MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 791 of 2103

Emission

ENGINE AND CONTROL

Vacuum

Engine speed

AFUOO

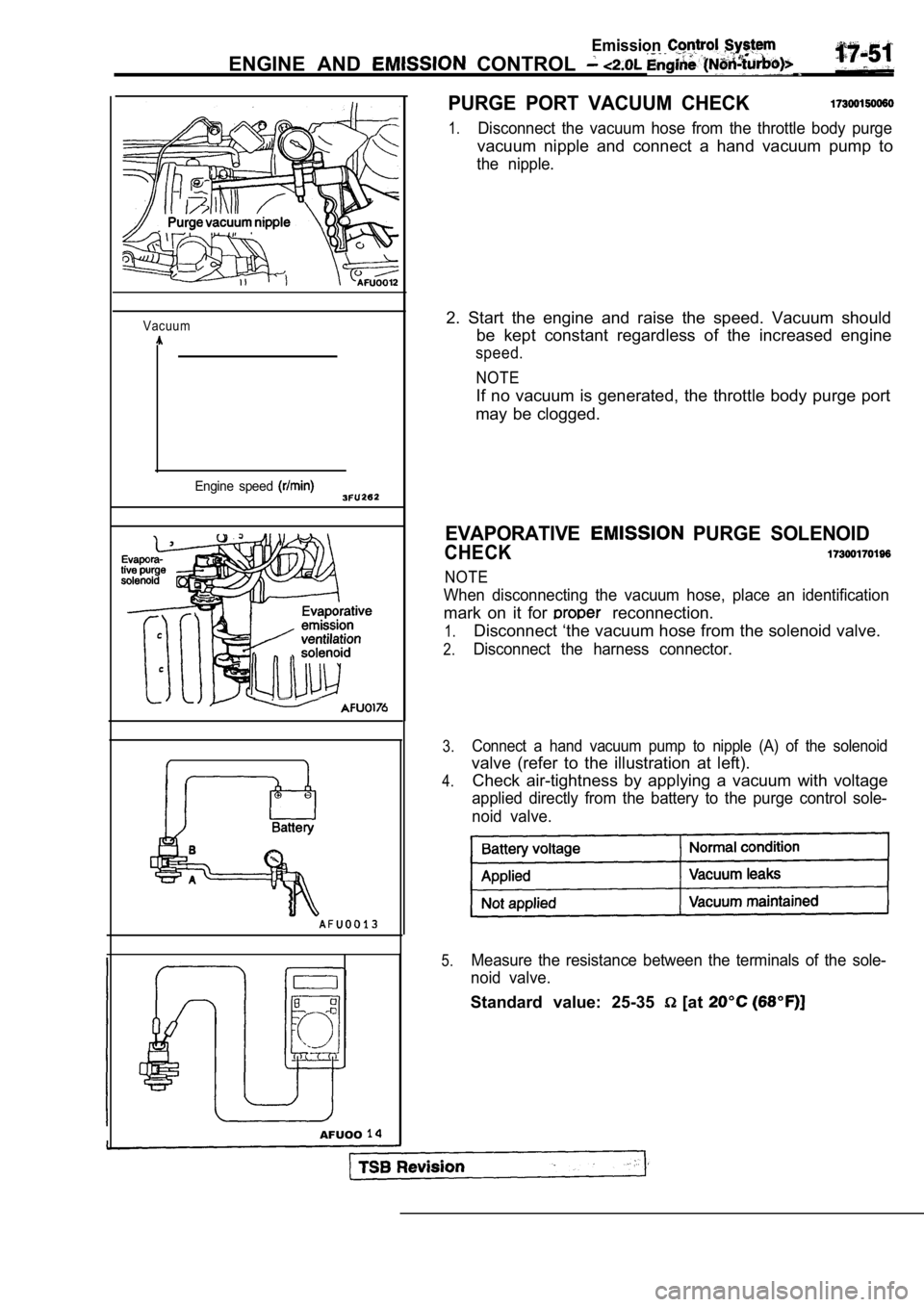

PURGE PORT VACUUM CHECK

1.Disconnect the vacuum hose from the throttle body purge

vacuum nipple and connect a hand vacuum pump to

the nipple.

2. Start the engine and raise the speed. Vacuum sho uld

be kept constant regardless of the increased engine

speed.

NOTE

If no vacuum is generated, the throttle body purge port

may be clogged.

EVAPORATIVE PURGE SOLENOID

CHECK

NOTE

When disconnecting the vacuum hose, place an identi fication

mark on it for reconnection.

1.

2.

3.

4.

5.

Disconnect ‘the vacuum hose from the solenoid valve .

Disconnect the harness connector.

Connect a hand vacuum pump to nipple (A) of the sol enoid

valve (refer to the illustration at left).

Check air-tightness by applying a vacuum with volta ge

applied directly from the battery to the purge control sole-

noid valve.

Measure the resistance between the terminals of the sole-

noid valve.

Standard value: 25-35 [at

Page 792 of 2103

ENGINE AND EMISSION CONTROL

ENGINE COOLANT TEMPERATURE SENSOR

AND INTAKE AIR TEMPERATURE SENSOR

To check these parts, refer to GROUP Troubleshooting.

AIR CONDITIONING SWITCH17300200031

To check the air conditioning switch, refer to GROU P 55

Air Conditioning Switch.

TSB Revision

Page 793 of 2103

Emission

ENGINE AND EMISSION CONTROL

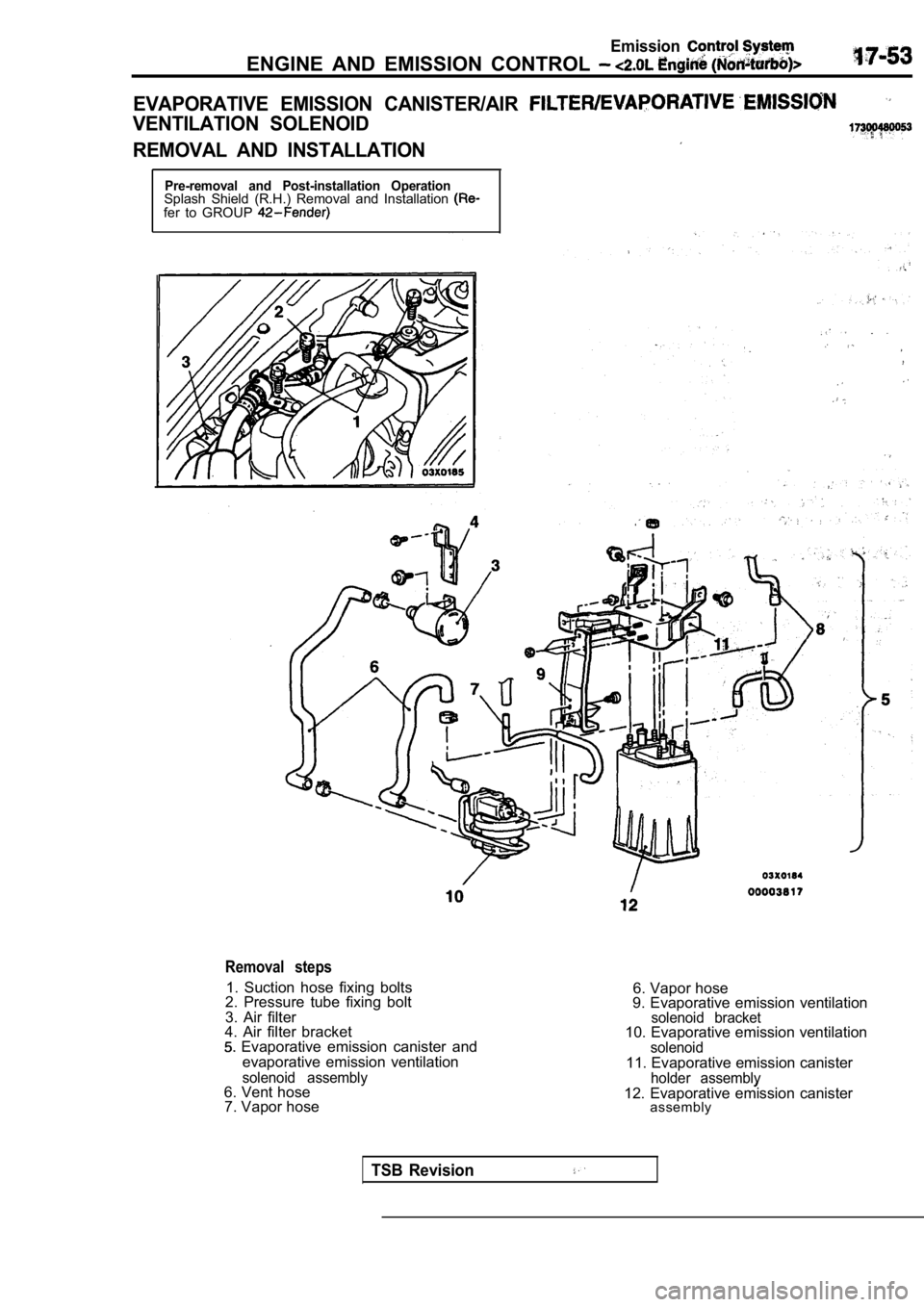

EVAPORATIVE EMISSION CANISTER/AIR

VENTILATION SOLENOID

REMOVAL AND INSTALLATION

Pre-removal and Post-installation OperationSplash Shield (R.H.) Removal and Installation fer to GROUP

Removal steps

1. Suction hose fixing bolts

2. Pressure tube fixing bolt

3. Air filter

4. Air filter bracket

Evaporative emission canister and

evaporative emission ventilation

solenoid assembly6. Vent hose7. Vapor hose 6. Vapor hose

9. Evaporative emission ventilation

solenoid bracket10. Evaporative emission ventilationsolenoid11. Evaporative emission canisterholder assemblv12. Evaporative emission canister assembly

TSB Revision

Page 794 of 2103

ENGINE AND EMISSION CONTROL

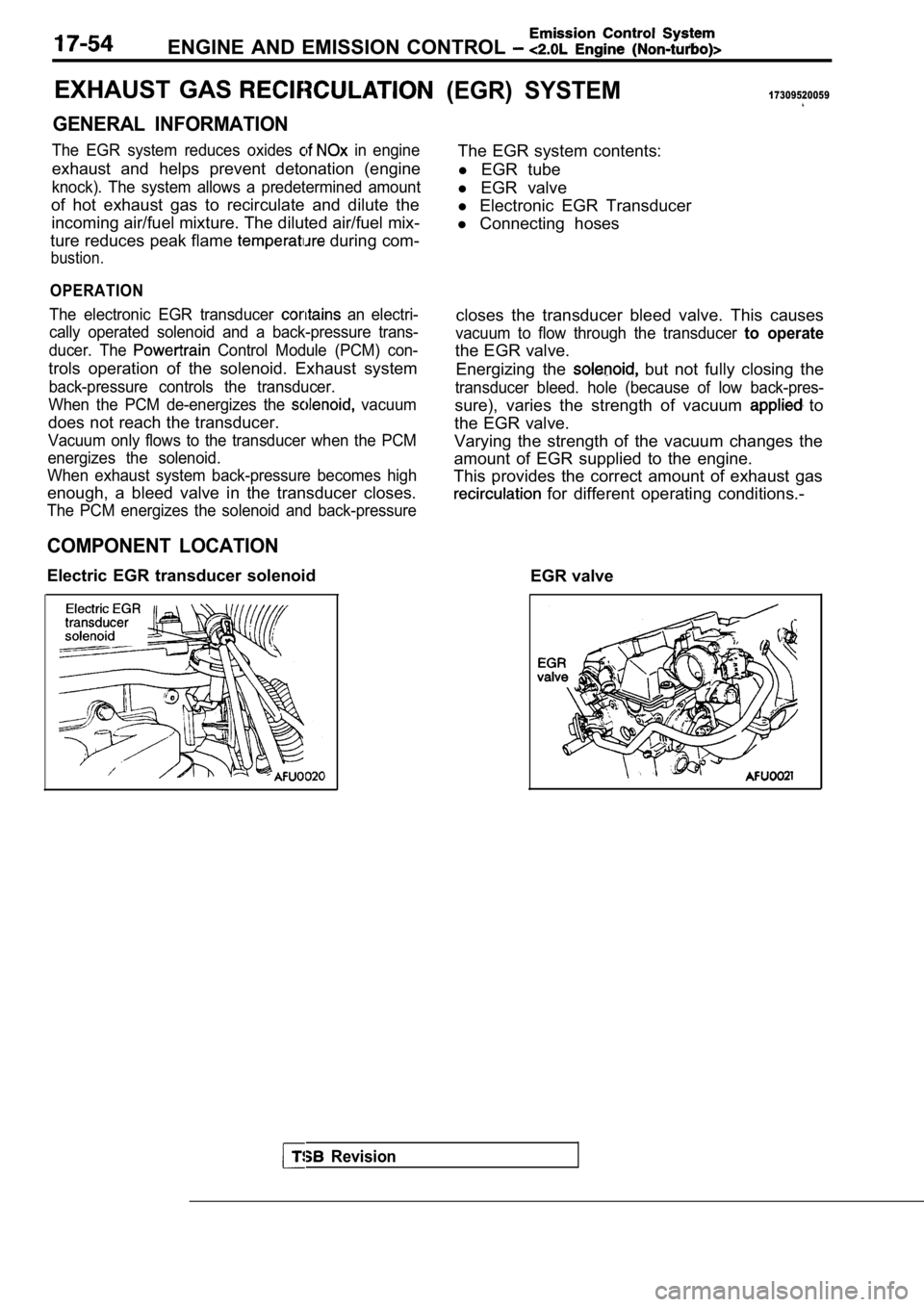

EXHAUST GAS

GENERAL INFORMATION

The EGR system reduces oxides in engine

exhaust and helps prevent detonation (engine

knock). The system allows a predetermined amount

of hot exhaust gas to recirculate and dilute theincoming air/fuel mixture. The diluted air/fuel mix -

ture reduces peak flame

during com-

bustion.

OPERATION

The electronic EGR transducer an electri-

cally operated solenoid and a back-pressure trans-

ducer. The

Control Module (PCM) con-

trols operation of the solenoid. Exhaust system

back-pressure controls the transducer.

When the PCM de-energizes the

vacuum

does not reach the transducer.

Vacuum only flows to the transducer when the PCM

energizes the solenoid.

When exhaust system back-pressure becomes high

enough, a bleed valve in the transducer closes.

The PCM energizes the solenoid and back-pressure

COMPONENT LOCATION

Electric EGR transducer solenoid

(EGR) SYSTEM17309520059

The EGR system contents:

l EGR tube

l EGR valve

l Electronic EGR Transducer

l Connecting hoses

closes the transducer bleed valve. This causes

vacuum to flow through the transducer to operate

the EGR valve. Energizing the

but not fully closing the

transducer bleed. hole (because of low back-pres-

sure), varies the strength of vacuum to

the EGR valve.

Varying the strength of the vacuum changes the

amount of EGR supplied to the engine.

This provides the correct amount of exhaust gas

for different operating conditions.-

EGR valve

Revision

Page 795 of 2103

Emission Control

Engine

C H E C K . .

To ensure proper operation of system, all

and moving parts must be free of

plugging or sticking.

Ensure that the system’ hoses do not leak.

Replace leaking components.

1.Check the EGR and valve with

engine fully warmed up and running coolant

perature over

2.With the transaxle in neutral and the allow.

the engine to idle seconds.

3. Abruptly accelerate the engine

approximately

but not over 3000

4, The valve ‘stem should move when accelerating

the engine. Repeat the test several- times-to

movement.

5.If the EGR valve stem moves, the control system is

ing normally.

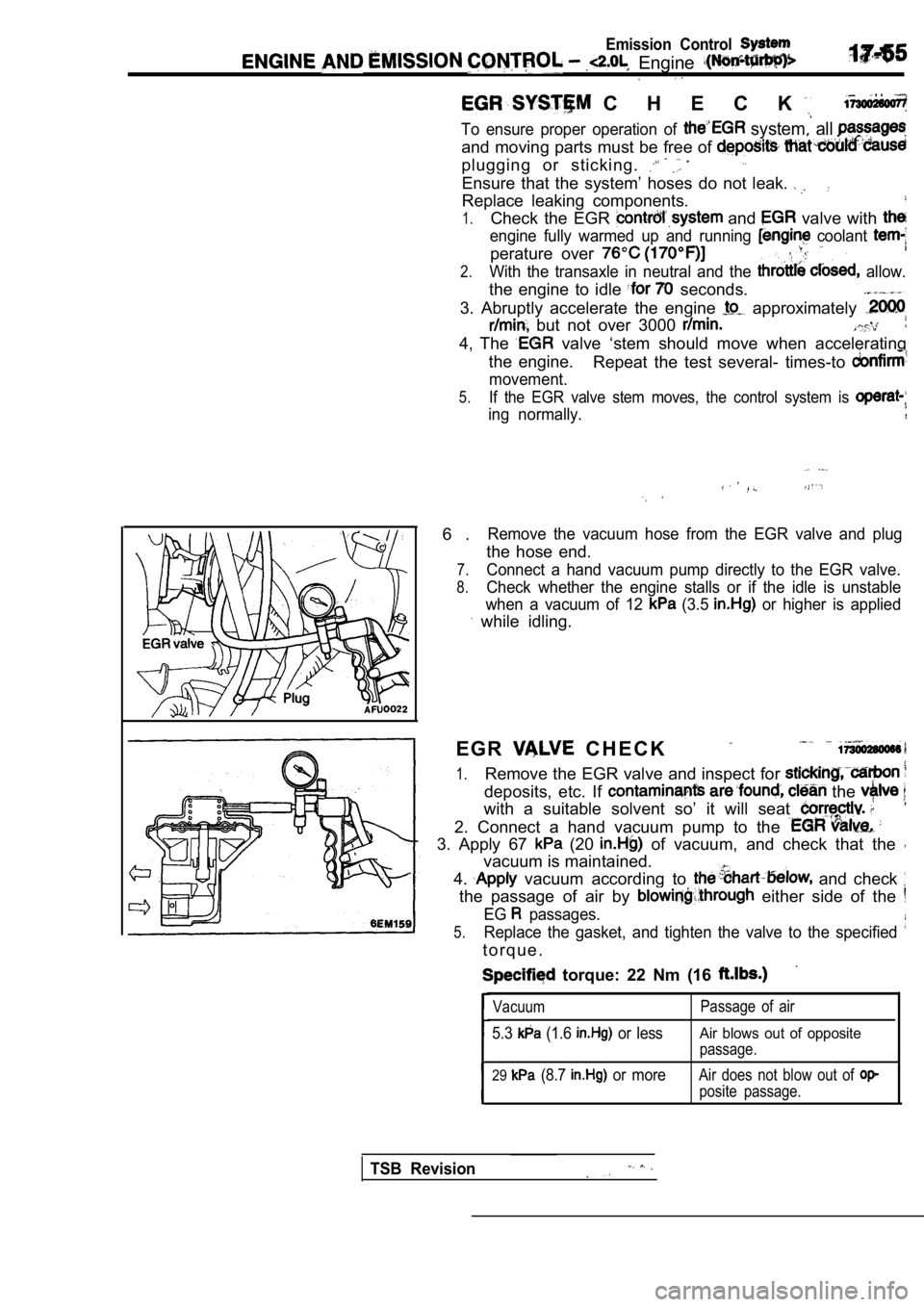

6 .Remove the vacuum hose from the EGR valve and plug

the hose end.

7.Connect a hand vacuum pump directly to the EGR valv e.

8.Check whether the engine stalls or if the idle is unstable

when a vacuum of 12

(3.5 or higher is applied

while idling.

E G R

C H E C K

1.Remove the EGR valve and inspect for

deposits, etc. If the

with a suitable solvent so’ it will seat

2. Connect a hand vacuum pump to the

3. Apply 67 (20 of vacuum, and check that the

vacuum is maintained.

4.

vacuum according to and check

the passage of air by either side of the

EG passages.

5.Replace the gasket, and tighten the valve to the sp ecified

t o r q u e .

torque: 22 Nm (16

Vacuum

5.3 (1.6 or less

Passage of air

Air blows out of opposite

passage.

29 (8.7 or moreAir does not blow out of

posite passage.

TSB Revision

Page 796 of 2103

ENGINE AND

Emission Control System

Vacuum

Engine speed

TSB Revision

4I

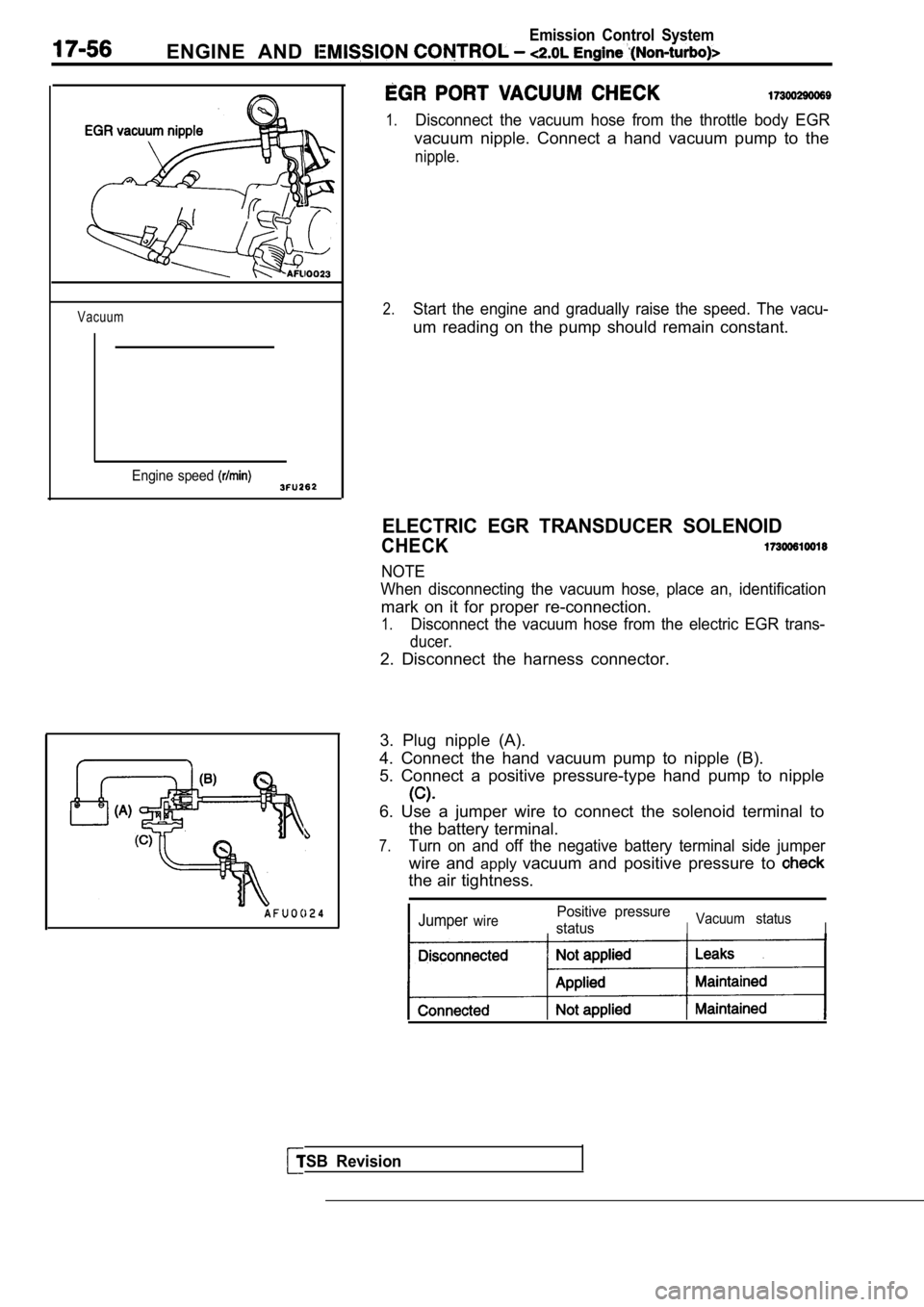

1.Disconnect the vacuum hose from the throttle body EGR

vacuum nipple. Connect a hand vacuum pump to the

nipple.

2.Start the engine and gradually raise the speed. The vacu-

um reading on the pump should remain constant.

ELECTRIC EGR TRANSDUCER SOLENOID

CHECK

NOTE

When disconnecting the vacuum hose, place an, ident ification

mark on it for proper re-connection.

1.Disconnect the vacuum hose from the electric EGR trans-

ducer.

2. Disconnect the harness connector.

3. Plug nipple (A).

4. Connect the hand vacuum pump to nipple (B).

5. Connect a positive pressure-type hand pump to ni pple

6. Use a jumper wire to connect the solenoid terminal to

the battery terminal.

7.Turn on and off the negative battery terminal side jumper

wire and applyvacuum and positive pressure to

the air tightness.

JumperwirePositive pressure

status

IVacuum statusI

Page 797 of 2103

Emission Control

AND EMISSION CONTROL

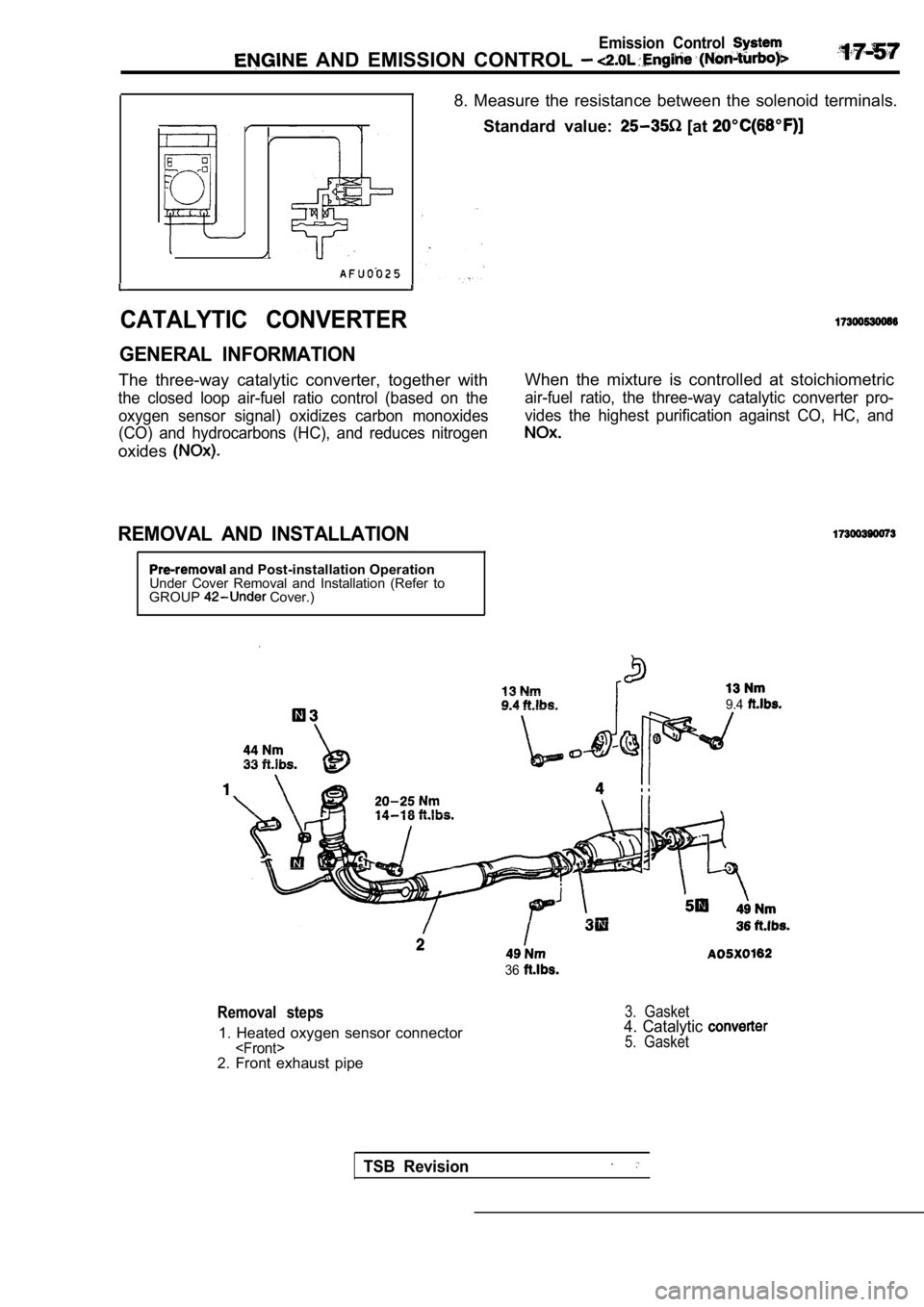

8. Measure the resistance between the solenoid terminals.

Standard value:

[at

CATALYTIC CONVERTER

GENERAL INFORMATION

The three-way catalytic converter, together with

the closed loop air-fuel ratio control (based on th e

oxygen sensor signal) oxidizes carbon monoxides

(CO) and hydrocarbons (HC), and reduces nitrogen

oxides

REMOVAL AND INSTALLATION

and Post-installation Operation

Under Cover Removal and Installation (Refer to

GROUP

Cover.) When the mixture is controlled at stoichiometric

air-fuel ratio, the three-way catalytic converter p

ro-

vides the highest purification against CO, HC, and

9.4

36

Removal steps

1. Heated oxygen sensor connector

3. Gasket4. Catalytic 5. Gasket

TSB Revision

Page 798 of 2103

ENGINE AND EMISSION CONTROL

INSPECTION

Check for damage, cracking or deterioration. Replace if faulty.

Caution

1. Stop the engine immediately if engine misfiring

occurs, otherwise an abnormally hot exhaust system

will damage the catalytic converter or other underb ody

parts.

2.

Correct and repair the ignition or fuel system if t here

are malfunctions, otherwise engine misfiring may

occur which will damage the catalytic converter.

3. Observe manufacturer’s specifications when doing

service work.

TSB Revision

Page 799 of 2103

(Turbo) 2.41 Engines

GENERAL INFORMATION

The emission control system consists of the following sub-systems:

l Positive crankcase ventilation system

l Evaporative emission control system

l Exhaust emission control system

SERVICE SPECIFICATIONS

Evaporative emission purge solenoid coil resistance

[at

Standard value

36-44

EGR solenoid coil resistance [at 36-44

SPECIAL TOOL

ToolTool number and name

Supersession Application

700Checking the purge control

system

TROUBLESHOOTING

SymptomProbable cause Remedy

Engine will not start or Vacuum hose disconnected or damaged. Repair or

is hard to start.

The EGR valve is not closed. Repair or replace

Malfunction of the evaporative emission purge Repair or replace

solenoid.

Rough idle or engine

stalls.The EGR valve is not closed.

Vacuum hose disconnected or damaged.

Malfunction of the positive crankcase ventilation

valve. Repair or replace

Repair or replace

Replace

Malfunction of the purge control system.

Engine hesitates or

poor acceleration.

Excessive oil

sumption.

Poor fuel mileage.

Malfunction of the exhaust gas recirculation

system.

Positive crankcase ventilation line clogged.

Malfunction of the exhaust gas recirculation

system. Check the system; if there

a prob-

lem, check its

parts.

Check the system; if there is a

check its component parts.

Check positive crankcase ventilation

system.

Check the system: if there is a

check its component parts.

TSB Revision

Page 800 of 2103

(Turbo) and Engine>

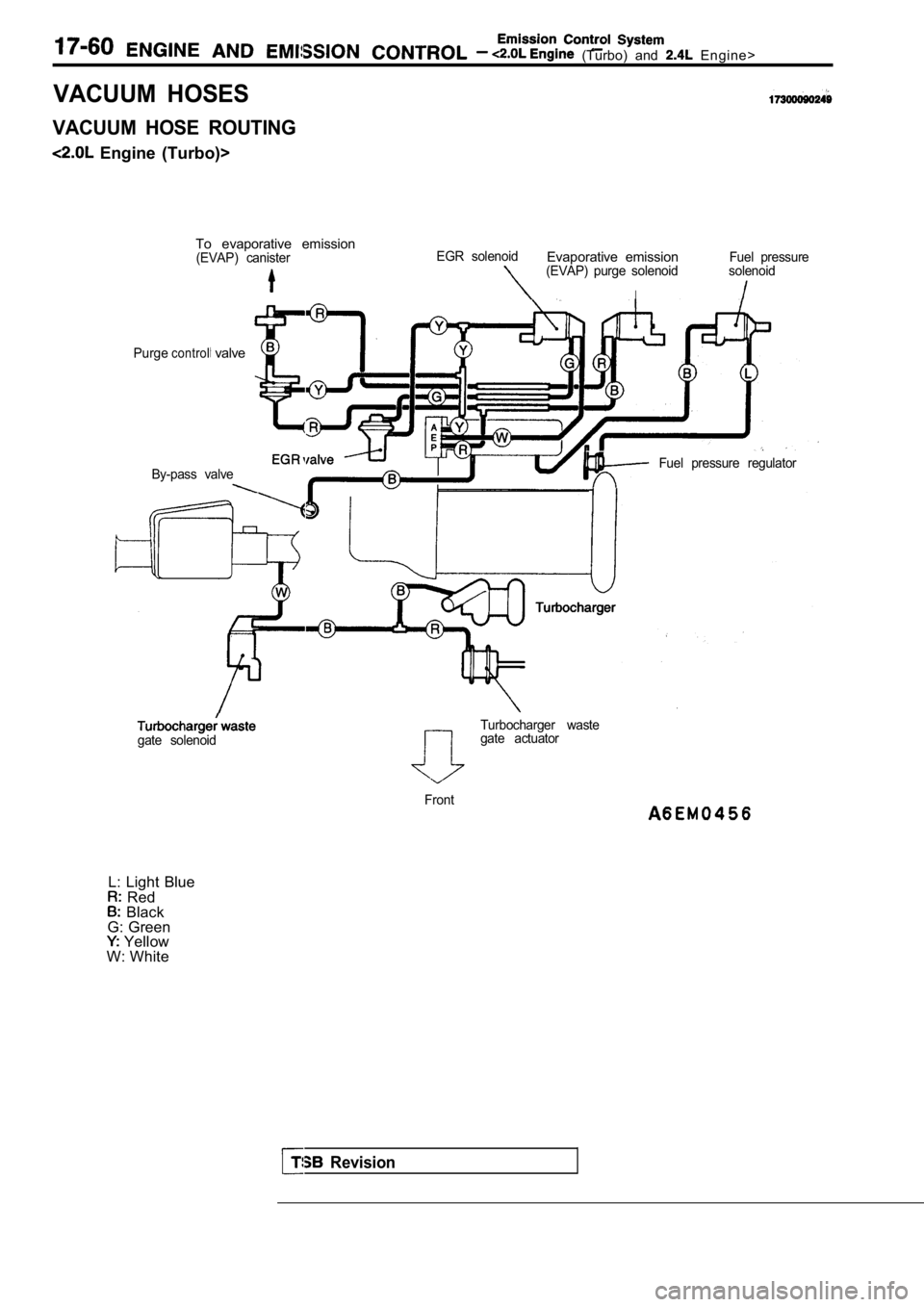

VACUUM HOSES

VACUUM HOSE ROUTING

Engine (Turbo)>To evaporative emission

(EVAP) canisterEGR solenoidEvaporative emissionFuel pressure(EVAP) purge solenoid solenoid

I

Purgecontrol valve

By-pass valveFuel pressure regulator

Revision

Turbocharger waste

gate solenoidgate actuator

Front

L: Light Blue Red Black

G: Green

Yellow

W: White