service MITSUBISHI MONTERO 2000 Service Workshop Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 2000, Model line: MONTERO, Model: MITSUBISHI MONTERO 2000Pages: 1839, PDF Size: 29.19 MB

Page 612 of 1839

DIESEL FUEL <4D5-stepIII>-General/General Information13E-2

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

DWhen an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

DWhen an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

DThe RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 614 of 1839

DIESEL FUEL <4D5-stepIII>-Service Specifications/Sealant13E-4

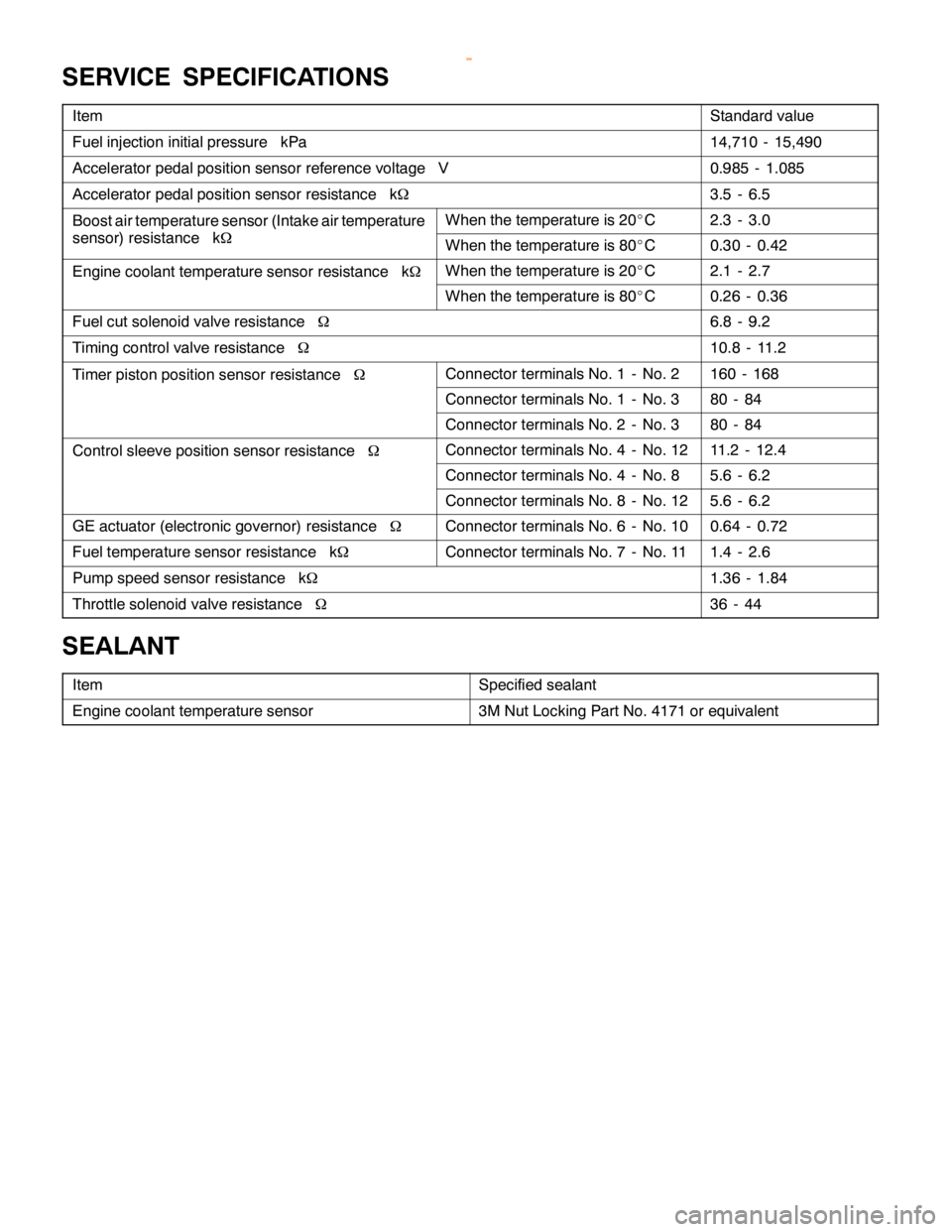

SERVICE SPECIFICATIONS

ItemStandard value

Fuel injection initial pressure kPa14,710 - 15,490

Accelerator pedal position sensor reference voltage V0.985 - 1.085

Accelerator pedal position sensor resistance kΩ3.5 - 6.5

Boost air temperature sensor (Intake air temperature

)itkΩ

When the temperature is 20_C2.3 - 3.0p(p

sensor) resistance kΩWhen the temperature is 80_C0.30 - 0.42

Engine coolant temperature sensor resistance kΩWhen the temperature is 20_C2.1 - 2.7gp

When the temperature is 80_C0.26 - 0.36

Fuel cut solenoid valve resistanceΩ6.8 - 9.2

Timing control valve resistanceΩ10.8 - 11.2

Timer piston position sensor resistanceΩConnector terminals No. 1 - No. 2160 - 168pp

Connector terminals No. 1 - No. 380 - 84

Connector terminals No. 2 - No. 380 - 84

Control sleeve position sensor resistanceΩConnector terminals No. 4 - No. 1211.2 - 12.4p

Connector terminals No. 4 - No. 85.6 - 6.2

Connector terminals No. 8 - No. 125.6 - 6.2

GE actuator (electronic governor) resistanceΩConnector terminals No. 6 - No. 100.64 - 0.72

Fuel temperature sensor resistance kΩConnector terminals No. 7 - No. 111.4 - 2.6

Pump speed sensor resistance kΩ1.36 - 1.84

Throttle solenoid valve resistanceΩ36 - 44

SEALANT

ItemSpecified sealant

Engine coolant temperature sensor3M Nut Locking Part No. 4171 or equivalent

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 634 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-24

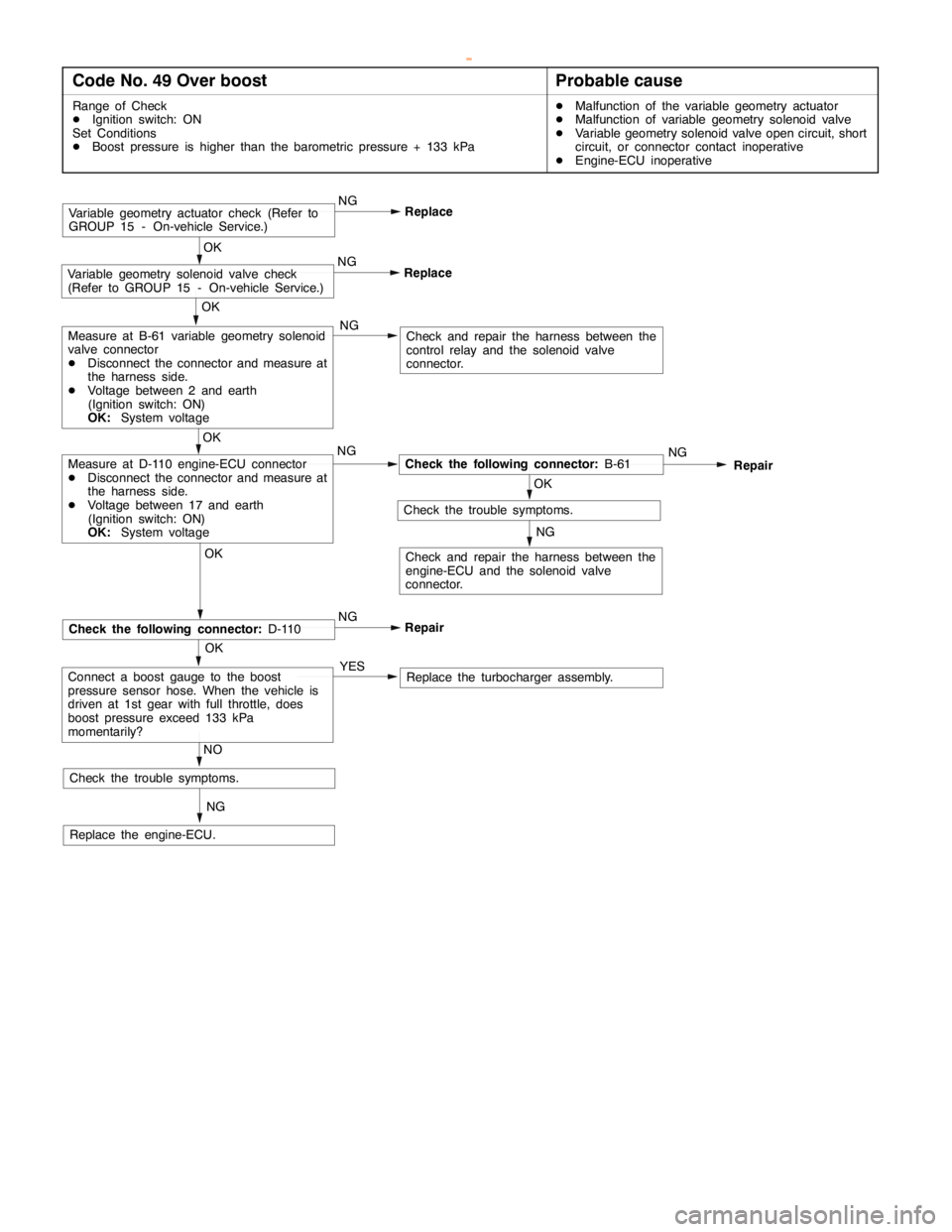

Code No. 49 Over boostProbable cause

Range of Check

DIgnition switch: ON

Set Conditions

DBoost pressure is higher than the barometric pressure + 133 kPaDMalfunction of the variable geometry actuator

DMalfunction of variable geometry solenoid valve

DVariable geometry solenoid valve open circuit, short

circuit, or connector contact inoperative

DEngine-ECU inoperative

OKOK

Check and repair the harness between the

control relay and the solenoid valve

connector.

Replace the engine-ECU.OK

ReplaceVariable geometry solenoid valve check

(Refer to GROUP 15 - On-vehicle Service.)

Check the trouble symptoms.NG

NG

Check the following connector:B-61NG

Repair

OK

Check the trouble symptoms.

NG

NGMeasure at D-110 engine-ECU connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 17 and earth

(Ignition switch: ON)

OK:System voltageOK

Measure at B-61 variable geometry solenoid

valve connector

DDisconnect the connector and measure at

the harness side.

DVoltage between 2 and earth

(Ignition switch: ON)

OK:System voltage

Check and repair the harness between the

engine-ECU and the solenoid valve

connector.

ReplaceVariable geometry actuator check (Refer to

GROUP 15 - On-vehicle Service.)NG

OK

Repair

Check the following connector:D-110NG

NG

Replace the turbocharger assembly. YESConnect a boost gauge to the boost

pressure sensor hose. When the vehicle is

driven at 1st gear with full throttle, does

boost pressure exceed 133 kPa

momentarily?

NO

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 648 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-38

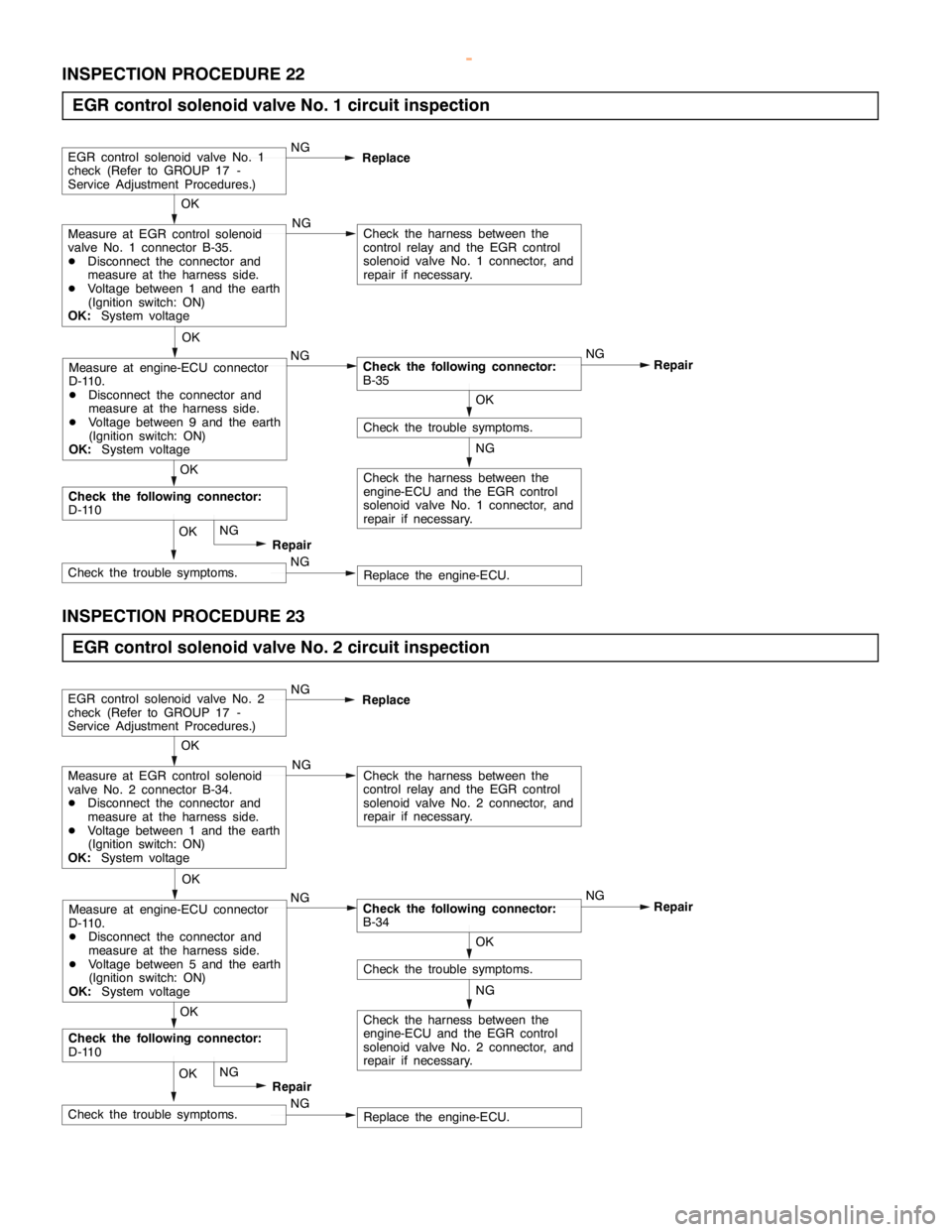

INSPECTION PROCEDURE 22

EGR control solenoid valve No. 1 circuit inspection

NG

Check the harness between the

engine-ECU and the EGR control

solenoid valve No. 1 connector, and

repair if necessary.

OK

Check the trouble symptoms.

OK

Measure at EGR control solenoid

valve No. 1 connector B-35.

DDisconnect the connector and

measure at the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:System voltage

NG

Check the following connector:

B-35NG

Repair NG

Check the harness between the

control relay and the EGR control

solenoid valve No. 1 connector, and

repair if necessary.

EGR control solenoid valve No. 1

check (Refer to GROUP 17 -

Service Adjustment Procedures.)NG

Replace

OK

Measure at engine-ECU connector

D-110.

DDisconnect the connector and

measure at the harness side.

DVoltage between 9 and the earth

(Ignition switch: ON)

OK:System voltage

NG

Replace the engine-ECU. NGCheck the trouble symptoms.OK

Repair

Check the following connector:

D-110OK

INSPECTION PROCEDURE 23

EGR control solenoid valve No. 2 circuit inspection

NG

Check the harness between the

engine-ECU and the EGR control

solenoid valve No. 2 connector, and

repair if necessary.

OK

Check the trouble symptoms.

OK

Measure at EGR control solenoid

valve No. 2 connector B-34.

DDisconnect the connector and

measure at the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

OK:System voltage

NG

Check the following connector:

B-34NG

Repair NG

Check the harness between the

control relay and the EGR control

solenoid valve No. 2 connector, and

repair if necessary.

EGR control solenoid valve No. 2

check (Refer to GROUP 17 -

Service Adjustment Procedures.)NG

Replace

OK

Measure at engine-ECU connector

D-110.

DDisconnect the connector and

measure at the harness side.

DVoltage between 5 and the earth

(Ignition switch: ON)

OK:System voltage

NG

Replace the engine-ECU. NGCheck the trouble symptoms.OK

Repair

Check the following connector:

D-110OK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 649 of 1839

DIESEL FUEL <4D5-stepIII>-Troubleshooting13E-39

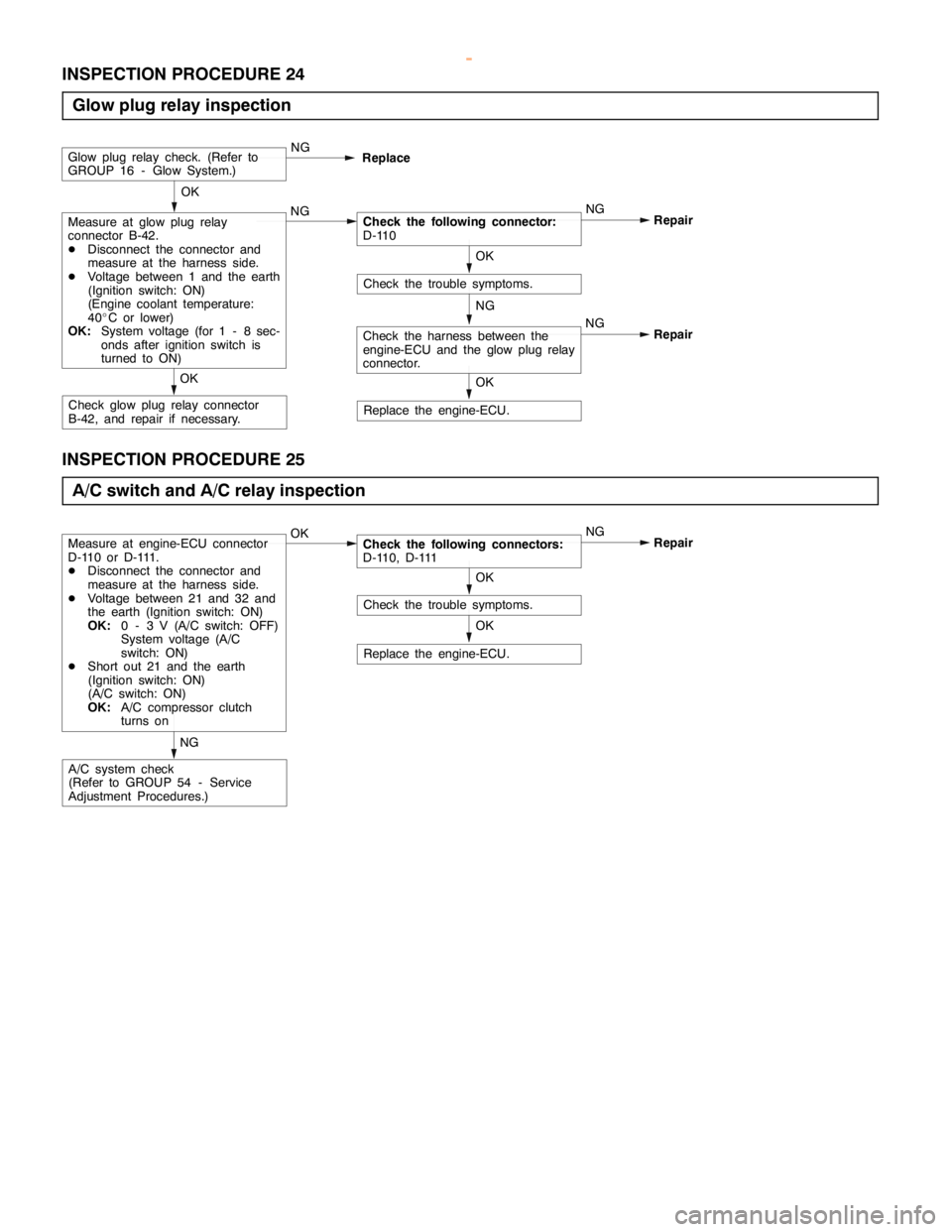

INSPECTION PROCEDURE 24

Glow plug relay inspection

NG

Replace the engine-ECU.

OK

Check the trouble symptoms.

OK

Measure at glow plug relay

connector B-42.

DDisconnect the connector and

measure at the harness side.

DVoltage between 1 and the earth

(Ignition switch: ON)

(Engine coolant temperature:

40_C or lower)

OK:System voltage (for 1 - 8 sec-

onds after ignition switch is

turned to ON)NGCheck the following connector:

D-110NG

Repair

Glow plug relay check. (Refer to

GROUP 16 - Glow System.)NG

Replace

Check glow plug relay connector

B-42, and repair if necessary.OK

OK

Check the harness between the

engine-ECU and the glow plug relay

connector.NG

Repair

INSPECTION PROCEDURE 25

A/C switch and A/C relay inspection

Replace the engine-ECU.

OK

Check the trouble symptoms.

Measure at engine-ECU connector

D-110 or D-111.

DDisconnect the connector and

measure at the harness side.

DVoltage between 21 and 32 and

the earth (Ignition switch: ON)

OK:0 - 3 V (A/C switch: OFF)

System voltage (A/C

switch: ON)

DShort out 21 and the earth

(Ignition switch: ON)

(A/C switch: ON)

OK:A/C compressor clutch

turns onOKCheck the following connectors:

D-110, D-111NG

Repair

A/C system check

(Refer to GROUP 54 - Service

Adjustment Procedures.)NGOK

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 678 of 1839

14-1

ENGINE COOLING

CONTENTS

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

LUBRICANT 2...............................

SEALANT 2..................................

ON-VEHICLE SERVICE 3.....................

Engine Coolant Leak Checking 3................

Radiator Cap Valve Opening Pressure Check

3 .............................................Engine Coolant Replacement 3..................

Concentration Measurement 5...................

COOLING FAN 6.............................

THERMOSTAT 8.............................

WATER PUMP 11............................

WATER HOSE AND WATER PIPE 15........

RADIATOR 20...............................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 679 of 1839

ENGINE COOLING -General Information/

Service Specifications/Lubricant/Sealant14-2

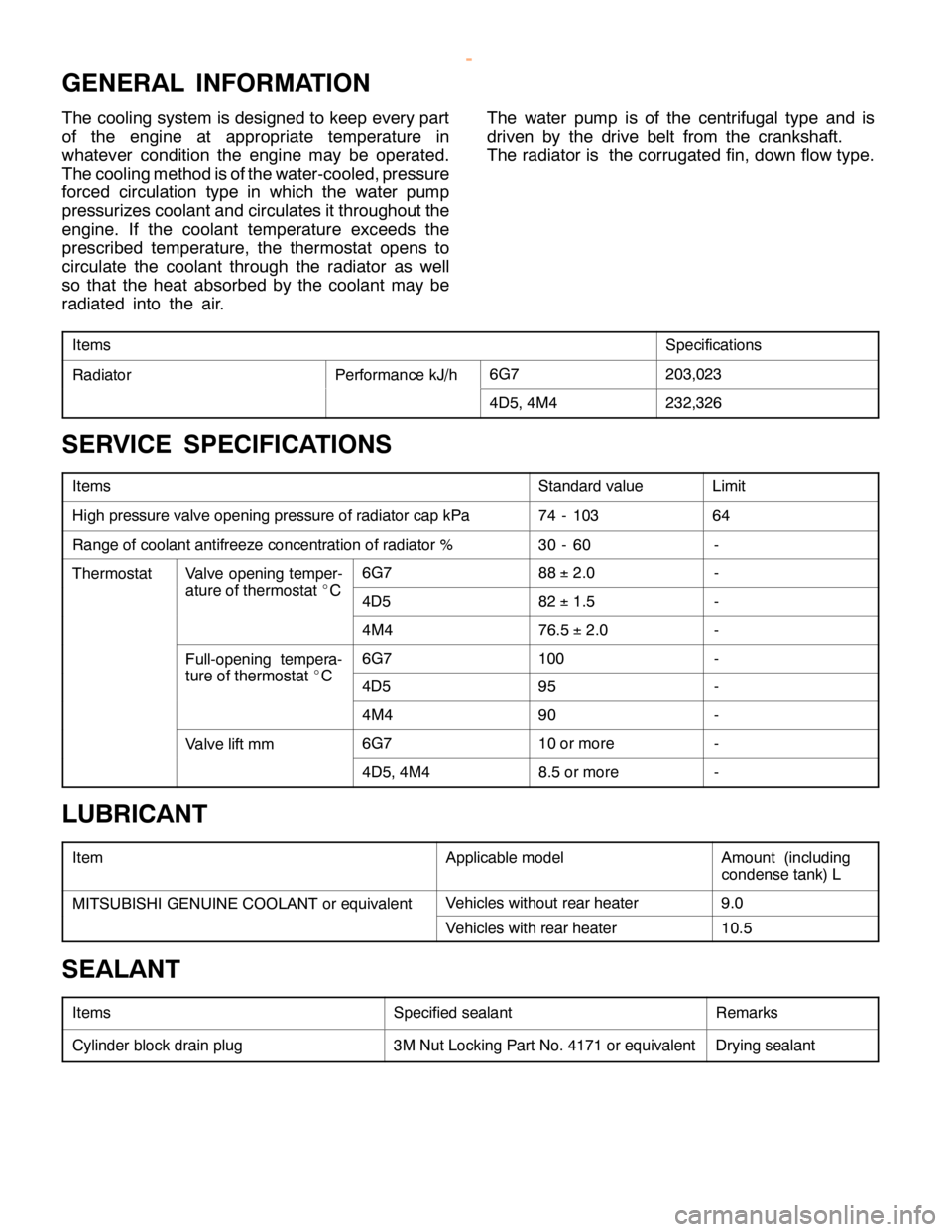

GENERAL INFORMATION

The cooling system is designed to keep every part

of the engine at appropriate temperature in

whatever condition the engine may be operated.

The cooling method is of the water-cooled, pressure

forced circulation type in which the water pump

pressurizes coolant and circulates it throughout the

engine. If the coolant temperature exceeds the

prescribed temperature, the thermostat opens to

circulate the coolant through the radiator as well

so that the heat absorbed by the coolant may be

radiated into the air.The water pump is of the centrifugal type and is

driven by the drive belt from the crankshaft.

The radiator is the corrugated fin, down flow type.

ItemsSpecifications

RadiatorPerformance kJ/h6G7203,023

4D5, 4M4232,326

SERVICE SPECIFICATIONS

ItemsStandard valueLimit

High pressure valve opening pressure of radiator cap kPa74 - 10364

Range of coolant antifreeze concentration of radiator %30 - 60-

ThermostatValve opening temper-6G788±

2.0-

ature of thermostat_

C4D582±

1.5-

4M476.5±

2.0-

Full-opening tempera-6G7100-

ture of thermostat_

C4D595-

4M490-

Valve lift mm6G710 or more-

4D5, 4M48.5 or more-

LUBRICANT

ItemApplicable modelAmount (including

condense tank) L

MITSUBISHI GENUINE COOLANT or equivalentVehicles without rear heater9.0

Vehicles with rear heater10.5

SEALANT

ItemsSpecified sealantRemarks

Cylinder block drain plug3M Nut Locking Part No. 4171 or equivalentDrying sealant

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 701 of 1839

ENGINE COOLING -General14-2

GENERAL

OUTLINE OF CHANGES

Some service procedures have been established as the following changes have been made due to the

compliance with the Emission Regulation Step III.

DThe turbocharger has been changed to a Variable Geometry (VG) type. Due to this change, an

EGR cooler has been added and section ”Water hose and water pipe” has been changed. <4D5>

DThe section ”Water hose and water pipe” has been changed due to the addition of the EGR cooler.

<4M4>

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 707 of 1839

15-1

INTAKE AND

EXHAUST

CONTENTS

SERVICE SPECIFICATIONS 2.................

SEALANT 2..................................

SPECIAL TOOL 2............................

ON-VEHICLE SERVICE 2.....................

Intake Manifold Vacuum Check <6G7> 2.........

Turbocharger Supercharging Check <4D5> 2.....

Waste Gate Actuator Check <4D5> 3..........

Waste Gate Actuator Check <4M4> 3..........

AIR CLEANER 4.............................

INTERCOOLER<4D5, 4M4> 5.................

INTAKE MANIFOLD <6G7> 6.................

INTAKE MANIFOLD AND THROTTLE BODY

<4M4> 8.....................................EXHAUST MANIFOLD <6G7> 11..............

INTAKE MANIFOLD AND EXHAUST

MANIFOLD, TURBOCHARGER <4D5> 12...

TURBOCHARGER AND EXHAUST

MANIFOLD <4M4> 14.....................

TURBOCHARGER <4D5> 16.................

TURBOCHARGER <4M4> 19.................

EXHAUST PIPE AND MAIN MUFFLER

<6G7> 21...................................

EXHAUST PIPE AND MAIN MUFFLER

<4D5> 23...................................

EXHAUST PIPE AND MAIN MUFFLER

<4M4> 25...................................

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

Page 719 of 1839

INTAKE AND EXHAUST -Intake and Exhaust Manifold,

Turbocharger <4D5>15-13

INSTALLATION SERVICE POINT

"

AA

TURBOCHARGER ASSEMBLY INSTALLATION

1. Check the internal surface, the eye bolt and the

mating surface of the oil pipe and water pipe for

clogging, and clean if necessary.

2. If deposits of carbon are accumulated on the

turbocharger oil passage, remove them and clean

using the compressed air.

Caution

Be careful not to allow foreign material to enter the

turbocharger.

3. Add clean engine oil through the oil feed pipe port

on the turbocharger.

INSPECTION

TURBOCHARGER ASSEMBLY CHECK

DVisually check the turbine wheel and the compressor

wheel for cracking or other damage.

DCheck whether the turbine wheel and the compressor

wheel can be easily turned by hand.

DCheck for oil leakage from the turbocharger assembly.

DCheck whether or not the waste gate valve remains open.

If any problem is found, replace the part after disassembly.

OIL PIPE AND OIL RETURN PIPE CHECK

Check the oil pipe and oil return pipe for clogging, bending,

or other damage. If there is clogging, clean it.

EXHAUST MANIFOLD CHECK

Damage or cracking of any part.

www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk