ignition MITSUBISHI MONTERO 2000 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 991 of 1839

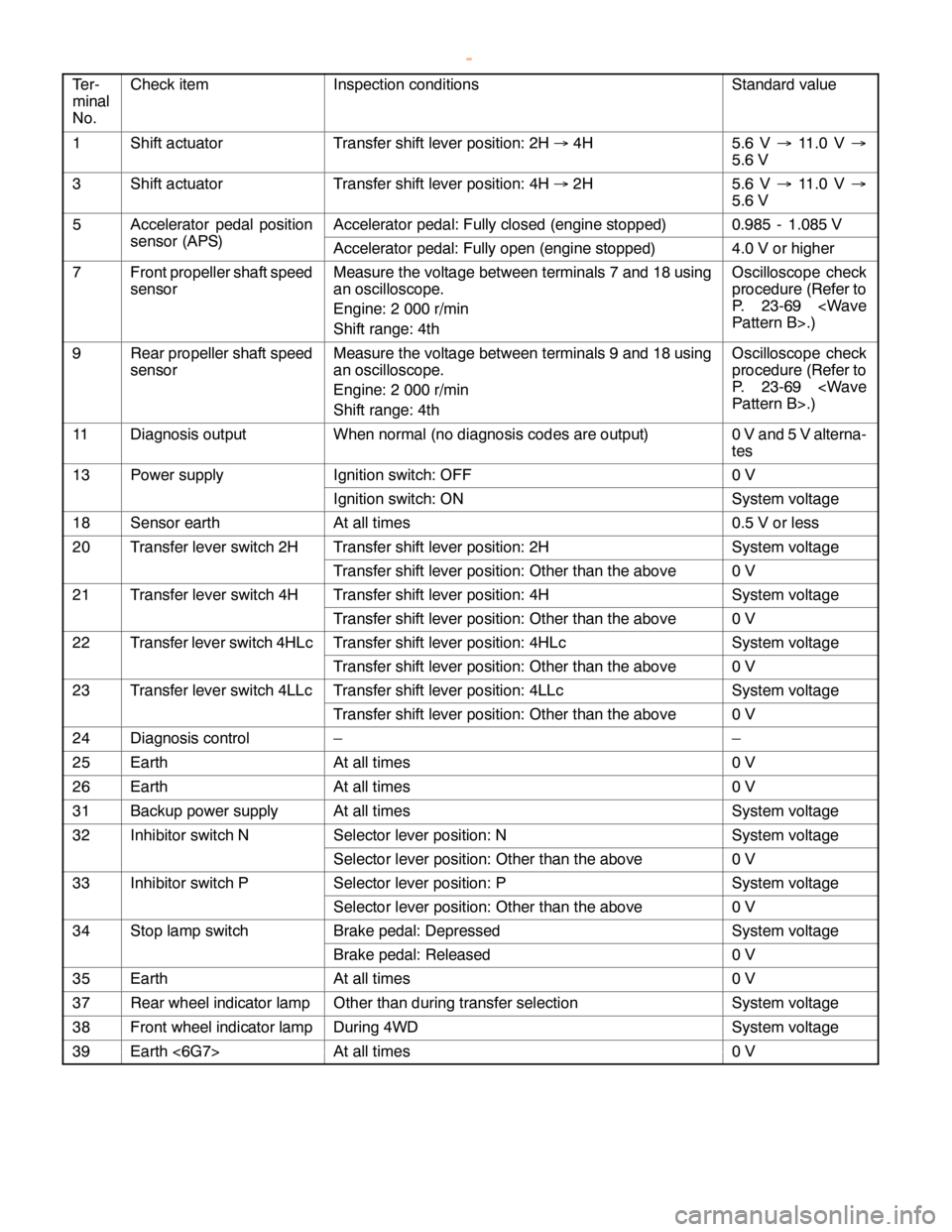

AUTOMATIC TRANSMISSION -Troubleshooting

Ter-

minal

No.Check itemInspection conditionsStandard value

1Shift actuatorTransfer shift lever position: 2H®4H5.6 V®11.0 V®

5.6 V

3Shift actuatorTransfer shift lever position: 4H®2H5.6 V®11.0 V®

5.6 V

5Accelerator pedal positionAccelerator pedal: Fully closed (engine stopped)0.985 - 1.085 V

sensor (APS)Accelerator pedal: Fully open (engine stopped)4.0 V or higher

7Front propeller shaft speed

sensorMeasure the voltage between terminals 7 and 18 using

an oscilloscope.

Engine: 2 000 r/min

Shift range: 4thOscilloscope check

procedure (Refer to

P. 23-69

9Rear propeller shaft speed

sensorMeasure the voltage between terminals 9 and 18 using

an oscilloscope.

Engine: 2 000 r/min

Shift range: 4thOscilloscope check

procedure (Refer to

P. 23-69

11Diagnosis outputWhen normal (no diagnosis codes are output)0 V and 5 V alterna-

tes

13Power supplyIgnition switch: OFF0V

Ignition switch: ONSystem voltage

18Sensor earthAt all times0.5 V or less

20Transfer lever switch 2HTransfer shift lever position: 2HSystem voltage

Transfer shift lever position: Other than the above0V

21Transfer lever switch 4HTransfer shift lever position: 4HSystem voltage

Transfer shift lever position: Other than the above0V

22Transfer lever switch 4HLcTransfer shift lever position: 4HLcSystem voltage

Transfer shift lever position: Other than the above0V

23Transfer lever switch 4LLcTransfer shift lever position: 4LLcSystem voltage

Transfer shift lever position: Other than the above0V

24Diagnosis control––

25EarthAt all times0V

26EarthAt all times0V

31Backup power supplyAt all timesSystem voltage

32Inhibitor switch NSelector lever position: NSystem voltage

Selector lever position: Other than the above0V

33Inhibitor switch PSelector lever position: PSystem voltage

Selector lever position: Other than the above0V

34Stop lamp switchBrake pedal: DepressedSystem voltage

Brake pedal: Released0V

35EarthAt all times0V

37Rear wheel indicator lampOther than during transfer selectionSystem voltage

38Front wheel indicator lampDuring 4WDSystem voltage

39Earth <6G7>At all times0V

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 993 of 1839

AUTOMATIC TRANSMISSION -

Troubleshooting

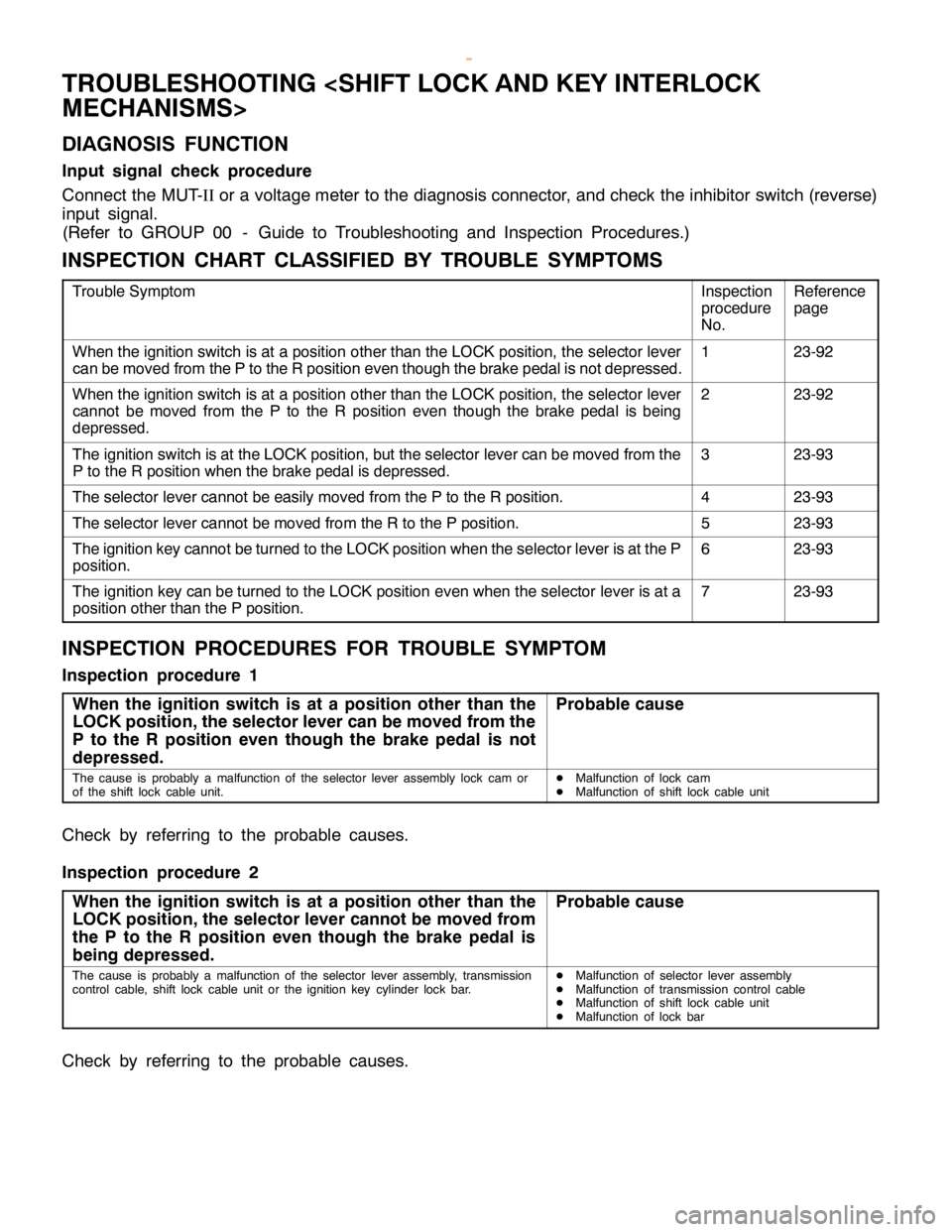

TROUBLESHOOTING

DIAGNOSIS FUNCTION

Input signal check procedure

Connect the MUT-II

or a voltage meter to the diagnosis connector, and check the inhibitor switch (reverse)

input signal.

(Refer to GROUP 00 - Guide to Troubleshooting and Inspection Procedures.)

INSPECTION CHART CLASSIFIED BY TROUBLE SYMPTOMS

Trouble SymptomInspection

procedure

No.Reference

page

When the ignition switch is at a position other than the LOCK position, the selector lever

can be moved from the P to the R position even though the brake pedal is not depressed.123-92

When the ignition switch is at a position other than the LOCK position, the selector lever

cannot be moved from the P to the R position even though the brake pedal is being

depressed.223-92

The ignition switch is at the LOCK position, but the selector lever can be moved from the

P to the R position when the brake pedal is depressed.323-93

The selector lever cannot be easily moved from the P to the R position.423-93

The selector lever cannot be moved from the R to the P position.523-93

The ignition key cannot be turned to the LOCK position when the selector lever is at the P

position.623-93

The ignition key can be turned to the LOCK position even when the selector lever is at a

position other than the P position.723-93

INSPECTION PROCEDURES FOR TROUBLE SYMPTOM

Inspection procedure 1

When the ignition switch is at a position other than the

LOCK position, the selector lever can be moved from the

P to the R position even though the brake pedal is not

depressed.

Probable cause

The cause is probably a malfunction of the selector lever assembly lock cam or

of the shift lock cable unit.DMalfunction of lock cam

DMalfunction of shift lock cable unit

Check by referring to the probable causes.

Inspection procedure 2

When the ignition switch is at a position other than the

LOCK position, the selector lever cannot be moved from

the P to the R position even though the brake pedal is

being depressed.

Probable cause

The cause is probably a malfunction of the selector lever assembly, transmission

control cable, shift lock cable unit or the ignition key cylinder lock bar.DMalfunction of selector lever assembly

DMalfunction of transmission control cable

DMalfunction of shift lock cable unit

DMalfunction of lock bar

Check by referring to the probable causes.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 994 of 1839

AUTOMATIC TRANSMISSION -Troubleshooting

Inspection procedure 3

The ignition switch is at the LOCK position, but the

selector lever can be moved from the P to the R position

when the brake pedal is depressed.

Probable cause

The cause is probably a malfunction of the shift lock cable unit or of the ignition

key cylinder lock bar.DMalfunction of shift lock cable unit

DMalfunction of lock bar

Check by referring to the probable causes.

Inspection procedure 4

The selector lever cannot be easily moved from the P to

the R position.

Probable cause

The cause is probably a malfunction of the selector lever assembly, transmission

control cable, shift lock cable unit or the ignition key cylinder lock bar.DMalfunction of selector lever assembly

DMalfunction of transmission control cable

DMalfunction of shift lock cable unit

DMalfunction of lock bar

Check by referring to the probable causes.

Inspection procedure 5

The selector lever cannot be moved from the R to the P

position.

Probable cause

The cause is probably a malfunction of the selector lever assembly or of the

transmission control cable.DMalfunction of selector lever assembly

DMalfunction of transmission control cable

Check by referring to the probable causes.

Inspection procedure 6

The ignition key cannot be turned to the LOCK position

when the selector lever is at the P position.

Probable cause

The cause is probably a malfunction of the selector lever assembly, shift lock

cable unit or the ignition key cylinder lock bar.DMalfunction of selector lever assembly

DMalfunction of shift lock cable unit

DMalfunction of lock bar

Check by referring to the probable causes.

Inspection procedure 7

The ignition key can be turned to the LOCK position even

when the selector lever is at a position other than the P

position.

Probable cause

The cause is probably a malfunction of the shift lock cable unit or of the ignition

key cylinder lock bar.DMalfunction of shift lock cable unit

DMalfunction of lock bar

Check by referring to the probable causes.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1165 of 1839

POWER PLANT MOUNT - No.1 Crossmember32-7

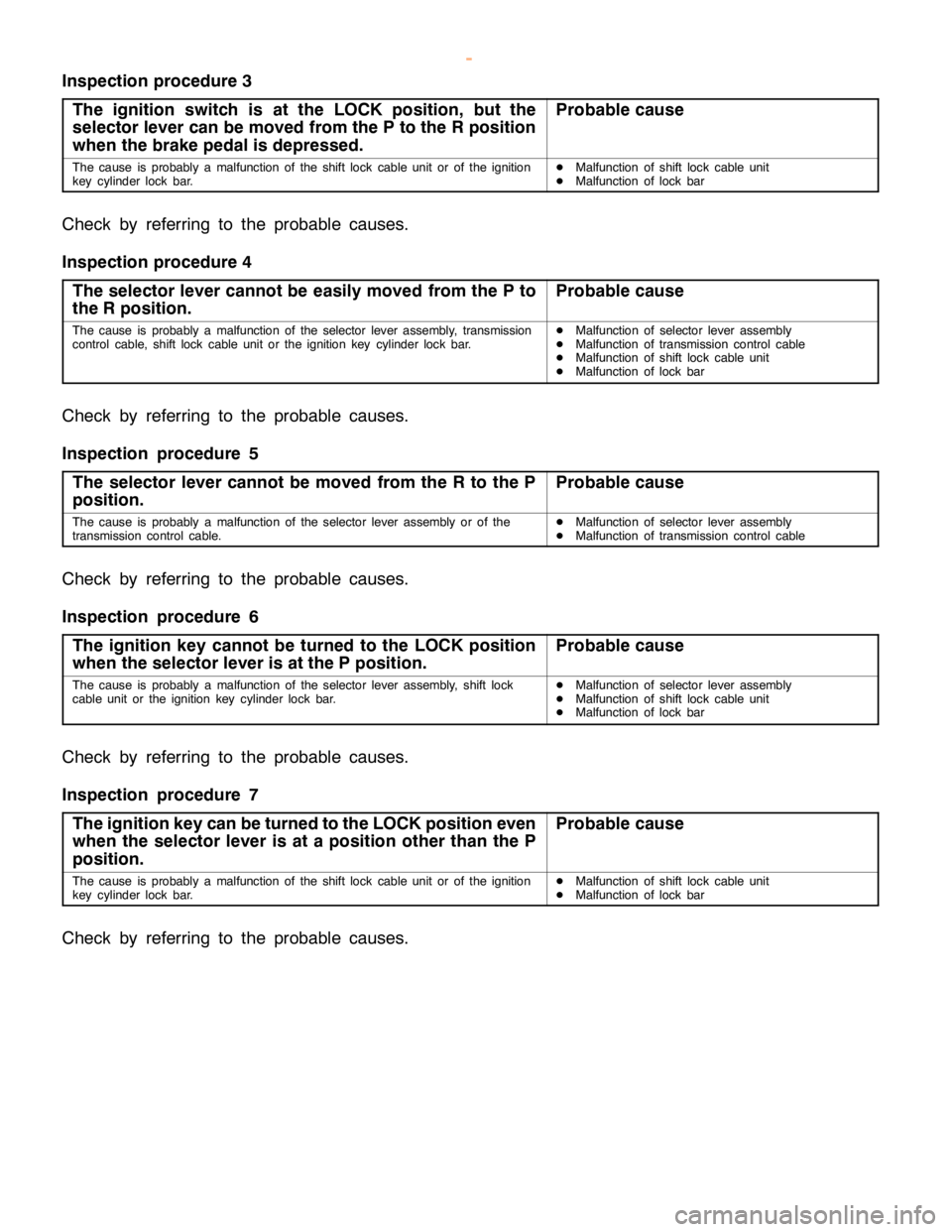

No.1 CROSSMEMBER

REMOVAL AND INSTALLATION

Caution

1. Before removing the steering wheel and airbag module assembly, always refer to GROUP 52B

- Service Precautions, Airbag Module and Clock Spring. Also, set the front wheels so that

they are facing straight forward, and remove the ignition key. If you fail to do this, the SRS

clock spring will be damaged, causing the SRS airbag to be inoperative and serious injury.

2. *: Indicates parts which should be initially tightened, and then fully tightened after placing

the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal Operation

DUnder Cover Removal

DDrive Shaft Removal

(Refer to GROUP 26.)

DDifferential Carrier and No.2 Crossmember

Assembly Removal (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DUpper Arm Removal

(Refer to GROUP 33A.)

DLower Arm Removal

(Refer to GROUP 33A.)

DStabilizer Bar Removal

(Refer to GROUP 33A.)

DEngine Oil Cooler Removal<6G7>

(Refer to GROUP 12.)

DAir Cleaner Removal<4M4>

(Refer to GROUP 15.)

DIntercooler Removal<4M4>

(Refer to GROUP 15.)

DEngine Cover Removal

(Refer to GROUP 11A - Timing Belt.)

DRadiator Removal

(Refer to GROUP 14.)

DPower Steering Fluid Draining

(Refer to GROUP 37A - On - vehicle Service.)Post - installation Operations

DDifferential Carrier and No.2 Crossmember

Assembly Installation (Refer to GROUP 26 -

Freewheel Assembly and Differential Carrier.)

DDrive Shaft Installation

(Refer to GROUP 26.)

DLower Arm Installation

(Refer to GROUP 33A.)

DUpper Arm Installation

(Refer to GROUP 33A.)

DStabilizer Bar Installation

(Refer to GROUP 33A.)

DAir Cleaner Installation<4M4>

(Refer to GROUP 15.)

DIntercooler Installation<4M4>

(Refer to GROUP 15.)

DRadiator Installation

(Refer to GROUP 14.)

DEngine Oil Cooler Installation

(Refer to GROUP 12.)

DPower Steering Fluid Supplying

(Refer to GROUP 37A - On - vehicle Service.)

DPower Steering Fluid Line Bleeding

(Refer to GROUP 37A - On - vehicle Service.)

DPress the dust cover with a finger tocheck whether

the dust cover is cracked or damaged.

DChecking Steering Wheel Position with Wheels

StraightAhead

DFront Wheel AlignmentCheck and Adjustment

(Refer to GROUP 37A - On - vehicle Service.)

DUnder Cover Installation

DEngine Cover Installation

(Refer to GROUP 11A - Timing Belt.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1217 of 1839

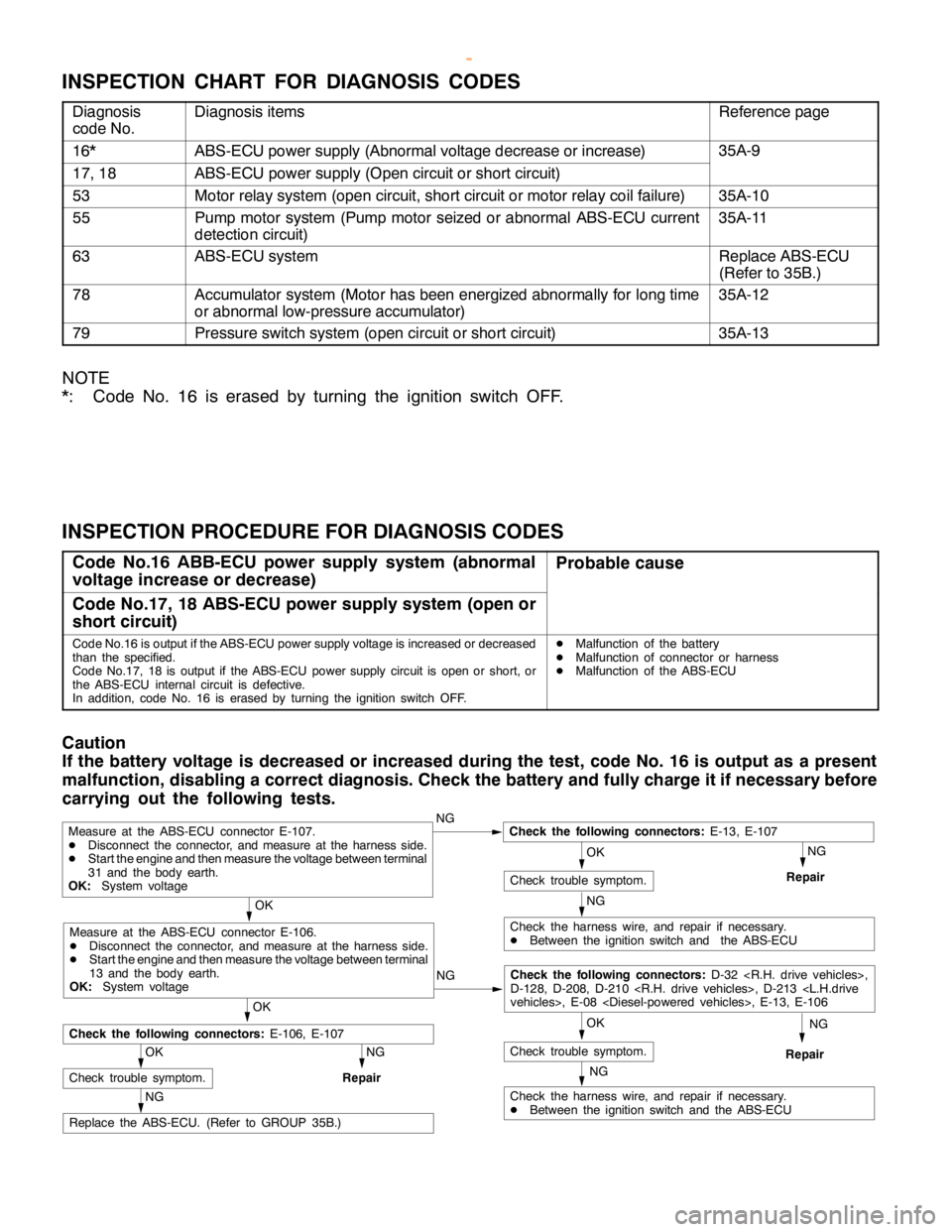

BASIC BRAKE SYSTEM -Troubleshooting35A-9

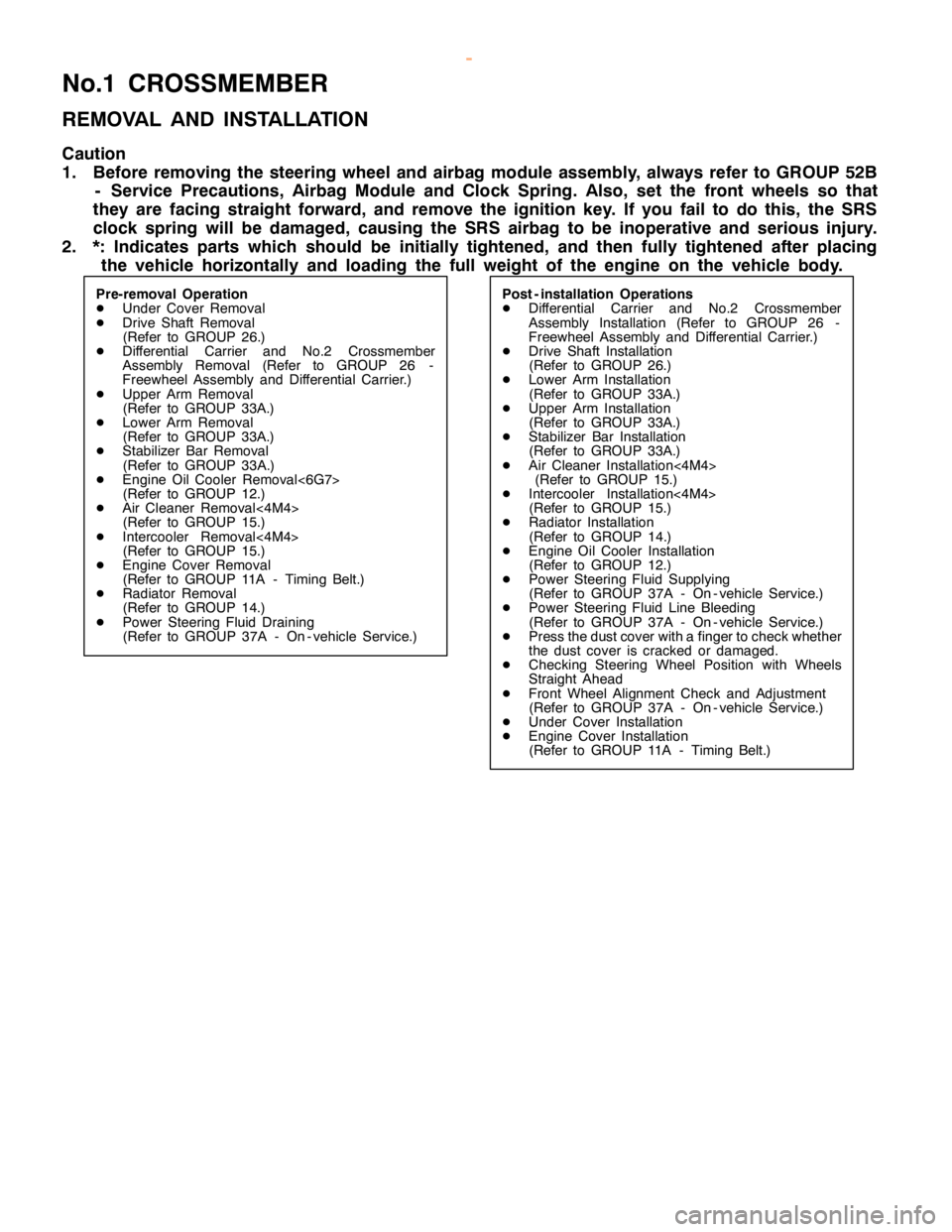

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemsReference page

16*ABS-ECU power supply (Abnormal voltage decrease or increase)35A-9

17, 18ABS-ECU power supply (Open circuit or short circuit)

53Motor relay system (open circuit, short circuit or motor relay coil failure)35A-10

55Pump motor system (Pump motor seized or abnormal ABS-ECU current

detection circuit)35A-11

63ABS-ECU systemReplace ABS-ECU

(Refer to 35B.)

78Accumulator system (Motor has been energized abnormally for long time

or abnormal low-pressure accumulator)35A-12

79Pressure switch system (open circuit or short circuit)35A-13

NOTE

*: Code No. 16 is erased by turning the ignition switch OFF.

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No.16 ABB-ECU power supply system (abnormal

voltage increase or decrease)Probable cause

Code No.17, 18 ABS-ECU power supply system (open or

short circuit)

Code No.16 is output if the ABS-ECU power supply voltage is increased or decreased

than the specified.

Code No.17, 18 is output if the ABS-ECU power supply circuit isopen orshort, or

the ABS-ECU internal circuit is defective.

In addition, code No. 16 is erased by turning the ignition switch OFF.DMalfunction of the battery

DMalfunction of connector or harness

DMalfunction of the ABS-ECU

Caution

If the battery voltage is decreased or increased during the test, code No. 16 is output as a present

malfunction, disabling a correct diagnosis. Check the battery and fully charge it if necessary before

carrying out the following tests.

NG

NG

OK

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

OK

Check trouble symptom.

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-107.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

31 and the body earth.

OK:System voltageNGCheck the following connectors:E-13, E-107

Repair

OK

Check the following connectors:E-106, E-107

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-106.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

13 and the body earth.

OK:System voltageNG

Check the following connectors:D-32

D-128, D-208, D-210

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

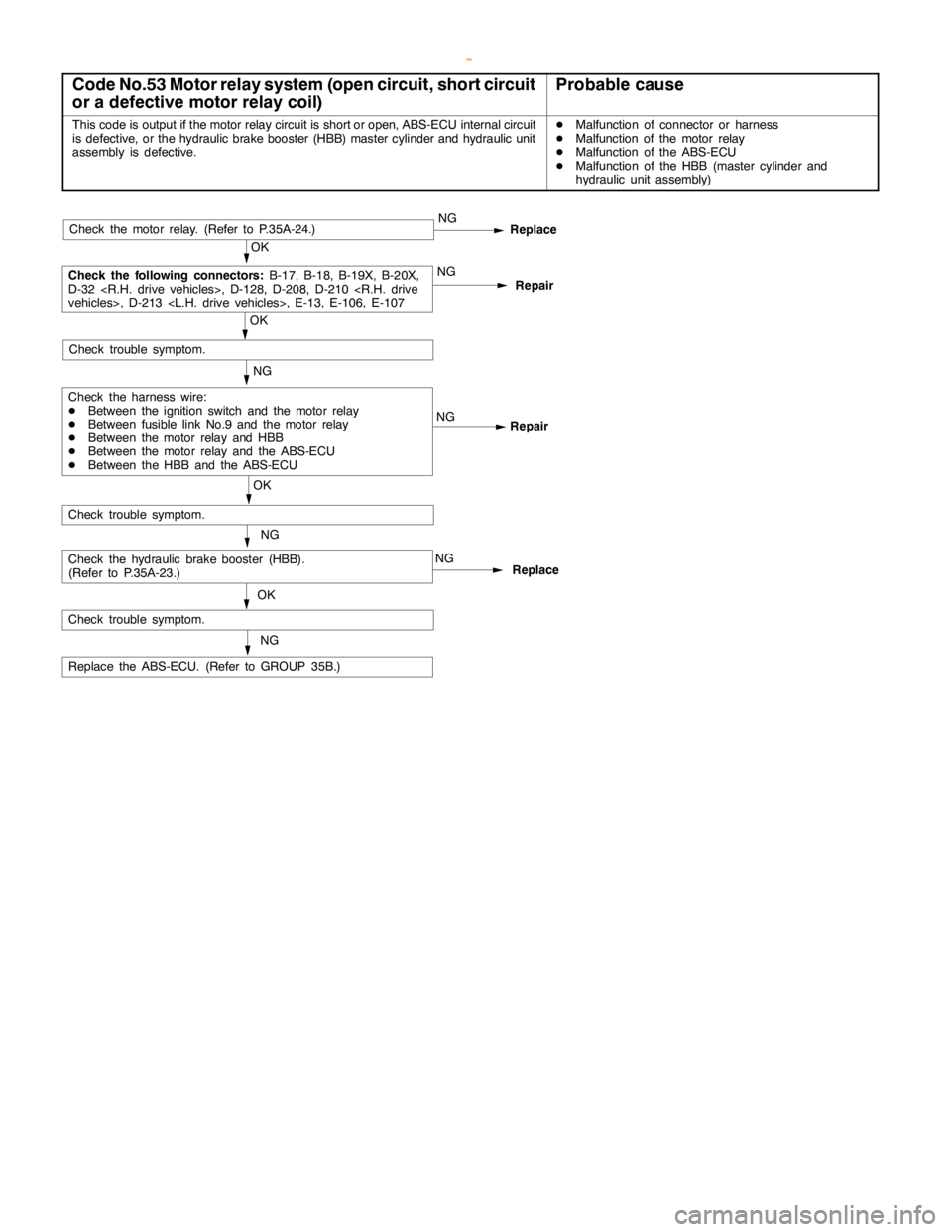

Page 1218 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-10

Code No.53 Motor relay system (open circuit, short circuit

or a defective motor relay coil)Probable cause

This code is output if the motor relay circuit is short or open, ABS-ECU internal circuit

is defective, or the hydraulic brake booster (HBB) master cylinder and hydraulic unit

assembly is defective.DMalfunction of connector or harness

DMalfunction of the motor relay

DMalfunction of the ABS-ECU

DMalfunction of the HBB (master cylinder and

hydraulic unit assembly)

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)NG

Repair

NG

OK

Check trouble symptom.

Repair NGNG

OK

Check trouble symptom.

Replace

OK

Check the following connectors:

B-17, B-18, B-19X, B-20X,

D-32

Check the harness wire:

DBetween the ignition switch and the motor relay

DBetween fusible link No.9 and the motor relay

DBetween the motor relay and HBB

DBetween the motor relay and the ABS-ECU

DBetween the HBB and the ABS-ECU

Check trouble symptom.

NG

NG

Replace

OK

Check the motor relay. (Refer to P.35A-24.)

Check the hydraulic brake booster (HBB).

(Refer to P.35A-23.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

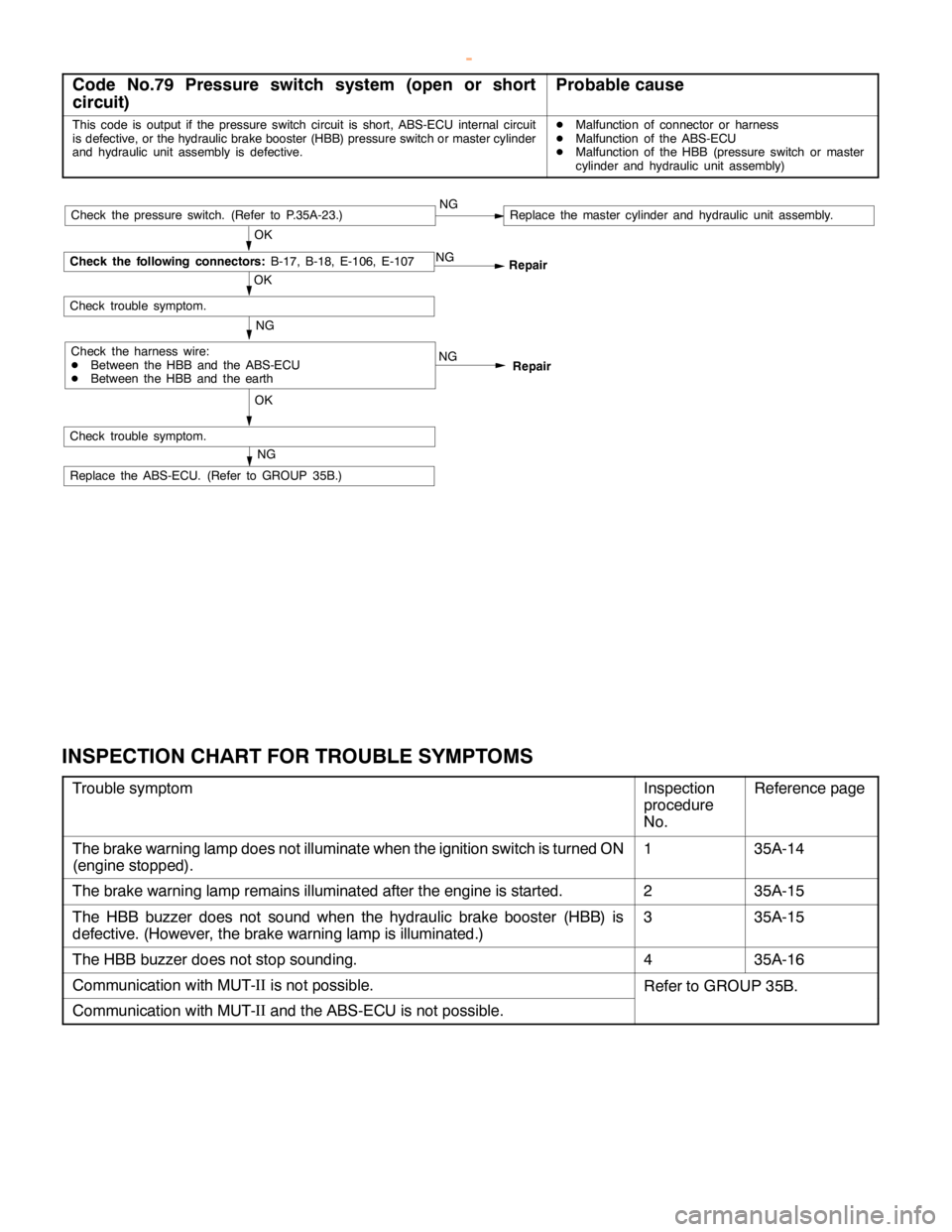

Page 1221 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-13

Code No.79 Pressure switch system (open or short

circuit)Probable cause

This code is output if the pressure switch circuit is short, ABS-ECU internal circuit

is defective, or the hydraulic brake booster (HBB) pressure switch or master cylinder

and hydraulic unit assembly is defective.DMalfunction of connector or harness

DMalfunction of the ABS-ECU

DMalfunction of the HBB (pressure switch or master

cylinder and hydraulic unit assembly)

NG

Repair

NG

OKRepair NG

OK

Check trouble symptom.

Check the following connectors:

B-17, B-18, E-106, E-107

Check the harness wire:

DBetween the HBB and the ABS-ECU

DBetween the HBB and the earthNG

Check trouble symptom.

Replace the ABS-ECU. (Refer to GROUP 35B.)

NG

OKCheck the pressure switch. (Refer to P.35A-23.)Replace the master cylinder and hydraulic unit assembly.

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptomInspection

procedure

No.Reference page

The brake warning lamp does not illuminate when the ignition switch is turned ON

(engine stopped).135A-14

The brake warning lamp remains illuminated after the engine is started.235A-15

The HBB buzzer does not sound when the hydraulic brake booster (HBB) is

defective. (However, the brake warning lamp is illuminated.)335A-15

The HBB buzzer does not stop sounding.435A-16

Communication with MUT-II

is not possible.Refer to GROUP 35B.

Communication with MUT-II

and the ABS-ECU is not possible.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

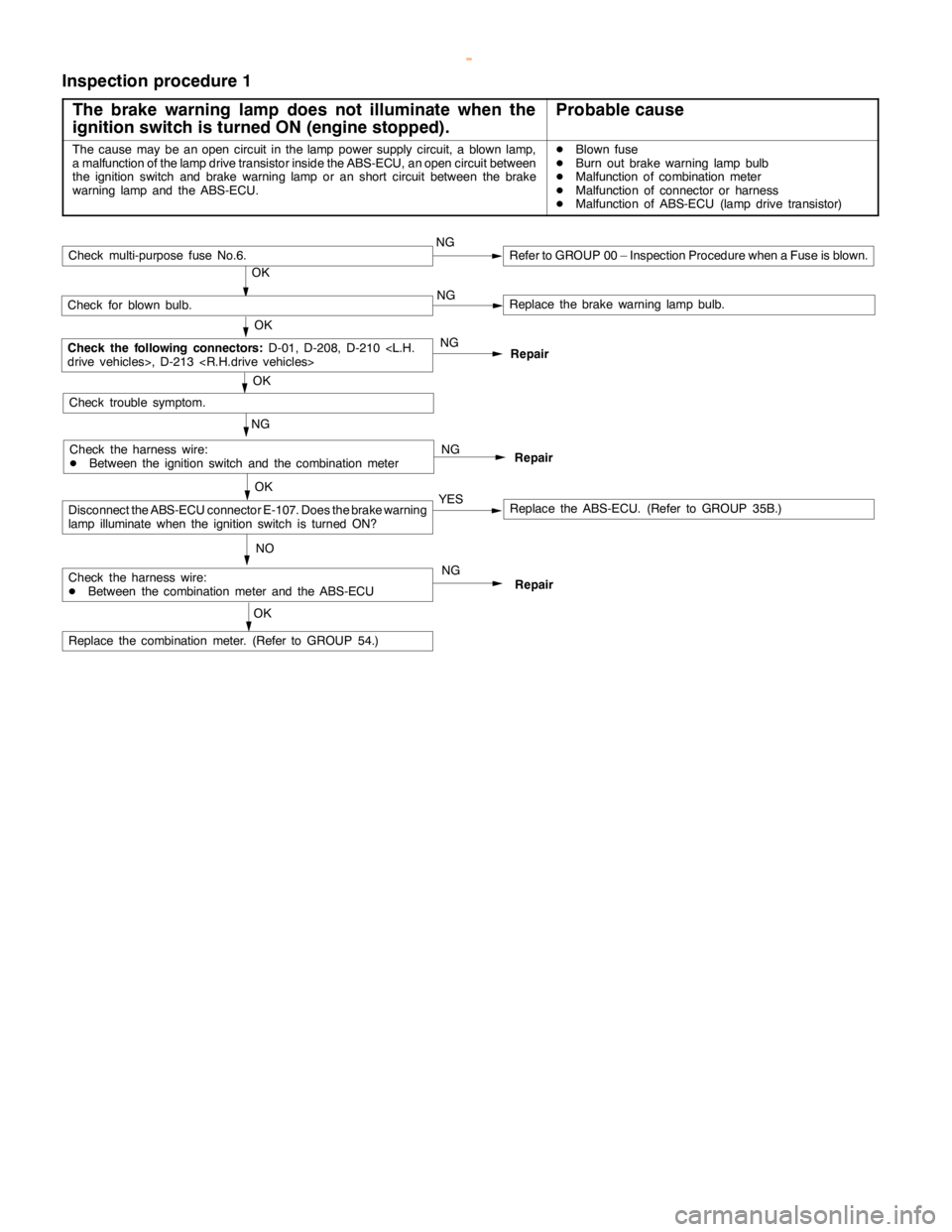

Page 1222 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-14

Inspection procedure 1

The brake warning lamp does not illuminate when the

ignition switch is turned ON (engine stopped).

Probable cause

The cause may be anopencircuit in thelamppower supply circuit, a blown lamp,

a malfunction of the lampdrive transistor inside the ABS-ECU, anopencircuit between

the ignition switch and brake warninglamp or anshort circuit between the brake

warning lamp and theABS-ECU.DBlown fuse

DBurn out brake warninglamp bulb

DMalfunction of combination meter

DMalfunction of connector or harness

DMalfunction of ABS-ECU (lamp drive transistor)

Repair NG NG

NO

Replace the ABS-ECU. (Refer to GROUP 35B.)

Repair

Repair

NG

OK

Check for blown bulb.Replace the brake warninglamp bulb.

OK

Check the following connectors:

D-01, D-208, D-210

NG

Replace the combination meter. (Refer to GROUP 54.)

OK

Check trouble symptom.

OK

YES

Check multi-purpose fuse No.6.NGRefer to GROUP 00 – Inspection Procedure when a Fuse is blown.

Check the harness wire:

DBetween the ignition switch and the combination meter

Check the harness wire:

DBetween the combination meter and the ABS-ECU

Disconnect the ABS-ECU connector E-107. Does the brake warning

lamp illuminatewhen the ignition switch is turned ON?

NG

OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1223 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-15

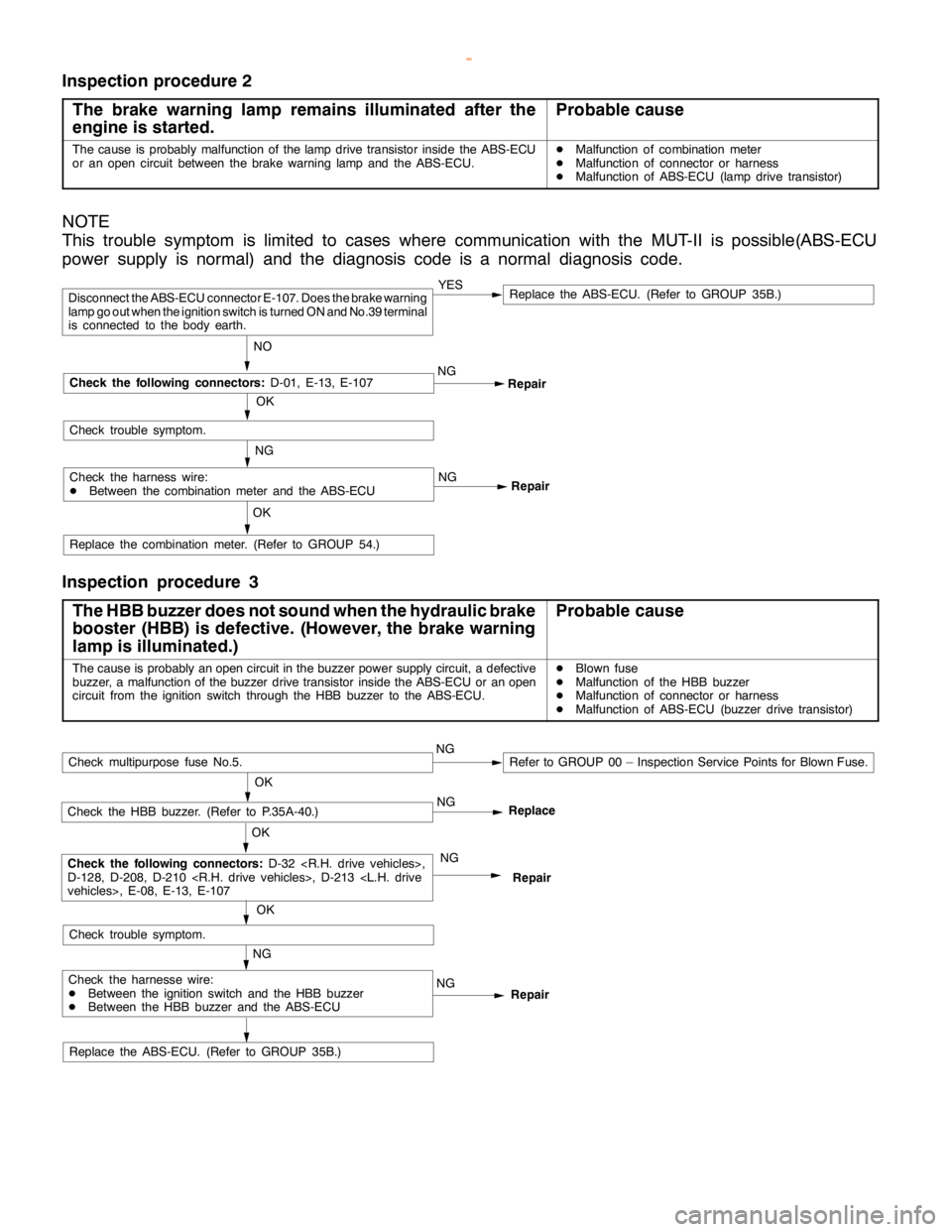

Inspection procedure 2

The brake warning lamp remains illuminated after the

engine is started.

Probable cause

The cause is probably malfunction of thelampdrive transistor inside the ABS-ECU

or an opencircuit between the brake warninglamp and theABS-ECU.DMalfunction of combination meter

DMalfunction of connector or harness

DMalfunction of ABS-ECU (lamp drive transistor)

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

Repair NG

Repair

Replace the combination meter. (Refer to GROUP 54.)

OK

YESReplace the ABS-ECU. (Refer to GROUP 35B.)

NO

Disconnect the ABS-ECU connector E-107. Does the brake warning

lamp go outwhen the ignition switch is turned ON and No.39 terminal

is connected to the body earth.

OK

Check the following connectors:

D-01, E-13, E-107

Check trouble symptom.

Check the harness wire:

DBetween the combination meter and the ABS-ECUNG

NG

Inspection procedure 3

The HBB buzzer does not sound when the hydraulic brake

booster (HBB) is defective. (However, thebrake warning

lamp is illuminated.)

Probable cause

The cause is probably anopencircuit in the buzzer power supply circuit, a defective

buzzer, a malfunction of the buzzer drive transistor inside the ABS-ECU or anopen

circuit from the ignition switch through the HBB buzzer to the ABS-ECU.DBlown fuse

DMalfunction of the HBB buzzer

DMalfunction of connector or harness

DMalfunction of ABS-ECU (buzzer drive transistor)

Replace the ABS-ECU. (Refer to GROUP 35B.)

Repair NG

Repair

NG

OK

Check the HBB buzzer. (Refer to P.35A-40.)

OK

Check the following connectors:

D-32

D-128, D-208, D-210

NG

OK

Check trouble symptom.

Check multipurpose fuse No.5.NGRefer to GROUP 00 – Inspection Service Points for Blown Fuse.

Check the harnesse wire:

DBetween the ignition switch and the HBB buzzer

DBetween the HBB buzzer and the ABS-ECUNGReplace

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1224 of 1839

BASIC BRAKE SYSTEM -Troubleshooting35A-16

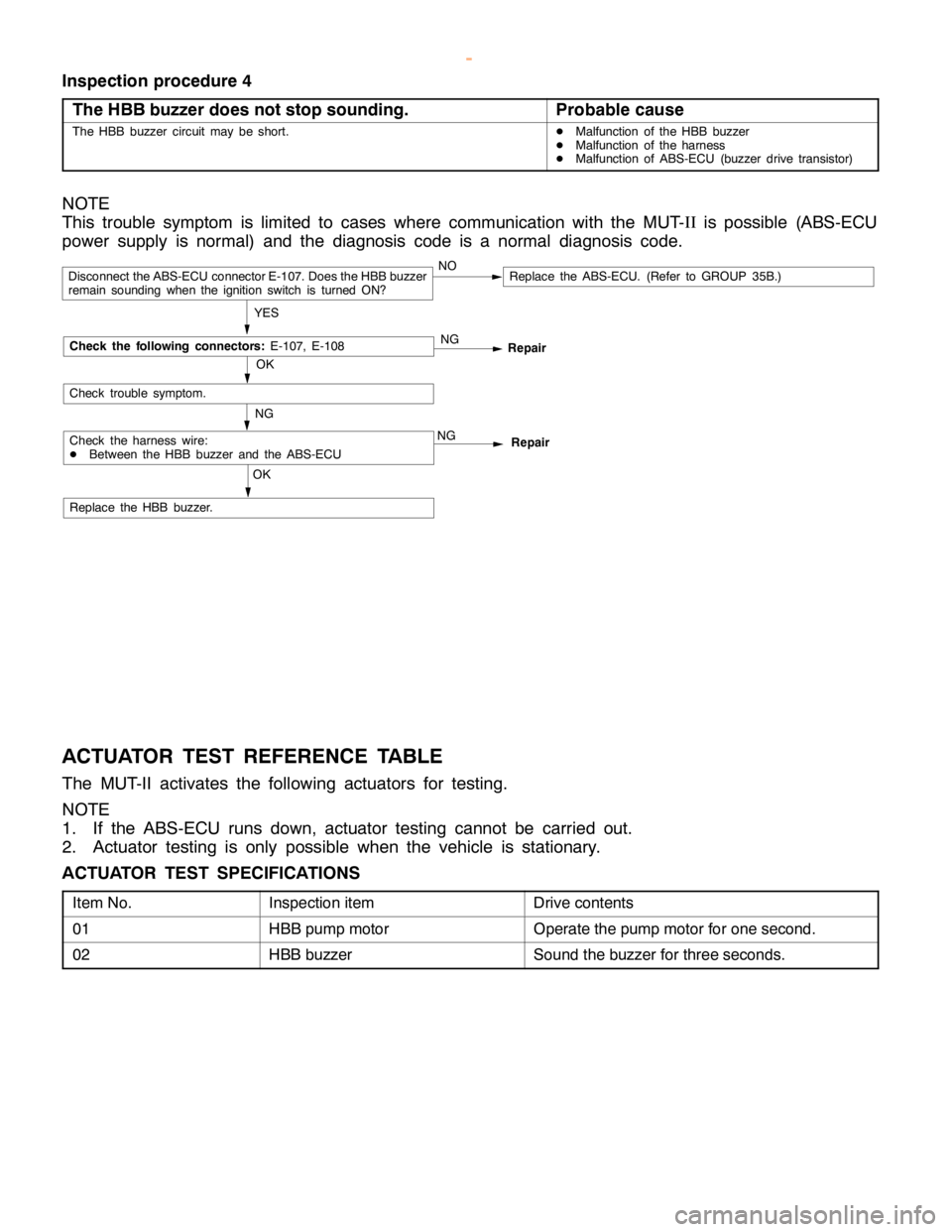

Inspection procedure 4

The HBB buzzer does not stop sounding.

Probable cause

The HBB buzzer circuit may be short.DMalfunction of the HBB buzzer

DMalfunction of the harness

DMalfunction of ABS-ECU (buzzer drive transistor)

NOTE

This trouble symptom is limited to cases where communication with the MUT-II

is possible (ABS-ECU

power supply is normal) and the diagnosis code is a normal diagnosis code.

OK

Repair NG

Repair

Replace the HBB buzzer.

OK

NG

YES

Replace the ABS-ECU. (Refer to GROUP 35B.)NODisconnect the ABS-ECU connector E-107. Does the HBB buzzer

remain sounding when the ignition switch is turned ON?

Check trouble symptom.

Check the harness wire:

DBetween the HBB buzzer and the ABS-ECUNG

Check the following connectors:

E-107, E-108

ACTUATOR TEST REFERENCE TABLE

The MUT-II activates the following actuators for testing.

NOTE

1. If the ABS-ECU runs down, actuator testing cannot be carried out.

2. Actuator testing is only possible when the vehicle is stationary.

ACTUATOR TEST SPECIFICATIONS

Item No.Inspection itemDrive contents

01HBB pump motorOperate the pump motor for one second.

02HBB buzzerSound the buzzer for three seconds.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk