relay MITSUBISHI MONTERO 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 315 of 1839

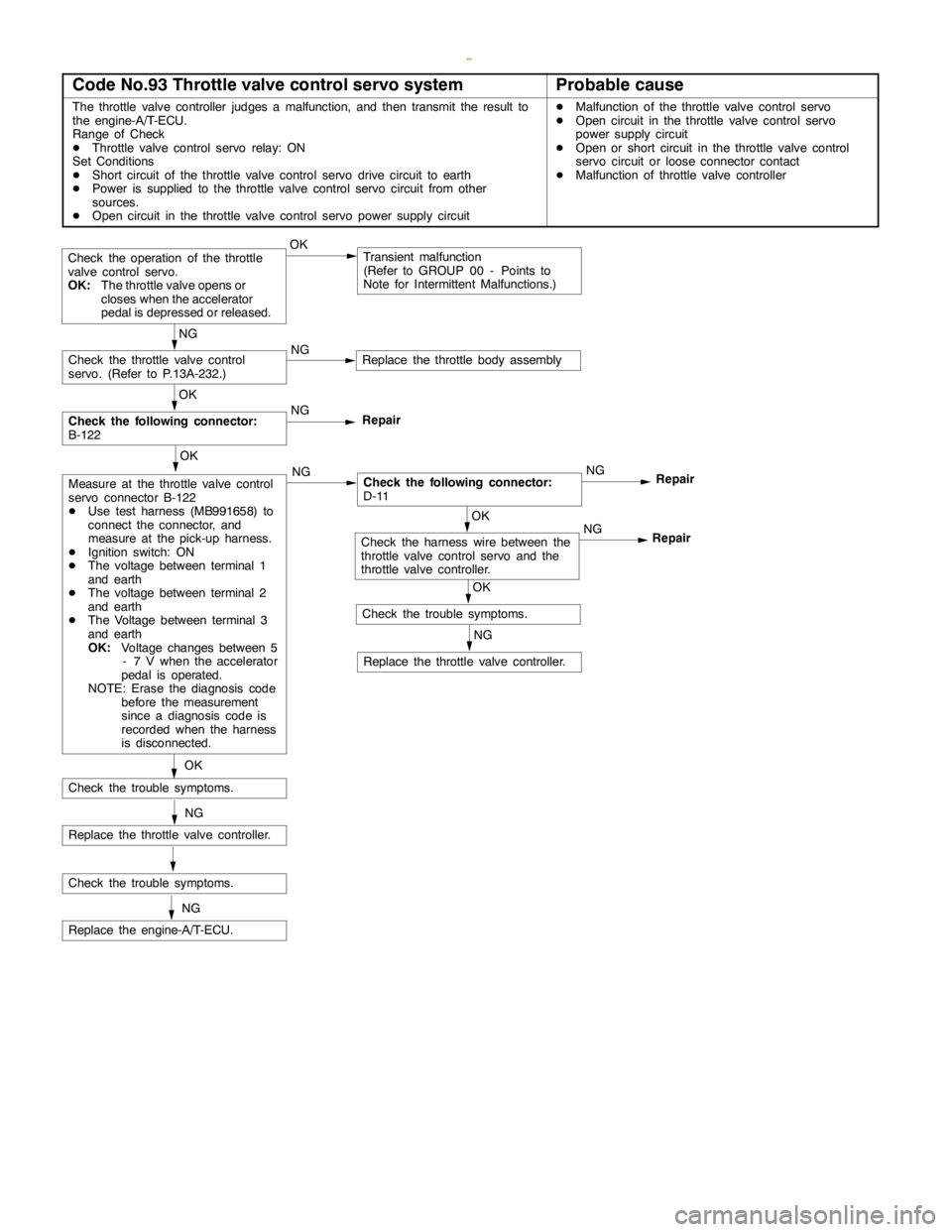

GDI -Troubleshooting

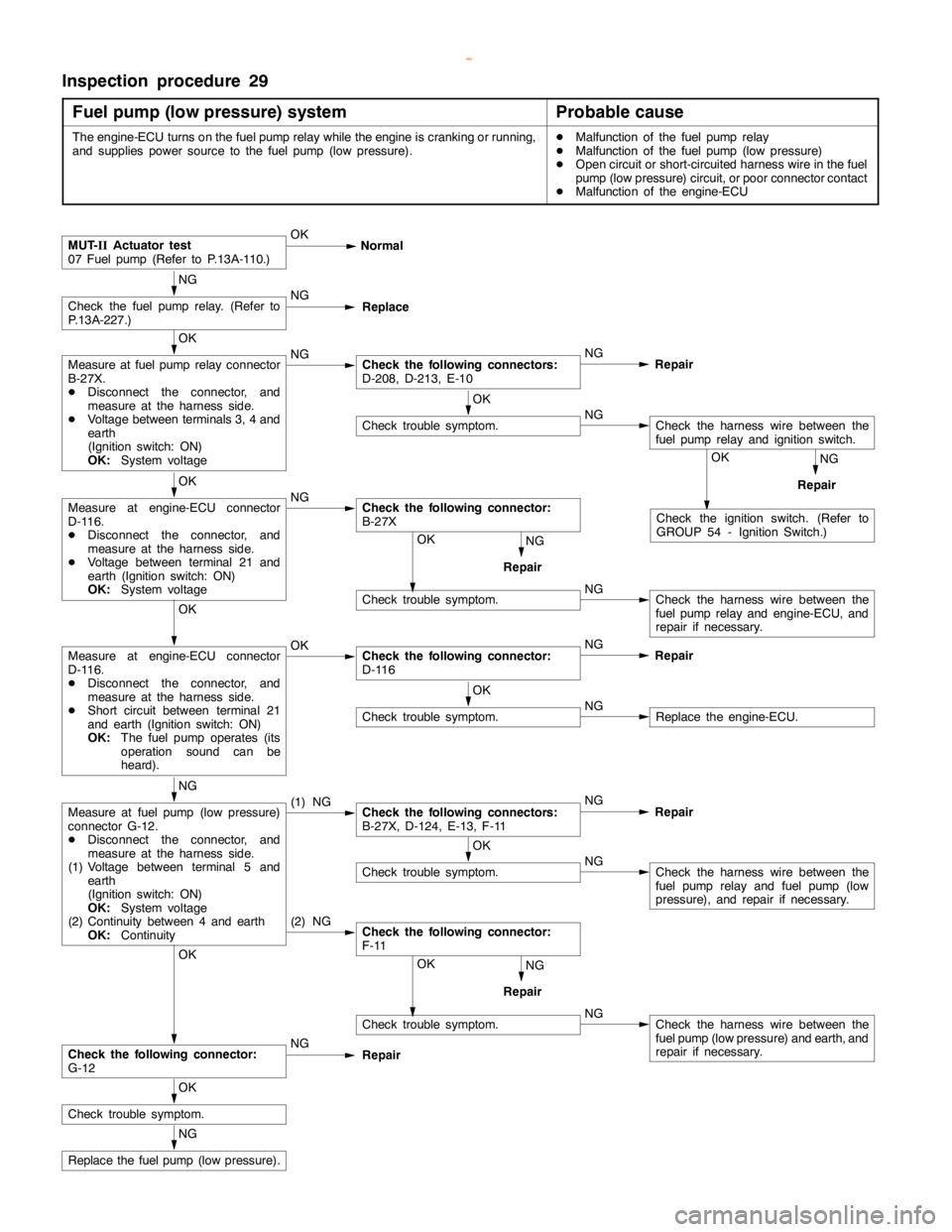

Inspection procedure 29

Fuel pump (low pressure) system

Probable cause

The engine-ECU turns on the fuelpumprelay while theengine iscranking or running,

and supplies power source to the fuelpump(low pressure).DMalfunction of the fuel pumprelay

DMalfunction of the fuel pump(low pressure)

DOpen circuit or short-circuited harness wire in the fuel

pump(low pressure) circuit, or poor connector contact

DMalfunction of the engine-ECU

Check trouble symptom.NGCheck the harness wire between the

fuel pump(low pressure) and earth, and

repair if necessary.

NG

RepairOK

Check trouble symptom.NGCheck the harness wire between the

fuel pumprelay and engine-ECU, and

repair if necessary.

NG

RepairOK

NG

RepairOK

Check the ignition switch. (Refer to

GROUP 54 - Ignition Switch.)

(2) NGCheck the following connector:

F-11

MUT-

IIActuator test

07 Fuel pump(Refer to P.13A-110.)OK

Normal

NG

Check the fuelpumprelay. (Refer to

P.13A-227.)NG

Replace

OK

Measure at fuel pumprelay connector

B-27X.

DDisconnect the connector, and

measure at the harness side.

DVoltage between terminals 3, 4 and

earth

(Ignition switch: ON)

OK:

System voltageNGCheck the following connectors:

D-208, D-213, E-10NG

Repair

OK

Check trouble symptom.NGCheck the harness wire between the

fuel pumprelay and ignition switch.

OK

Measure at engine-ECU connector

D-116.

DDisconnect the connector, and

measure at the harness side.

DVoltage between terminal 21 and

earth (Ignition switch: ON)

OK:

System voltageNGCheck the following connector:

B-27X

OK

Measure at engine-ECU connector

D-116.

DDisconnect the connector, and

measure at the harness side.

DShort circuit between terminal 21

and earth (Ignition switch: ON)

OK:

The fuel pump operates(its

operation sound can be

heard).OKCheck the following connector:

D-116NG

Repair

OK

Check trouble symptom.NGReplace the engine-ECU.

NG

Measure at fuel pump(low pressure)

connector G-12.

DDisconnect the connector, and

measure at the harness side.

(1) Voltage between terminal 5 and

earth

(Ignition switch: ON)

OK:

System voltage

(2) Continuity between 4 and earth

OK:

Continuity(1) NGCheck the following connectors:

B-27X, D-124, E-13, F-11NG

Repair

OK

Check trouble symptom.NGCheck the harness wire between the

fuel pumprelay and fuelpump(low

pressure), and repair if necessary.

OK

Check the following connector:

G-12NG

Repair

OK

Check trouble symptom.

NG

Replace the fuel pump(low pressure).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 316 of 1839

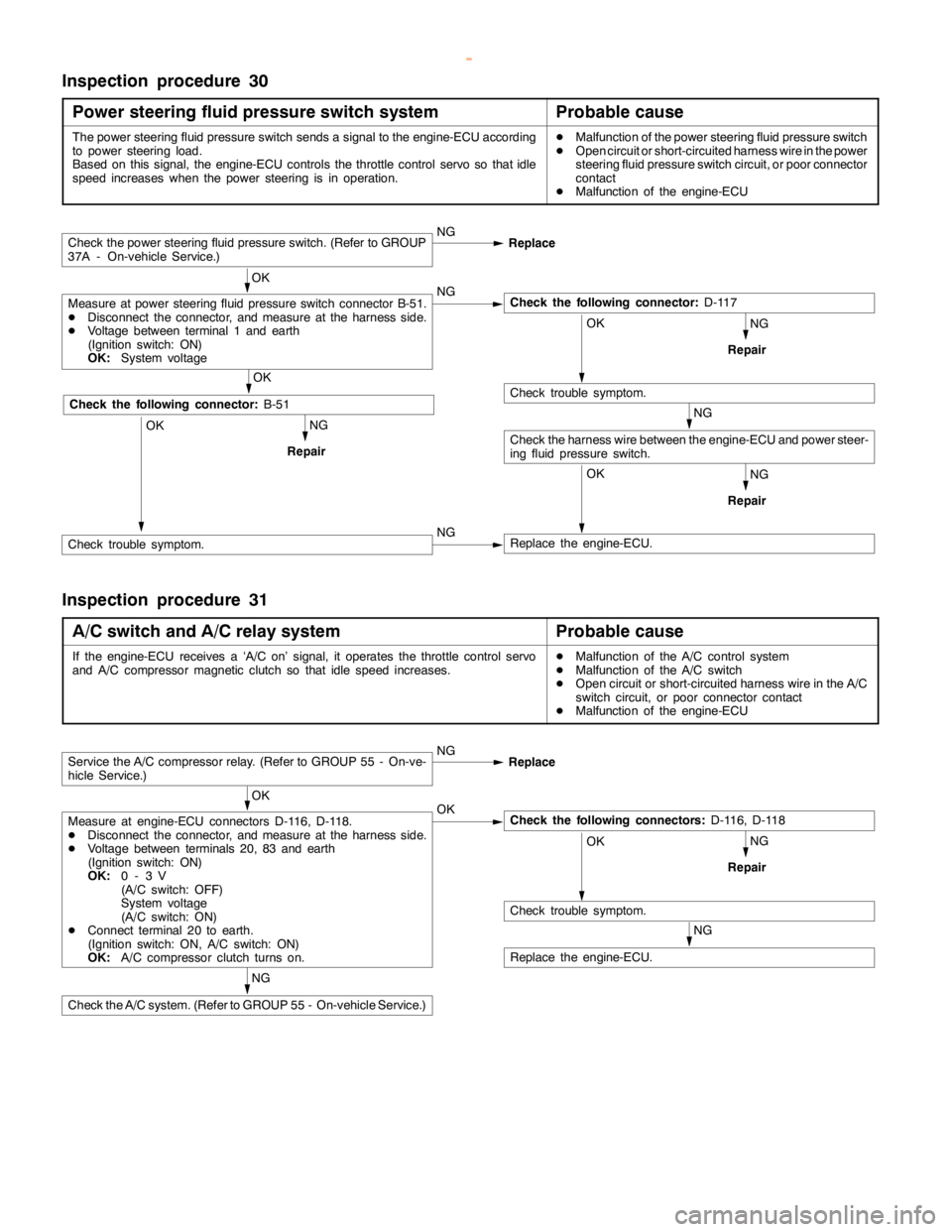

GDI -Troubleshooting

Inspection procedure 30

Power steering fluid pressure switch system

Probable cause

The power steering fluid pressure switch sends a signal to the engine-ECU according

to power steering load.

Based on this signal, the engine-ECU controls the throttle control servo so thatidle

speed increases when the power steering is in operation.DMalfunction of the power steering fluid pressure switch

DOpen circuit or short-circuited harness wire in the power

steering fluid pressure switch circuit, or poor connector

contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Replace the engine-ECU.

NG

Repair

Check the power steering fluid pressure switch. (Refer to GROUP

37A - On-vehicle Service.)NG

Replace

OK

Measure at power steering fluid pressure switch connector B-51.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 1 and earth

(Ignition switch: ON)

OK:

System voltageNGCheck the following connector:

D-117

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and power steer-

ing fluid pressure switch.NG

RepairOK

OK

Check the following connector:

B-51

Check trouble symptom.NG

Inspection procedure 31

A/C switch and A/C relay system

Probable cause

If the engine-ECU receives a ‘A/C on’ signal, it operates the throttle control servo

and A/C compressor magnetic clutch so thatidlespeed increases.DMalfunction of the A/C control system

DMalfunction of the A/C switch

DOpen circuit or short-circuited harness wire in the A/C

switch circuit, or poor connector contact

DMalfunction of the engine-ECU

NG

NG

RepairOK

Check trouble symptom.

NG

Replace the engine-ECU.

Service the A/C compressor relay. (Refer to GROUP 55 - On-ve-

hicle Service.)NG

Replace

OK

Measure at engine-ECU connectors D-116, D-118.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminals 20, 83 and earth

(Ignition switch: ON)

OK:

0-3V

(A/C switch: OFF)

System voltage

(A/C switch: ON)

DConnect terminal 20 to earth.

(Ignition switch: ON, A/C switch: ON)

OK:

A/C compressor clutch turns on.OKCheck the following connectors:

D-116, D-118

Check the A/C system. (Refer to GROUP 55 - On-vehicle Service.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 322 of 1839

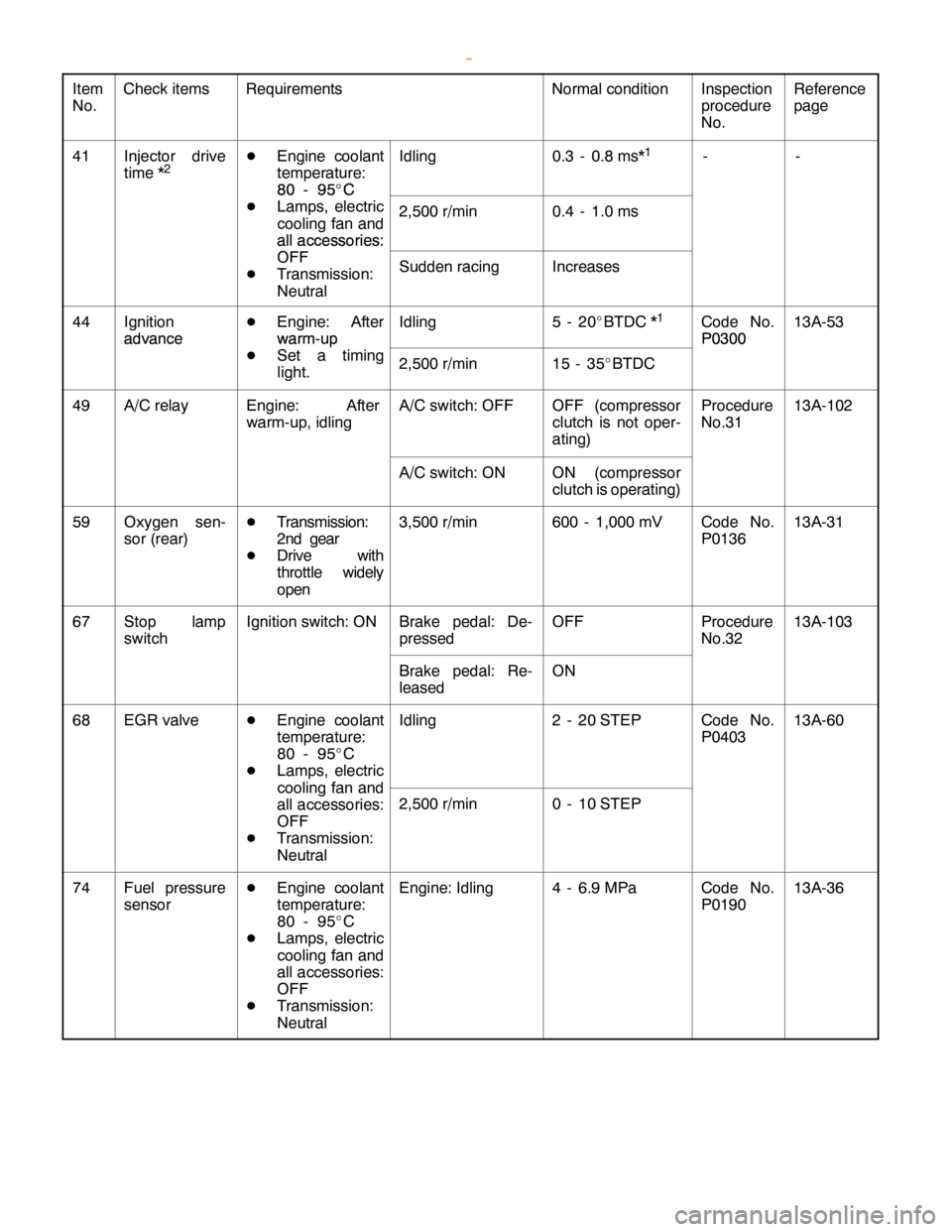

GDI -Troubleshooting

Item

No.Reference

page Inspection

procedure

No. Normal condition Requirements Check items

41Injector drive

time *2DEngine coolant

temperature:

80 - 95_CIdling0.3 - 0.8 ms*1--

80 - 95_C

DLamps, electric

cooling fan and

all accessories:

2,500 r/min0.4 - 1.0 ms

all accessories:

OFF

DTransmission:

Neutral

Sudden racingIncreases

44Ignition

advanceDEngine: After

warm-upIdling5-20_BTDC *1Code No.

P030013A-53

advancewarm-up

DSet a timing

light.

2,500 r/min15 - 35_BTDC

P0300

49A/C relayEngine: After

warm-up, idlingA/C switch: OFFOFF (compressor

clutch is not oper-

ating)Procedure

No.3113A-102

A/C switch: ONON (compressor

clutch is operating)

59Oxygen sen-

sor (rear)DTransmission:

2nd gear

DDrive with

throttle widely

open3,500 r/min600 - 1,000 mVCode No.

P013613A-31

67Stop lamp

switchIgnition switch: ONBrake pedal: De-

pressedOFFProcedure

No.3213A-103

Brake pedal: Re-

leasedON

68EGR valveDEngine coolant

temperature:

80 - 95_C

DLamps, electricIdling2 - 20 STEPCode No.

P040313A-60

cooling fan and

all accessories:

OFF

DTransmission:

Neutral

2,500 r/min0 - 10 STEP

74Fuel pressure

sensorDEngine coolant

temperature:

80 - 95_C

DLamps, electric

cooling fan and

all accessories:

OFF

DTransmission:

NeutralEngine: Idling4 - 6.9 MPaCode No.

P019013A-36

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 326 of 1839

GDI -Troubleshooting

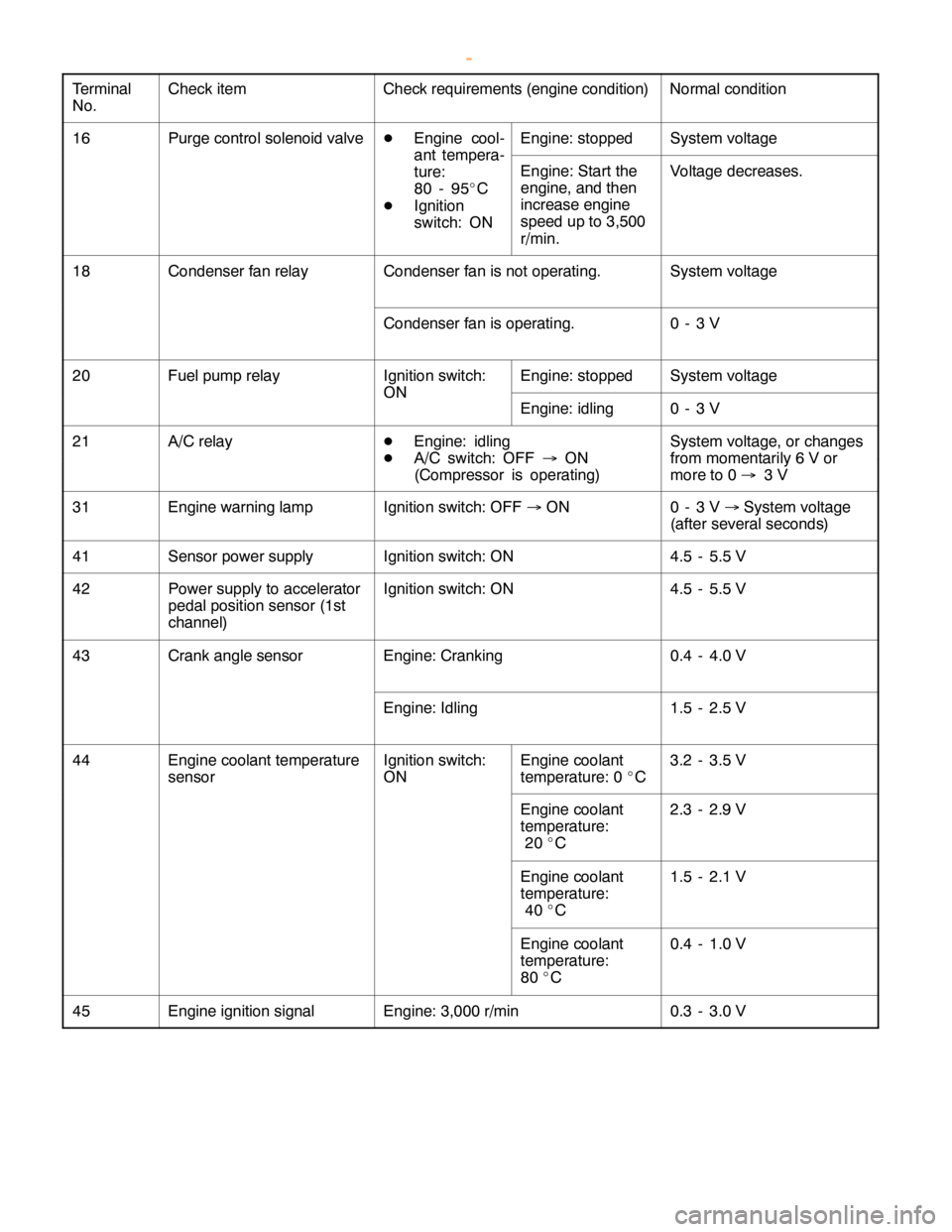

Terminal

No.Normal condition Check requirements (engine condition) Check item

16Purge control solenoid valveDEngine cool-Engine: stoppedSystem voltage

ant tempera-

ture:

80 - 95_C

DIgnition

switch: ON

Engine: Start the

engine, and then

increase engine

speed up to 3,500

r/min.Voltage decreases.

18Condenser fan relayCondenser fan is not operating.System voltage

Condenser fan is operating.0-3V

20Fuel pump relayIgnition switch:Engine: stoppedSystem voltage

ON

Engine: idling0-3V

21A/C relayDEngine: idlingSystem voltage, or changes

DA/C switch: OFF®ON

(Compressor is operating)from momentarily 6 V or

more to 0®3V

31Engine warning lampIgnition switch: OFF®ON0-3V®System voltage

(after several seconds)

41Sensor power supplyIgnition switch: ON4.5 - 5.5 V

42Power supply to accelerator

pedal position sensor (1st

channel)Ignition switch: ON4.5 - 5.5 V

43Crank angle sensorEngine: Cranking0.4 - 4.0 V

Engine: Idling1.5 - 2.5 V

44Engine coolant temperature

sensorIgnition switch:

ONEngine coolant

temperature: 0_C3.2 - 3.5 V

Engine coolant

temperature:

20_C2.3 - 2.9 V

Engine coolant

temperature:

40_C1.5 - 2.1 V

Engine coolant

temperature:

80_C0.4 - 1.0 V

45Engine ignition signalEngine: 3,000 r/min0.3 - 3.0 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

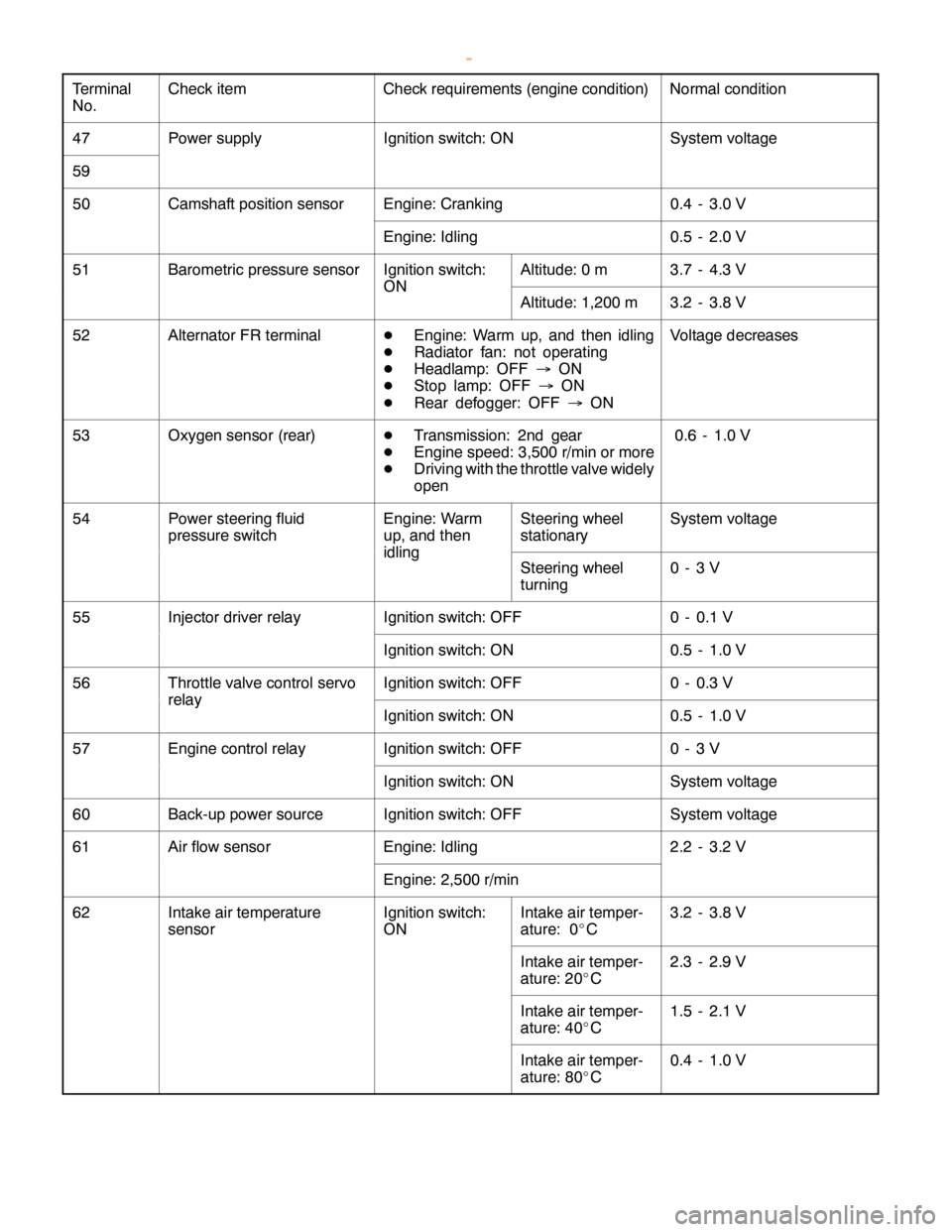

Page 327 of 1839

GDI -Troubleshooting

Terminal

No.Normal condition Check requirements (engine condition) Check item

47Power supplyIgnition switch: ONSystem voltage

59

50Camshaft position sensorEngine: Cranking0.4 - 3.0 V

Engine: Idling0.5 - 2.0 V

51Barometric pressure sensorIgnition switch:Altitude: 0 m3.7 - 4.3 V

ON

Altitude: 1,200 m3.2 - 3.8 V

52Alternator FR terminalDEngine: Warm up, and then idling

DRadiator fan: not operating

DHeadlamp: OFF®ON

DStop lamp: OFF®ON

DRear defogger: OFF®ONVoltage decreases

53Oxygen sensor (rear)DTransmission: 2nd gear

DEngine speed: 3,500 r/min or more

DDriving with the throttle valve widely

open0.6 - 1.0 V

54Power steering fluid

pressure switchEngine: Warm

up, and thenSteering wheel

stationarySystem voltage

idling

Steering wheel

turning0-3V

55Injector driver relayIgnition switch: OFF0 - 0.1 V

Ignition switch: ON0.5 - 1.0 V

56Throttle valve control servoIgnition switch: OFF0 - 0.3 V

relay

Ignition switch: ON0.5 - 1.0 V

57Engine control relayIgnition switch: OFF0-3V

Ignition switch: ONSystem voltage

60Back-up power sourceIgnition switch: OFFSystem voltage

61Air flow sensorEngine: Idling2.2 - 3.2 V

Engine: 2,500 r/min

62Intake air temperature

sensorIgnition switch:

ONIntake air temper-

ature: 0_C3.2 - 3.8 V

Intake air temper-

ature: 20_C2.3 - 2.9 V

Intake air temper-

ature: 40_C1.5 - 2.1 V

Intake air temper-

ature: 80_C0.4 - 1.0 V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

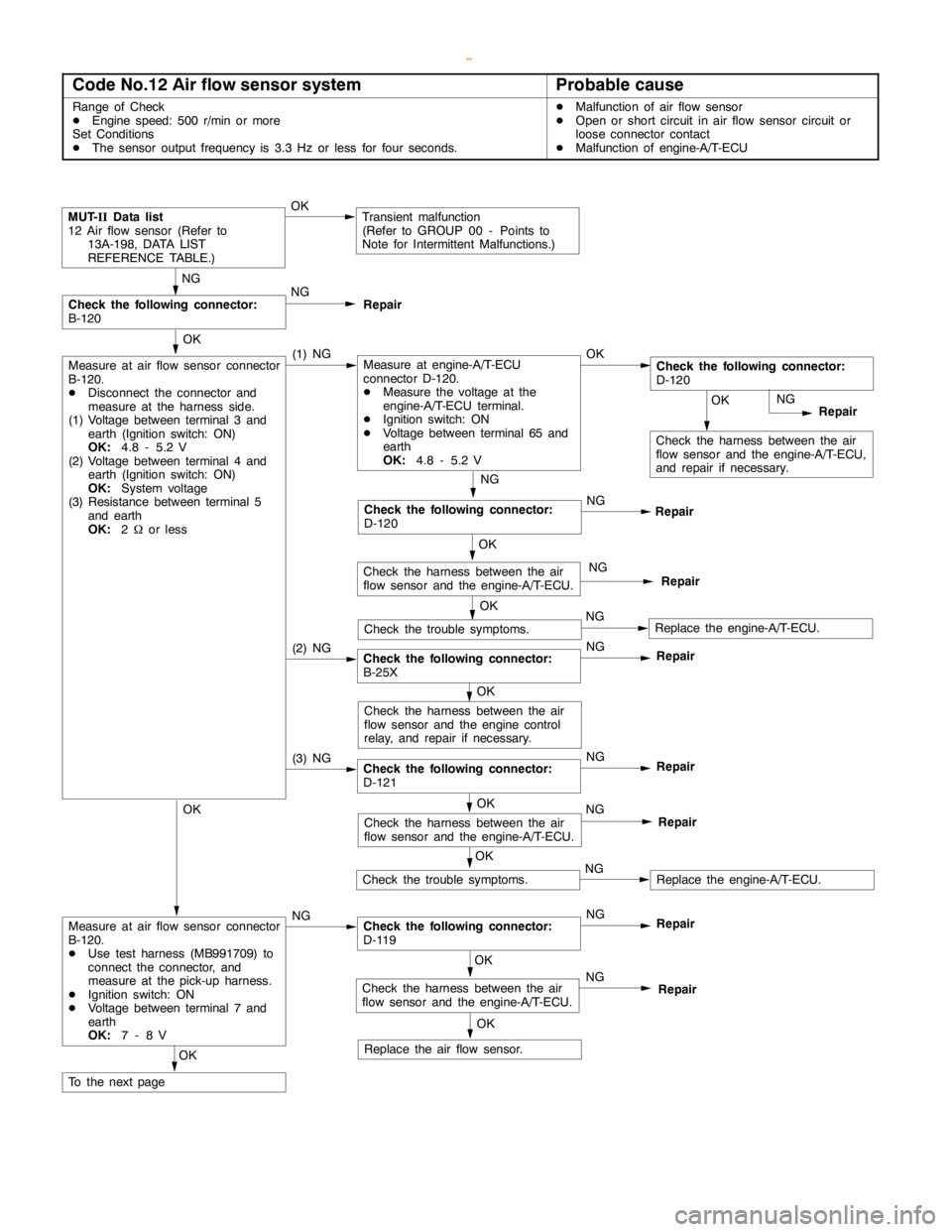

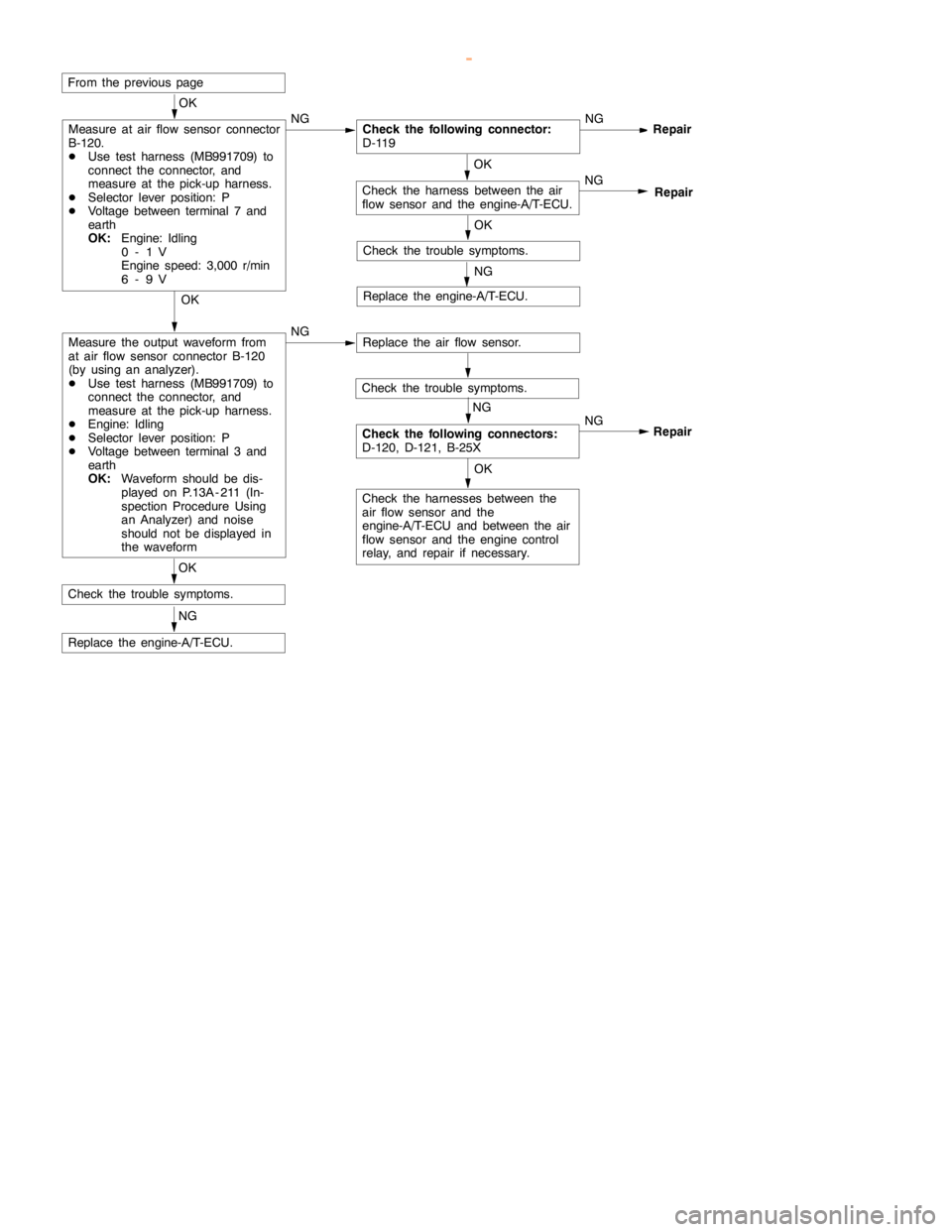

Page 347 of 1839

Page 348 of 1839

Page 355 of 1839

Page 357 of 1839

Page 377 of 1839