MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

LANCER EVOLUTION 2007

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57084/w960_57084-0.png

MITSUBISHI LANCER EVOLUTION 2007 Service Repair Manual

Trending: warning lights, adding oil, length, rear site, high beam, transmission, hood open

Page 861 of 1449

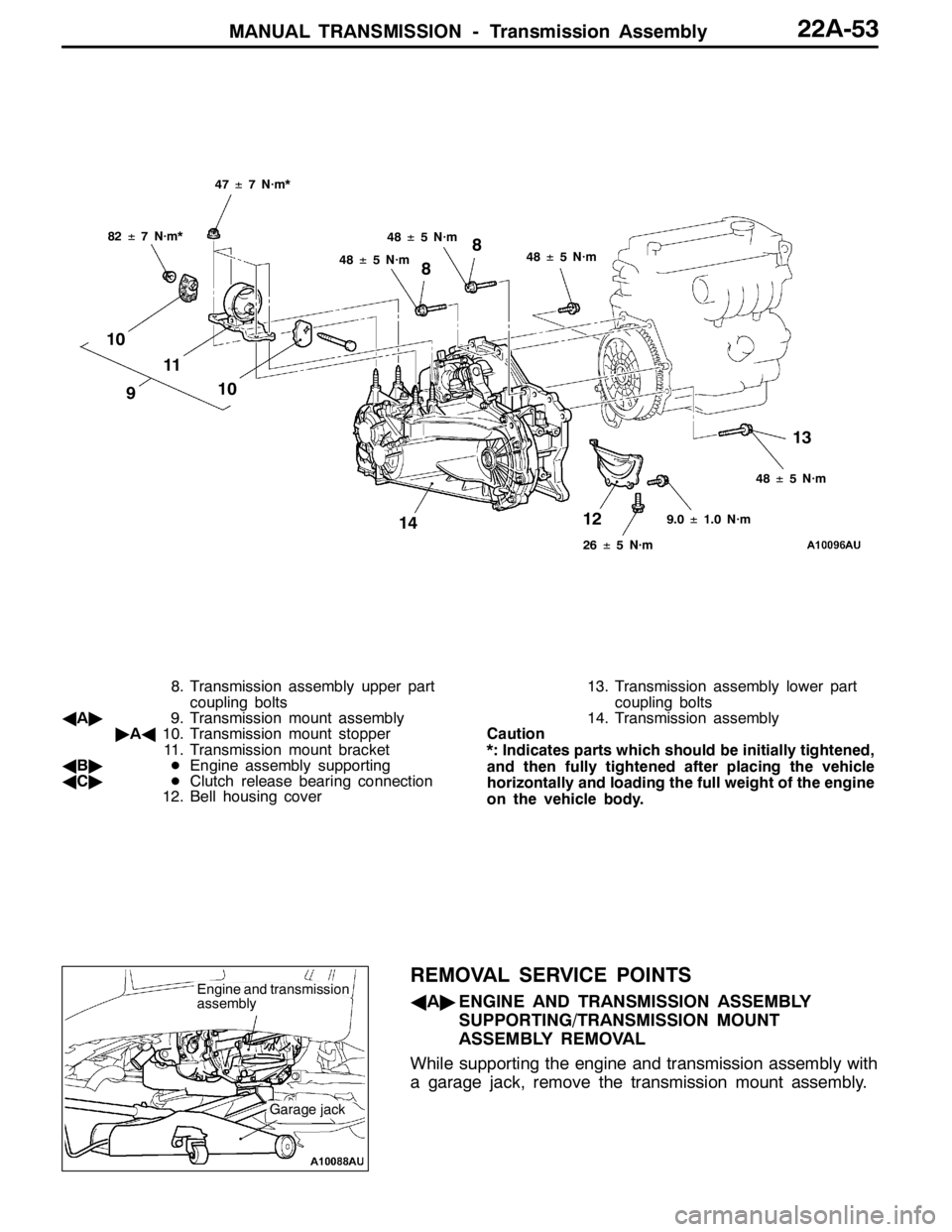

MANUAL TRANSMISSION - Transmission Assembly22A-53

10

10 11

9

1412 88

13

48±5 N·m

48±5 N·m

48±5 N·m

48±5 N·m

9.0±1.0 N·m

26±5 N·m

82±7 N·m*

47±7 N·m*

8. Transmission assembly upper part

coupling bolts

AA"9. Transmission mount assembly

"AA10. Transmission mount stopper

11. Transmission mount bracket

AB"DEngine assembly supporting

AC"DClutch release bearing connection

12. Bell housing cover13. Transmission assembly lower part

coupling bolts

14. Transmission assembly

Caution

*: Indicates parts which should be initially tightened,

and then fully tightened after placing the vehicle

horizontally and loading the full weight of the engine

on the vehicle body.

REMOVAL SERVICE POINTS

AA"ENGINE AND TRANSMISSION ASSEMBLY

SUPPORTING/TRANSMISSION MOUNT

ASSEMBLY REMOVAL

While supporting the engine and transmission assembly with

a garage jack, remove the transmission mount assembly.Engine and transmission

assembly

Garage jack

Page 862 of 1449

MANUAL TRANSMISSION - Transmission Assembly22A-54

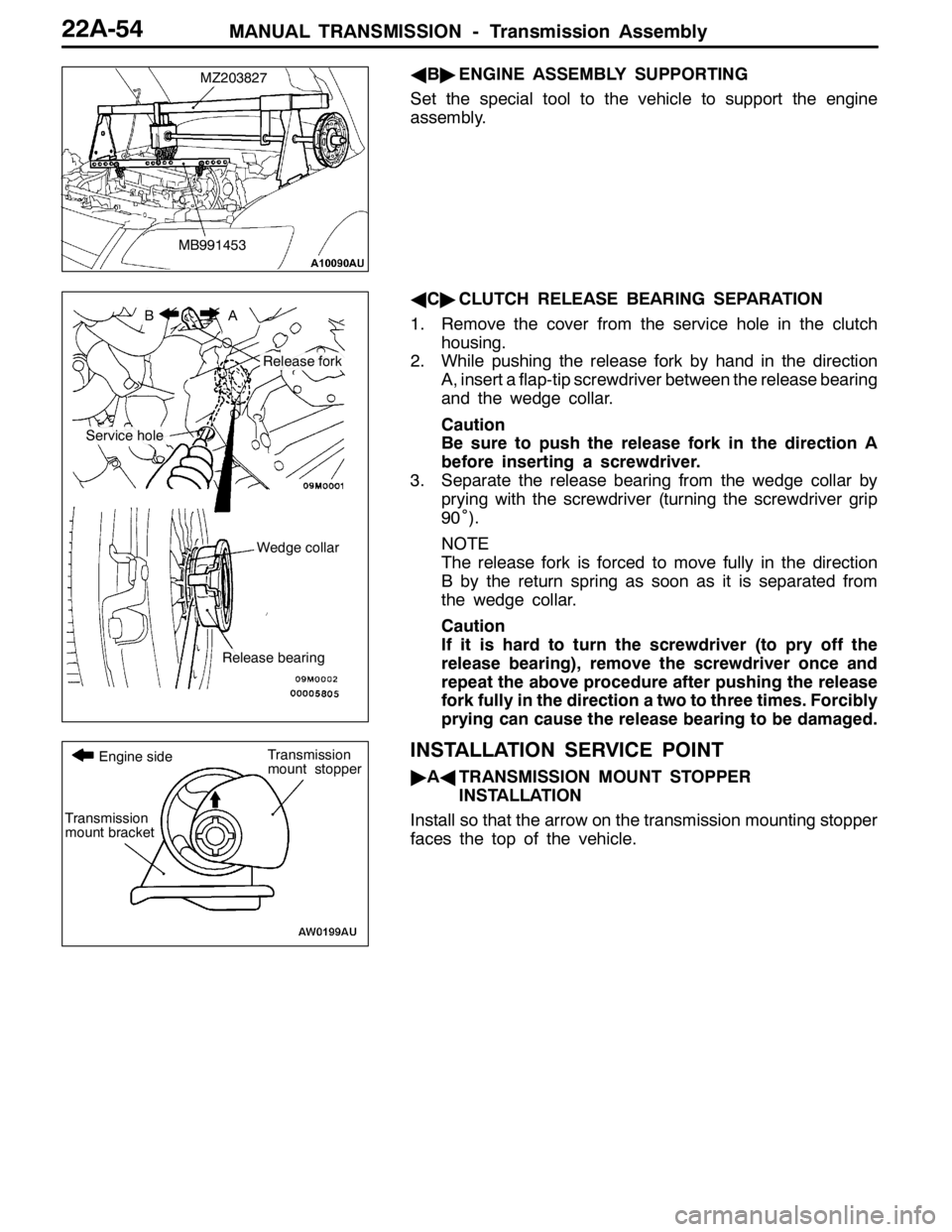

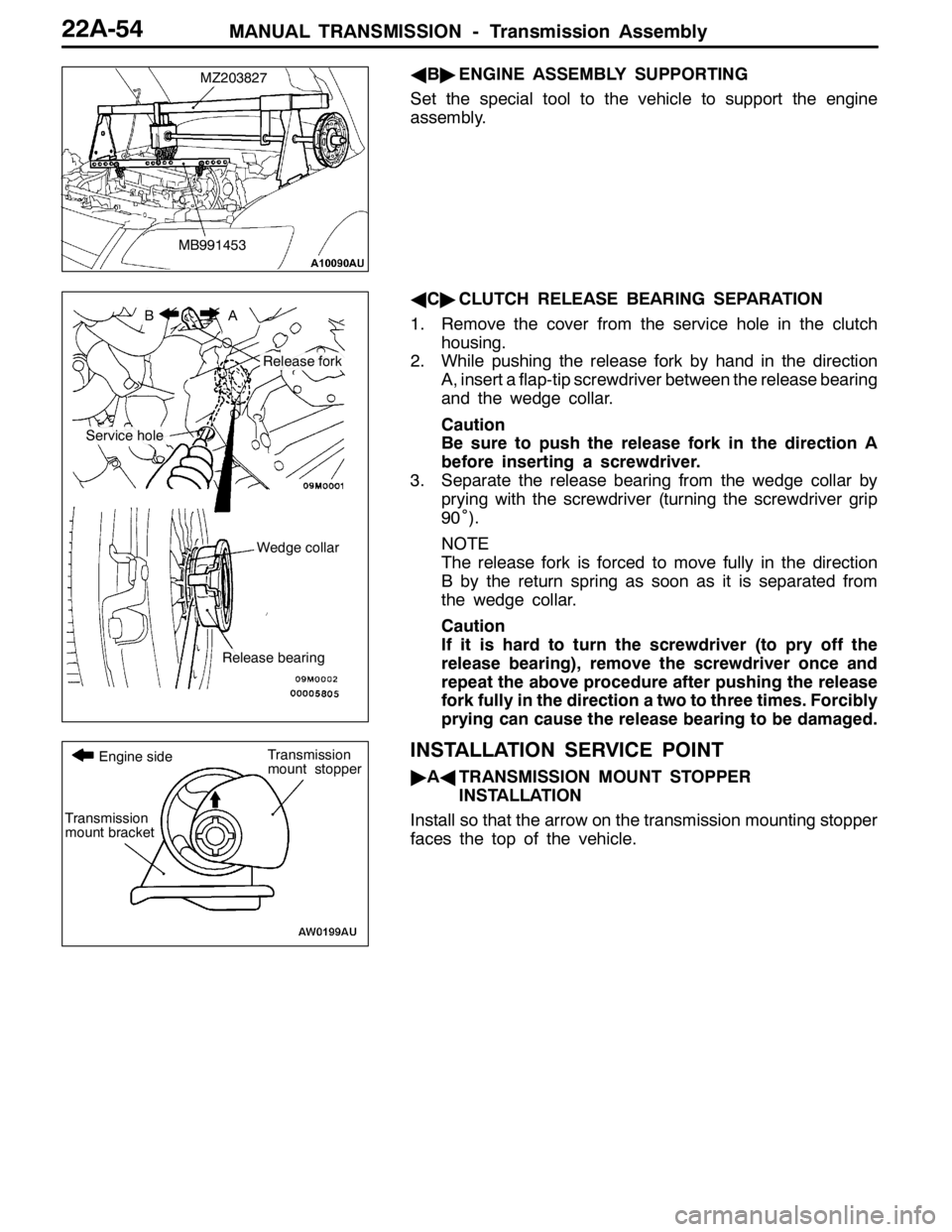

AB"ENGINE ASSEMBLY SUPPORTING

Set the special tool to the vehicle to support the engine

assembly.

AC"CLUTCH RELEASE BEARING SEPARATION

1. Remove the cover from the service hole in the clutch

housing.

2. While pushing the release fork by hand in the direction

A, insert a flap-tip screwdriver between the release bearing

and the wedge collar.

Caution

Be sure to push the release fork in the direction A

before inserting a screwdriver.

3. Separate the release bearing from the wedge collar by

prying with the screwdriver (turning the screwdriver grip

90˚).

NOTE

The release fork is forced to move fully in the direction

B by the return spring as soon as it is separated from

the wedge collar.

Caution

If it is hard to turn the screwdriver (to pry off the

release bearing), remove the screwdriver once and

repeat the above procedure after pushing the release

fork fully in the direction a two to three times. Forcibly

prying can cause the release bearing to be damaged.

INSTALLATION SERVICE POINT

"AATRANSMISSION MOUNT STOPPER

INSTALLATION

Install so that the arrow on the transmission mounting stopper

faces the top of the vehicle.

MZ203827

MB991453

BA

Service hole

Release fork

Wedge collar

Release bearing

Transmission

mount bracket

Transmission

mount stopper Engine side

Page 863 of 1449

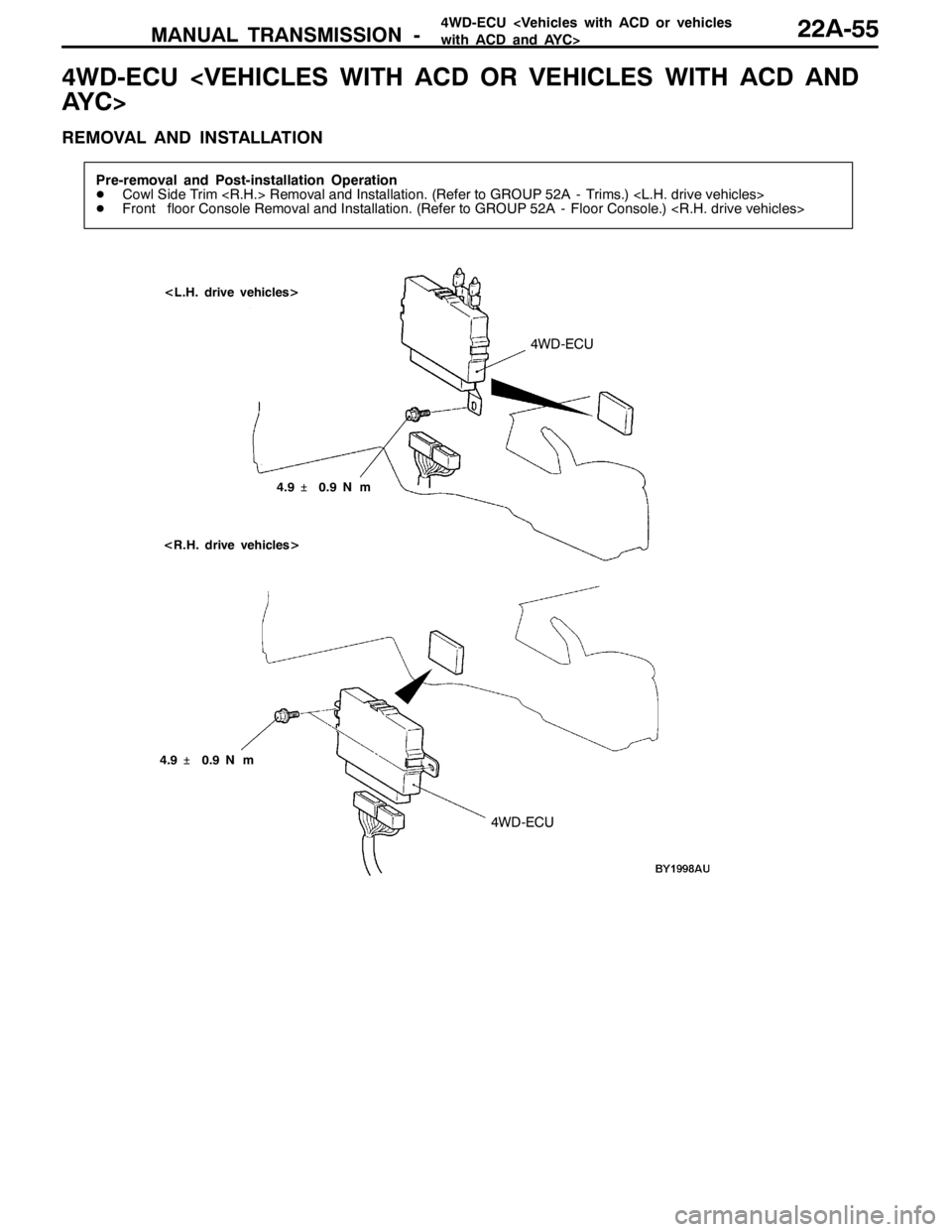

MANUAL TRANSMISSION -4WD-ECU

with ACD and AYC>22A-55

4WD-ECU

AYC>

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

DCowl Side Trim Removal and Installation. (Refer to GROUP 52A - Trims.)

DFront floor Console Removal and Installation. (Refer to GROUP 52A - Floor Console.)

4.9�¶0.9 N��m

4WD-ECU

4.9�¶0.9 N��m

4WD-ECU

Page 864 of 1449

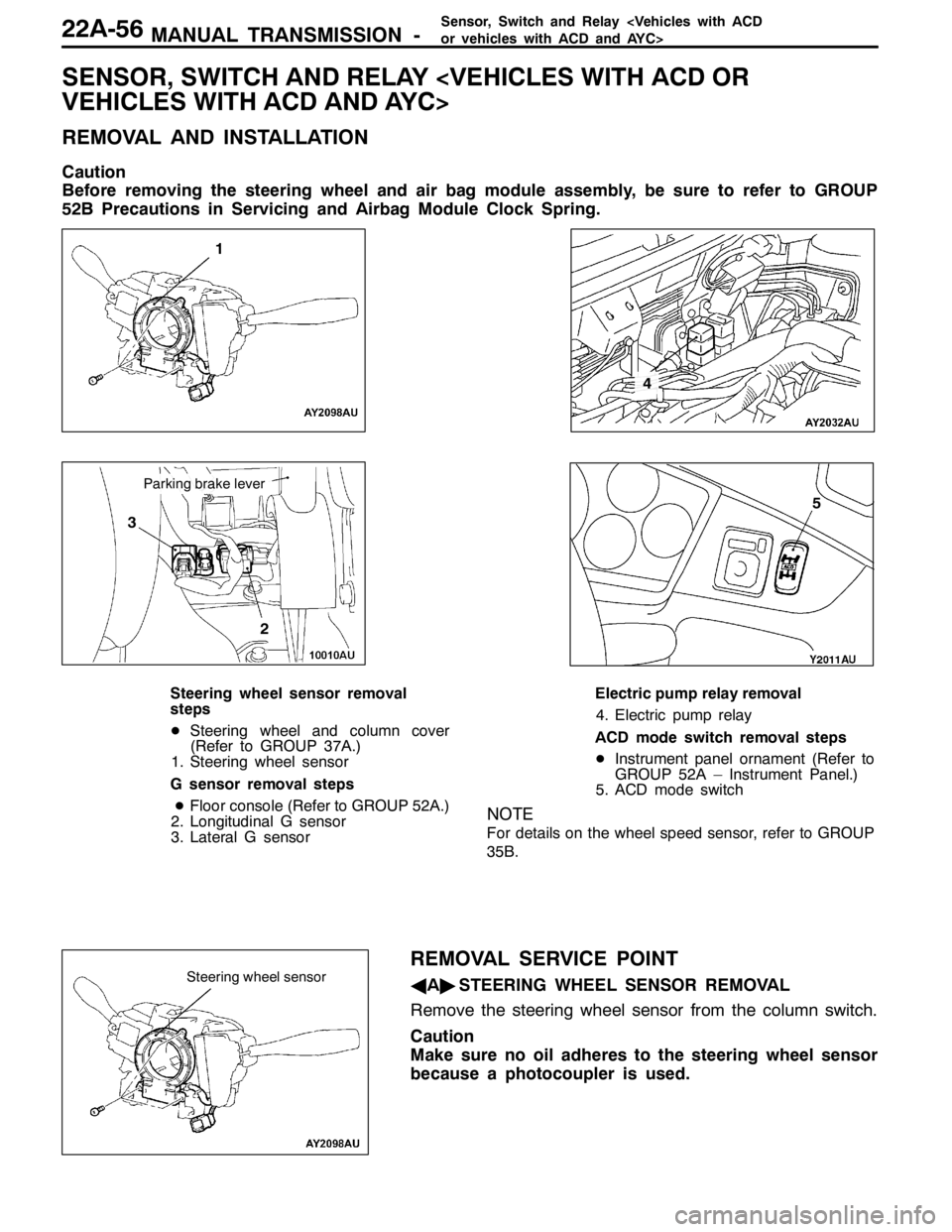

MANUAL TRANSMISSION -Sensor, Switch and Relay

or vehicles with ACD and AYC>22A-56

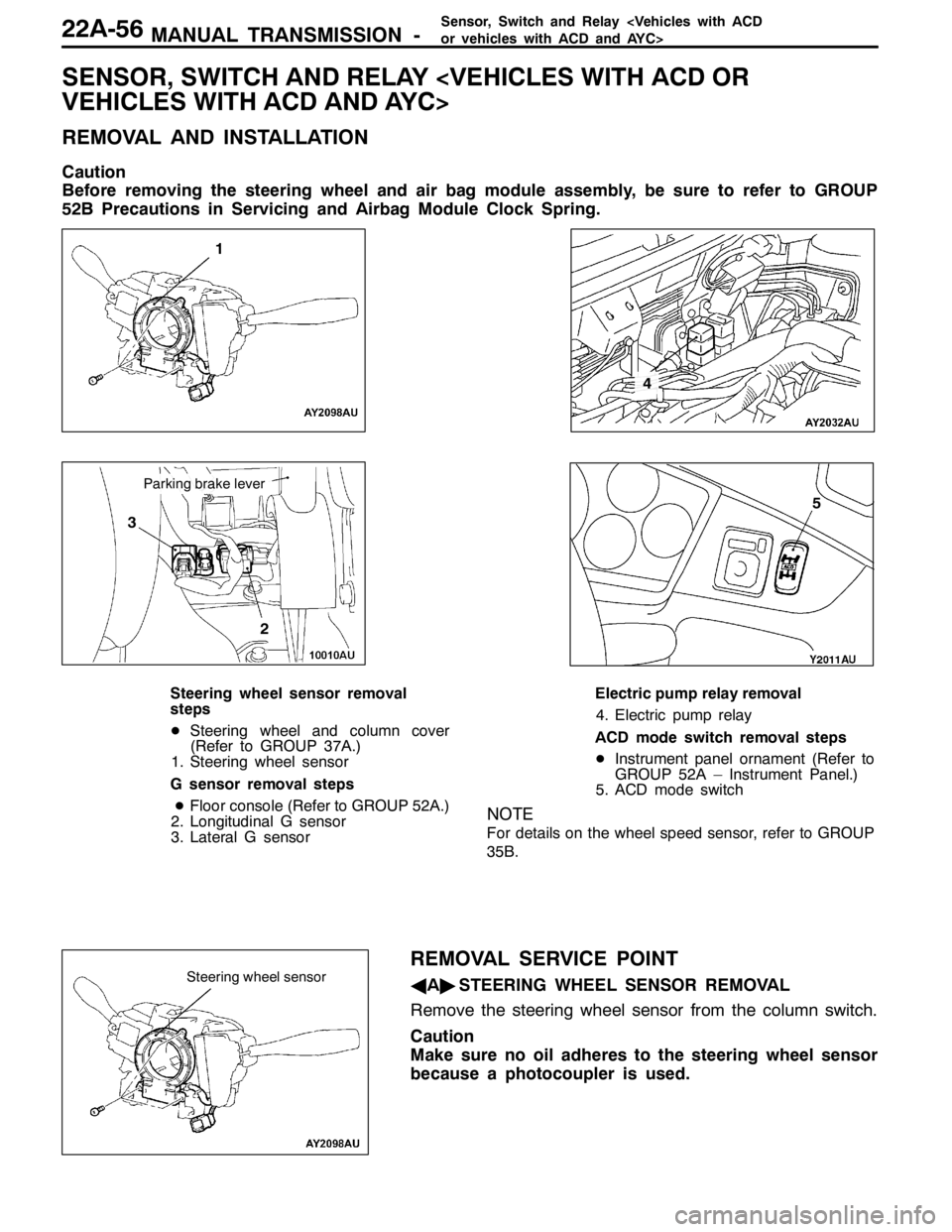

SENSOR, SWITCH AND RELAY

VEHICLES WITH ACD AND AYC>

REMOVAL AND INSTALLATION

Caution

Before removing the steering wheel and air bag module assembly, be sure to refer to GROUP

52B Precautions in Servicing and Airbag Module Clock Spring.

1

3

2

4

5

Parking brake lever

Steering wheel sensor removal

steps

DSteering wheel and column cover

(Refer to GROUP 37A.)

1. Steering wheel sensor

G sensor removal steps

DFloor console (Refer to GROUP 52A.)

2. Longitudinal G sensor

3. Lateral G sensorElectric pump relay removal

4. Electric pump relay

ACD mode switch removal steps

DInstrument panel ornament (Refer to

GROUP 52A – Instrument Panel.)

5. ACD mode switch

NOTE

For details on the wheel speed sensor, refer to GROUP

35B.

REMOVAL SERVICE POINT

AA"STEERING WHEEL SENSOR REMOVAL

Remove the steering wheel sensor from the column switch.

Caution

Make sure no oil adheres to the steering wheel sensor

because a photocoupler is used.Steering wheel sensor

Page 865 of 1449

MANUAL TRANSMISSION -Sensor,SwitchandRelay

vehicles with ACD and AYC>22A-57

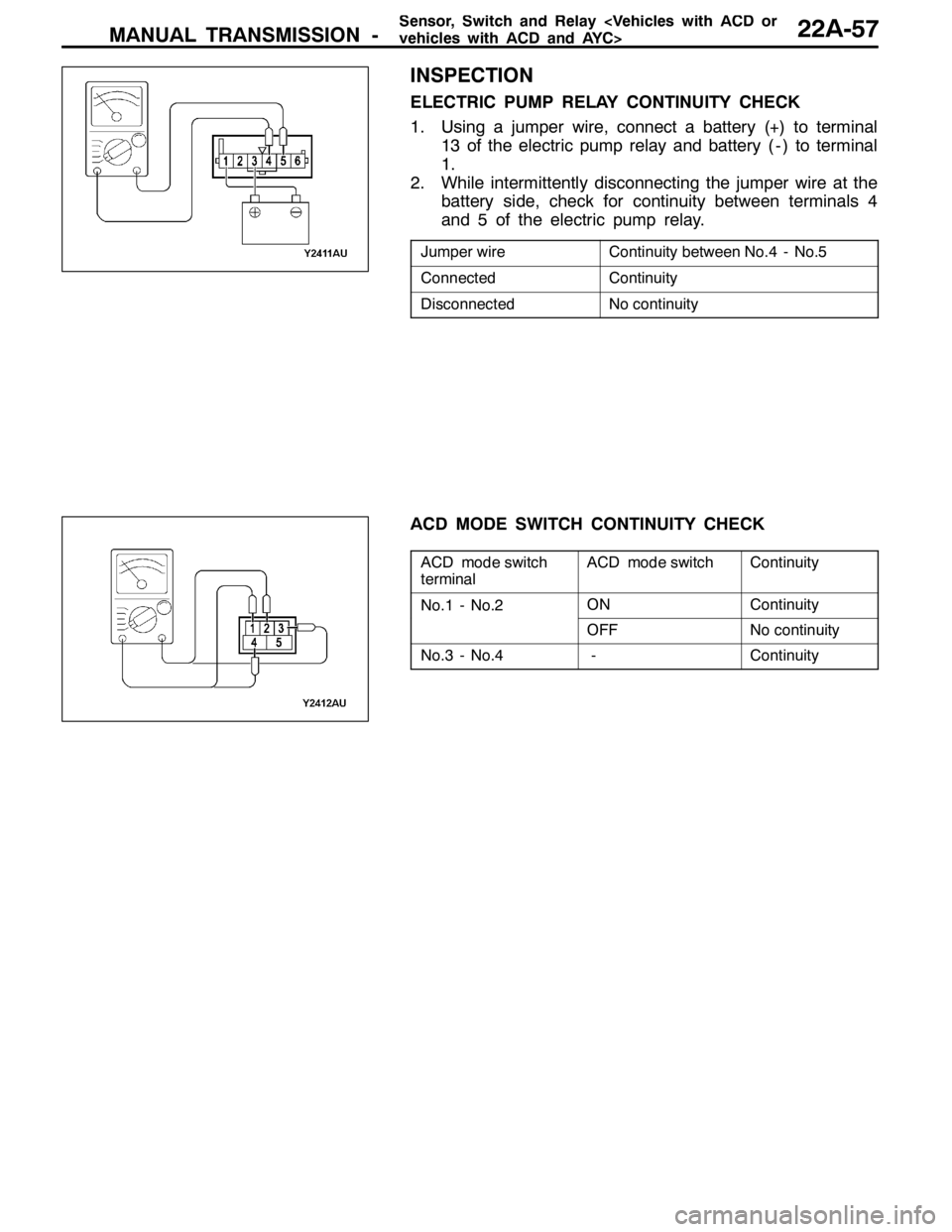

INSPECTION

ELECTRIC PUMP RELAY CONTINUITY CHECK

1. Using a jumper wire, connect a battery (+) to terminal

13 of the electric pump relay and battery ( - ) to terminal

1.

2. While intermittently disconnecting the jumper wire at the

battery side, check for continuity between terminals 4

and 5 of the electric pump relay.

Jumper wireContinuity between No.4 - No.5

ConnectedContinuity

DisconnectedNo continuity

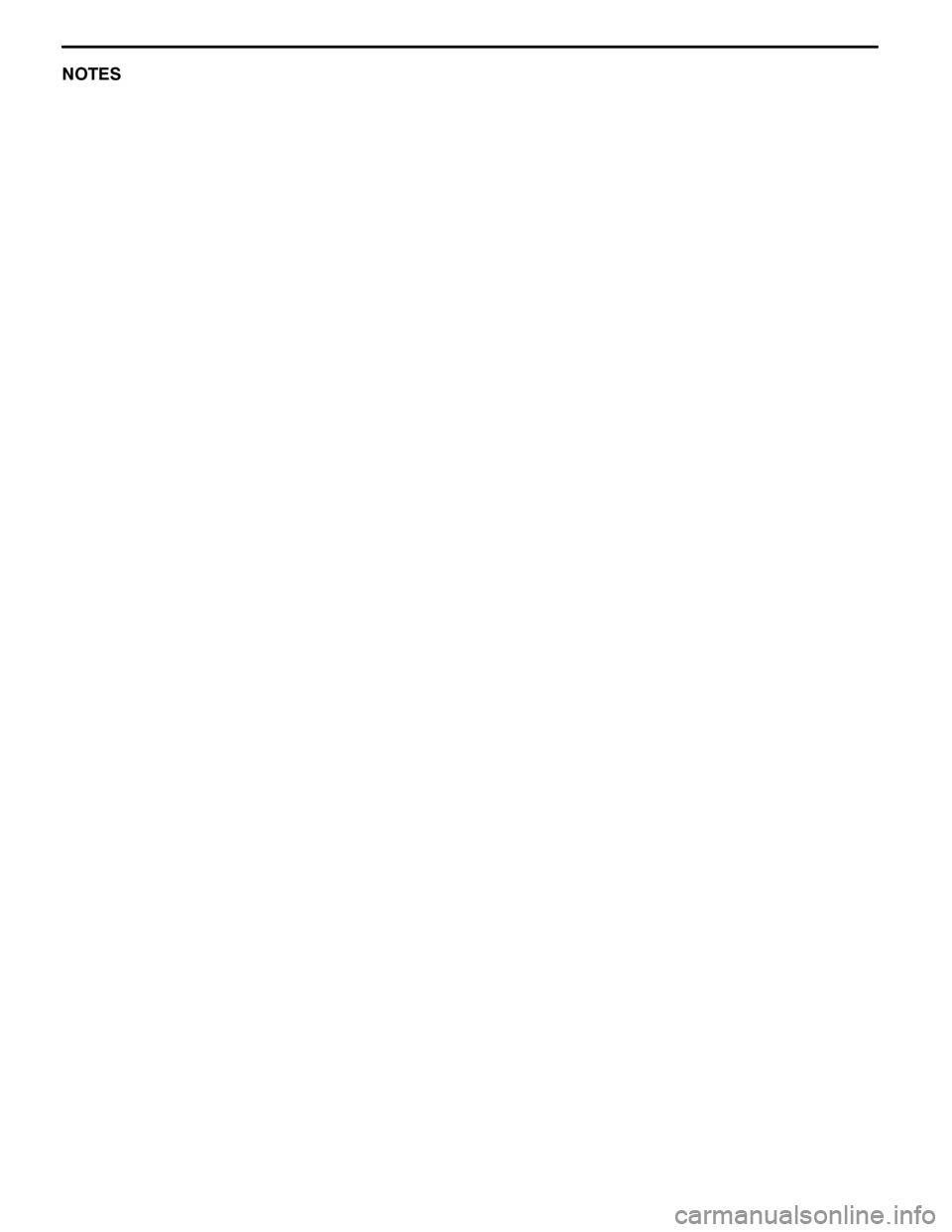

ACD MODE SWITCH CONTINUITY CHECK

ACD mode switch

terminalACD mode switchContinuity

No.1 - No.2ONContinuity

OFFNo continuity

No.3 - No.4-Continuity

Page 866 of 1449

Page 867 of 1449

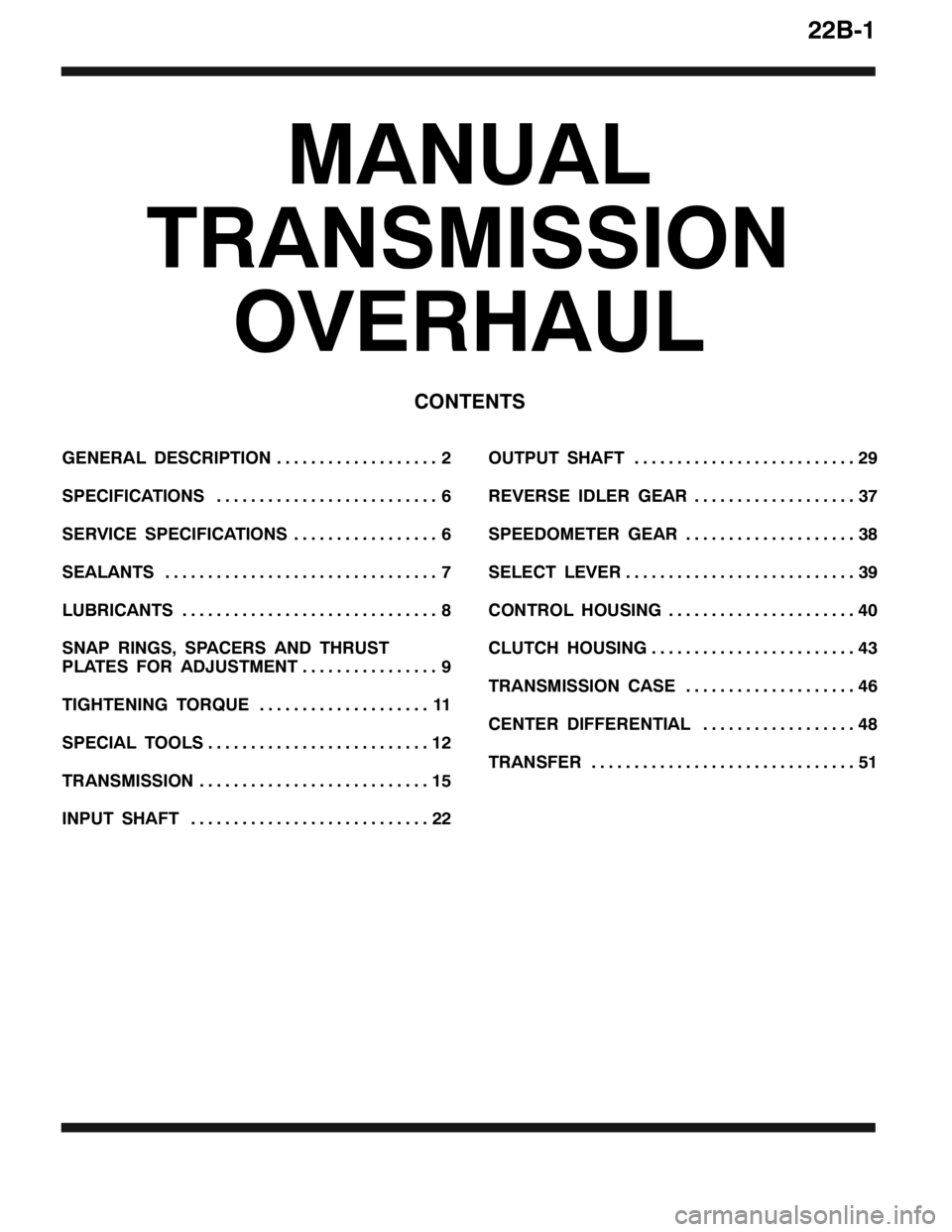

22B-1

MANUAL

TRANSMISSION

OVERHAUL

CONTENTS

GENERAL DESCRIPTION 2...................

SPECIFICATIONS 6..........................

SERVICE SPECIFICATIONS 6.................

SEALANTS 7................................

LUBRICANTS 8..............................

SNAP RINGS, SPACERS AND THRUST

PLATES FOR ADJUSTMENT 9................

TIGHTENING TORQUE 11....................

SPECIAL TOOLS 12..........................

TRANSMISSION 15...........................

INPUT SHAFT 22............................OUTPUT SHAFT 29..........................

REVERSE IDLER GEAR 37...................

SPEEDOMETER GEAR 38....................

SELECT LEVER 39...........................

CONTROL HOUSING 40......................

CLUTCH HOUSING 43........................

TRANSMISSION CASE 46....................

CENTER DIFFERENTIAL 48..................

TRANSFER 51...............................

Page 868 of 1449

MANUAL TRANSMISSION OVERHAUL -General Description22B-2

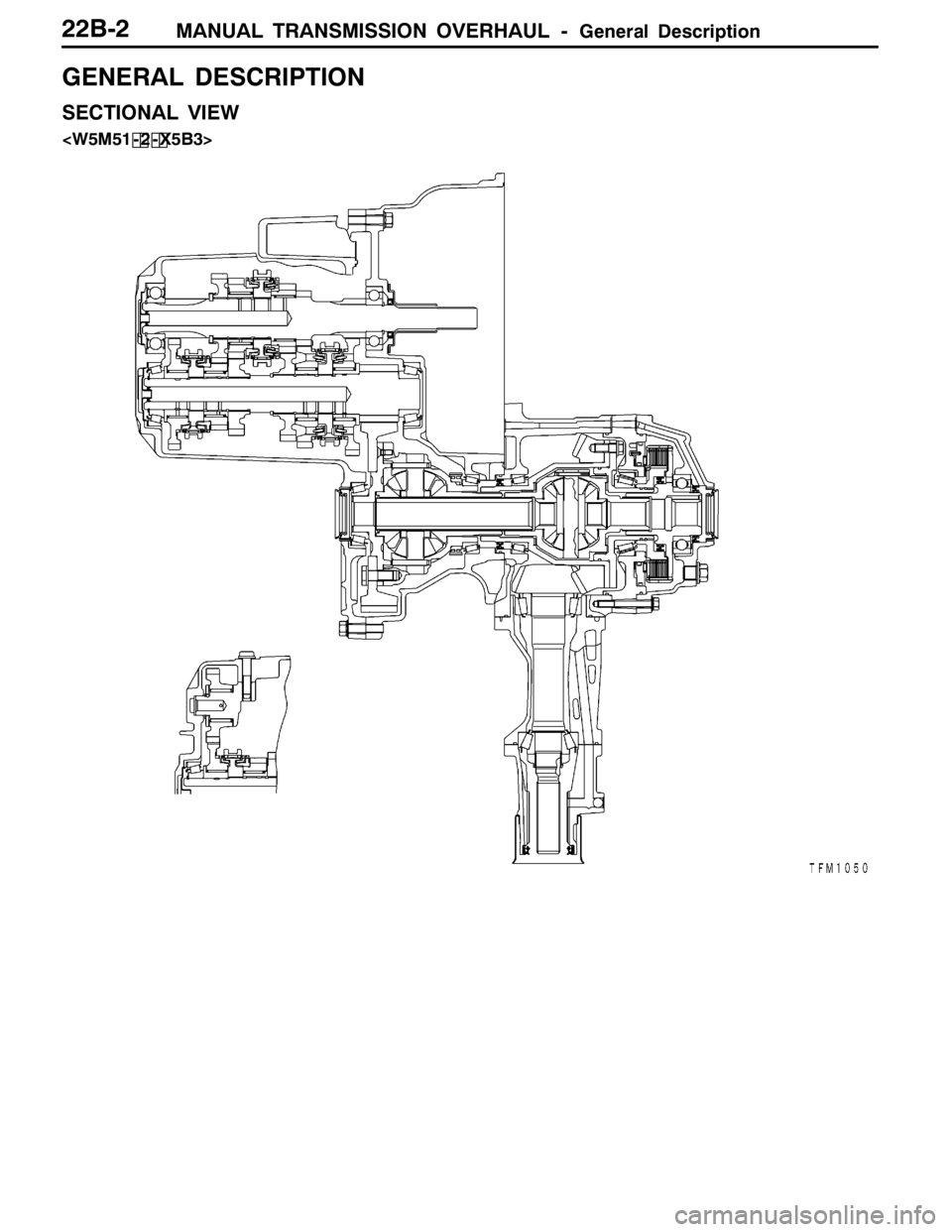

GENERAL DESCRIPTION

SECTIONAL VIEW

Page 869 of 1449

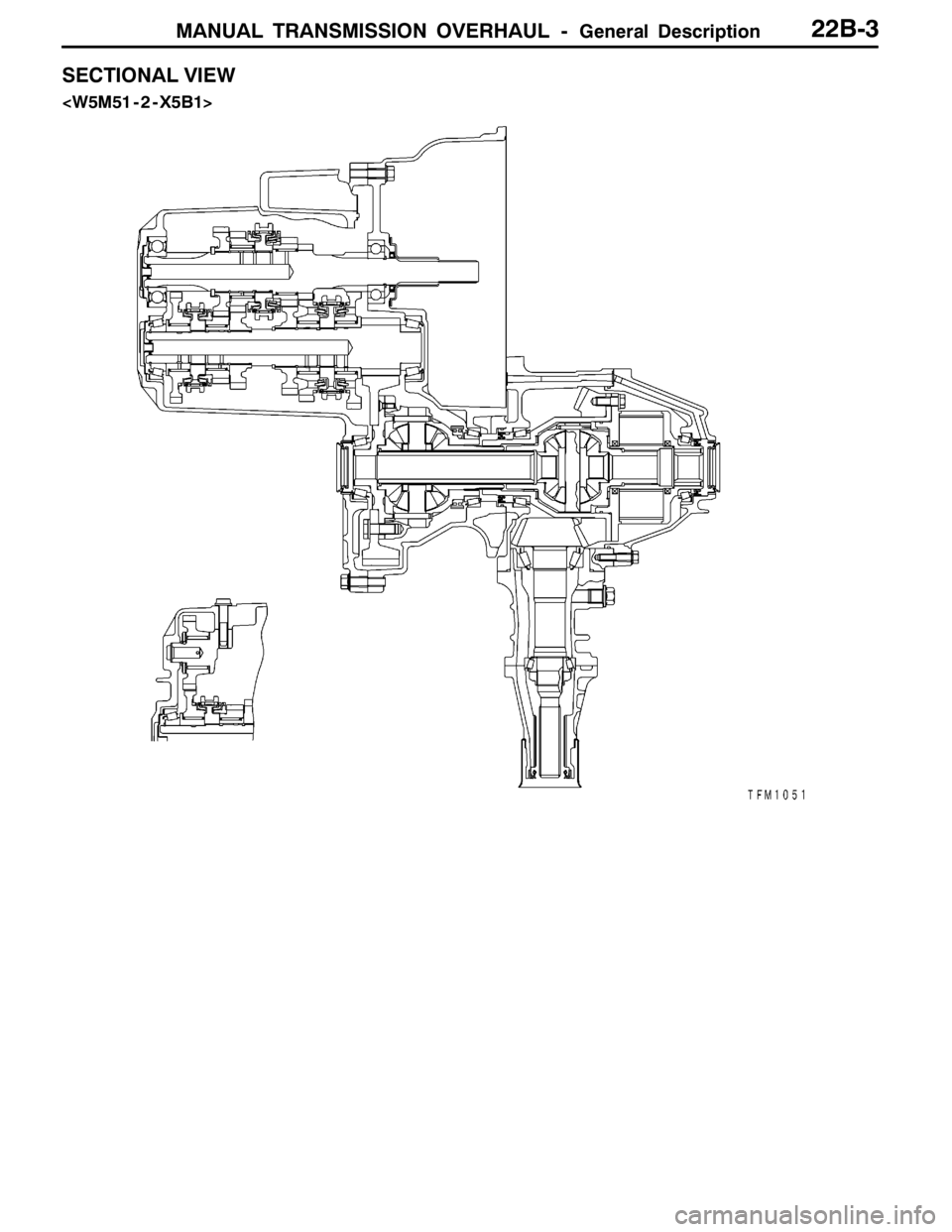

MANUAL TRANSMISSION OVERHAUL -General Description22B-3

SECTIONAL VIEW

Page 870 of 1449

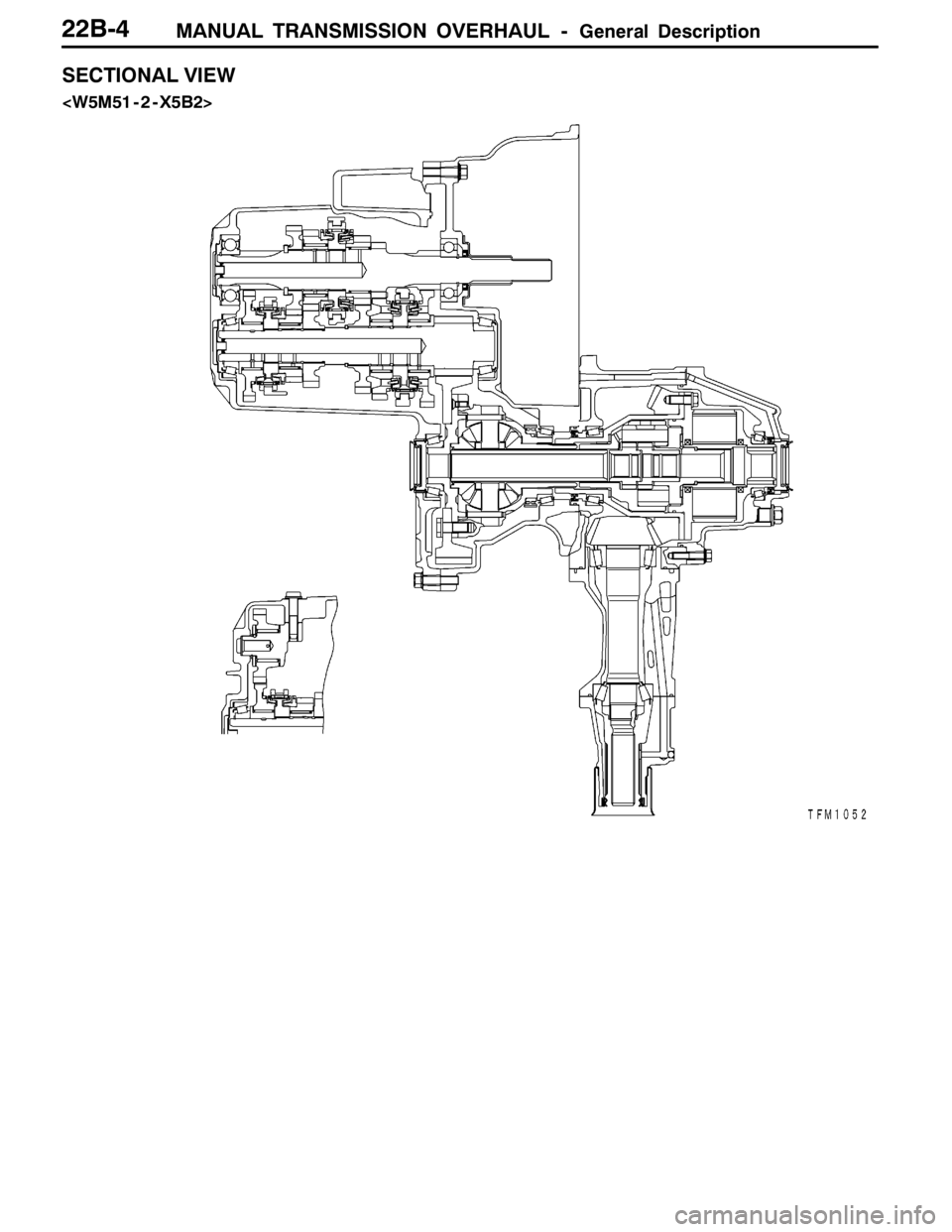

MANUAL TRANSMISSION OVERHAUL -General Description22B-4

SECTIONAL VIEW

Trending: oil pressure, roof, engine coolant, to pair, transmission fluid, brake fluid, warning light