battery MITSUBISHI MONTERO 2000 Service Owner's Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

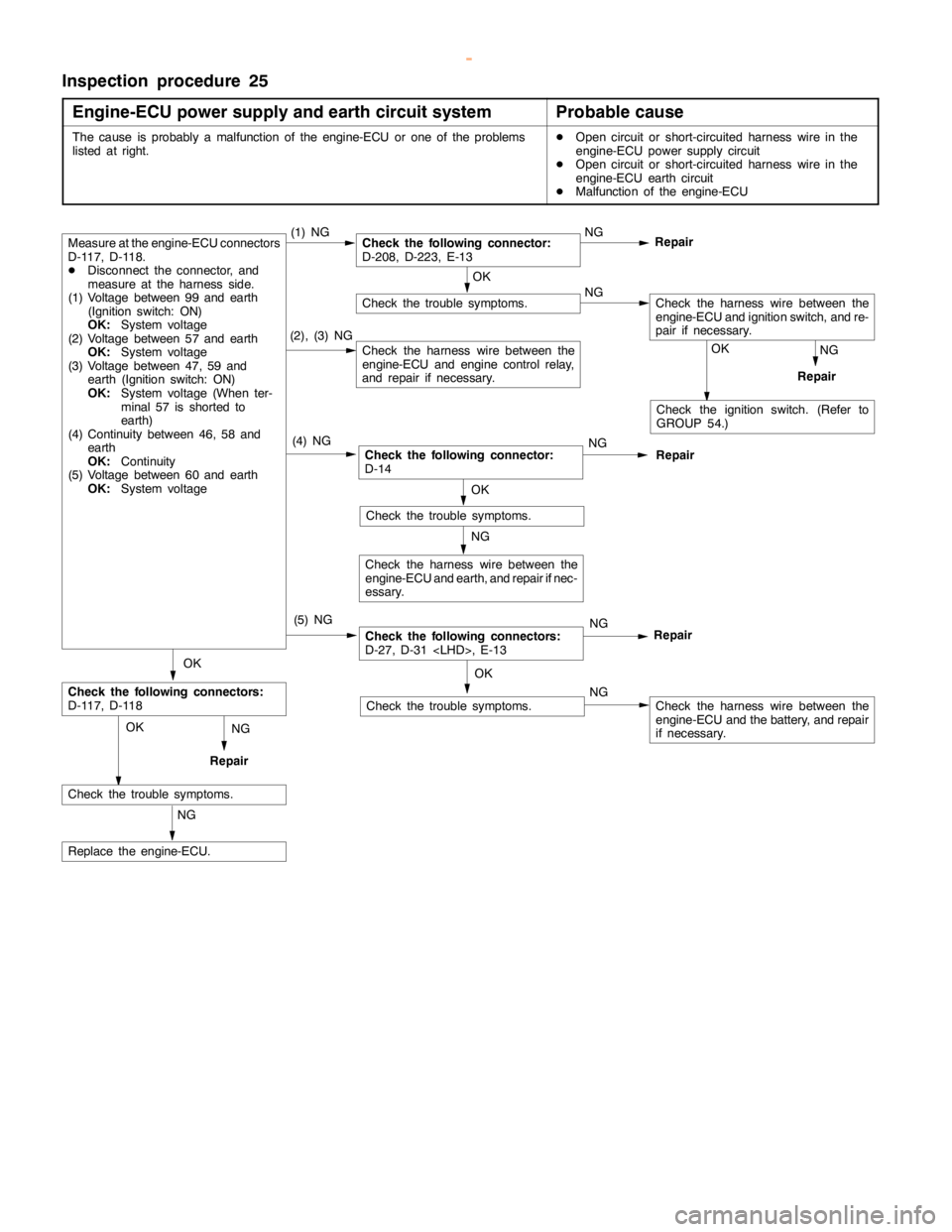

Page 299 of 1839

GDI -Troubleshooting

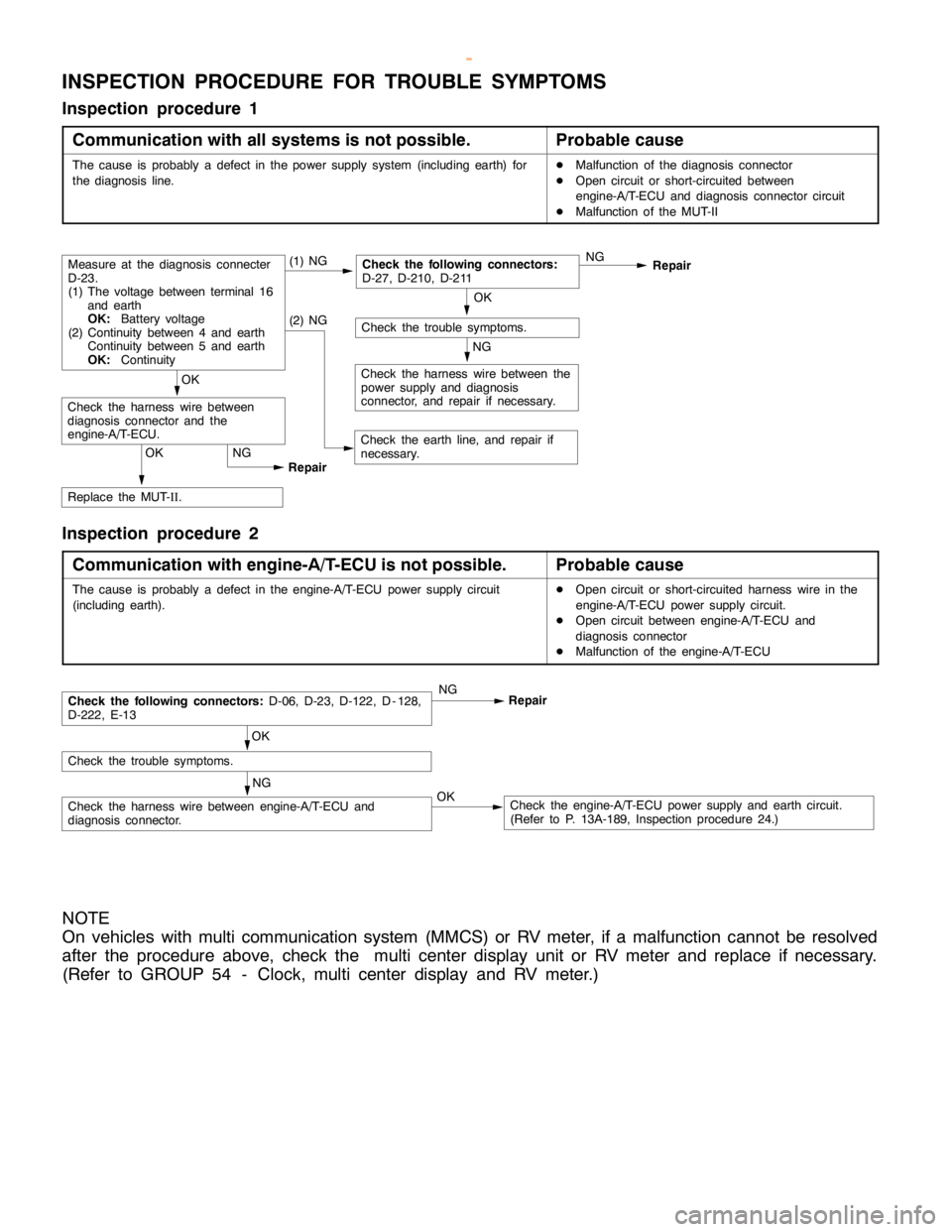

Inspection procedure 10

When the engine is hot, it stalls at idling. (Die out)

Probable cause

The cause is probably an improper air/fuel ratio, faulty electronic-controlled throttle

valve system, compression pressure. In addition, if theenginestalls suddenly, another

possible causemight be a poorconnector contact.DMalfunction of the ignition system

DMalfunction of air/fuel ratio control system

DMalfunction of electronic-controlled throttle valve

system

DMalfunction of the throttle body

DPoor connector contact

DImproper compression pressure

DAir stuck in the air intake system

NG

Repair

Have the battery terminalsbeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye sRefer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.

No

MUT-

IIData list

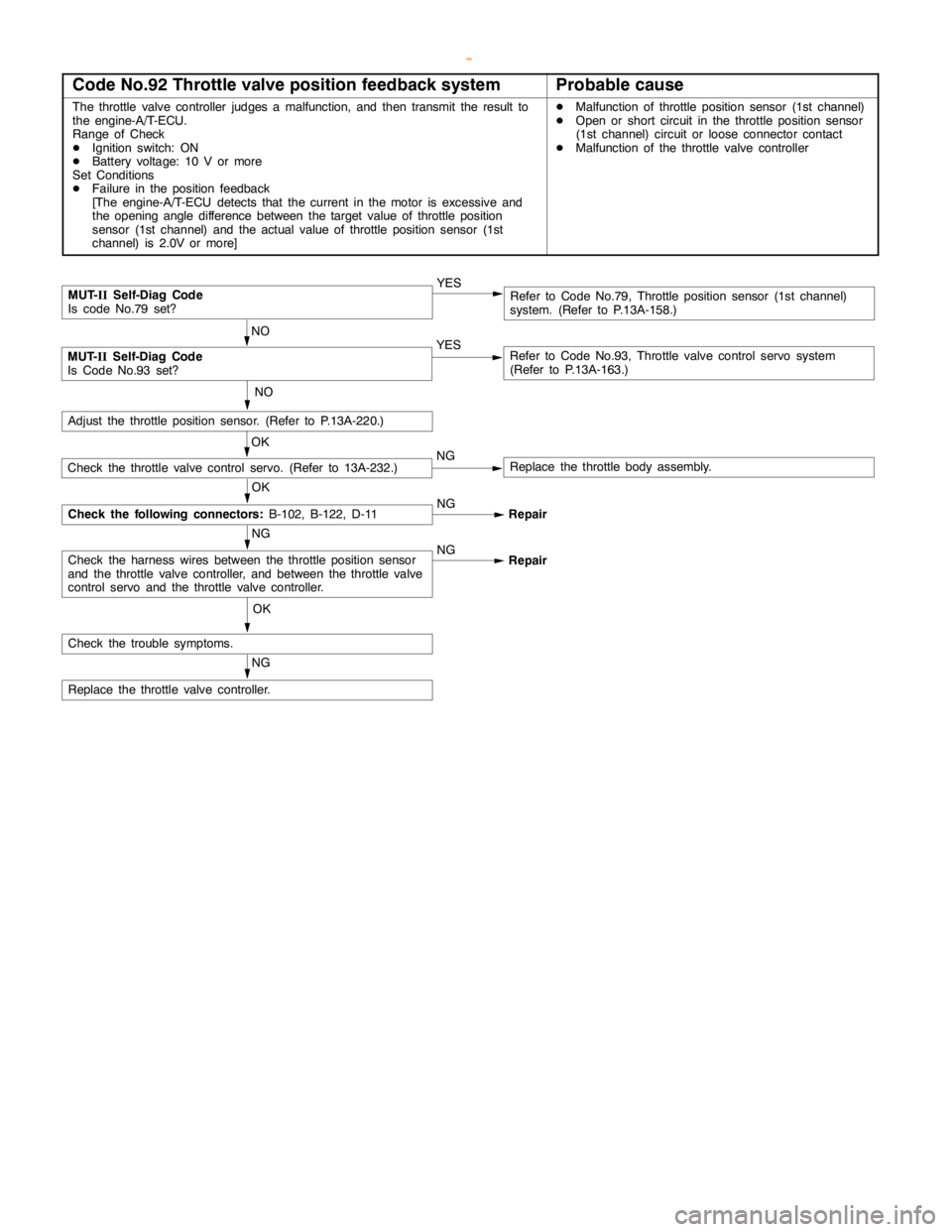

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

Is it easy to reproduce theengine stall?NoWhile carrying out an intermittent malfunction simulation test. (Refer

to GROUP 00 - Points to Note for Intermittent Malfunction.), check

for sudden changes in the following signals.

DCrankanglesensor signal

DInjector drive signal

DFuel pump(low pressure) drive signal

DAir flow sensor

DPrimary ignition signal

DPower supply to the engine-ECU

Ye s

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the acceleratorpedal positionswitch. (Refer to P.13A-100,

Inspection procedure 28.)

OK

MUT-

IIData list

13 Intake air temperature sensor (Refer to P.13A-105.)NGCheck the intake air temperature sensor. (Refer to P.13A-21, code

No. P0110.)

OK

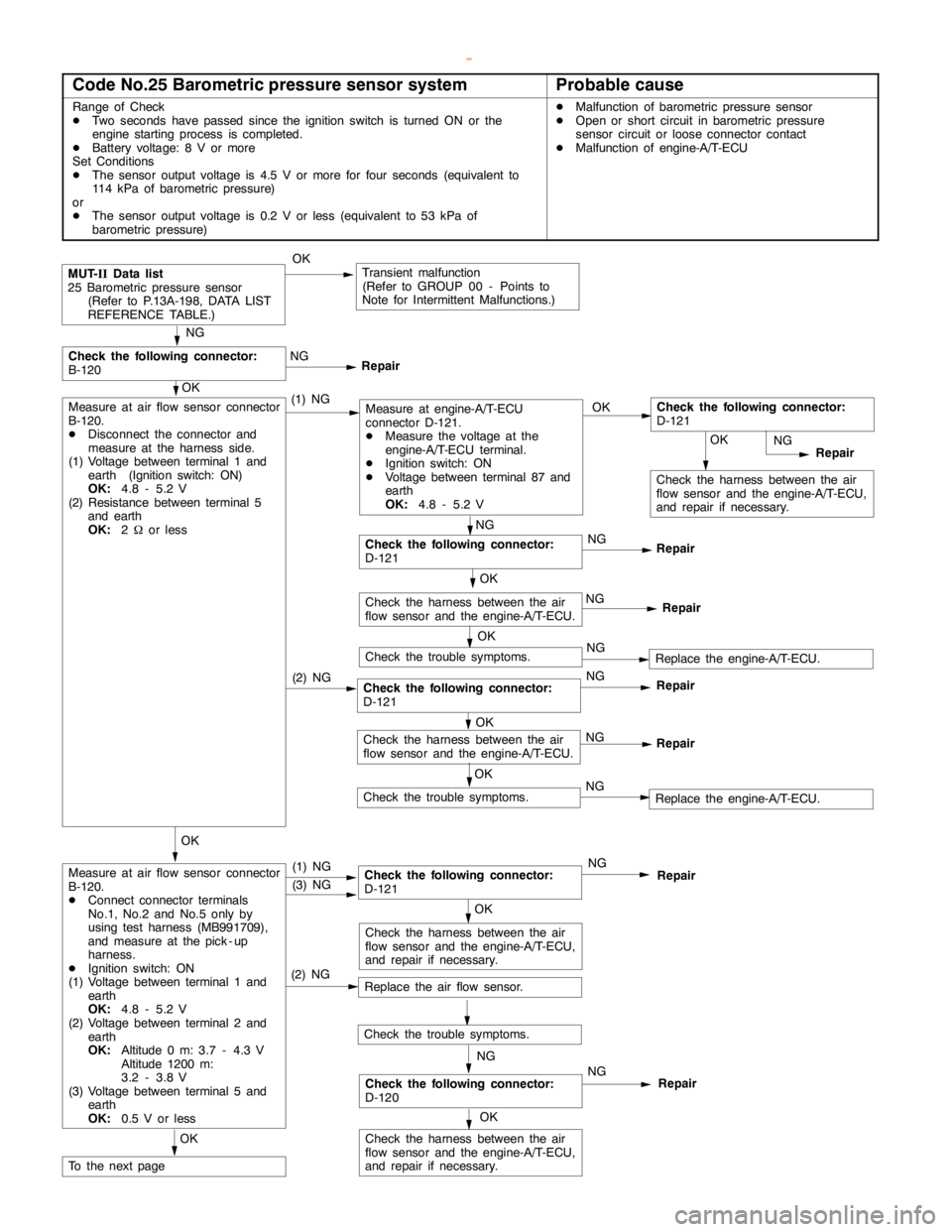

MUT-

IIData list

25 Barometric pressure sensor (Refer to P.13A-105.)NGCheck the barometric pressure sensor. (Refer to P.13A-19, code

No. P0105.)

OK

MUT-

IIData list

21 Engine coolant temperature sensor (Refer to P.13A-105.)NGCheck theengine coolant temperaturesensor. (Refer to P.13A-22,

code No. P0115.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

600 - 1,000 mV when theengine is suddenlyracedNGCheck the oxygen sensor (front) system. (Refer to P.13A-28, code

No. P0130.)

OK

MUT-

IIData list

11 Oxygen sensor (front)

OK:

0 - 400 mV and 600 - 1,000 mV alternates when the

engine is idling(wait for four minutes after theengine

started).NGMeasure fuel high-pressure between the fuel pump (highpressure)

and injector. (Refer to P.13A-224.)

OK

Check that air is sucked in the air intake system.

DBroken intakemanifoldgasket

DDamaged vacuum hose

DDamaged air intake hoseOK

To the nextpage

OK

MUT-

IIData list

59 Oxygen sensor (rear)

DTransmission: 2nd gear

DDriving with throttle widelyopen

OK:

600 - 1,000 mVNGCheck the oxygen sensor (rear) system. (Refer to P.13A-31, code

No. P0136.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 302 of 1839

GDI -Troubleshooting

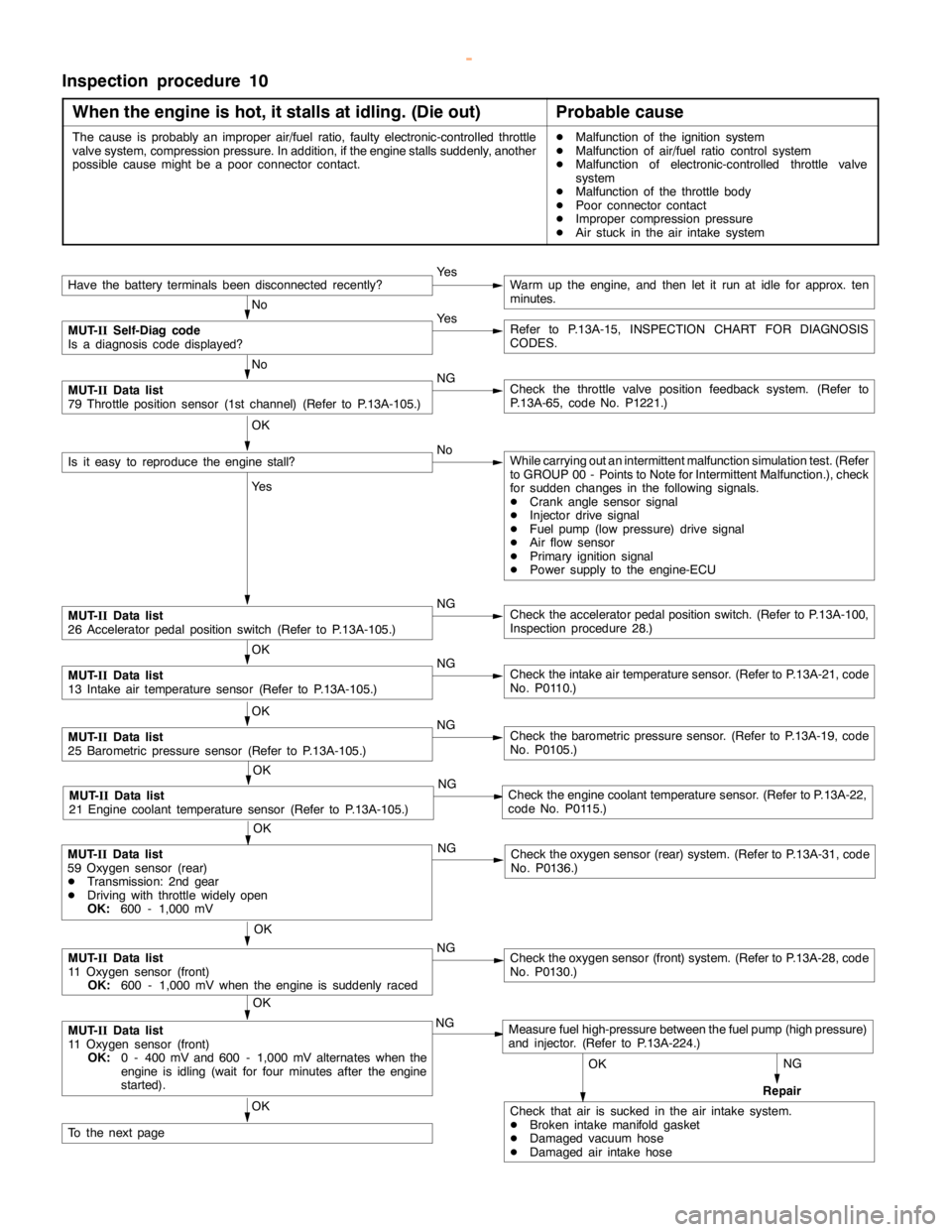

Inspection procedure 12

The engine stalls when decelerating.

Probable cause

The cause is probably an improper air/fuel ratio due to a faulty EGR system, or poor

intake air volume due to a faulty electronic-controlled throttle valve system.DMalfunction of the electronic-controlled throttle valve

system

DMalfunction of the EGR valve

Have the battery terminalsbeen disconnectedrecently?Ye sWarm up the engine, and then let it run at idle for approx. ten

minutes.

No

MUT-

IISelf-Diag code

Is a diagnosis code displayed?Ye s(Refer to P.13A-15, INSPECTION CHART FOR DIAGNOSIS

CODES.)

No

MUT-

IIData list

26 Acceleratorpedal positionswitch (Refer to P.13A-105.)NGCheck the acceleratorpedal positionswitch. (Refer to P.13A-100,

Inspection procedure 28.)

OK

MUT-

IIData list

79 Throttle position sensor (1st channel) (Refer to P.13A-105.)NGCheck the throttle valve position feedback system. (Refer to

P.13A-65, code No. P1221.)

OK

MUT-

IIData list

68 EGR valve (Refer to P.13A-105.)NGCheck the EGR valve system. (Refer to P.13A-69, code No. P0403.)

OK

Check ignition coil spark for each cylinder.

(1) Remove the ignition coil.

(2) Install a new sparkplug to the removed ignitioncoil.

(3) Disconnect the injector intermediate connector.

Caution

Never touch the connector terminal as approx. 100 V is

applied to the injector, or you are seriously injured.

(4) Earth the sparkplug electrodesecurely.

(5) Check that the sparkplug igniteswhen theengine iscranked.NGReplace the ignition coil.

OK

Check all the following items:

DSparkplug

DClean around the throttle valve (Refer to P.13A-220.)

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 312 of 1839

GDI -Troubleshooting

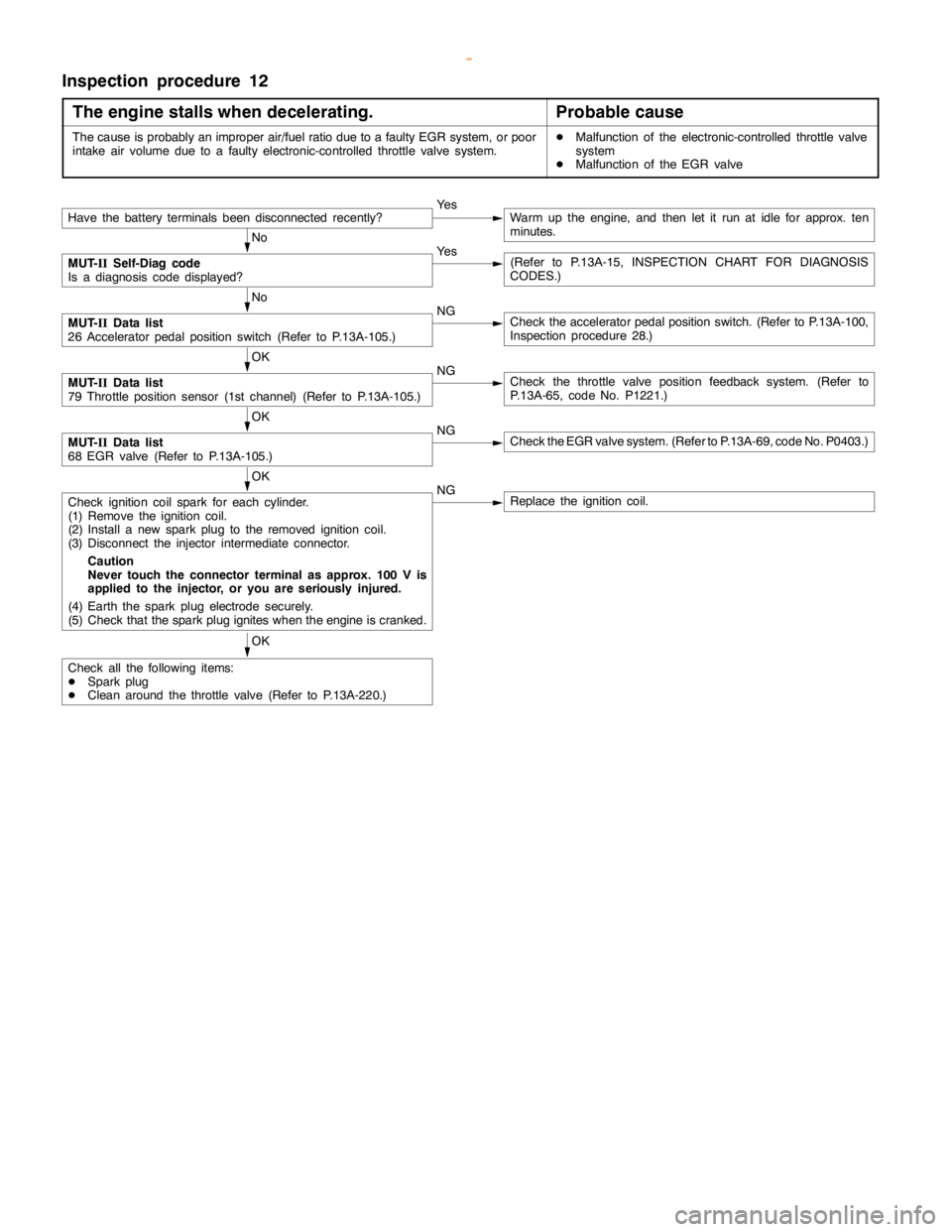

Inspection procedure 25

Engine-ECU power supply and earth circuit system

Probable cause

The cause is probably a malfunction of the engine-ECU or one of the problems

listed at right.DOpen circuit or short-circuited harness wire in the

engine-ECU power supply circuit

DOpen circuit or short-circuited harness wire in the

engine-ECU earth circuit

DMalfunction of the engine-ECU

NG

RepairOK

Check the ignition switch. (Refer to

GROUP 54.)

(2), (3) NGCheck the harness wire between the

engine-ECU and engine controlrelay,

and repair if necessary.

(4) NG

Check the harness wire between the

engine-ECU and earth, and repair if nec-

essary.

(5) NG

NG

Repair

OK

Check the trouble symptoms.NGCheck the harness wire between the

engine-ECU and the battery, and repair

if necessary.

NG

Repair

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

Check the following connectors:

D-117, D-118

Check the following connectors:

D-27, D-31

Check the trouble symptoms.NGCheck the harness wire between the

engine-ECU and ignition switch, and re-

pair if necessary.

Measure at the engine-ECU connectors

D-117, D-118.

DDisconnect the connector, and

measure at the harness side.

(1) Voltage between 99 and earth

(Ignition switch: ON)

OK:

System voltage

(2) Voltage between 57 and earth

OK:

System voltage

(3) Voltage between 47, 59 and

earth (Ignition switch: ON)

OK:

System voltage (When ter-

minal 57 is shorted to

earth)

(4) Continuity between 46, 58 and

earth

OK:

Continuity

(5) Voltage between 60 and earth

OK:

System voltage(1) NGCheck the following connector:

D-208, D-223, E-13NG

Repair

Check the following connector:

D-14NG

Repair

Check the trouble symptoms.OK

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 313 of 1839

GDI -Troubleshooting

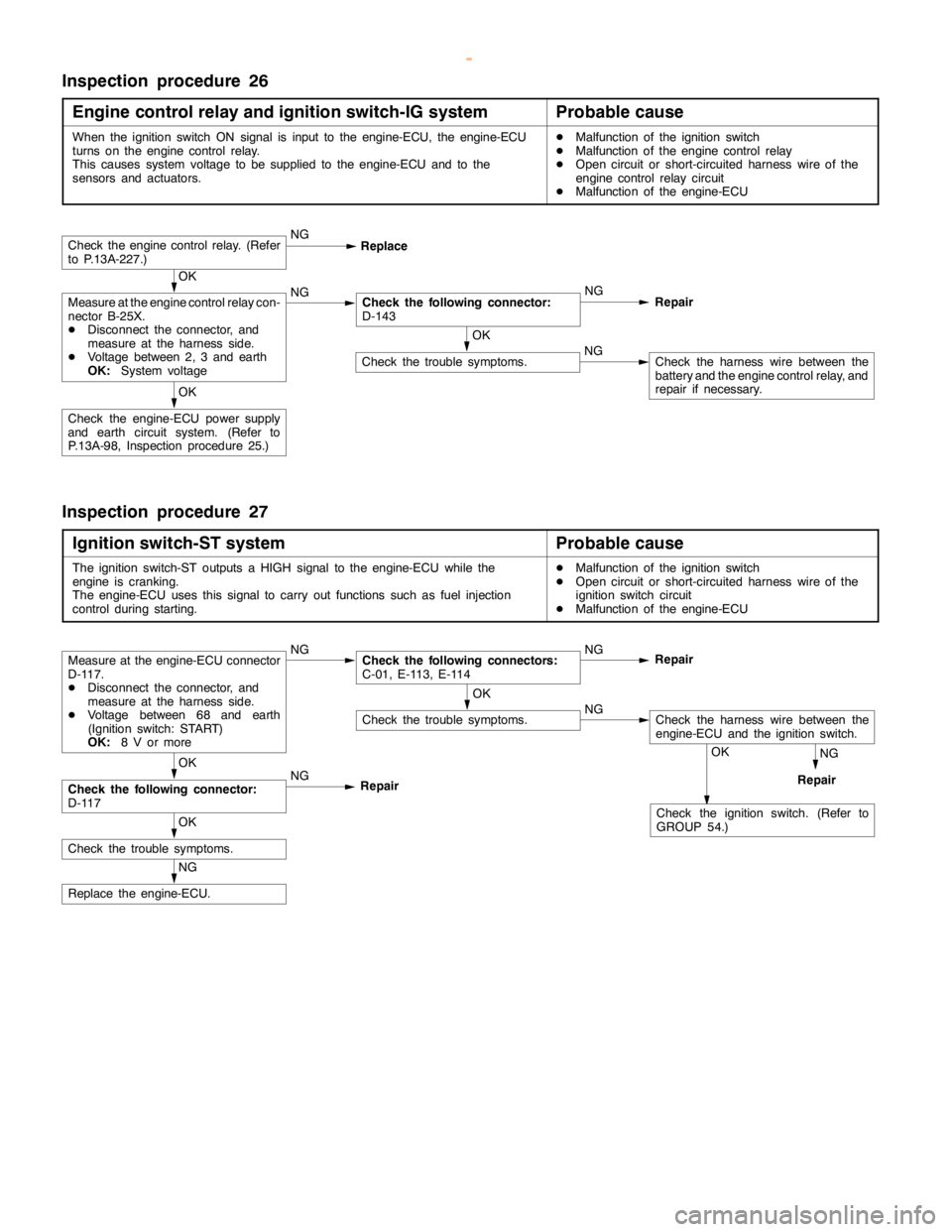

Inspection procedure 26

Engine control relay and ignition switch-IG system

Probable cause

When the ignition switch ON signal is input to the engine-ECU, the engine-ECU

turns on theengine controlrelay.

This causes system voltage to be supplied to the engine-ECU and to the

sensors and actuators.DMalfunction of the ignition switch

DMalfunction of the engine controlrelay

DOpen circuit or short-circuited harness wire of the

engine controlrelay circuit

DMalfunction of the engine-ECU

OK

Check the trouble symptoms.NGCheck the harness wire between the

battery and theengine controlrelay, and

repair if necessary.

OK

Check the engine-ECU power supply

and earth circuit system. (Refer to

P.13A-98, Inspection procedure 25.)

OK

Measure at the engine controlrelay con-

nector B-25X.

DDisconnect the connector, and

measure at the harness side.

DVoltage between 2, 3 and earth

OK:

System voltageNGCheck the following connector:

D-143NG

Repair

Check theengine controlrelay. (Refer

to P.13A-227.)NG

Replace

Inspection procedure 27

Ignition switch-ST system

Probable cause

The ignition switch-ST outputs a HIGH signal to the engine-ECU while the

engine iscranking.

The engine-ECU uses this signal to carry out functions such as fuel injection

control during starting.DMalfunction of the ignition switch

DOpen circuit or short-circuited harness wire of the

ignition switch circuit

DMalfunction of the engine-ECU

NG

RepairOK

Check the ignition switch. (Refer to

GROUP 54.)

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

Check the following connector:

D-117NG

RepairOK

Check the trouble symptoms.NGCheck the harness wire between the

engine-ECU and the ignition switch.

Measure at the engine-ECU connector

D-117.

DDisconnect the connector, and

measure at the harness side.

DVoltage between 68 and earth

(Ignition switch: START)

OK:

8 V or moreNGCheck the following connectors:

C-01, E-113, E-114NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 317 of 1839

GDI -Troubleshooting

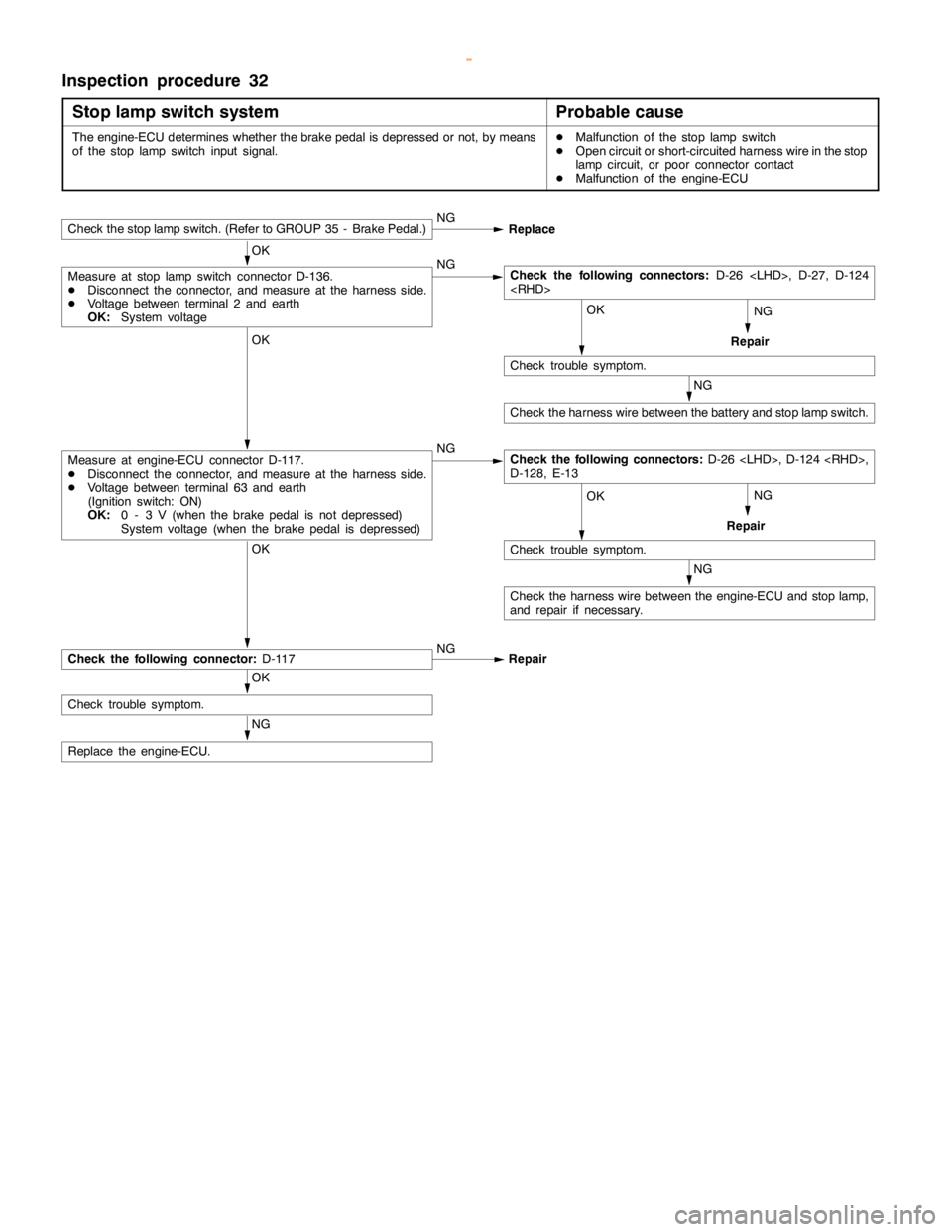

Inspection procedure 32

Stop lamp switch system

Probable cause

The engine-ECU determines whether the brakepedal is depressed or not, by means

of the stoplampswitch input signal.DMalfunction of the stoplampswitch

DOpen circuit or short-circuited harness wire in the stop

lampcircuit, or poor connector contact

DMalfunction of the engine-ECU

NG

NG

NG

Repair

Check the stoplampswitch. (Refer to GROUP 35 - Brake Pedal.)NG

Replace

OK

Measure at stoplampswitch connector D-136.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 2 and earth

OK:

System voltageNG

OK

Check trouble symptom.

Check the harness wire between the battery and stoplampswitch.

NG

Repair

OK

Measure at engine-ECU connector D-117.

DDisconnect the connector, and measure at the harness side.

DVoltage between terminal 63 and earth

(Ignition switch: ON)

OK:

0 - 3 V (when the brakepedal is not depressed)

System voltage (when the brakepedal is depressed)NG

OK

Check trouble symptom.

Check the harness wire between the engine-ECU and stoplamp,

and repair if necessary.

OK

Check the following connector:

D-117NG

Repair

OK

Check trouble symptom.

NG

Replace the engine-ECU.

Check the following connectors:

D-26

Check the following connectors:

D-26

D-128, E-13

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 359 of 1839

Page 361 of 1839

Page 376 of 1839

Page 378 of 1839

Page 383 of 1839