MITSUBISHI MONTERO 1987 1.G Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 111 of 284

STARTING SYSTEM-General Information 8-91

STARTING SYSTEM

GENERAL INFORMATION

NOBFAAJ

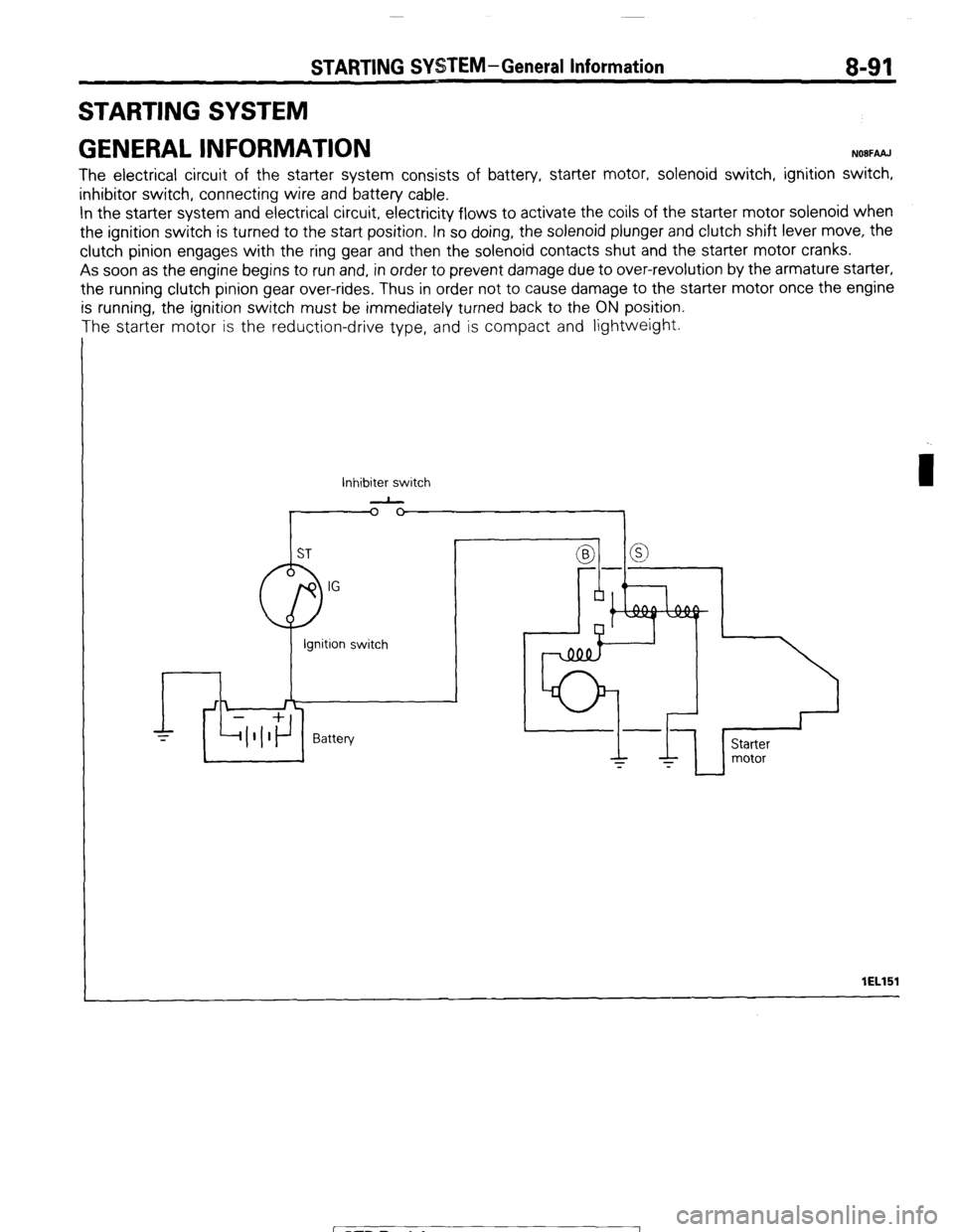

The electrical circuit of the starter system consists of battery, starter motor, solenoid switch, ignition switch,

inhibitor switch, connecting wire and battery cable.

In the starter system and electrical circuit, electricity flows to activate the coils of the starter motor solenoid when

the ignition switch is turned to the start position. In so doing, the solenoid plunger and clutch shift lever move, the

clutch pinion engages with the ring gear and then the solenoid contacts shut and the starter motor cranks.

As soon as the engine begins to run and, in order to prevent damage due to over-revolution by the armature starter,

the running clutch pinion gear over-rides, Thus in order not to cause damage to the starter motor once the engine

is running, the ignition switch must be immediately turned back to the ON position.

The starter motor is the reduction-drive type, and is compact and lightweight.

Inhibiter switch

-

I lEL151

1 STB Revision

Page 112 of 284

8-92 STARTING SYSTEM - General Information

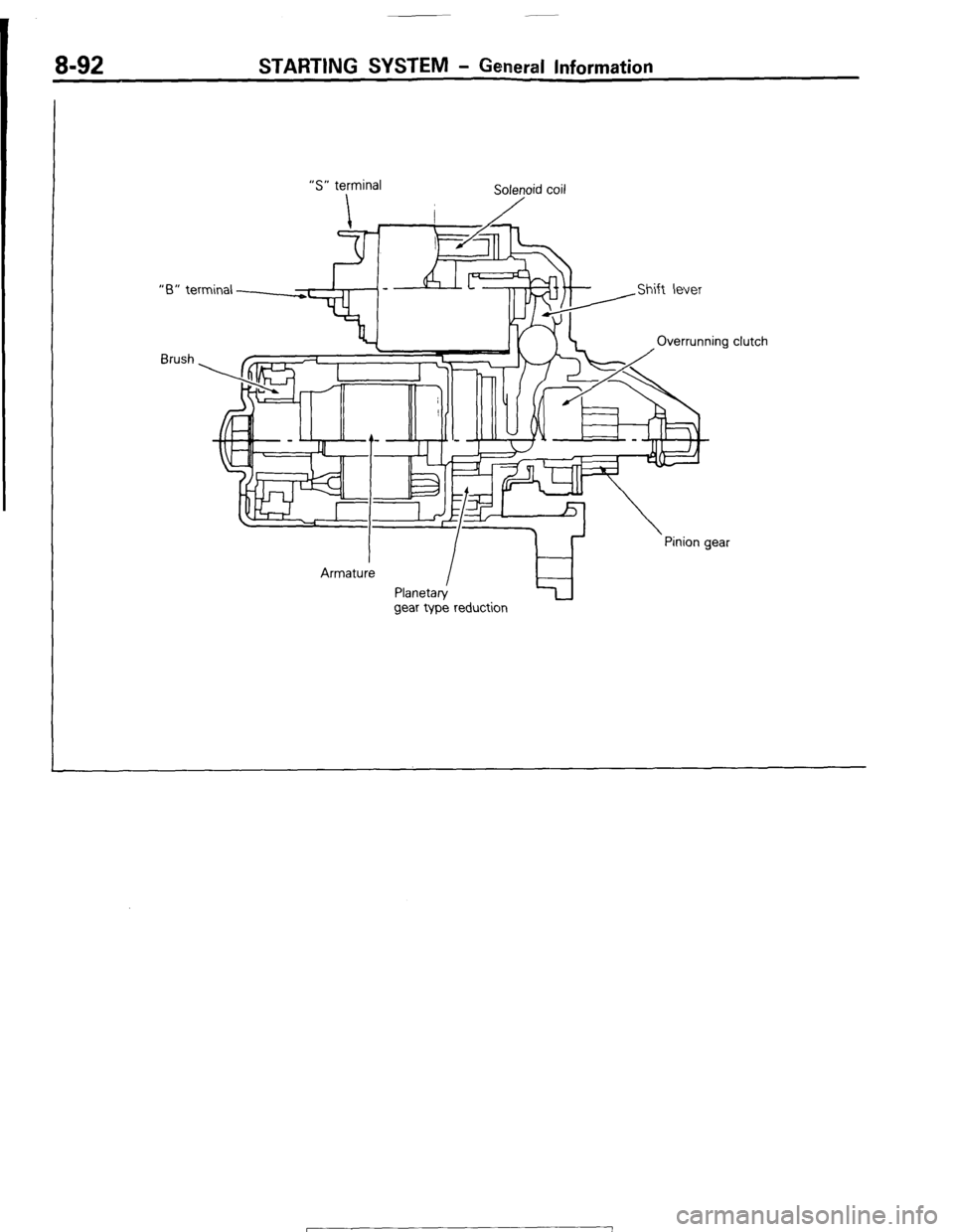

“S” terminal

Sole;oid coil

“6” terminal -

clutch

Brush

gear type reduction

1 ST6 Revision

Page 113 of 284

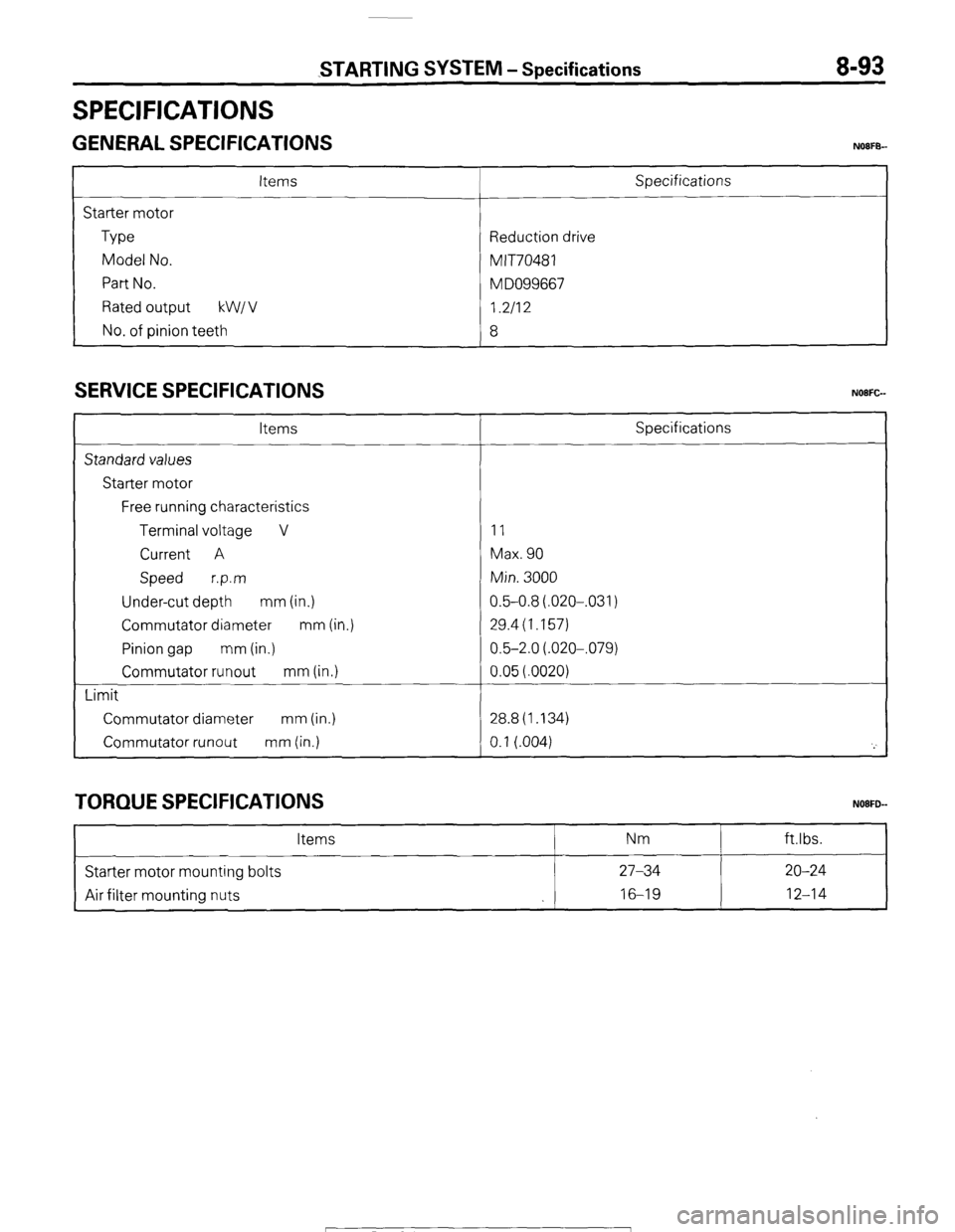

SPECIFICATIONS

STARTING SYSTEM - Specifications 8-93

GENERAL SPECIFICATIONS NOIFB-

Items

Starter motor

Type

Model No.

Part No.

Rated output kW1 v

No. of pinion teeth Specifications

Reduction drive

MIT70481

M DO99667

I.2112

8

SERVICE SPECIFICATIONS

Items

Standard values

Starter motor

Free running characteristics

Terminal voltage V

Current A

Speed r.p.m

Under-cut depth mm (in.)

Commutator diameter mm (in.)

Pinion gap mm (in.)

Commutator runout mm (in.)

Limit

Commutator diameter mm (in.)

Commutator runout mm (in.) Specifications

11

Max. 90

Min. 3000

0.5-0.8(.020-,031)

29.4(1.157)

0.5-2.0(.020-,079)

0.05(.0020)

28.8(1.134)

0.1 (.004)

'_'

TORQUE SPECIFICATIONS

Items Nm ftlbs.

Starter motor mounting bolts 27-34 20-24

Air filter mounting nuts 16-19

12-14

1 STB Revision

Page 114 of 284

8-94 STARTING SYSTEM -Troubleshooting

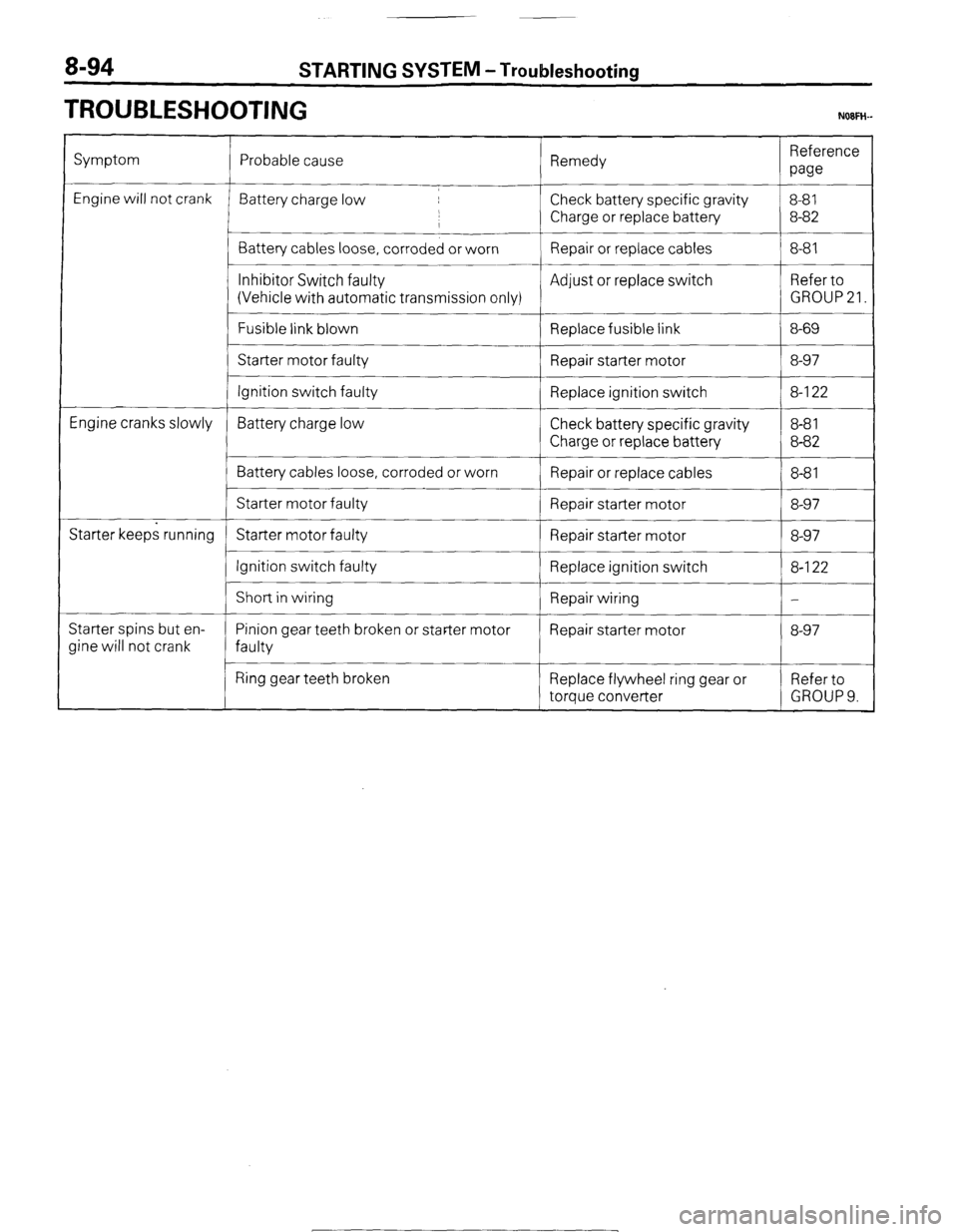

TROUBLESHOOTING NOFH-

Symptom

Engine will not crank

Engine cranks slowly

Starter keeps running

Starter spins but en-

Jine will not crank Probable cause Remedy Reference

paw

Battery charge low Check battery specific gravity 8-81

,

I Charge or replace battery 8-82

Battery cables loose, corroded or worn Repair or replace cables 8-81

__~

Inhibitor Switch faulty Adjust or replace switch Refer to

(Vehicle with automatic transmission only) GROUP 21.

Fusible link blown

Replace fusible link 8-69

Starter motor faulty

Repair starter motor 8-97

Ignition switch faulty Replace ignition switch 8-l 22

Battery charge low Check battery specific gravity 8-8 1

Charge or replace battery 8-82

Battery cables loose, corroded or worn

Repair or replace cables 8-8 1

Starter motor faulty Repair starter motor 8-97

Starter motor faulty Repair starter motor 8-97

Ignition switch faulty

Replace ignition switch 8-l 22

I

Short in wiring

Repair wiring -

Pinion gear teeth broken or starter motor Repair starter motor 8-97

faulty

Ring gear teeth broken Replace flywheel ring gear or Refer to

torque converter GROUP 9.

1 STB Revision

-7

Page 115 of 284

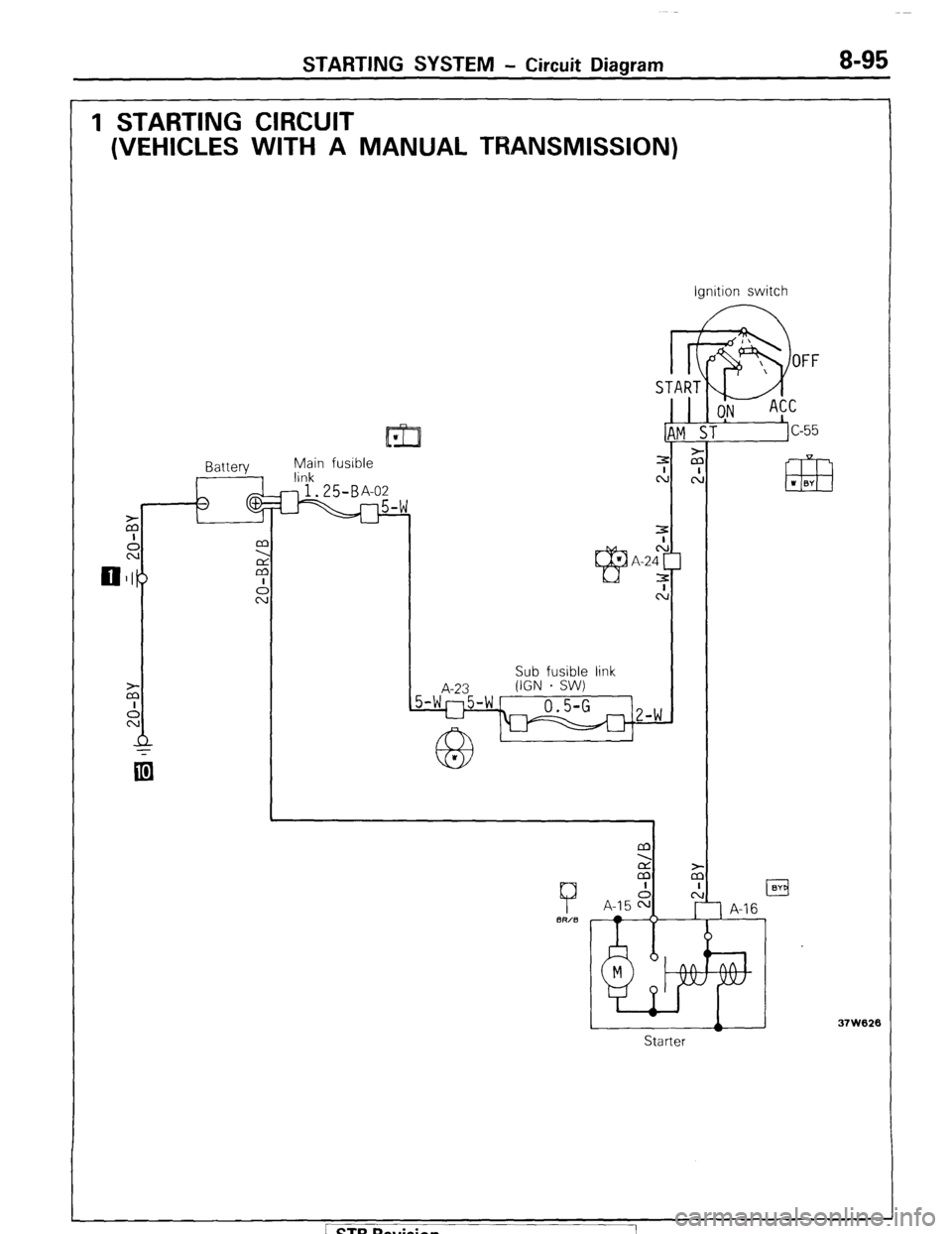

STARTING SYSTEM - Circuit Diagram 8-95

1 STARTING CIRCUIT

(VEHICLES WITH A MANUAL TRANSMISSION)

11171 w

$in fusible

START

I k

9

OFF

ON ACC

ST

c-55

.I

m I BY

Sub fusible link Ignition switch

Starter

37W626 / STB Revision

Page 116 of 284

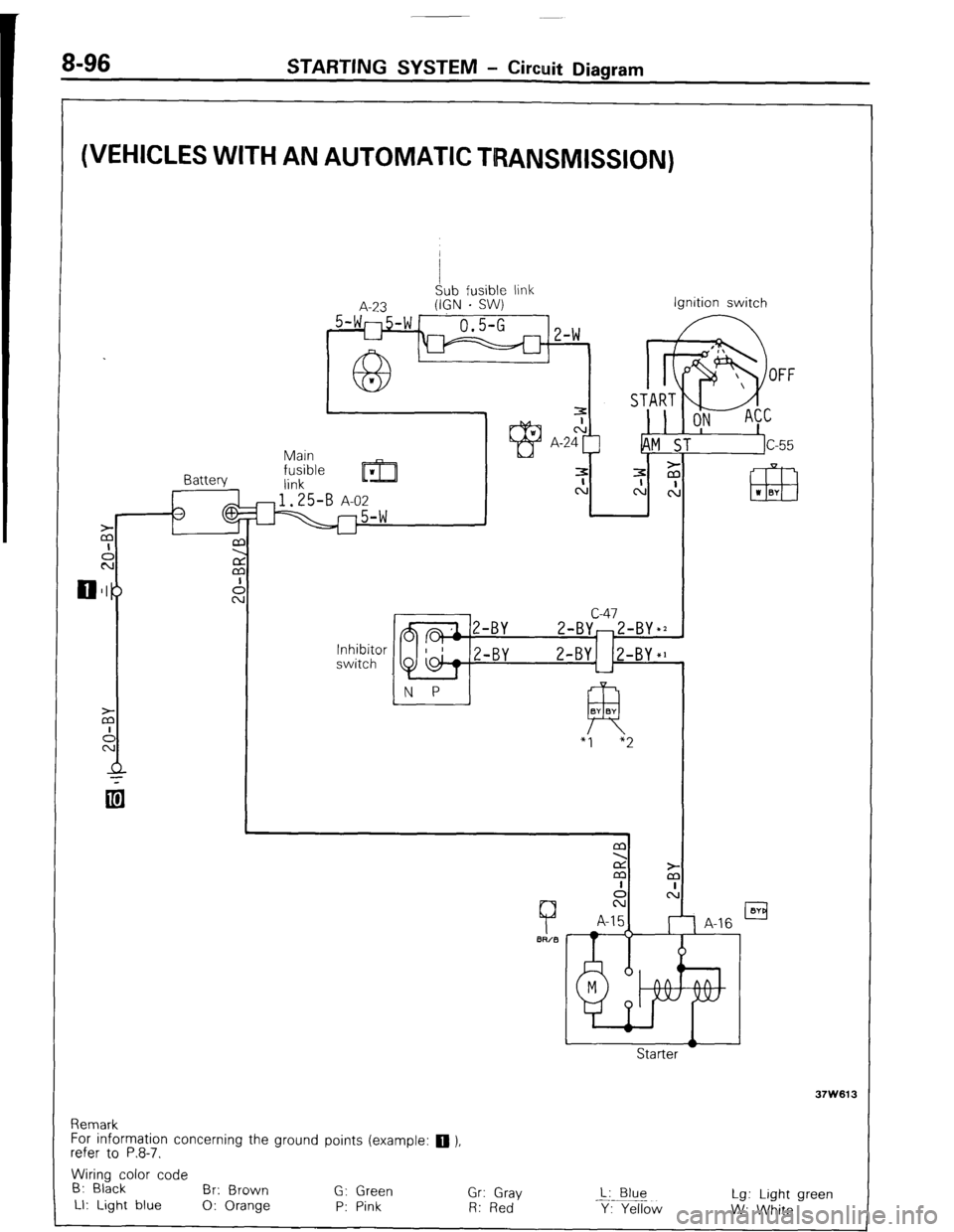

8-96 STARTING SYSTEM - Circuit Diagram

(VEHICLES WITH AN AUTOMATIC TRANSMISSION)

I

Sub fusible link

A-23 (IGN . SW)

_ 5-WI-754 1

0.5-G 1, 1,

L-l m 1 L-W

Battery Ignition switch

c-47

2-BY-Z-BY*2

N P

!-BY Z-BY1 (Z-BY*]

L-l

R BY BY

“I “2

Remark

For information concerning the ground points (example:

q ),

refer to P.8-7.

Wiring color code

B: Black

Br: Brown

G: Green

Gr: Gray L: Blue

LI: Light blue

0: Orange P: Pink Lg: Light green

R: Red

Y: Yellow

W: White

STB Revision

Page 117 of 284

STARTING WSTEM - Starter Motor 8-97

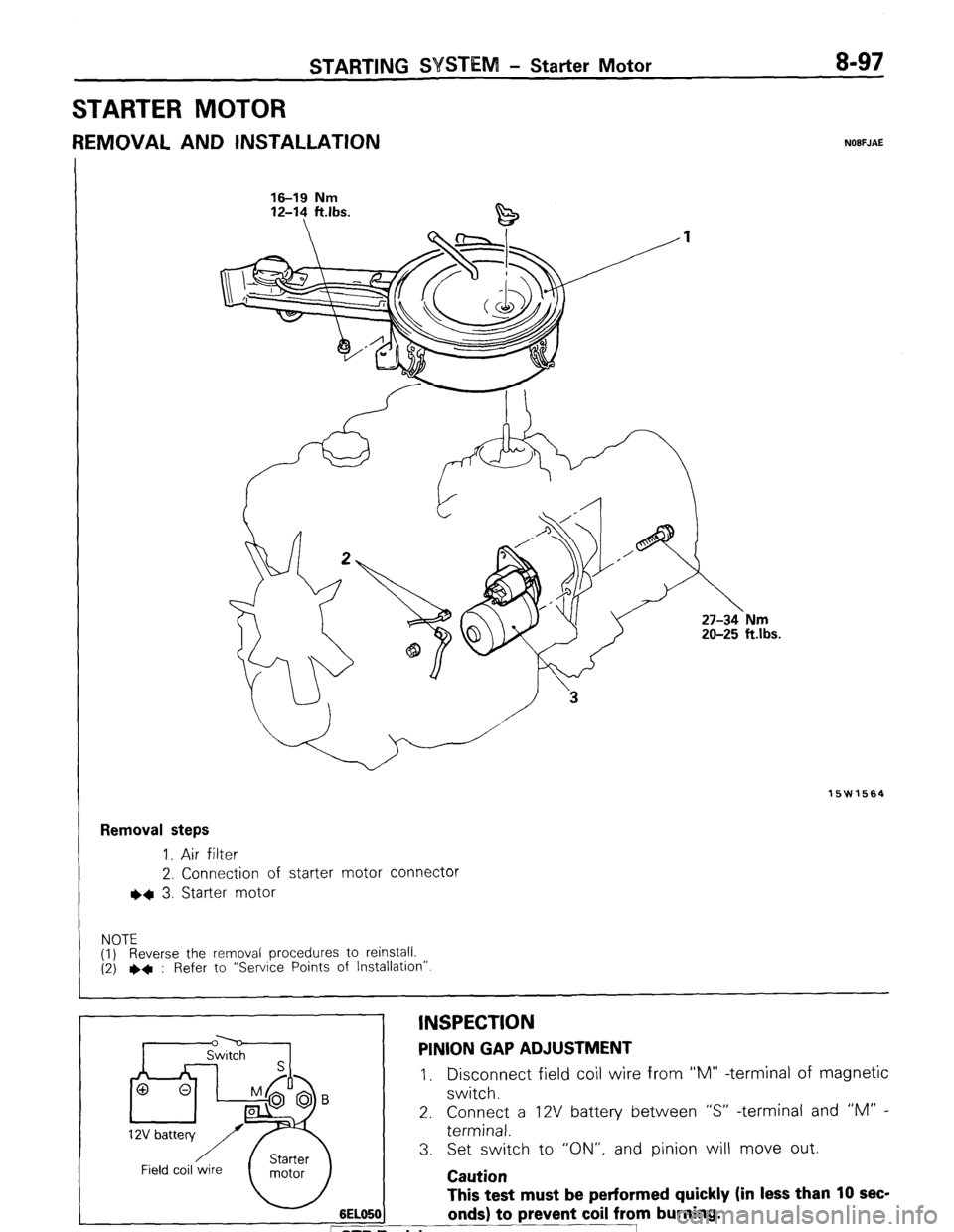

STARTER MOTOR

REMOVAL AND INSTALLATION NOBFJAE

16-19 Nm 16-19 Nm

12-l? ft.lbs. 12-14 ft.lbs.

15W1564

Removal steps

1. Air filter

2. Connection of starter motor connector

l * 3. Starter motor

NOTE

(1) Reverse the removal procedures to reinstall.

(2) ++ : Refer to “Service Points of Installation”

6EL05( This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning. D Revision

INSPECTION PINION GAP ADJUSTMENT

I, Disconnect field coil wire from “M” -terminal of magnetic

switch.

2. Connect a 12V battery between “S” -terminal and “M” -

terminal.

3. Set switch to “ON”, and pinion will move out.

Caution

Page 118 of 284

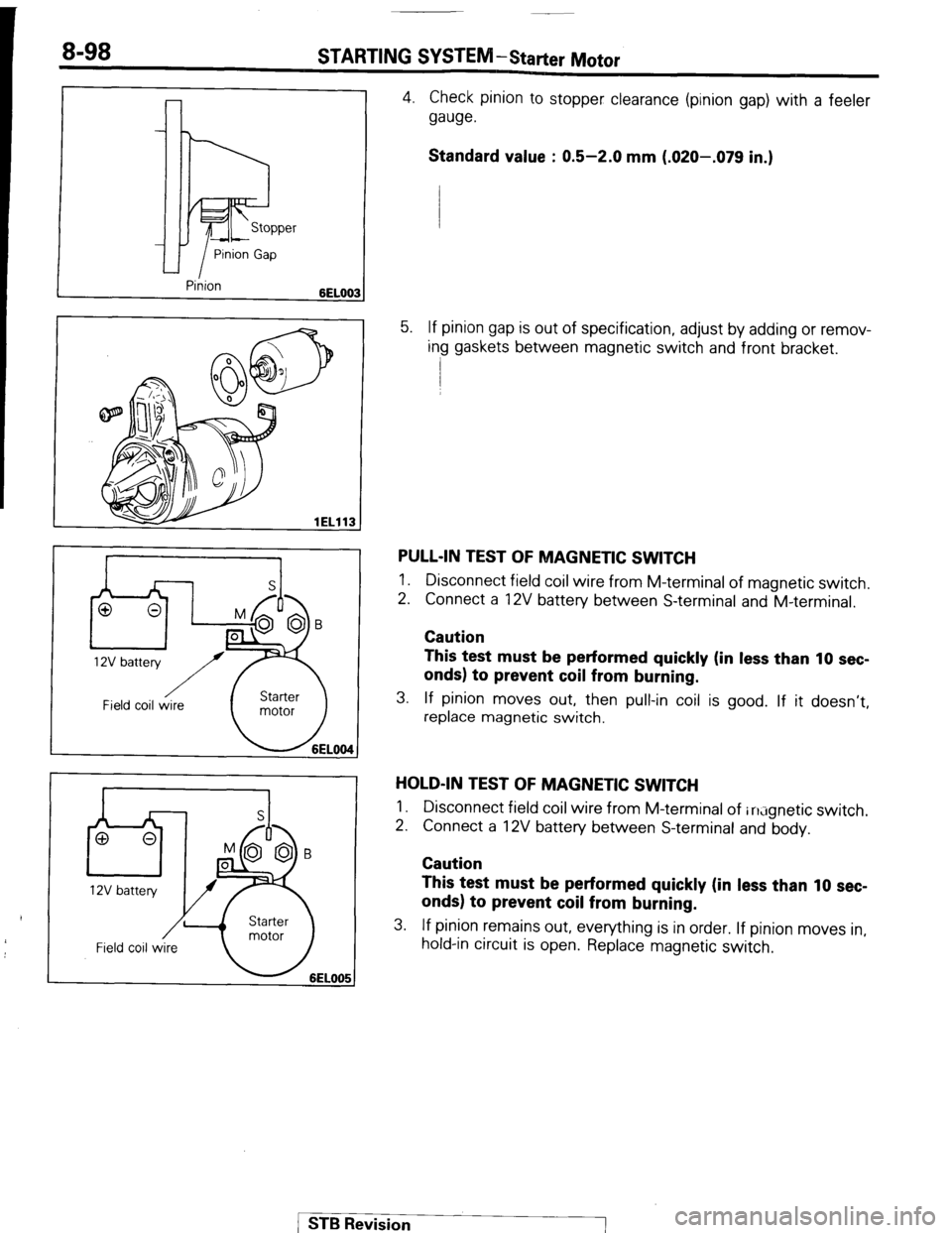

8-98 STARTING SYSTEM -Starter Motor

Pinion

6EL003

lEL113

/ Field coil wire

Field coil wire

4. Check pinion to stopper clearance (pinion gap) with a feeler

gauge.

Standard value : 0.5-2.0 mm (.020-.079 in.)

5. If pinion gap is out of specification, adjust by adding or remov-

ing gaskets between magnetic switch and front bracket.

PULL-IN TEST OF MAGNETIC SWITCH

1. Disconnect field coil wire from M-terminal of magnetic switch.

2. Connect a 12V battery between S-terminal and M-terminal.

Caution

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning.

3. If pinion moves out, then pull-in coil is good. If it doesn’t,

replace magnetic switch.

HOLD-IN TEST OF MAGNETIC SWITCH

1.

2. Disconnect field coil wire from M-terminal of in;ignetic switch.

Connect a 12V battery between S-terminal and body.

Caution

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning.

3. If pinion remains out, everything is in order. If pinion moves in,

hold-in circuit is open. Replace magnetic switch.

1 ST6 Revision

Page 119 of 284

WEEM -Starter Motor 8-99

I-

Carbon-pile rheostat

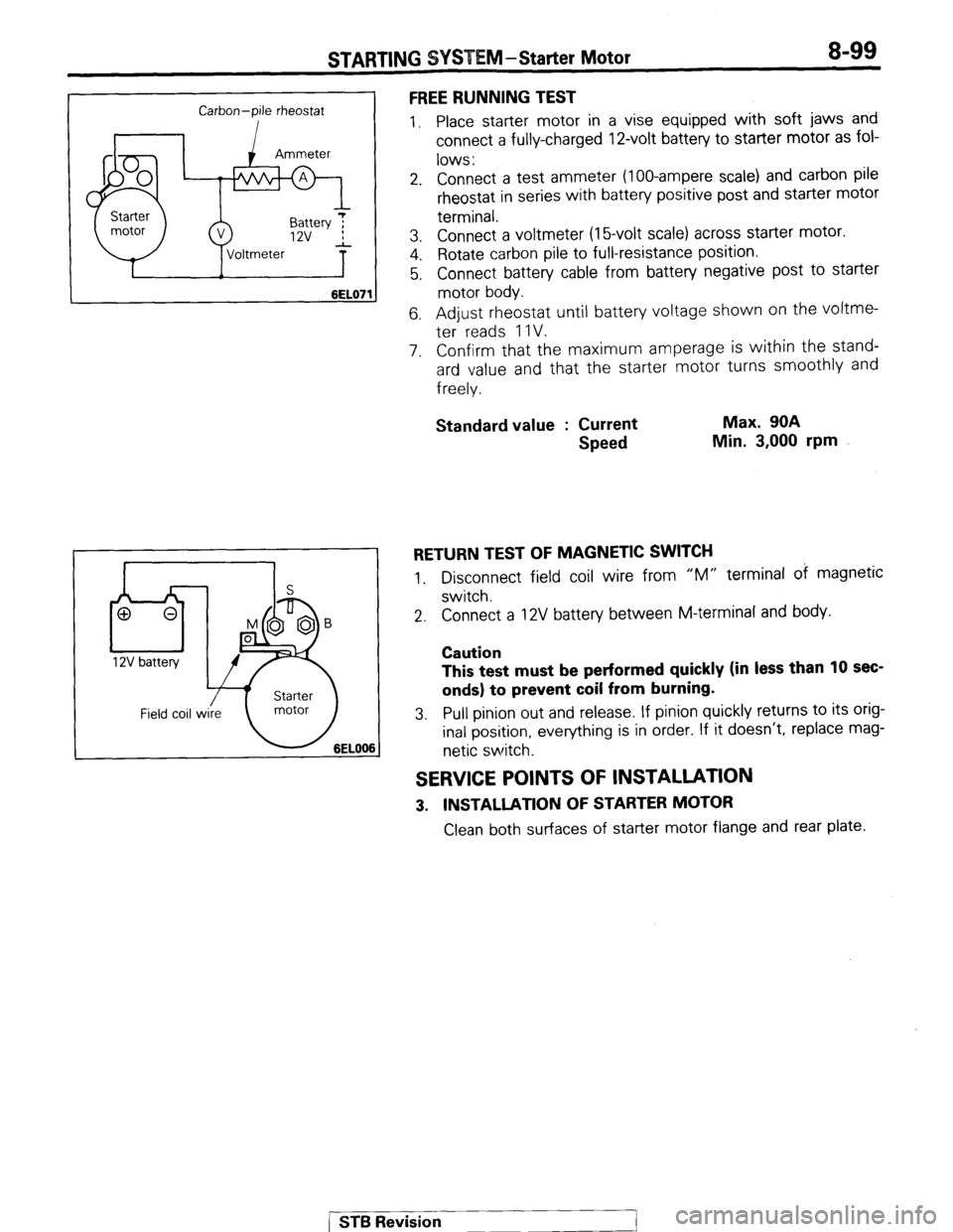

6EL07’ FREE RUNNING TEST

1. Place starter motor in a vise equipped with soft jaws and

connect a fully-charged 12-volt battery to starter motor as fol-

lows :

2. Connect a test ammeter (loo-ampere scale) and carbon pile

rheostat in series with battery positive post and starter motor

terminal.

3. Connect a voltmeter (16volt scale) across starter motor.

4. Rotate carbon pile to full-resistance position.

5. Connect battery cable from battery negative post to starter

motor body.

6. Adjust rheostat until battery voltage shown on the voltme-

ter reads 1 IV.

7. Confirm that the maximum amperage is within the stand-

ard value and that the starter motor turns smoothly and

freely.

Standard value : Current

Speed Max. 90A

Min. 3,000 rpm

RETURN TEST OF MAGNETIC SWITCH

1. Disconnect field coil wire from “M” terminal of magnetic

switch.

2. Connect a 12V battery between M-terminal and body.

Caution

This test must be performed quickly (in less than 10 sec-

onds) to prevent coil from burning.

3. Pull pinion out and release. If pinion quickly returns to its orig-

inal position, everything is in order. If it doesn’t, replace mag-

netic switch.

SERVICE POINTS OF INSTALLATION

3. INSTALLATlON OF STARTER MOTOR

Clean both surfaces of starter motor flange and rear plate.

[ ST6 Revision

1

Page 120 of 284

STARTING SYSTEM -Starter Motor

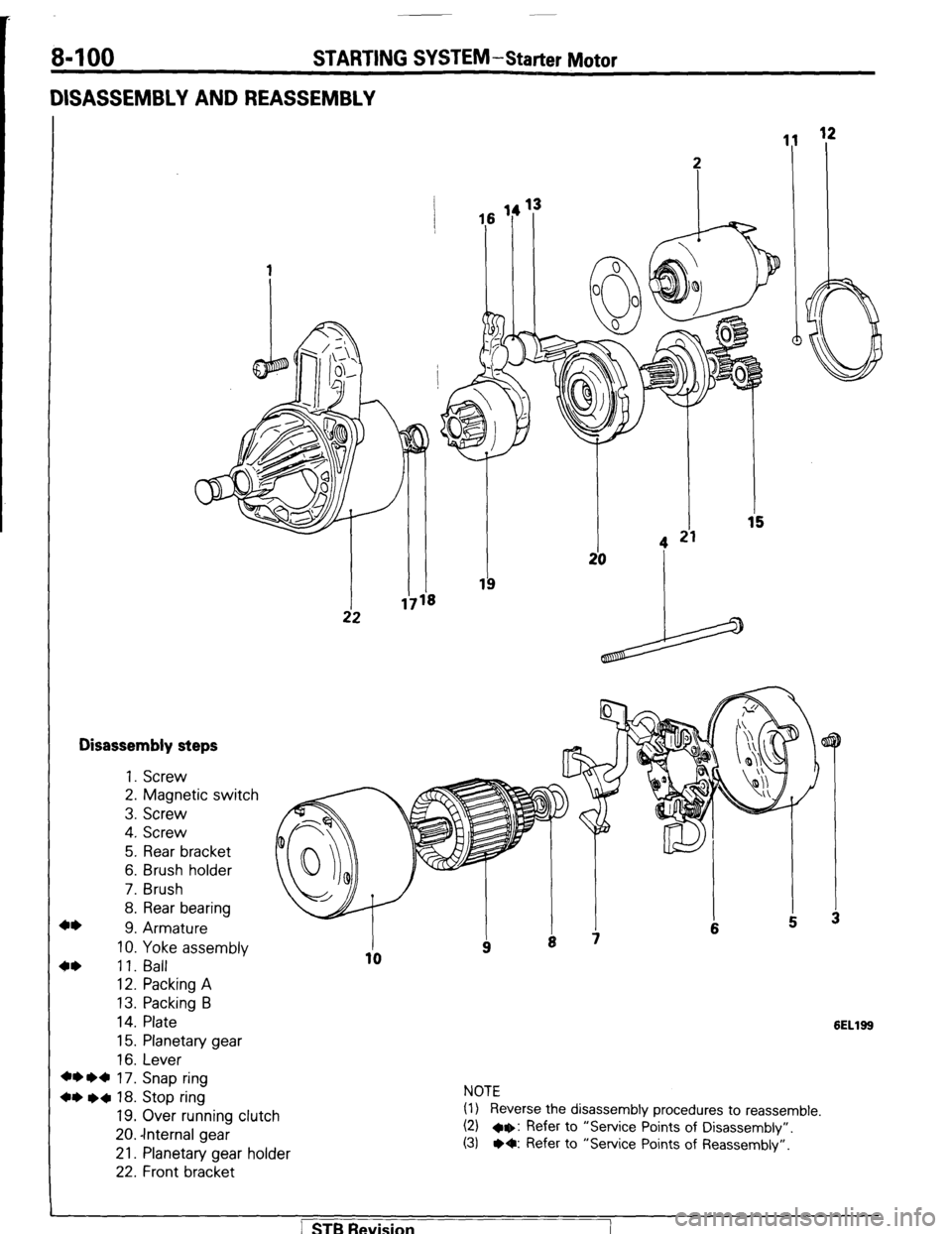

DISASSEMBLY AND REASSEMBLY

Disassembly steps

+* 1. Screw

2. Magnetic switch

3. Screw

4. Screw

5. Rear bracket

6. Brush holder

7. Brush

8. Rear bearing

9. Armature

10. Yoke assembly

4* 11. Ball

12. Packing A

13. Packing B

14. Plate

15. Planetary gear

16. Lever

+* l d 17. Snap ring

+* l a 18. Stop ring

19. Over running clutch

20. -Internal gear

21. Planetary gear holder

22. Front bracket

6ELlSS

NOTE

(1) Reverse the disassembly procedures to reassemble.

(2) a+: Refer to “Service Points of Disassembly”.

(3) l O: Refer to “Service Points of Reassembly”.

] STB Revision