relay MITSUBISHI MONTERO 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 510 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-19

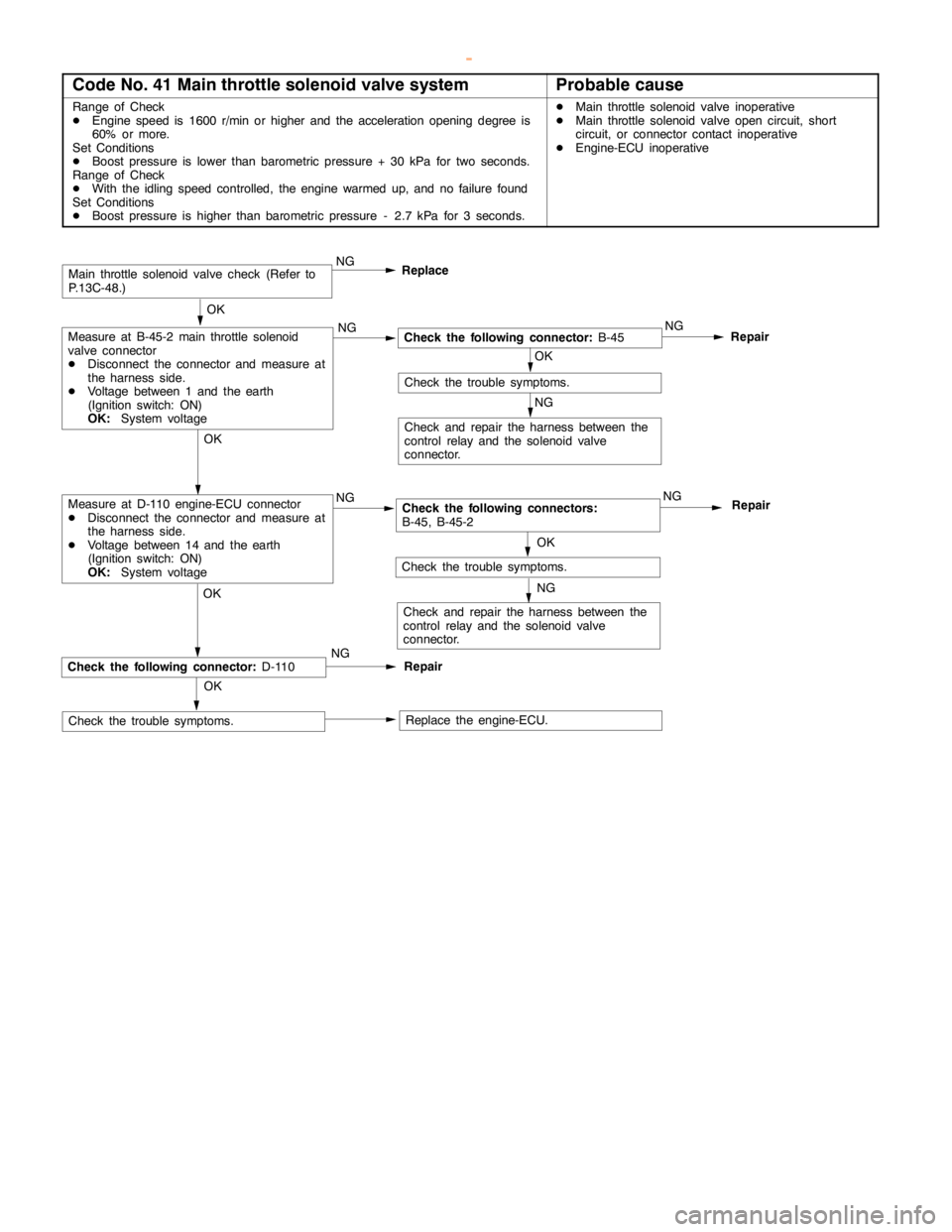

Code No. 41 Main throttle solenoid valve systemProbable cause

Range of Check

DEngine speed is 1600 r/min or higher and the accelerationopening degree is

60% or more.

Set Conditions

DBoost pressure is lower than barometric pressure + 30 kPa for two seconds.

Range of Check

DWith the idlingspeed controlled, theengine warmed up, and no failure found

Set Conditions

DBoost pressure is higher than barometric pressure - 2.7 kPa for 3 seconds.DMain throttle solenoidvalve inoperative

DMain throttle solenoidvalveopencircuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

Check the following connector:

B-45NG

Repair

OK

OK

Check and repair the harness between the

control relay and the solenoid valve

connector.

Main throttle solenoidvalve check (Refer to

P.13C-48.)

Check the trouble symptoms.

Replace the engine-ECU.

NG

OK

RepairCheck the following connector:

D-110

Check the trouble symptoms.NGReplace

NG NG

Check the following connectors:

B-45, B-45-2NG

Repair

OK

Check and repair the harness between the

control relay and the solenoid valve

connector.

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 14 and the earth

(Ignition switch: ON)

OK:

System voltageOK

Measure at B-45-2 main throttle solenoid

valve connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:

System voltage

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 511 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-20

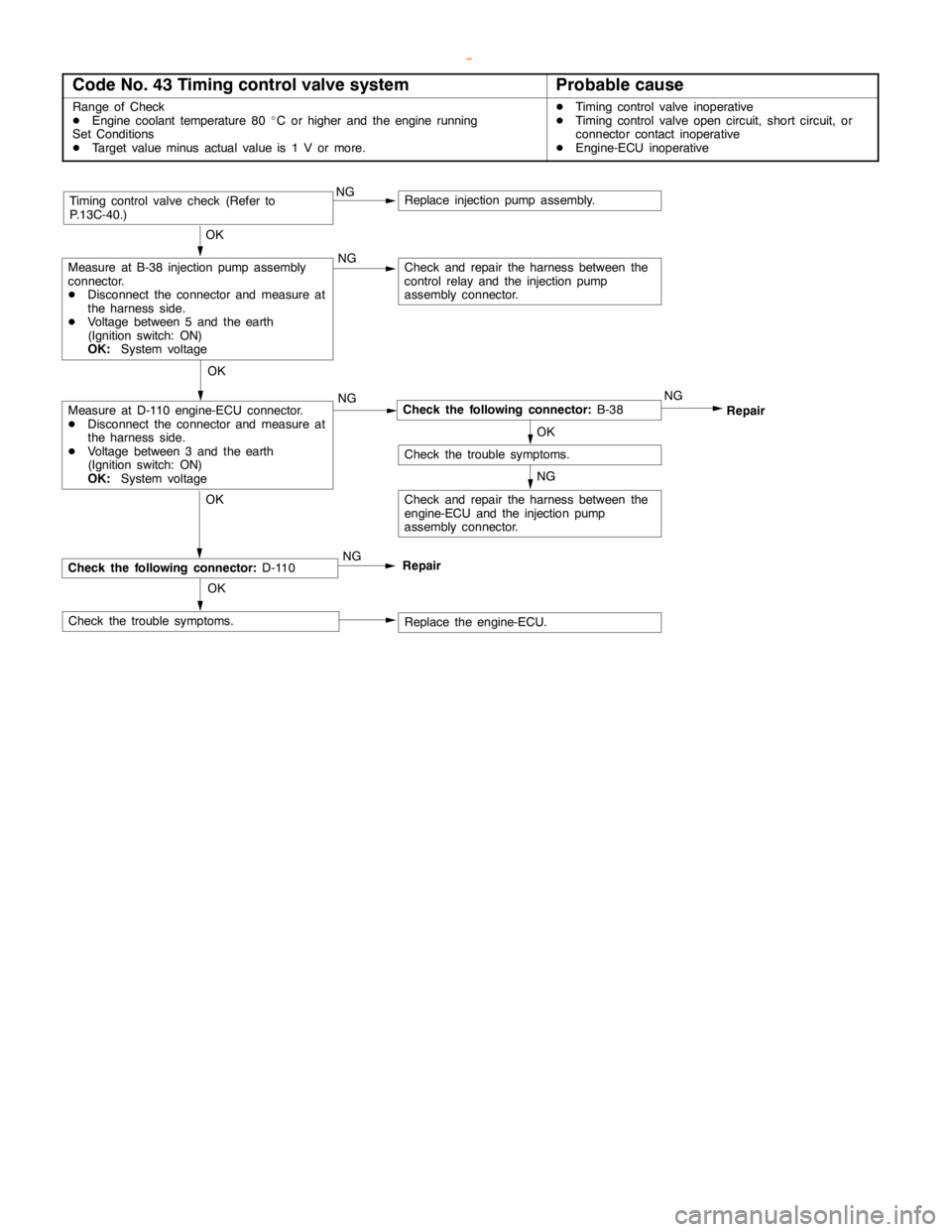

Code No. 43 Timing control valve systemProbable cause

Range of Check

DEngine coolant temperature 80_C or higher and the engine running

Set Conditions

DTarget value minus actual value is 1 V or more.DTiming controlvalve inoperative

DTiming controlvalveopencircuit, short circuit, or

connector contact inoperative

DEngine-ECU inoperative

OK

OK

Check and repair the harness between the

control relay and the injectionpump

assembly connector.

Timing controlvalve check (Refer to

P.13C-40.)

Replace the engine-ECU. OK

RepairCheck the following connector:

D-110

Check the trouble symptoms.NG NG NG

Check the following connector:

B-38NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 3 and the earth

(Ignition switch: ON)

OK:

System voltageOK

Measure at B-38 injectionpumpassembly

connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 5 and the earth

(Ignition switch: ON)

OK:

System voltage

Replace injection pumpassembly.

Check and repair the harness between the

engine-ECU and the injection pump

assembly connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 512 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-21

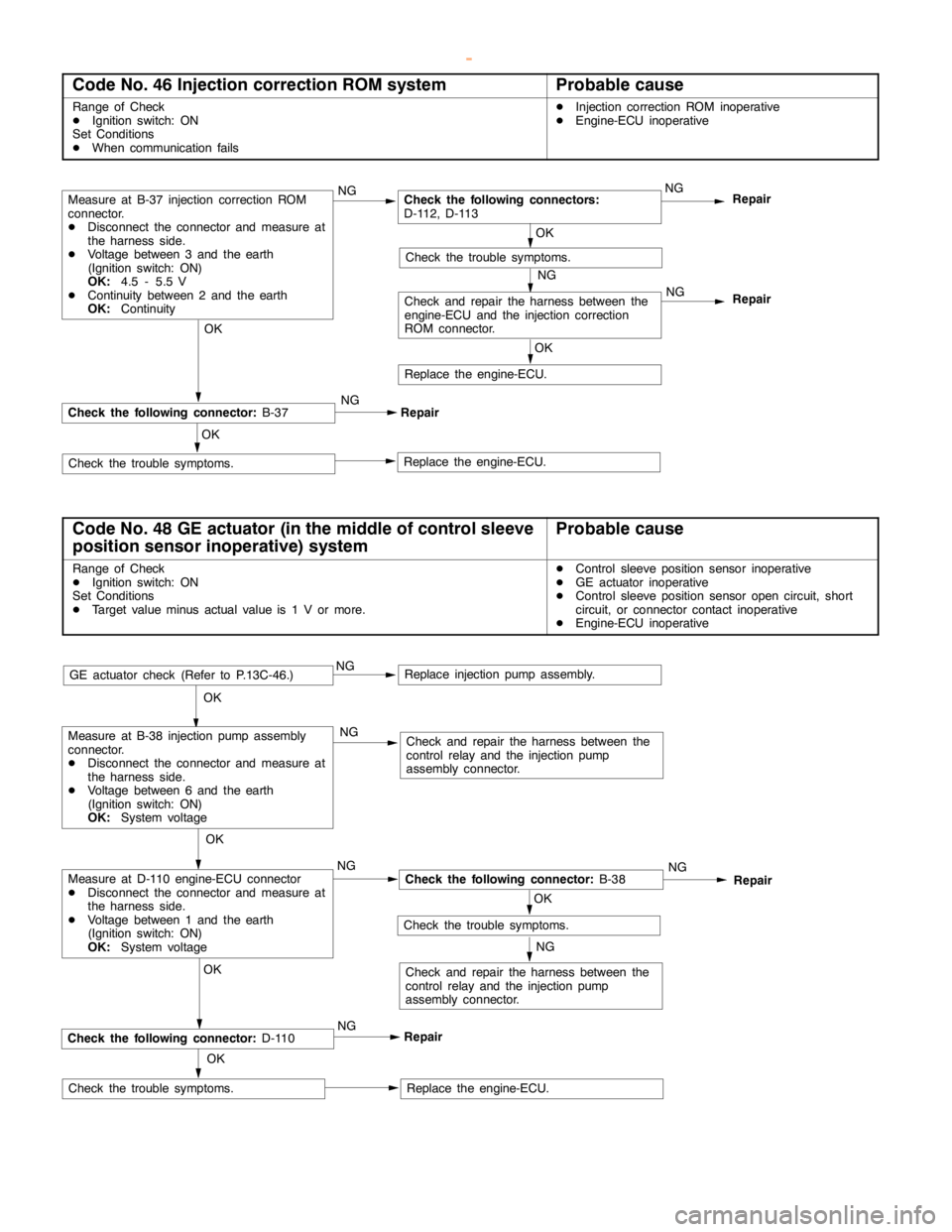

Code No. 46 Injection correction ROM systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DWhen communication failsDInjection correction ROM inoperative

DEngine-ECU inoperative

Repair

OK

Replace the engine-ECU. OK

RepairCheck the following connector:

B-37

Check the trouble symptoms.NG NG

Check the following connectors:

D-112, D-113

NG

Repair

OK

Check the trouble symptoms.

NG

Measure at B-37 injection correction ROM

connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 3 and the earth

(Ignition switch: ON)

OK:

4.5 - 5.5 V

DContinuity between 2 and the earth

OK:

Continuity

Check and repair the harness between the

engine-ECU and the injection correction

ROM connector.

OK

Replace the engine-ECU.NG

Code No. 48 GE actuator (in the middle of control sleeve

position sensor inoperative) systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DTarget value minus actual value is 1 V or more.DControl sleeve position sensor inoperative

DGE actuator inoperative

DControl sleeve position sensoropencircuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OK

OK

Check and repair the harness between the

control relay and the injectionpump

assembly connector.

GE actuator check (Refer to P.13C-46.)

Replace the engine-ECU. OK

RepairCheck the following connector:

D-110

Check the trouble symptoms.NGNG NG

Check the following connector:

B-38NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:

System voltageOK

Measure at B-38 injectionpumpassembly

connector.

DDisconnect the connector and measure at

the harness side.

DVoltage between 6 and the earth

(Ignition switch: ON)

OK:

System voltage

Replace injection pumpassembly.

Check and repair the harness between the

control relay and the injectionpump

assembly connector.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 517 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-26

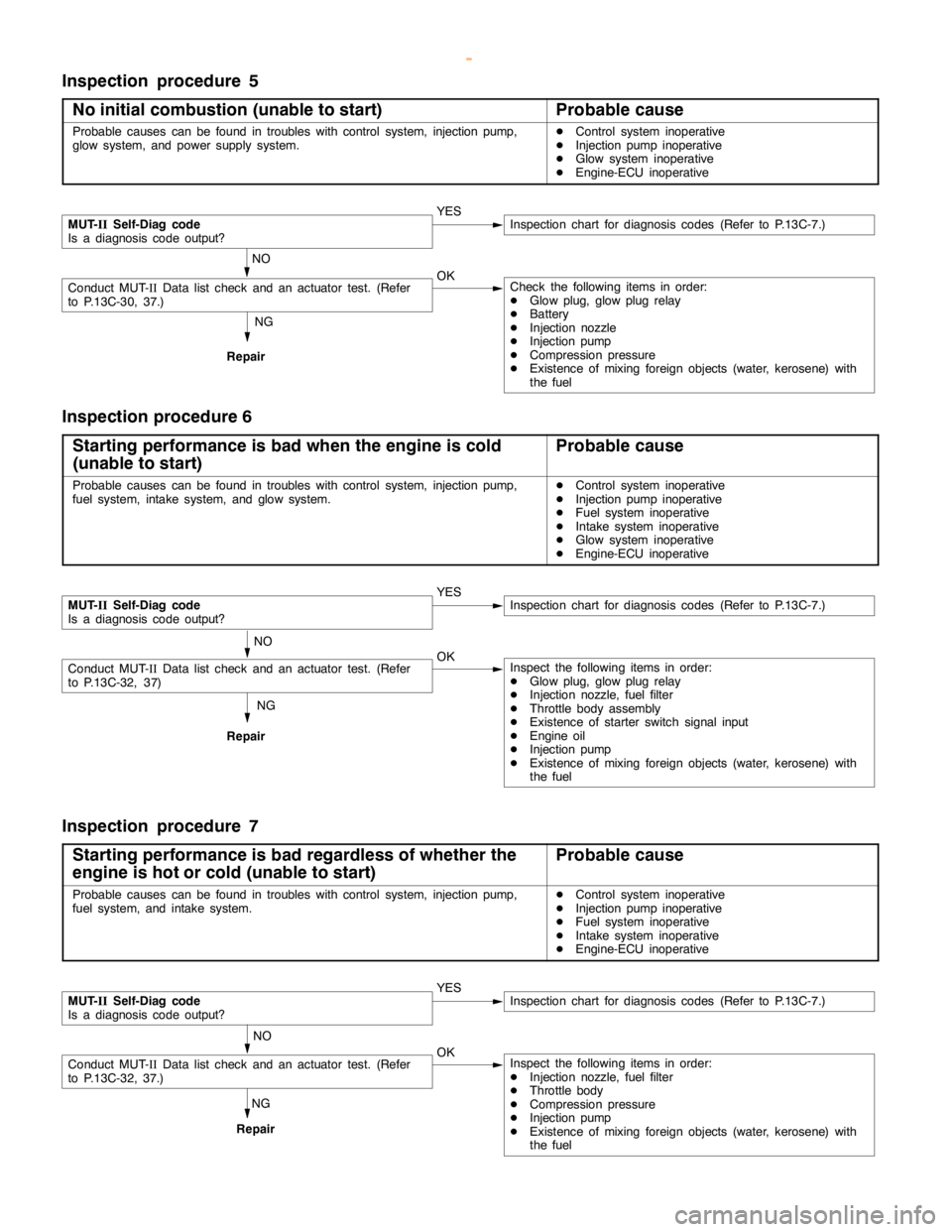

Inspection procedure 5

No initial combustion (unable to start)

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

glow system, and power supply system.DControl system inoperative

DInjection pump inoperative

DGlow system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-30, 37.)OKCheck the following items in order:

DGlow plug, glowplugrelay

DBattery

DInjection nozzle

DInjection pump

DCompression pressure

DExistence of mixing foreign objects (water, kerosene) with

the fuel

Inspection procedure 6

Starting performance is bad when the engine is cold

(unable to start)

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

fuel system, intake system, and glow system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DGlow system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37)OKInspect the following items in order:

DGlow plug, glowplugrelay

DInjection nozzle, fuel filter

DThrottle body assembly

DExistence of starter switch signal input

DEngine oil

DInjection pump

DExistence of mixing foreign objects (water, kerosene) with

the fuel

Inspection procedure 7

Starting performance is bad regardless of whether the

engine is hot or cold (unable to start)

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

fuel system, and intake system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37.)OKInspect the following items in order:

DInjection nozzle, fuel filter

DThrottle body

DCompression pressure

DInjection pump

DExistence of mixing foreign objects (water, kerosene) with

the fuel

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 519 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-28

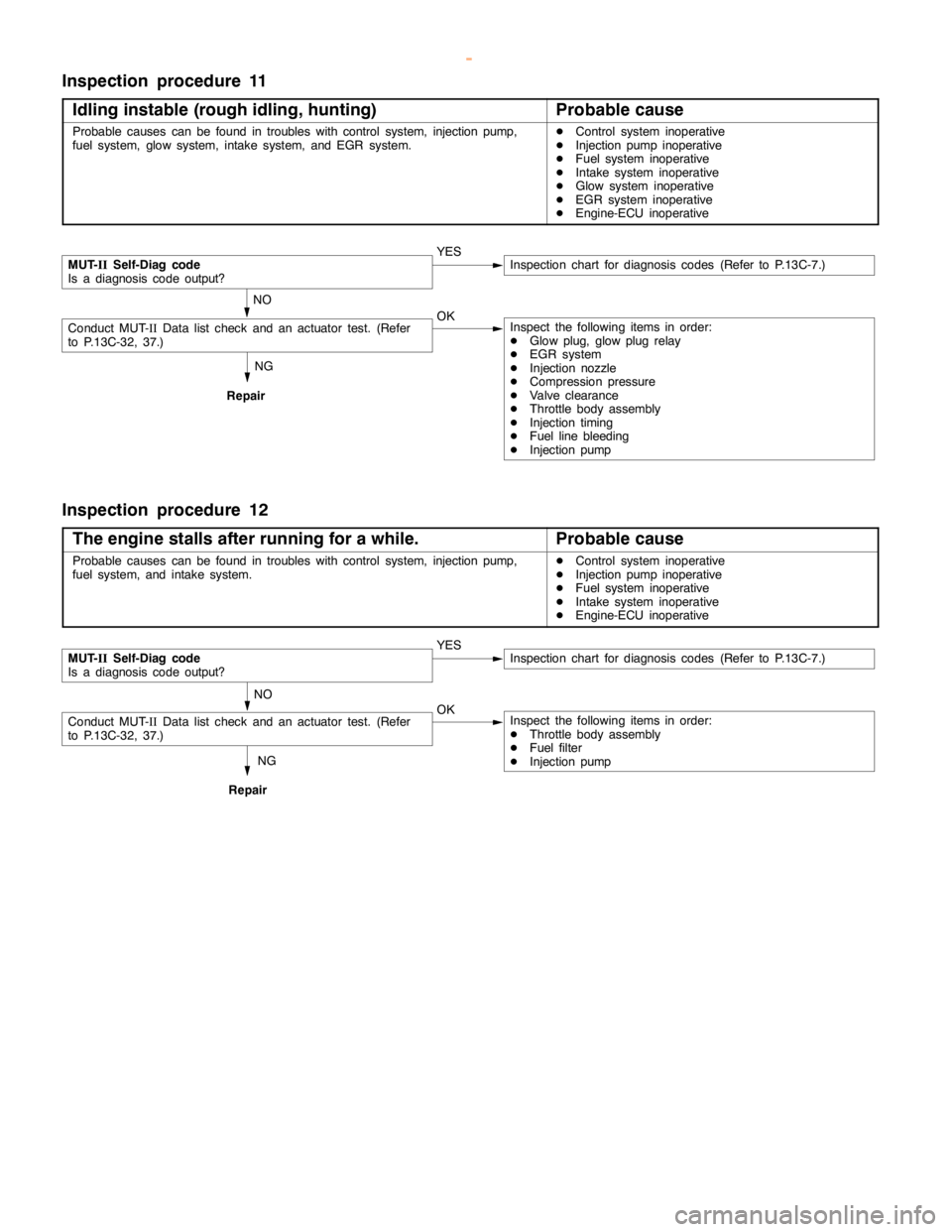

Inspection procedure 11

Idling instable (rough idling, hunting)

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

fuel system, glow system, intake system, and EGR system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DGlow system inoperative

DEGR system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37.)OKInspect the following items in order:

DGlow plug, glowplugrelay

DEGR system

DInjection nozzle

DCompression pressure

DValve clearance

DThrottle body assembly

DInjection timing

DFuel line bleeding

DInjection pump

Inspection procedure 12

The engine stalls after running for a while.

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

fuel system, and intake system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37.)OKInspect the following items in order:

DThrottle body assembly

DFuel filter

DInjection pump

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 521 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-30

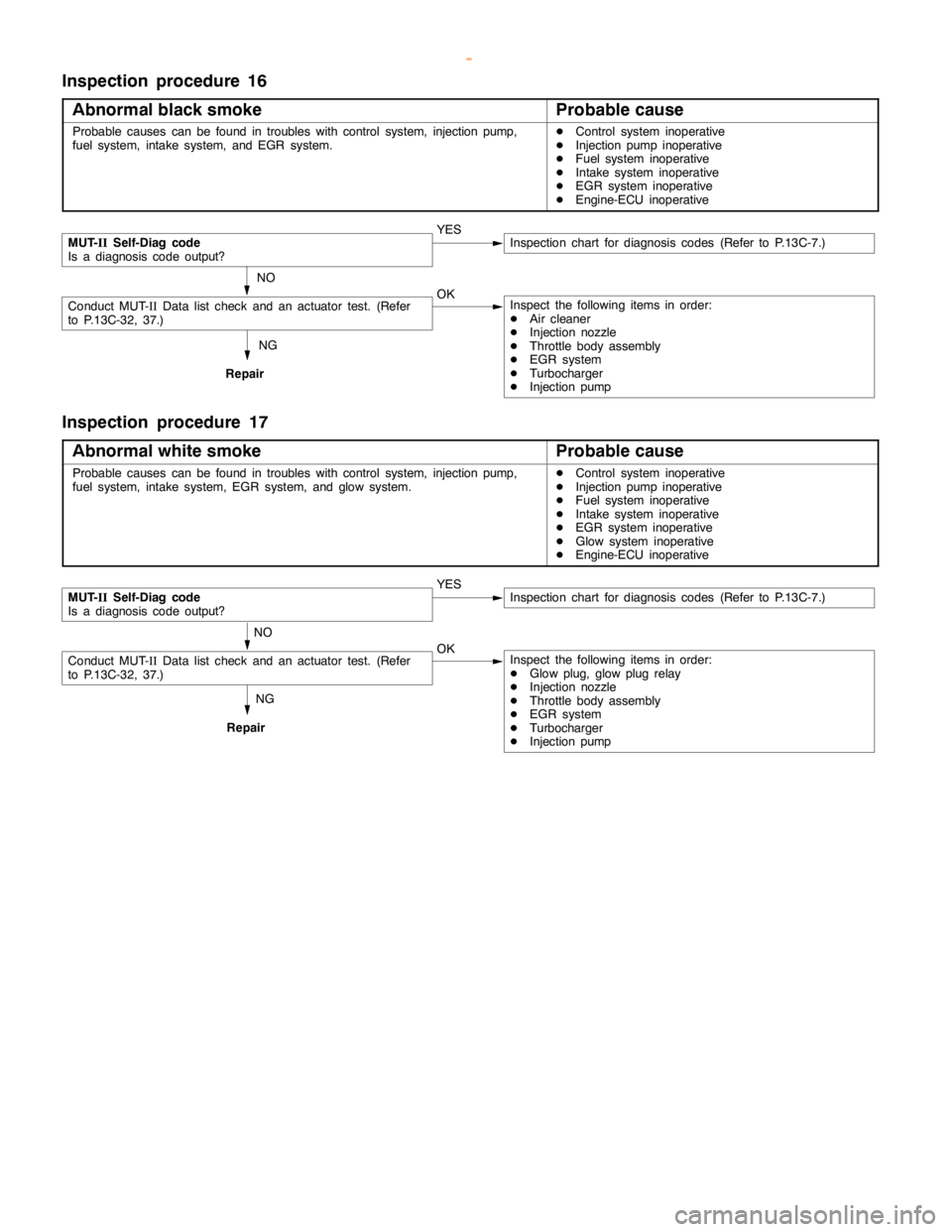

Inspection procedure 16

Abnormal black smoke

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

fuel system, intake system, and EGR system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEGR system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37.)OKInspect the following items in order:

DAir cleaner

DInjection nozzle

DThrottle body assembly

DEGR system

DTurbocharger

DInjection pump

Inspection procedure 17

Abnormal white smoke

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

fuel system, intake system, EGR system, and glow system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DIntake system inoperative

DEGR system inoperative

DGlow system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37.)OKInspect the following items in order:

DGlow plug, glowplugrelay

DInjection nozzle

DThrottle body assembly

DEGR system

DTurbocharger

DInjection pump

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 522 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-31

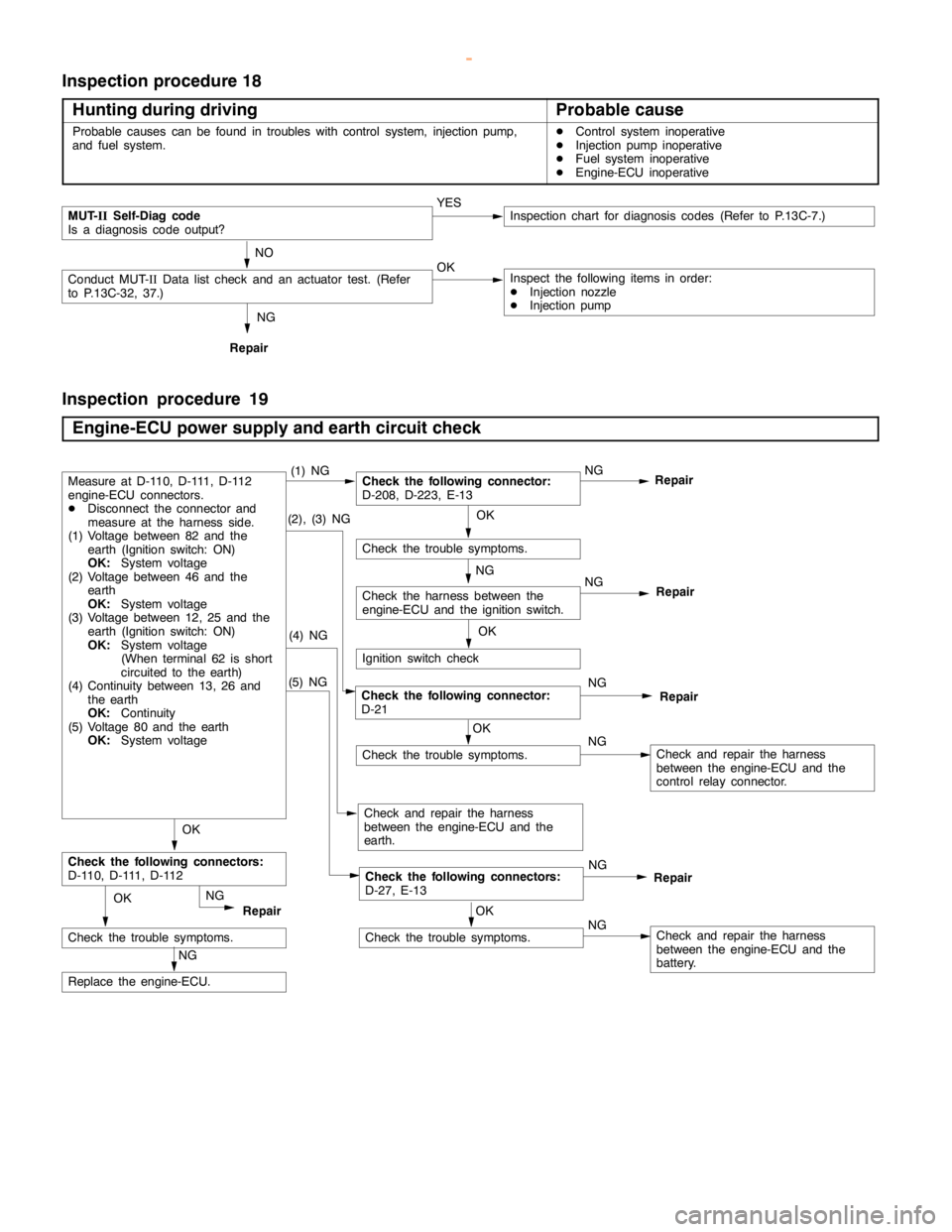

Inspection procedure 18

Hunting during driving

Probable cause

Probable causes can be found in troubles with control system, injectionpump,

and fuel system.DControl system inoperative

DInjection pump inoperative

DFuel system inoperative

DEngine-ECU inoperative

NG

Repair

MUT-

IISelf-Diag code

Is a diagnosis code output?YESInspection chart for diagnosis codes (Refer to P.13C-7.)

NO

Conduct MUT-IIData list check and an actuator test. (Refer

to P.13C-32, 37.)OKInspect the following items in order:

DInjection nozzle

DInjection pump

Inspection procedure 19

Engine-ECU power supply and earth circuit check

(5) NG

Check the trouble symptoms.

NG

Repair

(2), (3) NGOK

Check the trouble symptoms.

OK

NG

Check the harness between the

engine-ECU and the ignition switch.

Ignition switch check

(4) NG

Check and repair the harness

between the engine-ECU and the

earth.

OK

Check the following connectors:

D-110, D-111, D-112

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

Check the following connectors:

D-27, E-13Repair NG

NG

RepairCheck the following connector:

D-21

NG

Check and repair the harness

between the engine-ECU and the

control relay connector.

NG

Repair

OK

Check the trouble symptoms.NGCheck and repair the harness

between the engine-ECU and the

battery.

Check the following connector:

D-208, D-223, E-13NG

RepairMeasure at D-110, D-111, D-112

engine-ECU connectors.

DDisconnect the connector and

measure at the harness side.

(1) Voltage between 82 and the

earth (Ignition switch: ON)

OK:

System voltage

(2) Voltage between 46 and the

earth

OK:

System voltage

(3) Voltage between 12, 25 and the

earth (Ignition switch: ON)

OK:

System voltage

(When terminal 62 is short

circuited to theearth)

(4) Continuity between 13, 26 and

the earth

OK

:Continuity

(5) Voltage 80 and the earth

OK:

System voltage(1) NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 525 of 1839

DIESEL FUEL <4M4> -Troubleshooting13C-34

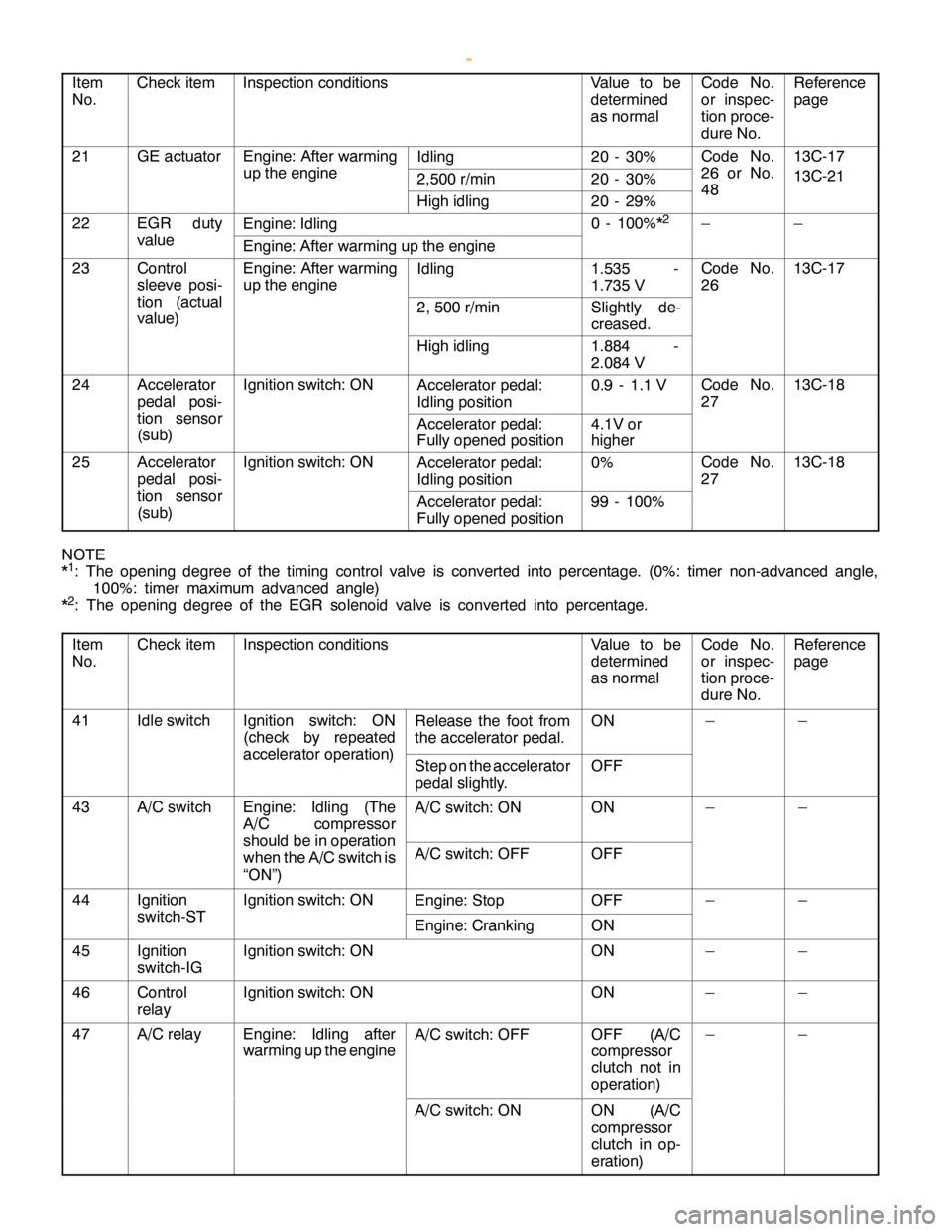

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be

determined

as normal Inspection conditions Check item

21GE actuatorEngine: After warmingIdling20 - 30%Code No.13C-17

up the engine2,500 r/min20 - 30%26 or No.13C-21

High idling20 - 29%48

22EGR dutyEngine: Idling0 - 100%*2––

valueEngine: After warming up the engine

23Control

sleeve posi-Engine: After warming

up the engineIdling1.535 -

1.735 VCode No.

2613C-17

tion (actual

value)2, 500 r/minSlightly de-

creased.

High idling1.884 -

2.084 V

24Accelerator

pedal posi-Ignition switch: ONAccelerator pedal:

Idling position0.9 - 1.1 VCode No.

2713C-18

tion sensor

(sub)Accelerator pedal:

Fully opened position4.1V or

higher

25Accelerator

pedal posi-Ignition switch: ONAccelerator pedal:

Idling position0%Code No.

2713C-18

tion sensor

(sub)Accelerator pedal:

Fully opened position99 - 100%

NOTE

*1: The opening degree of the timing control valve is converted into percentage. (0%: timer non-advanced angle,

100%: timer maximum advanced angle)

*

2: The opening degree of the EGR solenoid valve is converted into percentage.

Item

No.

Check itemInspection conditionsValue to be

determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

41Idle switchIgnition switch: ON

(check by repeatedRelease the foot from

the accelerator pedal.ON––

accelerator operation)Step on the accelerator

pedal slightly.OFF

43A/C switchEngine: Idling (The

A/C compressorA/C switch: ONON––

should be in operation

when the A/C switch is

“ON”)A/C switch: OFFOFF

44IgnitionIgnition switch: ONEngine: StopOFF––

switch-STEngine: CrankingON

45Ignition

switch-IGIgnition switch: ONON––

46Control

relayIgnition switch: ONON––

47A/C relayEngine: Idling after

warming up the engineA/C switch: OFFOFF (A/C

compressor

clutch not in

operation)––

A/C switch: ONON (A/C

compressor

clutch in op-

eration)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 526 of 1839

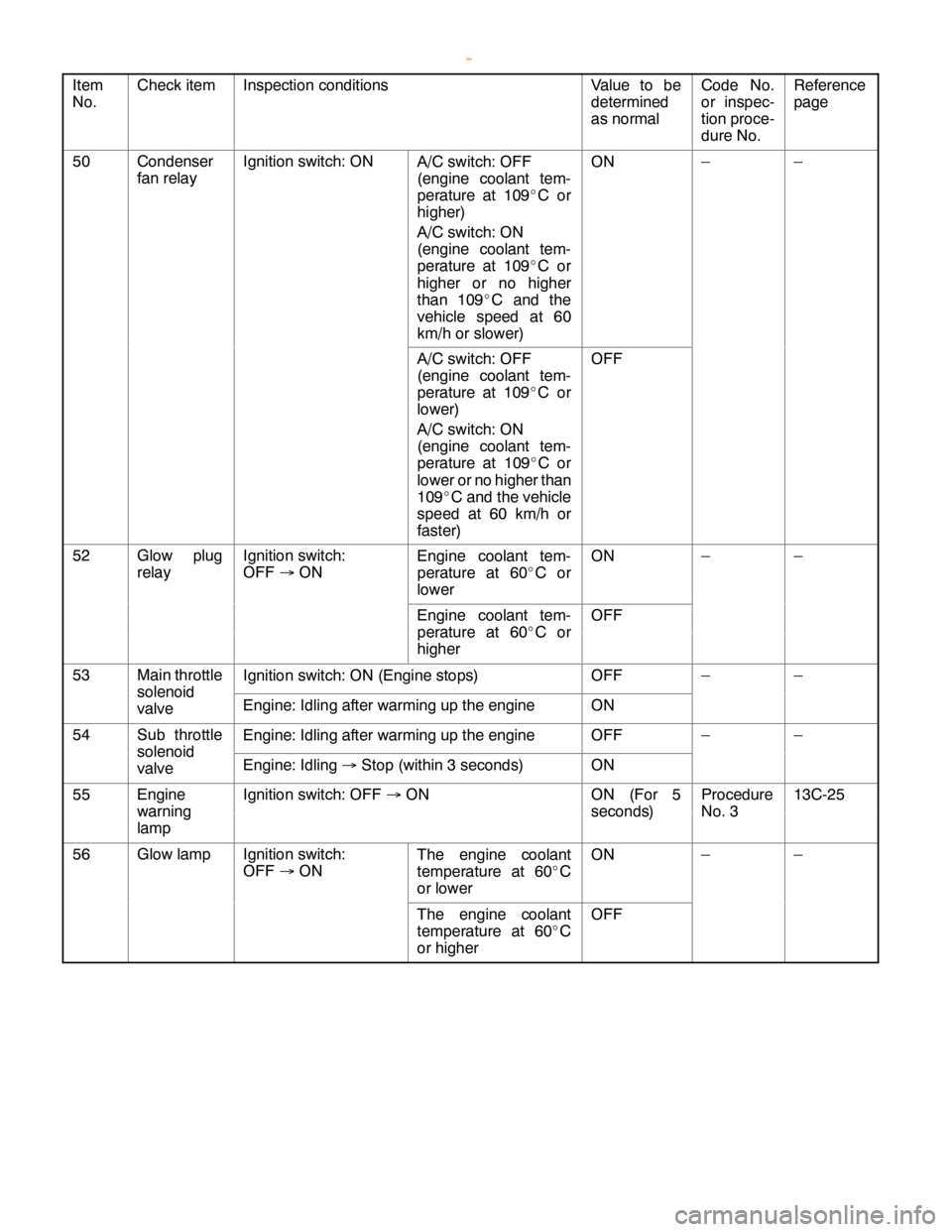

DIESEL FUEL <4M4> -Troubleshooting13C-35

Item

No.Check itemInspection conditionsValue to be

determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

50Condenser

fan relayIgnition switch: ONA/C switch: OFF

(engine coolant tem-

perature at 109_Cor

higher)

A/C switch: ON

(engine coolant tem-

perature at 109_Cor

higher or no higher

than 109_C and the

vehicle speed at 60

km/h or slower)ON––

A/C switch: OFF

(engine coolant tem-

perature at 109_Cor

lower)

A/C switch: ON

(engine coolant tem-

perature at 109_Cor

lower or no higher than

109_C and the vehicle

speed at 60 km/h or

faster)OFF

52Glow plug

relayIgnition switch:

OFF®ONEngine coolant tem-

perature at 60_Cor

lowerON––

Engine coolant tem-OFF

perature at 60_Cor

higher

53Main throttleIgnition switch: ON (Engine stops)OFF––

solenoid

valveEngine: Idling after warming up the engineON

54Sub throttleEngine: Idling after warming up the engineOFF––

solenoid

valveEngine: Idling®Stop (within 3 seconds)ON

55EngineIgnition switch: OFF®ONON (For 5Procedure13C-25

warning

lampseconds)No. 3

56Glow lampIgnition switch:

OFF®ONThe engine coolant

temperature at 60_C

or lowerON––

The engine coolant

temperature at 60_C

or higherOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 527 of 1839

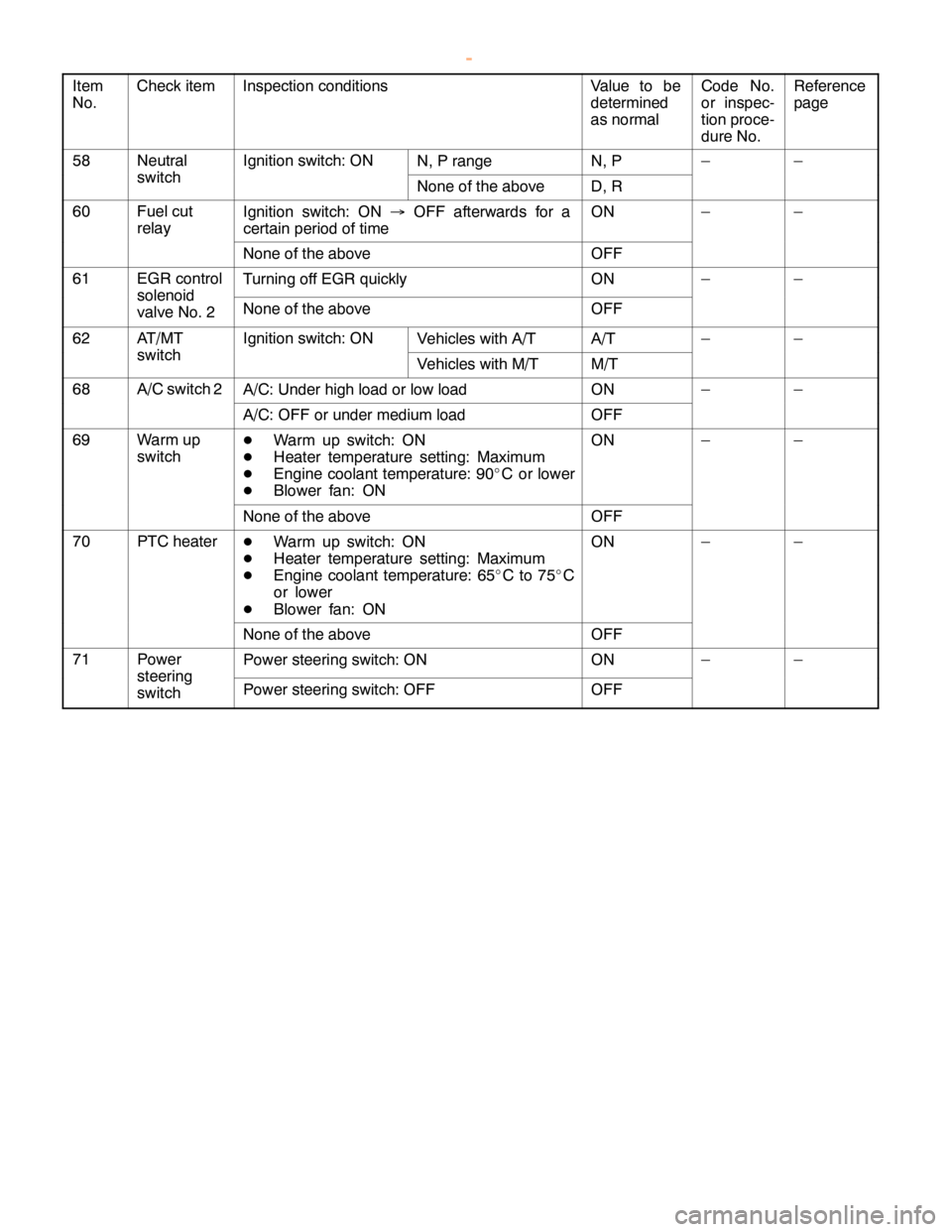

DIESEL FUEL <4M4> -Troubleshooting13C-36

Item

No.Reference

page Code No.

or inspec-

tion proce-

dure No. Value to be

determined

as normal Inspection conditions Check item

58NeutralIgnition switch: ONN, P rangeN, P––

switchNone of the aboveD, R

60Fuel cut

relayIgnition switch: ON®OFF afterwards for a

certain period of timeON––

None of the aboveOFF

61EGR controlTurning off EGR quicklyON––

solenoid

valve No. 2None of the aboveOFF

62AT/MTIgnition switch: ONVehicles with A/TA/T––

switchVehicles with M/TM/T

68A/C switch 2A/C: Under high load or low loadON––

A/C: OFF or under medium loadOFF

69Warm up

switchDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 90_C or lower

DBlower fan: ONON––

None of the aboveOFF

70PTC heaterDWarm up switch: ON

DHeater temperature setting: Maximum

DEngine coolant temperature: 65_Cto75_C

or lower

DBlower fan: ONON––

None of the aboveOFF

71PowerPower steering switch: ONON––

steering

switchPower steering switch: OFFOFF

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk