service MITSUBISHI MONTERO 2000 Service Manual PDF

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 721 of 1839

INTAKE AND EXHAUST -Turbocharger and Exhaust

Manifold <4M4>15-15

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

Check the following points; replace the part if a problem is

found.

EXHAUST MANIFOLD CHECK

1. Check for damage or cracking of any part.

2. Using a straight edge and a thickness gauge, check for

distortion of the cylinder head installation surface.

Standard value: 0.15 mm or less

Limit: 0.20 mm

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 733 of 1839

15-1

INTAKE AND

EXHAUST

CONTENTS

GENERAL 2.................................

Outline of Changes 2...........................

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

ON-VEHICLE SERVICE 4.....................

Turbocharger Supercharging Check 4............

Supercharging Pressure Control

System Check 5...............................

Variable Geometry Actuator Check 6.............Variable Geometry Solenoid Valve Check 6.......

INTAKE MANIFOLD AND THROTTLE BODY

<4M4> 7.....................................

INTAKE MANIFOLD AND EXHAUST

MANIFOLD, THROTTLE BODY AND

TURBOCHARGER <4D5> 10..................

TURBOCHARGER AND EXHAUST

MANIFOLD <4M4> 12........................

EXHAUST PIPE AND MAIN MUFFLER

<4D5> 14....................................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 735 of 1839

INTAKE AND EXHAUST -General Information/Service Specifications/Sealant15-3

At starting and driving at low speed, the duty control

value of the variable geometry solenoid valve is

increased to apply the vacuum pressure of the

vacuum pump to the variable geometry actuator.

Applying the vacuum pressure to the variable

geometry actuator pulls the actuator rod so that

it can move towards the direction of closing the

variable nozzle of the variable geometry

turbocharger. As closing the nozzle reduces the

exhaust gas mass, the speed of exhaust gas flow

will be increased and efficiency will be improved.

Since the characteristic of boost pressure becomes

a low speed type, boost pressure will suddenly

rise from low speed.

At driving at high speed, the duty control value

of the variable geometry solenoid valve is

decreased to reduce the vacuum pressure from

the vacuum pump so that the actuator rod can

return to the deactivated status and move towards

the direction of opening the nozzle of the variable

geometry turbocharger.Opening the nozzle allows the characteristic of

boost pressure to become a high speed type so

that the appropriate boost pressure can be

maintained.

Therefore, boost pressure can be controlled by

appropriate duty control of the variable geometry

solenoid valve. The engine-ECU calculates the

correct boost pressure based on the engine speed

and fuel injection amount. Furthermore, the duty

control of the variable geometry solenoid valve is

given feedback of the signals from the variable

geometry control pressure sensor and the boost

pressure sensor so that the variable nozzle opening

angle of the variable geometry turbocharger can

be quickly adjusted to obtain the desired boost

pressure.

SERVICE SPECIFICATIONS

ItemsStandard value

Variable geometry actuator activation vacuum

(Approximately 1 mm stroke) kPaApproximately 10.5 - 12.5

Variable geometry solenoid valve coil resistance

(at 20°C)Ω29 - 35

SEALANT

ItemSpecified sealantRemarks

Thread of the intake manifold mounting

bolts3M Stud Locking No.4170 or equivalentAnaerobic sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 745 of 1839

INTAKE AND EXHAUST -Turbocharger and Exhaust

Manifold <4M4>15-13

INSTALLATION SERVICE POINT

"AATURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 749 of 1839

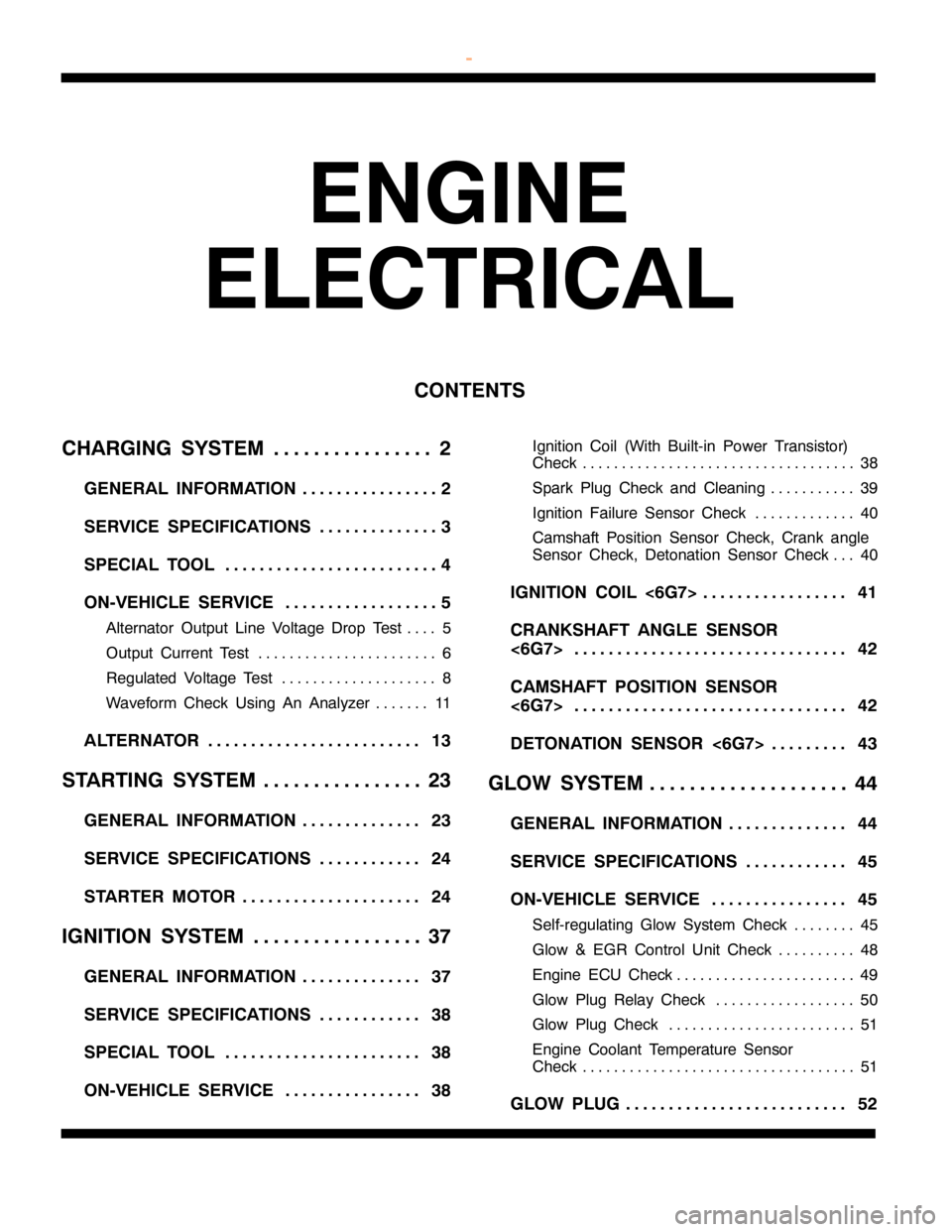

16-1

ENGINE

ELECTRICAL

CONTENTS

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3..............

SPECIAL TOOL 4.........................

ON-VEHICLE SERVICE 5..................

Alternator Output Line Voltage Drop Test 5....

Output Current Test 6.......................

Regulated Voltage Test 8....................

Waveform Check Using An Analyzer 11.......

ALTERNATOR 13.........................

STARTING SYSTEM 23................

GENERAL INFORMATION 23..............

SERVICE SPECIFICATIONS 24............

STARTER MOTOR 24.....................

IGNITION SYSTEM 37.................

GENERAL INFORMATION 37..............

SERVICE SPECIFICATIONS 38............

SPECIAL TOOL 38.......................

ON-VEHICLE SERVICE 38................

Ignition Coil (With Built-in Power Transistor)

Check 38...................................

Spark Plug Check and Cleaning 39...........

Ignition Failure Sensor Check 40.............

Camshaft Position Sensor Check, Crank angle

Sensor Check, Detonation Sensor Check 40...

IGNITION COIL <6G7> 41.................

CRANKSHAFT ANGLE SENSOR

<6G7> 42................................

CAMSHAFT POSITION SENSOR

<6G7> 42................................

DETONATION SENSOR <6G7> 43.........

GLOW SYSTEM 44....................

GENERAL INFORMATION 44..............

SERVICE SPECIFICATIONS 45............

ON-VEHICLE SERVICE 45................

Self-regulating Glow System Check 45........

Glow & EGR Control Unit Check 48..........

Engine ECU Check 49.......................

Glow Plug Relay Check 50..................

Glow Plug Check 51........................

Engine Coolant Temperature Sensor

Check 51...................................

GLOW PLUG 52..........................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 803 of 1839

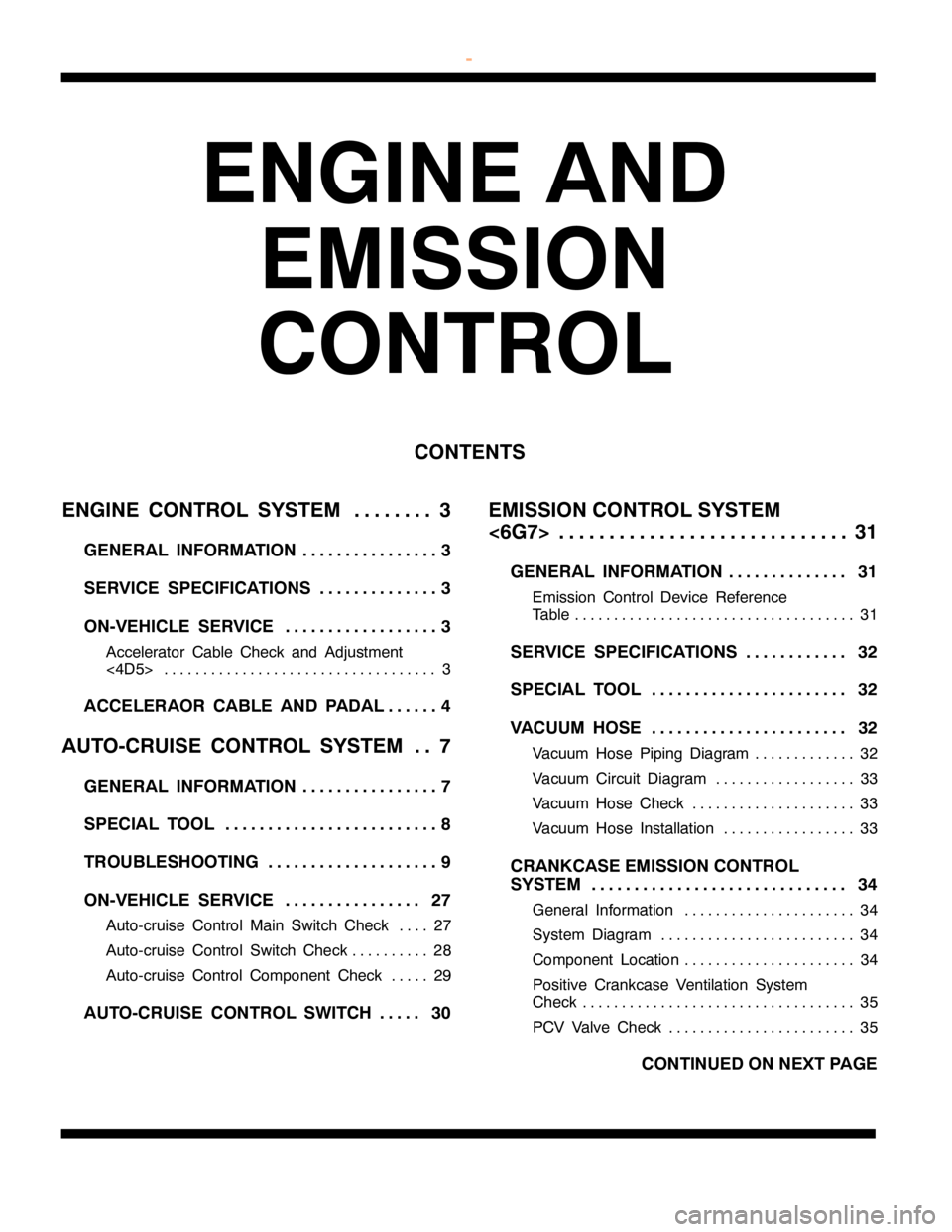

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 3........

GENERAL INFORMATION 3................

SERVICE SPECIFICATIONS 3..............

ON-VEHICLE SERVICE 3..................

Accelerator Cable Check and Adjustment

<4D5> 3...................................

ACCELERAOR CABLE AND PADAL 4......

AUTO-CRUISE CONTROL SYSTEM 7..

GENERAL INFORMATION 7................

SPECIAL TOOL 8.........................

TROUBLESHOOTING 9....................

ON-VEHICLE SERVICE 27................

Auto-cruise Control Main Switch Check 27....

Auto-cruise Control Switch Check 28..........

Auto-cruise Control Component Check 29.....

AUTO-CRUISE CONTROL SWITCH 30.....

EMISSION CONTROL SYSTEM

<6G7> 31.............................

GENERAL INFORMATION 31..............

Emission Control Device Reference

Table 31....................................

SERVICE SPECIFICATIONS 32............

SPECIAL TOOL 32.......................

VACUUM HOSE 32.......................

Vacuum Hose Piping Diagram 32.............

Vacuum Circuit Diagram 33..................

Vacuum Hose Check 33.....................

Vacuum Hose Installation 33.................

CRANKCASE EMISSION CONTROL

SYSTEM 34..............................

General Information 34......................

System Diagram 34.........................

Component Location 34......................

Positive Crankcase Ventilation System

Check 35...................................

PCV Valve Check 35........................

CONTINUED ON NEXT PAGE

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

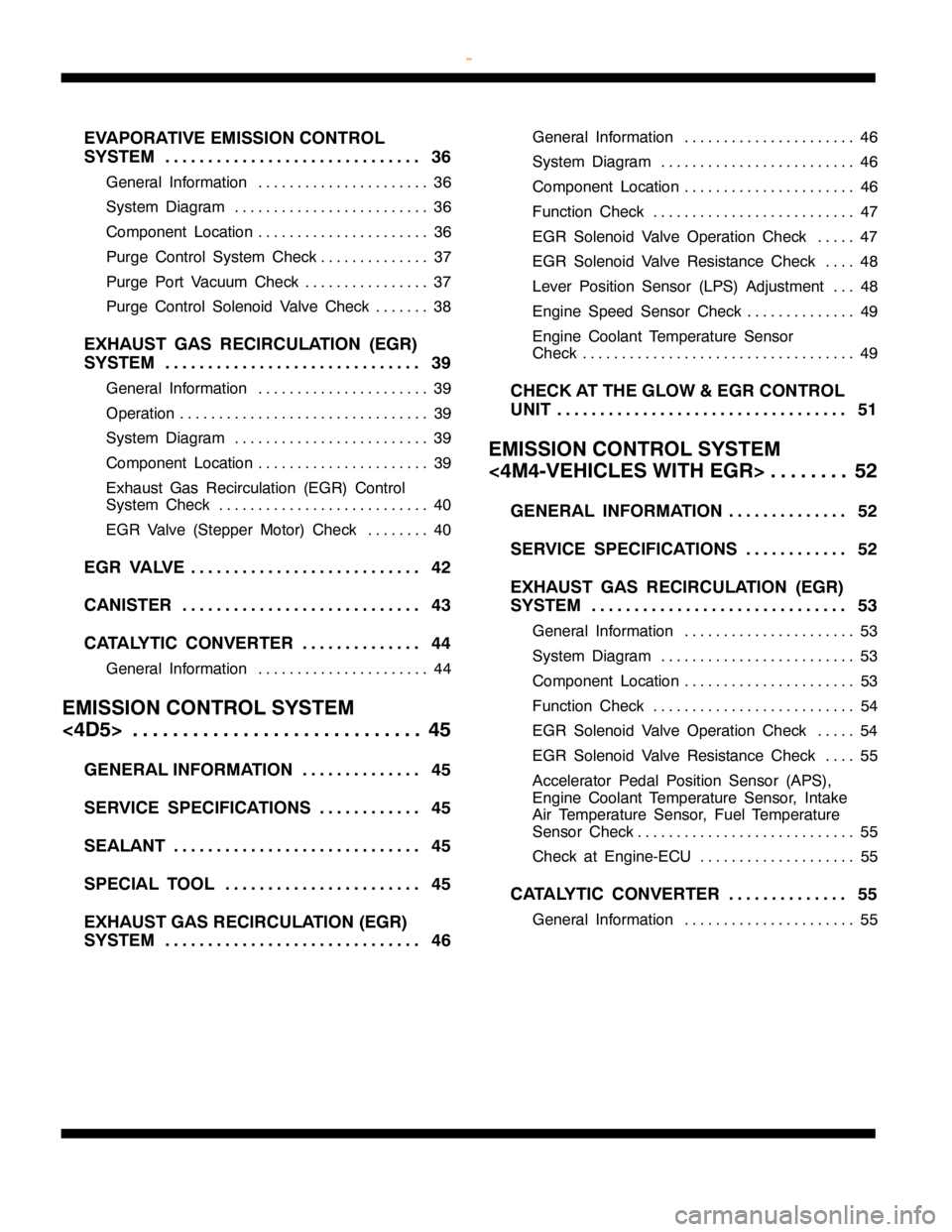

Page 804 of 1839

17-2

EVAPORATIVE EMISSION CONTROL

SYSTEM 36..............................

General Information 36......................

System Diagram 36.........................

Component Location 36......................

Purge Control System Check 37..............

Purge Port Vacuum Check 37................

Purge Control Solenoid Valve Check 38.......

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 39..............................

General Information 39......................

Operation 39................................

System Diagram 39.........................

Component Location 39......................

Exhaust Gas Recirculation (EGR) Control

System Check 40...........................

EGR Valve (Stepper Motor) Check 40........

EGR VALVE 42...........................

CANISTER 43............................

CATALYTIC CONVERTER 44..............

General Information 44......................

EMISSION CONTROL SYSTEM

<4D5> 45.............................

GENERAL INFORMATION 45..............

SERVICE SPECIFICATIONS 45............

SEALANT 45.............................

SPECIAL TOOL 45.......................

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 46..............................

General Information 46......................

System Diagram 46.........................

Component Location 46......................

Function Check 47..........................

EGR Solenoid Valve Operation Check 47.....

EGR Solenoid Valve Resistance Check 48....

Lever Position Sensor (LPS) Adjustment 48...

Engine Speed Sensor Check 49..............

Engine Coolant Temperature Sensor

Check 49...................................

CHECK AT THE GLOW & EGR CONTROL

UNIT 51..................................

EMISSION CONTROL SYSTEM

<4M4-VEHICLES WITH EGR> 52........

GENERAL INFORMATION 52..............

SERVICE SPECIFICATIONS 52............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 53..............................

General Information 53......................

System Diagram 53.........................

Component Location 53......................

Function Check 54..........................

EGR Solenoid Valve Operation Check 54.....

EGR Solenoid Valve Resistance Check 55....

Accelerator Pedal Position Sensor (APS),

Engine Coolant Temperature Sensor, Intake

Air Temperature Sensor, Fuel Temperature

Sensor Check 55............................

Check at Engine-ECU 55....................

CATALYTIC CONVERTER 55..............

General Information 55......................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

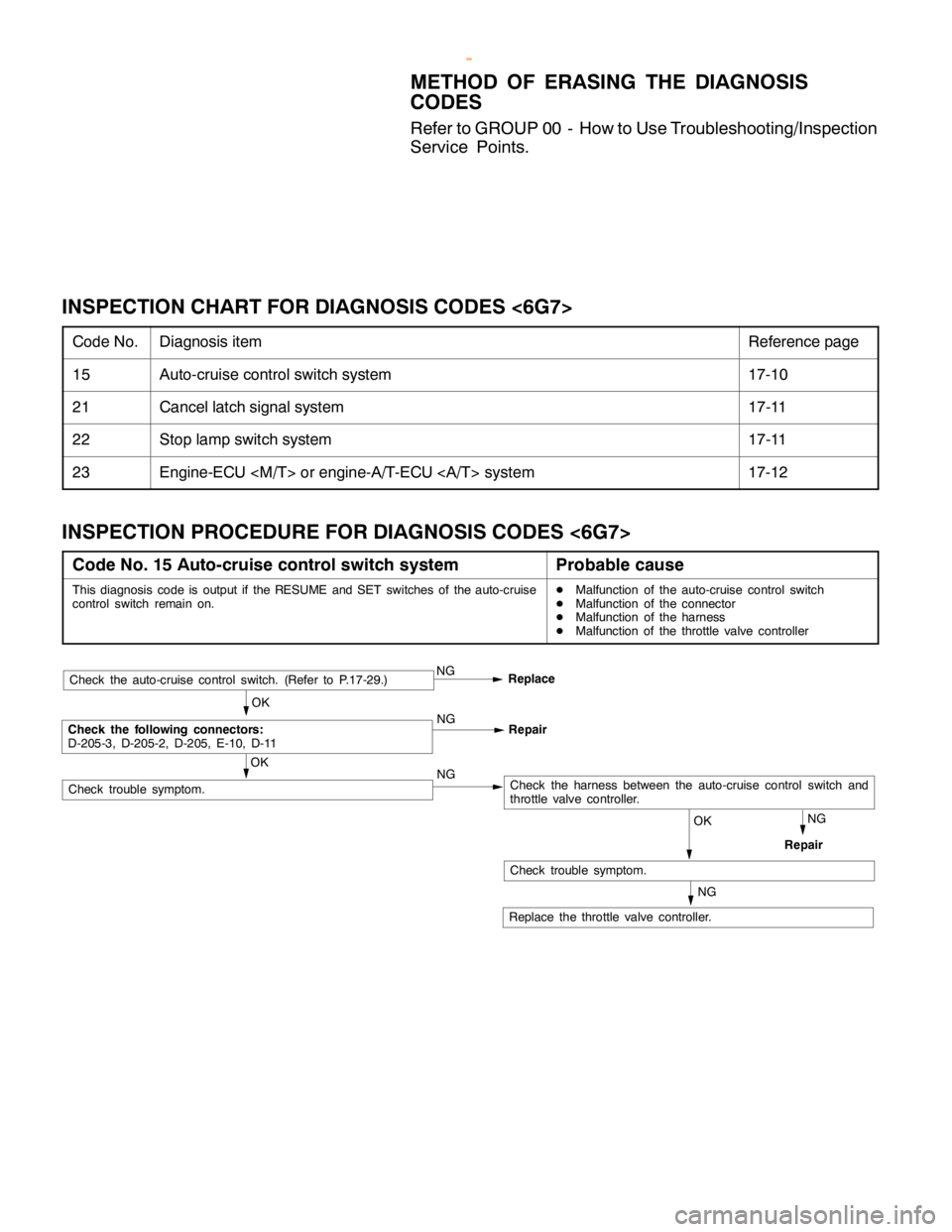

Page 812 of 1839

ENGINE AND EMISSION CONTROL -Auto-cruise Control System17-10

METHOD OF ERASING THE DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

INSPECTION CHART FOR DIAGNOSIS CODES <6G7>

Code No.Diagnosis itemReference page

15Auto-cruise control switch system17-10

21Cancel latch signal system17-11

22Stop lamp switch system17-11

23Engine-ECU

INSPECTION PROCEDURE FOR DIAGNOSIS CODES <6G7>

Code No. 15 Auto-cruise control switch systemProbable cause

This diagnosis code is output if the RESUME and SET switches of the auto-cruise

control switch remain on.DMalfunction of the auto-cruise control switch

DMalfunction of the connector

DMalfunction of the harness

DMalfunction of the throttle valve controller

Repair

Check the auto-cruise control switch. (Refer to P.17-29.)NG

Replace

OK

Check the following connectors:

D-205-3, D-205-2, D-205, E-10, D-11NG

Repair

NGCheck the harness between the auto-cruise control switch and

throttle valve controller.

NG

OK

Replace the throttle valve controller.

OK

Check trouble symptom.

Check trouble symptom.

NG

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 854 of 1839

ENGINE AND EMISSION CONTROL -Emission Control System

<4M4-Vehicles with EGR>17-52

EMISSION CONTROL SYSTEM <4M4-VEHICLES WITH

EGR>

GENERAL INFORMATION

The electronically-controlled EGR system and the

fuel injection timing control system (load timer)

reduce the level of exhaust gases (NO

x).

ItemsNameSpecification

Exhaust emission

control systemExhaust gas recirculation system

DEGR valve

DEGR solenoid valve No.1

DEGR solenoid valve No.2Electronically-controlled EGR system

Single type

Duty cycle solenoid valve

ON-OFFsolenoid valve

SERVICE SPECIFICATIONS

ItemsStandard value

EGR solenoid valve No.1/No. 2 resistance (at 20_C)W36 - 44

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 859 of 1839

17-1

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL SYSTEM 2........

GENERAL 2...............................

Outline of Change 2.........................

EMISSION CONTROL SYSTEM

<4D5-STEPIII>

2 .....................................

GENERAL 2...............................

Outline of Changes 2........................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2..............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 3................................EGR VALVE AND EGR COOLER 6.........

CATALYTIC CONVERTER 8................

EMISSION CONTROL SYSTEM <4M4>

9 .....................................

GENERAL 9...............................

Outline of Change 9.........................

SERVICE SPECIFICATIONS 9..............

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 9................................

EGR VALVE AND EGR COOLER 11........

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk