battery MITSUBISHI MONTERO 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 647 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-37

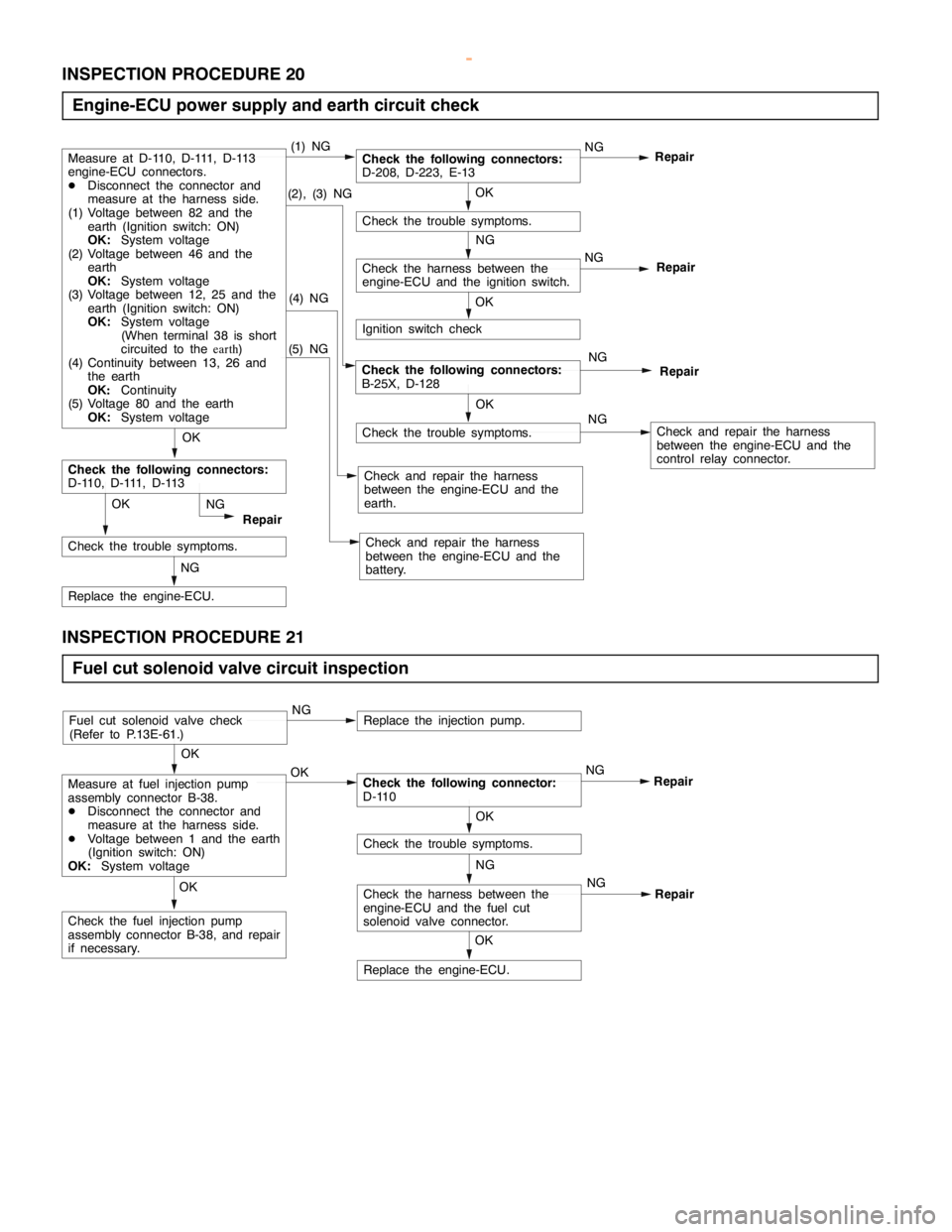

INSPECTION PROCEDURE 20

Engine-ECU power supply and earth circuit check

(5) NG

Check the trouble symptoms.

NG

Repair

(2), (3) NGOK

Check the trouble symptoms.

OK

NG

Check the harness between the

engine-ECU and the ignition switch.

Ignition switch check

(4) NG

Check and repair the harness

between the engine-ECU and the

earth.

OK

Check the following connectors:

D-110, D-111, D-113

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.Repair NG

NG

RepairCheck the following connectors:

B-25X, D-128

NG

Check and repair the harness

between the engine-ECU and the

control relay connector.

Check and repair the harness

between the engine-ECU and the

battery.

Check the following connectors:

D-208, D-223, E-13NG

RepairMeasure at D-110, D-111, D-113

engine-ECU connectors.

DDisconnect the connector and

measure at the harness side.

(1) Voltage between 82 and the

earth (Ignition switch: ON)

OK:System voltage

(2) Voltage between 46 and the

earth

OK:System voltage

(3) Voltage between 12, 25 and the

earth (Ignition switch: ON)

OK:System voltage

(When terminal 38 is short

circuited to theearth)

(4) Continuity between 13, 26 and

the earth

OK:Continuity

(5) Voltage 80 and the earth

OK:System voltage(1) NG

OK

INSPECTION PROCEDURE 21

Fuel cut solenoid valve circuit inspection

NG

Check the harness between the

engine-ECU and the fuel cut

solenoid valve connector.

OK

Replace the engine-ECU.

OK

Check the fuel injection pump

assembly connector B-38, and repair

if necessary.

OK

Check the trouble symptoms.

OK

Measure at fuel injection pump

assembly connector B-38.

DDisconnect the connector and

measure at the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:System voltageOKCheck the following connector:

D-110NG

Repair

Fuel cut solenoid valve check

(Refer to P.13E-61.)NGReplace the injection pump.

NG

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 654 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-44

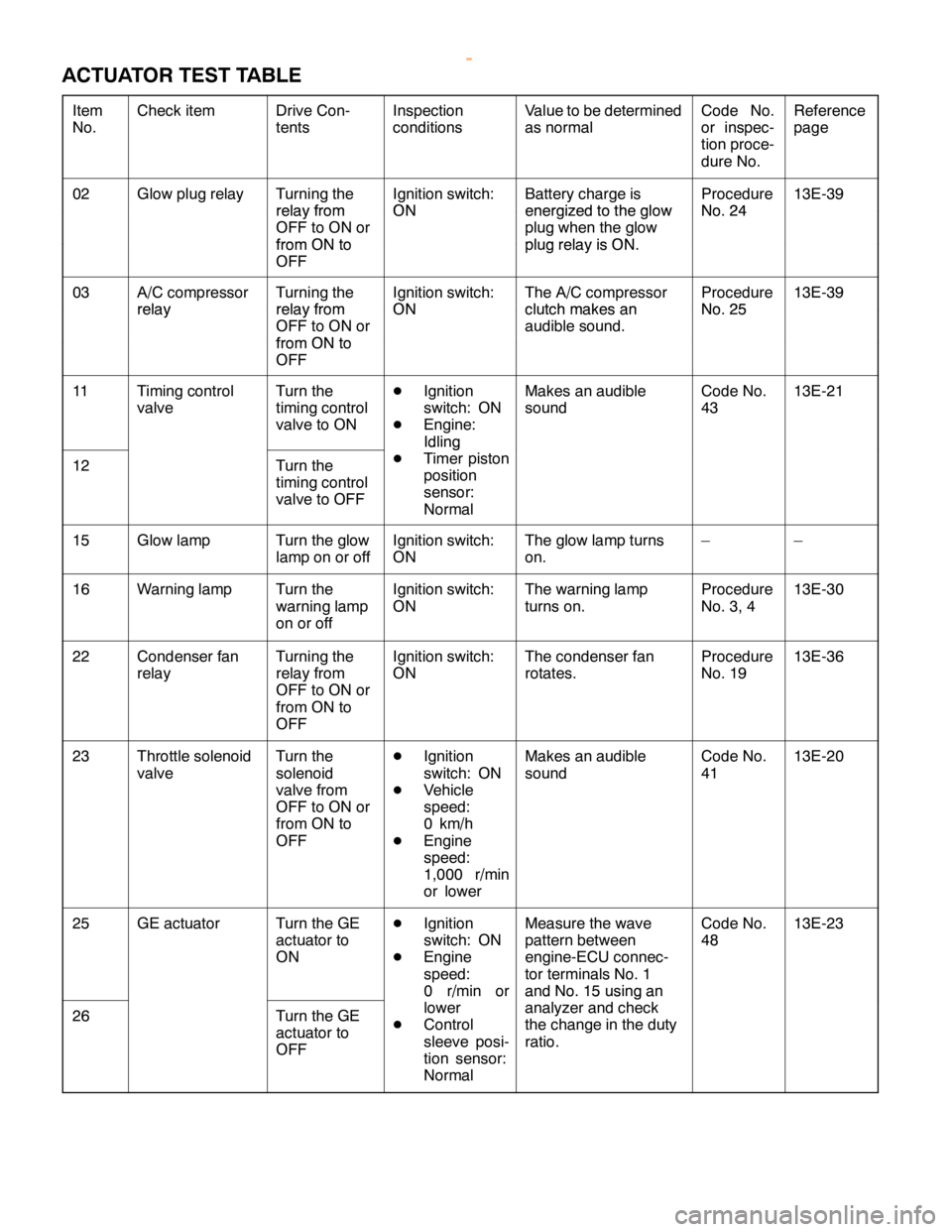

ACTUATOR TEST TABLE

Item

No.Check itemDrive Con-

tentsInspection

conditionsValue to be determined

as normalCode No.

or inspec-

tion proce-

dure No.Reference

page

02Glow plug relayTurning the

relayfrom

Ignition switch:

ON

Battery charge is

energizedtotheglow

Procedure

No24

13E-39

relayfrom

OFF to ON or

fromONto

ONenergizedtotheglow

plug when the glow

plugrelayisON

No.24

fromONto

OFFplug relayisON.

03A/C compressor

relay

Turning the

relayfrom

Ignition switch:

ON

The A/C compressor

clutchmakesan

Procedure

No25

13E-39

relayrelayfrom

OFF to ON or

fromONto

ONclutchmakes an

audible sound.No.25

fromONto

OFF

11Timing control

valveTurn the

timing control

valve to ONDIgnition

switch: ON

DEngine:

Idlin

g

Makes an audible

soundCode No.

4313E-21

12Turn the

timing control

valve to OFF

Idling

DTimer piston

position

sensor:

Normal

15Glow lampTurn the glow

lamp on or offIgnition switch:

ONThe glow lamp turns

on.––

16Warning lampTurn the

warning lamp

on or offIgnition switch:

ONThe warning lamp

turns on.Procedure

No. 3, 413E-30

22Condenser fan

relayTurning the

relay from

OFF to ON or

from ON to

OFFIgnition switch:

ONThe condenser fan

rotates.Procedure

No. 1913E-36

23Throttle solenoid

valveTurn the

solenoid

valve from

OFF to ON or

from ON to

OFFDIgnition

switch: ON

DVehicle

speed:

0 km/h

DEngine

speed:

1,000 r/min

or lowerMakes an audible

soundCode No.

4113E-20

25GE actuatorTurn the GE

actuator to

ONDIgnition

switch: ON

DEngine

speed:

0 r/min orMeasure the wave

pattern between

engine-ECU connec-

tor terminals No. 1

and No. 15 using anCode No.

4813E-23

26Turn the GE

actuator to

OFF

0r/minor

lower

DControl

sleeve posi-

tion sensor:

Normal

andNo.15usingan

analyzer and check

the change in the duty

ratio.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 758 of 1839

ENGINE ELECTRICAL -Charging System16-10

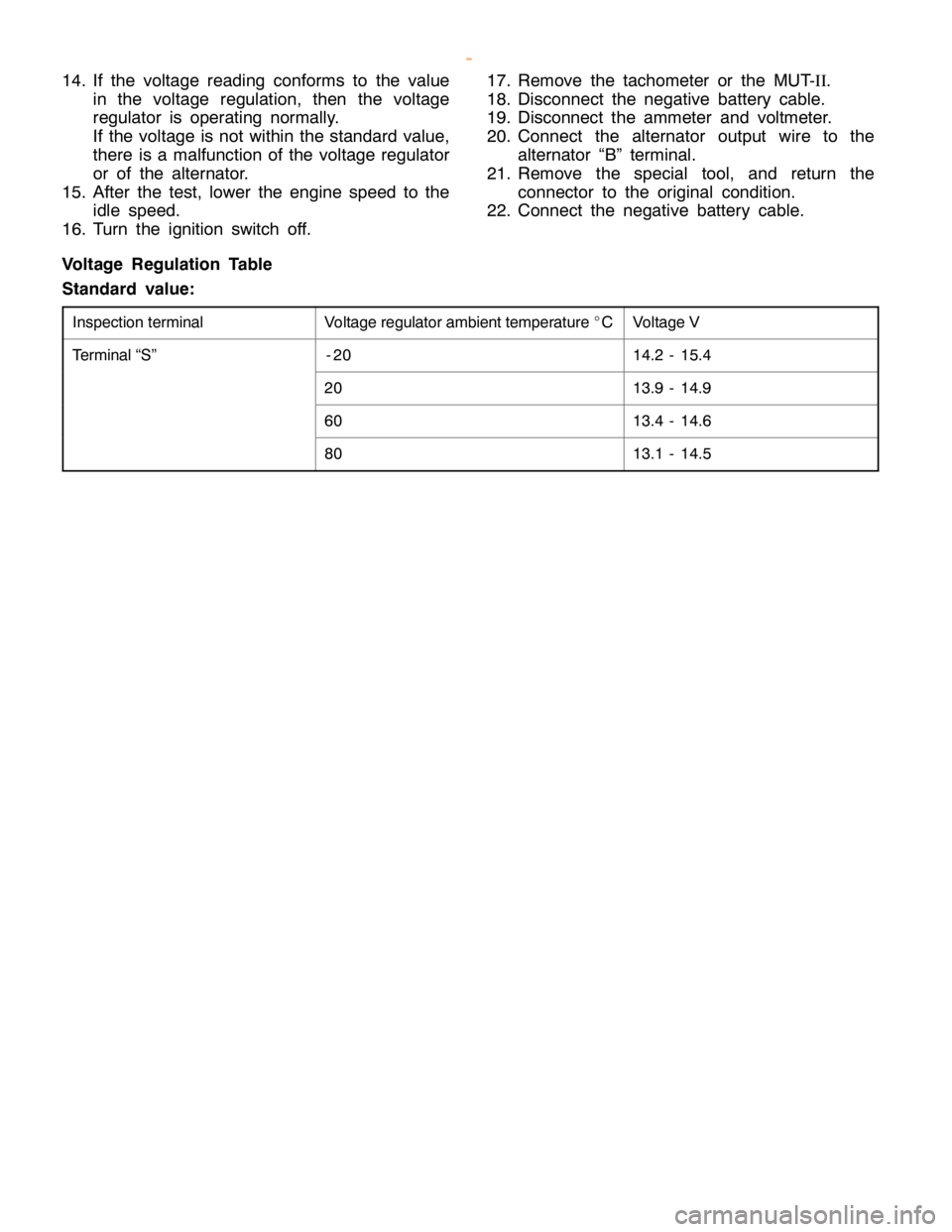

14. If the voltage reading conforms to the value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

15. After the test, lower the engine speed to the

idle speed.

16. Turn the ignition switch off.17. Remove the tachometer or the MUT-II.

18. Disconnect the negative battery cable.

19. Disconnect the ammeter and voltmeter.

20. Connect the alternator output wire to the

alternator “B” terminal.

21. Remove the special tool, and return the

connector to the original condition.

22. Connect the negative battery cable.

Voltage Regulation Table

Standard value:

Inspection terminalVoltage regulator ambient temperature_

CVoltage V

Terminal “S”-2014.2 - 15.4

2013.9 - 14.9

6013.4 - 14.6

8013.1 - 14.5

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 926 of 1839

Page 946 of 1839

Page 980 of 1839

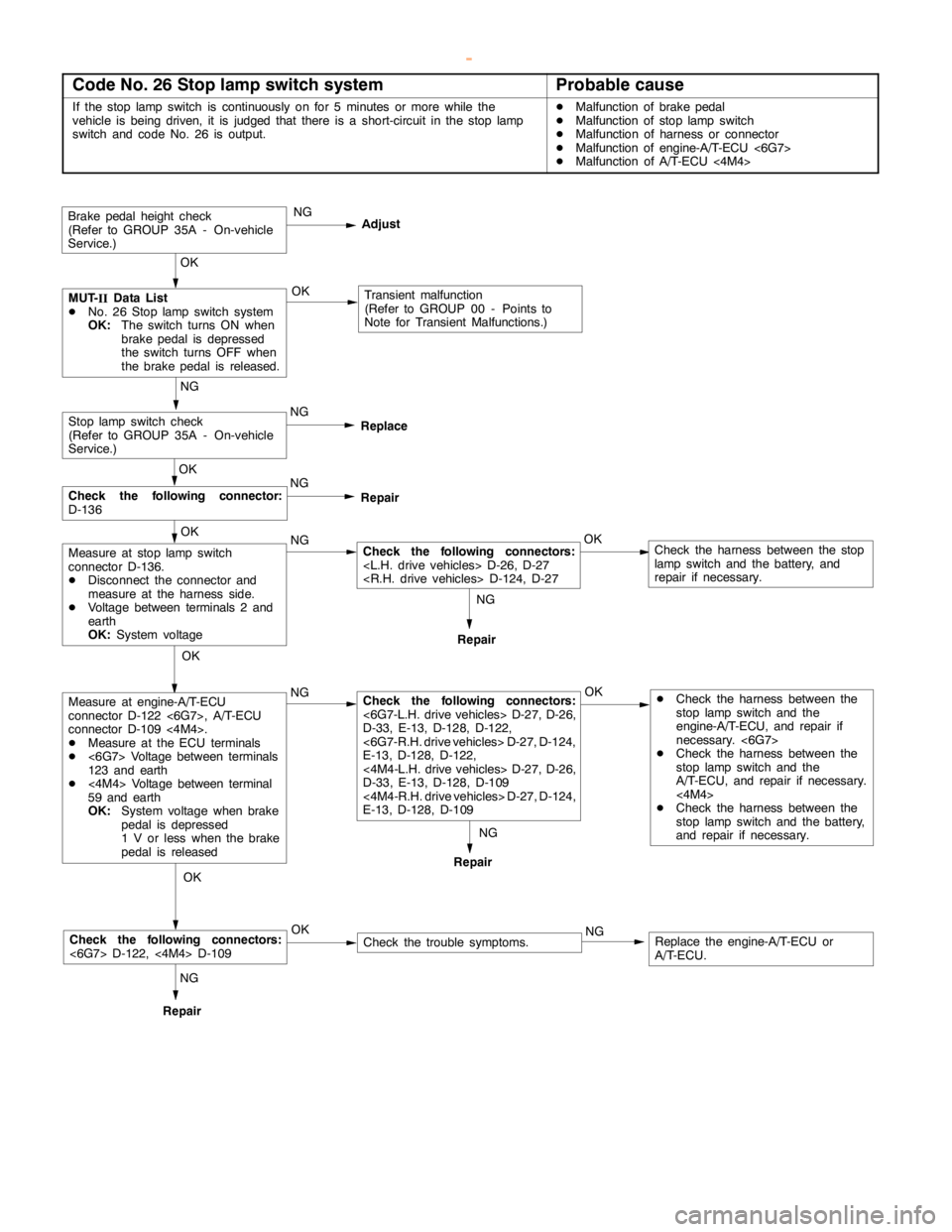

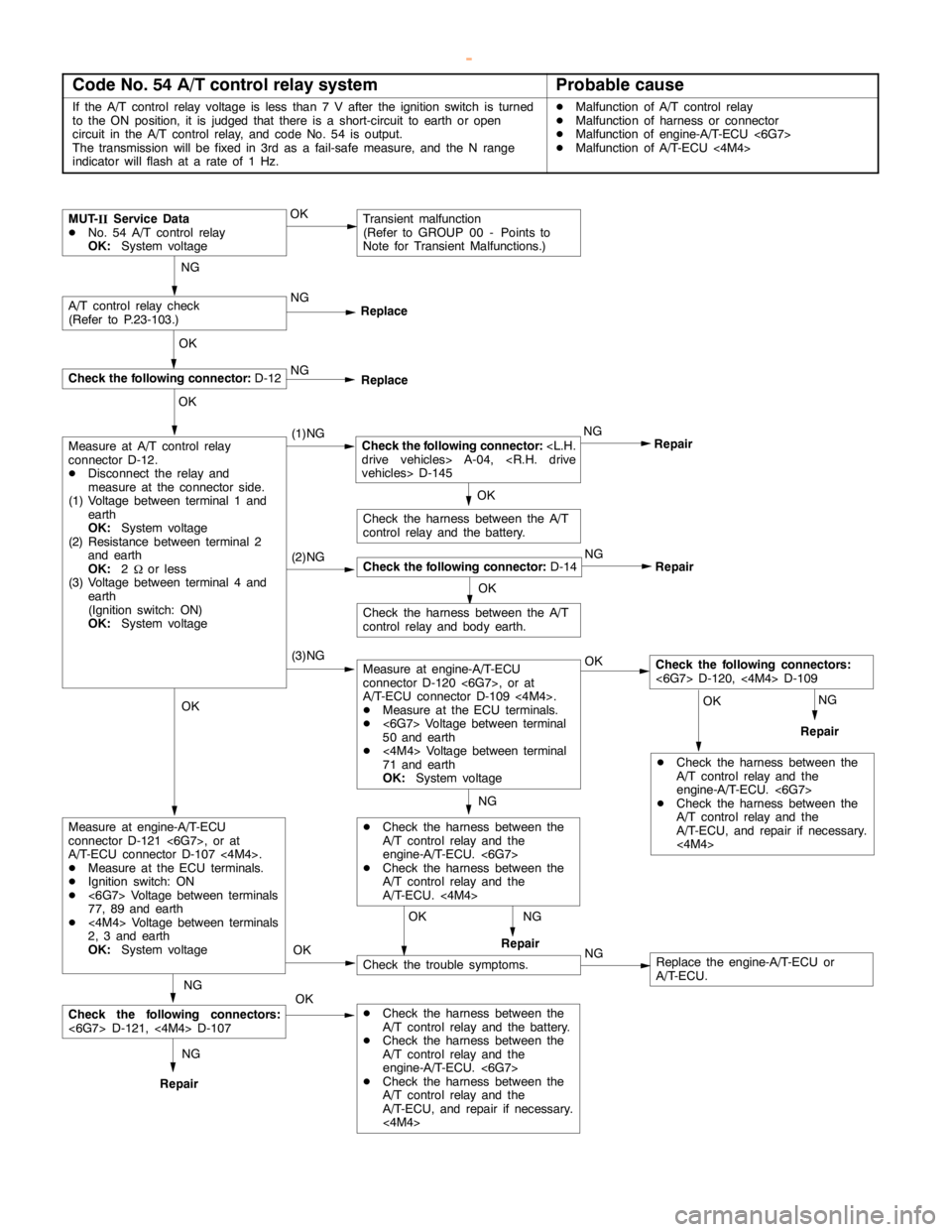

AUTOMATIC TRANSMISSION -Troublehshooting

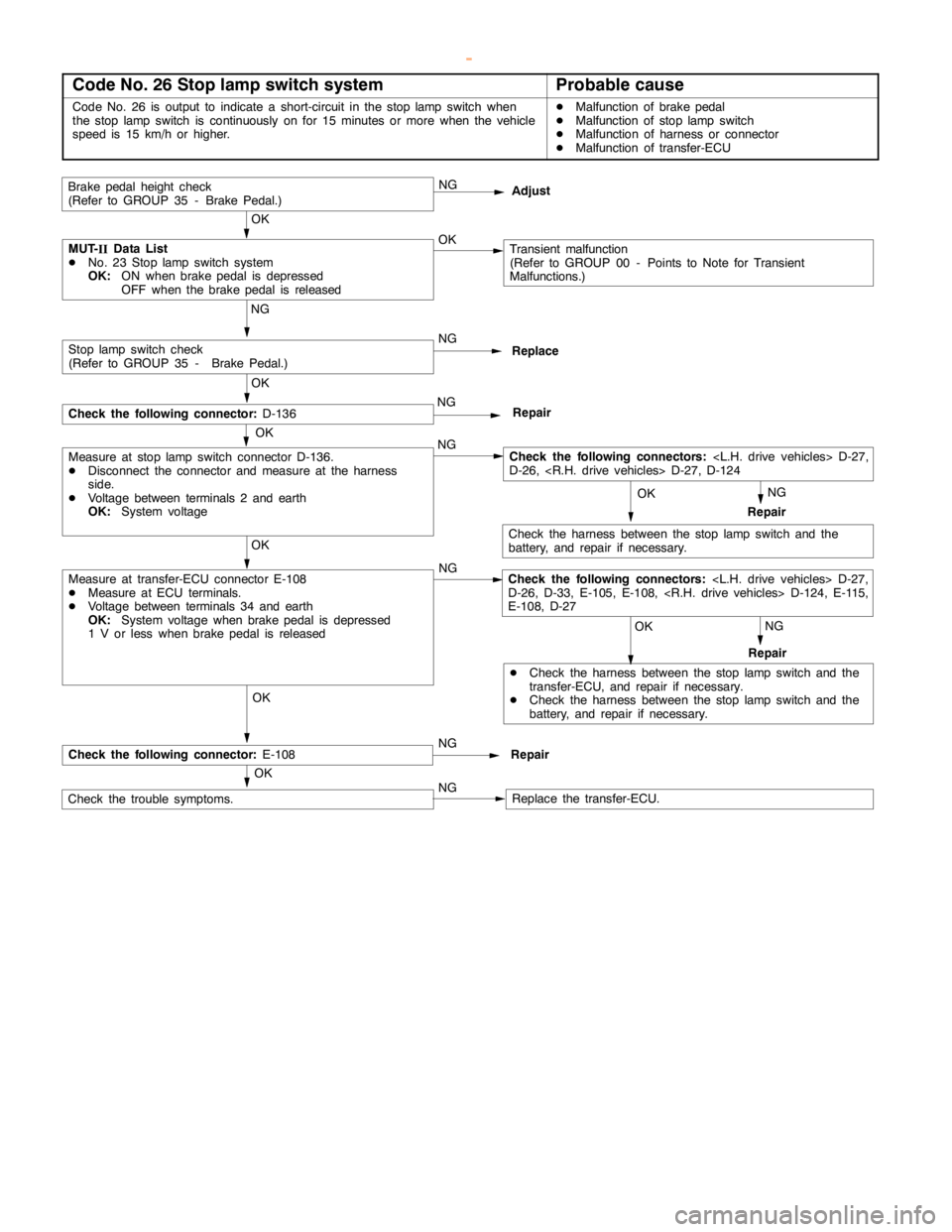

Code No. 26 Stop lamp switch systemProbable cause

Code No. 26 is output to indicate a short-circuit in the stoplampswitch when

the stoplampswitch is continuously on for 15 minutes or more when the vehicle

speed is 15 km/h or higher.DMalfunction of brakepedal

DMalfunction of stoplampswitch

DMalfunction of harness or connector

DMalfunction of transfer-ECU

NG

NG

NG

MUT-

IIData List

DNo. 23 Stoplampswitch system

OK:ON when brakepedal is depressed

OFF when the brakepedal is releasedTransient malfunction

(Refer to GROUP 00 - Points to Note for Transient

Malfunctions.) OK

OK OK OK NG

DCheck the harness between the stoplampswitch and the

transfer-ECU, and repair if necessary.

DCheck the harness between the stoplampswitch and the

battery, and repair if necessary.Repair

Check the harness between the stoplampswitch and the

battery, and repair if necessary.

OK OK

Brakepedal heightcheck

(Refer to GROUP 35 - Brake Pedal.)

OKNG

Adjust

OK

OK

NG

NG

Check the trouble symptoms.Replace the transfer-ECU.

Measure at transfer-ECU connector E-108

DMeasure at ECU terminals.

DVoltage between terminals 34 and earth

OK:System voltage when brakepedal is depressed

1 V or less when brakepedal is released

Measure at stoplampswitch connector D-136.

DDisconnect the connector and measure at the harness

side.

DVoltage between terminals 2 and earth

OK:System voltageNG

Replace

NG

Repair

Stoplampswitch check

(Refer to GROUP 35 - Brake Pedal.)

Check the following connector:D-136

Repair NG

Check the following connector:E-108Repair

Check the following connectors:

D-26, D-33, E-105, E-108,

E-108, D-27

Check the following connectors:

D-26,

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1217 of 1839

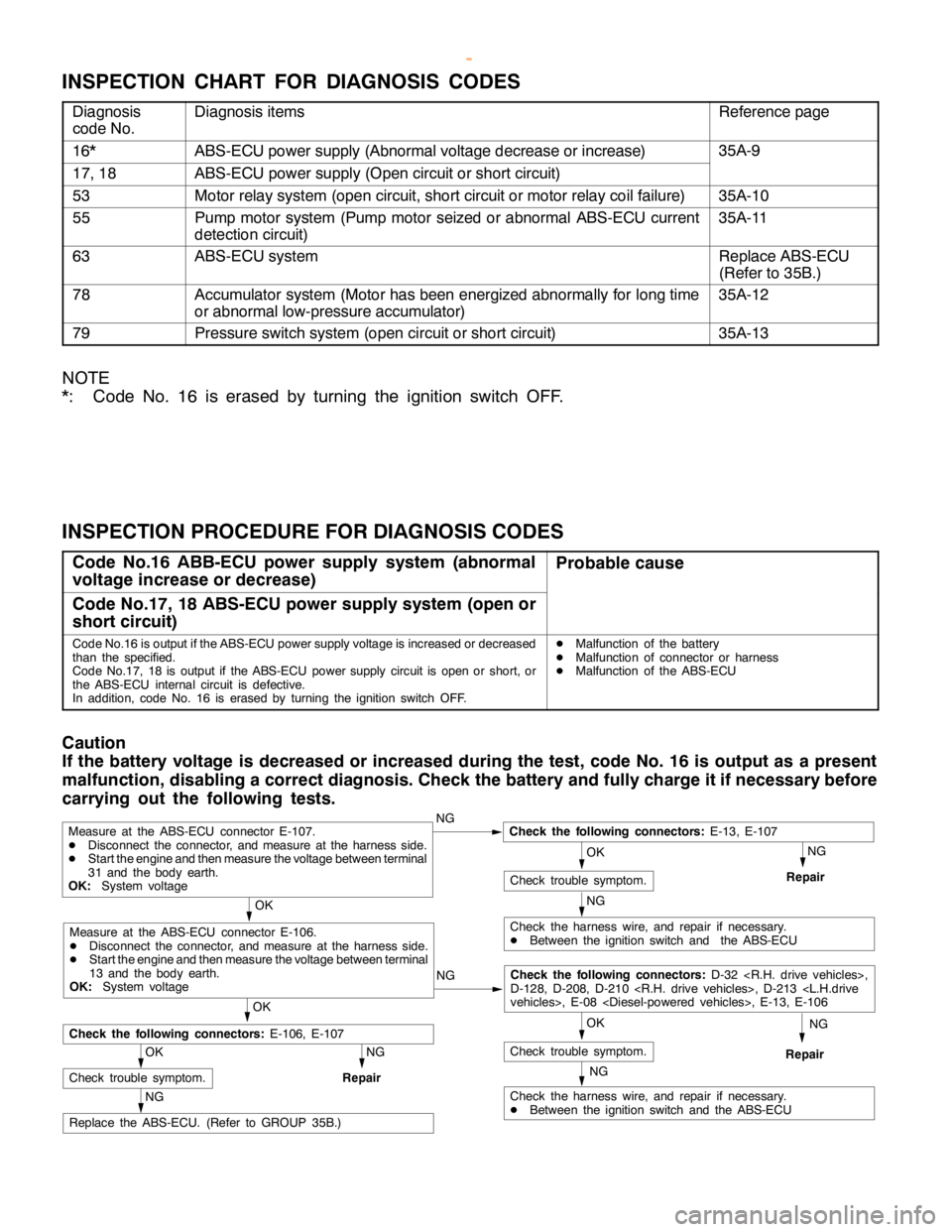

BASIC BRAKE SYSTEM -Troubleshooting35A-9

INSPECTION CHART FOR DIAGNOSIS CODES

Diagnosis

code No.Diagnosis itemsReference page

16*ABS-ECU power supply (Abnormal voltage decrease or increase)35A-9

17, 18ABS-ECU power supply (Open circuit or short circuit)

53Motor relay system (open circuit, short circuit or motor relay coil failure)35A-10

55Pump motor system (Pump motor seized or abnormal ABS-ECU current

detection circuit)35A-11

63ABS-ECU systemReplace ABS-ECU

(Refer to 35B.)

78Accumulator system (Motor has been energized abnormally for long time

or abnormal low-pressure accumulator)35A-12

79Pressure switch system (open circuit or short circuit)35A-13

NOTE

*: Code No. 16 is erased by turning the ignition switch OFF.

INSPECTION PROCEDURE FOR DIAGNOSIS CODES

Code No.16 ABB-ECU power supply system (abnormal

voltage increase or decrease)Probable cause

Code No.17, 18 ABS-ECU power supply system (open or

short circuit)

Code No.16 is output if the ABS-ECU power supply voltage is increased or decreased

than the specified.

Code No.17, 18 is output if the ABS-ECU power supply circuit isopen orshort, or

the ABS-ECU internal circuit is defective.

In addition, code No. 16 is erased by turning the ignition switch OFF.DMalfunction of the battery

DMalfunction of connector or harness

DMalfunction of the ABS-ECU

Caution

If the battery voltage is decreased or increased during the test, code No. 16 is output as a present

malfunction, disabling a correct diagnosis. Check the battery and fully charge it if necessary before

carrying out the following tests.

NG

NG

OK

NG

Replace the ABS-ECU. (Refer to GROUP 35B.)

OK

Check trouble symptom.

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-107.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

31 and the body earth.

OK:System voltageNGCheck the following connectors:E-13, E-107

Repair

OK

Check the following connectors:E-106, E-107

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

OK

Check trouble symptom.

Measure at the ABS-ECU connector E-106.

DDisconnect the connector, and measure at the harness side.

DStart theengine and then measure the voltage between terminal

13 and the body earth.

OK:System voltageNG

Check the following connectors:D-32

D-128, D-208, D-210

Repair

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1264 of 1839

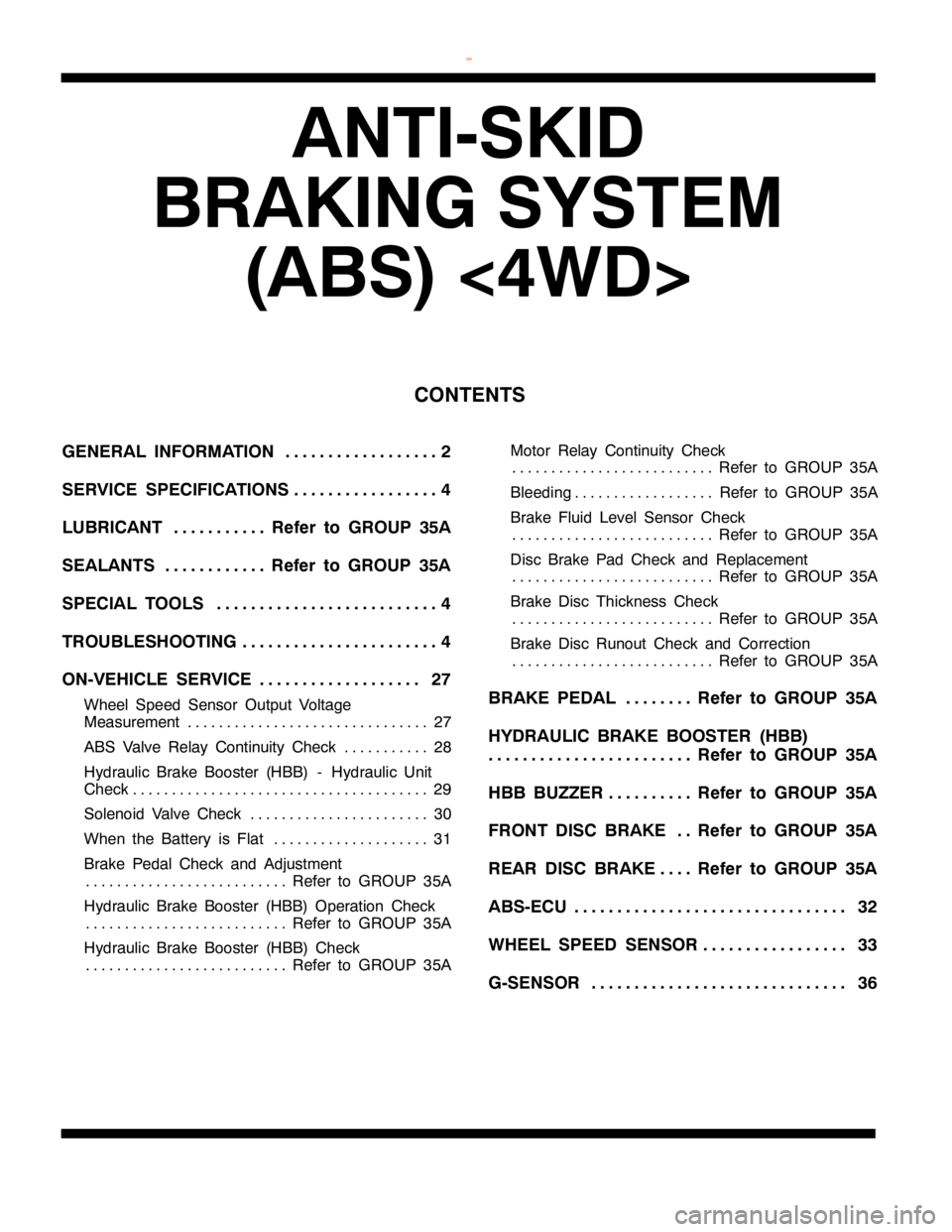

35B-1

ANTI-SKID

BRAKING SYSTEM

(ABS) <4WD>

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 4.................

LUBRICANT Refer to GROUP 35A...........

SEALANTS Refer to GROUP 35A............

SPECIAL TOOLS 4..........................

TROUBLESHOOTING 4.......................

ON-VEHICLE SERVICE 27...................

Wheel Speed Sensor Output Voltage

Measurement 27...............................

ABS Valve Relay Continuity Check 28...........

Hydraulic Brake Booster (HBB) - Hydraulic Unit

Check 29......................................

Solenoid Valve Check 30.......................

When the Battery is Flat 31....................

Brake Pedal Check and Adjustment

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Operation Check

Refer to GROUP 35A ..........................

Hydraulic Brake Booster (HBB) Check

Refer to GROUP 35A ..........................Motor Relay Continuity Check

Refer to GROUP 35A ..........................

Bleeding Refer to GROUP 35A..................

Brake Fluid Level Sensor Check

Refer to GROUP 35A ..........................

Disc Brake Pad Check and Replacement

Refer to GROUP 35A ..........................

Brake Disc Thickness Check

Refer to GROUP 35A ..........................

Brake Disc Runout Check and Correction

Refer to GROUP 35A ..........................BRAKE PEDAL Refer to GROUP 35A........

HYDRAULIC BRAKE BOOSTER (HBB)

Refer to GROUP 35A ........................

HBB BUZZER Refer to GROUP 35A..........

FRONT DISC BRAKE Refer to GROUP 35A..

REAR DISC BRAKE Refer to GROUP 35A....

ABS-ECU 32................................

WHEEL SPEED SENSOR 33.................

G-SENSOR 36..............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1273 of 1839

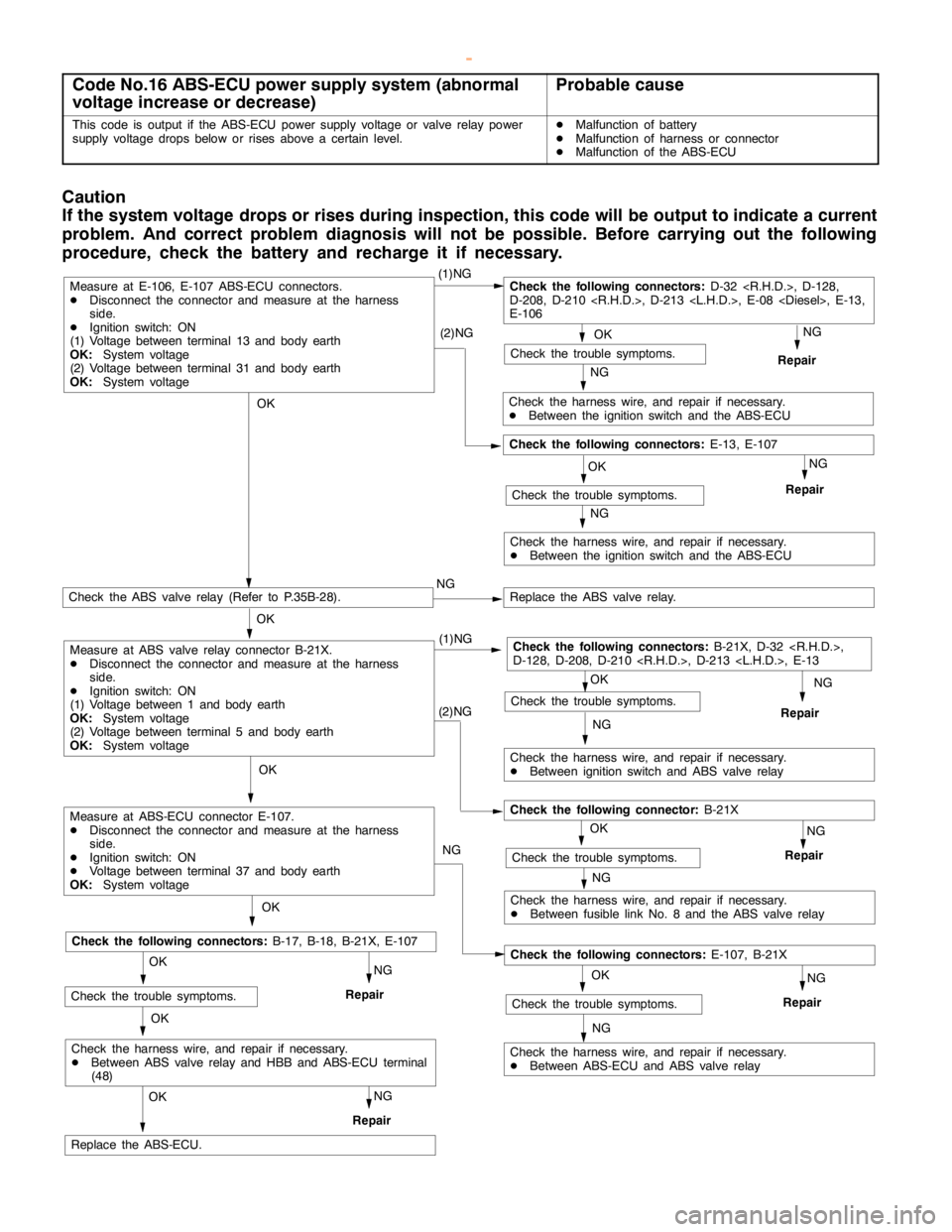

ABS <4WD> -Troubleshooting35B-10

Code No.16 ABS-ECU power supply system (abnormal

voltage increase or decrease)Probable cause

This code is output if the ABS-ECU power supply voltage or valve relay power

supply voltage drops below or rises above a certain level.DMalfunction of battery

DMalfunction of harness or connector

DMalfunction of the ABS-ECU

Caution

If the system voltage drops or rises during inspection, this code will beoutput to indicate a current

problem. And correct problem diagnosis will not be possible. Before carrying out the following

procedure, check the battery and recharge it if necessary.

OKNG

Repair

OK

(1)NGCheck the following connectors:D-32

D-208, D-210

E-106

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU (2)NG

OK

Check the trouble symptoms.

NG

Repair

NG

Check the harness wire, and repair if necessary.

DBetween the ignition switch and the ABS-ECU

Check the following connectors:E-13, E-107

Measure at E-106, E-107 ABS-ECU connectors.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

(1) Voltage between terminal 13 and body earth

OK:System voltage

(2) Voltage between terminal 31 and body earth

OK:System voltage

NG (1)NG

Check the ABS valve relay (Refer to P.35B-28).NGReplace the ABS valve relay.

OK

Check the harness wire, and repair if necessary.

DBetween ignition switch and ABS valve relay

OK

Repair

OK

Replace the ABS-ECU.

Check the trouble symptoms.

Check the following connectors:B-21X, D-32

D-128, D-208, D-210

NG(2)NG

Check the harness wire, and repair if necessary.

DBetween fusible link No. 8 and the ABS valve relay

OK

NG

Repair

NGCheck the trouble symptoms.

Check the following connector:B-21X

OK

NG

OK

NG

Repair

Check the harness wire, and repair if necessary.

DBetween ABS-ECU and ABS valve relayNG

Check the trouble symptoms.

Check the following connectors:E-107, B-21X

OK

OK

NG

RepairCheck the trouble symptoms.

Check the following connectors:B-17, B-18, B-21X, E-107

NG

Repair

Check the harness wire, and repair if necessary.

DBetween ABS valve relay and HBB and ABS-ECU terminal

(48)

Measure at ABS-ECU connector E-107.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DVoltage between terminal 37 and body earth

OK:System voltage

Measure at ABS valve relay connector B-21X.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

(1) Voltage between 1 and body earth

OK:System voltage

(2) Voltage between terminal 5 and body earth

OK:System voltage

Check the trouble symptoms.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 1281 of 1839

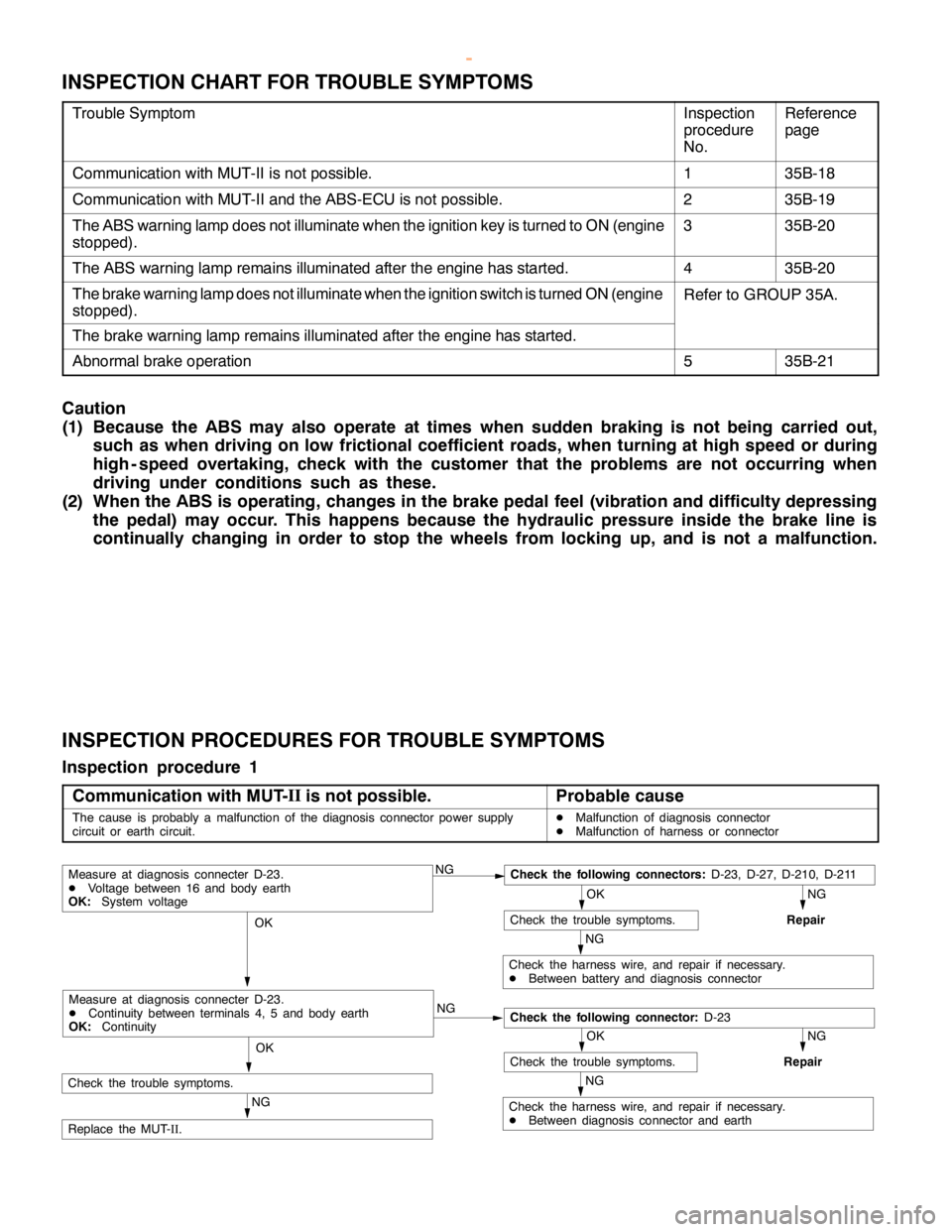

ABS <4WD> -Troubleshooting35B-18

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble SymptomInspection

procedure

No.Reference

page

Communication with MUT-II is not possible.135B-18

Communication with MUT-II and the ABS-ECU is not possible.235B-19

The ABS warning lamp does not illuminate when the ignition key is turned to ON (engine

stopped).335B-20

The ABS warning lamp remains illuminated after the engine has started.435B-20

The brake warning lamp does not illuminate when the ignition switch is turned ON (engine

stopped).Refer to GROUP 35A.

The brake warning lamp remains illuminated after the engine has started.

Abnormal brake operation535B-21

Caution

(1) Because the ABS may also operate at times when sudden braking is not being carried out,

such as when driving on low frictional coefficient roads, when turning at high speed or during

high - speed overtaking, check with the customer that the problems are not occurring when

driving under conditions such as these.

(2) When the ABS is operating, changes in the brake pedal feel (vibration and difficulty depressing

the pedal) may occur. This happens because the hydraulic pressure inside the brake line is

continually changing in order to stop the wheels from locking up, and is not a malfunction.

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 1

Communication with MUT-II

is not possible.

Probable cause

The cause is probably a malfunction of the diagnosis connector power supply

circuit or earth circuit.DMalfunction of diagnosis connector

DMalfunction of harness or connector

NGCheck the following connectors:D-23, D-27, D-210, D-211

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire, and repair if necessary.

DBetween battery and diagnosis connector

OK

NG

NG

Repair

OK

Check the trouble symptoms.

NG

Check the harness wire, and repair if necessary.

DBetween diagnosis connector and earth

OK

NG

Replace the MUT-

II.

Measure at diagnosis connecter D-23.

DVoltage between 16 and body earth

OK:System voltage

Check the following connector:D-23

Measure at diagnosis connecter D-23.

DContinuity between terminals 4, 5 and body earth

OK:Continuity

Check the trouble symptoms.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk