ENGINE (TURBO)

AND

ENGINE> Troubleshooting

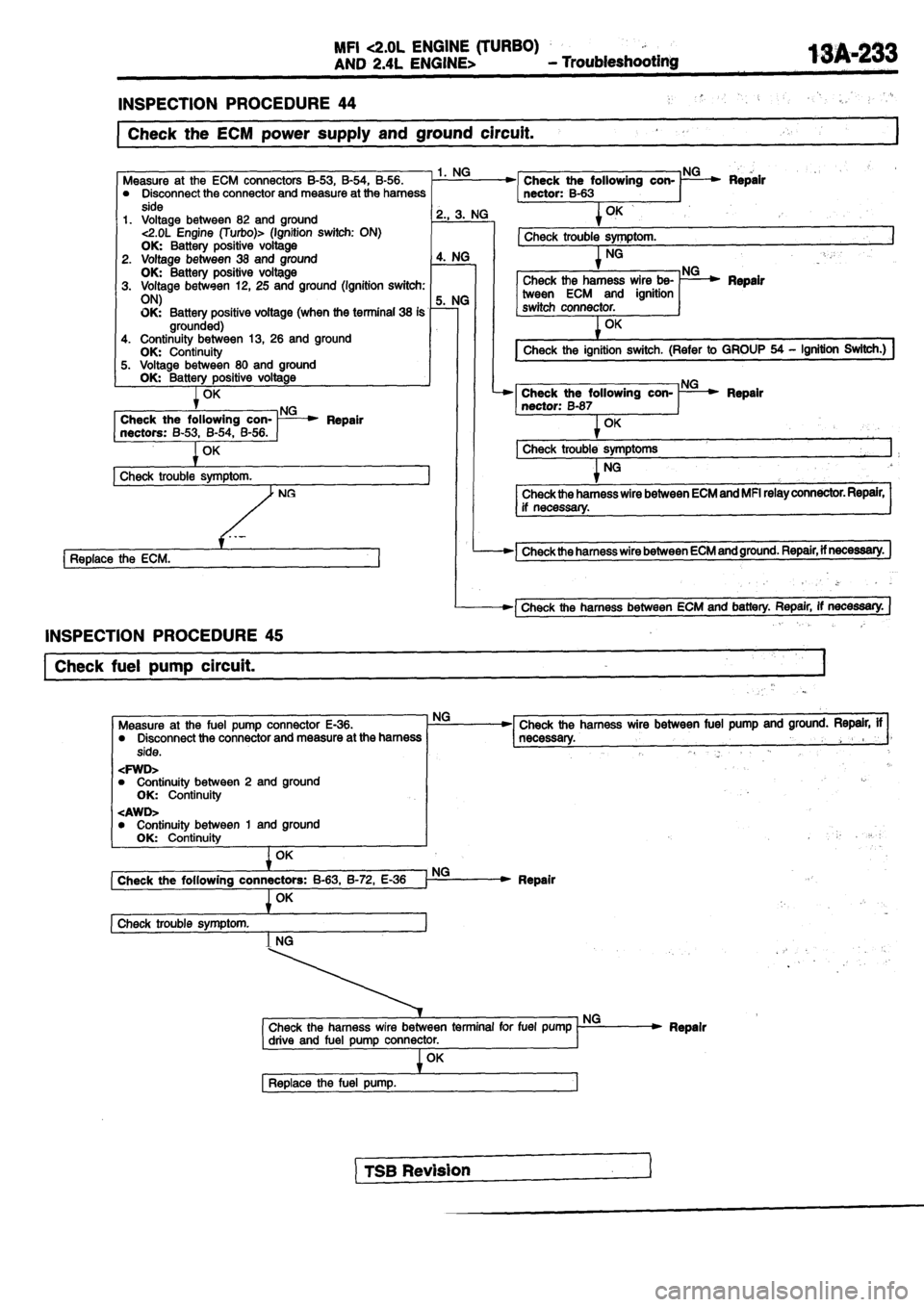

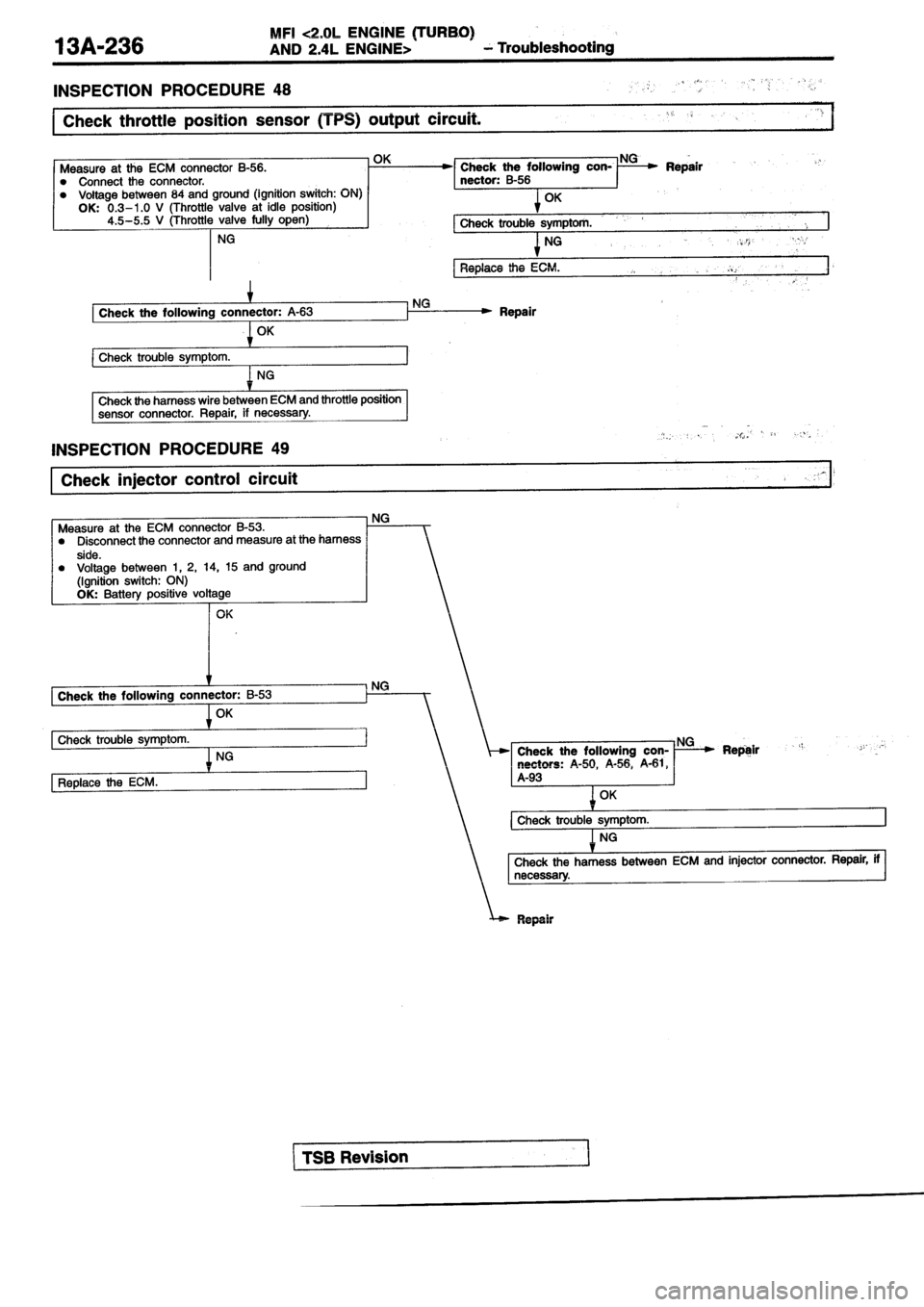

INSPECTION PROCEDURE 50

Check the ignition signal circuit.

lDisconnect the connector and measure at the harness

side.

lVoltage between 58 and ground (engine: 3000 OK:

OK

Replace the ECM. Check trouble symptom.

sistor unit and ignition switch

connector.

OK

Check the ignition switch. (Refer to GROUP 54 Switch.)

An open or short circuit has somewhere in ignition signaloutput harness between the and ‘the ignition power transistor

unit, inspect and repair the

Check trouble symptom.

OK

Replace the power transistor unit.

INSPECTION PROCEDURE 51

Check the boost meter circuit Engine (Turbo)>I

Measure at the ECM connector lDisconnect the connector, and mea-sure at the harness side.

l Voltage between 16 and ground.

(Ignition switch: ON)

OK:

oositive

NG

OKRepair

Replace the ECM.

Check the

boost meter (Refer to N G

GROUP 54 Meters and Gauges) Replace

Measure at the combination meter con-nectorlDisconnect the connector, sure at the harness side.

l Voltage between 10 and ground.

(Ignition switch: ON)

OK: Battery positive voltage

NG

Check the boost meter power supply

circuit. Repair. if

N G Check the

OK

Check trouble symptom.

NG

Check harness wire between the ECMand the combination meter connector.

Repair, if necessary.

TSB Revision

ENGINE (TURBO)

AND

ENGINE>

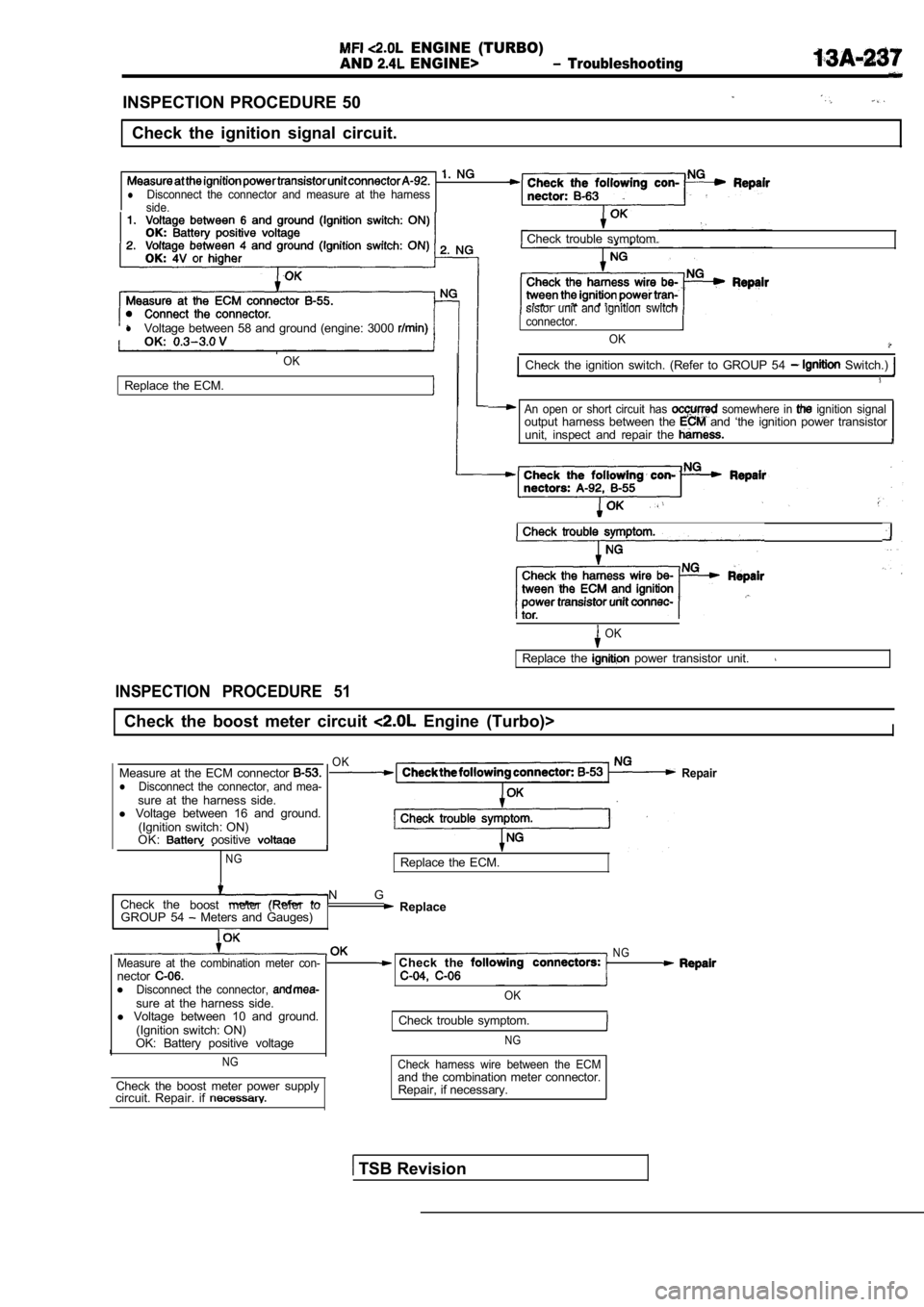

DATA LIST REFERENCE TABLE

Item No.

1 1

12

13

14

16

18

21

22

Inspection item

Heated oxygen sensor (Front)

Volume air flow sensor

Intake air temperature sensor

Throttle position sensor Power supply voltage

Cranking signal (Ignition switch-ST)

Engine coolant temperature sensor

Crankshaft position sensorGeneral-

scan tool

, . .

,

,

TSB Revision

ENGINE (TURBO)

AND ENGINE>

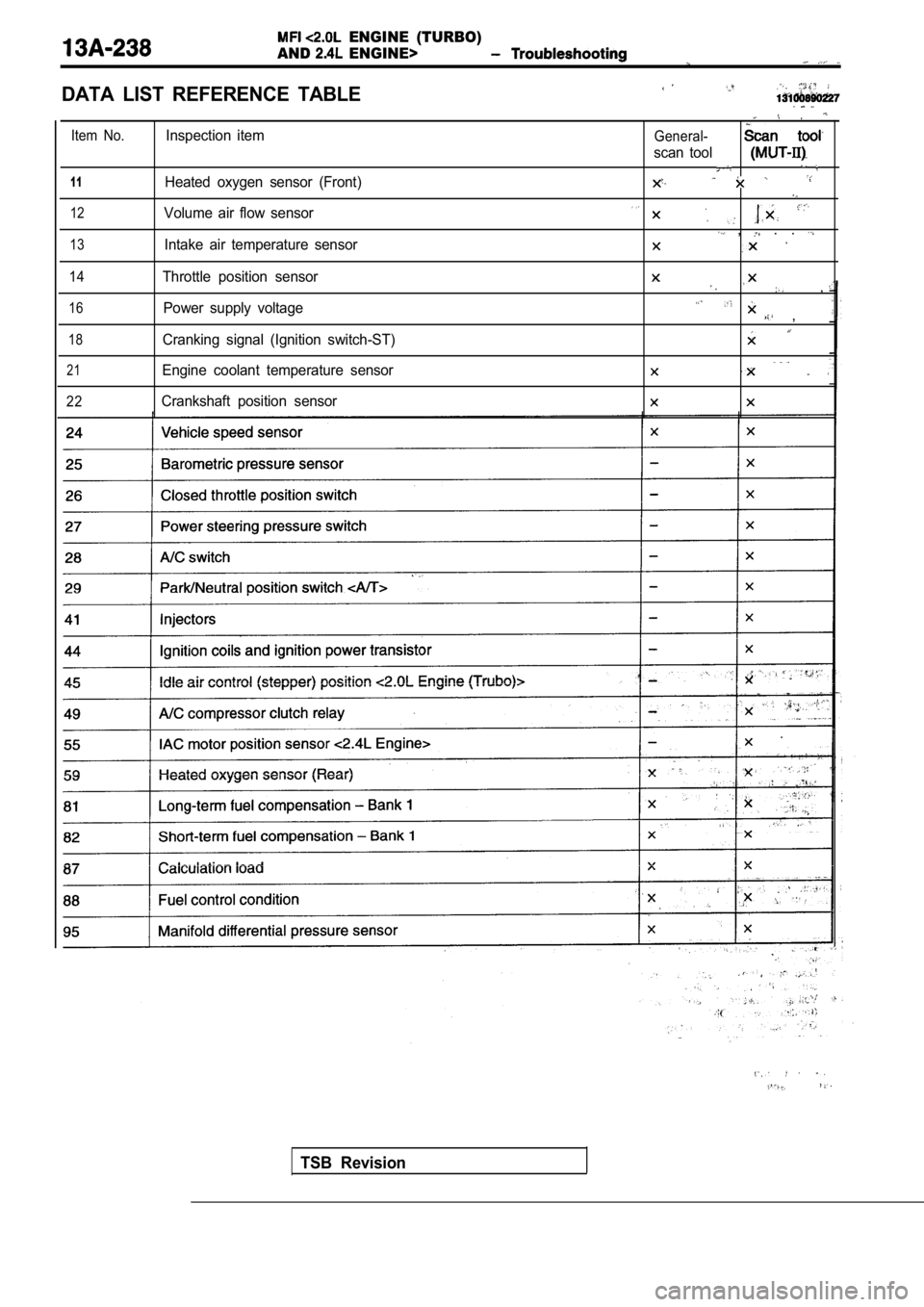

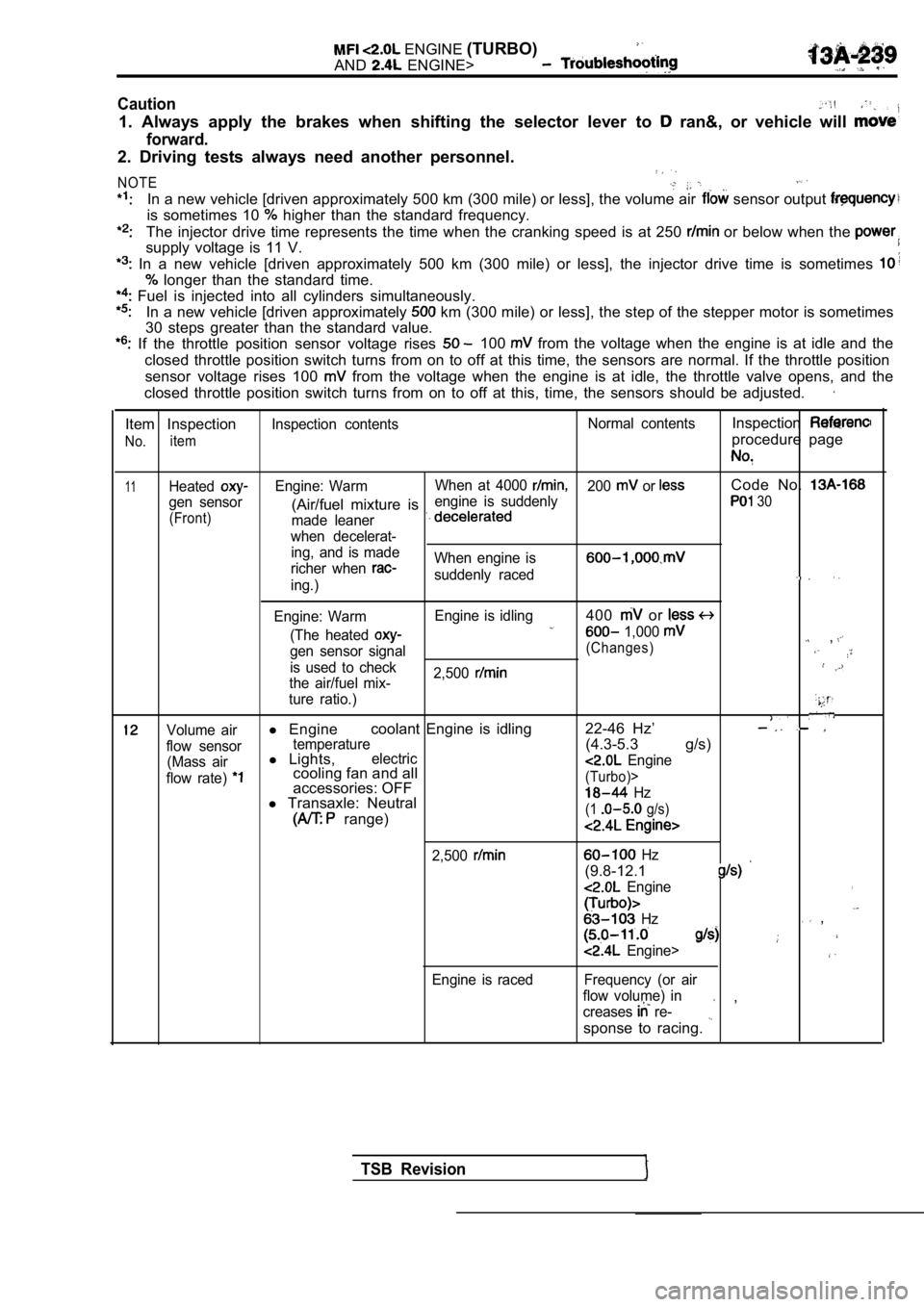

Caution

1. Always apply the brakes when shifting the select or lever to ran&, or vehicle will

forward.

2. Driving tests always need another personnel.

NOTE

In a new vehicle [driven approximately 500 km (300 mile) or less], the volume air sensor output

is sometimes 10 higher than the standard frequency.

The injector drive time represents the time when the cranking speed is at 250 or below when the

supply voltage is 11 V.

In a new vehicle [driven approximately 500 km (300 mile) or less], the injector drive time is sometimes

longer than the standard time.

Fuel is injected into all cylinders simultaneously.

In a new vehicle [driven approximately km (300 mile) or less], the step of the stepper mo tor is sometimes

30 steps greater than the standard value.

If the throttle position sensor voltage rises 100 from the voltage when the engine is at idle and th e

closed throttle position switch turns from on to of f at this time, the sensors are normal. If the throttle position

sensor voltage rises 100

from the voltage when the engine is at idle, the t hrottle valve opens, and the

closed throttle position switch turns from on to of f at this, time, the sensors should be adjusted.

Item Inspection

No.item

Inspection contents Normal contentsInspection

procedure page

11HeatedEngine: WarmWhen at 4000 200 or Code No.

gen sensor engine is suddenly(Air/fuel mixture is 30

(Front)

made leaner

when decelerat- ing, and is made

richer when

When engine is

suddenly raceding.)

Engine: Warm Engine is idling

400 or

(The heated 1,000 ,gen sensor signal(Changes)

is used to check

2,500

the air/fuel mix-

ture ratio.)

Volume airl Engine coolant Engine is idling 22-46 Hz’

flow sensortemperature(4.3-5.3 g/s)

(Mass airl

Lights,electric

flow rate) cooling fan and all Engine

accessories: OFF(Turbo)>

l Transaxle: Neutral Hz

range)(1 g/s)

2,500

Engine is raced

Hz

(9.8-12.1

Engine,

Hz ,

Engine>

Frequency (or air

flow volume) in

creases

re- ,

sponse to racing.

TSB Revision

E N G I N E .

AND ENGINE> Troubleshooting

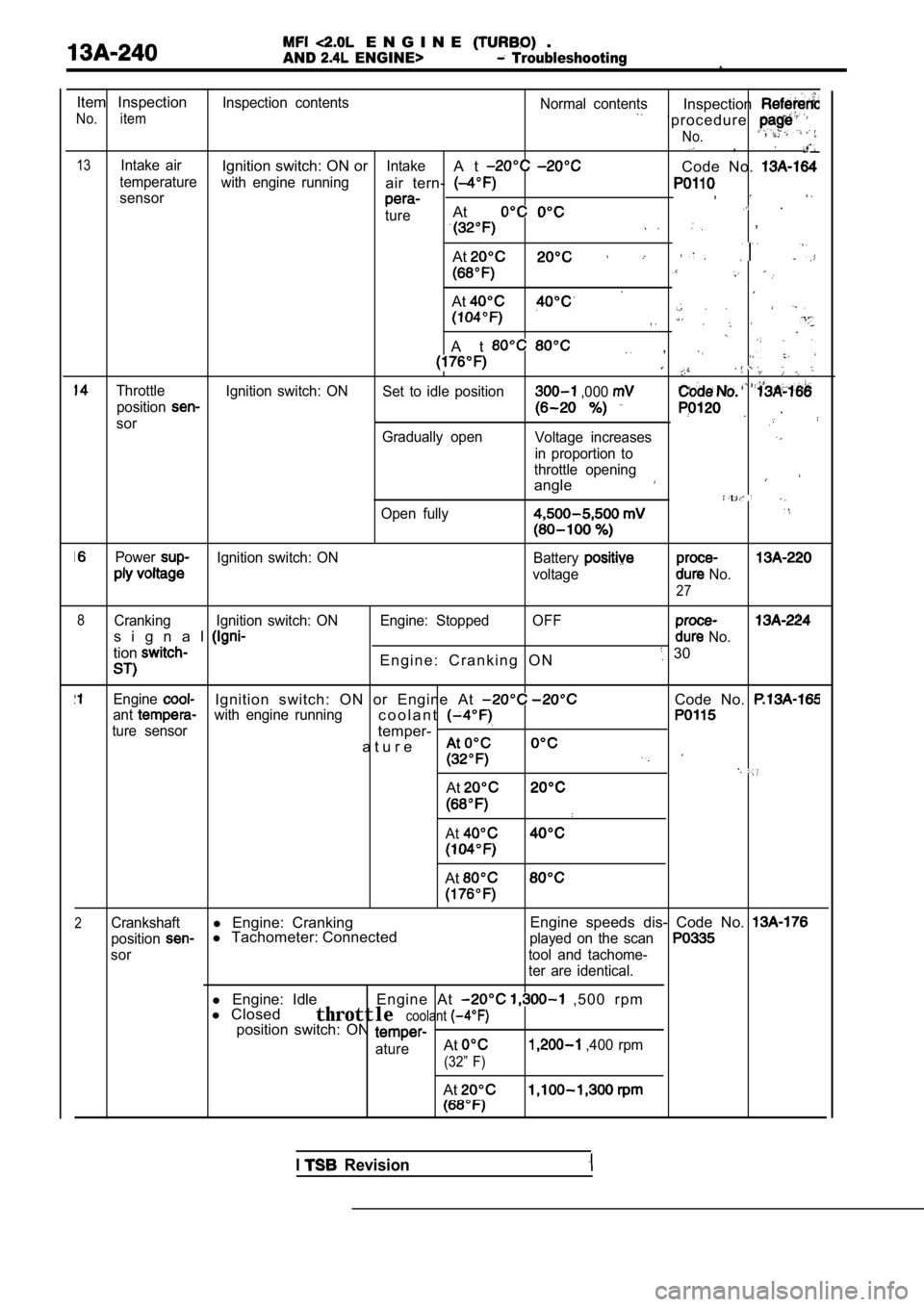

Item InspectionInspection contentsNormal contents

No. itemInspection

‘ p r o c e d u r e

No., ,

13Intake airIgnition switch: ON orIntakeA tCode No. temperaturewith engine runningair tern- sensor,

tureAt .

,

At

At

A t ,

Throttle Ignition switch: ON Set to idle position ,000 position

sor .

Gradually openVoltage increases

in proportion to

throttle opening

angle

Open fully

PowerIgnition switch: ON Battery

voltage No.

27

8

Cranking Ignition switch: ON Engine: Stopped OFF

s i g n a l No.

tionE n g i n e : C r a n k i n g O N 30

EngineIgnition switch: ON or Engine At Code No. antwith engine runningc o o l a n t

ture sensortemper-

a t u r e

At

At

At

2Crankshaftl Engine: Cranking Engine speeds dis- Code No.

positionl

Tachometer: Connectedplayed on the scan

sor tool and tachome-

ter are identical.

l Engine: Idle

l Closed Engine At , 5 0 0 r p m

throttlecoolantposition switch: ON

atureAt ,400 rpm

(32” F)

At

I Revision