torque MITSUBISHI SPYDER 1990 Service Repair Manual

[x] Cancel search | Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1388 of 2103

AUTOMATIC TRANSAXLE

. .

Using the

from the transfer gear.

BEARING REMOVAL

‘the special tool, remove the taper roller bearing

from the center differential flange.

R E A S S E M B L Y S E R V I C E

SPACERS SELECTION

(1) install the spacer, side gear

pinion shaft in the center differential case.

(2) While pressing the pinion shaft, select the thi ckest

to gently rotate the pinion.

(3) Install the side gear (front), spacer and cente r differential

flange and tighten the bolts to torque.

Center differential

(4) Using the front output side

and select the thickest , gently! rotate side

gear front.

.

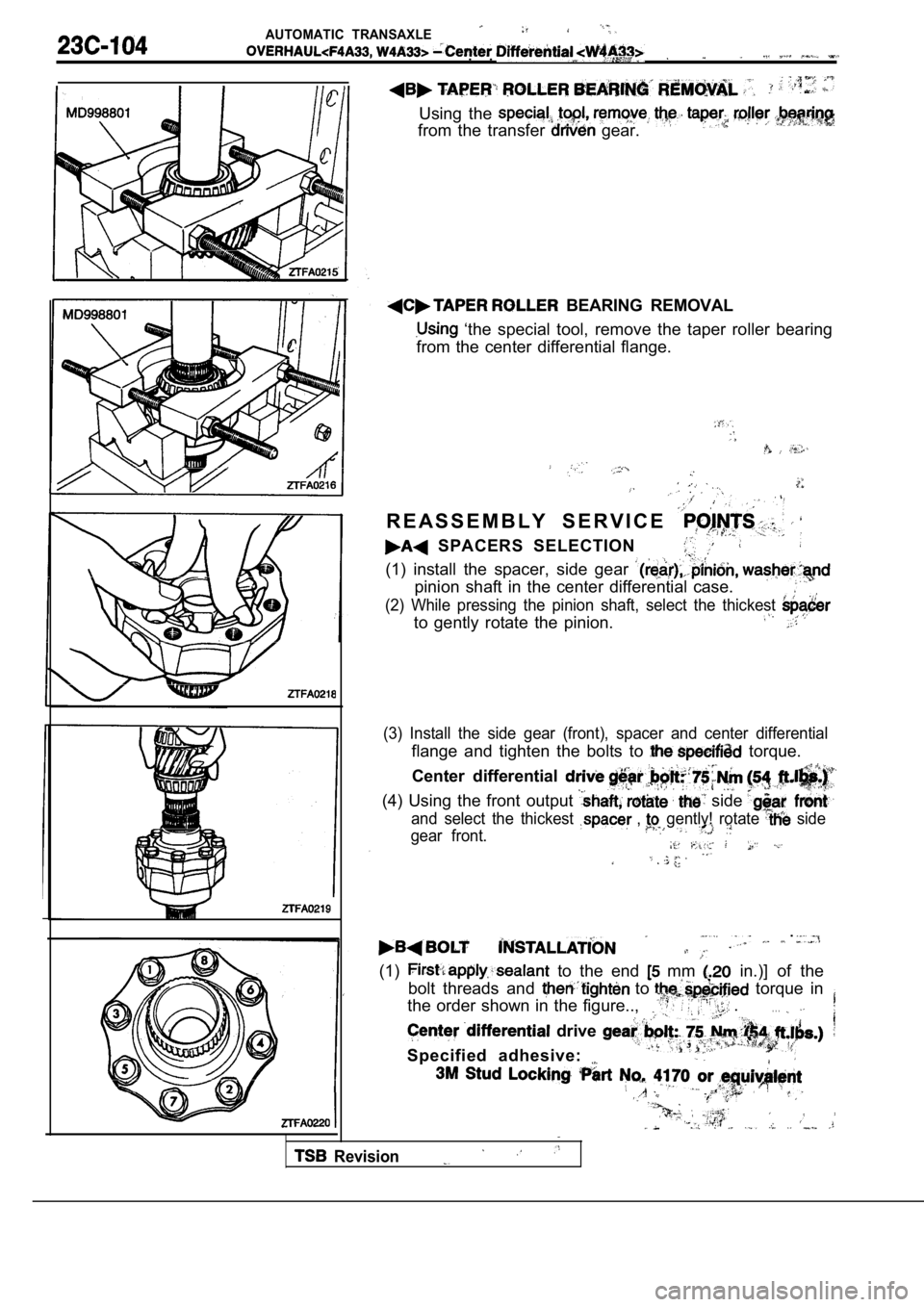

(1) to the end mm in.)] of the

bolt threads and

to torque in

the order shown in the figure..,

.. . .

drive

Specified adhesive:

,

Revision

Page 1392 of 2103

AUTOMATIC TRANSAXLE

Transfer .

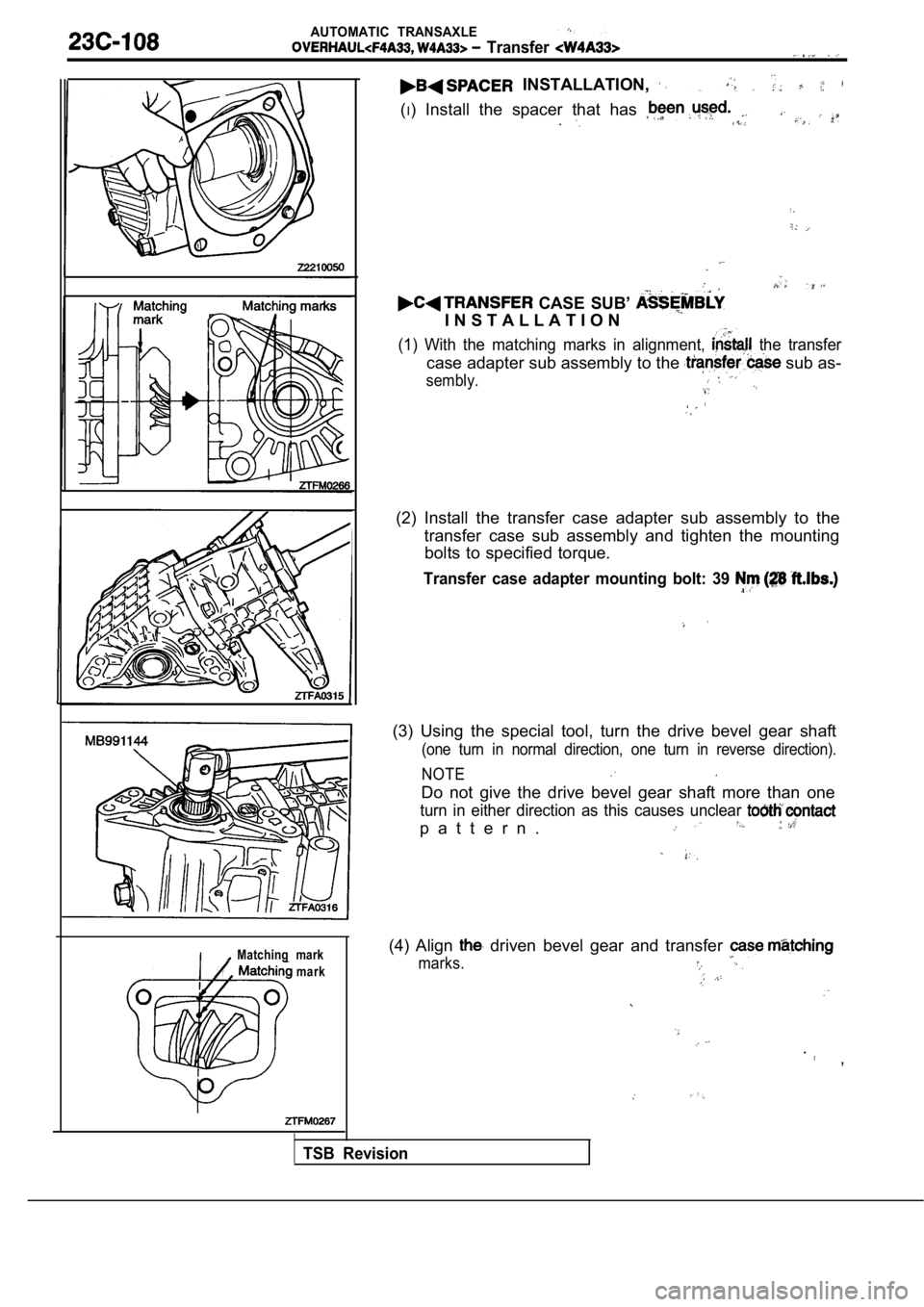

INSTALLATION,

(I) Install the spacer that has

CASE SUB’

I N S T A L L A T I O N

(1) With the matching marks in alignment, the transfer

case adapter sub assembly to the sub as-

sembly.

(2) Install the transfer case adapter sub assembly to the

transfer case sub assembly and tighten the mounting bolts to specified torque.

Transfer case adapter mounting bolt: 39

(3) Using the special tool, turn the drive bevel ge ar shaft

(one turn in normal direction, one turn in reverse direction).

NOTE

Do not give the drive bevel gear shaft more than on e

turn in either direction as this causes unclear

p a t t e r n .

Matching mark

mark(4) Align driven bevel gear and transfer

marks.

. ,

TSB Revision

Page 1398 of 2103

AUTOMATIC TRANSAXLE

Transfer Case Adapter

2

Matching mark

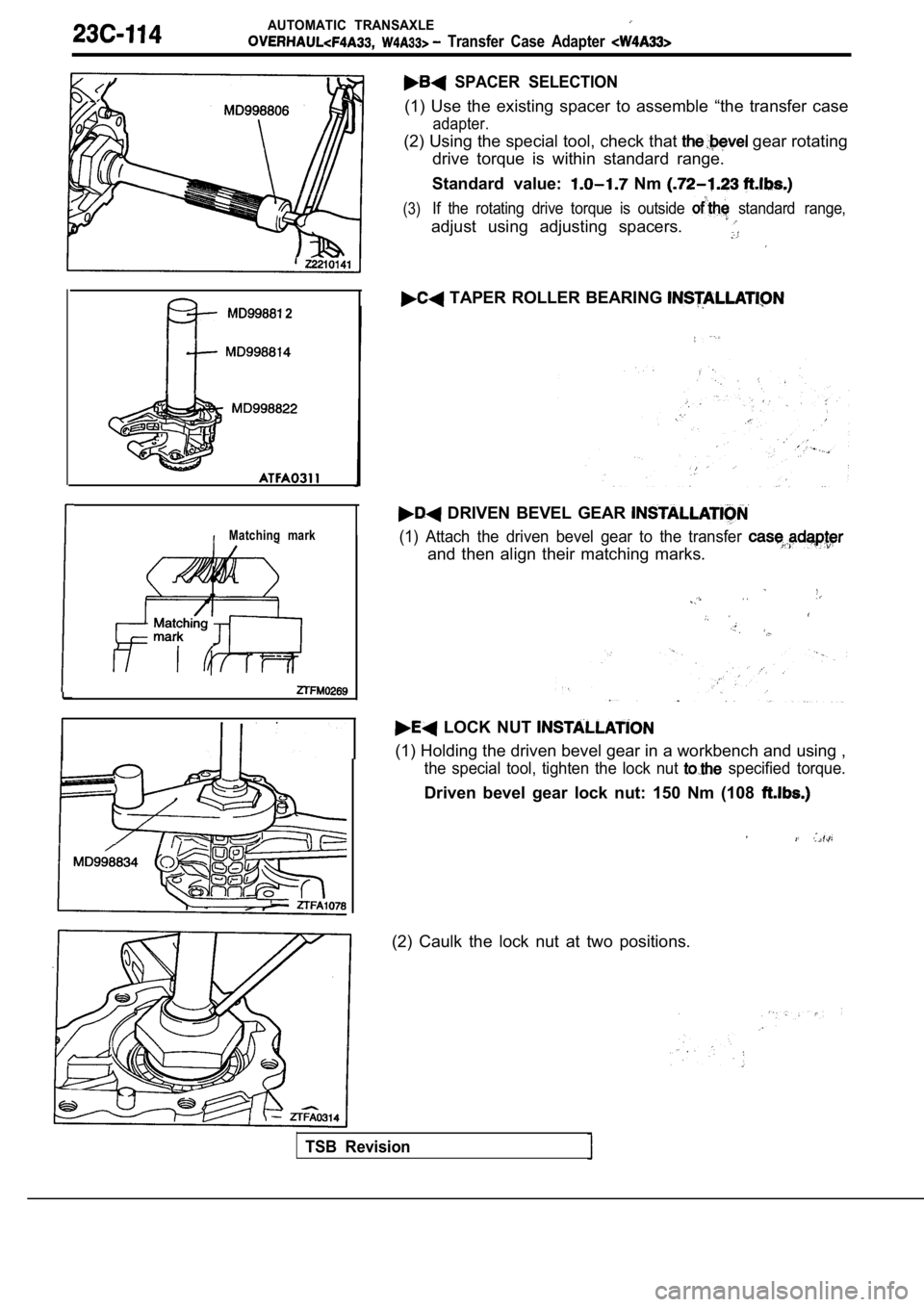

SPACER SELECTION

(1) Use the existing spacer to assemble “the transfer case

adapter.

(2) Using the special tool, check that gear rotating

drive torque is within standard range.

Standard value:

Nm

(3)If the rotating drive torque is outside standard range,

adjust using adjusting spacers.

TAPER ROLLER BEARING

DRIVEN BEVEL GEAR

(1) Attach the driven bevel gear to the transfer

and then align their matching marks.

. .

LOCK NUT

(1) Holding the driven bevel gear in a workbench an d using ,

the special tool, tighten the lock nut specified torque.

Driven bevel gear lock nut: 150 Nm (108

(2) Caulk the lock nut at two positions.

TSB Revision

Page 1401 of 2103

AUTOMATIC TRANSAXLE

Transfer Case

S E A L

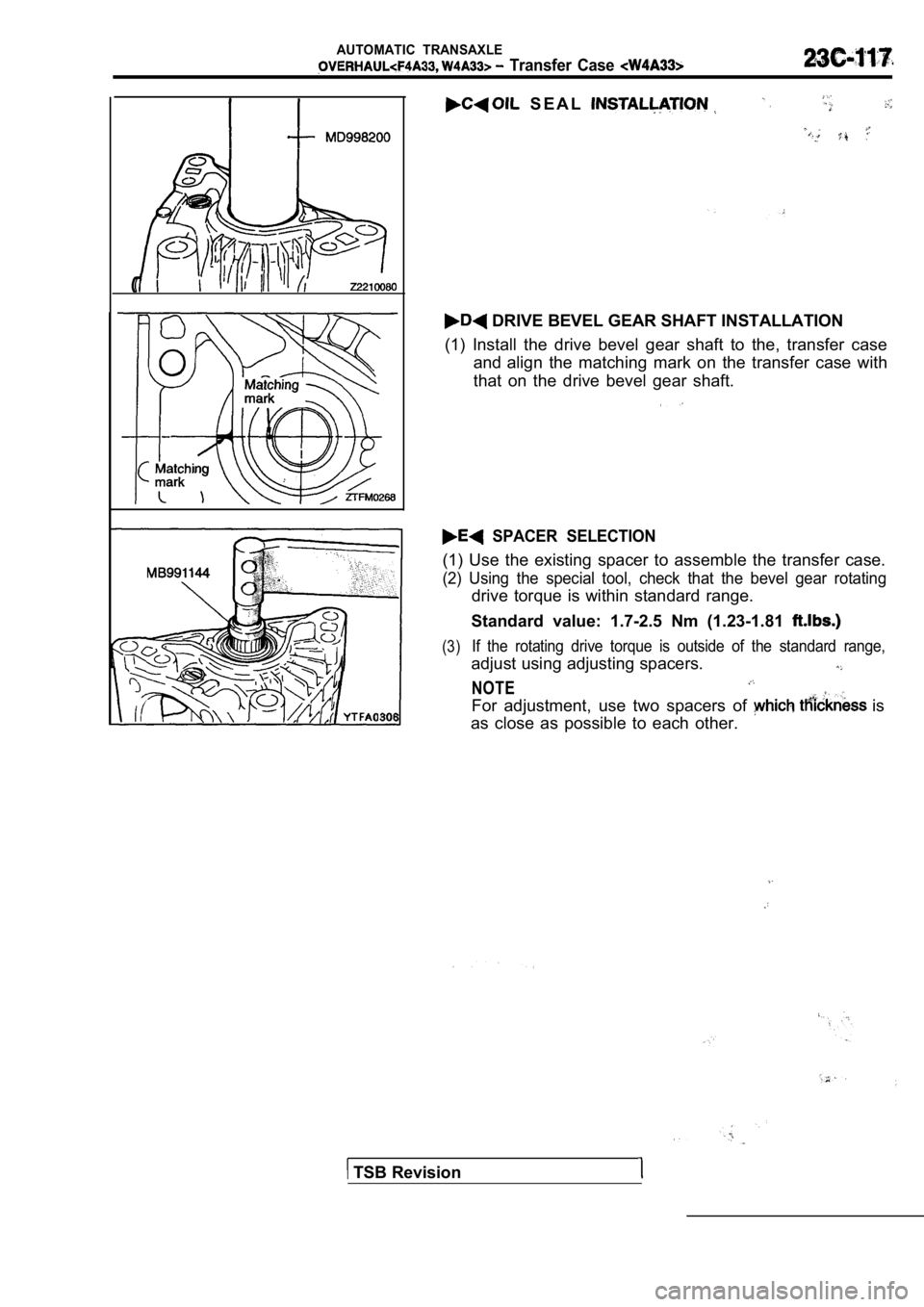

DRIVE BEVEL GEAR SHAFT INSTALLATION

(1) Install the drive bevel gear shaft to the, tran sfer case

and align the matching mark on the transfer case wit h

that on the drive bevel gear shaft.

SPACER SELECTION

(1) Use the existing spacer to assemble the transfe r case.

(2) Using the special tool, check that the bevel gear rotating

drive torque is within standard range.

Standard value: 1.7-2.5 Nm (1.23-1.81

(3)If the rotating drive torque is outside of the stan dard range,

adjust using adjusting spacers.

NOTE

For adjustment, use two spacers of is

as close as possible to each other.

TSB Revision

Page 1403 of 2103

TRANSAXLE

O V E R H A U L

CONTENTS

DIFFERENTIAL77SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . .4. . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . .

2General Specifications. . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

INPUT CLUTCHES49Service Specifications. . . . . . . . . . . . . . . . . . . . . . . .4. . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . .5

OIL PUMP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

TRANSAXLE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

OIL PUMP SEAL . . . . . . . . . . . . . . . . . . . . . . . . . .72

VALVE BODY. . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . .10

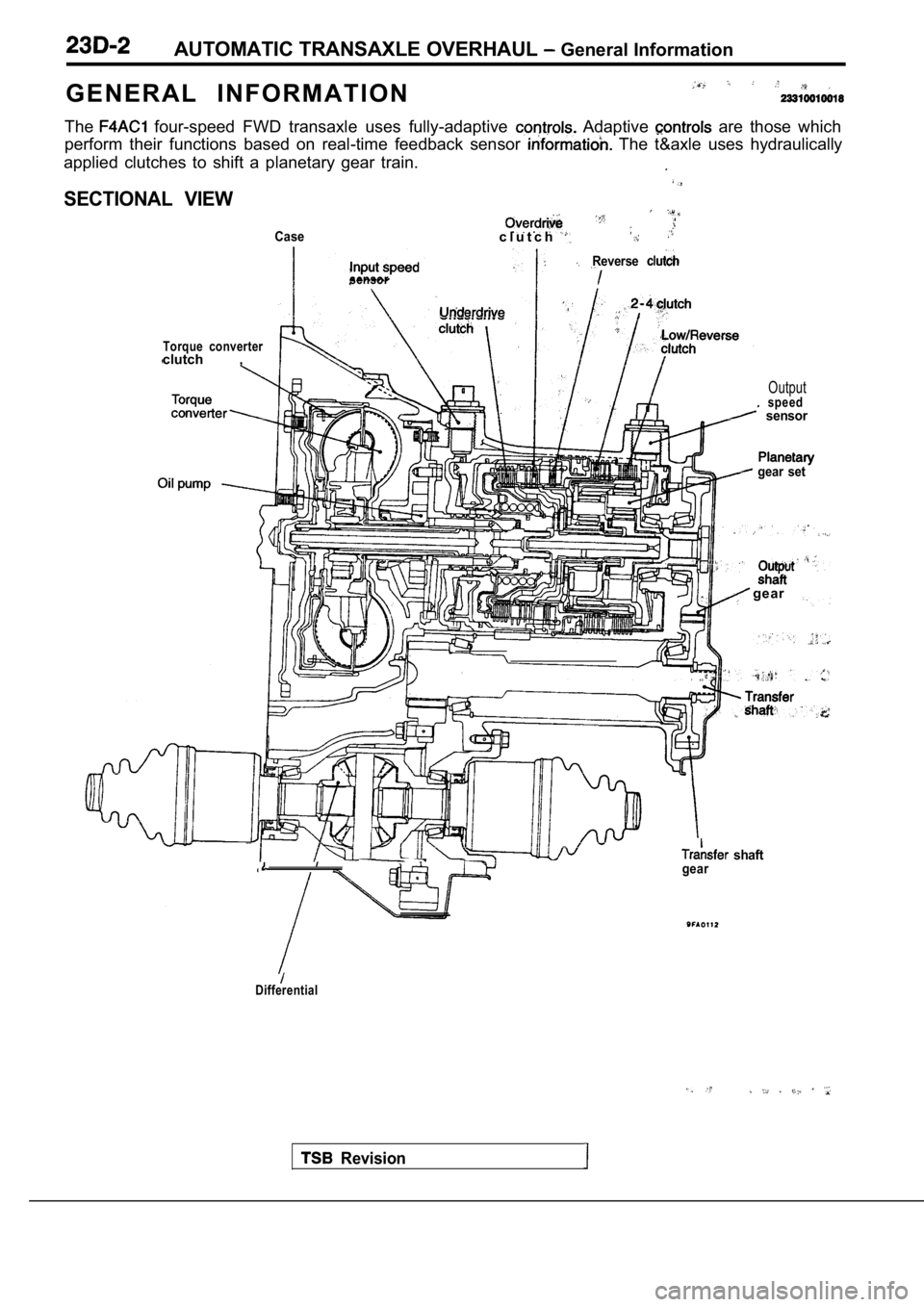

Page 1404 of 2103

AUTOMATIC TRANSAXLE OVERHAUL General Information

G E N E R A L I N F O R M A T I O N

The four-speed FWD transaxle uses fully-adaptive Adaptive are those which

perform their functions based on real-time feedback sensor

The t&axle uses hydraulically

applied clutches to shift a planetary gear train.

SECTIONAL VIEW

Casec l u t c h

sensor

Torque converterclutch ,

Reverse

Outputspeed sensor

gear set

Revision

gear

shaftgear

Differential

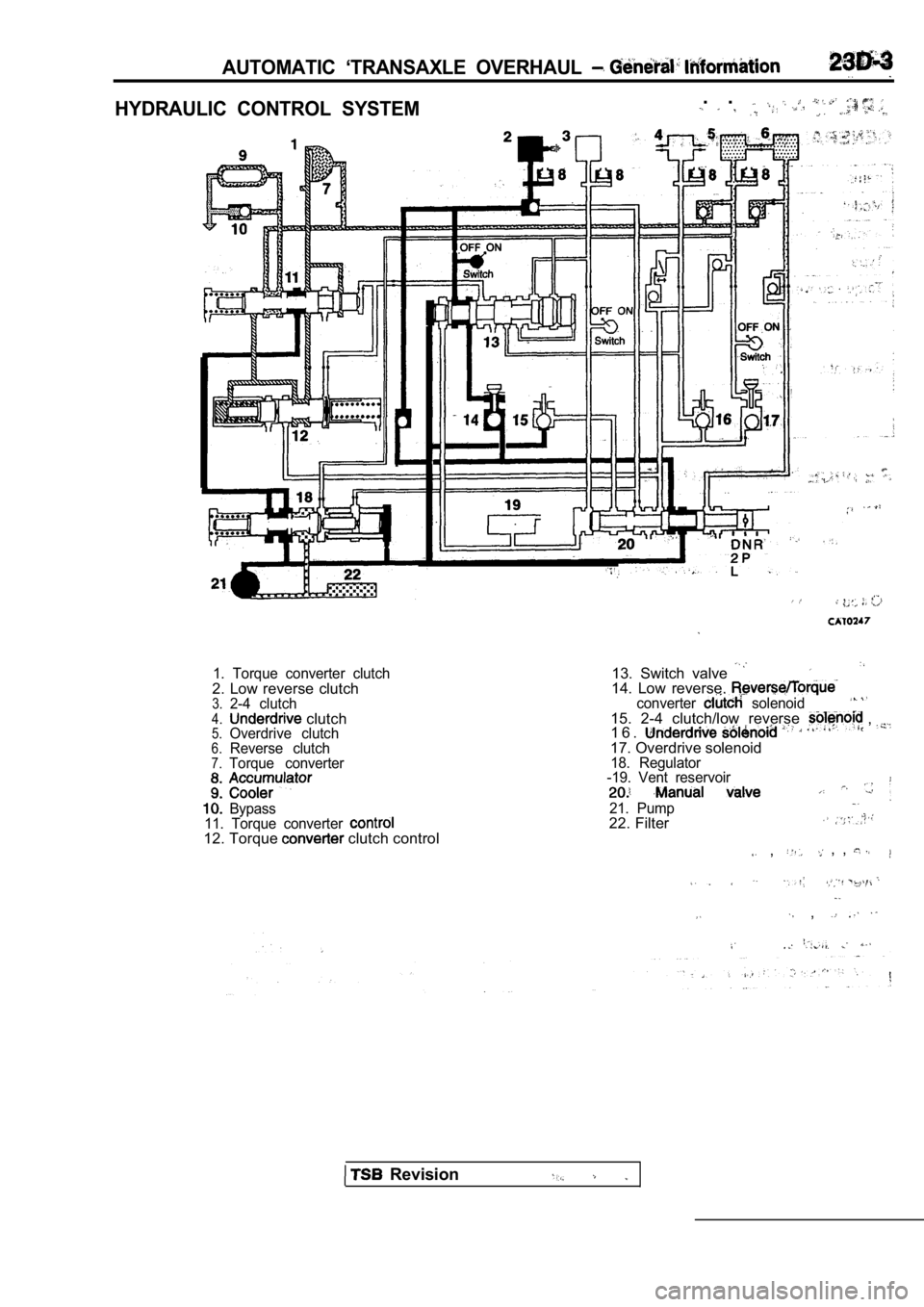

Page 1405 of 2103

AUTOMATIC ‘TRANSAXLE OVERHAUL

HYDRAULIC CONTROL SYSTEM. .

1. Torque converter clutch2. Low reverse clutch3.2-4 clutch4. clutch5.Overdrive clutch6.Reverse clutch7.Torque converter

Bypass

11. Torque converter

12. Torque clutch control

13. Switch valve 14. Low reverse, converter solenoid15. 2-4 clutch/low reverse , 1 6 .17. Overdrive solenoid18. Regulator

-19. Vent reservoir

21. Pump22. Filter

, , ,

,

Revision

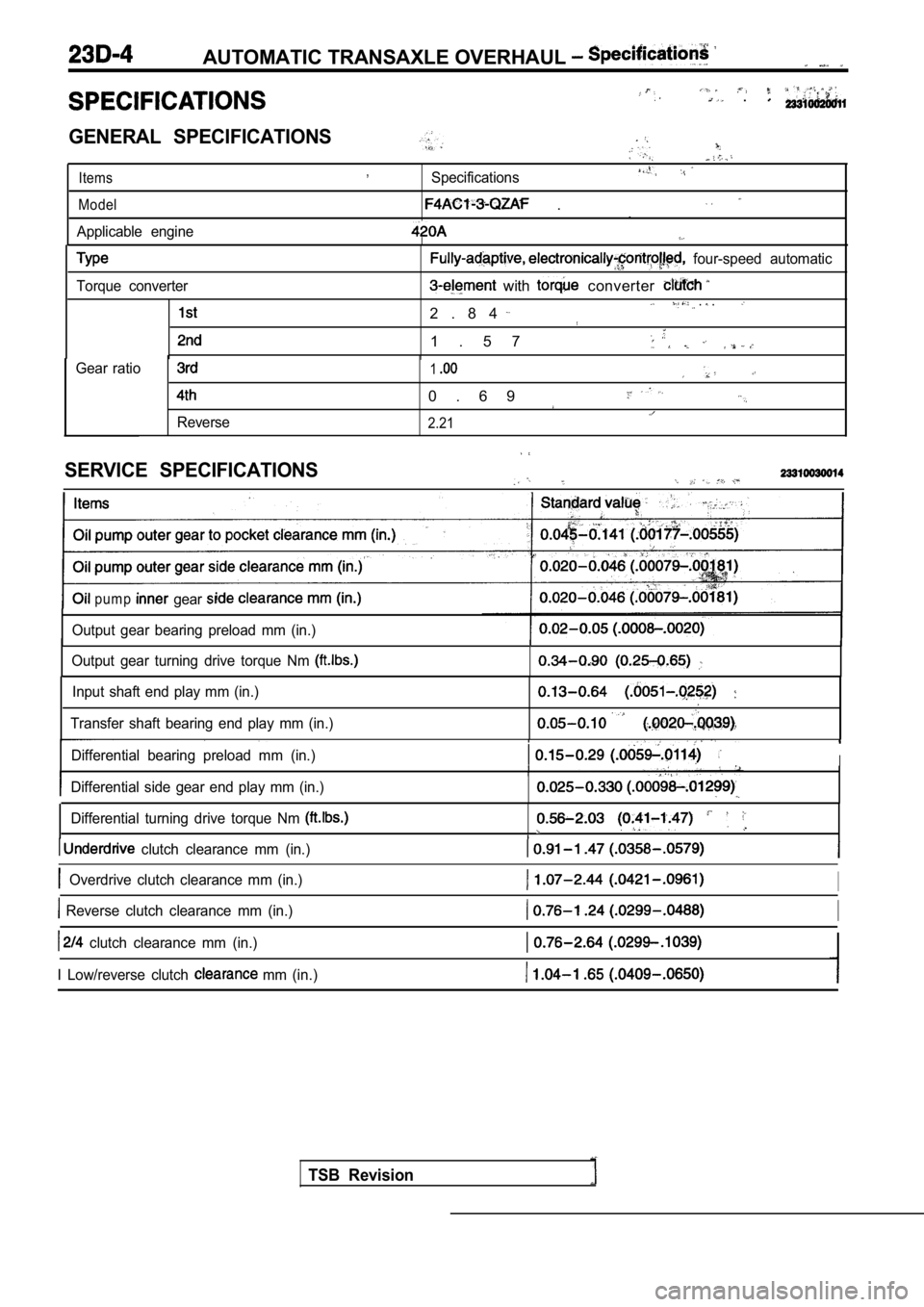

Page 1406 of 2103

AUTOMATIC TRANSAXLE OVERHAUL

. ..

GENERAL SPECIFICATIONS

Items,Specifications

Model

Applicable engine

..

Torque converter

four-speed automatic

with converter

2 . 8 4 . .

1 . 5 7

Gear ratio

Reverse

1

0 . 6 9

2.21

SERVICE SPECIFICATIONS

p u m p gear

Output gear bearing preload mm (in.)

Output gear turning drive torque Nm

Input shaft end play mm (in.)

Transfer shaft bearing end play mm (in.)

Differential bearing preload mm (in.)I

Differential side gear end play mm (in.)

Differential turning drive torque Nm

clutch clearance mm (in.)

Overdrive clutch clearance mm (in.)I

Reverse clutch clearance mm (in.)I

clutch clearance mm (in.)

I Low/reverse clutch

mm (in.)

TSB Revision

Page 1407 of 2103

AUTOMATIC TRANSAXLE OVERHAUL

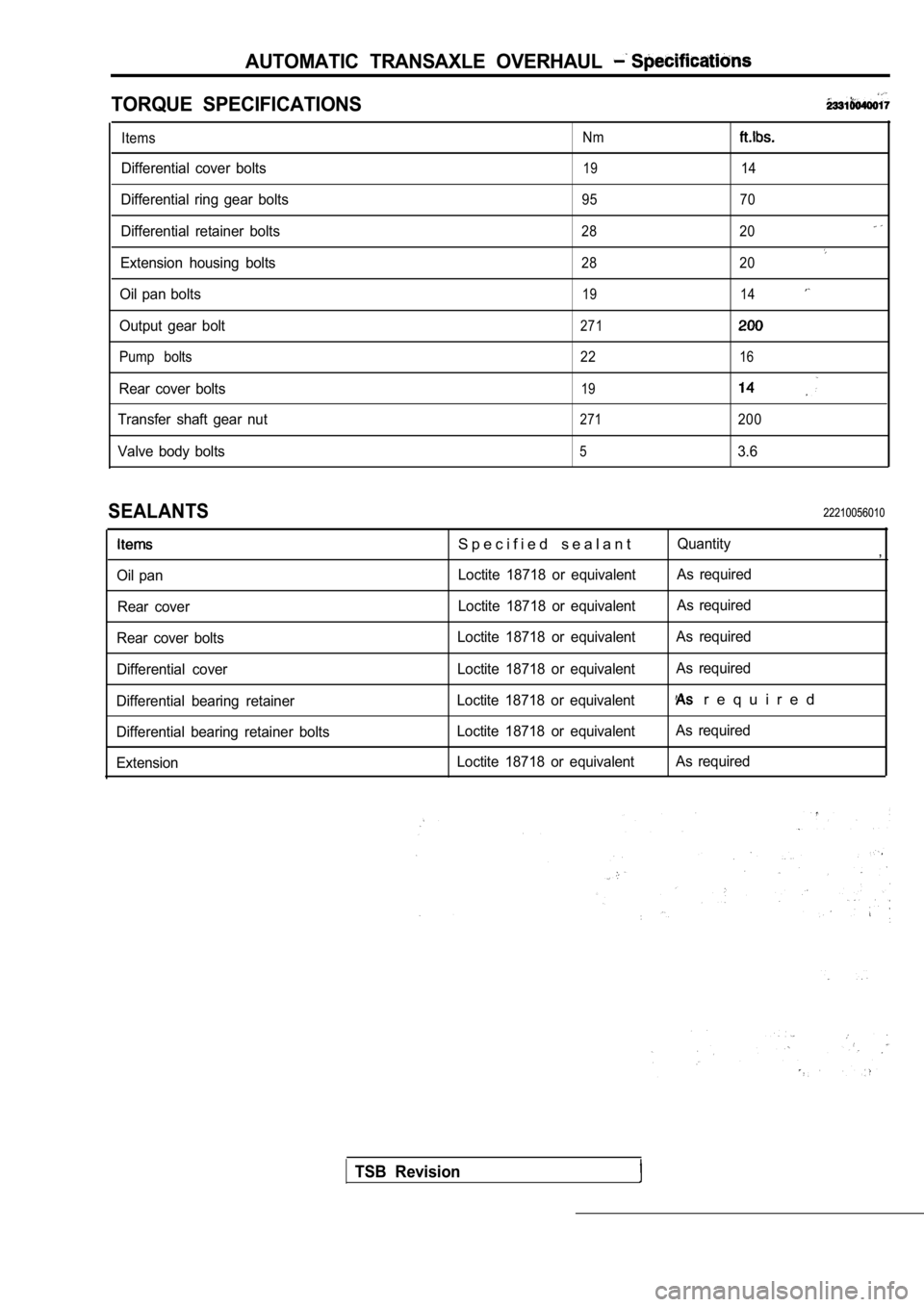

TORQUE SPECIFICATIONS

Items

Differential cover bolts

Differential ring gear bolts

Differential retainer bolts

Extension housing bolts

Oil pan bolts

Output gear bolt

Pump bolts

Rear cover bolts

Transfer shaft gear nut

Valve body bolts

Nm

19

95

28

28

19

271

22

19

271

5

14

70

20

20

14

16

200

3.6

SEALANTS

Oil pan Rear cover

Rear cover bolts

Differential cover

Differential bearing retainer

Differential bearing retainer bolts

Extension

S p e c i f i e d s e a l a n t

Loctite 18718 or equivalent

Loctite 18718 or equivalent

Loctite 18718 or equivalent

Loctite 18718 or equivalent

Loctite 18718 or equivalent

Loctite 18718 or equivalent

Loctite 18718 or equivalent

22210056010

Quantity,

As required

As required

As required

As required

r e q u i r e d

As required

As required

TSB Revision

Page 1436 of 2103

AUTOMATICTRANSAXLE,,

W r

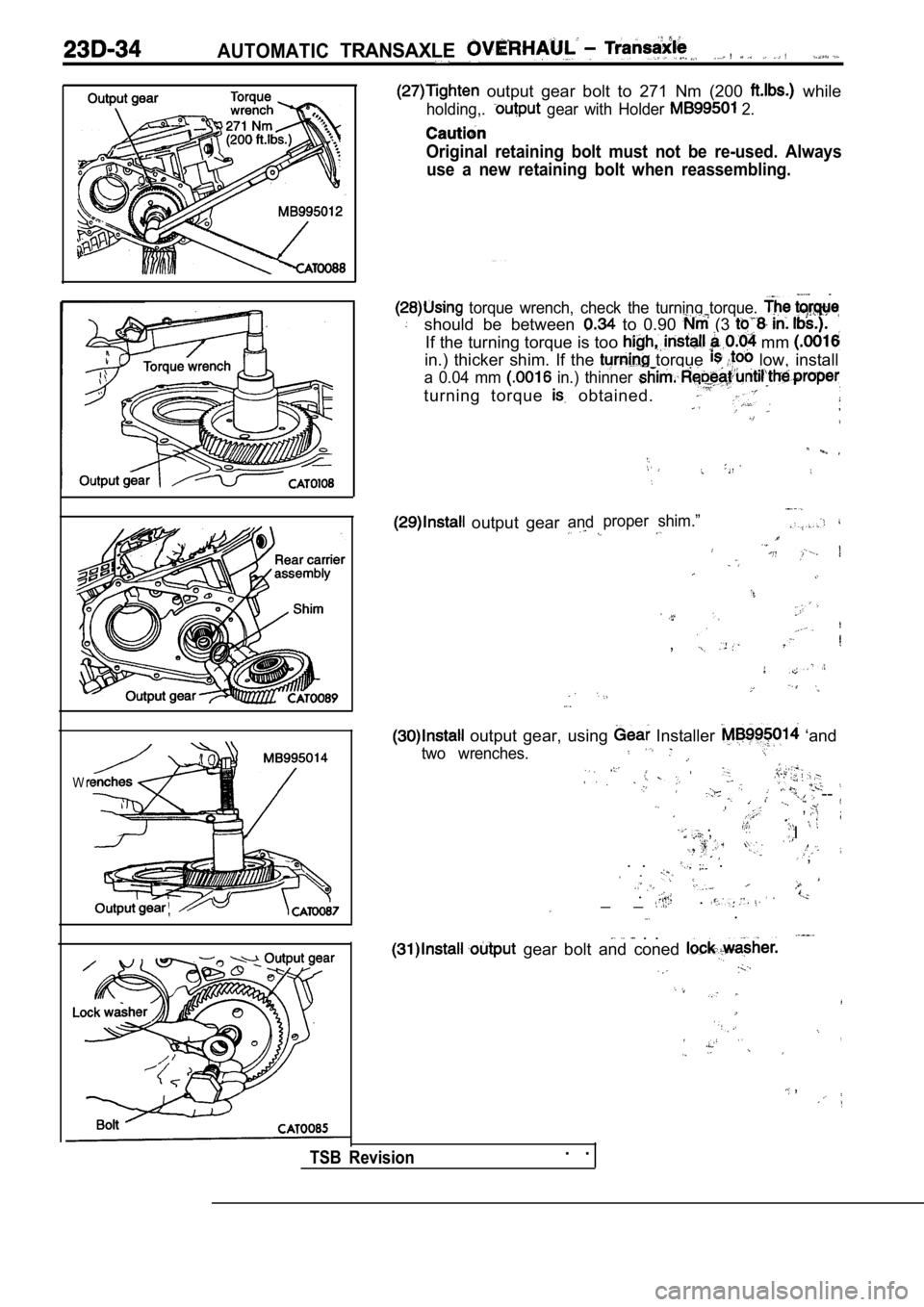

output gear bolt to 271 Nm (200 while

holding,. gear with Holder 2.

Original retaining bolt must not be re-used. Alwaysuse a new retaining bolt when reassembling.

torque wrench, check the turning torque.

should be between to 0.90 (3

If the turning torque is too mm

in.) thicker shim. If the torque low, install

a 0.04 mm in.) thinner

turning torque obtained.

output gearand

TSB Revision. .

proper shim.”

,

output gear, using Installer ‘and

two wrenches.

-- ,

. ,I

. . , .

.

_ _..

. .

gear bolt and coned

,

,