service MITSUBISHI MONTERO 2000 Service Service Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 494 of 1839

DIESEL FUEL <4M4> -Service Specifications/Sealant13C-3

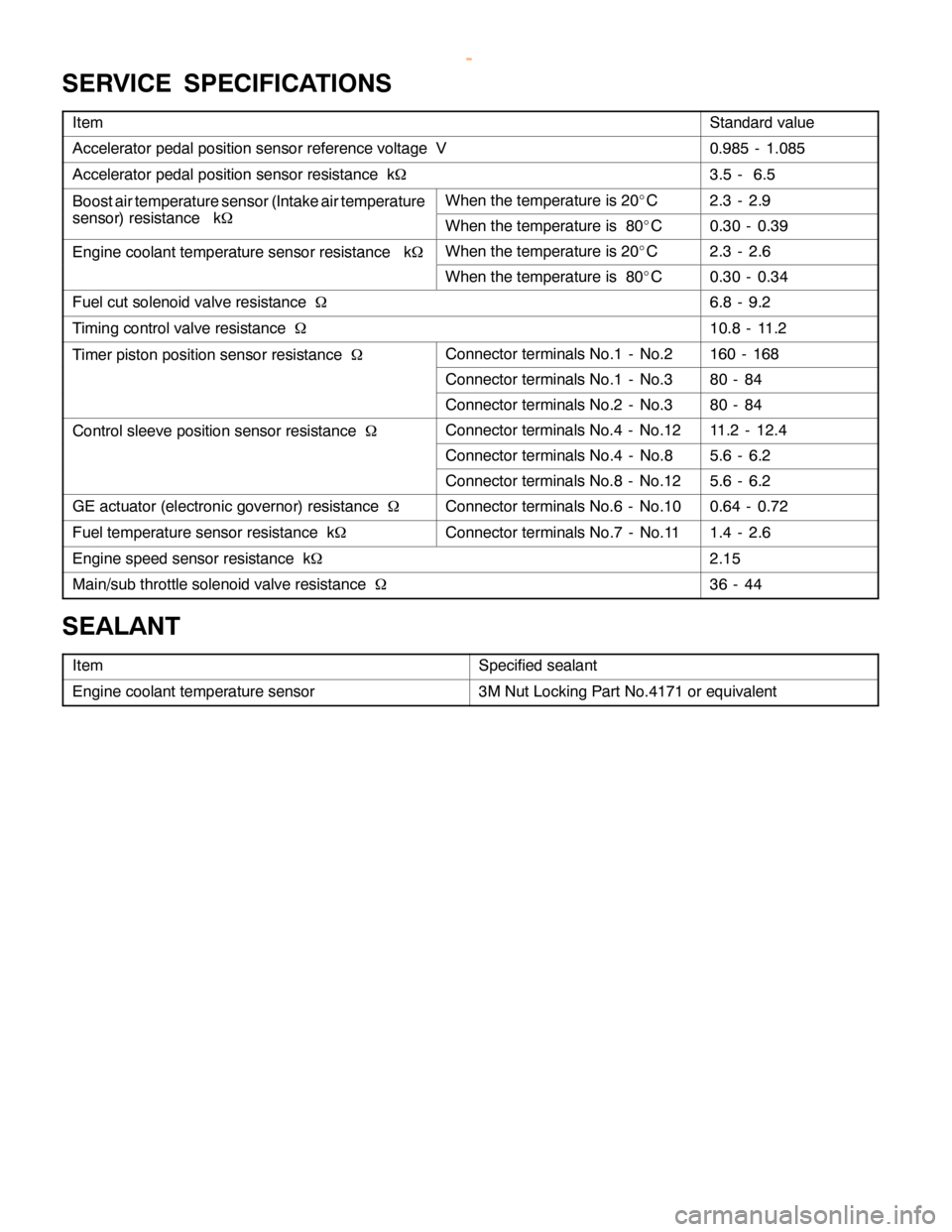

SERVICE SPECIFICATIONS

ItemStandard value

Accelerator pedal position sensor reference voltage V0.985 - 1.085

Accelerator pedal position sensor resistance kW3.5 - 6.5

Boost air temperature sensor (Intake air temperatureWhen the temperature is 20_C2.3 - 2.9

sensor) resistance kWWhen the temperature is 80_C0.30 - 0.39

Engine coolant temperature sensor resistance kWWhen the temperature is 20_C2.3 - 2.6

When the temperature is 80_C0.30 - 0.34

Fuel cut solenoid valve resistanceW6.8 - 9.2

Timing control valve resistanceW10.8 - 11.2

Timer piston position sensor resistanceWConnector terminals No.1 - No.2160 - 168

Connector terminals No.1 - No.380 - 84

Connector terminals No.2 - No.380 - 84

Control sleeve position sensor resistanceWConnector terminals No.4 - No.1211.2 - 12.4

Connector terminals No.4 - No.85.6 - 6.2

Connector terminals No.8 - No.125.6 - 6.2

GE actuator (electronic governor) resistanceWConnector terminals No.6 - No.100.64 - 0.72

Fuel temperature sensor resistance kWConnector terminals No.7 - No.111.4 - 2.6

Engine speed sensor resistance kW2.15

Main/sub throttle solenoid valve resistanceW36 - 44

SEALANT

ItemSpecified sealant

Engine coolant temperature sensor3M Nut Locking Part No.4171 or equivalent

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 513 of 1839

DIESEL FUEL <4M4> -TroubleshootingDIESEL FUEL <4M4> -Troubleshooting13C-22

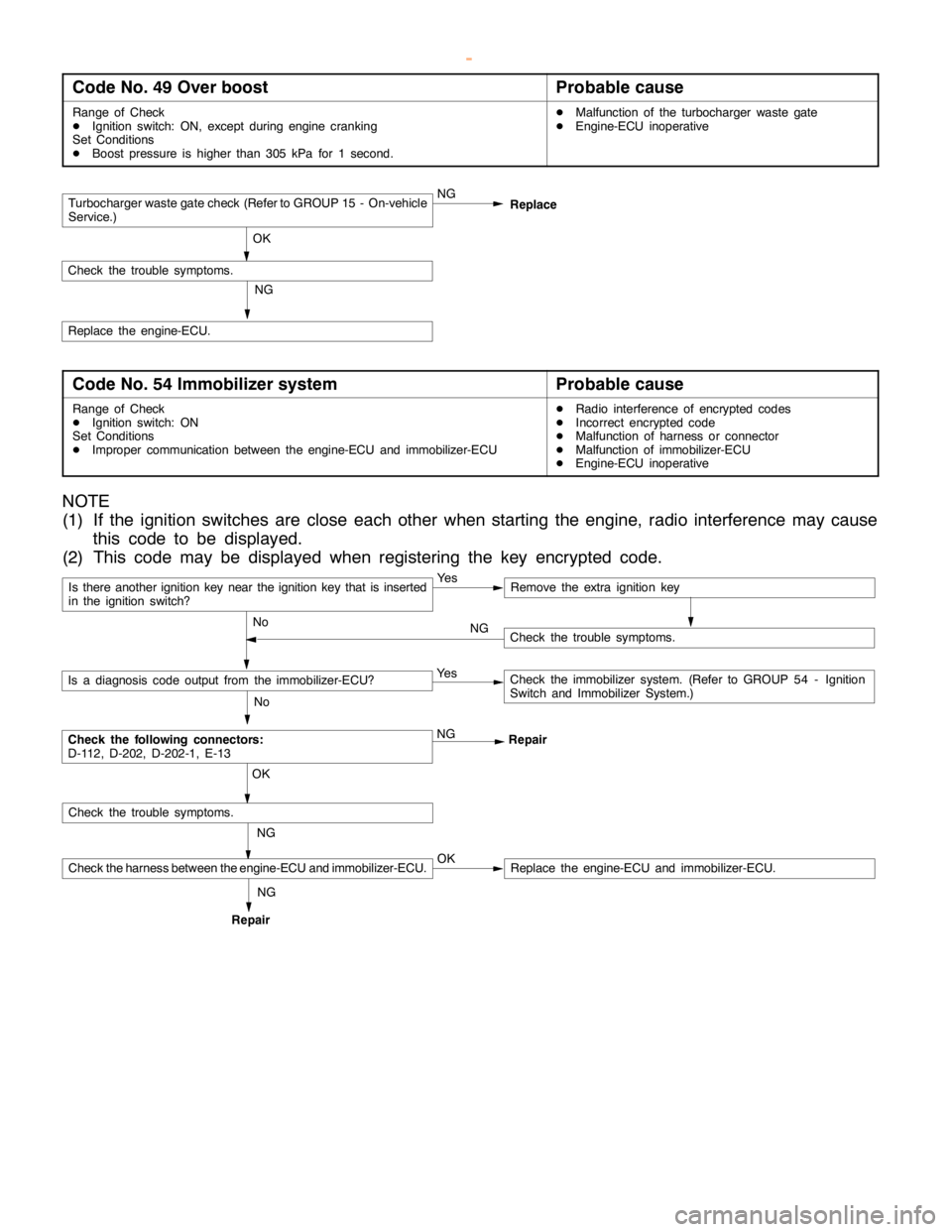

Code No. 49 Over boostProbable cause

Range of Check

DIgnition switch: ON, except duringenginecranking

Set Conditions

DBoost pressure is higher than 305 kPa for 1 second.DMalfunction of the turbocharger waste gate

DEngine-ECU inoperative

Turbocharger waste gate check (Refer to GROUP 15 - On-vehicle

Service.)NG

OK

Check the trouble symptoms.

NG

Replace the engine-ECU.Replace

Code No. 54 Immobilizer systemProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DImproper communication between the engine-ECU and immobilizer-ECUDRadio interference of encrypted codes

DIncorrect encrypted code

DMalfunction of harness or connector

DMalfunction of immobilizer-ECU

DEngine-ECU inoperative

NOTE

(1) If the ignition switches are close each other when starting the engine, radio interference may cause

this code to be displayed.

(2) This code may be displayed when registering the key encrypted code.

Is there another ignition key near the ignition key that is inserted

in the ignition switch?Ye sRemove the extra ignition key

No

Check the following connectors:

D-112, D-202, D-202-1, E-13NG

Repair

No

Is a diagnosis code output from the immobilizer-ECU?Ye sCheck the immobilizer system. (Refer to GROUP 54 - Ignition

Switch and Immobilizer System.)

NG OK

Check the trouble symptoms.

Check the harness between the engine-ECU and immobilizer-ECU.OKReplace the engine-ECU and immobilizer-ECU.

Check the trouble symptoms. NG

RepairNG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 552 of 1839

Service Bulletins

Click on the applicable bookmark to select the Service Bulletin.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 556 of 1839

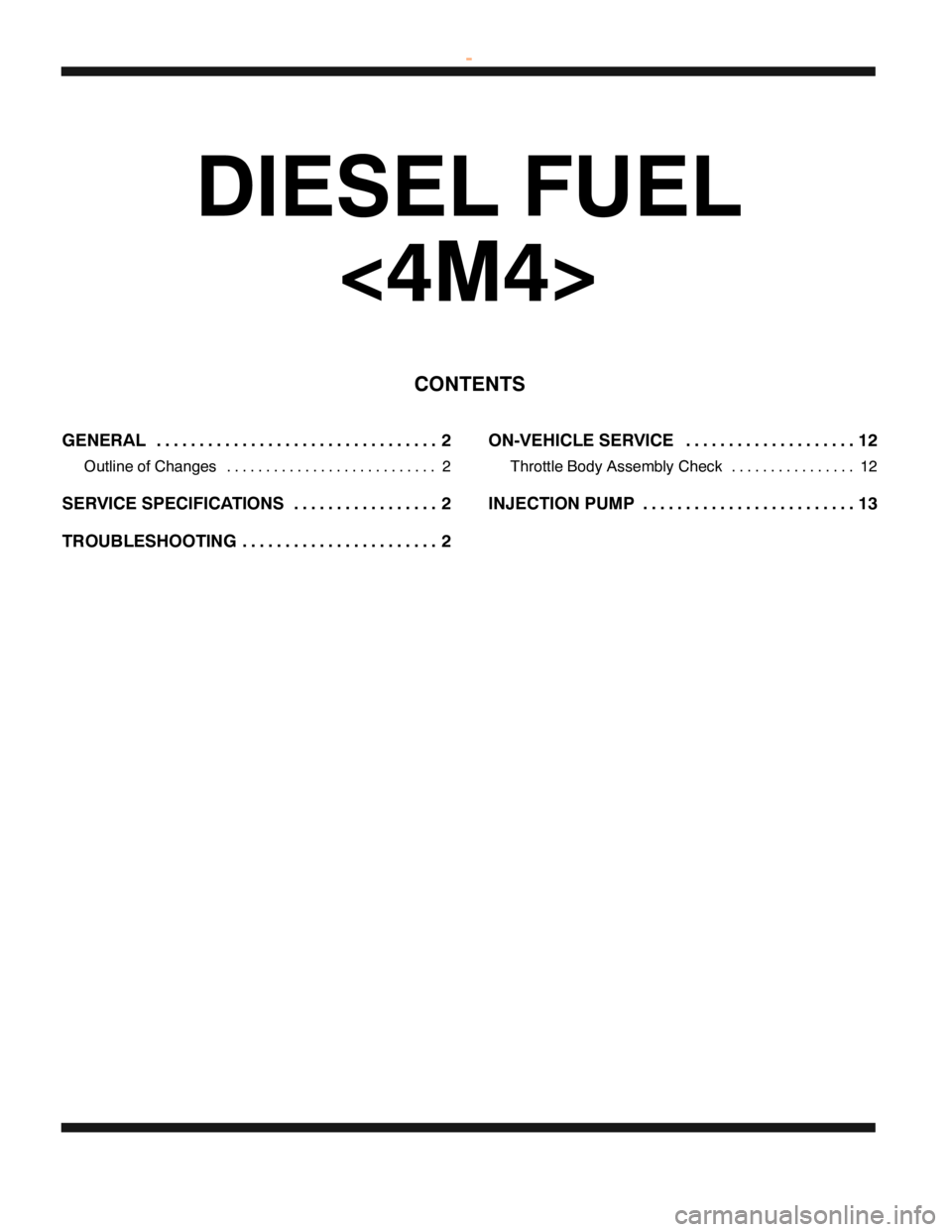

13C-1

DIESEL FUEL

<4M4>

CONTENTS

GENERAL 2.................................

Outline of Changes 2...........................

SERVICE SPECIFICATIONS 2.................

TROUBLESHOOTING 2.......................ON-VEHICLE SERVICE 12....................

Throttle Body Assembly Check 12................

INJECTION PUMP 13.........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 557 of 1839

DIESEL FUEL <4M4> -General/Service Specifications/Troubleshooting13C-2

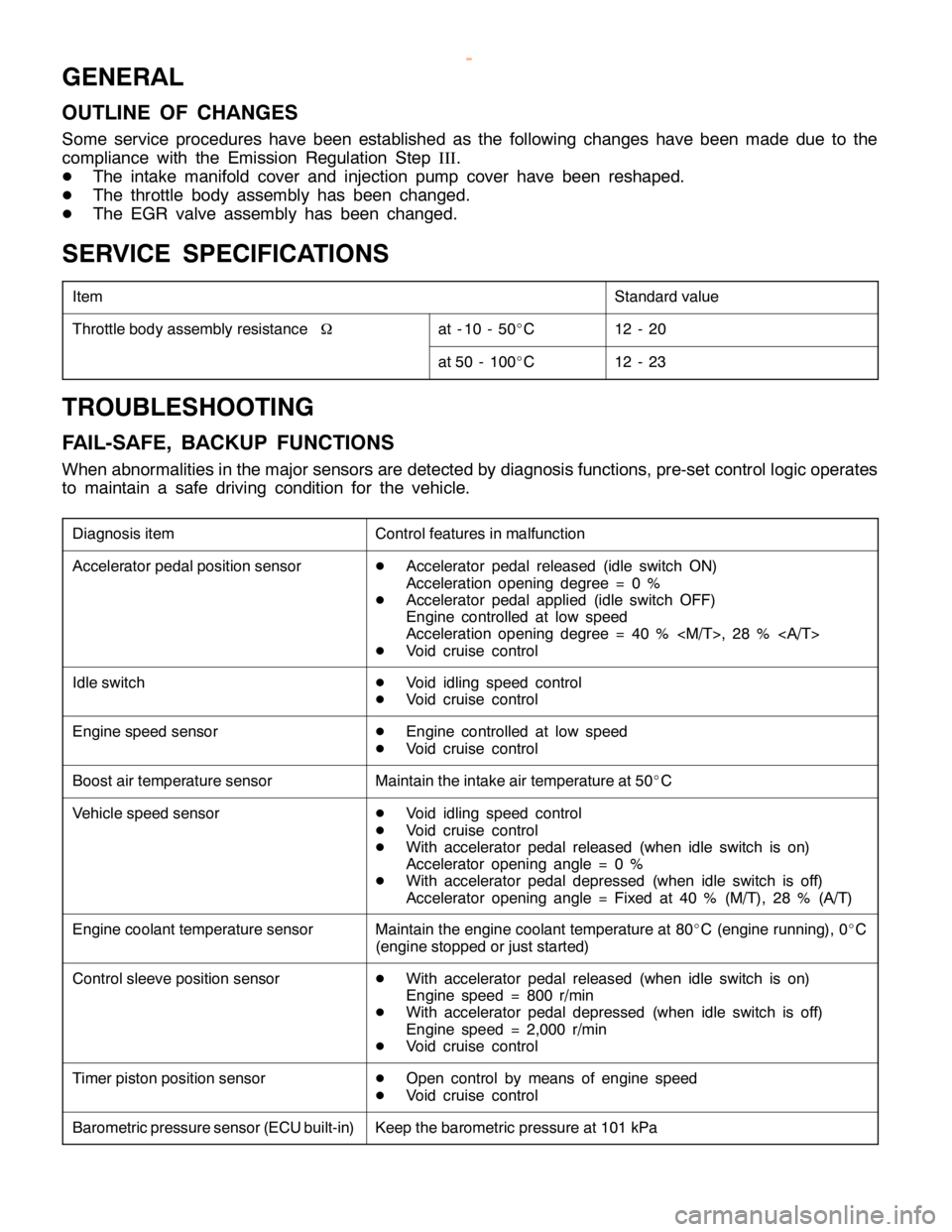

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation StepIII.

DThe intake manifold cover and injection pump cover have been reshaped.

DThe throttle body assembly has been changed.

DThe EGR valve assembly has been changed.

SERVICE SPECIFICATIONS

ItemStandard value

Throttle body assembly resistanceΩat - 10 - 50_C12 - 20

at 50 - 100_C12 - 23

TROUBLESHOOTING

FAIL-SAFE, BACKUP FUNCTIONS

When abnormalities in the major sensors are detected by diagnosis functions, pre-set control logic operates

to maintain a safe driving condition for the vehicle.

Diagnosis itemControl features in malfunction

Accelerator pedal position sensorDAccelerator pedal released (idle switch ON)

Acceleration opening degree = 0 %

DAccelerator pedal applied (idle switch OFF)

Engine controlled at low speed

Acceleration opening degree = 40 %

DVoid cruise control

Idle switchDVoid idling speed control

DVoid cruise control

Engine speed sensorDEngine controlled at low speed

DVoid cruise control

Boost air temperature sensorMaintain the intake air temperature at 50_C

Vehicle speed sensorDVoid idling speed control

DVoid cruise control

DWith accelerator pedal released (when idle switch is on)

Accelerator opening angle = 0 %

DWith accelerator pedal depressed (when idle switch is off)

Accelerator opening angle = Fixed at 40 % (M/T), 28 % (A/T)

Engine coolant temperature sensorMaintain the engine coolant temperature at 80_C (engine running), 0_C

(engine stopped or just started)

Control sleeve position sensorDWith accelerator pedal released (when idle switch is on)

Engine speed = 800 r/min

DWith accelerator pedal depressed (when idle switch is off)

Engine speed = 2,000 r/min

DVoid cruise control

Timer piston position sensorDOpen control by means of engine speed

DVoid cruise control

Barometric pressure sensor (ECU built-in)Keep the barometric pressure at 101 kPa

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 564 of 1839

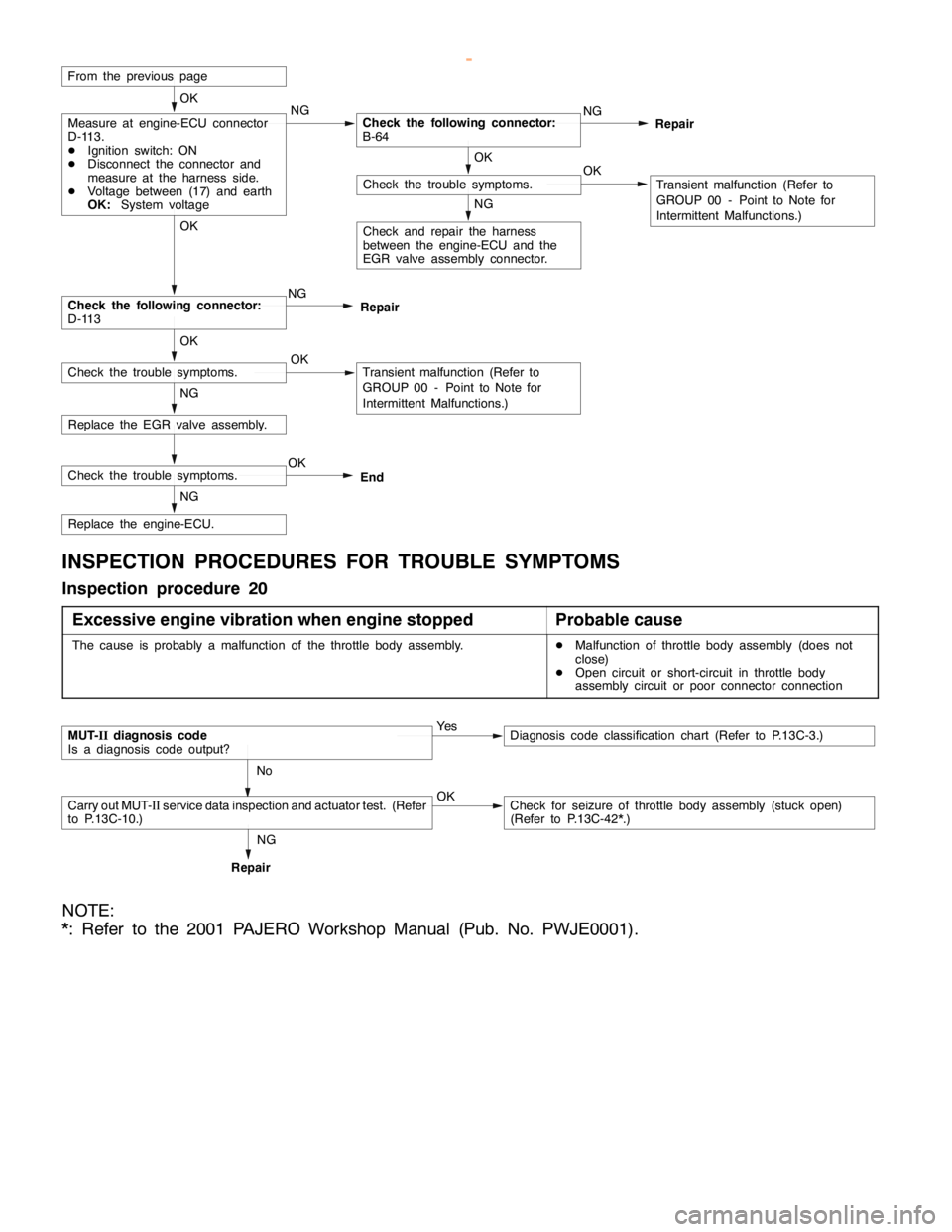

DIESEL FUEL <4M4> -Troubleshooting13C-9

Replace the engine-ECU.

Replace the EGR valve assembly.NG

Check the following connector:

D-113NG OK

Check and repair the harness

between the engine-ECU and the

EGR valve assembly connector.

NG

OKCheck the trouble symptoms.

OK

Transient malfunction (Refer to

GROUP 00 - Point to Note for

Intermittent Malfunctions.)

From the previous page

NGMeasure at engine-ECU connector

D-113.

DIgnition switch: ON

DDisconnect the connector and

measure at the harness side.

DVoltage between (17) and earth

OK:System voltageCheck the following connector:

B-64NG

Repair OK

NG

OKCheck the trouble symptoms.Transient malfunction (Refer to

GROUP 00 - Point to Note for

Intermittent Malfunctions.) OKRepair

Check the trouble symptoms.OK

End

INSPECTION PROCEDURES FOR TROUBLE SYMPTOMS

Inspection procedure 20

Excessive engine vibration when engine stopped

Probable cause

The cause is probably a malfunction of the throttle body assembly.DMalfunction of throttle body assembly (does not

close)

DOpen circuit or short-circuit in throttle body

assembly circuit or poor connector connection

MUT-IIdiagnosis code

Is a diagnosis code output?Ye sDiagnosis code classification chart (Refer to P.13C-3.)

No

Carry out MUT-IIservice data inspection and actuator test. (Refer

to P.13C-10.)OKCheck for seizure of throttle body assembly (stuck open)

(Refer to P.13C-42*.)

RepairNG

NOTE:

*: Refer to the 2001 PAJERO Workshop Manual (Pub. No. PWJE0001).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 590 of 1839

13E-1

MITSUBISHI STABILITY

CONTROL

(MITSUBISHI SC)

CONTENTS

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 4..............

SPECIAL TOOLS 4........................

TROUBLESHOOTING 5....................

ON-VEHICLE SERVICE 18.................

Operation Test of MITSUBISHI SC 18.........Wheel Speed Sensor (FR) Check 18..........

Vehicle Speed Sensor Check 18..............

SC-ECU* 19...............................

G SENSOR 20.............................

WHEEL SPEED SENSOR (FR) 20..........

VEHICLE SPEED SENSOR 20..............

WARNINGS REGARDING SERVICING OF SUPPLEMENTAL RESTRAINT SYSTEM (SRS) EQUIPPED VEHICLES

WARNING!

(1) Improper service or maintenance of any component of the SRS, or any SRS-related component, can lead to personal

injury or death to service personnel (from inadvertent firing of the air bag) or to the driver and passenger (from rendering

the SRS inoperative).

(2) Service or maintenance of any SRS component or SRS-related component must be performed only at an authorized

MITSUBISHI dealer.

(3) MITSUBISHI dealer personnel must thoroughly review this manual, and especially its GROUP 52B - Supplemental

Restraint System (SRS) before beginning any service or maintenance of any component of the SRS or any SRS-related

component.

NOTE

The SRS includes the following components: front impact sensors, SRS-ECU, SRS warning lamp, air bag module, clock spring and

interconnecting wiring. Other SRS-related components (that may have to be removed/installed in connection with SRS service or

maintenance) are indicated in the table of contents by an asterisk (*).

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 603 of 1839

MITSUBISHI SC-Troubleshooting13E-14

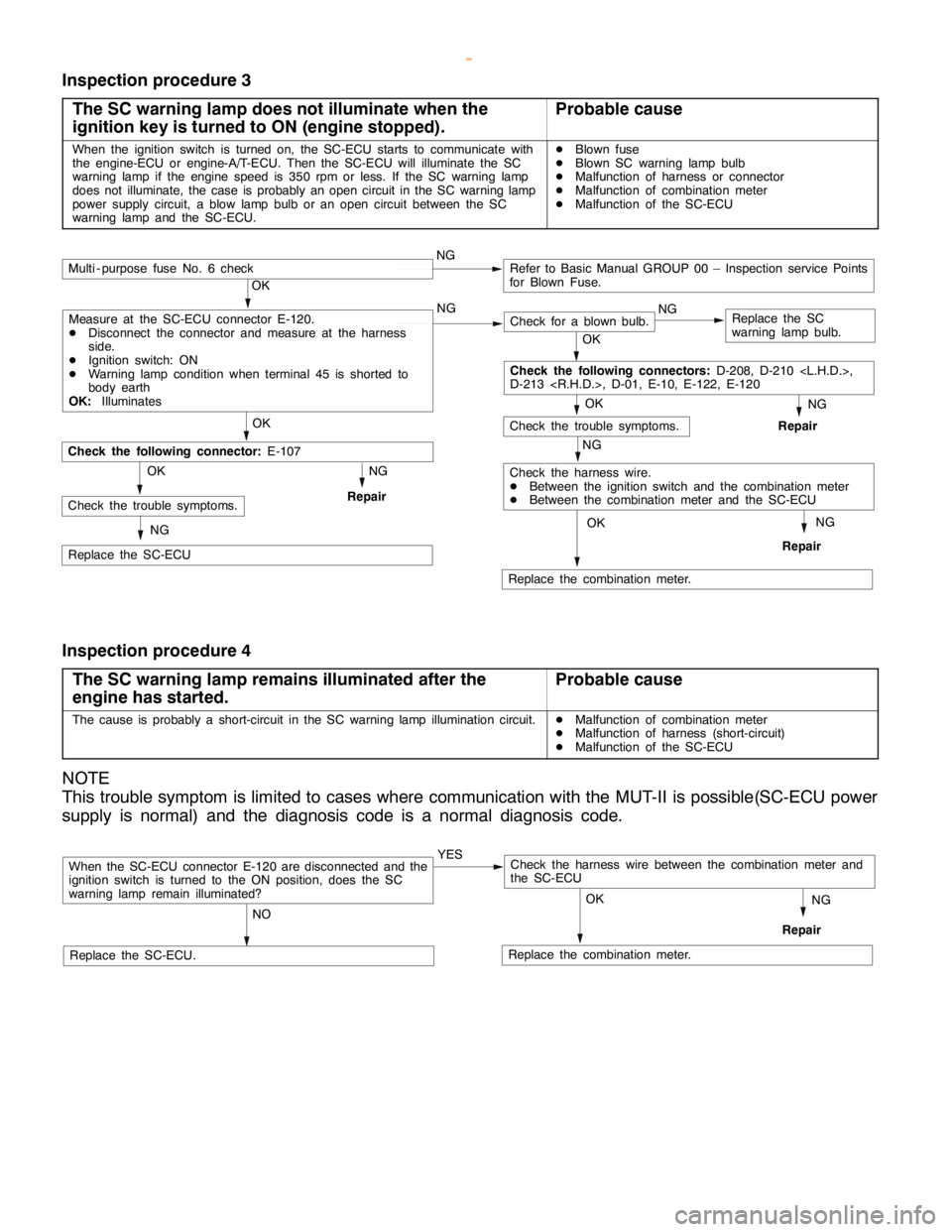

Inspection procedure 3

The SC warning lamp does not illuminate when the

ignition key is turned to ON (engine stopped).

Probable cause

When the ignition switch is turned on, the SC-ECU starts to communicate with

the engine-ECU or engine-A/T-ECU. Then the SC-ECU will illuminate the SC

warning lamp if the engine speed is 350 rpm or less. If the SC warning lamp

does not illuminate, the case is probably an open circuit in the SC warning lamp

power supply circuit, a blow lamp bulb or an open circuit between the SC

warning lamp and the SC-ECU.DBlown fuse

DBlown SC warning lamp bulb

DMalfunction of harness or connector

DMalfunction of combination meter

DMalfunction of the SC-ECU

NG

Replace the combination meter.

NG

Repair

OK

NG

Check for a blown bulb.Replace the SC

warning lamp bulb.

OK

NG

Repair

OK

Check the trouble symptoms.

Multi - purpose fuse No. 6 checkNGRefer to Basic Manual GROUP 00 – Inspection service Points

for Blown Fuse.

NG

Check the harness wire.

DBetween the ignition switch and the combination meter

DBetween the combination meter and the SC-ECU

OK

OK

Replace the SC-ECU

Check the following connector:

E-107

NG

RepairCheck the trouble symptoms.OK

NG

Check the following connectors:

D-208, D-210

D-213

Measure at the SC-ECU connector E-120.

DDisconnect the connector and measure at the harness

side.

DIgnition switch: ON

DWarning lamp condition when terminal 45 is shorted to

body earth

OK:

Illuminates

Inspection procedure 4

The SC warning lamp remains illuminated after the

engine has started.

Probable cause

The cause is probably a short-circuit in the SC warning lamp illumination circuit.DMalfunction of combination meter

DMalfunction of harness (short-circuit)

DMalfunction of the SC-ECU

NOTE

This trouble symptom is limited to cases where communication with the MUT-II is possible(SC-ECU power

supply is normal) and the diagnosis code is a normal diagnosis code.

When the SC-ECU connector E-120 are disconnected and the

ignition switch is turned to the ON position, does the SC

warning lamp remain illuminated?YES

NO

Replace the SC-ECU.Replace the combination meter.

NG

Repair

OK

Check the harness wire between the combination meter and

the SC-ECU

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 607 of 1839

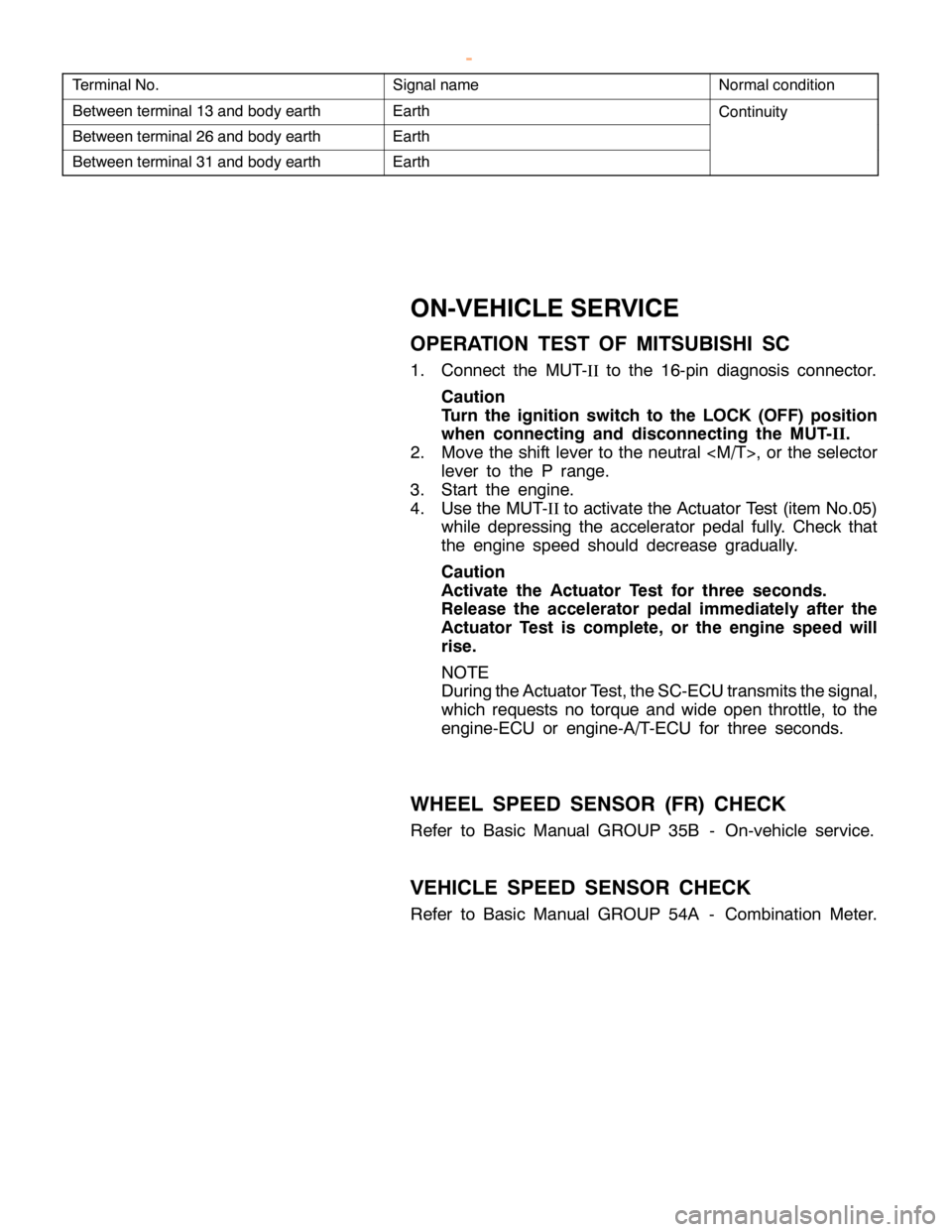

MITSUBISHI SC-Troubleshooting/On-vehicle Service13E-18

Terminal No.Signal nameNormal condition

Between terminal 13 and body earthEarthContinuity

Between terminal 26 and body earthEarth

Between terminal 31 and body earthEarth

ON-VEHICLE SERVICE

OPERATION TEST OF MITSUBISHI SC

1. Connect the MUT-

IIto the 16-pin diagnosis connector.

Caution

Turn the ignition switch to the LOCK (OFF) position

when connecting and disconnecting the MUT-

II.

2. Move the shift lever to the neutral

lever to the P range.

3. Start the engine.

4. Use the MUT-

IIto activate the Actuator Test (item No.05)

while depressing the accelerator pedal fully. Check that

the engine speed should decrease gradually.

Caution

Activate the Actuator Test for three seconds.

Release the accelerator pedal immediately after the

Actuator Test is complete, or the engine speed will

rise.

NOTE

During the Actuator Test, the SC-ECU transmits the signal,

which requests no torque and wide open throttle, to the

engine-ECU or engine-A/T-ECU for three seconds.

WHEEL SPEED SENSOR (FR) CHECK

Refer to Basic Manual GROUP 35B - On-vehicle service.

VEHICLE SPEED SENSOR CHECK

Refer to Basic Manual GROUP 54A - Combination Meter.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 611 of 1839

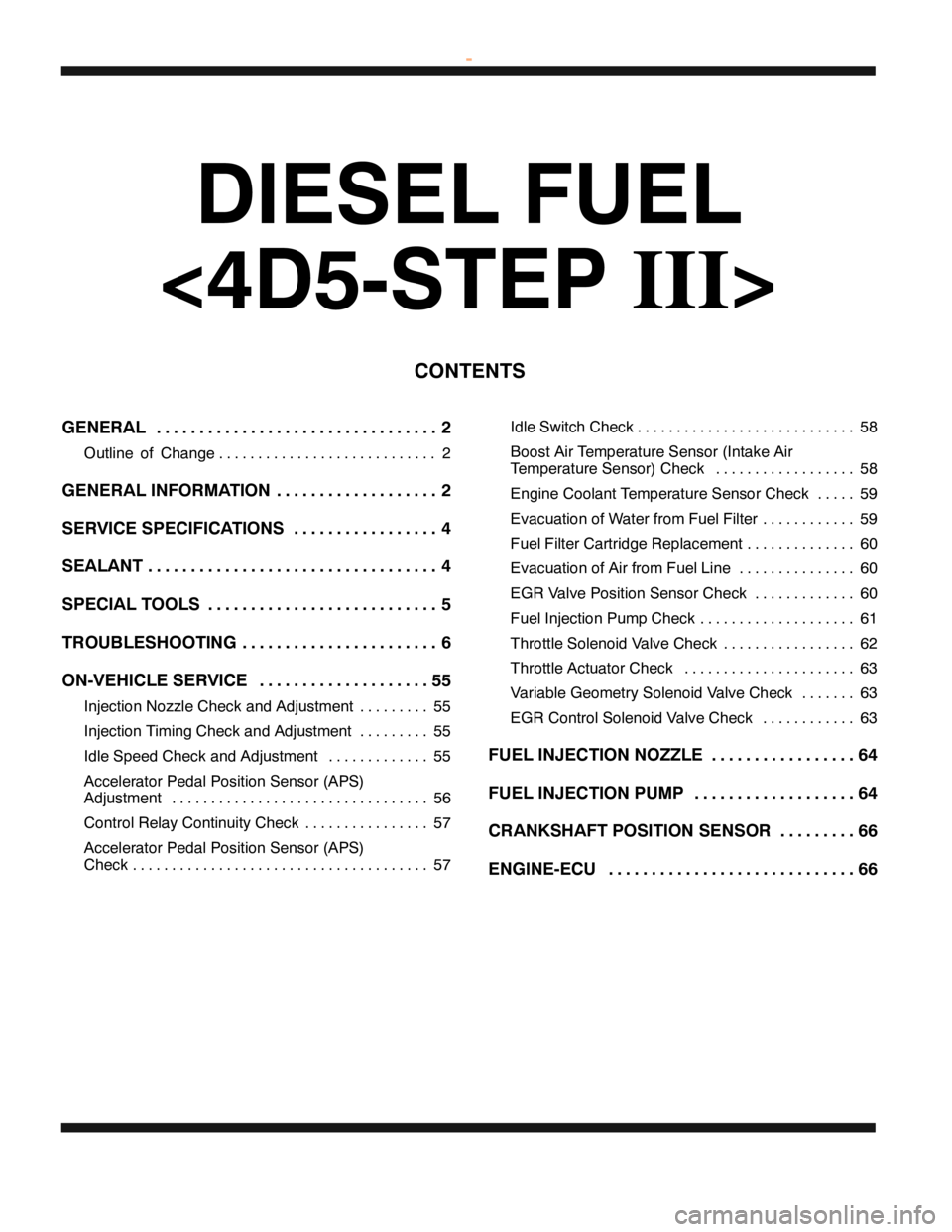

13E-1

DIESEL FUEL

<4D5-STEPIII

>

CONTENTS

GENERAL 2.................................

Outline of Change 2............................

GENERAL INFORMATION 2...................

SERVICE SPECIFICATIONS 4.................

SEALANT 4..................................

SPECIAL TOOLS 5...........................

TROUBLESHOOTING 6.......................

ON-VEHICLE SERVICE 55....................

Injection Nozzle Check and Adjustment 55.........

Injection Timing Check and Adjustment 55.........

Idle Speed Check and Adjustment 55.............

Accelerator Pedal Position Sensor (APS)

Adjustment 56.................................

Control Relay Continuity Check 57................

Accelerator Pedal Position Sensor (APS)

Check 57......................................Idle Switch Check 58............................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 58..................

Engine Coolant Temperature Sensor Check 59.....

Evacuation of Water from Fuel Filter 59............

Fuel Filter Cartridge Replacement 60..............

Evacuation of Air from Fuel Line 60...............

EGR Valve Position Sensor Check 60.............

Fuel Injection Pump Check 61....................

Throttle Solenoid Valve Check 62.................

Throttle Actuator Check 63......................

Variable Geometry Solenoid Valve Check 63.......

EGR Control Solenoid Valve Check 63............

FUEL INJECTION NOZZLE 64.................

FUEL INJECTION PUMP 64...................

CRANKSHAFT POSITION SENSOR 66.........

ENGINE-ECU 66.............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk