service MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2007, Model line: LANCER EVOLUTION, Model: MITSUBISHI LANCER EVOLUTION 2007Pages: 1449, PDF Size: 56.82 MB

Page 768 of 1449

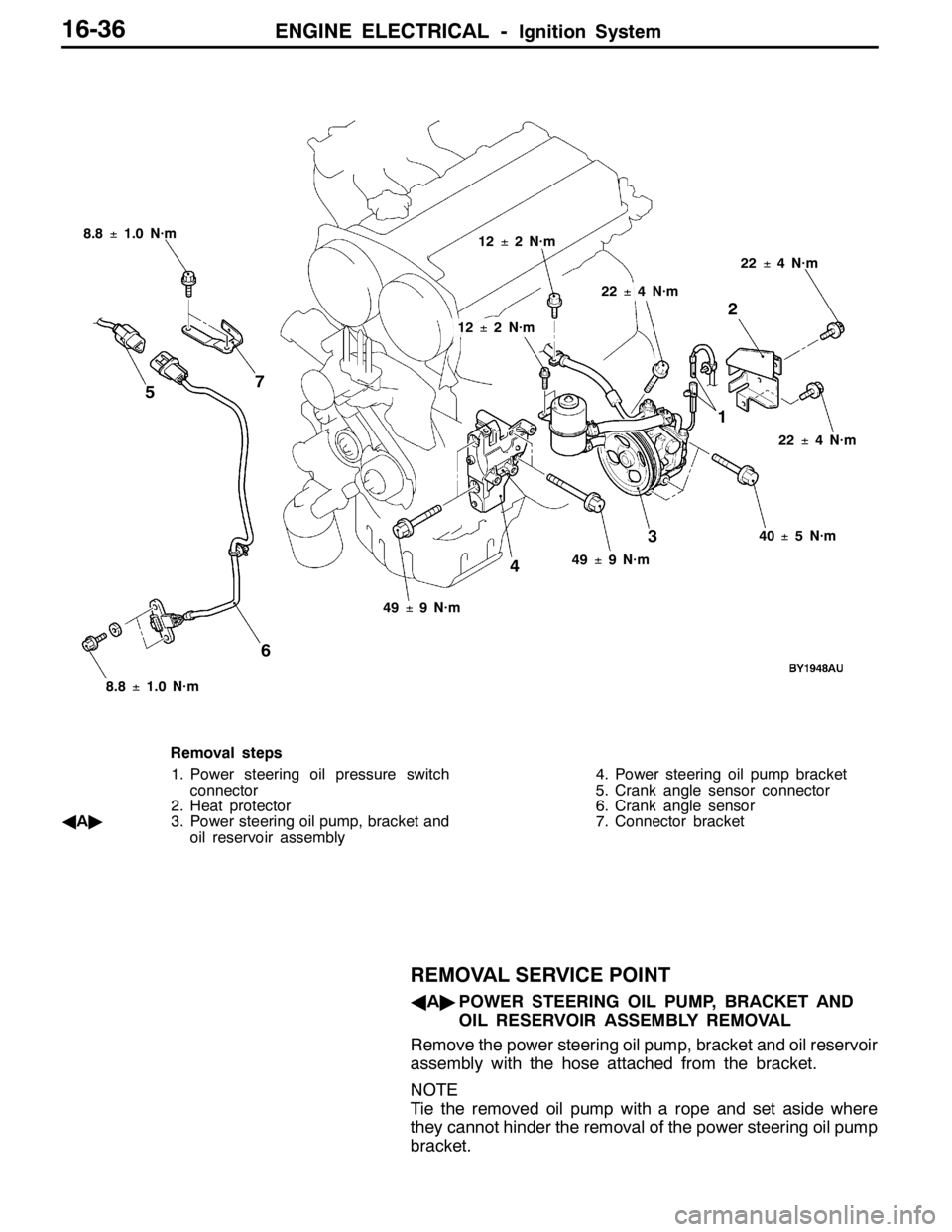

ENGINE ELECTRICAL -Ignition System16-36

12

3

8.8±1.0 N·m

4 5

6 7

8.8±1.0 N·m49±9 N·m

49±9 N·m40±5 N·m 12±2 N·m

22±4 N·m

22±4 N·m

12±2 N·m

22±4 N·m

Removal steps

1. Power steering oil pressure switch

connector

2. Heat protector

AA"3. Power steering oil pump, bracket and

oil reservoir assembly4. Power steering oil pump bracket

5. Crank angle sensor connector

6. Crank angle sensor

7. Connector bracket

REMOVAL SERVICE POINT

AA"POWER STEERING OIL PUMP, BRACKET AND

OIL RESERVOIR ASSEMBLY REMOVAL

Remove the power steering oil pump, bracket and oil reservoir

assembly with the hose attached from the bracket.

NOTE

Tie the removed oil pump with a rope and set aside where

they cannot hinder the removal of the power steering oil pump

bracket.

Page 769 of 1449

ENGINE ELECTRICAL -Ignition System16-37

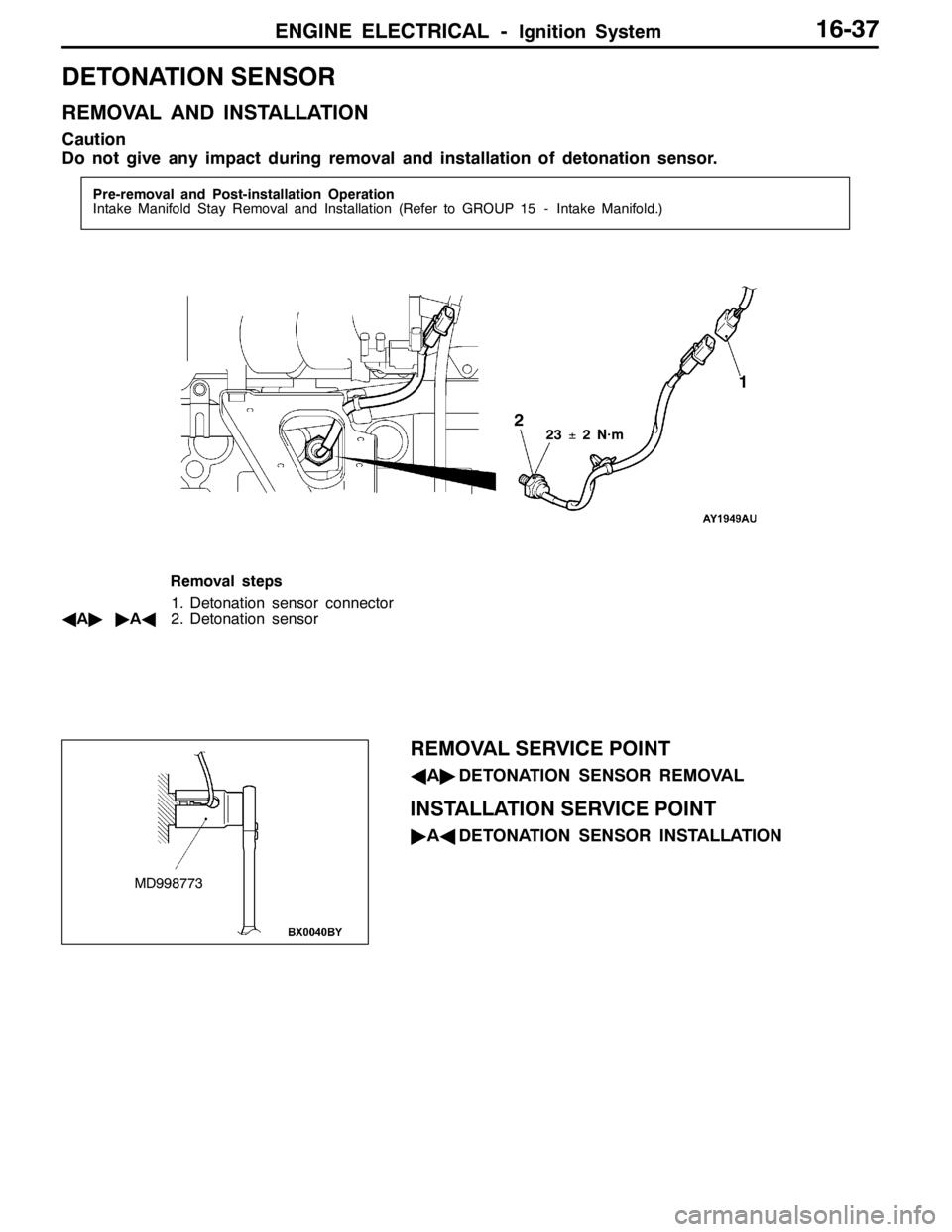

DETONATION SENSOR

REMOVAL AND INSTALLATION

Caution

Do not give any impact during removal and installation of detonation sensor.

Pre-removal and Post-installation Operation

Intake Manifold Stay Removal and Installation (Refer to GROUP 15 - Intake Manifold.)

1

2

23±2 N·m

Removal steps

1. Detonation sensor connector

AA""AA2. Detonation sensor

REMOVAL SERVICE POINT

AA"DETONATION SENSOR REMOVAL

INSTALLATION SERVICE POINT

"AADETONATION SENSOR INSTALLATION

MD998773

Page 771 of 1449

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 2.........

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2...............

ON-VEHICLE SERVICE 2...................

Accelerator Cable Check and

Adjustment 2................................

ACCELERATOR CABLE AND PEDAL 3......

EMISSION CONTROL SYSTEM 4......

GENERAL INFORMATION 4................

Emission Control Device Reference

Table 4.....................................

SERVICE SPECIFICATIONS 5..............

VACUUM HOSE 5..........................

Vacuum Hose Piping Diagram 5..............

Vacuum Circuit Diagram 6....................

Vacuum Hose Check 7......................

Vacuum Hose Installation 7..................

CRANKCASE EMISSION CONTROL

SYSTEM 8................................

General Information 8........................

System Diagram 8..........................

Component Location 9.......................

Positive Crankcase Ventilation System Check 9....

PCV Valve Check 9.........................

EVAPORATIVE EMISSION CONTROL

SYSTEM 10...............................

General Information 10.......................

System Diagram 10..........................

Component Location 10......................

Purge Control System Check 11...............

Purge Port Vacuum Check 11.................

Purge Control Solenoid Valve Check 12.........

Check Valve Check 12.......................

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 13...............................

General Information 13.......................

Operation 13................................

System Diagram 13..........................

Component Location 14......................

Exhaust Gas Recirculation (EGR) Control System

Check 14...................................

EGR Valve Check 15.........................

EGR Port Vacuum Check 15..................

EGR Control Solenoid Valve Check 16..........

EGR VALVE 17............................

CANISTER 18.............................

CATALYTIC CONVERTER 19................

General Information 19.......................

Page 772 of 1449

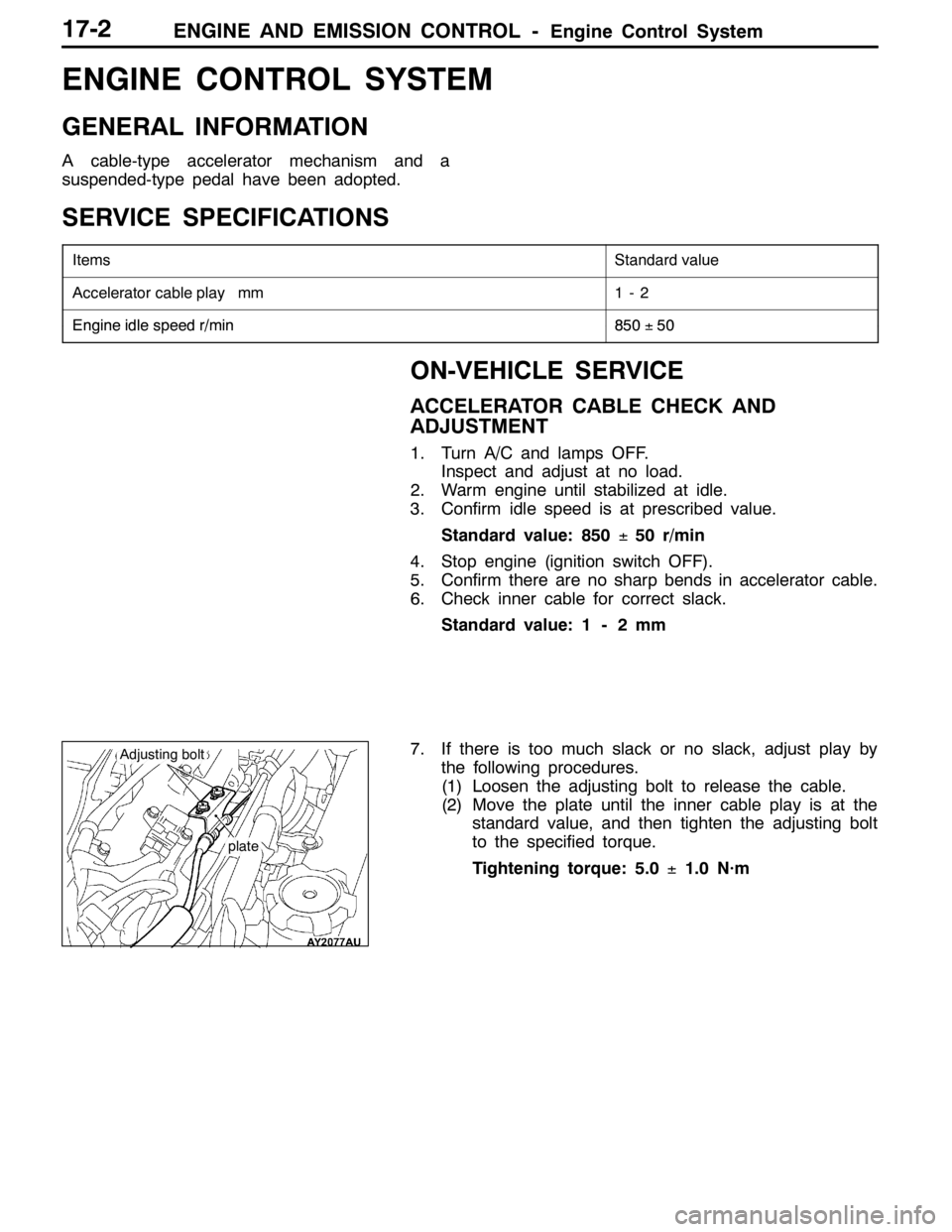

ENGINE AND EMISSION CONTROL -Engine Control System17-2

ENGINE CONTROL SYSTEM

GENERAL INFORMATION

A cable-type accelerator mechanism and a

suspended-type pedal have been adopted.

SERVICE SPECIFICATIONS

ItemsStandard value

Accelerator cable play mm1-2

Engineidlespeedr/min850±50Engineidle speed±/min850±50

ON-VEHICLE SERVICE

ACCELERATOR CABLE CHECK AND

ADJUSTMENT

1. Turn A/C and lamps OFF.

Inspect and adjust at no load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at prescribed value.

Standard value: 850±50 r/min

4. Stop engine (ignition switch OFF).

5. Confirm there are no sharp bends in accelerator cable.

6. Check inner cable for correct slack.

Standard value: 1 - 2 mm

7. If there is too much slack or no slack, adjust play by

the following procedures.

(1) Loosen the adjusting bolt to release the cable.

(2) Move the plate until the inner cable play is at the

standard value, and then tighten the adjusting bolt

to the specified torque.

Tightening torque: 5.0±1.0 N·m

plate

Adjusting bolt

Page 775 of 1449

ENGINE AND EMISSION CONTROL -Emission Control System17-5

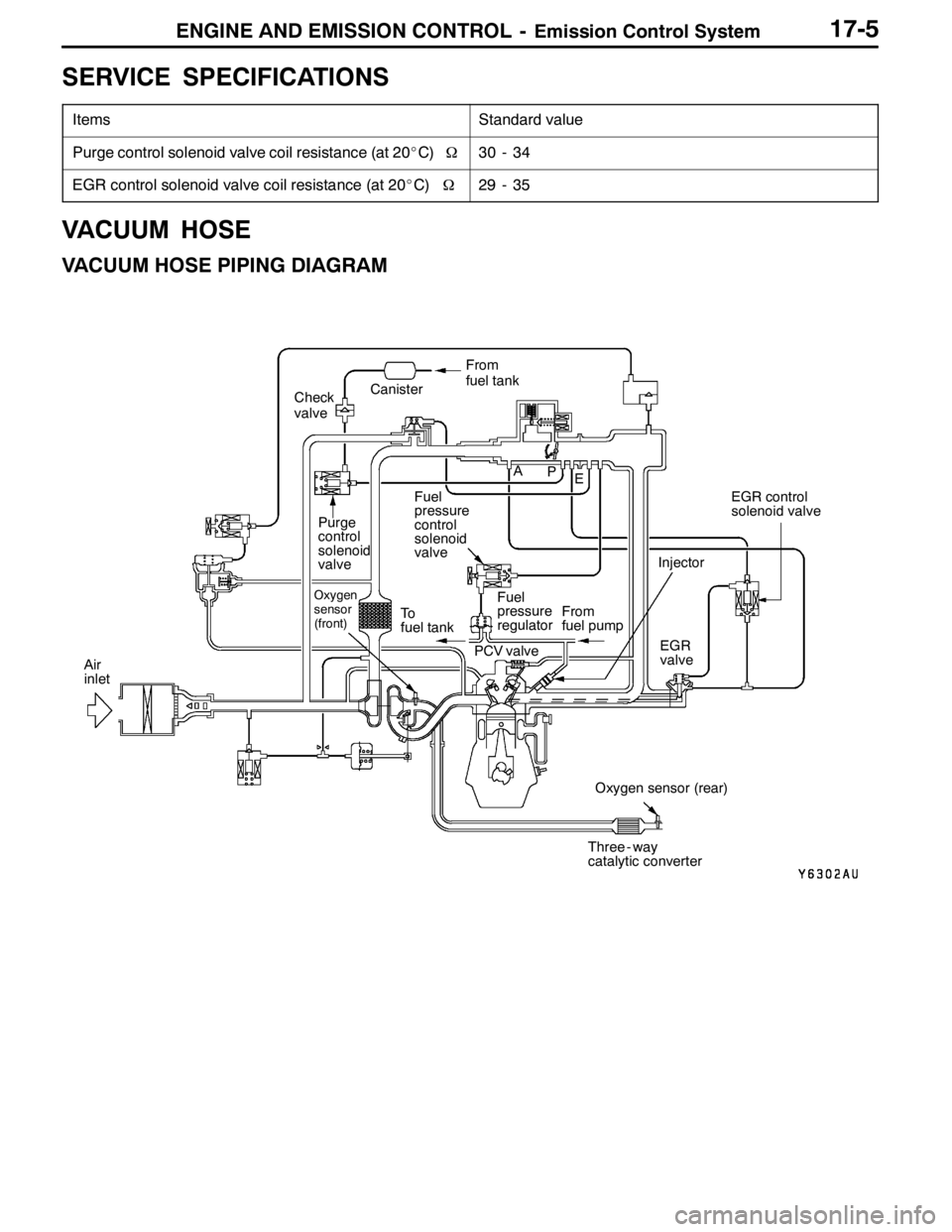

SERVICE SPECIFICATIONS

ItemsStandard value

Purge control solenoid valve coil resistance (at 20_C)Ω30 - 34

EGR control solenoid valve coil resistance (at 20_C)Ω29 - 35

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAM

Fuel

pressure

control

solenoid

valve

Oxygen

sensor

(front)

Check

valve

Fuel

pressure

regulator

PCV valve To

fuel tank

Oxygen sensor (rear) From

fuel pump

Air

inletEGR control

solenoid valve

Purge

control

solenoid

valveCanisterFrom

fuel tank

EGR

valve Injector

Three - way

catalytic converter A

P

E

Page 792 of 1449

21A-2

CLUTCH

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 3.................

LUBRICANTS 3..............................

ON-VEHICLE SERVICE 3.....................

Clutch Pedal Inspection and Adjustment 3........Bleeding 4.....................................

Clutch Pedal Position Switch Adjustment 4.......

CLUTCH PEDAL 5............................

CLUTCH CONTROL 7........................

Clutch Master Cylinder 9.......................

Page 793 of 1449

CLUTCH -General Information/Service Specifications/Lubricants/On-vehicle Service21A-3

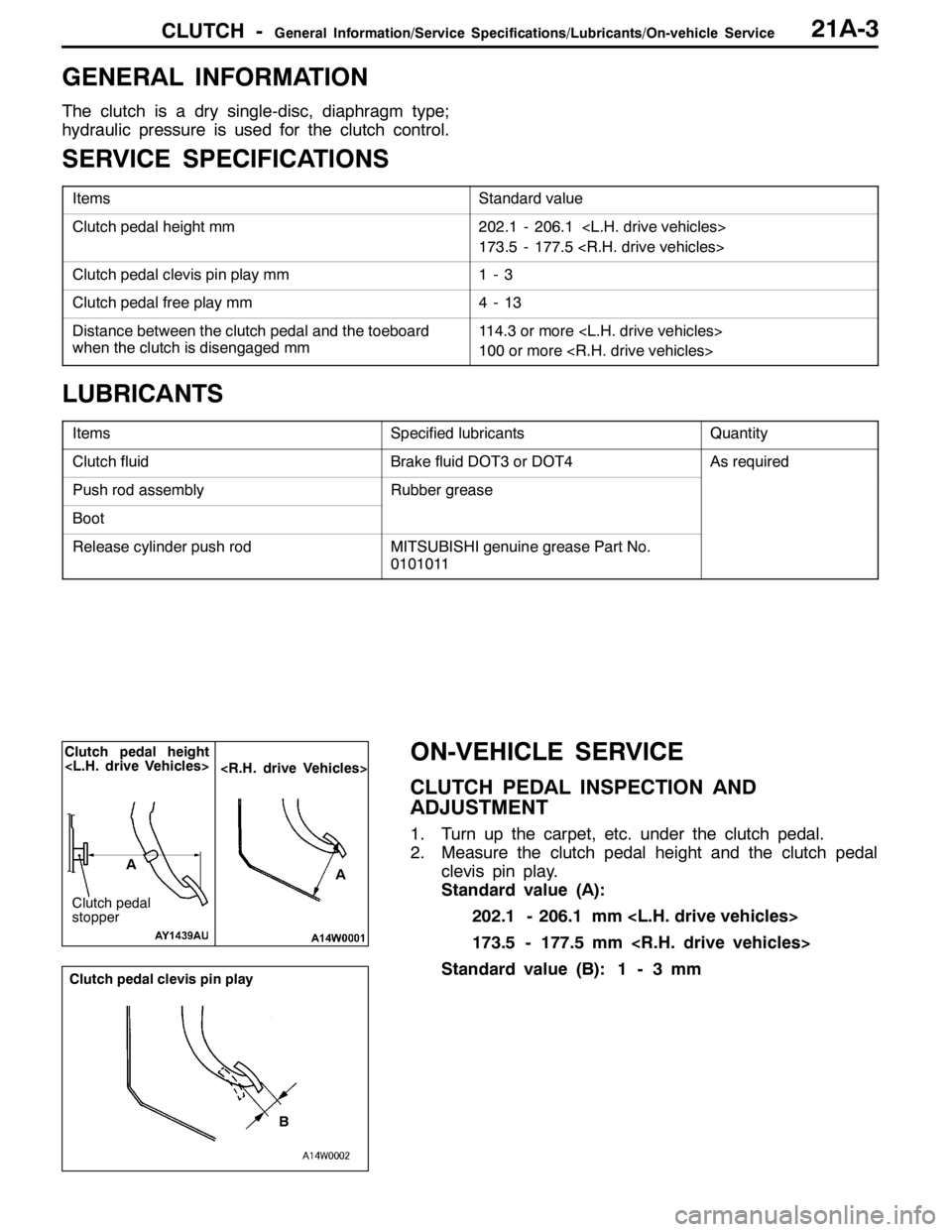

GENERAL INFORMATION

The clutch is a dry single-disc, diaphragm type;

hydraulic pressure is used for the clutch control.

SERVICE SPECIFICATIONS

ItemsStandard value

Clutch pedal height mm202.1 - 206.1

173.5 - 177.5

Clutch pedal clevis pin play mm1-3

Clutch pedal free play mm4-13

Distance between the clutch pedal and the toeboard

when the clutch is disengaged mm114.3 or more

100 or more

LUBRICANTS

ItemsSpecified lubricantsQuantity

Clutch fluidBrake fluid DOT3 or DOT4As required

Push rod assemblyRubber grease

Boot

Release cylinder push rodMITSUBISHI genuine grease Part No.

0101011

ON-VEHICLE SERVICE

CLUTCH PEDAL INSPECTION AND

ADJUSTMENT

1. Turn up the carpet, etc. under the clutch pedal.

2. Measure the clutch pedal height and the clutch pedal

clevis pin play.

Standard value (A):

202.1 - 206.1 mm

173.5 - 177.5 mm

Standard value (B): 1 - 3 mm

Clutch pedal height

A

A

Clutch pedal

stopper

Clutch pedal clevis pin play

B

Page 794 of 1449

CLUTCH -On-Vehicle Service21A-4

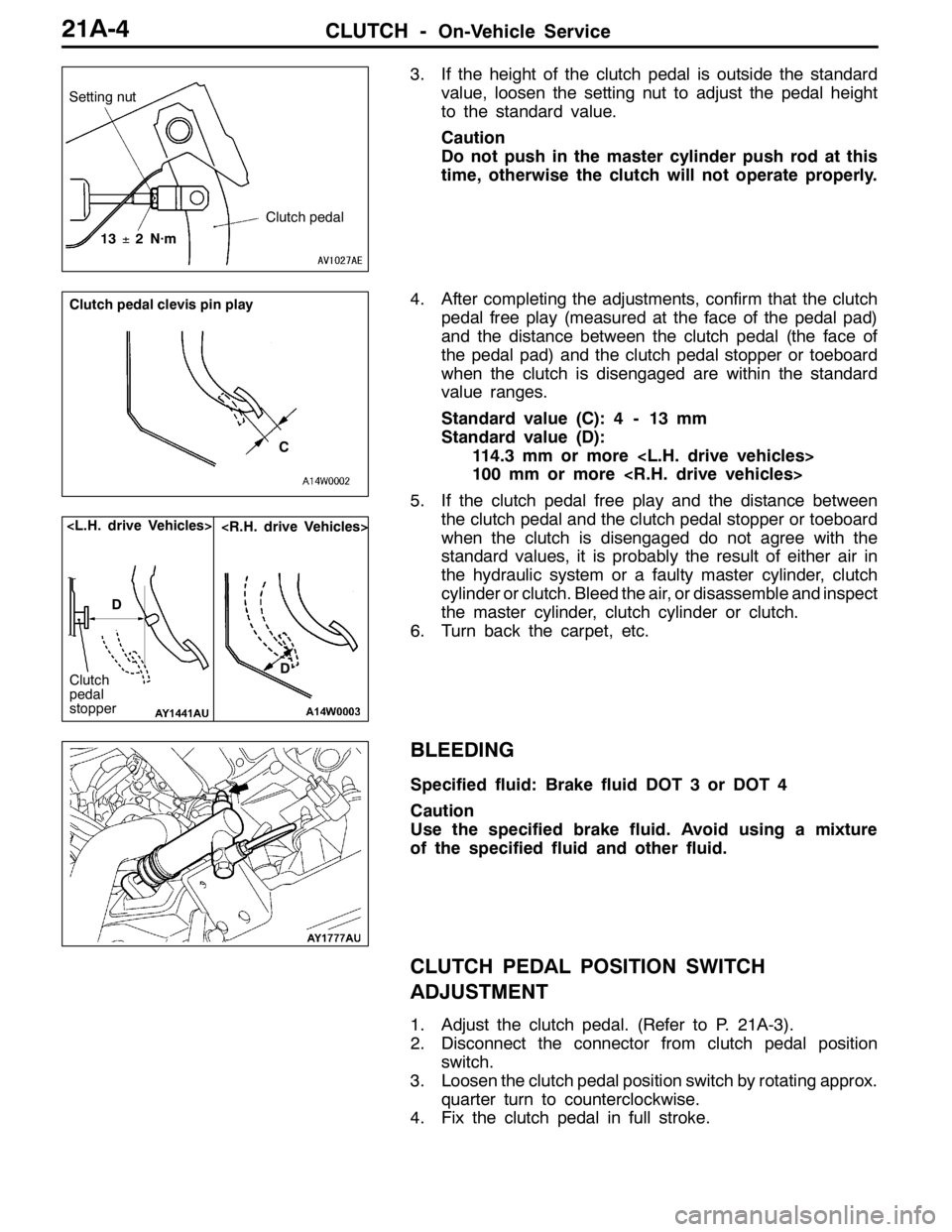

3. If the height of the clutch pedal is outside the standard

value, loosen the setting nut to adjust the pedal height

to the standard value.

Caution

Do not push in the master cylinder push rod at this

time, otherwise the clutch will not operate properly.

4. After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between the clutch pedal (the face of

the pedal pad) and the clutch pedal stopper or toeboard

when the clutch is disengaged are within the standard

value ranges.

Standard value (C): 4 - 13 mm

Standard value (D):

114.3 mm or more

100 mm or more

5. If the clutch pedal free play and the distance between

the clutch pedal and the clutch pedal stopper or toeboard

when the clutch is disengaged do not agree with the

standard values, it is probably the result of either air in

the hydraulic system or a faulty master cylinder, clutch

cylinder or clutch. Bleed the air, or disassemble and inspect

the master cylinder, clutch cylinder or clutch.

6. Turn back the carpet, etc.

BLEEDING

Specified fluid: Brake fluid DOT 3 or DOT 4

Caution

Use the specified brake fluid. Avoid using a mixture

of the specified fluid and other fluid.

CLUTCH PEDAL POSITION SWITCH

ADJUSTMENT

1. Adjust the clutch pedal. (Refer to P. 21A-3).

2. Disconnect the connector from clutch pedal position

switch.

3. Loosen the clutch pedal position switch by rotating approx.

quarter turn to counterclockwise.

4. Fix the clutch pedal in full stroke.

Clutch pedal Setting nut

13±2 N·m

Clutch pedal clevis pin play

C

Clutch

pedal

stopper

D D

Page 795 of 1449

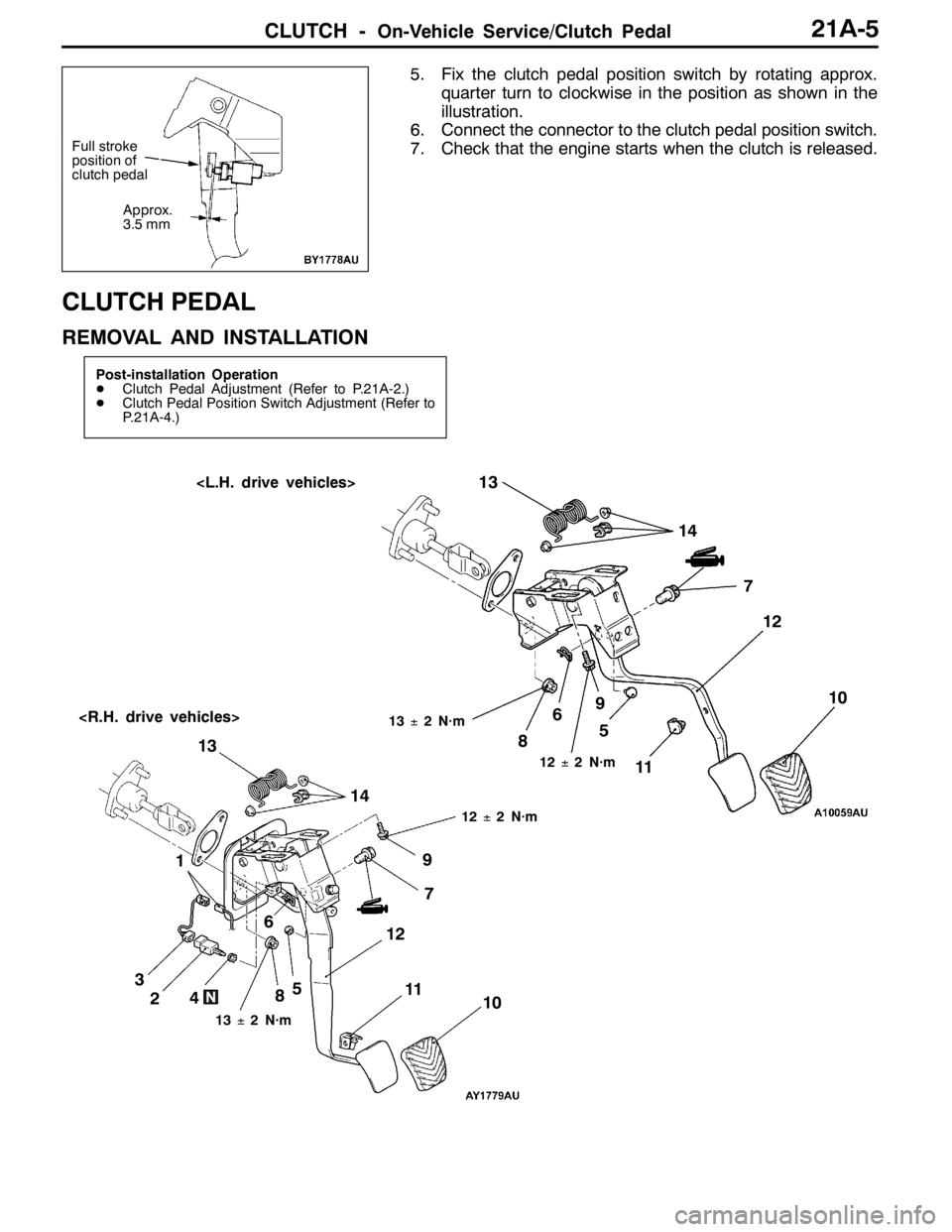

CLUTCH -On-Vehicle Service/Clutch Pedal21A-5

5. Fix the clutch pedal position switch by rotating approx.

quarter turn to clockwise in the position as shown in the

illustration.

6. Connect the connector to the clutch pedal position switch.

7. Check that the engine starts when the clutch is released.

CLUTCH PEDAL

REMOVAL AND INSTALLATION

Post-installation Operation

DClutch Pedal Adjustment (Refer to P.21A-2.)

DClutch Pedal Position Switch Adjustment (Refer to

P.21A-4.)

6713±2 N·m

1

12±2 N·m

8

11

2459

12±2 N·m

67

13±2 N·m

10 8

12 13

3145 910

1112 13

14

Full stroke

position of

clutch pedal

Approx.

3.5 mm

Page 799 of 1449

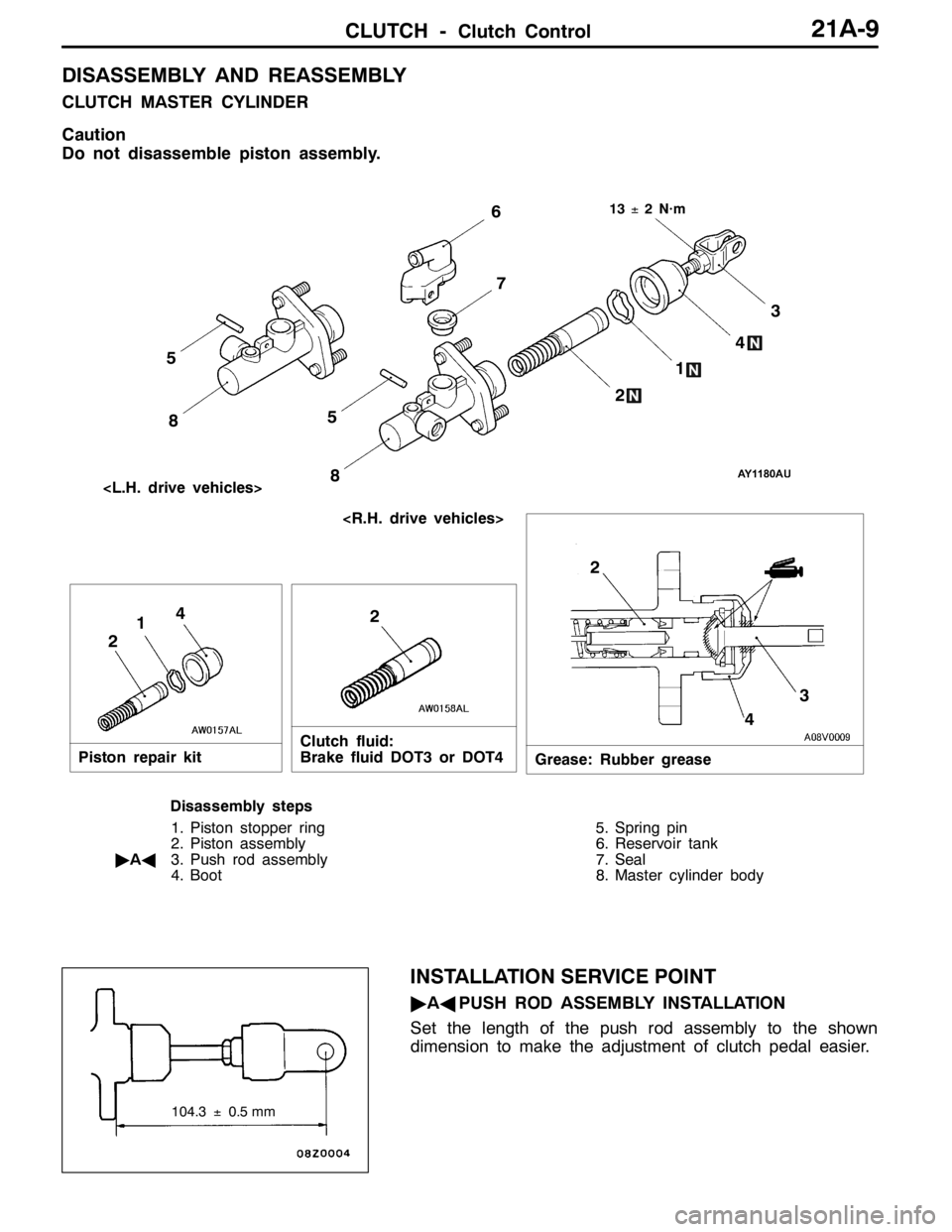

CLUTCH -Clutch Control21A-9

DISASSEMBLY AND REASSEMBLY

CLUTCH MASTER CYLINDER

Caution

Do not disassemble piston assembly.

1

4 5

27

223

4

Grease: Rubber grease

Clutch fluid:

Brake fluid DOT3 or DOT4

Piston repair kit

13±2 N·m

12

3

6

8

4 5

8

Disassembly steps

1. Piston stopper ring

2. Piston assembly

"AA3. Push rod assembly

4. Boot5. Spring pin

6. Reservoir tank

7. Seal

8. Master cylinder body

INSTALLATION SERVICE POINT

"AAPUSH ROD ASSEMBLY INSTALLATION

Set the length of the push rod assembly to the shown

dimension to make the adjustment of clutch pedal easier.

104.3±0.5 mm