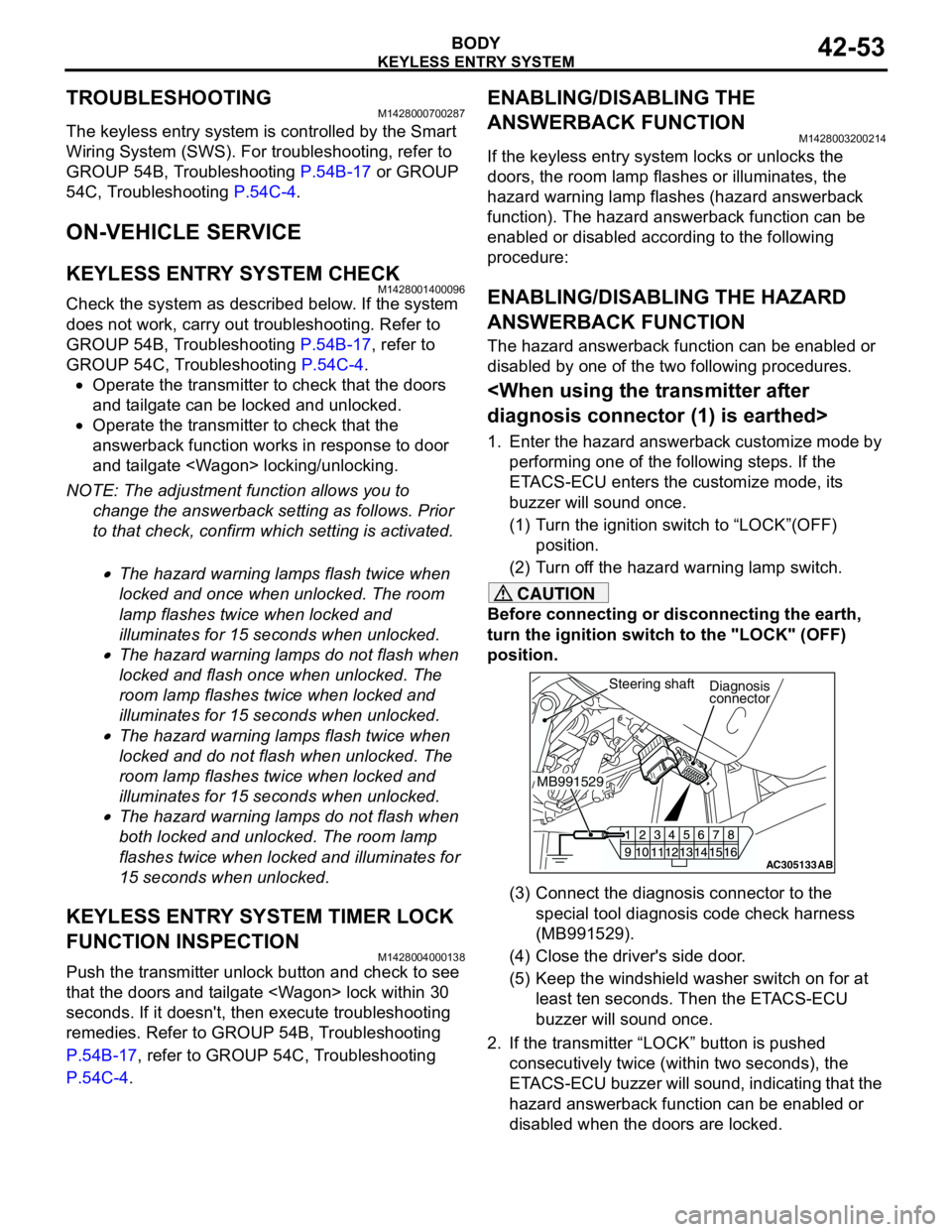

1. Enter the hazard answerback customize mode by

performing one of the following steps. If the

ETACS-ECU enters the customize mode, its

buzzer will sound once.

(1) Turn the ignition switch to “LOCK”(OFF)

position.

(2) Turn off the hazard warning lamp switch.

CAUTION

Before connecting or disconnecting the earth,

turn the ignition switch to the "LOCK" (OFF)

position.

(3) Connect the diagnosis connector to the

special tool diagnosis code check harness

(MB991529).

(4) Close the driver's side door.

(5) Keep the windshield washer switch on for at

least ten seconds. Then the ETACS-ECU

buzzer will sound once.

2. If the transmitter “LOCK” button is pushed

consecutively twice (within two seconds), the

ETACS-ECU buzzer will sound, indicating that the

hazard answerback function can be enabled or

disabled when the doors are locked.

AC305133AB

Diagnosis

connector

MB991529Steering shaft