Special tool MITSUBISHI LANCER 2006 Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2006, Model line: LANCER, Model: MITSUBISHI LANCER 2006Pages: 800, PDF Size: 45.03 MB

Page 144 of 800

FRONT AXLE HUB ASSEMBLY

FRONT AXLE26-12

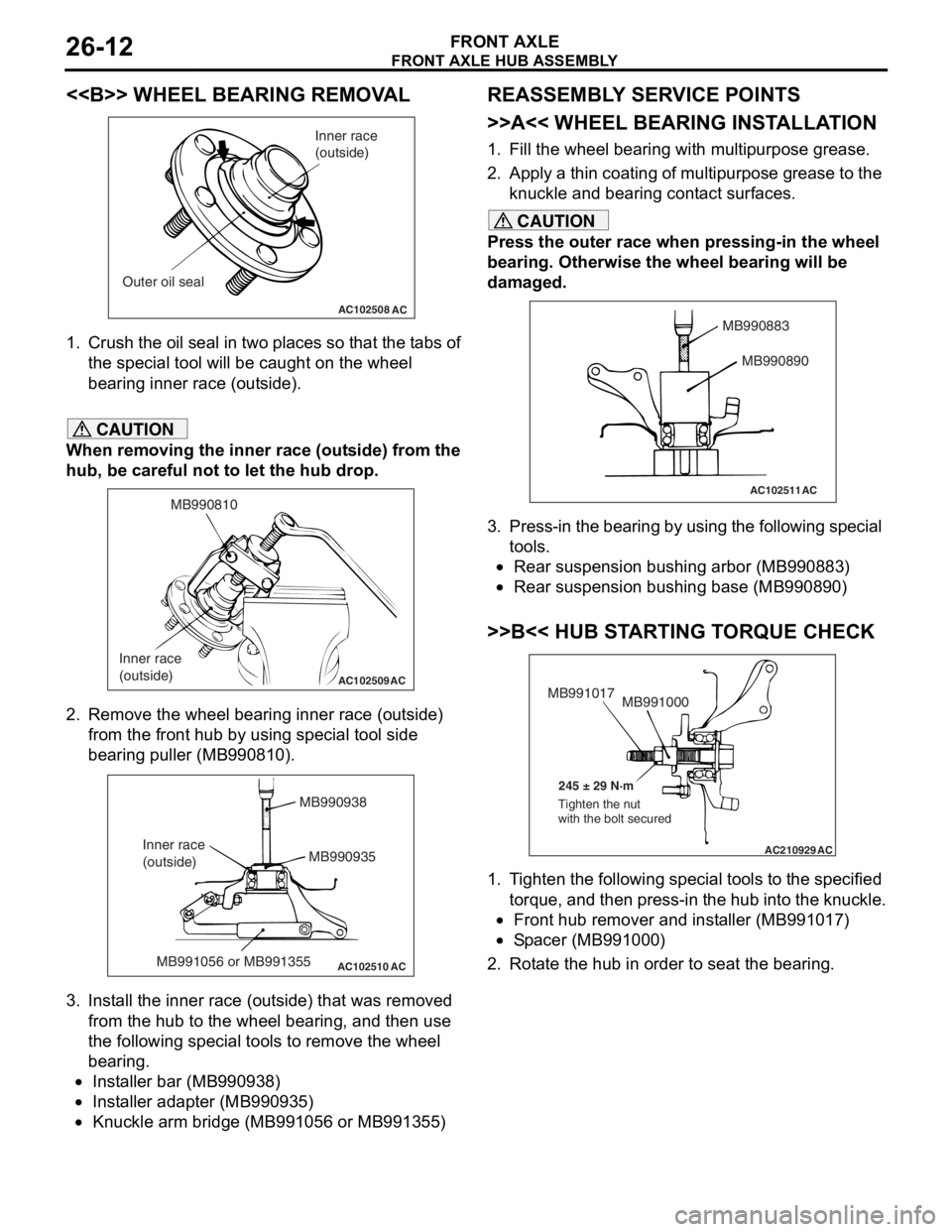

<> WHEEL BEARING REMOVAL

AC102508AC

Inner race

(outside)

Outer oil seal

1. Crush th e oil seal in two pl ace s so t hat t he t abs of

th e spe c ia l too l will be caugh t on th e wheel

be aring inne r race (out side).

CAUTION

When removing the inner race (outside) from the

hub, be careful not to let the hub drop.

AC102509

MB990810

Inner race

(outside)

AC

2. Remove the wheel bearing inner race (outside) from the front hub by using special tool side

bearing puller (MB990810).

AC102510 AC

MB990938

MB990935

MB991056 or MB991355

Inner race

(outside)

3. Install the inner race (outside) that was removed

from the hub to the wheel bearing, and then use

the following special tools to remove the wheel

bearing.

•Installer bar (MB990938)

•Installer adapter (MB990935)

•Knuckle arm bridge (MB991056 or MB991355)

REASSEMBLY SERVICE POINTS

>>A<< WHEEL BEARING INSTALLATION

1. Fill the wheel bearing with multipurpose grease.

2. Apply a thin coating of multipurpose grease to the knuckle and bearing contact surfaces.

CAUTION

Press the outer race when pressing-in the wheel

bearing. Otherwise the wheel bearing will be

damaged.

AC102511

MB990883

MB990890

AC

3. Press-in the bearing by using the following special tools.

•Rear suspension bushing arbor (MB990883)

•Rear suspension bushing base (MB990890)

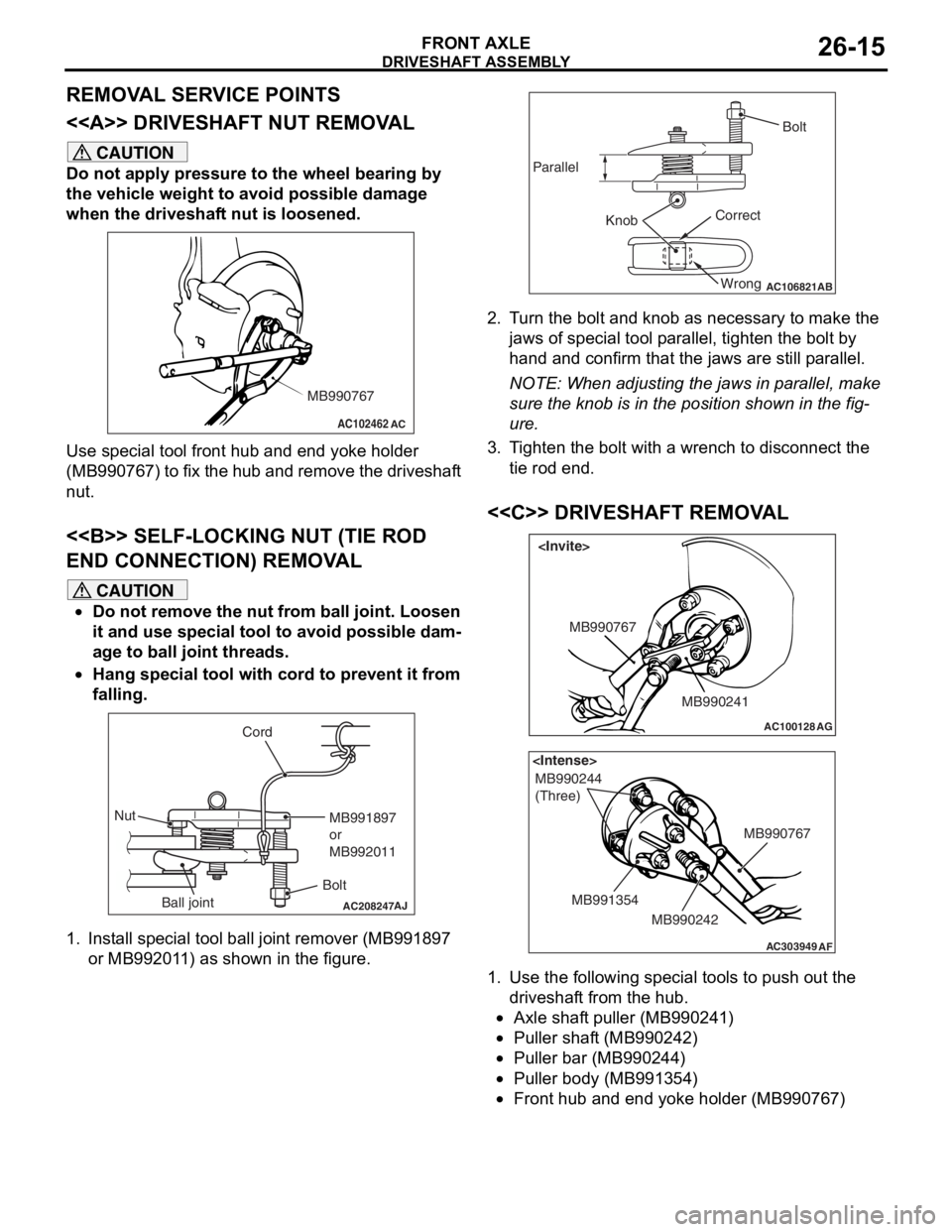

>>B<< HUB STARTING TORQUE CHECK

AC210929AC

MB991000

MB991017

245 ± 29 N·m

Tighten the nut

with the bolt secured

1. Tighten the following special tools to the specified torque, and then press-in the hub into the knuckle.

•Front hub remover and installer (MB991017)

•Spacer (MB991000)

2. Rotate the hub in order to seat the bearing.

Page 147 of 800

Page 148 of 800

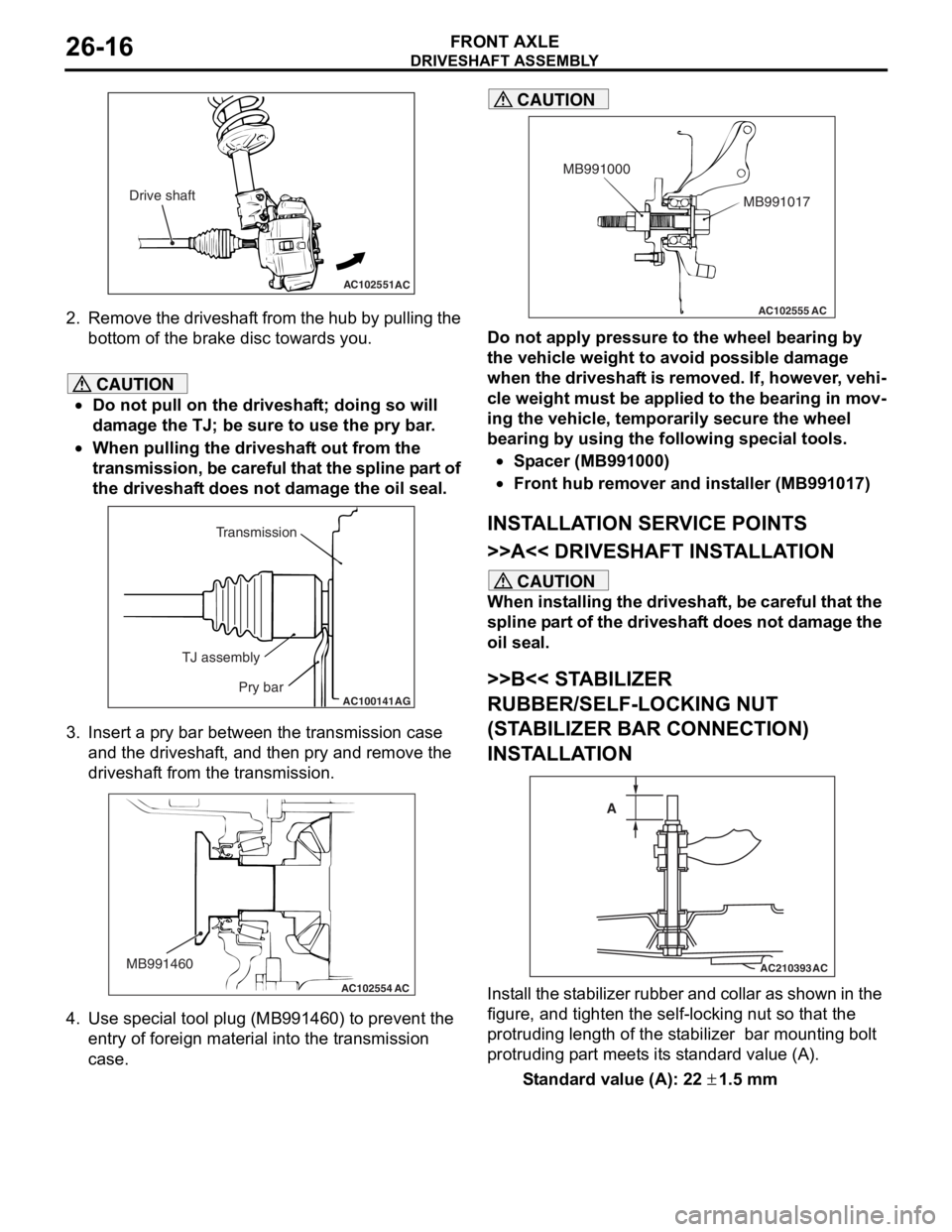

AC102551AC

Drive shaft

DRIVESHAFT ASSEMBL Y

FRONT AXLE26-16

2.Remove th e dr ivesh a f t from th e h ub b y p u lling the

bo ttom of the brake disc toward s you.

CAUTION

•Do not pull on the driveshaft; doing so will

damage the TJ; be sure to use the pry bar.

•

AC100141

Transmission

TJ assembly Pry bar

AG

When pulling the driveshaft out from the

transmission, be careful that the spline part of

the driveshaft does not damage the oil seal.

3. Insert a pry bar between the transmission case and the driveshaft, and then pry and remove the

driveshaft from the transmission.

AC102554

MB991460

AC

4. Use special tool plug (MB991460) to prevent the

entry of foreign material into the transmission

case.

AC102555 AC

MB991017

MB991000

CAUTION

Do not apply pressure to the wheel bearing by

the vehicle weight to avoid possible damage

when the driveshaft is removed. If, however, vehi

-

cle weight must be applied to the bearing in mov-

ing the vehicle, temporarily secure the wheel

bearing by using the following special tools.

•Spacer (MB991000)

•Front hub remover and installer (MB991017)

INSTALLATION SERVICE POINTS

>>A<< DRIVESHAFT INSTALLATION

CAUTION

When installing the driveshaft, be careful that the

spline part of the driveshaft does not damage the

oil seal.

>>B<< STABILIZER

RUBBER/SELF-LOCKING NUT

(STABILIZER BAR CONNECTION)

INSTALLATION

AC210393

AC

A

Install the stabilizer rubber and collar as shown in the

figure, and tighten the self-locking nut so that the

protruding length of the stabilizer bar mounting bolt

protruding part meets its standard value (A).

Standard value (A): 22 ± 1.5 mm

Page 149 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-17

>>C<< WASHER/DRIVESHAFT NUT

INSTALLATION

AC102465AD

MB990767

Washer

1.

Be sure t o inst a ll t he driveshaf t washe r in th e

specifie d dire ctio n.

CAUTION

Before securely tightening the driveshaft nuts,

make sure there is no load on the wheel bear

-

ings. Otherwise the wheel bearing will be dam-

aged.

2. Using special tool front hub and end yoke holder (MB990767), tighten the driveshaft nut to the

specified torque.

Tightening torque: 245 ± 29 N⋅m

Page 153 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-21

INSPECTION

M1261003800130

•Check the driveshaft for damage, bending or cor-

rosion.

•Check the driveshaft spline part for wear or dam-

age.

•Check the spider assembly for roller rotation,

wear or corrosion.

•Check the groove inside TJ case for wear or cor-

rosion.

•Check the dynamic damper for damage or crack-

ing.

•Check the boots for deterioration, damage or

cracking.

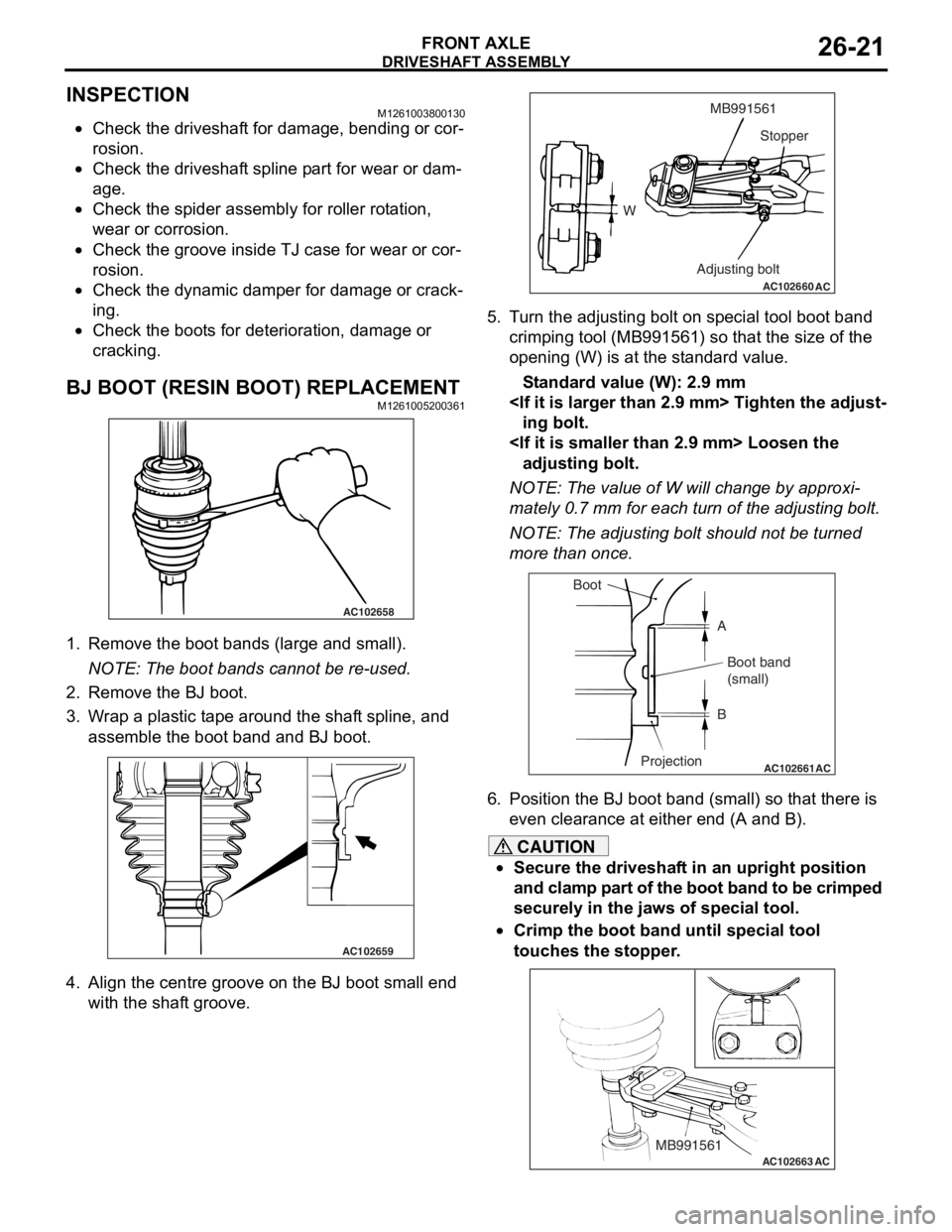

BJ BOOT (RESIN BOOT) REPLACEMENTM1261005200361

AC102658

1.Remove the bo ot ban ds (large a nd small).

NOTE: The boot ba nds canno t be re -used .

2.Remove the BJ boot.

3.W r ap a plastic t a pe arou nd the shaf t spline, an d

asse mble the b oot ba nd and BJ boo t.

AC102659

4.Align th e ce ntre gro o ve o n the BJ boot small end

wit h the shaf t groo ve.

AC102660

WMB991561

Stopper

Adjusting bolt

AC

5. T u rn the ad justing bolt o n sp ecial too l boo t band

crimping tool (MB9915 61) so that the size of the

o penin g (W) is at t he st and ard value .

St andard va lue (W): 2 . 9 mm

ing bolt.

adjustin g bolt.

NOTE: The value of W will chang e by approxi-

mately 0.7 mm for ea ch tu rn of th e adjusting bolt.

NOTE: The ad justing bolt shou ld no t be tu rned

more th an once.

AC102661AC

Boot

ABoot band

(small)

B

Projection

6. Position the BJ boo t band (small) so th at there is

e v en clea rance at either en d (A and B).

CAUTION

•Secure the driveshaft in an upright position

and clamp part of the boot band to be crimped

securely in the jaws of special tool.

•

AC102663 ACMB991561

Crimp the boot band until special tool

touches the stopper.

Page 154 of 800

DRIVESHAFT ASSEMBLY

FRONT AXLE26-22

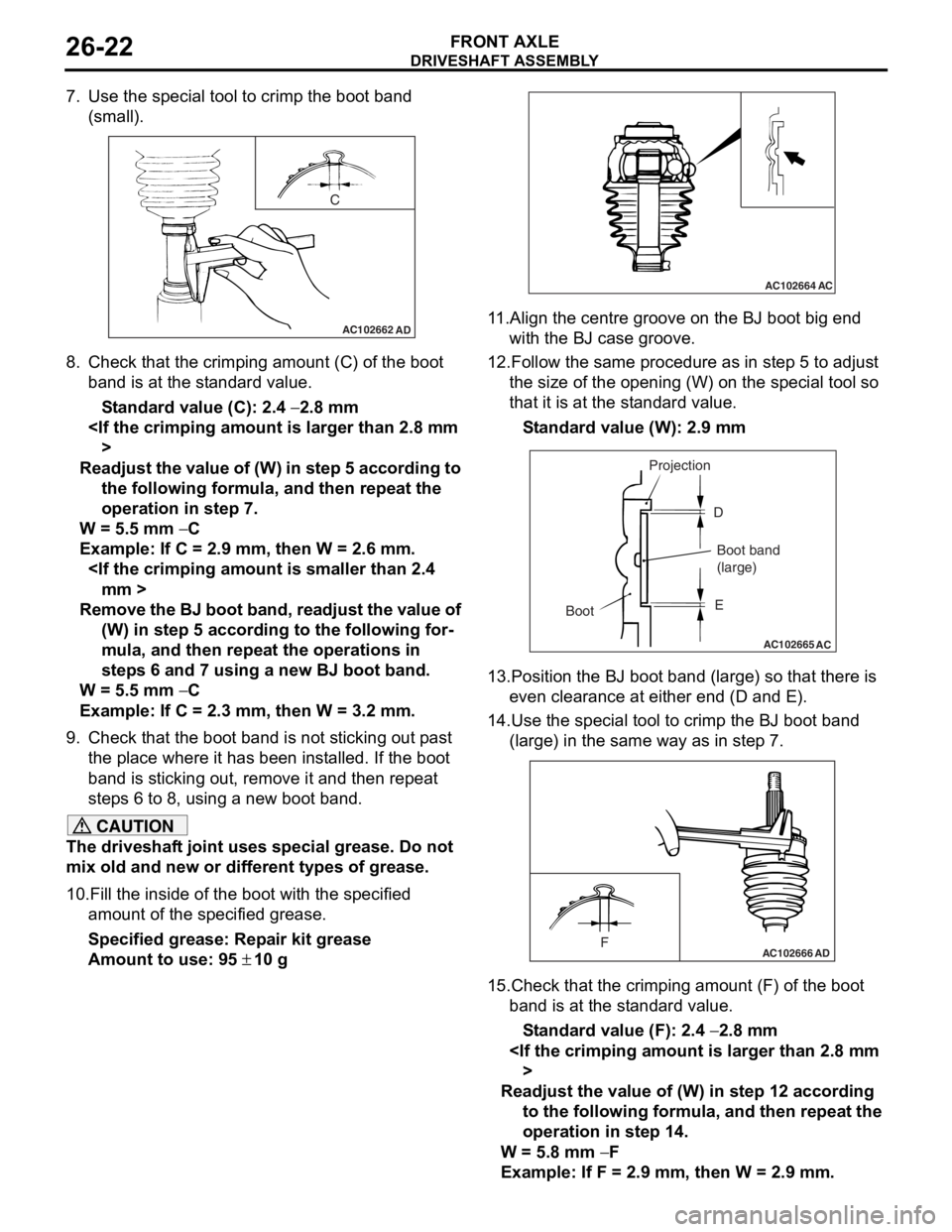

7. Use the special tool to crimp the boot band (small).

AC102662

C

AD

8.Check t hat the crimpin g amount (C) of the bo ot

ba nd is at th e st and ard value.

St andard va lue (C): 2.4 − 2.8 mm

Readjust th e value of (W) in s t ep 5 acc ord i ng to

the following fo rm ula, and then repea t the

operation in step 7.

W = 5.5 mm − C

Example : If C = 2.9 mm, the n W = 2.6 mm.

Rem o v e the BJ bo ot ba nd , re ad ju st the v a l ue of

(W) in ste p 5 acc ord i ng to the following for

-

mula, and then repe at the o perations i n

step

s 6 and 7 using a new BJ boot band .

W = 5.5 mm − C

Example : If C = 2.3 mm, the n W = 3.2 mm.

9.Check t hat the boot b and is no t sticking o u t p a st

th e pla c e wher e it h a s be en in st alled. If t he boo t

ba nd is st icking out, remove it a nd the n repea t

step s 6 to 8, u s in g a new b oot ban d.

CAUTION

The driveshaft joint uses special grease. Do not

mix old and new or different types of grease.

10.Fill the inside of the boot with the specified amount of the specified grease.

Specified grease: Repair kit grease

Amount to use: 95 ± 10 g

AC102664AC

11.Align the centre groove on the BJ boot big end with the BJ case groove.

12.Follow the same procedure as in step 5 to adjust

the size of the opening (W) on the special tool so

that it is at the standard value.

Standard value (W): 2.9 mm

AC102665 AC

Boot Projection

Boot band

(large)

D

E

13.Position the BJ boot band (large) so that there is even clearance at either end (D and E).

14.Use the special tool to crimp the BJ boot band

(large) in the same way as in step 7.

AC102666FAD

15.Check that the crimping amount (F) of the boot band is at the standard value.

Standard value (F): 2.4 − 2.8 mm

Readjust the value of (W) in step 12 according to the following formula, and then repeat the

operation in step 14.

W = 5.8 mm − F

Example: If F = 2.9 mm, then W = 2.9 mm.

Page 157 of 800

27-1

GROUP 27

REAR AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . .27-2

SERVICE SPECIFICATIONS . . . . . . .27-2

SEALANT . . . . . . . . . . . . . . . . . . . . . .27-2

SPECIAL TOOLS . . . . . . . . . . . . . . . .27-3

ON-VEHICLE SERVICE . . . . . . . . . . .27-4

WHEEL BEARING AXIAL PLAY CHECK . . 27-4

REAR HUB ROTARY-SLIDING

RESISTANCE CHECK . . . . . . . . . . . . . . . . 27-4

HUB BOLT REPLACEMENT . . . . . . . . . . . . 27-4

REAR AXLE HUB ASSEMBLY . . . . .27-5

REMOVAL AND INSTALLATION . . . . . . . . 27-5

INSPECTION. . . . . . . . . . . . . . . . . . . . . . . . 27-6

Page 159 of 800

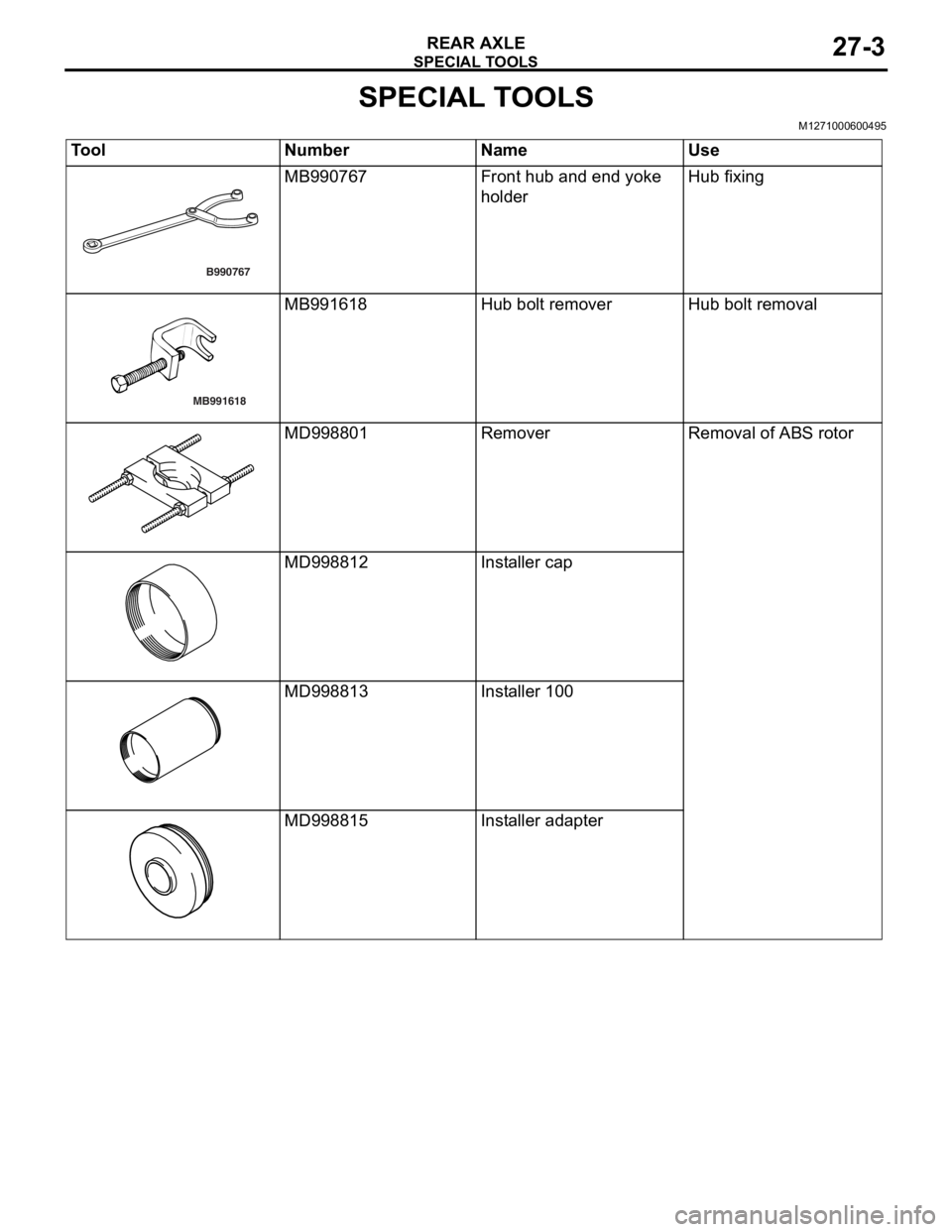

SPECIAL TOOLS

REAR AXLE27-3

SPECIAL TOOLS

M1271000600495

ToolNumberNameUse

B990767

MB990767Front hu b and end yoke

holde

rHub fixin g

MB991618

MB991618Hub bolt remo verHub bolt remova l

MD998801Remov e rRemoval of ABS rotor

MD998812Installer cap

MD9988 13Installer 100

MD9988 15Installer ada pter

Page 171 of 800

32-1

GROUP 32

POWER PLANT

MOUNT

CONTENTS

GENERAL INFORMATIO N . . . . . . . .32-2

SERVICE SPECIFICATION . . . . . . . .32-3

SPECIAL TOOL . . . . . . . . . . . . . . . . .32-3

ENGINE MOUNTING . . . . . . . . . . . . .32-4

REMOVAL AND INSTALLATION . . . . . . . . 32-4

TRANSMISSION MOUNTING . . . . . .32-5

REMOVAL AND INSTALLATION . . . . . . . . 32-5

ENGINE ROLL STOPPER,

CENTREMEMBER . . . . . . . . . . . . . . .32-7

REMOVAL AND INSTALLATION . . . . . . . . 32-7

CROSSMEMBER . . . . . . . . . . . . . . . .32-8

REMOVAL AND INSTALLATION . . . . . . . . 32-8

Page 173 of 800

SERVICE SPECIFICATION

POWER PLANT MOUNT32-3

SERVICE SPECIFICATION

M1321000300333

ItemStandard value

Protruding length of stabilizer bar mounting bolt mm22 ± 1.5

SPECIAL TOOL

M1321000600378

ToolNumberNameUse

AC106827

MB991897Ball j o in t remo verKnuckle and tie rod e nd ball joint

discon

nection

NOTE: St eering linkage pu lle r

(MB990 635 o r MB991 1 13) is also

ava

ilab

l e to disconn ect knuckle and

tie ro

d end ball joint.