MITSUBISHI MONTERO 1987 1.G Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 1987, Model line: MONTERO, Model: MITSUBISHI MONTERO 1987 1.GPages: 284, PDF Size: 14.74 MB

Page 151 of 284

METERS AND GAUGES - Service Adiustment Procedures 8-131

r

(harness side) 16W834

Stopper (upper)

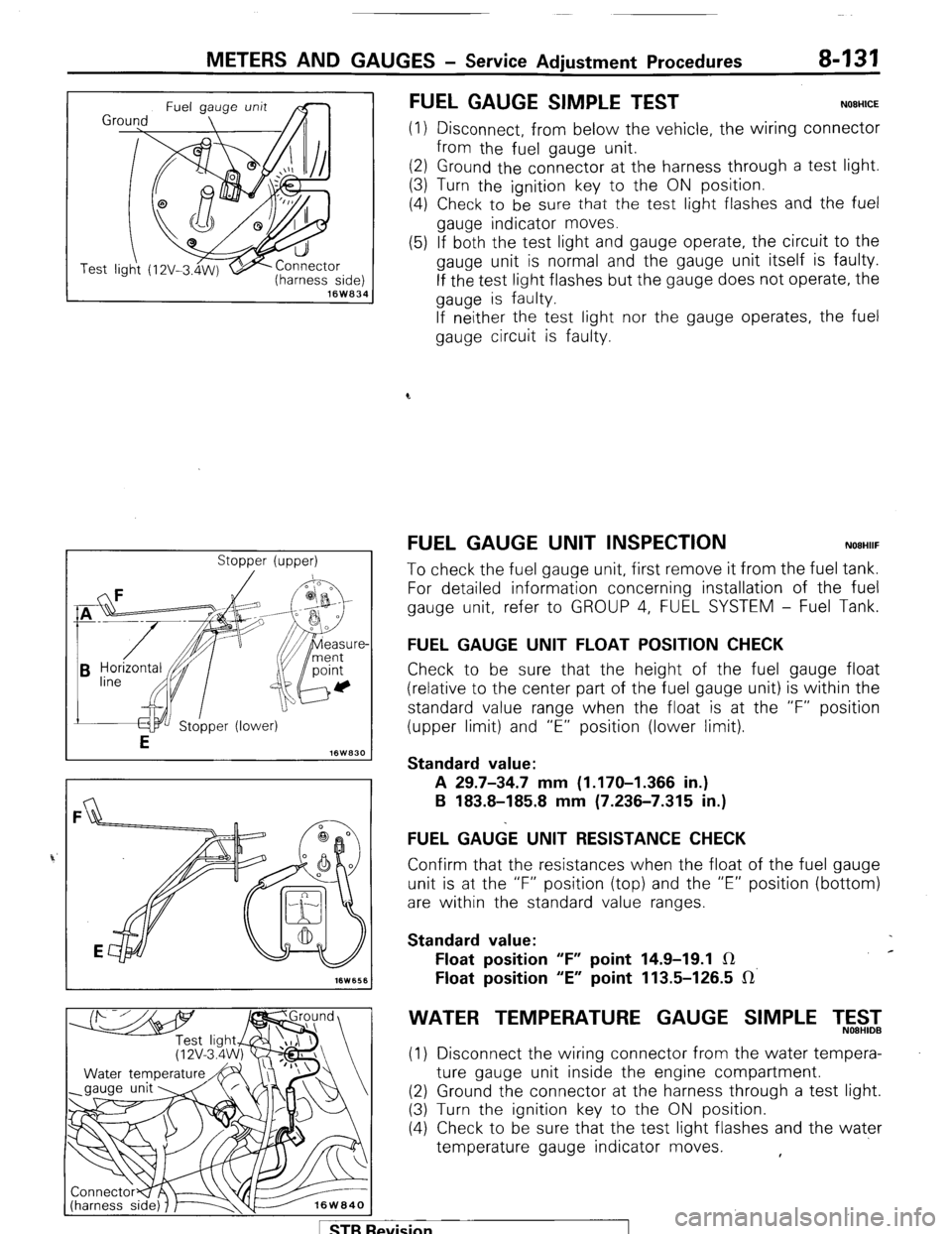

FUEL GAUGE SIMPLE TEST NOEHICE

(1) Disconnect, from below the vehicle, the wiring connector

from the fuel gauge unit.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be

sure that the test light flashes and the fuel

gauge indicator moves.

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If neither the test light nor the gauge operates, the fuel

gauge circuit is faulty.

FUEL GAUGE UNIT INSPECTION NOEHIIF

To check the fuel gauge unit, first remove it from the fuel tank.

For detailed information concerning installation of the fuel

gauge unit, refer to GROUP 4, FUEL SYSTEM - Fuel Tank.

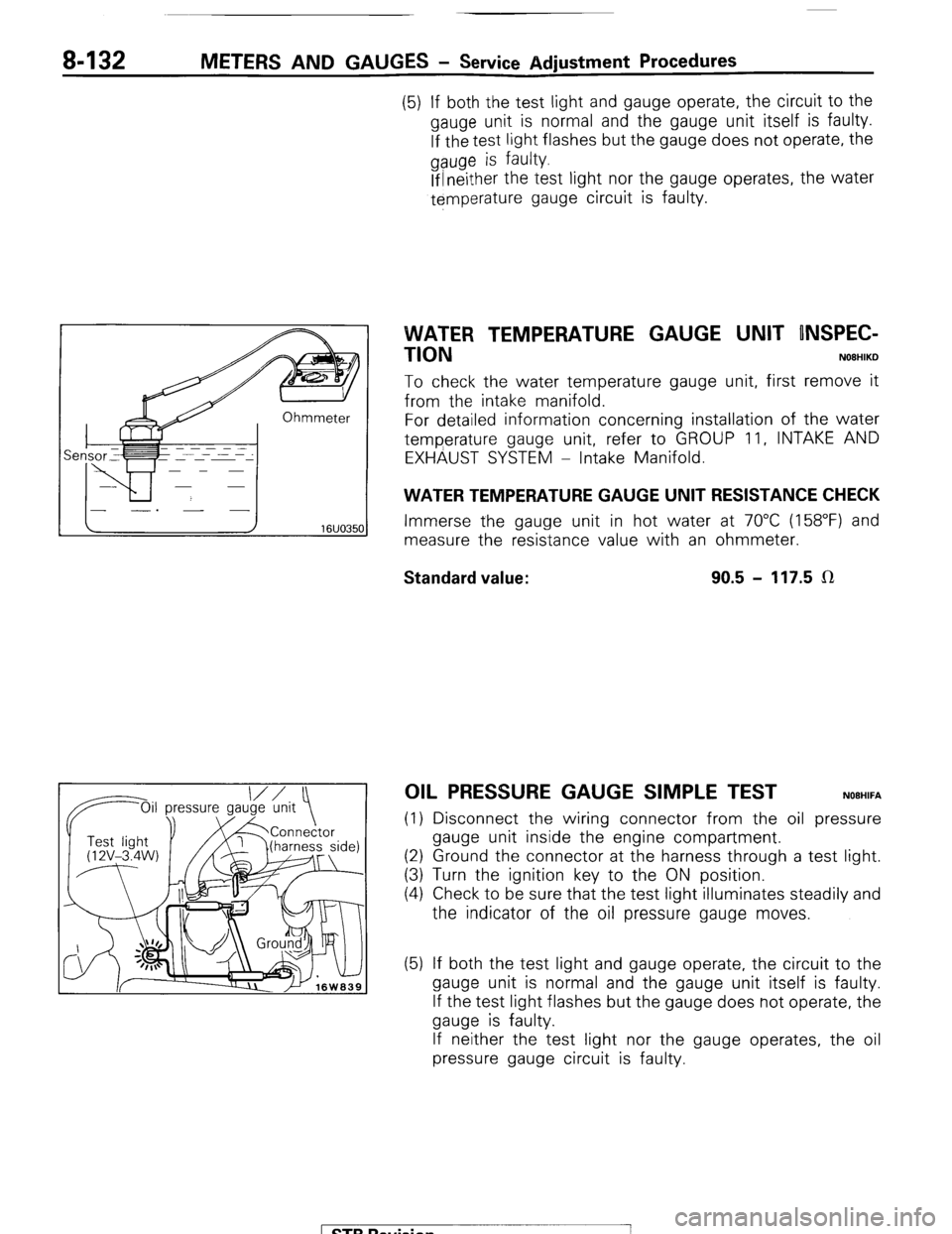

FUEL GAUGE UNIT FLOAT POSITION CHECK

Check to be sure that the height of the fuel gauge float

(relative to the center part of the fuel gauge unit) is within the

standard value range when the float is at the “F” position

(upper limit) and “E” position (lower limit).

Standard value:

A 29.7-34.7 mm (1.170-I .366 in.)

B 183.8-185.8 mm (7.236-7.315 in.)

FUEL GA&E UNIT RESISTANCE CHECK

Confirm that the resistances when the float of the fuel gauge

unit is at the “F” position (top) and the “E” position (bottom)

are within the standard value ranges.

Standard value:

Float position “F” point 14.9-19.1 IR c

Float position “E” point 113.5-126.5 IR’

WATER TEMPERATURE GAUGE SIMPLE T,5$2

(1) Disconnect the wiring connector from the water tempera-

ture gauge unit inside the engine compartment.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be sure that the test light flashes and the water

temperature gauge indicator moves. ,

1 STB Revision

Page 152 of 284

8-132 METERS AND GAUGES - Service Adjustment Procedures

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If 1 neither the test light nor the gauge operates, the water

temperature gauge circuit is faulty.

Se

VVATER TEMPERATURE GAUGE UNIT ONSPEC-

TION

NOBHIKD

To check the water temperature gauge unit, first remove it

from the intake manifold.

For detailed information concerning installation of the water

temperature gauge unit, refer to GROUP 11, INTAKE AND

EXHAUST SYSTEM - Intake Manifold.

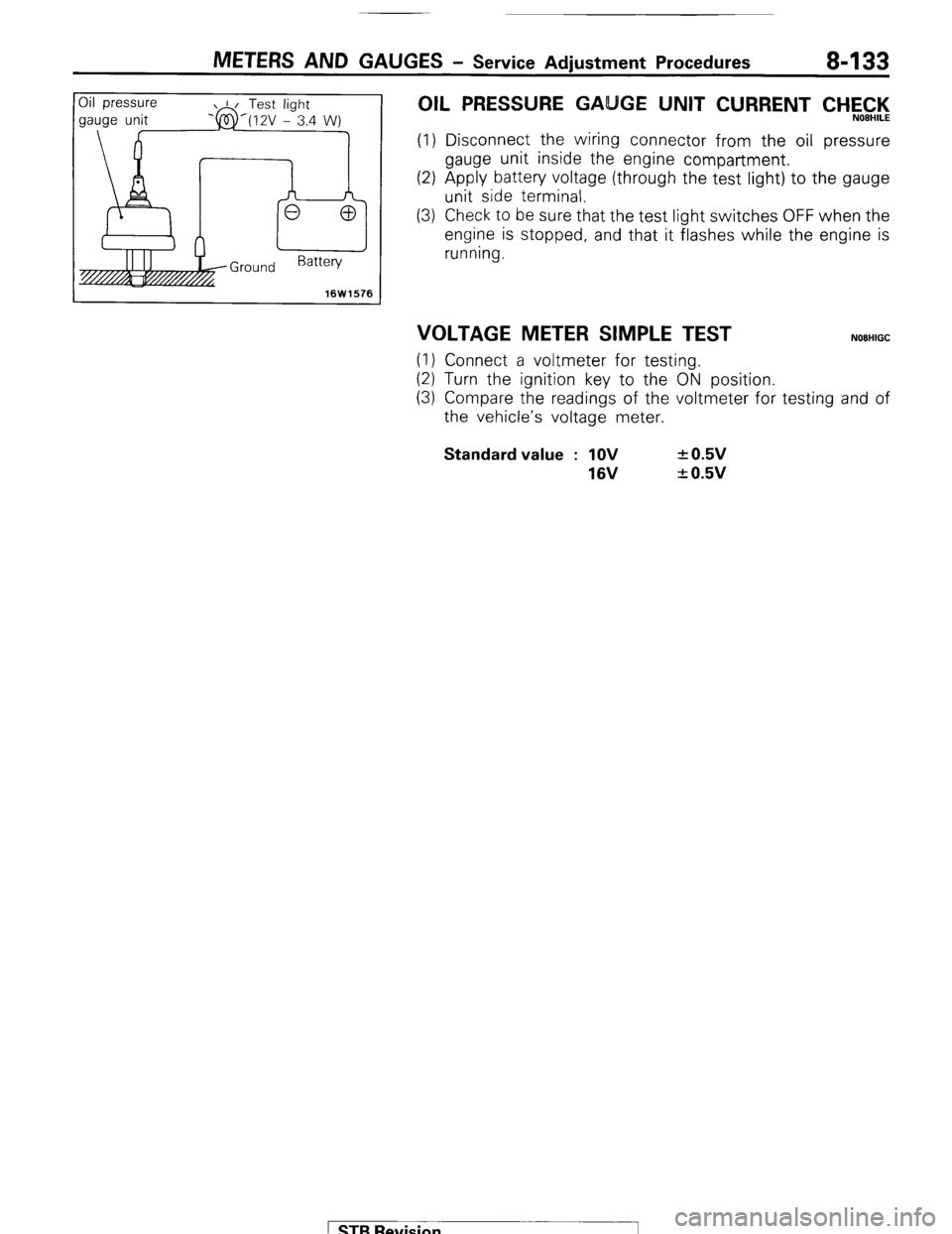

WATER TEMPERATURE GAUGE UNIT RESISTANCE CHECK

Immerse the gauge unit in hot water at 70°C (158°F) and

measure the resistance value with an ohmmeter.

Standard value: 90.5 - 117.5 LR

OIL PRESSURE GAUGE SIMPLE TEST NOEHIFA

(1) Disconnect the wiring connector from the oil pressure

gauge unit inside the engine compartment.

(2) Ground the connector at the harness through a test light.

(3) Turn the ignition key to the ON position.

(4) Check to be sure that the test light illuminates steadily and

the indicator of the oil pressure gauge moves.

(5) If both the test light and gauge operate, the circuit to the

gauge unit is normal and the gauge unit itself is faulty.

If the test light flashes but the gauge does not operate, the

gauge is faulty.

If neither the test light nor the gauge operates, the oil

pressure gauge circuit is faulty.

1 STB Revision

-7

Page 153 of 284

METERS AND GAUGES - Service Adjustment Procedures 8-133

IOil p Oil pressure ressure

gauge unit

1 I Test light

‘@‘(12V - 3.4 I

W)

16W1576

OIL PRESSURE GA GE UNIT CURRENT CHEC,‘l<,

(1) Disconnect the wiring connector from the oil pressure

gauge unit inside the engine compartment.

(2) Apply battery voltage (through the test light) to the gauge

unit side terminal.

(3) Check to be sure that the test light switches OFF when the

engine is stopped, and that it flashes while the engine is

running.

VOLTAGE METER SIMPLE TEST NOEHIGC

(1) Connect a voltmeter for testing.

(2) Turn the ignition key to the ON position.

(3) Compare the readings of the voltmeter for testing and of

the vehicle’s voltage meter. Standard value : 1OV

16V + 0.5v

+ 0.5v

1 STB Revision

Page 154 of 284

8-134 METERS AND GAUGES - Combination Meter

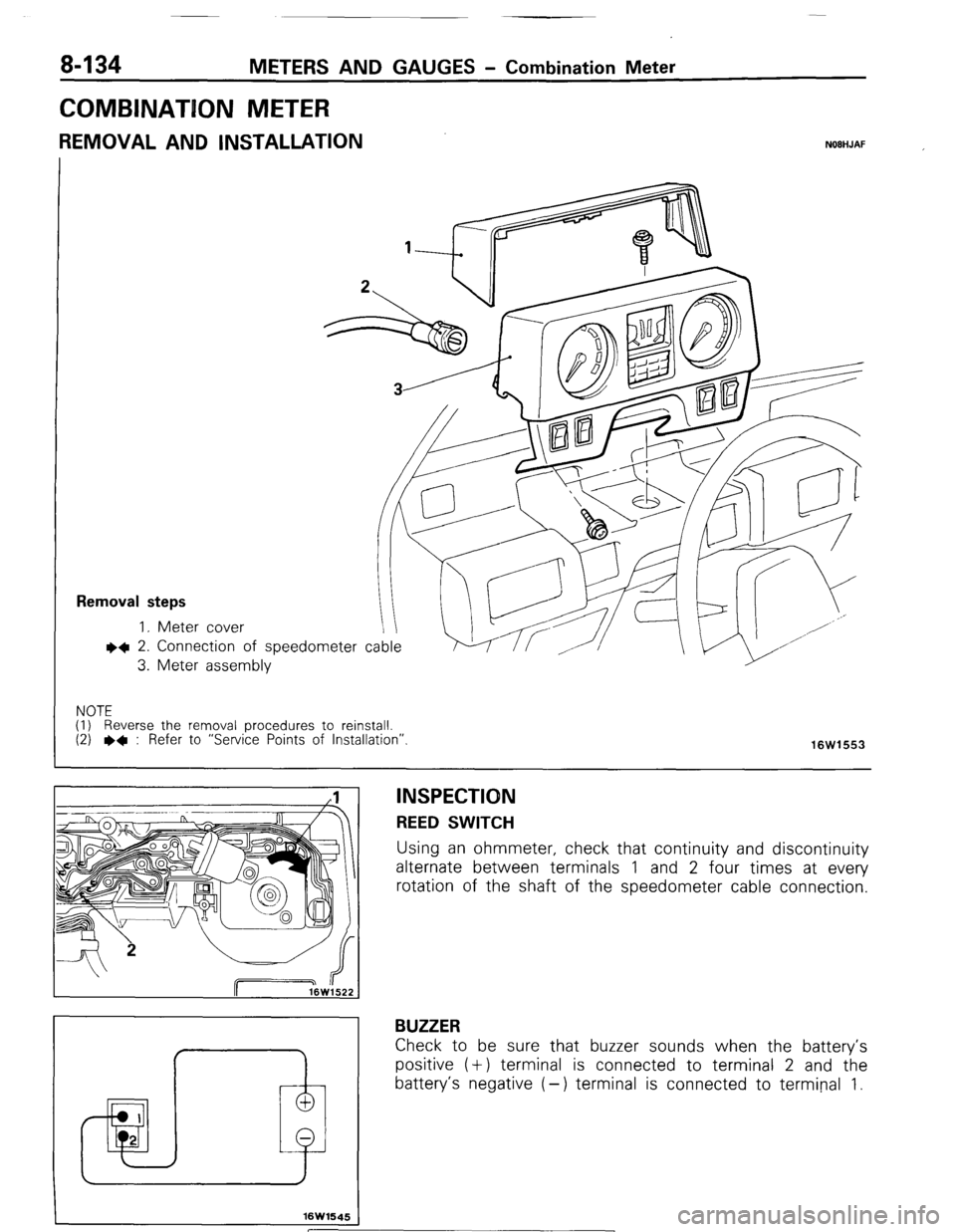

COMBINATION METER

REMOVAL AND INSTALLATION NOBHJAF

Removal steps

1. Meter cover

l 4 2. Connection

3. Meter asset of speedometer cable

nbly

NOTE

(I) Reverse the removal procedures to reinstall.

(2)

l + : Refer to “Service Points of Installation”.

16W1553

I 1 I

I

f

16W1645

INSPECTION REED SWITCH

Using an ohmmeter, check that continuity and discontinuity

alternate between terminals 1 and 2 four times at every

rotation of the shaft of the speedometer cable connection.

BUZZER

Check to be sure that buzzer sounds when the battery’s

positive (+) terminal is connected to terminal 2 and the

battery’s negative (-) terminal is connected to terminal 1.

[ STB Revision

Page 155 of 284

METERS AND GAUGES - Combination Meter 8-135

.3

16WQ25

16W925

10W926

16F554

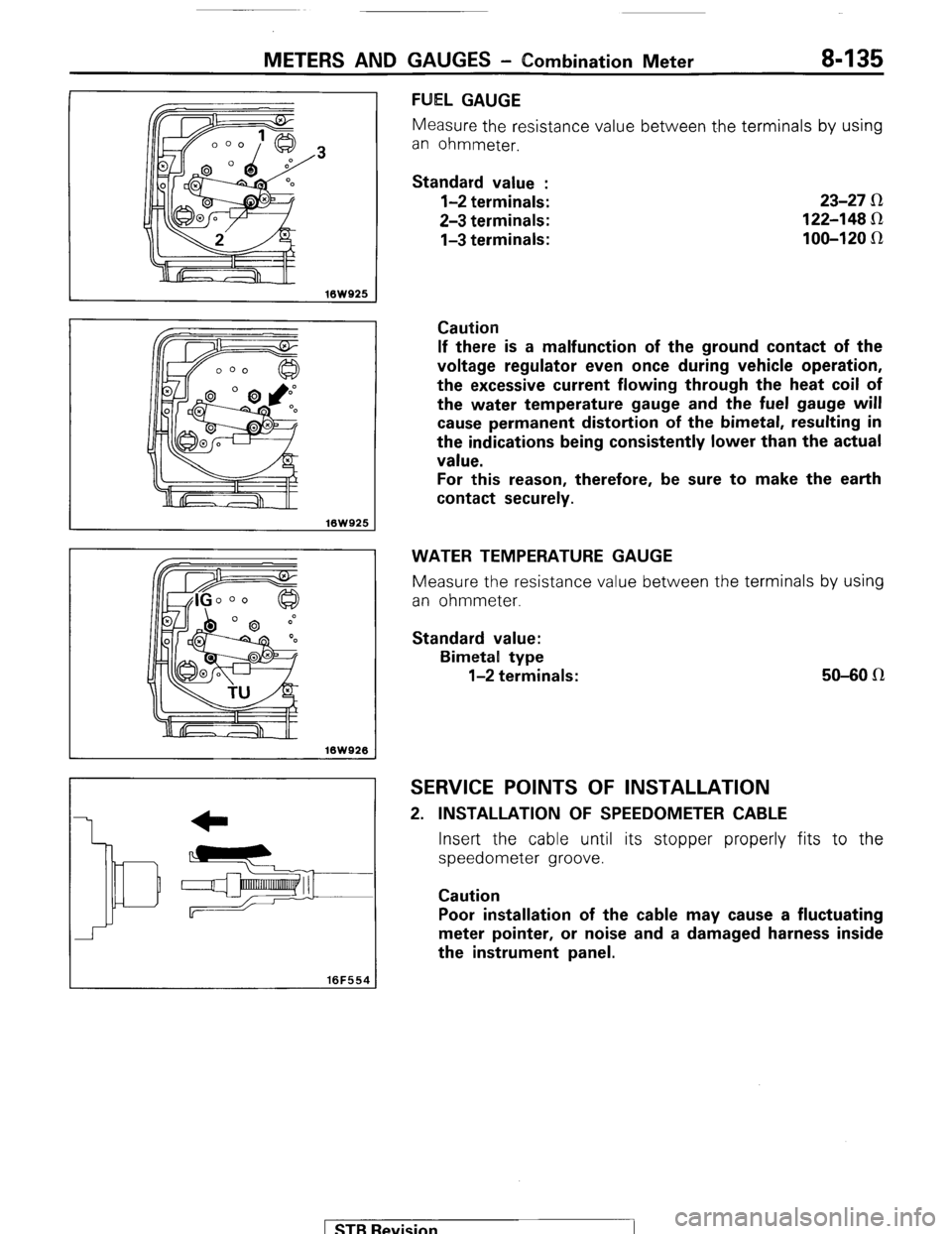

FUEL GAUGE

Measure the resistance value between t.he terminals by using

an ohmmeter.

Standard value :

l-2 terminals:

2-3 terminals:

l-3 terminals: 23-27 R

122-148 Sz

100-120 IR

Caution

If there is a malfunction of the ground contact of the

voltage regulator even once during vehicle operation,

the excessive current flowing through the heat coil of

the water temperature gauge and the fuel gauge will

cause permanent distortion of the bimetal, resulting in

the indications being consistently lower than the actual

value.

For this reason, therefore, be sure to make the earth

contact securely.

WATER TEMPERATURE GAUGE

Measure the resistance value between the terminals by using

an ohmmeter.

Standard value:

Bimetal type

l-2 terminals: 50-80 n

SERVICE POINTS OF INSTALLATION

2. INSTALLATION OF SPEEDOMETER CABLE

Insert the cable until its stopper properly fits to the

speedometer groove.

Caution

Poor installation of the cable may cause a fluctuating

meter pointer, or noise and a damaged harness inside

the instrument panel.

) STB Revision

Page 156 of 284

8-136 METERS AND GAUGES - Combination Meter

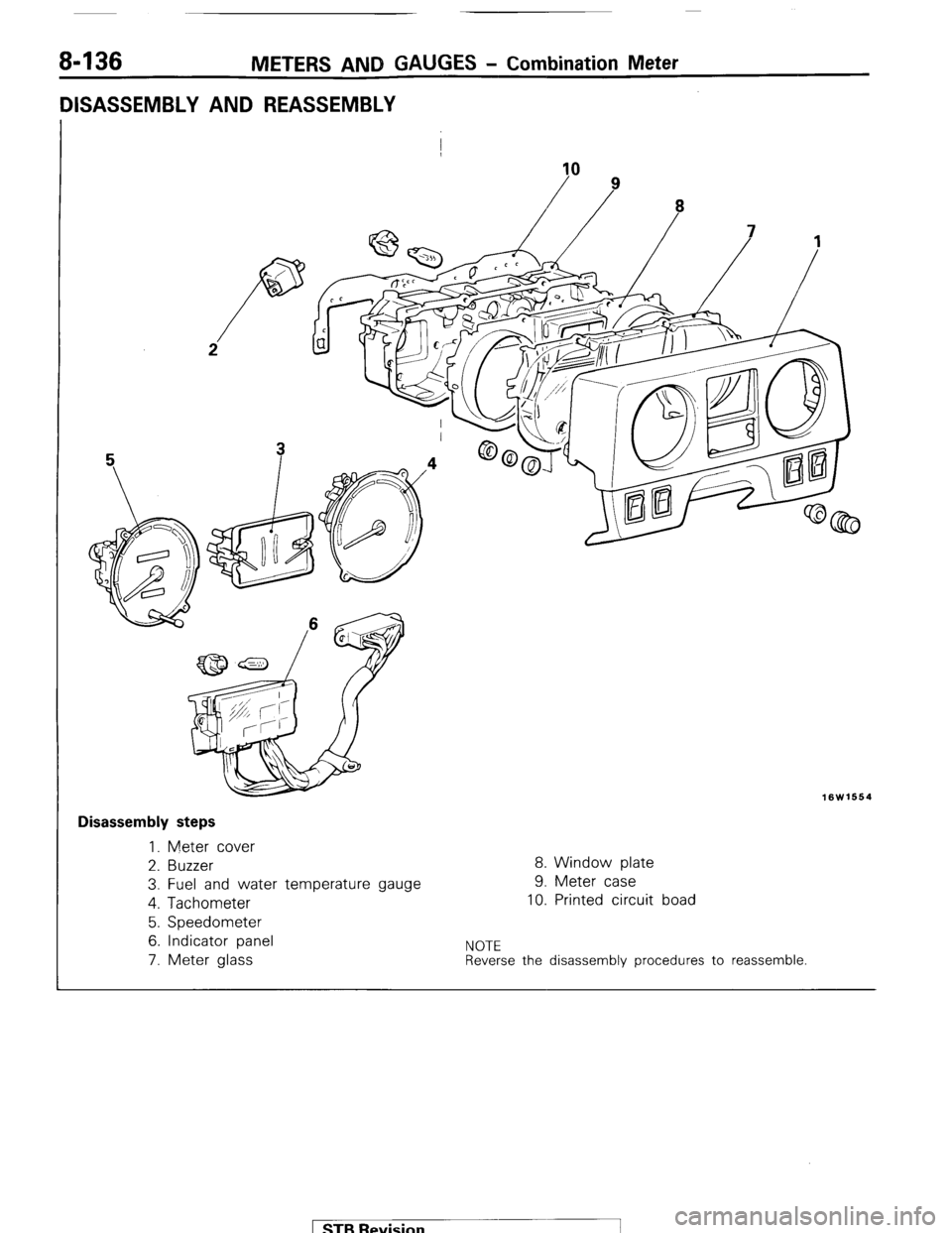

DISASSEMBLY AND REASSEMBLY

I

10

16W1664

I Disassembly steps

1. Meter cover

2. Buzzer

8. Window plate

3. Fuel and water temperature gauge 9. Meter case

4. Tachometer

10. Printed circuit boad

5. Speedometer

6. Indicator panel

NOTE 7. Meter glass Reverse the disassembly procedures to reassemble. 1 STB Revision -1

Page 157 of 284

METERS AND GAUGES - 3-meter Unit

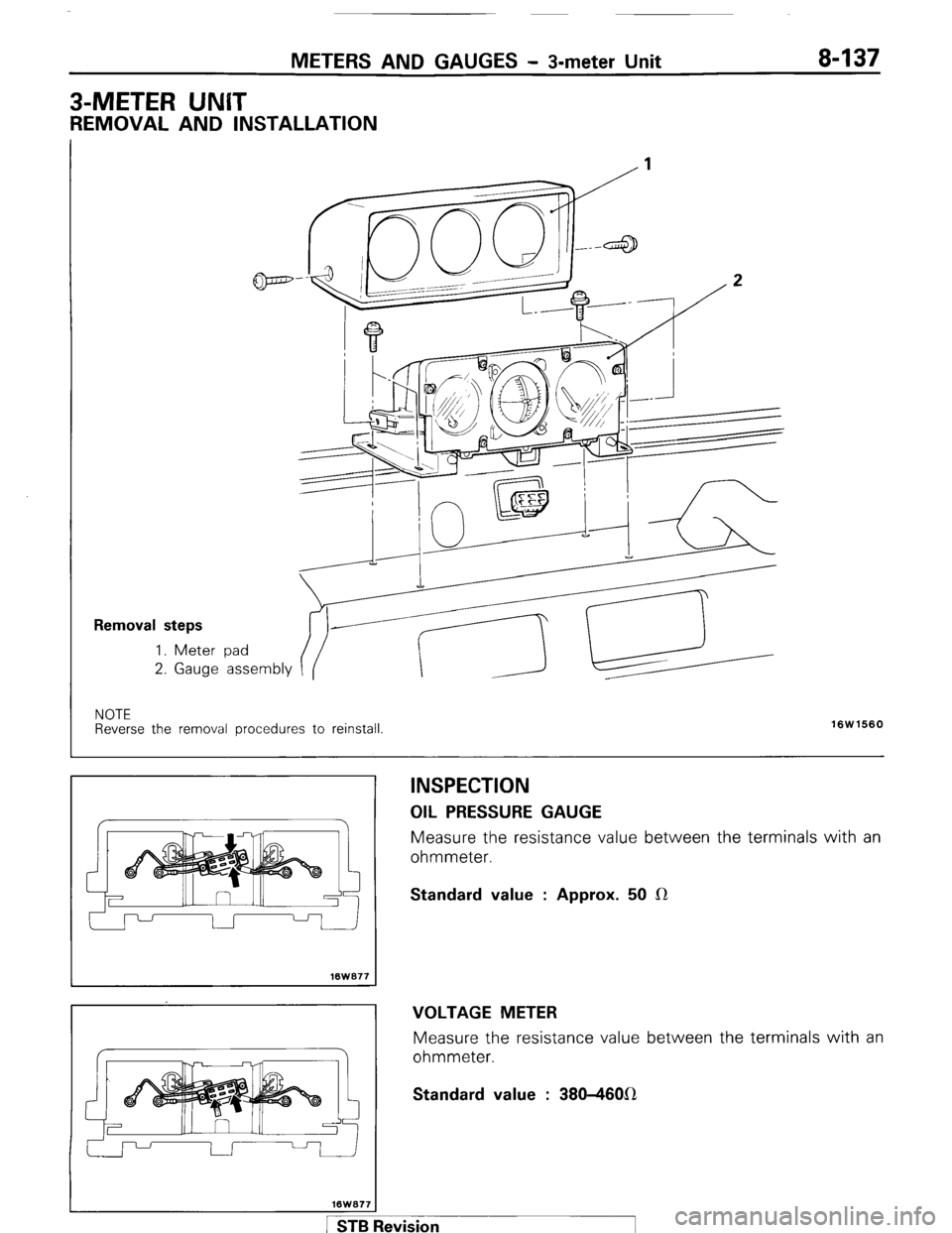

3-METER lJN(IT

REMOVAL AND INSTALLATION

Removal steps

1. Meter 2.

Gauge

pad

assembly

NOTE

Reverse the removal procedures to reinstall

16W1560

lBW077

INSPECTION OIL

PRESSURE GAUGE

Measure the resistance value between the terminals with an

ohmmeter. Standard value : Approx. 50 CR

VOLTAGE METER

Measure the resistance value between the terminals with an

ohmmeter. Standard value : 380-4601(1

1 STB Revision

Page 158 of 284

8-138 METERS AND GAUGES - s-meter Unit

16W678

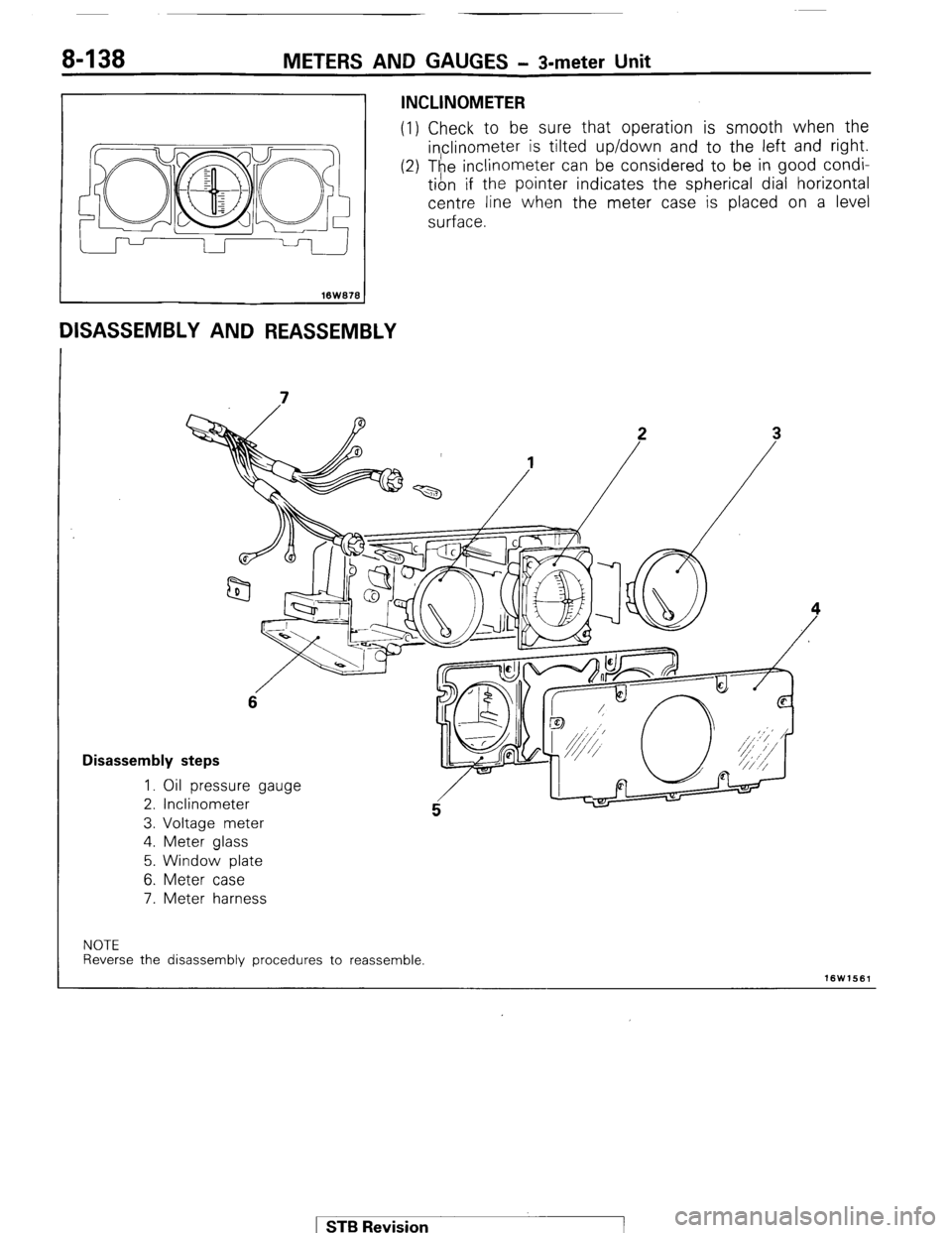

DISASSEMBLY AND REASSEMBLY

INCLINOMETER

(1) Check to be sure that operation is smooth when the

inclinometer is tilted up/down and to the left and right.

(2) The i,nclinometer can be considered to be in good condi-

tion If the pointer indicates the spherical dial horizontal

centre line when the meter case is placed on a level

surface.

6

Disassembly steps

1. Oil pressure gauge

2. Inclinometer

3. Voltage meter

4. Meter glass

5. Window plate

6. Meter case

7. Meter harness

NOTE

Reverse the disassembly procedures to reassemble.

16W1561

1 ST6 Revision

Page 159 of 284

METERS AND GAUGES - s-meter Unit 8-139

Center shaft of

pitching damper plate

Pointer

16W 600

Spherical dial

Spherical

horizontal

16W966

Spherical dial Dial support plate

/ Oil case

Gxizontal centerlinewtationaryframe

Blind plate

16W627

;ide to side inclination Forward or backwarc

Hokizontal line Horizbntal line

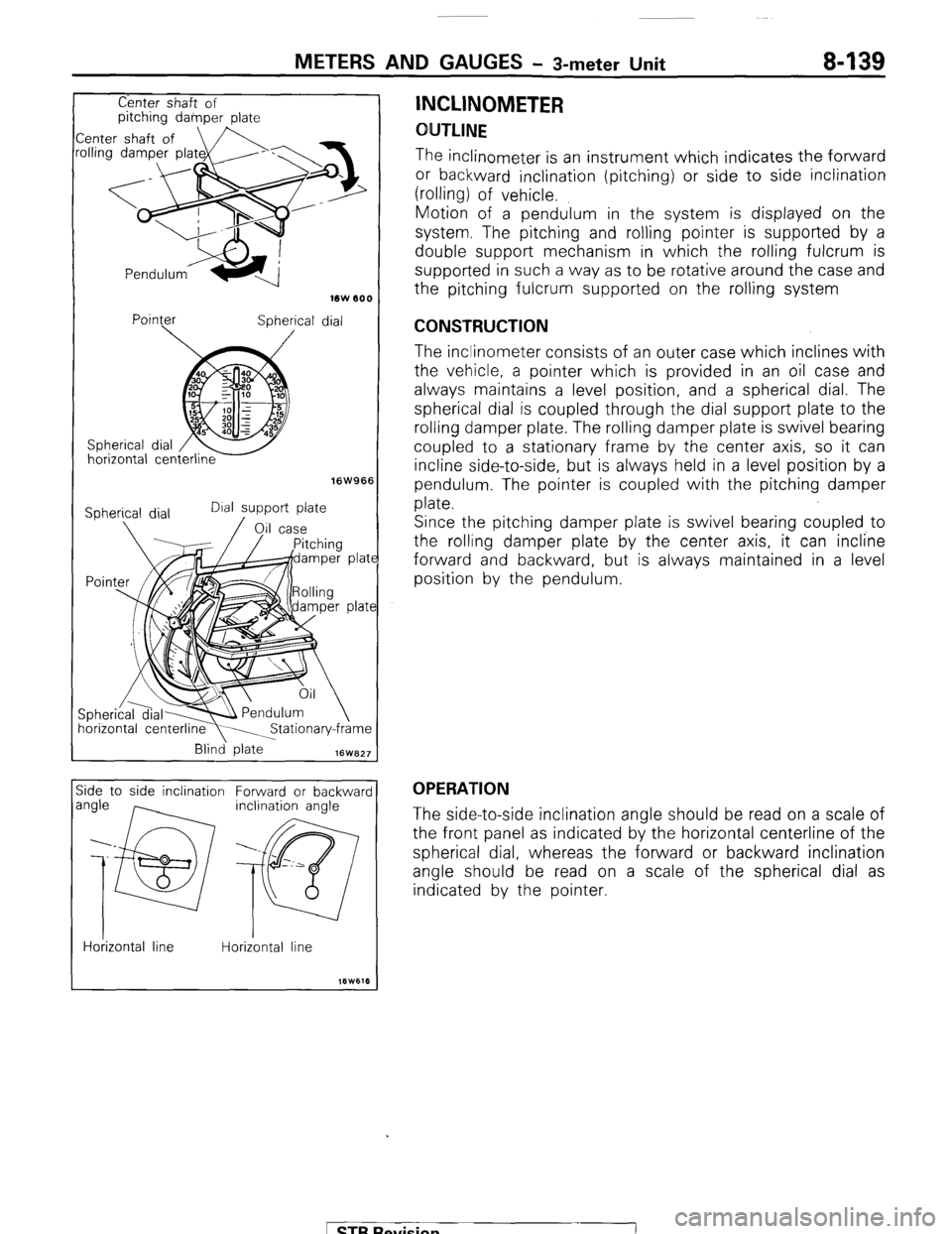

INCLINOMETER

OUTLINE

The inclinometer is an instrument which indicates the forward

or backward inclination (pitching) or side to side inclination

(ding) of vehicle.

Motion of a pendulum in the system is displayed on the

system. The pitching and rolling pointer is supported by a

double support mechanism in which the rolling fulcrum is

supported in such a way as to be rotative around the case and

the pitching fulcrum supported on the rolling system

CONSTRUCTION

The inclinometer consists of an outer case which inclines with

the vehicle, a pointer which is provided in an oil case and

always maintains a level position, and a spherical dial. The

spherical dial is coupled through the dial support plate to the

rolling damper plate. The rolling damper plate is swivel bearing

coupled to a stationary frame by the center axis, so it can

incline side-to-side, but is always held in a level position by a

pendulum. The pointer is coupled with the pitching damper

plate.

Since the pitching damper plate is swivel bearing coupled to

the rolling damper plate by the center axis, it can incline

forward and backward, but is always maintained in a level

position by the pendulum.

OPERATION

The side-to-side inclination angle should be read on a scale of

the front panel as indicated by the horizontal centerline of the

spherical dial, whereas the forward or backward inclination

angle should be read on a scale of the spherical dial as

indicated by the pointer.

[ STB Revision

Page 160 of 284

8-140 METERS AND GAUGES - 3-meter Unit

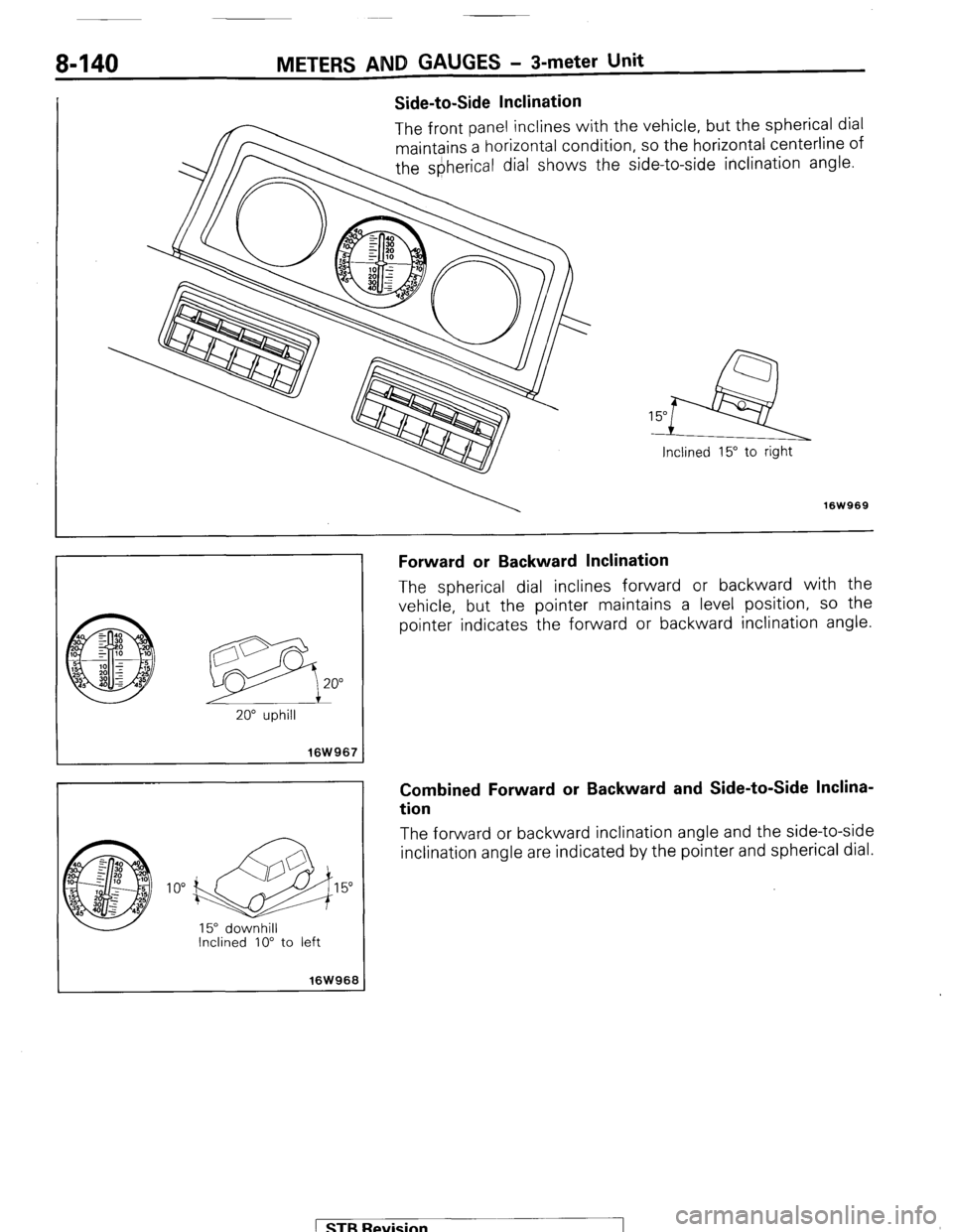

Side-to-Side Inclination

The front panel inclines with the vehicle, but the spherical dial

maintains a horizontal condition, so the horizontal centerline of

the s&lerical dial shows the side-to-side inclination angle.

7

Inclined 15" to right

16W969

@ 10” d15

15” downhill

Inclined IO” to left

I 16W968 I

Forward or Backward Inclination

The spherical dial inclines forward or backward with the

vehicle, but the pointer maintains a level position, so the

pointer indicates the forward or backward inclination angle.

Combined Forward or Backward and Side-to-Side Inclina-

tion

The forward or backward inclination angle and the side-to-side

inclination angle are indicated by the pointer and spherical dial.

1 STB Revision

-7