relay MITSUBISHI MONTERO 2000 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 409 of 1839

Page 410 of 1839

Page 411 of 1839

Page 415 of 1839

Page 419 of 1839

Page 420 of 1839

Page 492 of 1839

13C-1

DIESEL FUEL

<4M4>

CONTENTS

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

SPECIAL TOOLS 4...........................

TROUBLESHOOTING 5.......................

ON-VEHICLE SERVICE 42...................

Injection Timing Check and Adjustment 42.........

Idle Speed Check and Adjustment 42.............

Accelerator Pedal Position Sensor (APS)

Adjustment 42.................................

Control Relay Continuity Check 43................

Accelerator Pedal Position Sensor (APS) Check 43.Idle Switch Check 43...........................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 44..................

Engine Coolant Temperature Sensor Check 44.....

Evacuation of Water from Fuel Filter 45...........

Fuel Filter Cartridge Replacement 45.............

Evacuation of Air from Fuel Line 45...............

Fuel Injection Pump Check 46...................

Intake Air Restriction Equipment Check 48.........

Injection Nozzle Check and Adjustment 49.........

INJECTION NOZZLE 50......................

INJECTION PUMP 56........................

ENGINE-ECU 59............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 493 of 1839

DIESEL FUEL <4M4> -General Information13C-2

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine is idling after having warmed up, the throttle valve is half opened to restrict the

amount of intake air in order to reduce vibration and noise.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Fan motor relay control

The radiator fan and condenser fan operating speeds are controlled in accordance with the engine

coolant temperature and the vehicle speed.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 504 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-13

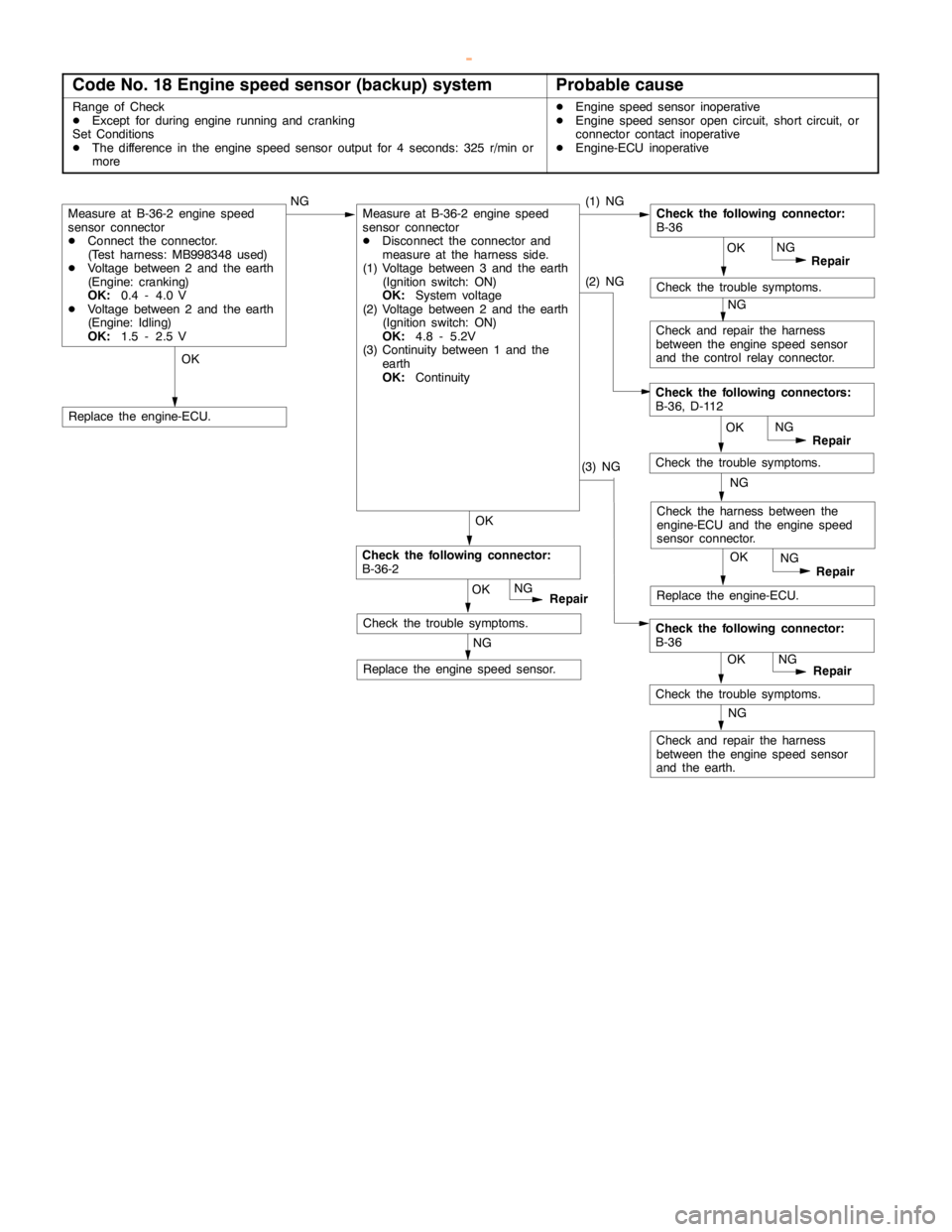

Code No. 18 Engine speed sensor (backup) systemProbable cause

Range of Check

DExcept for duringengine running andcranking

Set Conditions

DThe difference in the enginespeed sensor output for 4 seconds: 325 r/min or

moreDEngine speed sensor inoperative

DEngine speed sensoropencircuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

Check the trouble symptoms.

OK

Check and repair the harness

between the enginespeed sensor

and the control relay connector.OK

OK

NG

Repair

(1) NGMeasure at B-36-2 enginespeed

sensor connector

DConnect the connector.

(Test harness: MB998348 used)

DVoltage between 2 and the earth

(Engine: cranking)

OK:

0.4 - 4.0 V

DVoltage between 2 and the earth

(Engine: Idling)

OK:

1.5 - 2.5 V

NG

Replace the enginespeed sensor.

Replace the engine-ECU.

Check the following connector:

B-36

NG

NG

Check the trouble symptoms.

OK

Repair NG

OK

Repair NG NG

OKRepair NG

NG

OKRepair NG

Check the following connector:

B-36-2

Check the trouble symptoms.

Measure at B-36-2 enginespeed

sensor connector

DDisconnect the connector and

measure at the harness side.

(1) Voltage between 3 and the earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between 2 and the earth

(Ignition switch: ON)

OK:

4.8 - 5.2V

(3) Continuity between 1 and the

earth

OK:

Continuity(2) NG

(3) NG

Check the harness between the

engine-ECU and the enginespeed

sensor connector.

Replace the engine-ECU.

Check and repair the harness

between the enginespeed sensor

and the earth.

Check the following connector:

B-36

Check the trouble symptoms.

Check the following connectors:

B-36, D-112

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 505 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-14

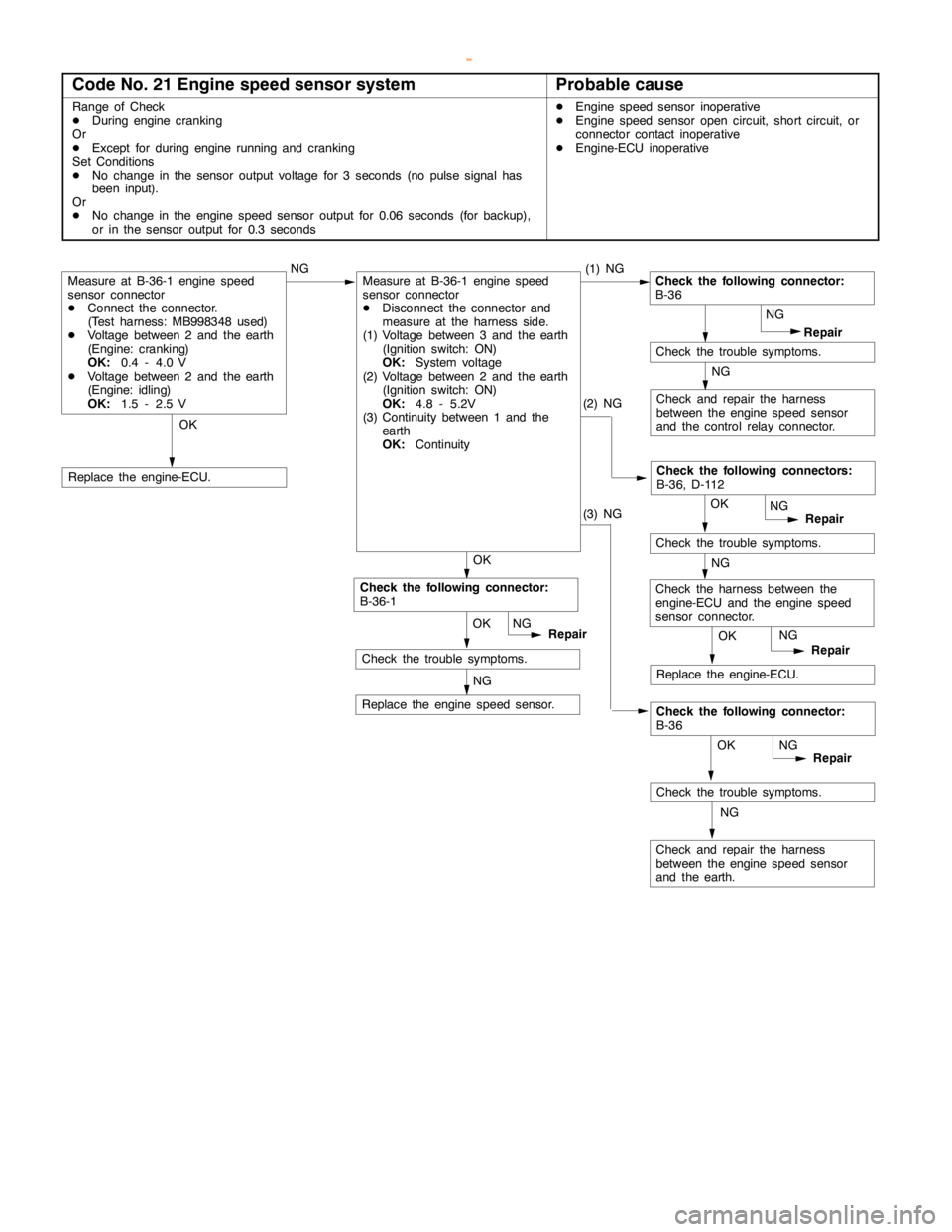

Code No. 21 Engine speed sensor systemProbable cause

Range of Check

DDuring enginecranking

Or

DExcept for duringengine running andcranking

Set Conditions

DNo change in the sensor output voltage for 3 seconds (no pulse signal has

been input).

Or

DNo change in the enginespeed sensor output for 0.06 seconds (for backup),

or in the sensor output for 0.3 secondsDEngine speed sensor inoperative

DEngine speed sensoropencircuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

OK

Check and repair the harness

between the enginespeed sensor

and the control relay connector.OK

OK

NG

Repair

(1) NGMeasure at B-36-1 enginespeed

sensor connector

DConnect the connector.

(Test harness: MB998348 used)

DVoltage between 2 and the earth

(Engine: cranking)

OK:

0.4 - 4.0 V

DVoltage between 2 and the earth

(Engine: idling)

OK:

1.5 - 2.5 V

NG

Replace the enginespeed sensor.

Replace the engine-ECU.

Check the following connector:

B-36

NG

NG

Check the trouble symptoms.

OK

Repair

Check the following connectors:

B-36, D-112

NG

OK

Repair NG

Check the harness between the

engine-ECU and the enginespeed

sensor connector.NG

Check the trouble symptoms.

Replace the engine-ECU.

Check and repair the harness

between the enginespeed sensor

and the earth.OK

Repair

Check the following connector:

B-36

NG

NG

Check the trouble symptoms. OK

Repair NG

Check the following connector:

B-36-1

Check the trouble symptoms.

Measure at B-36-1 enginespeed

sensor connector

DDisconnect the connector and

measure at the harness side.

(1) Voltage between 3 and the earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between 2 and the earth

(Ignition switch: ON)

OK:

4.8 - 5.2V

(3) Continuity between 1 and the

earth

OK:

Continuity(2) NG

(3) NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk