MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: parking brake, trailer, horn, battery, tire size, fuel fill door release, maintenance reset

Page 821 of 2103

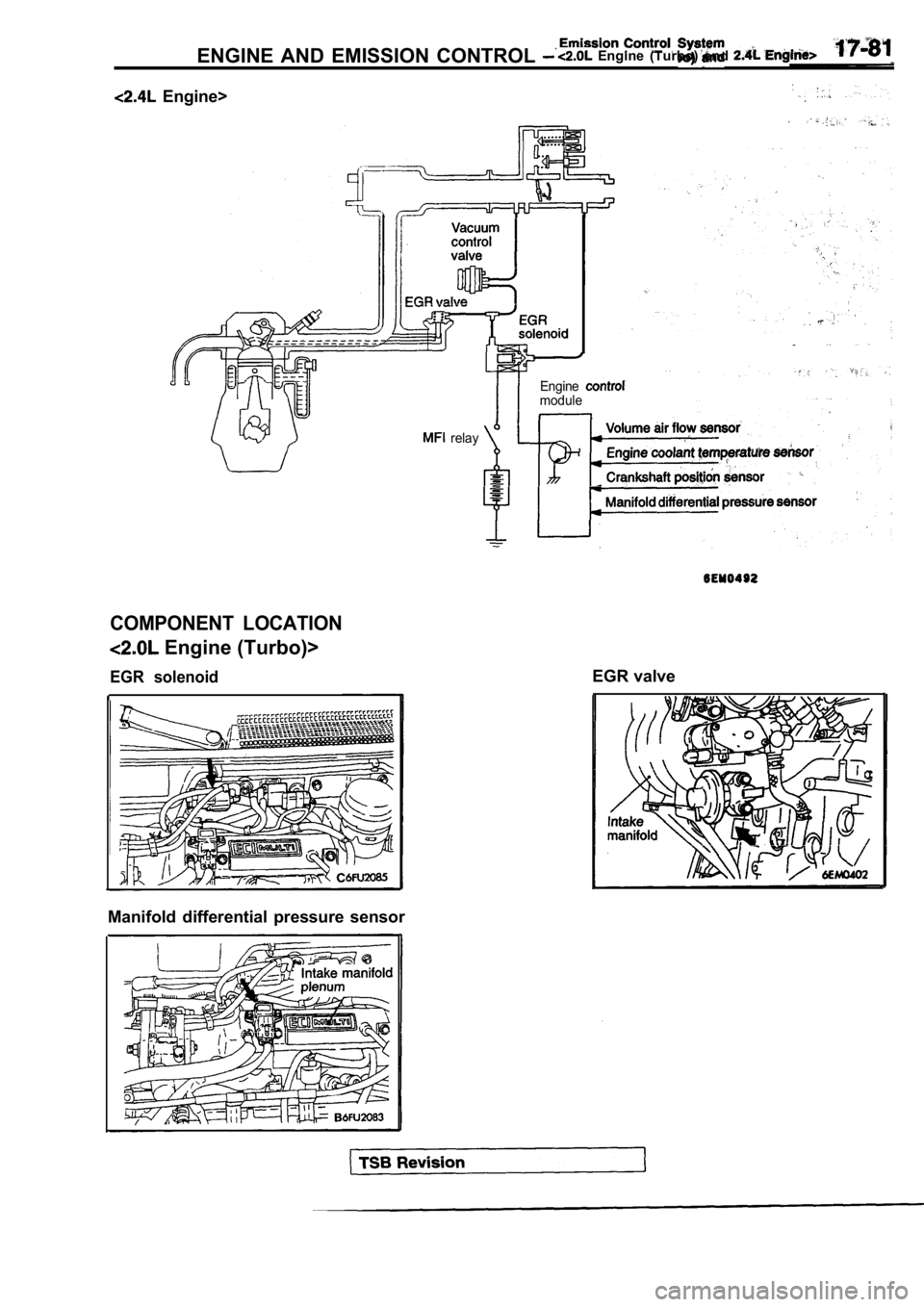

ENGINE AND EMISSION CONTROL Engine (Turbo) end

Engine>

COMPONENT LOCATION

Engine (Turbo)>

EGR solenoid

Manifold differential pressure sensor

relayEngine

module

EGR valve

Page 822 of 2103

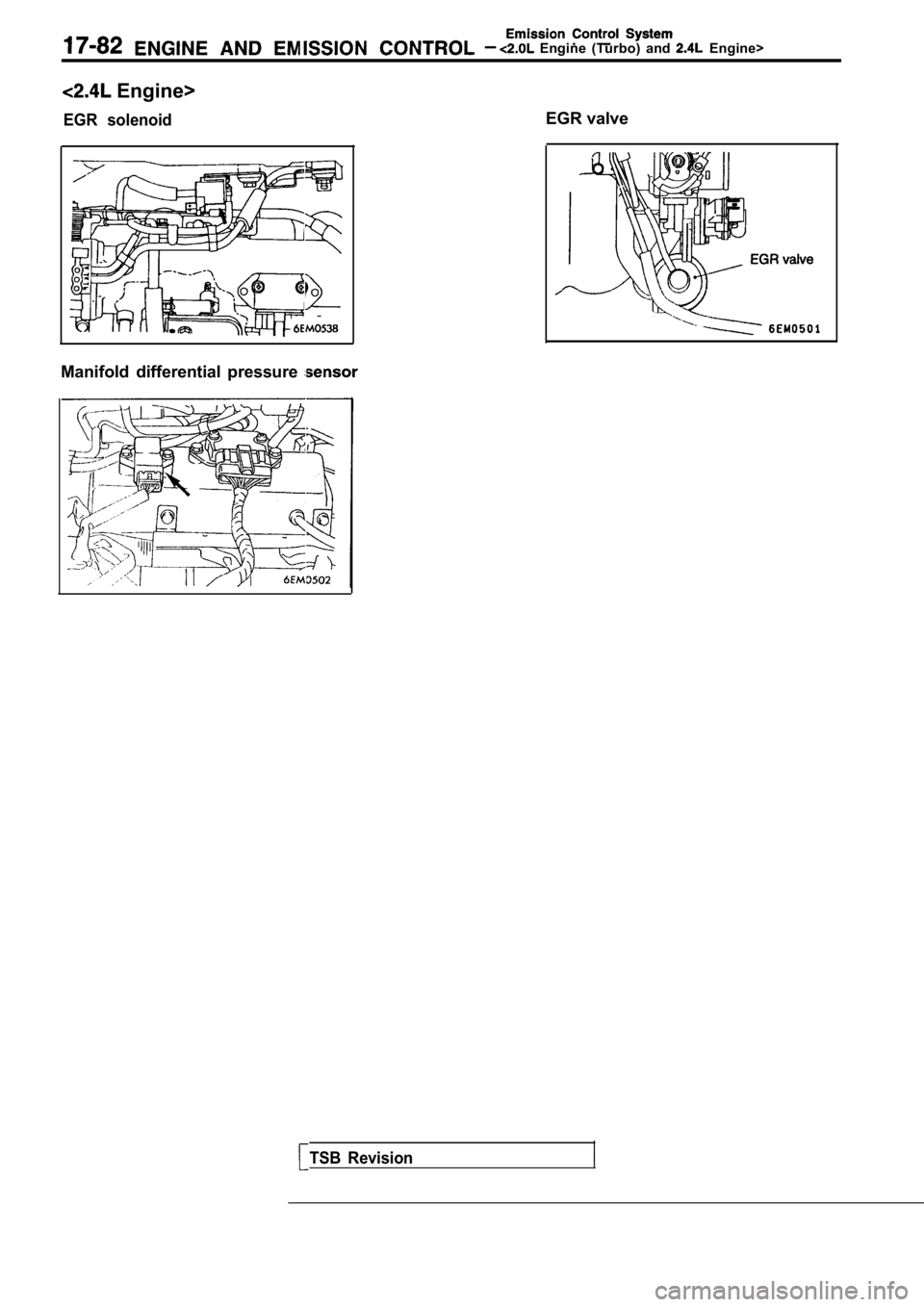

Engine (Turbo) and Engine>

Engine>

EGR solenoidEGR valve

Manifold differential pressure

TSB Revision

Page 823 of 2103

Emission Control

ENGINE AND EMISSION CONTROL Engine

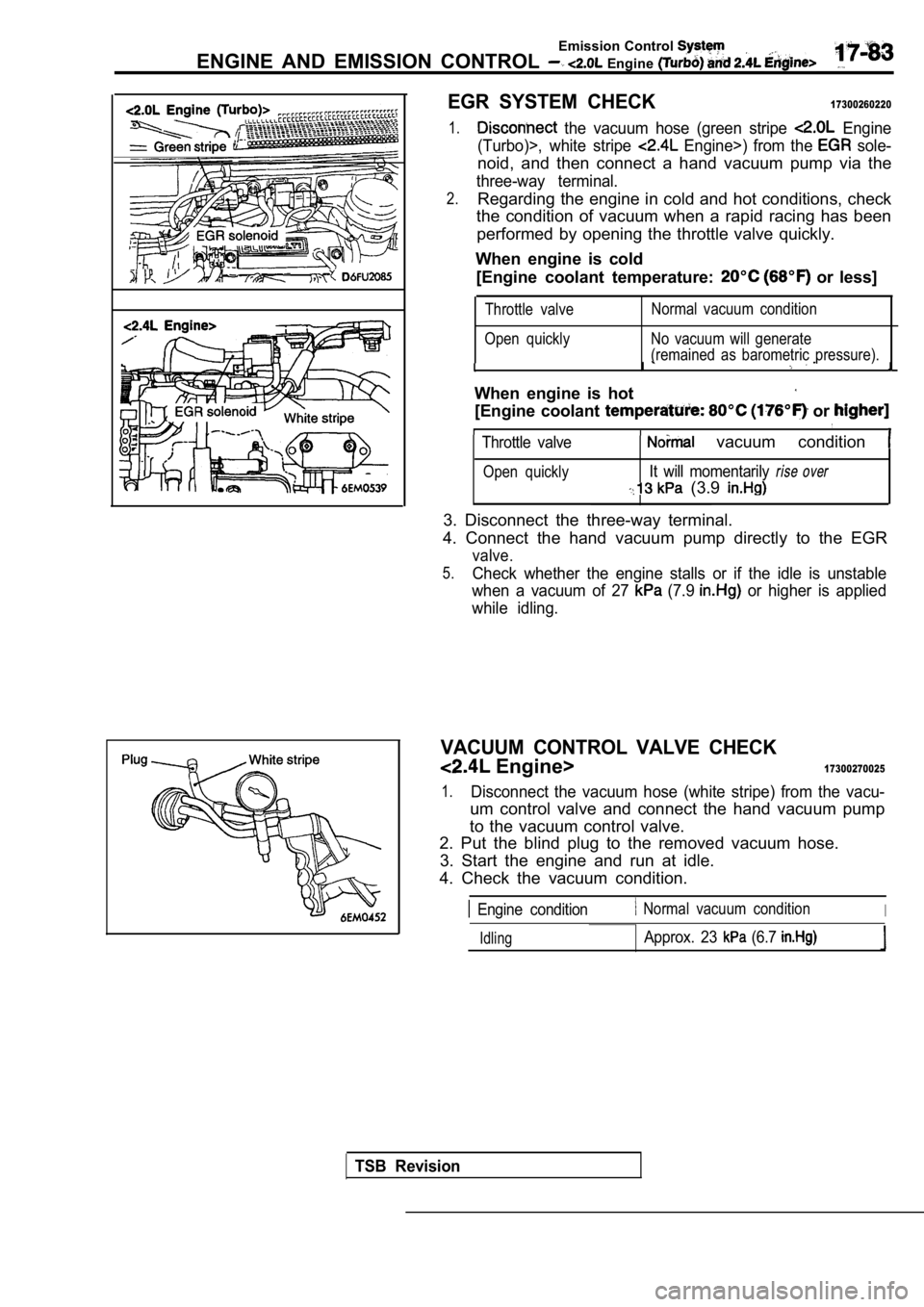

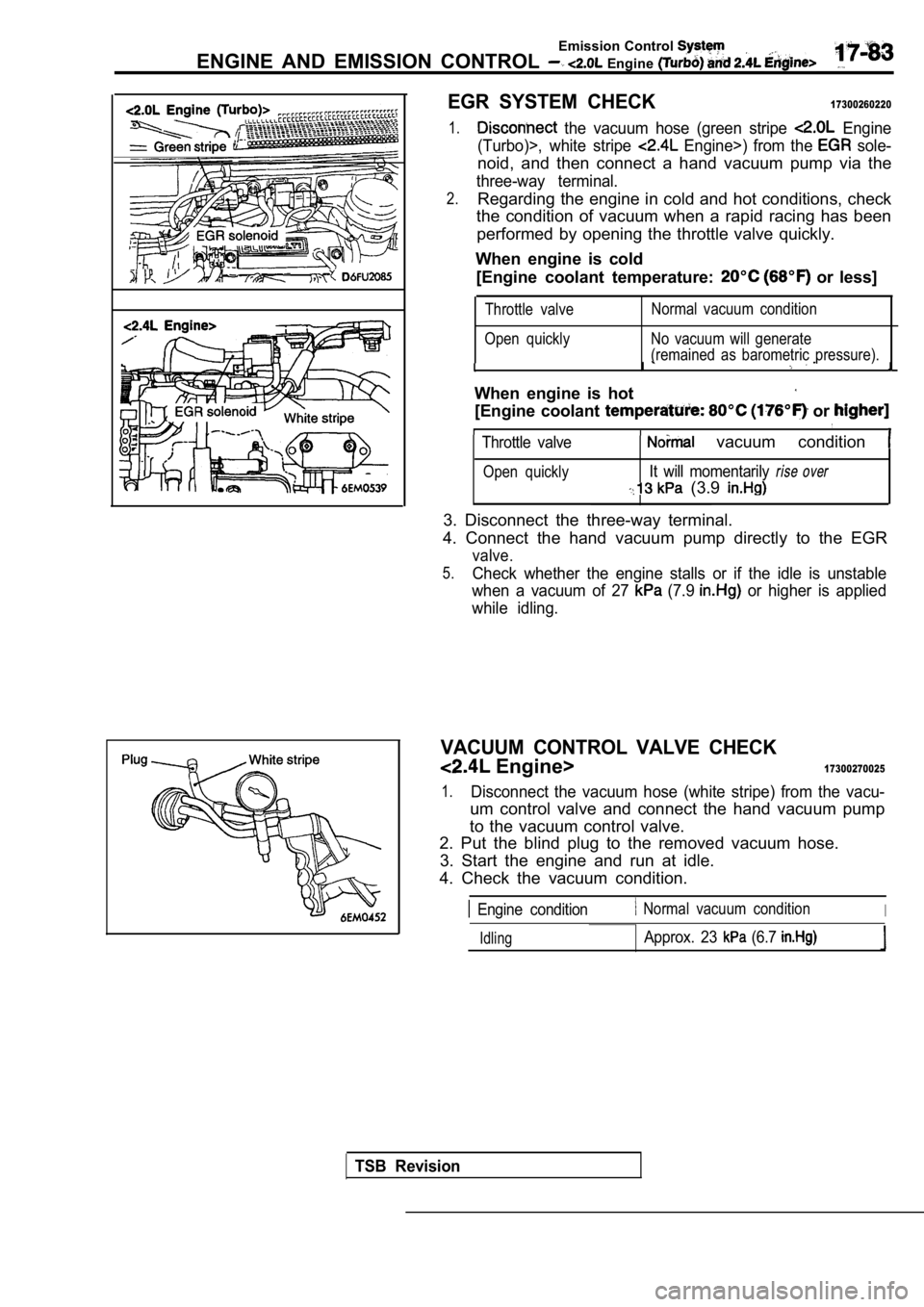

EGR SYSTEM CHECK17300260220

1. the vacuum hose (green stripe Engine

(Turbo)>, white stripe

Engine>) from the sole-

noid, and then connect a hand vacuum pump via the

three-way terminal.

2.Regarding the engine in cold and hot conditions, ch eck

the condition of vacuum when a rapid racing has bee n

performed by opening the throttle valve quickly.

When engine is cold [Engine coolant temperature:

or less]

Throttle valve

Open quickly Normal vacuum condition

No vacuum will generate

(remained as barometric pressure).

I

When engine is hot

[Engine coolant or

Throttle valve vacuum condition

Open quicklyIt will momentarily rise over

(3.9

3. Disconnect the three-way terminal.

4. Connect the hand vacuum pump directly to the EGR

valve.

5.Check whether the engine stalls or if the idle is u nstable

when a vacuum of 27

(7.9 or higher is applied

while idling.

VACUUM CONTROL VALVE CHECK

Engine>17300270025

1.Disconnect the vacuum hose (white stripe) from the vacu-

um control valve and connect the hand vacuum pump

to the vacuum control valve.

2. Put the blind plug to the removed vacuum hose.

3. Start the engine and run at idle.

4. Check the vacuum condition.

Engine condition Normal vacuum conditionI

IdlingApprox. 23 (6.7

TSB Revision

Page 824 of 2103

(Turbo) and Engine>

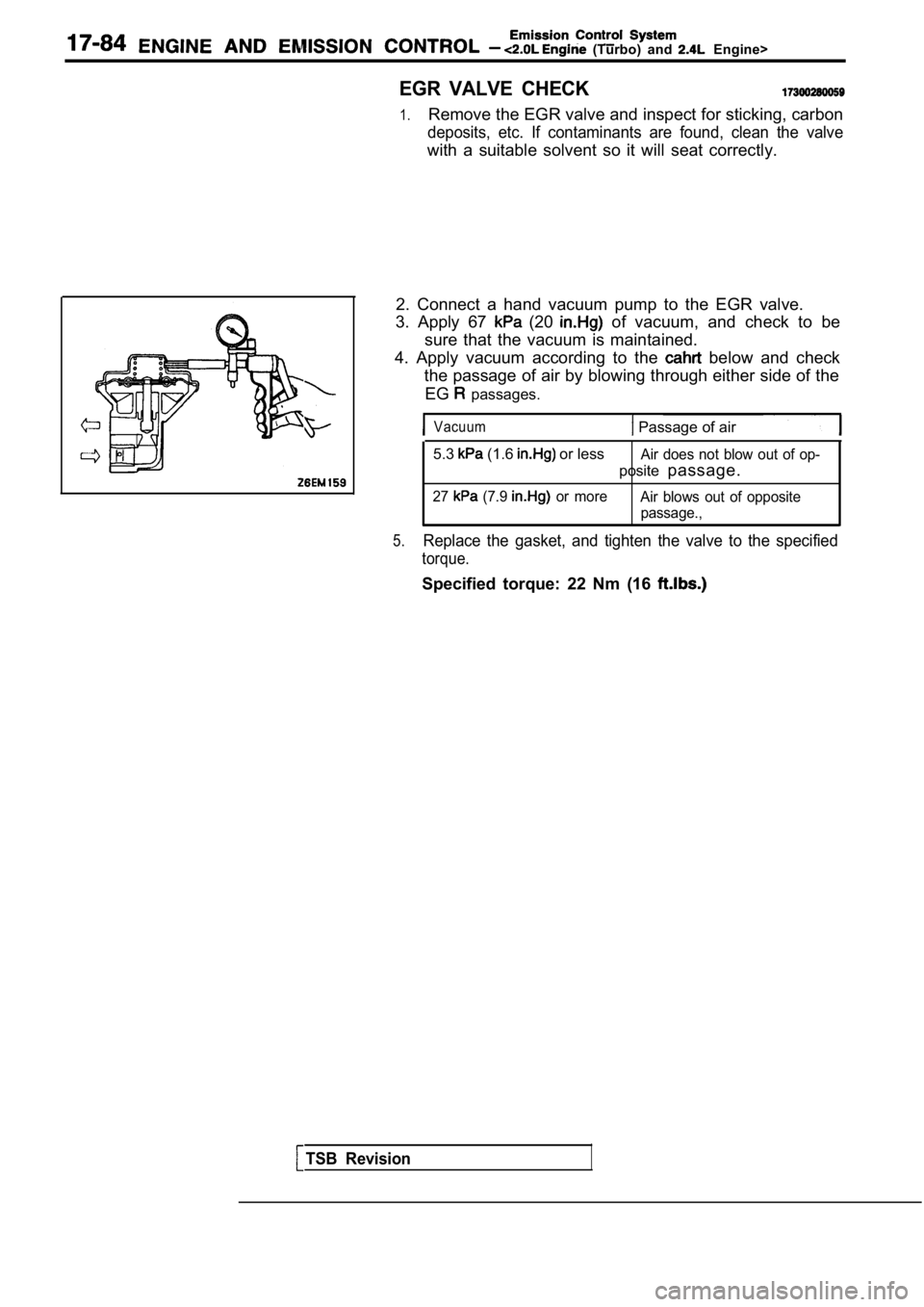

EGR VALVE CHECK

1.Remove the EGR valve and inspect for sticking, carbon

deposits, etc. If contaminants are found, clean the valve

with a suitable solvent so it will seat correctly.

2. Connect a hand vacuum pump to the EGR valve.

3. Apply 67

(20 of vacuum, and check to be

sure that the vacuum is maintained.

4. Apply vacuum according to the

below and check

the passage of air by blowing through either side o f the

EG

passages.

Vacuum Passage of air

5.3 (1.6 or lessAir does not blow out of op-

posite passage.

27 (7.9 or more

Air blows out of opposite

passage.,

5.Replace the gasket, and tighten the valve to the sp ecified

torque.

Specified torque: 22 Nm (16

TSB Revision

Page 825 of 2103

and

Engine

Engine>

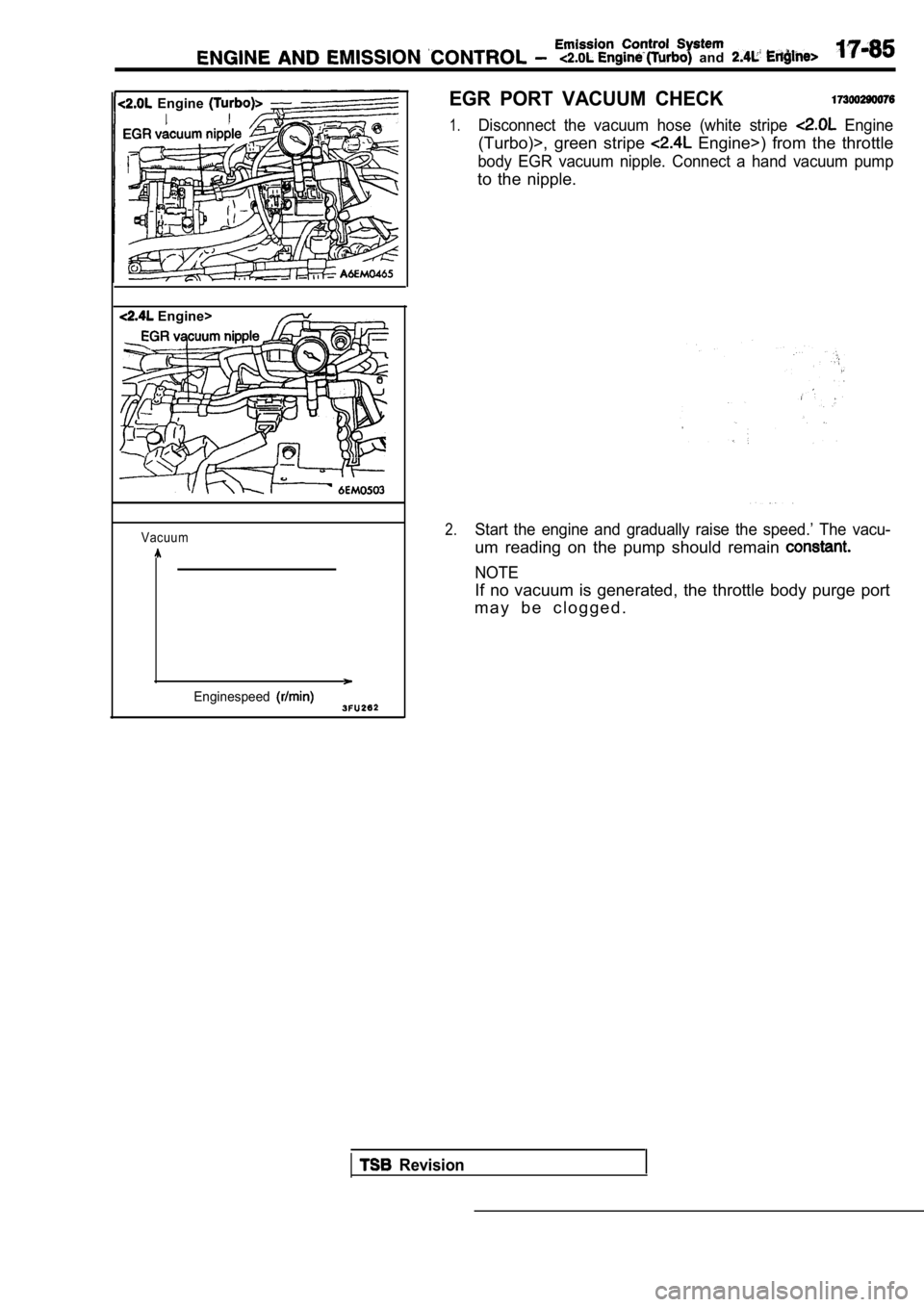

Vacuum

Enginespeed

EGR PORT VACUUM CHECK

1.Disconnect the vacuum hose (white stripe Engine

(Turbo)>, green stripe Engine>) from the throttle

body EGR vacuum nipple. Connect a hand vacuum pump

to the nipple.

2.Start the engine and gradually raise the speed.’ The vacu-

um reading on the pump should remain

NOTE

If no vacuum is generated, the throttle body purge port

m a y b e c l o g g e d .

Revision

Page 826 of 2103

E N G I N E A N D E M I S S I O N C O N T R O L ( T u r b o )

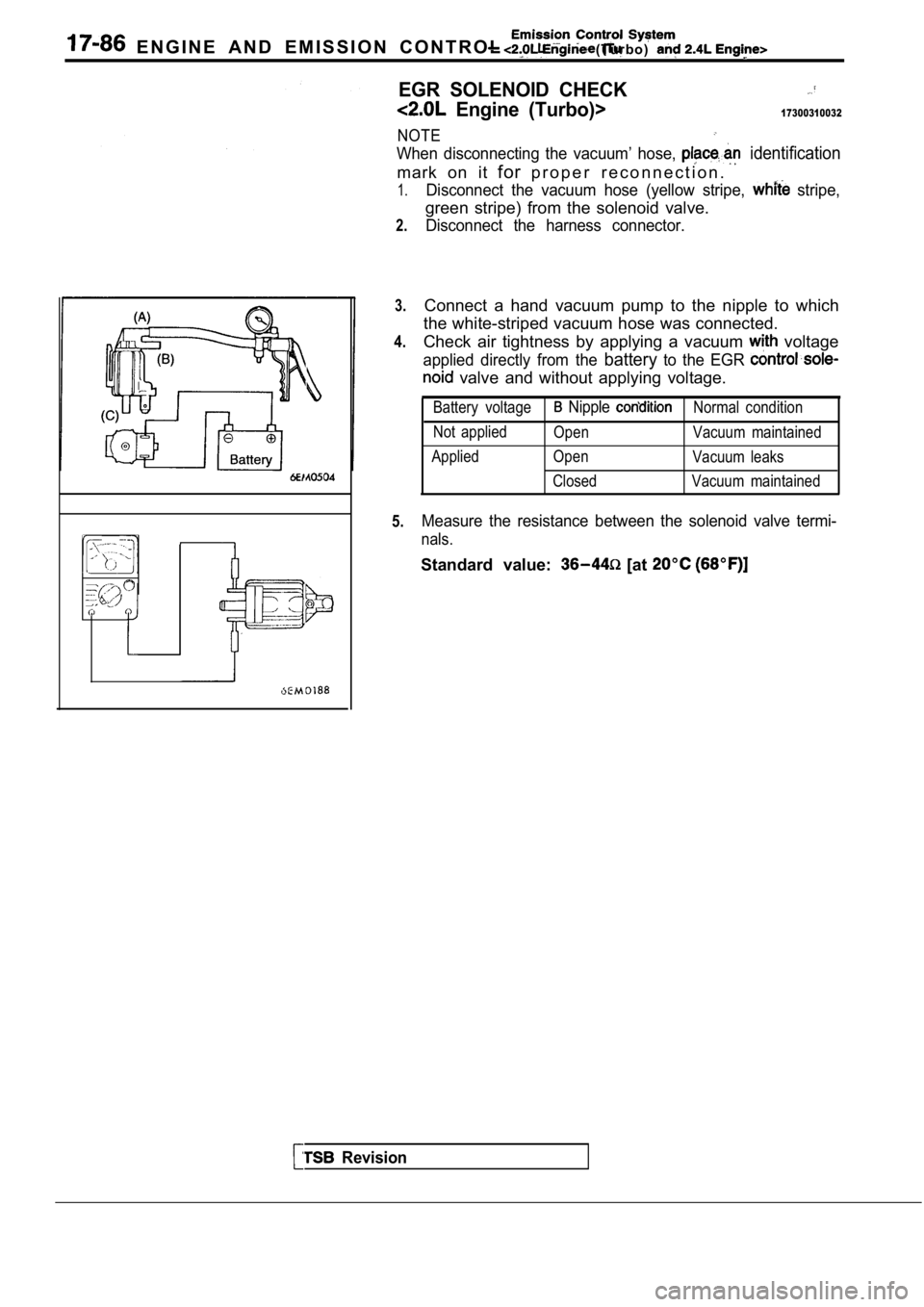

EGR SOLENOID CHECK

Engine (Turbo)>17300310032

NOTE

When disconnecting the vacuum’ hose, identification

mark on it forp r o p e r r e c o n n e c t i o n .

1.

2.

3.

4.

5.

Disconnect the vacuum hose (yellow stripe, stripe,

green stripe) from the solenoid valve.

Disconnect the harness connector.

Connect a hand vacuum pump to the nipple to which

the white-striped vacuum hose was connected.

Check air tightness by applying a vacuum

voltage

applied directly from the batteryto the EGR

valve and without applying voltage.

Battery voltage Nipple Normal condition

Not applied Open Vacuum maintained

Applied Open Vacuum leaks

Closed Vacuum maintained

Measure the resistance between the solenoid valve t ermi-

nals.

Standard value: [at

Revision

Page 827 of 2103

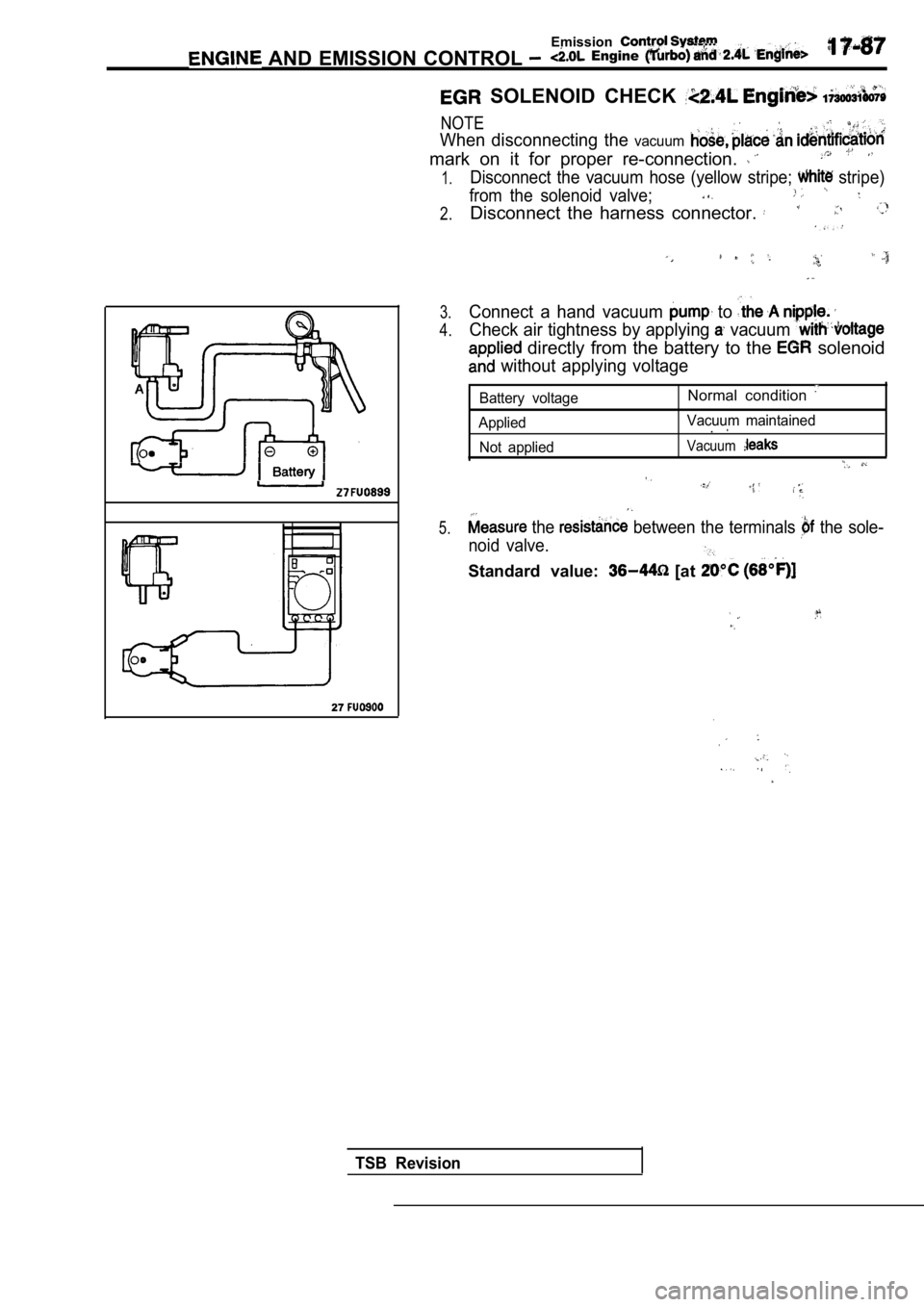

AND EMISSION CONTROL

Emission Engine

27

SOLENOID CHECK

NOTE,

When disconnecting the vacuum

mark on it for proper re-connection.

Disconnect the vacuum hose (yellow stripe; stripe)1.

2.

3.

4.

5.

from the solenoid valve;

Disconnect the harness connector.

Connect a hand vacuum to

Check air tightness by applying vacuum

directly from the battery to the solenoid

without applying voltage

Battery voltage

Applied Not appliedNormal condition

Vacuum maintained.

Vacuum

the between the terminals the sole-

noid valve.

Standard value: [at

.

,

TSB Revision

Page 828 of 2103

Emission Control System ENGINE AND EMISSION CONTROL Engine (Turbo) and

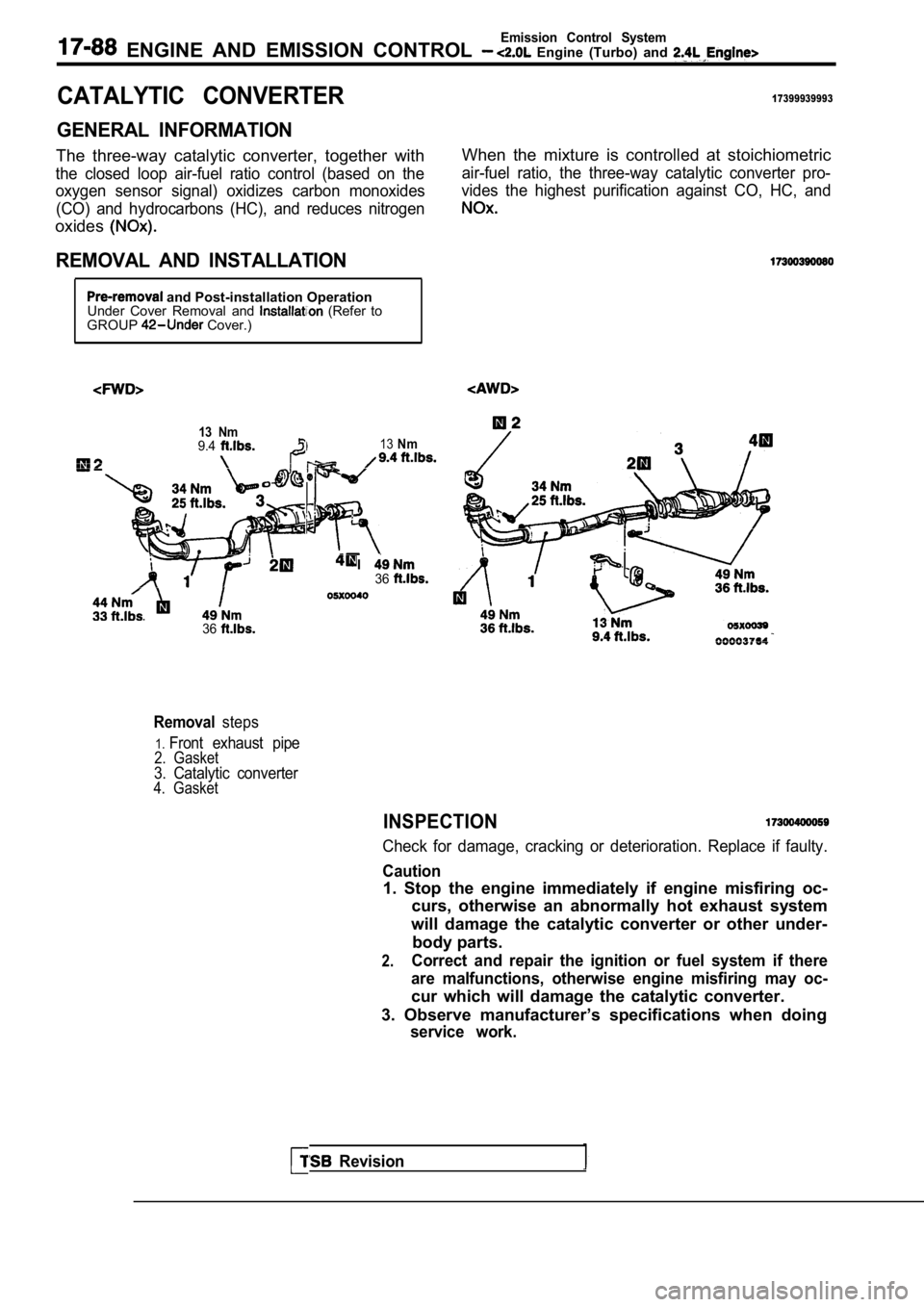

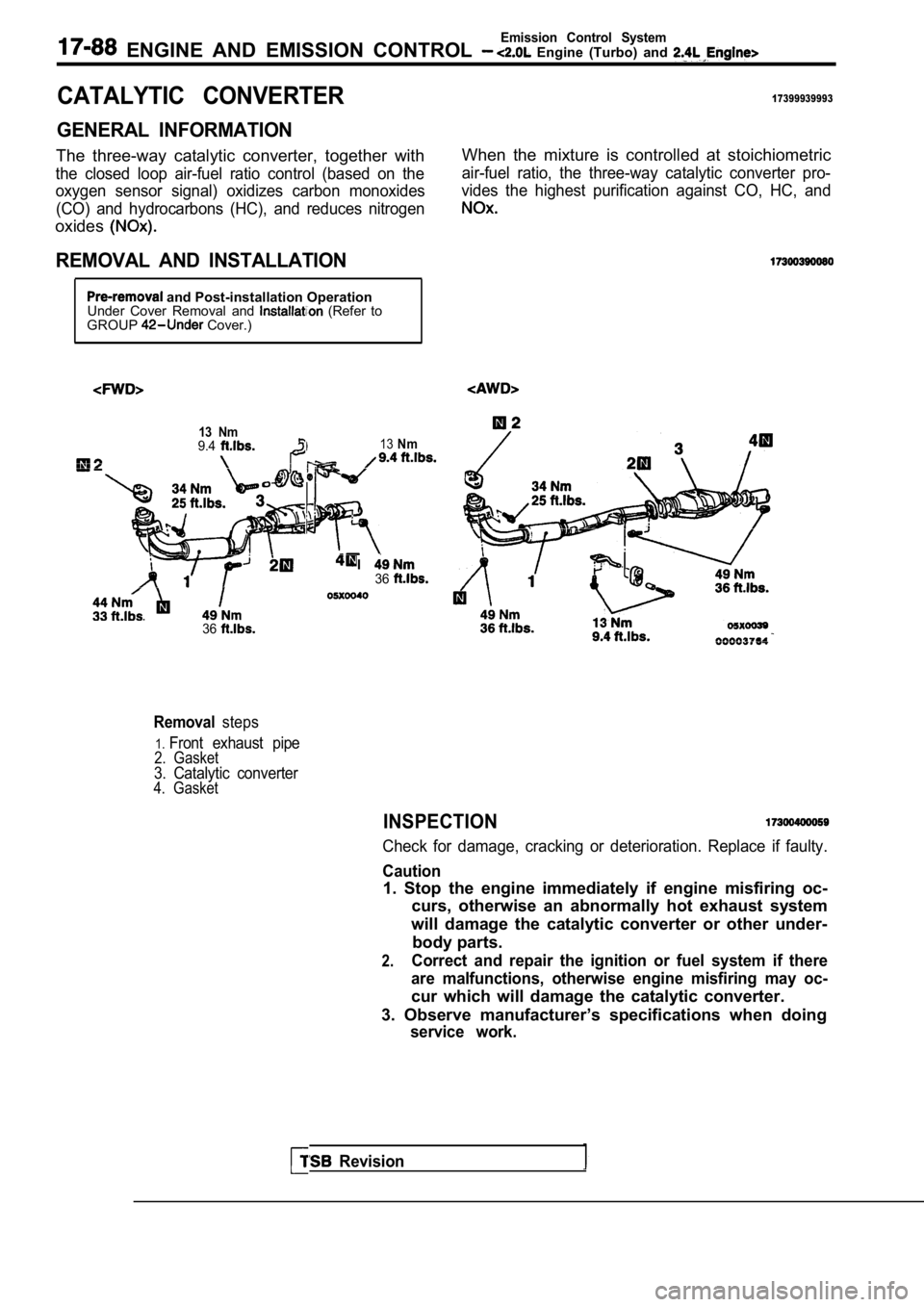

CATALYTIC CONVERTER17399939993

GENERAL INFORMATION

The three-way catalytic converter, together with

the closed loop air-fuel ratio control (based on the

oxygen sensor signal) oxidizes carbon monoxides

(CO) and hydrocarbons (HC), and reduces nitrogen

oxides

REMOVAL AND INSTALLATION

When the mixture is controlled at stoichiometric

air-fuel ratio, the three-way catalytic converter p ro-

vides the highest purification against CO, HC, and

and Post-installation Operation

Under Cover Removal and (Refer to

GROUP Cover.)

13 Nm9.413Nm

I36

. .

Revision

36

Removalsteps

1.Front exhaust pipe2. Gasket3. Catalytic converter4. Gasket

INSPECTION

Check for damage, cracking or deterioration. Replac e if faulty.

Caution

1. Stop the engine immediately if engine misfiring oc-

curs, otherwise an abnormally hot exhaust system

will damage the catalytic converter or other under- body parts.

2.Correct and repair the ignition or fuel system if t here

are malfunctions, otherwise engine misfiring may oc -

cur which will damage the catalytic converter.

3. Observe manufacturer’s specifications when doing

service work.

Page 829 of 2103

CLUTCH

CONTENTS

CLUTCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .

CLUTCHOVERHAUL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 830 of 2103

Trending: driver seat adjustment, coolant reservoir, water pump, windshield wipers, length, clutch, child lock