relay MITSUBISHI MONTERO 2000 Service User Guide

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 276 of 1839

GDI -Troubleshooting

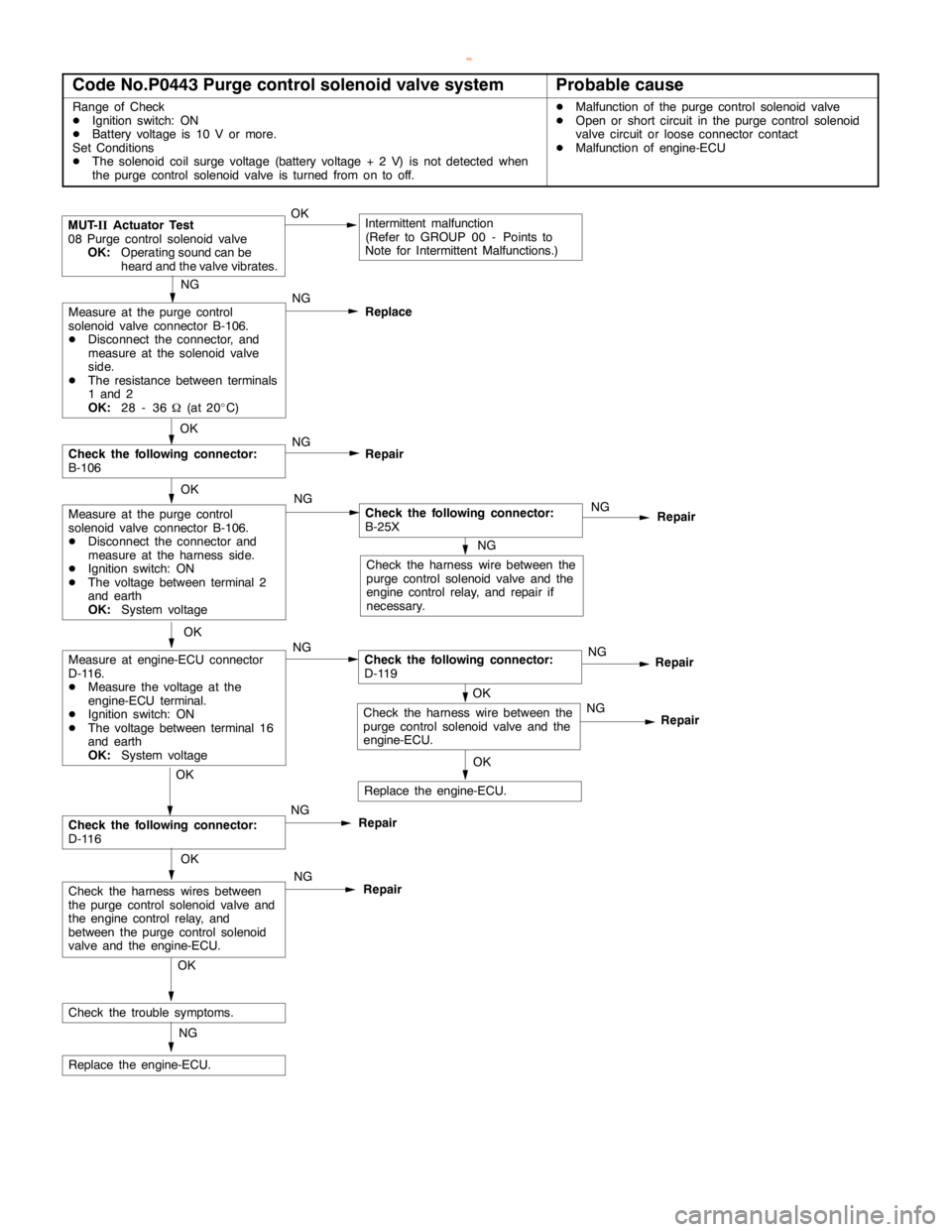

Code No.P0443 Purge control solenoid valve systemProbable cause

Range of Check

DIgnition switch: ON

DBattery voltage is 10 V or more.

Set Conditions

DThe solenoid coil surge voltage (battery voltage + 2 V) is not detected when

the purge control solenoid valve is turned from on to off.DMalfunction of the purge control solenoid valve

DOpen or short circuit in the purge control solenoid

valve circuit or loose connector contact

DMalfunction of engine-ECU

Repair

MUT-

IIActuator Test

08 Purge control solenoid valve

OK:

Operating sound can be

heard and the valve vibrates.OKIntermittent malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

NG

Check the harness wire between the

purge control solenoid valve and the

engine controlrelay, and repair if

necessary.

NG

Measure at the purge control

solenoid valve connector B-106.

DDisconnect the connector, and

measure at the solenoid valve

side.

DThe resistance between terminals

1 and 2

OK:

28 - 36W(at 20_C)NG

Replace

OK

Measure at the purge control

solenoid valve connector B-106.

DDisconnect the connector and

measure at the harness side.

DIgnition switch: ON

DThe voltage between terminal 2

and earth

OK:

System voltageNGCheck the following connector:

B-25XNG

Repair

OK

Check the following connector:

B-106NG

Repair

OK

OK

Measure at engine-ECU connector

D-116.

DMeasure the voltage at the

engine-ECU terminal.

DIgnition switch: ON

DThe voltage between terminal 16

and earth

OK:

System voltageNGCheck the following connector:

D-119NG

Repair

OK

Check the following connector:

D-116NG

Repair

OK

NG

Repair

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.OKNG

Replace the engine-ECU.

Check the harness wires between

the purge control solenoid valve and

the engine controlrelay, and

between the purge control solenoid

valve and the engine-ECU.

Check the harness wire between the

purge control solenoid valve and the

engine-ECU.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 280 of 1839

GDI -Troubleshooting

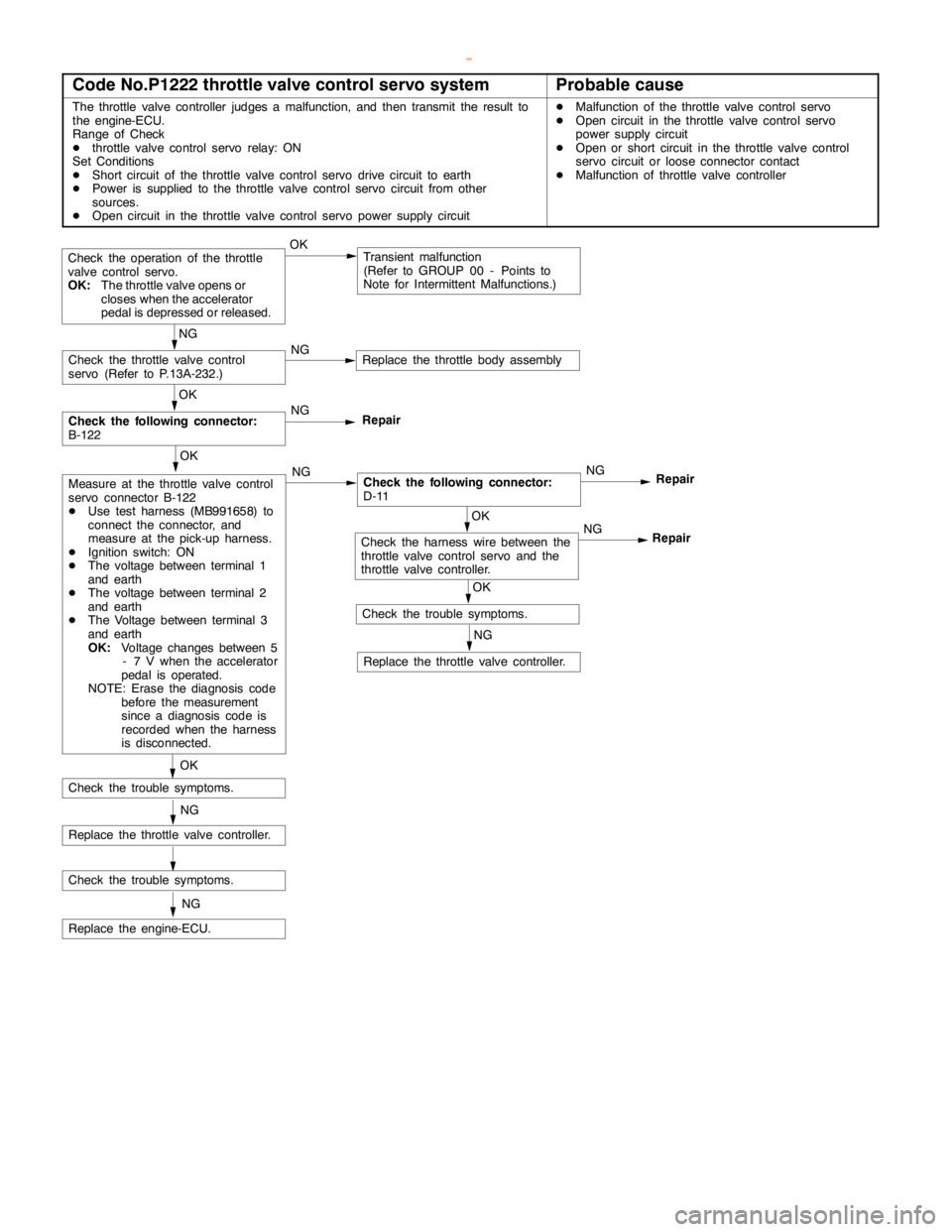

Code No.P1222 throttle valve control servo systemProbable cause

The throttle valve controller judges a malfunction, and then transmit the result to

the engine-ECU.

Range of Check

Dthrottle valve control servo relay: ON

Set Conditions

DShort circuit of the throttle valve control servo drive circuit to earth

DPower is supplied to the throttle valve control servo circuit from other

sources.

DOpen circuit in the throttle valve control servo power supply circuitDMalfunction of the throttle valve control servo

DOpen circuit in the throttle valve control servo

power supply circuit

DOpen or short circuit in the throttle valve control

servo circuit or loose connector contact

DMalfunction of throttle valve controller

OKTransient malfunction

(Refer to GROUP 00 - Points to

Note for Intermittent Malfunctions.)

OK

Check the following connector:

B-122NG

Repair

OK

Measure at the throttle valve control

servo connector B-122

DUse test harness (MB991658) to

connect the connector, and

measure at the pick-up harness.

DIgnition switch: ON

DThe voltage between terminal 1

and earth

DThe voltage between terminal 2

and earth

DThe Voltage between terminal 3

and earth

OK:

Voltage changes between 5

- 7 V when the accelerator

pedal is operated.

NOTE: Erase the diagnosis code

before the measurement

since a diagnosis code is

recorded when the harness

is disconnected.NGCheck the following connector:

D-11NG

Repair

OK

Check the trouble symptoms.

OK

Check the trouble symptoms.

OK

Check the harness wire between the

throttle valve control servo and the

throttle valve controller.NG

Repair

NG

Check the throttle valve control

servo (Refer to P.13A-232.)NGReplace the throttle body assembly

NG

Replace the throttle valve controller.

NG

Replace the throttle valve controller.

Check the trouble symptoms.

NG

Replace the engine-ECU.

Check the operation of the throttle

valve control servo.

OK:

The throttle valve opens or

closes when the accelerator

pedal is depressed or released.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 281 of 1839

GDI -Troubleshooting

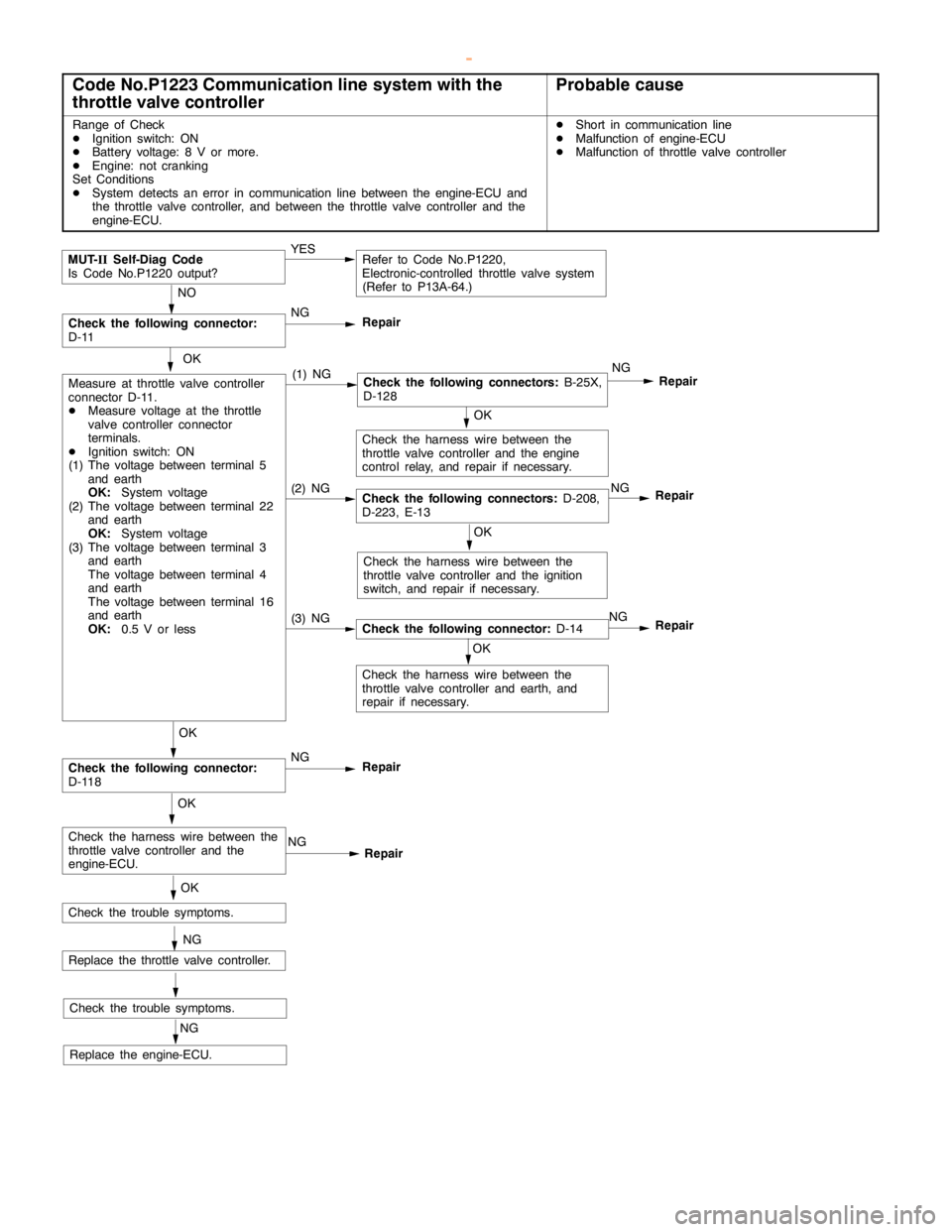

Code No.P1223 Communication line system with the

throttle valve controllerProbable cause

Range of Check

DIgnition switch: ON

DBattery voltage: 8 V or more.

DEngine: not cranking

Set Conditions

DSystem detects an error in communicationline between the engine-ECU and

the throttle valve controller, and between the throttle valve controller and the

engine-ECU.DShort in communicationline

DMalfunction of engine-ECU

DMalfunction of throttle valve controller

MUT-

IISelf-Diag Code

Is Code No.P1220 output?YESRefer to Code No.P1220,

Electronic-controlled throttle valve system

(Refer to P13A-64.)

NO

NG

Repair

OK

Measure at throttle valve controller

connector D-11.

DMeasure voltage at the throttle

valve controller connector

terminals.

DIgnition switch: ON

(1) The voltage between terminal 5

and earth

OK:

System voltage

(2) The voltage between terminal 22

and earth

OK:

System voltage

(3) The voltage between terminal 3

and earth

The voltage between terminal 4

and earth

The voltage between terminal 16

and earth

OK:

0.5 V or less(1) NGCheck the following connectors:

B-25X,

D-128NG

Repair

Check the trouble symptoms.OK

Check the harness wire between the

throttle valve controller and theengine

control relay, and repair if necessary.

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.

(2) NGCheck the following connectors:

D-208,

D-223, E-13NG

Repair

OK

Check the harness wire between the

throttle valve controller and the ignition

switch, and repair if necessary.

(3) NGCheck the following connector:

D-14NG

Repair

OK

Check the harness wire between the

throttle valve controller and earth, and

repair if necessary.

OK

Check the following connector:

D-118NG

Repair

OK

Check the harness wire between the

throttle valve controller and the

engine-ECU.NG

Repair

NG

Replace the throttle valve controller.

Check the following connector:

D-11

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 291 of 1839

GDI -Troubleshooting

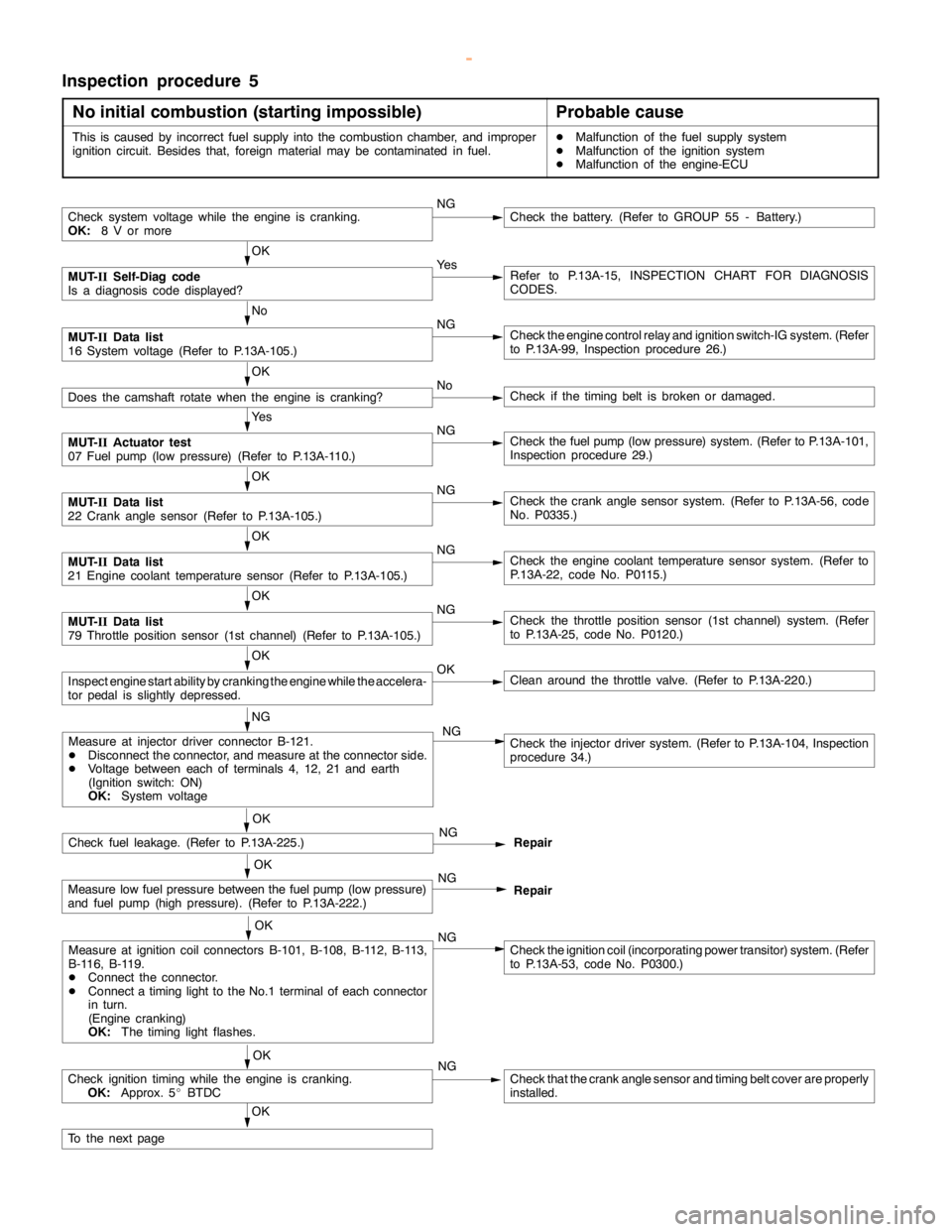

Inspection procedure 5

No initial combustion (starting impossible)

Probable cause

This is caused by incorrect fuel supply into the combustion chamber, and improper

ignition circuit. Besides that, foreign material may be contaminated in fuel.DMalfunction of the fuel supply system

DMalfunction of the ignition system

DMalfunction of the engine-ECU

Check system voltage while theengine iscranking.

OK:

8 V or moreNGCheck the battery. (Refer to GROUP 55 - Battery.)

OK

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIData list

16 System voltage (Refer to P.13A-105.)NGCheck theengine controlrelay and ignition switch-IG system. (Refer

to P.13A-99, Inspection procedure 26.)

OK

Does the camshaft rotate when theengine is cranking?NoCheck if thetiming belt isbroken ordamaged.

Ye s

MUT-

IIActuator test

07 Fuel pump(low pressure) (Refer to P.13A-110.)NGCheck the fuelpump(low pressure) system. (Refer to P.13A-101,

Inspection procedure 29.)

OK

MUT-

IIData list

22 Crankanglesensor (Refer to P.13A-105.)NGCheck the crankanglesensor system. (Refer to P.13A-56, code

No. P0335.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor system. (Refer to

P.13A-22, code No. P0115.)

OK

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle position sensor (1st channel) system. (Refer

to P.13A-25, code No. P0120.)

OK

Inspectenginestart ability by cranking theengine while theaccelera-

tor pedal isslightly depressed.OKClean around the throttle valve. (Refer to P.13A-220.)

NG

Check fuel leakage. (Refer to P.13A-225.)NG

Repair

OK

Measure low fuel pressure between the fuelpump(low pressure)

and fuel pump (highpressure). (Refer to P.13A-222.)NG

Repair

OK

Measure at ignition coil connectors B-101, B-108, B-112, B-113,

B-116, B-119.

DConnect the connector.

DConnect atiming light to theNo.1 terminal of each connector

in turn.

(Engine cranking)

OK:

The timing lightflashes.NGCheck the ignition coil (incorporating power transitor) system. (Refer

to P.13A-53, code No. P0300.)

OK

Check ignitiontiming while the engine iscranking.

OK:

Approx. 5_BTDCNGCheck that the crankanglesensor andtiming beltcover are properly

installed.

OK

To the nextpage

Measure at injector driver connector B-121.

DDisconnect the connector, and measure at the connector side.

DVoltage between each of terminals 4, 12, 21 and earth

(Ignition switch: ON)

OK:

System voltageCheck the injector driver system. (Refer to P.13A-104, Inspection

procedure 34.) NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 296 of 1839

GDI -Troubleshooting

OK

Check that air is sucked in the air intake system.

DBroken intake manifold gasket

DDamaged vacuum hose

DDamaged air intake hose

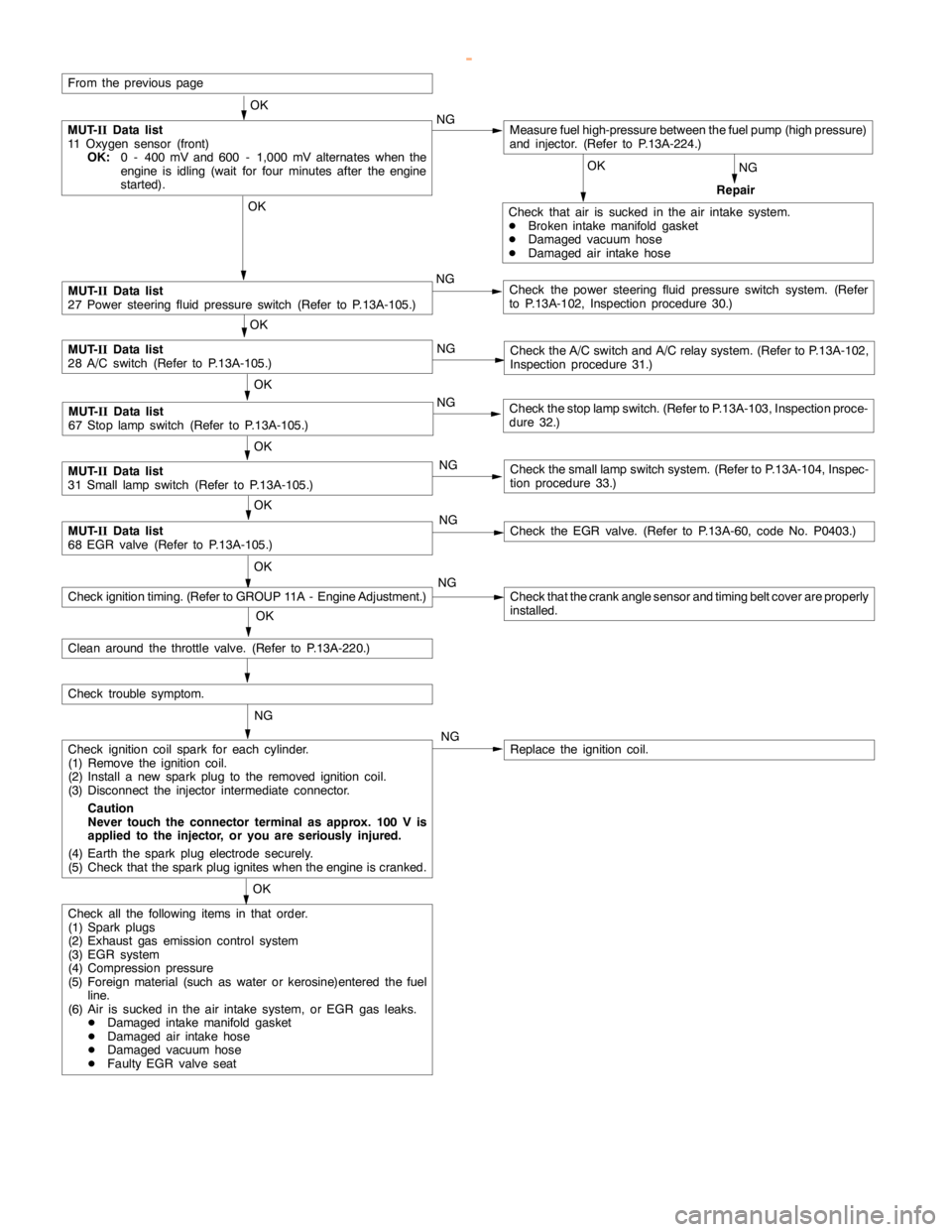

From the previouspage

OK

MUT-

IIData list

27 Power steering fluid pressure switch (Refer to P.13A-105.)NGCheck the power steering fluid pressure switch system. (Refer

to P.13A-102, Inspection procedure 30.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

OK

MUT-

IIData list

67 Stoplampswitch (Refer to P.13A-105.)NGCheck the stoplampswitch. (Refer to P.13A-103, Inspection proce-

dure 32.)

OK

MUT-

IIData list

31 Small lampswitch (Refer to P.13A-105.)NGCheck the smalllampswitch system. (Refer to P.13A-104, Inspec-

tion procedure 33.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve. (Refer to P.13A-60, code No. P0403.)

OK

NG

Check that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check trouble symptom.

Check all the following items in that order.

(1) Spark plugs

(2) Exhaust gas emission control system

(3) EGR system

(4) Compression pressure

(5) Foreign material (such as water or kerosine)entered the fuel

line.

(6) Air is sucked in the air intake system, or EGR gas leaks.

DDamaged intake manifoldgasket

DDamaged air intake hose

DDamaged vacuum hose

DFaulty EGR valve seat

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).NG

NG

Repair

Measure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)

Clean around the throttle valve. (Refer to P.13A-220.)

NG

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 297 of 1839

GDI -Troubleshooting

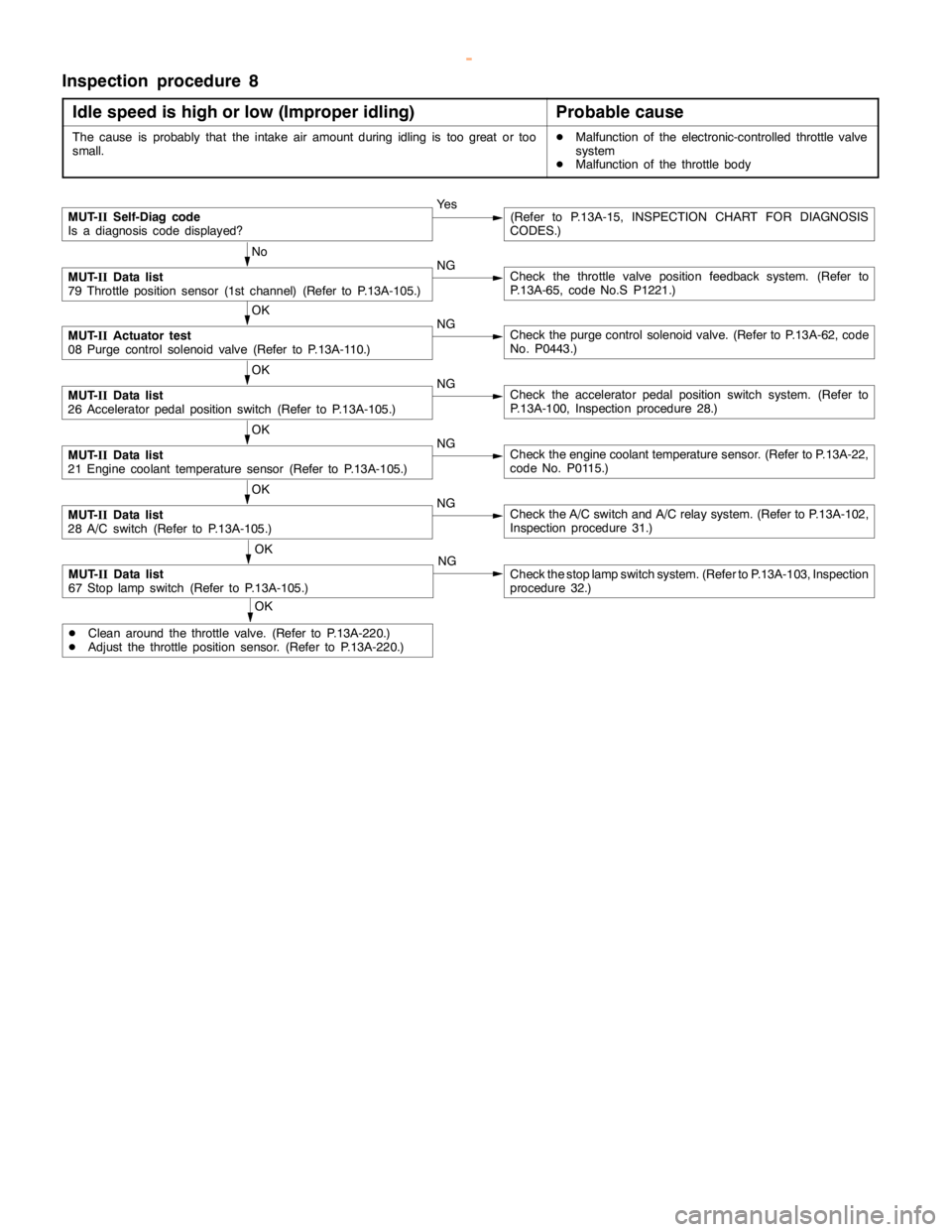

Inspection procedure 8

Idle speed is high or low (Improper idling)

Probable cause

The cause is probably that the intake airamount during idling is too great or too

small.DMalfunction of the electronic-controlled throttle valve

system

DMalfunction of the throttle body

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No.S P1221.)

OK

MUT-

IIActuator test

08 Purge control solenoid valve (Refer to P.13A-110.)NGCheck the purge control solenoid valve. (Refer to P.13A-62, code

No. P0443.)

OK

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the acceleratorpedal positionswitch system. (Refer to

P.13A-100, Inspection procedure 28.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

OK

MUT-

IIData list

67 Stoplampswitch (Refer to P.13A-105.)NGCheck the stoplampswitch system. (Refer to P.13A-103, Inspection

procedure 32.)

OK

DClean around the throttle valve. (Refer to P.13A-220.)

DAdjust the throttle position sensor. (Refer to P.13A-220.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 300 of 1839

GDI -Troubleshooting

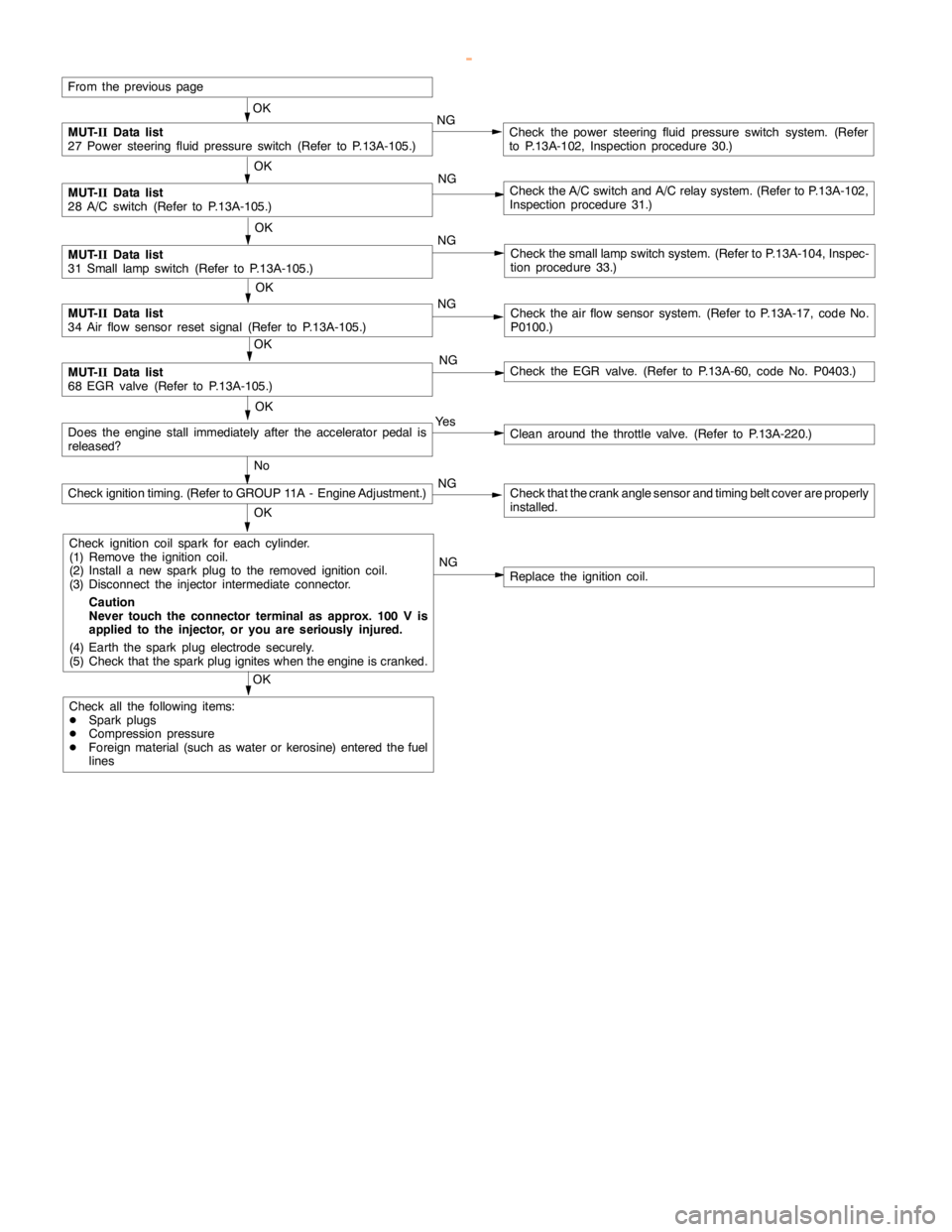

From the previouspage

OK

MUT-

IIData list

27 Power steering fluid pressure switch (Refer to P.13A-105.)NGCheck the power steering fluid pressure switch system. (Refer

to P.13A-102, Inspection procedure 30.)

OK

MUT-

IIData list

28 A/C switch (Refer to P.13A-105.)NGCheck the A/C switch and A/C relay system. (Refer to P.13A-102,

Inspection procedure 31.)

MUT-

IIData list

31 Small lampswitch (Refer to P.13A-105.)NGCheck the smalllampswitch system. (Refer to P.13A-104, Inspec-

tion procedure 33.)

OK

MUT-

IIData list

34 Air flow sensor reset signal (Refer to P.13A-105.)NGCheck the air flow sensor system. (Refer to P.13A-17, code No.

P0100.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve. (Refer to P.13A-60, code No. P0403.)

OK

Ye s

Clean around the throttle valve. (Refer to P.13A-220.)

No

NG

Check that the crankanglesensor andtiming beltcover are properly

installed.

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NG

Replace the ignition coil.

OK

Check all the following items:

DSpark plugs

DCompression pressure

DForeign material (such as water or kerosine) entered the fuel

linesOK

Check ignition timing. (Refer to GROUP 11A - Engine Adjustment.)

Does theenginestall immediately after the acceleratorpedal is

released?

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 309 of 1839

GDI -Troubleshooting

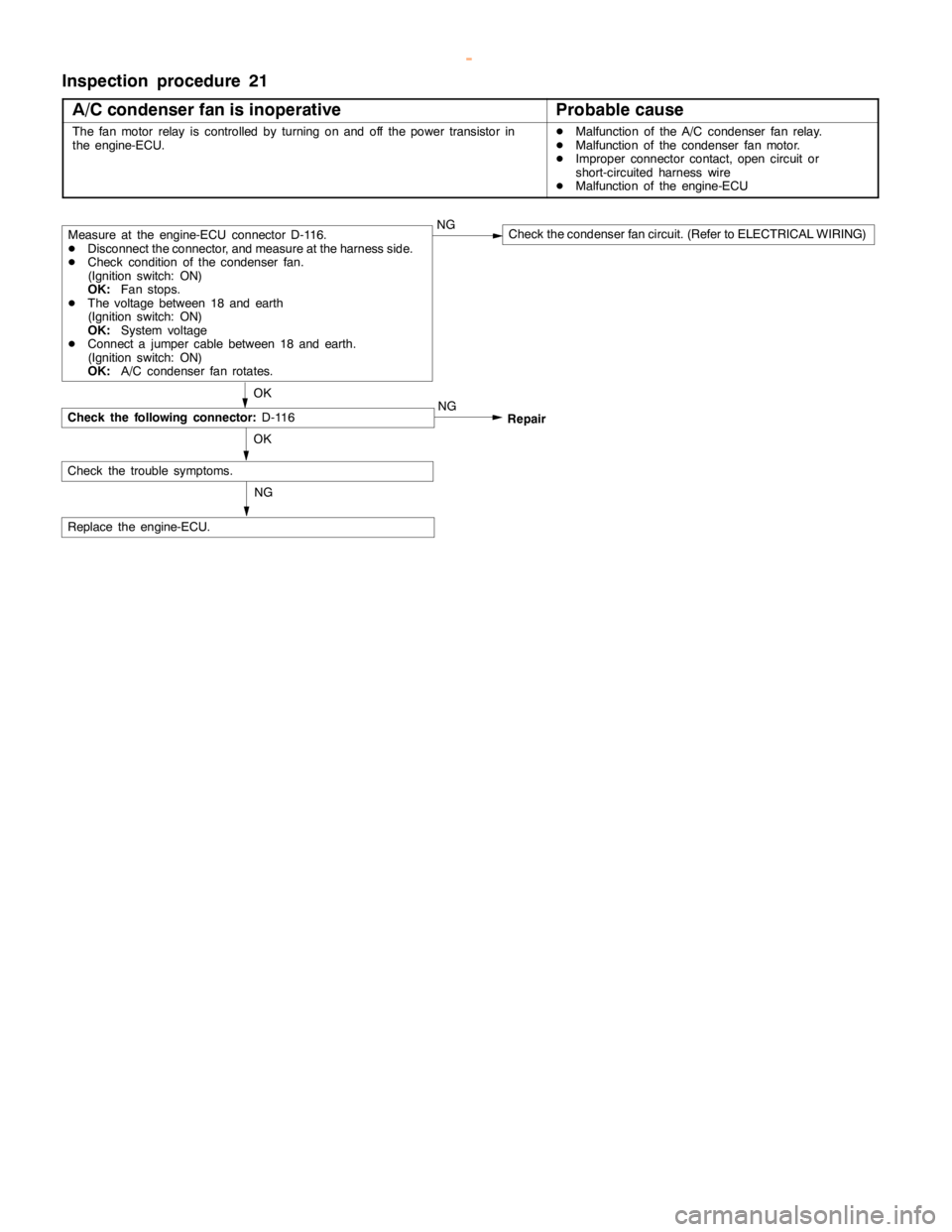

Inspection procedure 21

A/C condenser fan is inoperative

Probable cause

The fan motor relay is controlled by turning on and off the power transistor in

the engine-ECU.DMalfunction of the A/C condenser fan relay.

DMalfunction of the condenser fan motor.

DImproper connector contact,opencircuit or

short-circuited harness wire

DMalfunction of the engine-ECU

OK

Replace the engine-ECU.NG

Repair

OK

Check the trouble symptoms.

Check the following connector:

D-116

Measure at the engine-ECU connector D-116.

DDisconnect the connector, and measure at the harness side.

DCheck condition of the condenser fan.

(Ignition switch: ON)

OK:

Fan stops.

DThe voltage between 18 and earth

(Ignition switch: ON)

OK:

System voltage

DConnect a jumper cable between 18 and earth.

(Ignition switch: ON)

OK:

A/C condenser fan rotates.NGCheck the condenser fan circuit. (Refer to ELECTRICAL WIRING)

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 312 of 1839

GDI -Troubleshooting

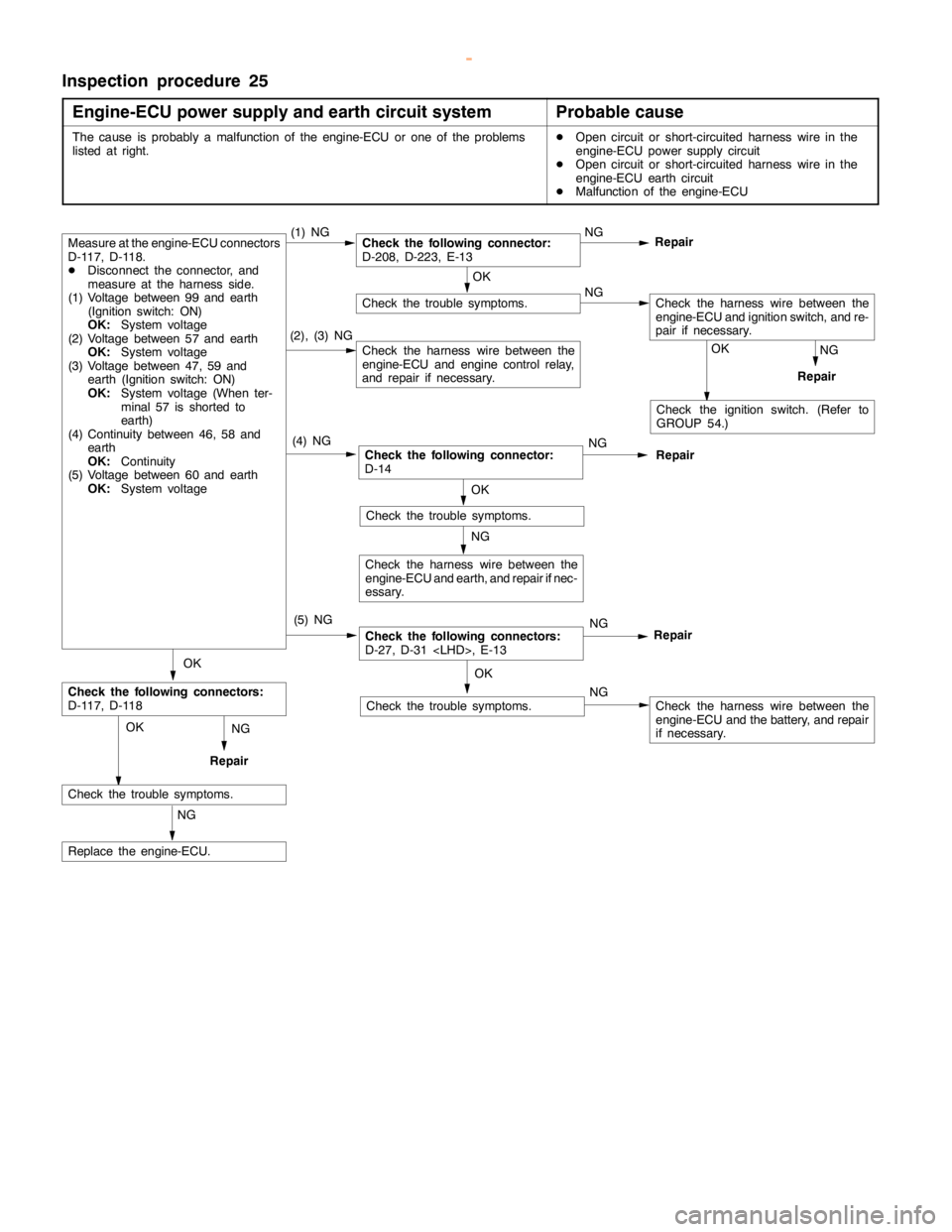

Inspection procedure 25

Engine-ECU power supply and earth circuit system

Probable cause

The cause is probably a malfunction of the engine-ECU or one of the problems

listed at right.DOpen circuit or short-circuited harness wire in the

engine-ECU power supply circuit

DOpen circuit or short-circuited harness wire in the

engine-ECU earth circuit

DMalfunction of the engine-ECU

NG

RepairOK

Check the ignition switch. (Refer to

GROUP 54.)

(2), (3) NGCheck the harness wire between the

engine-ECU and engine controlrelay,

and repair if necessary.

(4) NG

Check the harness wire between the

engine-ECU and earth, and repair if nec-

essary.

(5) NG

NG

Repair

OK

Check the trouble symptoms.NGCheck the harness wire between the

engine-ECU and the battery, and repair

if necessary.

NG

Repair

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

Check the following connectors:

D-117, D-118

Check the following connectors:

D-27, D-31

Check the trouble symptoms.NGCheck the harness wire between the

engine-ECU and ignition switch, and re-

pair if necessary.

Measure at the engine-ECU connectors

D-117, D-118.

DDisconnect the connector, and

measure at the harness side.

(1) Voltage between 99 and earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between 57 and earth

OK:

System voltage

(3) Voltage between 47, 59 and

earth (Ignition switch: ON)

OK:

System voltage (When ter-

minal 57 is shorted to

earth)

(4) Continuity between 46, 58 and

earth

OK:

Continuity

(5) Voltage between 60 and earth

OK:

System voltage(1) NGCheck the following connector:

D-208, D-223, E-13NG

Repair

Check the following connector:

D-14NG

Repair

Check the trouble symptoms.OK

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 313 of 1839

GDI -Troubleshooting

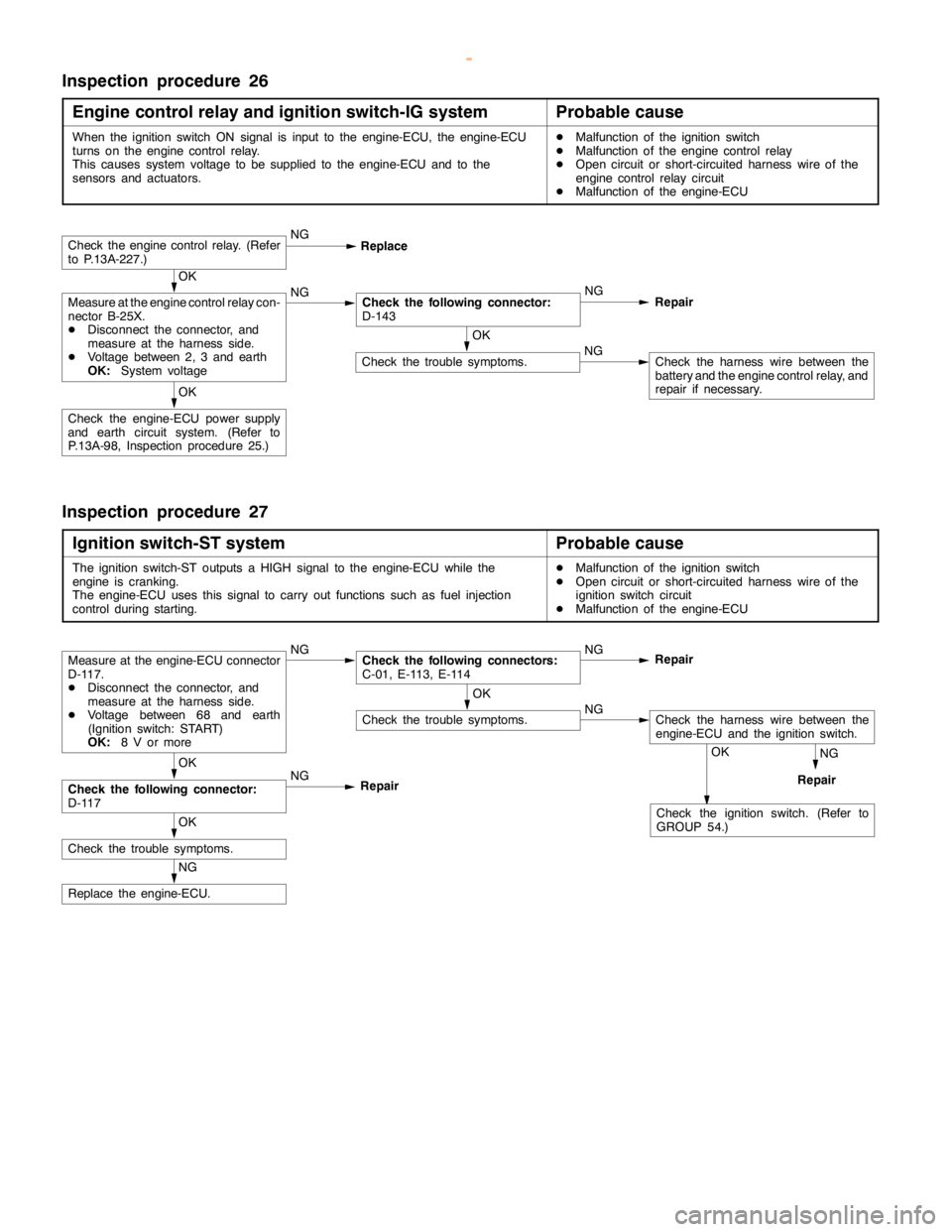

Inspection procedure 26

Engine control relay and ignition switch-IG system

Probable cause

When the ignition switch ON signal is input to the engine-ECU, the engine-ECU

turns on theengine controlrelay.

This causes system voltage to be supplied to the engine-ECU and to the

sensors and actuators.DMalfunction of the ignition switch

DMalfunction of the engine controlrelay

DOpen circuit or short-circuited harness wire of the

engine controlrelay circuit

DMalfunction of the engine-ECU

OK

Check the trouble symptoms.NGCheck the harness wire between the

battery and theengine controlrelay, and

repair if necessary.

OK

Check the engine-ECU power supply

and earth circuit system. (Refer to

P.13A-98, Inspection procedure 25.)

OK

Measure at the engine controlrelay con-

nector B-25X.

DDisconnect the connector, and

measure at the harness side.

DVoltage between 2, 3 and earth

OK:

System voltageNGCheck the following connector:

D-143NG

Repair

Check theengine controlrelay. (Refer

to P.13A-227.)NG

Replace

Inspection procedure 27

Ignition switch-ST system

Probable cause

The ignition switch-ST outputs a HIGH signal to the engine-ECU while the

engine iscranking.

The engine-ECU uses this signal to carry out functions such as fuel injection

control during starting.DMalfunction of the ignition switch

DOpen circuit or short-circuited harness wire of the

ignition switch circuit

DMalfunction of the engine-ECU

NG

RepairOK

Check the ignition switch. (Refer to

GROUP 54.)

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

Check the following connector:

D-117NG

RepairOK

Check the trouble symptoms.NGCheck the harness wire between the

engine-ECU and the ignition switch.

Measure at the engine-ECU connector

D-117.

DDisconnect the connector, and

measure at the harness side.

DVoltage between 68 and earth

(Ignition switch: START)

OK:

8 V or moreNGCheck the following connectors:

C-01, E-113, E-114NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk