MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 601 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

INSPECTION PROCEDURE 29 ,

Fuel pump system Engine>

[Comment]l of the fuel pump The ECM judges the engine (Low, Middle, High), and outputs the result MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

INSPECTION PROCEDURE 29 ,

Fuel pump system Engine>

[Comment]l of the fuel pump The ECM judges the engine (Low, Middle, High), and outputs the result](/img/19/57345/w960_57345-600.png)

ENGINE (TURBO)

AND ENGINE>

INSPECTION PROCEDURE 29 ,

Fuel pump system Engine>

[Comment]l of the fuel pump The ECM judges the engine (Low, Middle, High), and outputs the result of this judgement tol Malfunction fuel the fuel pump relay module. The fuel pump relay mod ule controls the operation of the fuel pump

in accordance with the engine which is input from the ECM. When the engine is high, Malfunction, of the fuel pump moduleImproper connector contact, open orthe fuel pump operates at high speed, and when the engine is low, the fuel pump operates

short-circuited harness at low speed.l Malfunction of the ECM,,

Check the fuel pump

OK

Measure at the fuel pump relay connector l Connect the connector.

l Voltage between 1 and ground switch: ON)

OK: Battery positive voltage Check the fuel pump drive

circuit 46.)

NG Repair lDisconnect the connector and measure at the harness

side.connector.. . 1. Voltage between 1 and ground (Ignition switch: O N)OK: Battery positive voltage2. Continuity between 5 and ground

OK: Continuity

OK

Check trouble ,

3. 2 and ground (Engine: Cranking)

4.

the terminal to the terminal 3

negative the terminal 4.

OK: Fuel pump operates.

U K

Check the following NG Repairc o n n e c t o r .

OK

Check trouble symptom

N G

Replace the fuel pump relay module

Check the harness wire between the fuel pump relay module con-nector and fuel pump relayconnector and repair if necessary.

Check the harness wire between the fuel pump relay con-nector and around and if

Check the following Repairconnector.

Check trouble

NG

Replace the ECMI

- - - Check the following Repairconnectors.

OK

Check trouble symptom.

Replace the fuel pump

TSB Revision

Page 602 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>,

INSPECTION PROCEDURE 30

Ignition switch-ST system

[Comment]l Malfunction, of ignition switch ,

The ignition switch ST inputs a HIGH signal to the whi MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>,

INSPECTION PROCEDURE 30

Ignition switch-ST system

[Comment]l Malfunction, of ignition switch ,

The ignition switch ST inputs a HIGH signal to the whi](/img/19/57345/w960_57345-601.png)

ENGINE (TURBO)

AND ENGINE>,

INSPECTION PROCEDURE 30

Ignition switch-ST system

[Comment]l Malfunction, of ignition switch ,

The ignition switch ST inputs a HIGH signal to the while the engine is cranking.Improper connector

The ECM controls fuel injection, etc. during starti ng based on this input. . l t h e .

Measure at the ECM connector lDisconnect the connector, and measure at the harnes s

side.

1. Voltage between 71 and ground (Ignition switch: START)

OK: or more

2. Continuity between 91 and ground OK: Continuity

OK

R e p a i r

Check trouble symptom.

Replace the ECM. 1. NG

2. NG

. . .,

TSB Revision

Page 603 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

INSPECTION PROCEDURE 31Ignition switch-ST and park/neutral position

system

[Comment]

l The ignition switch ST inputs a HIGH signal to the ECM while t MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND ENGINE>

INSPECTION PROCEDURE 31Ignition switch-ST and park/neutral position

system

[Comment]

l The ignition switch ST inputs a HIGH signal to the ECM while t](/img/19/57345/w960_57345-602.png)

ENGINE (TURBO)

AND ENGINE>

INSPECTION PROCEDURE 31Ignition switch-ST and park/neutral position

system

[Comment]

l The ignition switch ST inputs a HIGH signal to the ECM while the engin e is cranking.

The ECM controls fuel injection, etc. during starti ng based on this input.

l The park/neutral position switch inputs the conditi on of the select lever, i.e. whether it is

in

or range or in some other range, to the The ECM controls the idle air control motor based o n this input.l

Malfunction of

switch park/neutral switchImproper connector contact, open circuit or

shortcircuited harness wire

l Malfunction of the

I , .

,

.Check the park/neutral position switch. (Refer to G ROUP Replace On-vehicle Service.)

park/neutral position switchand ignition switch connector.

OK

Check the ignition switch. (Refer to GROUP 54 Switch.)

1. NG

Measure at the position switch connector

lDisconnect the connector, and measure at the harnes s2. NGOKside.Voltage between 8 and ground Engine (Turbo)>(Ignition switch: ON) Check trouble symptom.ING . ,

Voltage between 5 and ground Engine>(Ignition switch: ON) NGOK: Battery positive voltage 3. NGCheck harness wire between

2. Continuity between 7 and ground ECM and park/neutral Engine (Turbo)>tion switch connector.

Continuity between 8 and ground Engine>OK

OK: Continuity3.Voltage between 8 and ground Engine Replace the ECM.

Voltage between 5 and ground

l Ignition switch: START

l Disconnect ECM connector.Check harness wire between park/neutral OK: Battery positive voltage and starter terminal. Repair, if necessary.

OK, ,

TSB Revision

Page 604 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

AND ‘ENGINE> Troubleshooting

INSPECTION PROCEDURE 32

switch and compressor clutch relay system, . .

(Comment]l Malfunction of control When an A/C ON signal is i MITSUBISHI SPYDER 1990 Service Repair Manual E N G I N E

AND ‘ENGINE> Troubleshooting

INSPECTION PROCEDURE 32

switch and compressor clutch relay system, . .

(Comment]l Malfunction of control When an A/C ON signal is i](/img/19/57345/w960_57345-603.png)

E N G I N E

AND ‘ENGINE> Troubleshooting

INSPECTION PROCEDURE 32

switch and compressor clutch relay system, . .

(Comment]l Malfunction of control When an A/C ON signal is input to the the ECM carries out control of the idle air control Malfunction of motor, and also operates the compressor magnetic clutch.lImproper connector open circuit or harness .

NG

(Refer toGROUP55 On-vehicleService.) Replace

OK

Measure at the ECM connectors lDisconnect the connector, and measure at the harness

lVoltage between 22 and ground, and 45 and ground

(Ignition switch: ON)

(A/C switch: ON)

OK: Battery positive voltage

l Shortcircuit between 22 and ground

(Ignition switch: ON)

switch: ON)

OK: compressor clutch turns ON.

OK

N G

OK

Check trouble symptom.

the

NG

TSB RevisionI

Page 605 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND

INSPECTION PROCEDURE 33

Fan motor relay system (Radiator fan, A/C condenser fan)Probable cause

[Comment]l Malfunction of fan motor relay

The fan motor relay is MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND

INSPECTION PROCEDURE 33

Fan motor relay system (Radiator fan, A/C condenser fan)Probable cause

[Comment]l Malfunction of fan motor relay

The fan motor relay is](/img/19/57345/w960_57345-604.png)

ENGINE (TURBO)

AND

INSPECTION PROCEDURE 33

Fan motor relay system (Radiator fan, A/C condenser fan)Probable cause

[Comment]l Malfunction of fan motor relay

The fan motor relay is controlled by the power tran sistor inside the ECM turning ON and OFF.l Malfunction of fan motorImproper connector open shortclrcuitedl Malfunction of the ECM

Disconnect the connector, and measure at the harnes s

Voltage between 20 and ground, and 21 and ground

l Shortcircuit between 20 and ground (Ignition switch :

Check the Repair

O K

Check trouble symptom.

OK: Radiator fan and condenser fan rotate at highspeed.l Shortcircuit between 21 and ground (Ignition switch :

OK: Radiator fan and condenser fan rotate at lowspeed.

l Check the radiator fan circuit

l Check the condenser fan circuit.

TSB RevisionI

Page 606 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)AND Troubleshooting

INSPECTION PROCEDURE 34

Ignition circuit system cause’

[Comment]l Malfunction of ignition The interrupts the ignition coil current by turning the MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)AND Troubleshooting

INSPECTION PROCEDURE 34

Ignition circuit system cause’

[Comment]l Malfunction of ignition The interrupts the ignition coil current by turning the](/img/19/57345/w960_57345-605.png)

ENGINE (TURBO)AND Troubleshooting

INSPECTION PROCEDURE 34

Ignition circuit system cause’

[Comment]l Malfunction of ignition The interrupts the ignition coil current by turning the transistor in- of side the ECM ON and OFF.l Improper connector contact, open circuit or,

shortcircuited harness wire

l Malfunction

the ECM

Engine (Turbo)>

Measure at the ignition coil connector

lDisconnect the connector and measure at the harness

side.

l Voltage between 3 and ground (Ignition switch: ON)

OK: Battery positive voltage

Engine>

Measure at the ignition coil connectors 0, lDisconnect the connectors and measure at the harnes s

side.

l Voltage between 1 and ground (Ignition switch: ON)

OK: Battery positive voltage

OK

lDisconnect the connector, and measure at the harnes s

side.

l Continuity between 3 and ground

OK: Continuitv

Check trouble symptom.

Check the ignition switch. (Refer to Ignition Switch.)

N GCheck the harness wire between ignition connectorand ground. Repair, if necessary.

OK

Check the following connectors: EngineNG Repair(Turbo)>, Engine>, A-l 11

OK

Check trouble symptom.

NG Replace

(Refer toGROUP16 Ignition System.)

Check the ignition power tranNG Replace

(Refer to GROUP 16 Ignition

OK

lDisconnect the connector, and measure at the harnes s

side.

1. Voltage between each of 1, and ground

(Ignition switch: ON)

OK: Battery positive voltage

2.

between each of 2. 7 and around Cranking)

OK:

Check the following con- NG Repair

I

Check trouble symptom.

NGI

Check the harness wire between the ignition coil an d ignition power

transistor unit connector. Repair, if necessary.

.

Check trouble symptom.

Check trouble symptom.

NG

Check the ignition signal circuit. (Refer to INSPECTION PROCEDURE

Replace the ECM.

TSB Revision

Page 607 of 2103

![MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND

ENGINE> Troubleshooting

INSPECTION PROCEDURE 35

Idle air control motor (DC motor) Engine>P r o b a b l e c a u s e

[Comment]l Malfunction of idle air control mo MITSUBISHI SPYDER 1990 Service Repair Manual ENGINE (TURBO)

AND

ENGINE> Troubleshooting

INSPECTION PROCEDURE 35

Idle air control motor (DC motor) Engine>P r o b a b l e c a u s e

[Comment]l Malfunction of idle air control mo](/img/19/57345/w960_57345-606.png)

ENGINE (TURBO)

AND

ENGINE> Troubleshooting

INSPECTION PROCEDURE 35

Idle air control motor (DC motor) Engine>P r o b a b l e c a u s e

[Comment]l Malfunction of idle air control motor

The ECM controls the intake air volume during idlin g by opening and closing the I m p r o p e r c o n n e c t o r open “circuit’ servo valve located in the bypass passage.

l Malfunction of the

at the idle air control motor connector Connect the connector. (Use test harness: Voltage between 5 and ground (Ignition switch: ON)

OK: 2 or more to 0 (momentarily) Voltage between 6 and ground (Ignition switch: ON)OK: 4 or more to 0 (momentarily)

OK

the idle air control motor.1

Check symptom.

Replace

INSPECTION PROCEDURE 36

Scan tool: Inspection when no initial combustion oc curs

SCAN TOOL Data listNGCheck the power and ignition 16 Voltage of ECM power source (Refer to (Refer to I PROCEDURE 27.)

(Whenoil filler cap is removed.)

SCAN TOOL DTC

Are the diagnostic trouble codes output

Check timing belt for breakage.

INSPECTION CHART FOR TROUBLE CODES.

(Refer to

SCAN TOOL list NG

22 Crankshaft position sensor OK: Cranking speed is displayed.

OK

Check the crankshaft position sensor circuit malfu nction. (Refer to INSPECTION PROCEDURE FOR DIAGNOSTIC

TROUBLE CODES

SCAN TOOL Actuator testCheck the fuel pump system Engine 07 Fuel pump (Refer to (Refer to INSPECTION PROCEDURE 28.)

OKCheck the fuel pump system (Refer to INSPECTION PROCEDURE 29) .

SCAN TOOL list21 Check the engine coolant temperature circuit (Refer to INSPECTION PROCEDURE FOR DIAGNOSTICTROUBLE CODES

TSB Revision

Page 608 of 2103

ENGINE (TURBO)

AND ENGINE> Troubleshooting

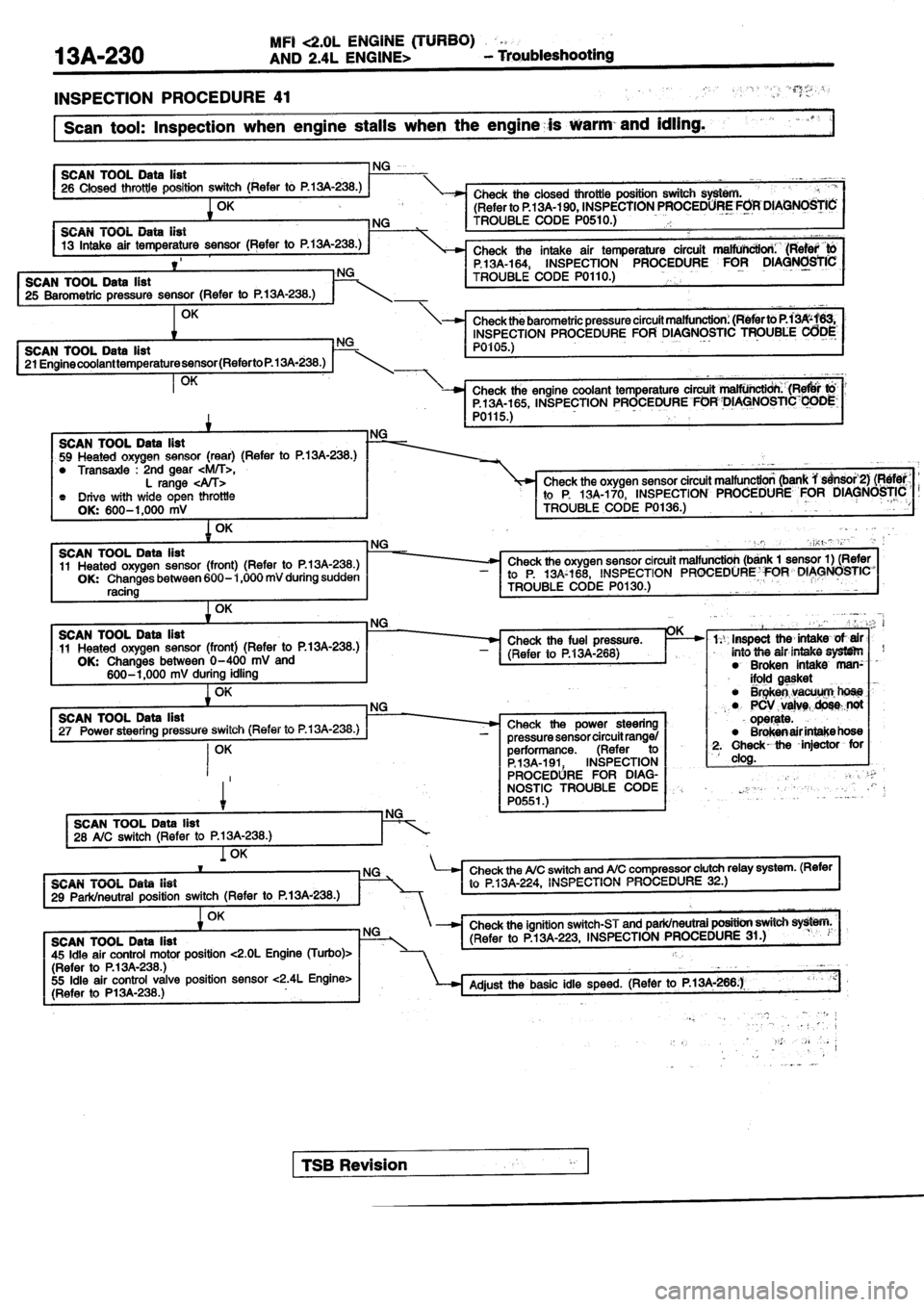

INSPECTION PROCEDURE 37 ,

Ignition system: Inspection when no initial occurs,

Engine (Turbo)> NGMeasure at the ignition coil connector Check ignition circuit system.

l Connect the connector. (Use the test harness:

(Refer to INSPECTION PROCEDURE 34.)

lTo inspect, connect the primary voltage detection-typetachometer to the terminal 1 (red clip) and terminal 2

(black clip).

OK: Each terminal displays a speed on the engine tachometer that is

of the cranking speed.

OK

Engine>

Measure at the ignition coil connectors

l Connect the connector.

(Use the test harness:

lTo inspect, connect the primary voltage detection-t ypetachometer to the terminal 2.OK: Each terminal displays a speed on the engine

tachometer that is of the cranking speed.

OK

NGCheck the ignition circuit system.(Refer to INSPECTION PROCEDURE 34.)

OK:

NG Check that the crankshaft position sensor are properly installed.

INSPECTION PROCEDURE 38

Scan tool: Inspection when incomplete combustion oc curs.

YESINSPECTION CHART FOR DIAGNOSTIC Arediagnostic trouble code output (Refer to

SCAN TOOL Actuator te

07 Fuel pump (Refer toNG, Check the fuel pump system Engine (Turbo)>.(Refer to INSPECTION PROCEDURE 28.)Check the fuel pump system Engine>. (Refer-to IN-

SPECTION PROCEDURE 29.)

./I,’

SCAN TOOL Date list21(Refer to INSPECTION PROCEDURE TROUBLE CODE

NGSCAN TOOL Data Check the ignition switch-ST 18 Ignition switch-ST (Refer to (Refer to INSPECTION PROCEDURE 30.)

Check the ignition switch-ST andpark/neutralswitch

INSPECTION PROCEDURE 39 ,

when huntina occurs.

Clean the throttle body. (Refer to

I

Check and adiust the fixed SAS (Refer to

Check trouble symptom.

NG

Inspect air into the air intake system for vacuum l eaks.

l Broken intake manifold gasket

Broken air intake hose

l Broken vacuum hose

Page 609 of 2103

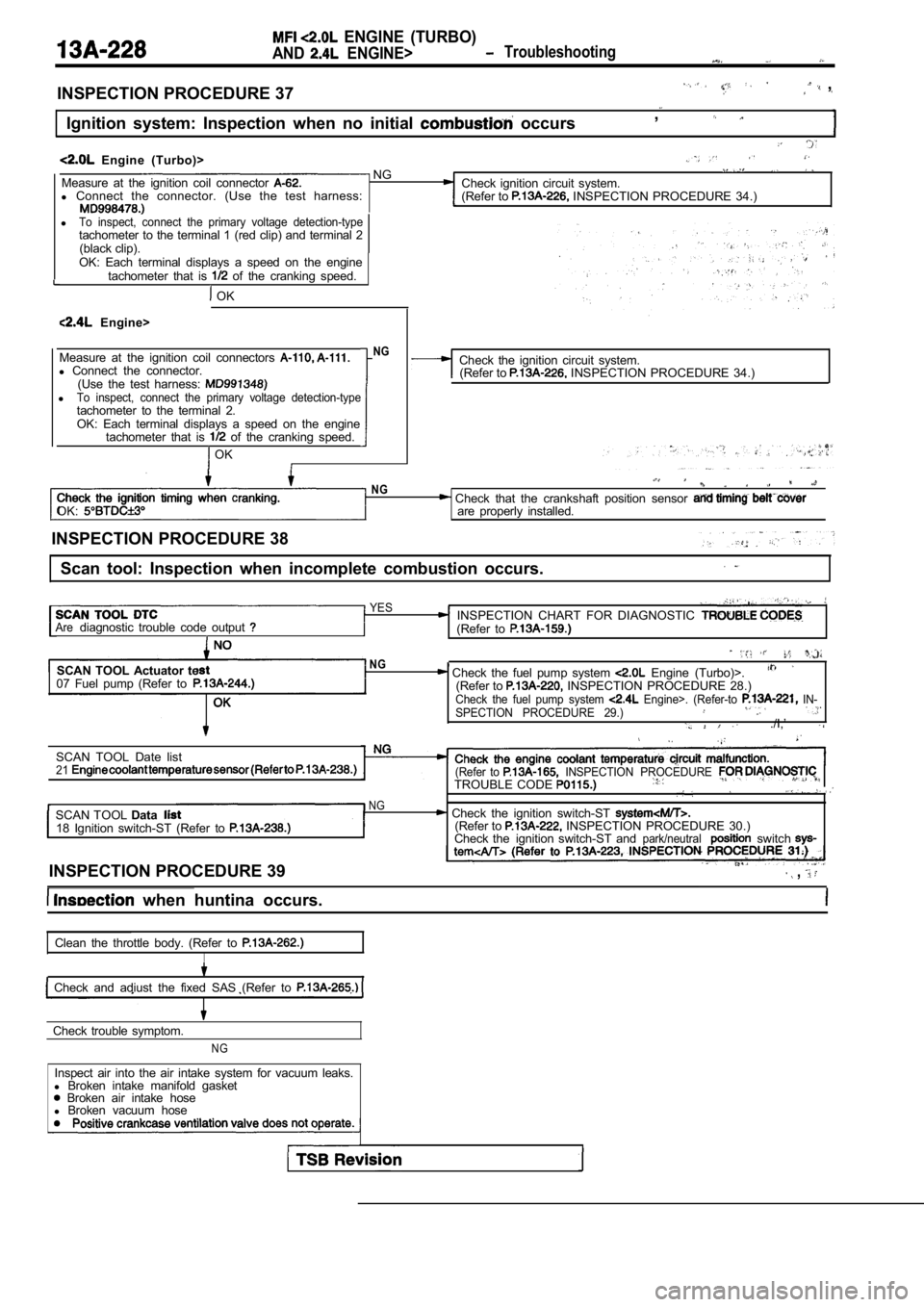

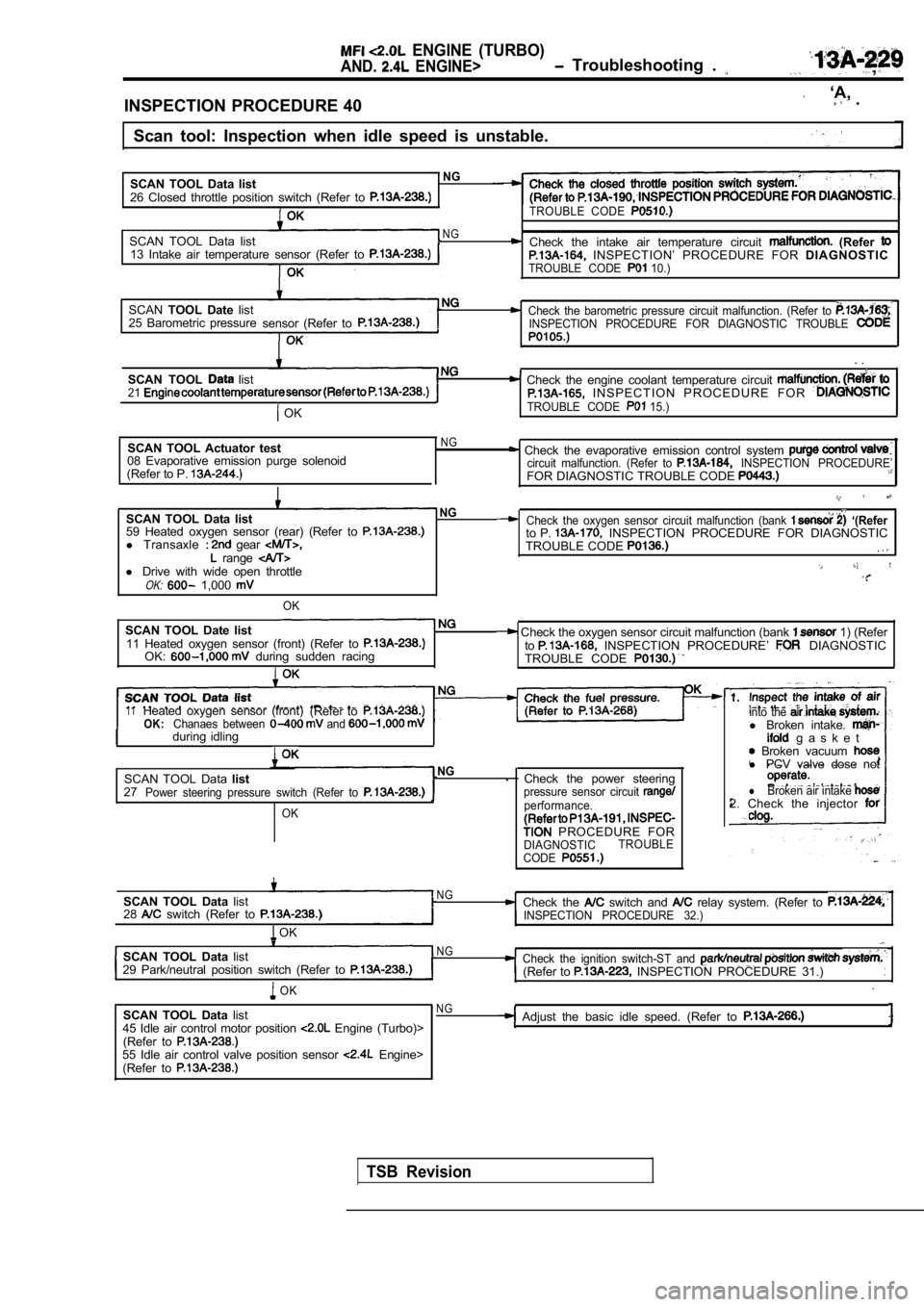

ENGINE (TURBO)

AND. ENGINE> Troubleshooting . ,

INSPECTION PROCEDURE 40

‘A, .

Scan tool: Inspection when idle speed is unstable.

SCAN TOOL Data list

NG

26 Closed throttle position switch (Refer to TROUBLE CODE

SCAN TOOL Data listNG Check the intake air temperature circuit (Refer 13 Intake air temperature sensor (Refer to INSPECTION’ PROCEDURE FOR DIAGNOSTICTROUBLE CODE 10.)

SCANTOOL Date listCheck the barometric pressure circuit malfunction. (Refer to 25 Barometric pressure

sensor (Refer toINSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE

.

SCAN TOOL list Check the engine coolant temperature circuit 21 I N S P E C T I O N P R O C E D U R E F O R

OKTROUBLE CODE 15.)

SCAN TOOL Actuator test

08 Evaporative emission purge solenoid

(Refer to P. NG Check the evaporative emission control system circuit malfunction. (Refer to INSPECTION PROCEDURE’FOR DIAGNOSTIC TROUBLE CODE

SCAN TOOL Data listNG

59 Heated oxygen sensor (rear) (Refer to l Transaxle gear range l Drive with wide open throttleOK: 1,000

OK

SCAN TOOL Date list11 Heated oxygen sensor (front) (Refer to OK: during sudden racing

Check the oxygen sensor circuit malfunction (bank ‘(Referto P. INSPECTION PROCEDURE FOR DIAGNOSTIC

TROUBLE CODE

Check the oxygen sensor circuit malfunction (bank 1) (Refer

to INSPECTION PROCEDURE’ DIAGNOSTIC

TROUBLE CODE

11Heated oxygen sensor (front) (Refer toOK:Chanaes between and during idlingI

SCAN TOOL Data listNG.

27

Power steering pressure switch (Refer to

OK

Check the power steeringpressure sensor circuit performance.

PROCEDURE FORDIAGNOSTIC TROUBLE

CODE

into the l Broken intake. g a s k e t Broken vacuum l PCV valve dose not

lBroken air intake 2. Check the injector

SCAN TOOL Data list

28 switch (Refer to

OK

N GCheck the switch and relay system. (Refer to INSPECTION PROCEDURE 32.)

SCAN TOOL Data listN G

29 Park/neutral position switch (Refer to Check the ignition switch-ST and (Refer to INSPECTION PROCEDURE 31.)

OK

SCAN TOOL Data list

45 Idle air control motor position Engine (Turbo)>

(Refer to

55 Idle air control valve position sensor Engine>

(Refer to

NGAdjust the basic idle speed. (Refer to

TSB Revision

Page 610 of 2103