MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 831 of 2103

C O N T E N T S

CLUTCH CONTROL . . . . . . . . . . . . . . . . . . . . . . . 10

CLUTCH MASTER CYLINDER . . . . . . . . . . . . . 13

Bleeding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .‘7

Clutch Pedal Check and . . . . . . .

Interlock Switch Check and Adjustment . . . . . . . . 6

CLUTCH PEDAL

. . . . . . . . . . . . . . . . . . . . . . . . . . .8Interlock Switch Operating Check . . . . . . . . . . . . . 6

GENERAL INFORMATION2SERVICE SPECIFICATIONS. . . . . . . . . . . . . . . . .3. . . . . . . . . . . . . . . . . .

LUBRICANTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . .4

ON-VEHICLE SERVICE. . . . . . . . . . . . . . . . . . . . .5

Page 832 of 2103

21CLUTCH General Information

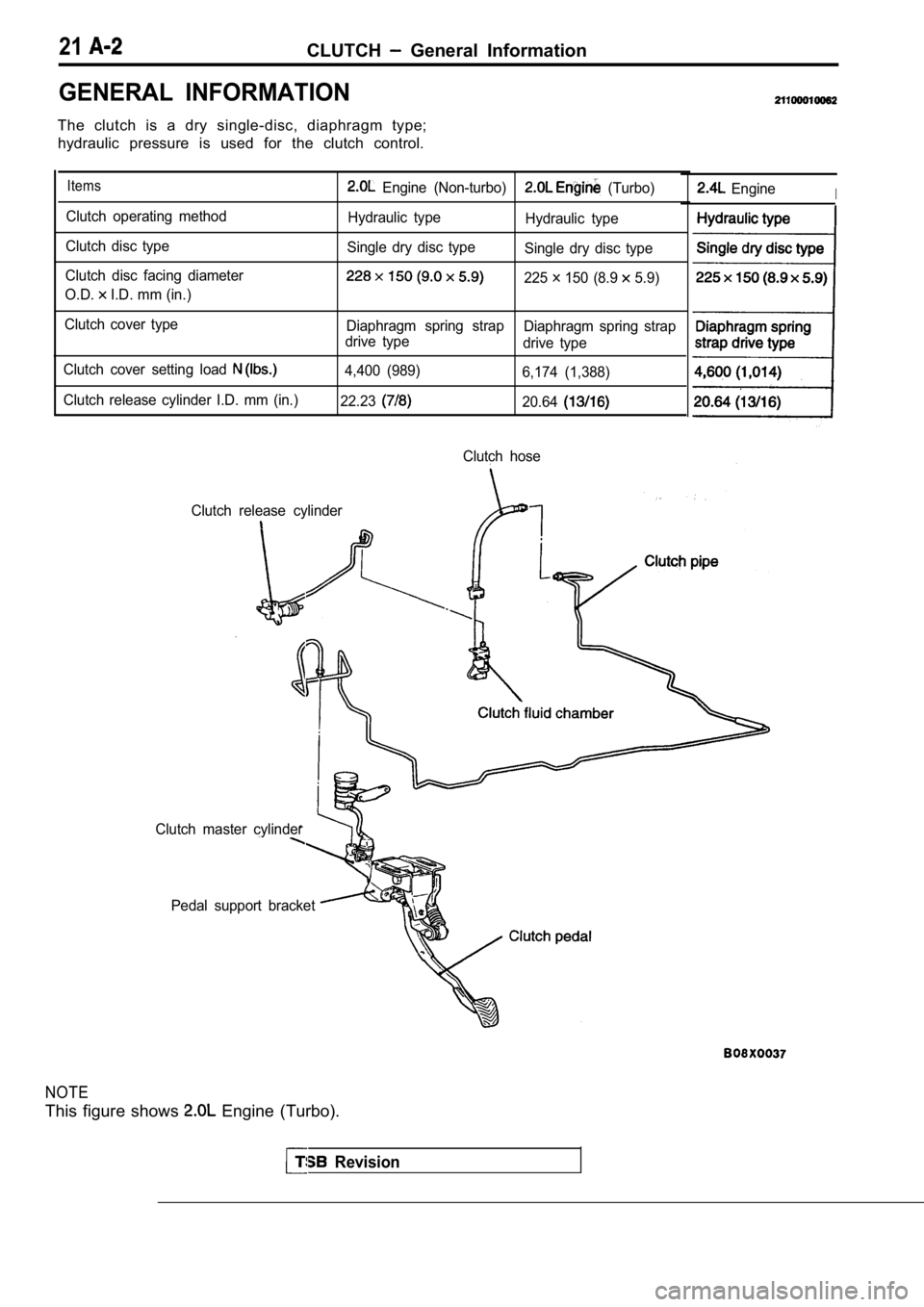

GENERAL INFORMATION

The clutch is a dry single-disc, diaphragm type;hydraulic pressure is used for the clutch control.

Items

Clutch operating method

Clutch disc type

Clutch disc facing diameter

O.D.

I.D. mm (in.)

Clutch cover type

Clutch cover setting load

Clutch release cylinder I.D. mm (in.)

Engine (Non-turbo) (Turbo)

Hydraulic type Hydraulic type

Single dry disc type Single dry disc type

225 150 (8.9 5.9)

Diaphragm spring strap

drive type Diaphragm spring strap

drive type

4,400 (989) 6,174 (1,388)

22.23

20.64

Clutch hose

Clutch release cylinder

EngineI

NOTE

This figure shows Engine (Turbo).

Revision

Clutch master cylinder

Pedal support bracket

Page 833 of 2103

CLUTCH Service Specifications/Lubricants

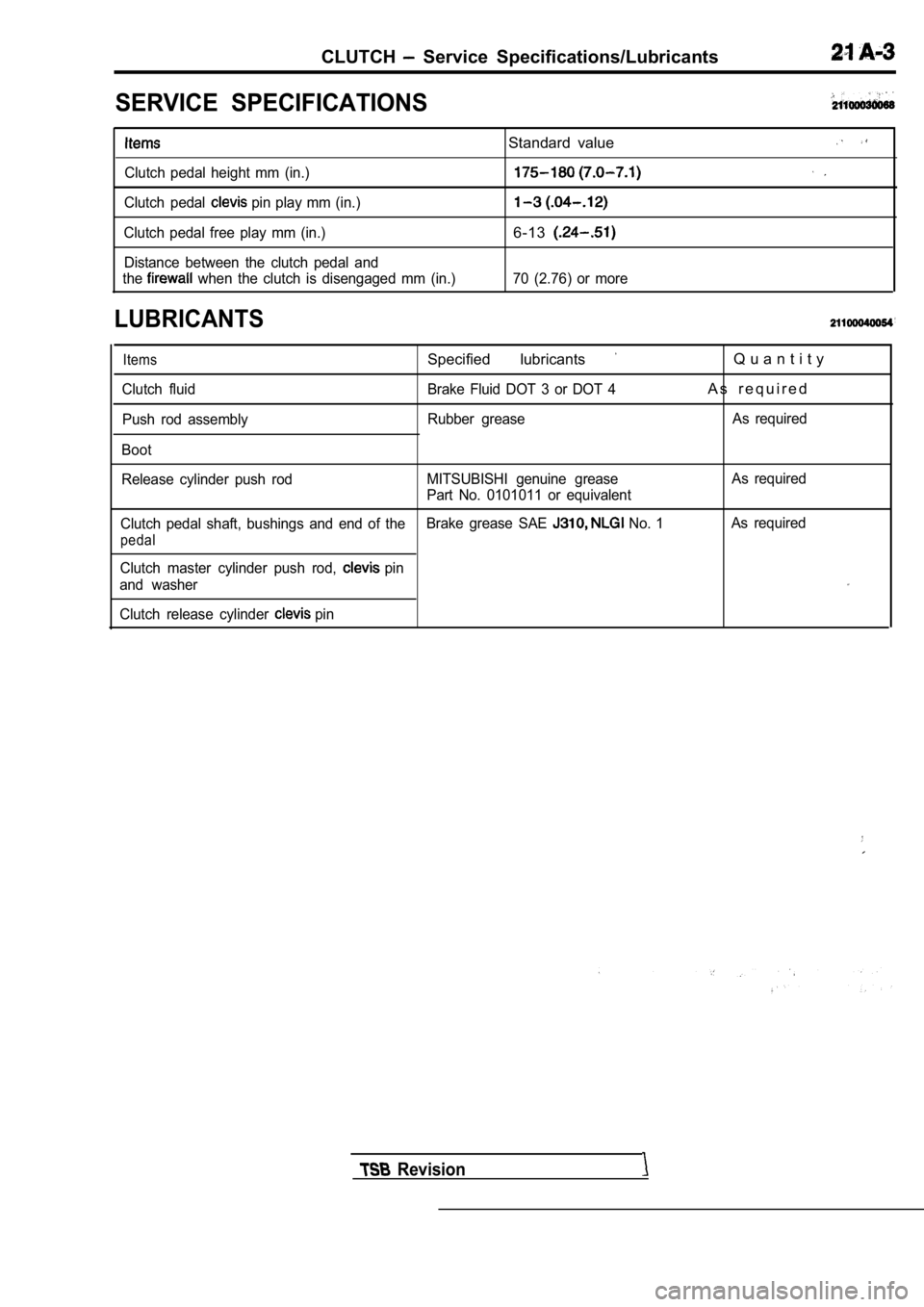

SERVICE SPECIFICATIONS

Clutch pedal height mm (in.)

Clutch pedal

pin play mm (in.)

Clutch pedal free play mm (in.) Distance between the clutch pedal and

the

when the clutch is disengaged mm (in.)

LUBRICANTS

Standard value

6-13

70 (2.76) or more

Items

Clutch fluid

Push rod assembly

Boot

Specified lubricants

Brake Fluid DOT 3 or DOT 4

Rubber grease

Q u a n t i t y

A s r e q u i r e d

As required

Release cylinder push rod MITSUBISHI genuine grease

Part No. 0101011 or equivalentAs required

Clutch pedal shaft, bushings and end of the Brake grease SAE

No. 1As required

pedal

Clutch master cylinder push rod, pin

and washer

Clutch release cylinder

pin

Revision

Page 834 of 2103

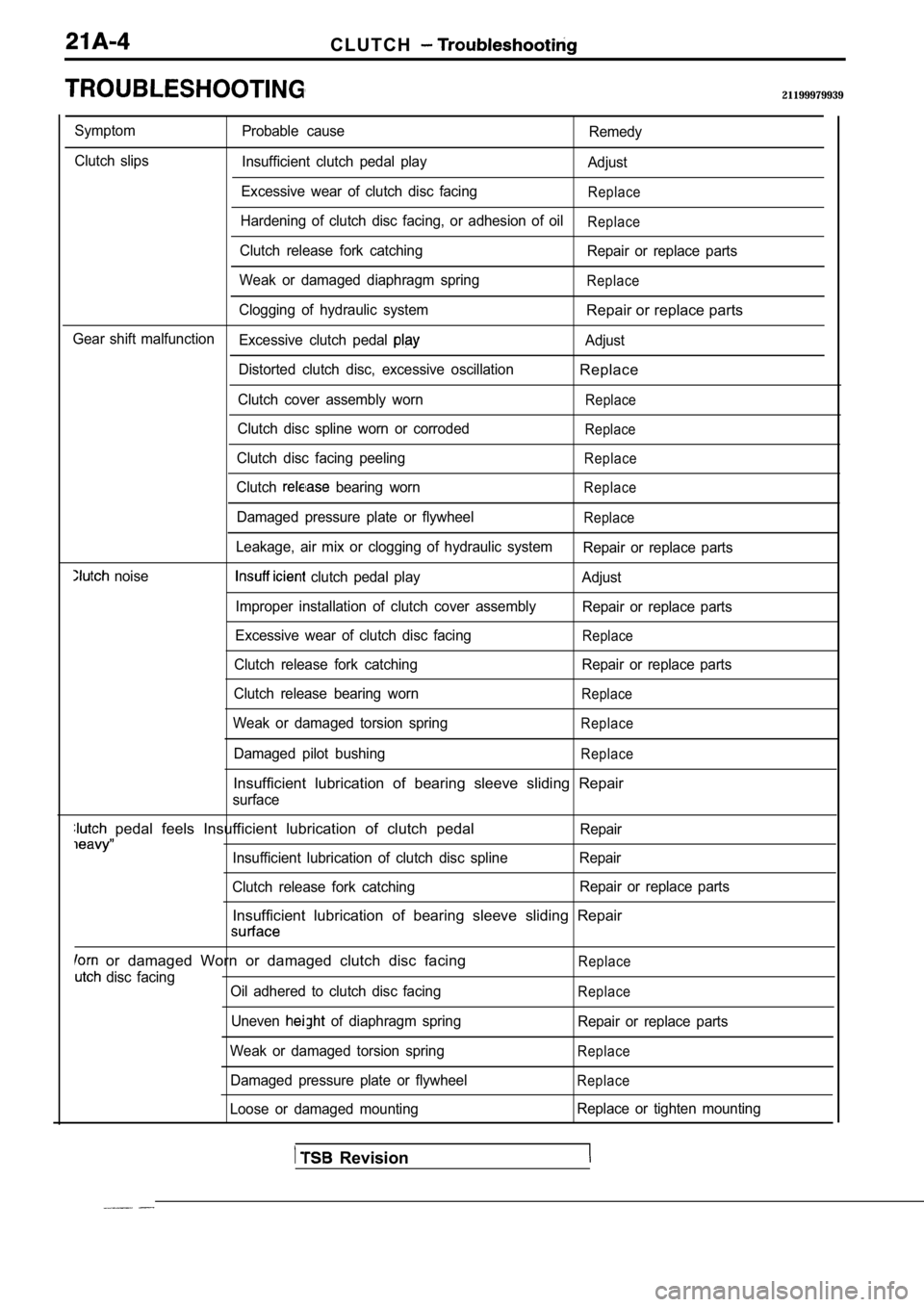

C L U T C H

21199979939

SymptomProbable cause

Remedy

Clutch slips Insufficient clutch pedal play Adjust

Excessive wear of clutch disc facing

Replace

Hardening of clutch disc facing, or adhesion of oilReplace

Clutch release fork catching Repair or replace parts

Weak or damaged diaphragm spring

Replace

Clogging of hydraulic systemRepair or replace parts

Gear shift malfunction Excessive clutch pedal Adjust

Distorted clutch disc, excessive oscillation

Replace

Clutch cover assembly wornReplace

Clutch disc spline worn or corrodedReplace

Clutch disc facing peelingReplace

Clutch bearing wornReplace

Damaged pressure plate or flywheelReplace

Leakage, air mix or clogging of hydraulic system Repair or replace parts

noise clutch pedal playAdjust

Improper installation of clutch cover assembly Repair or replace parts

Excessive wear of clutch disc facing

Replace

Clutch release fork catching Repair or replace parts

Clutch release bearing worn

Replace

Weak or damaged torsion springReplace

Damaged pilot bushingReplace

Insufficient lubrication of bearing sleeve sliding Repair

surface

pedal feels Insufficient lubrication of clutch ped alRepair

Insufficient lubrication of clutch disc spline Repai r

Clutch release fork catching Repair or replace parts

Insufficient lubrication of bearing sleeve sliding

Repair

or damaged Worn or damaged clutch disc facing

disc facing

Oil adhered to clutch disc facing

Uneven

of diaphragm spring

Weak or damaged torsion spring Damaged pressure plate or flywheel

Loose or damaged mounting

Replace

Replace

Repair or replace parts

Replace

Replace

Replace or tighten mounting

Revision

Page 835 of 2103

CLUTCH -On-vehicle Service

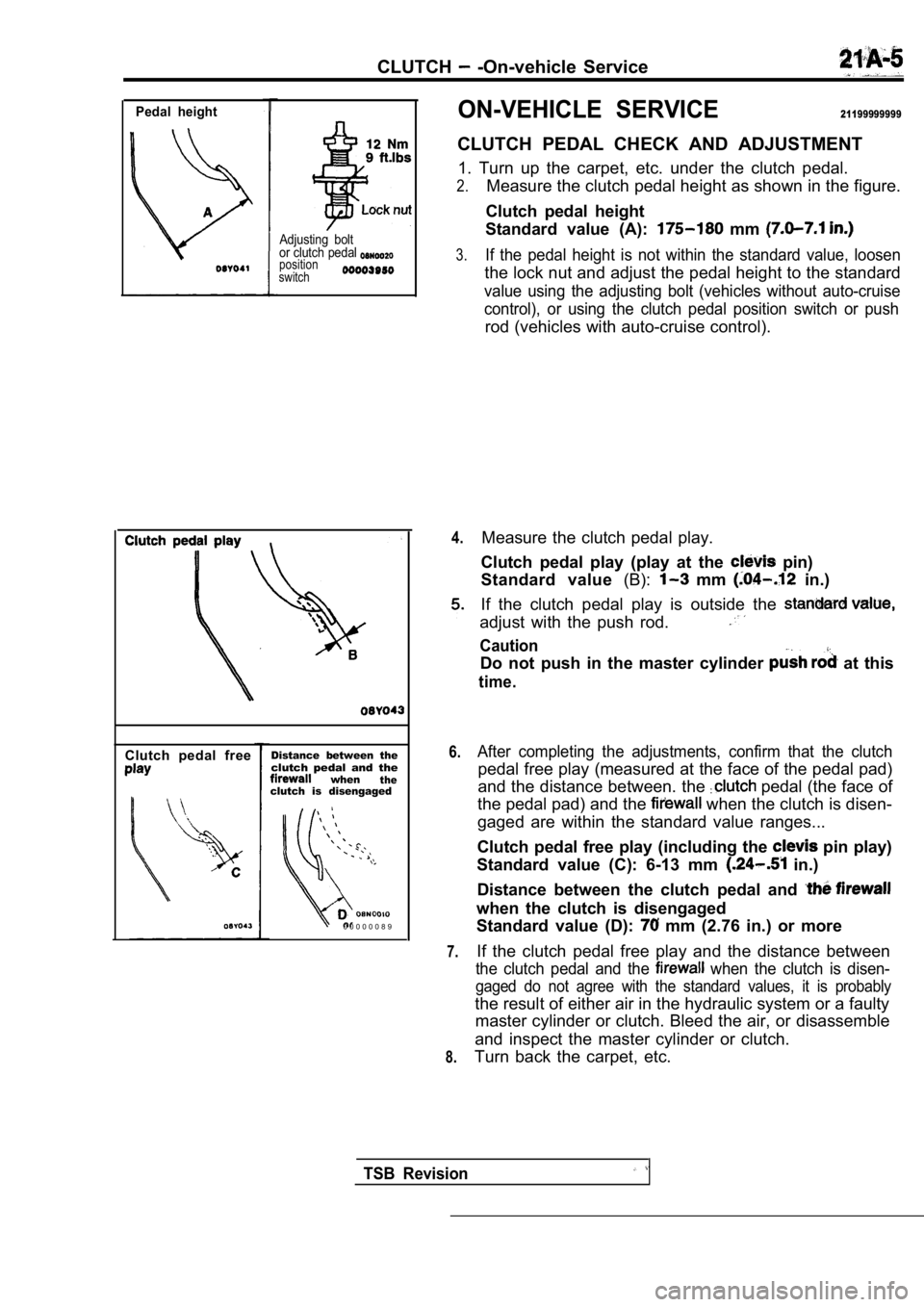

Pedal height

Adjusting bolt

or clutch pedal

position

switch

Clutch pedal freeDistance between theclutch pedal and thewhentheclutch is disengaged

0 0 0 0 0 0 8 9

ON-VEHICLE SERVICE21199999999

CLUTCH PEDAL CHECK AND ADJUSTMENT

1. Turn up the carpet, etc. under the clutch pedal.

2.Measure the clutch pedal height as shown in the fig ure.

Clutch pedal height

Standard value (A):

mm

3.If the pedal height is not within the standard valu e, loosen

the lock nut and adjust the pedal height to the sta ndard

value using the adjusting bolt (vehicles without au to-cruise

control), or using the clutch pedal position switch or push

rod (vehicles with auto-cruise control).

4.

6.

7.

8.

Measure the clutch pedal play.

Clutch pedal play (play at the

pin)

Standard value (B):

mm in.)

If the clutch pedal play is outside the

adjust with the push rod.

Caution

Do not push in the master cylinder at this

time.

After completing the adjustments, confirm that the clutch

pedal free play (measured at the face of the pedal pad)

and the distance between. the

pedal (the face of

the pedal pad) and the

when the clutch is disen-

gaged are within the standard value ranges...

Clutch pedal free play (including the

pin play)

Standard value (C): 6-13 mm

in.)

Distance between the clutch pedal and

when the clutch is disengaged

Standard value (D):

mm (2.76 in.) or more

If the clutch pedal free play and the distance betw een

the clutch pedal and the when the clutch is disen-

gaged do not agree with the standard values, it is probably

the result of either air in the hydraulic system or a faulty

master cylinder or clutch. Bleed the air, or disass emble

and inspect the master cylinder or clutch.

Turn back the carpet, etc.

TSB Revision

Page 836 of 2103

CLUTCH On-vehicle Service

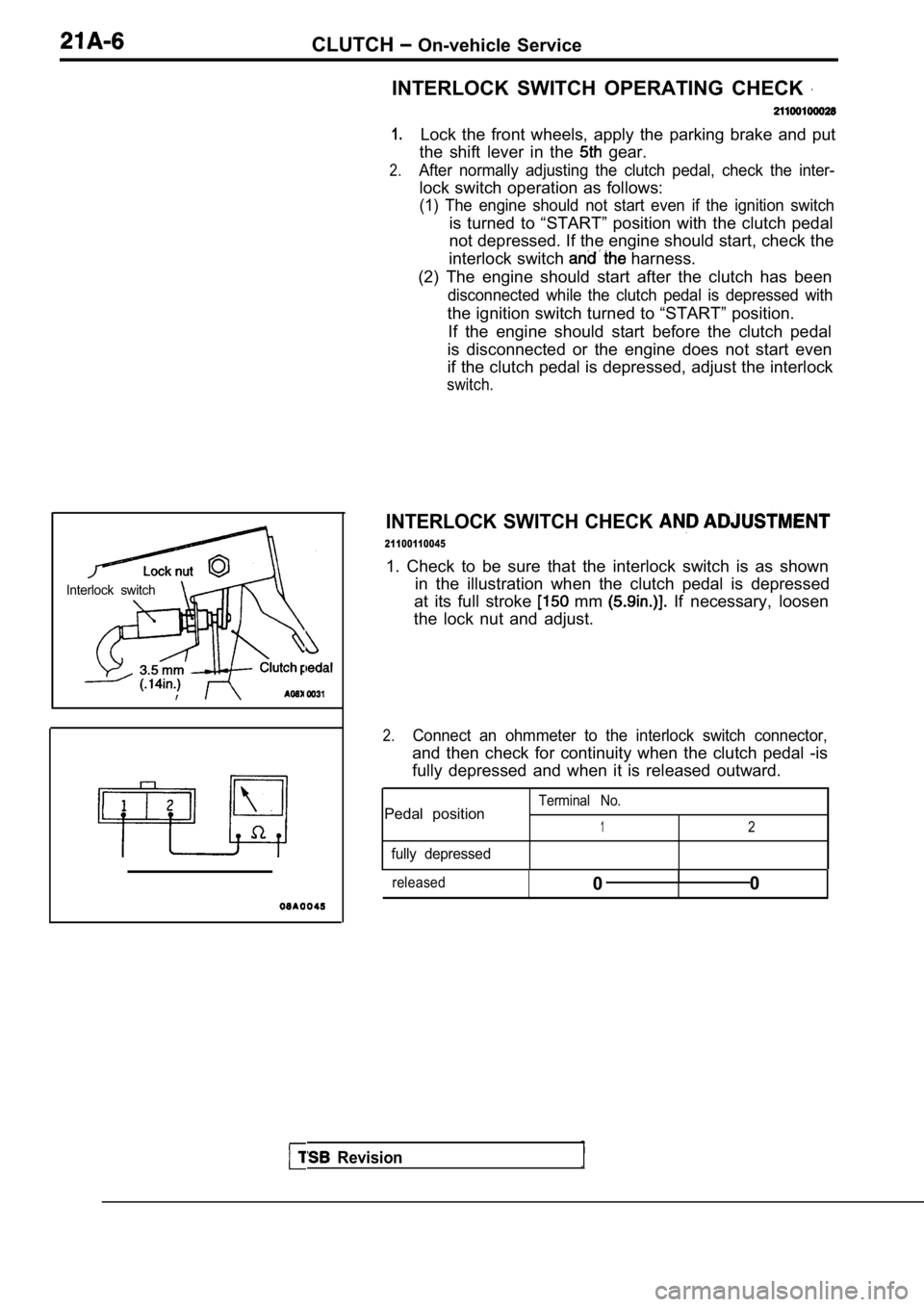

Interlock switch

Revision

INTERLOCK SWITCH OPERATING CHECK

1.

2.

Lock the front wheels, apply the parking brake and put

the shift lever in the

gear.

After normally adjusting the clutch pedal, check th e inter-

lock switch operation as follows:

(1) The engine should not start even if the ignition switch

is turned to “START” position with the clutch pedal

not depressed. If the engine should start, check th e

interlock switch

harness.

(2) The engine should start after the clutch has be en

disconnected while the clutch pedal is depressed with

the ignition switch turned to “START” position.

If the engine should start before the clutch pedal

is disconnected or the engine does not start even

if the clutch pedal is depressed, adjust the interl ock

switch.

INTERLOCK SWITCH CHECK

21100110045

1. Check to be sure that the interlock switch is as shown

in the illustration when the clutch pedal is depres sed

at its full stroke

mm If necessary, loosen

the lock nut and adjust.

2.Connect an ohmmeter to the interlock switch connect or,

and then check for continuity when the clutch pedal -is

fully depressed and when it is released outward.

Terminal No.Pedal position12

fully depressed

released0I0

Page 837 of 2103

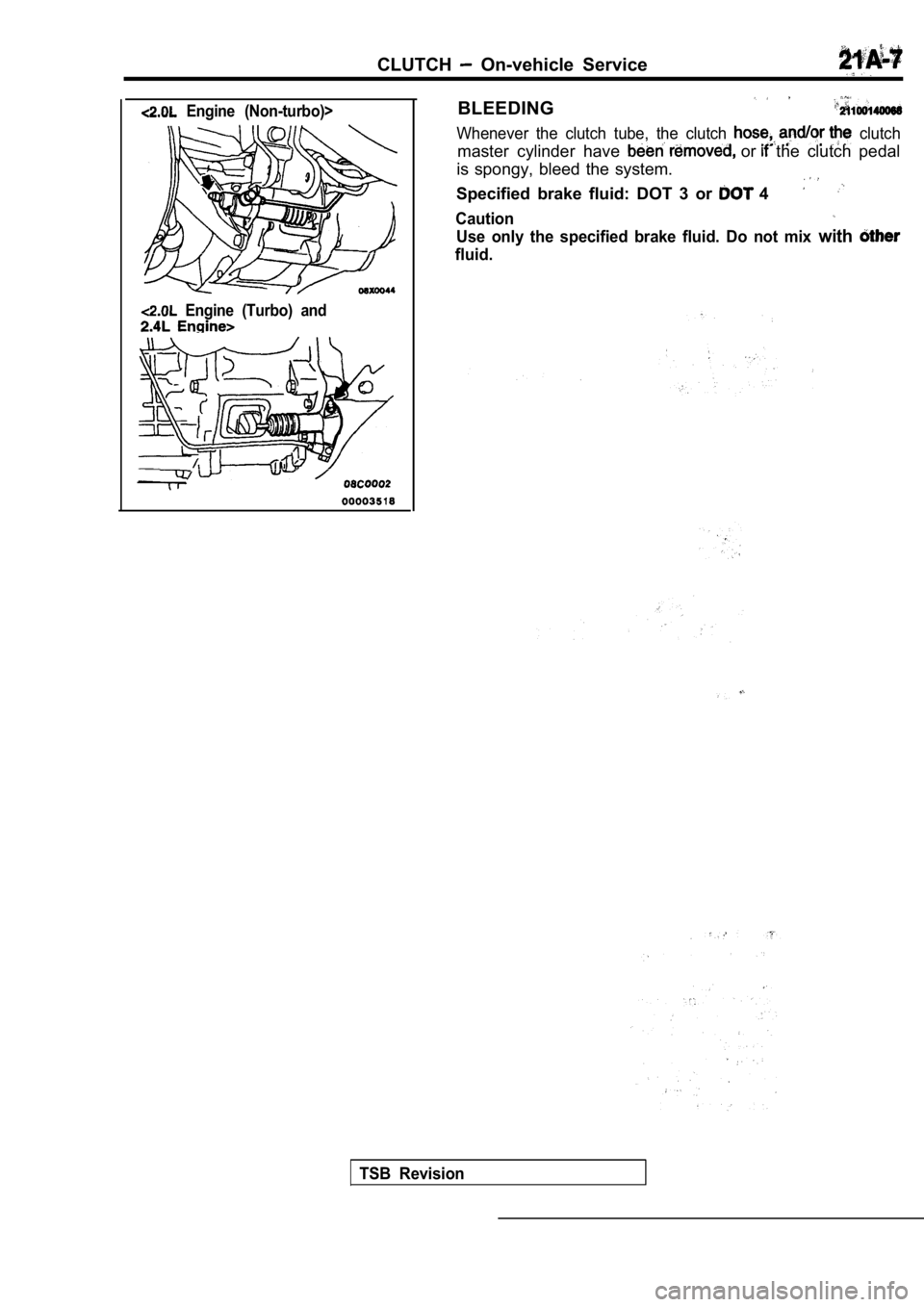

CLUTCH On-vehicle Service

Engine (Non-turbo)>

Engine (Turbo) and

BLEEDING

Whenever the clutch tube, the clutch clutch

master cylinder have or the clutch pedal

is spongy, bleed the system.

Specified brake fluid: DOT 3 or 4

Caution

Use only the specified brake fluid. Do not mix with

fluid.

TSB Revision

Page 838 of 2103

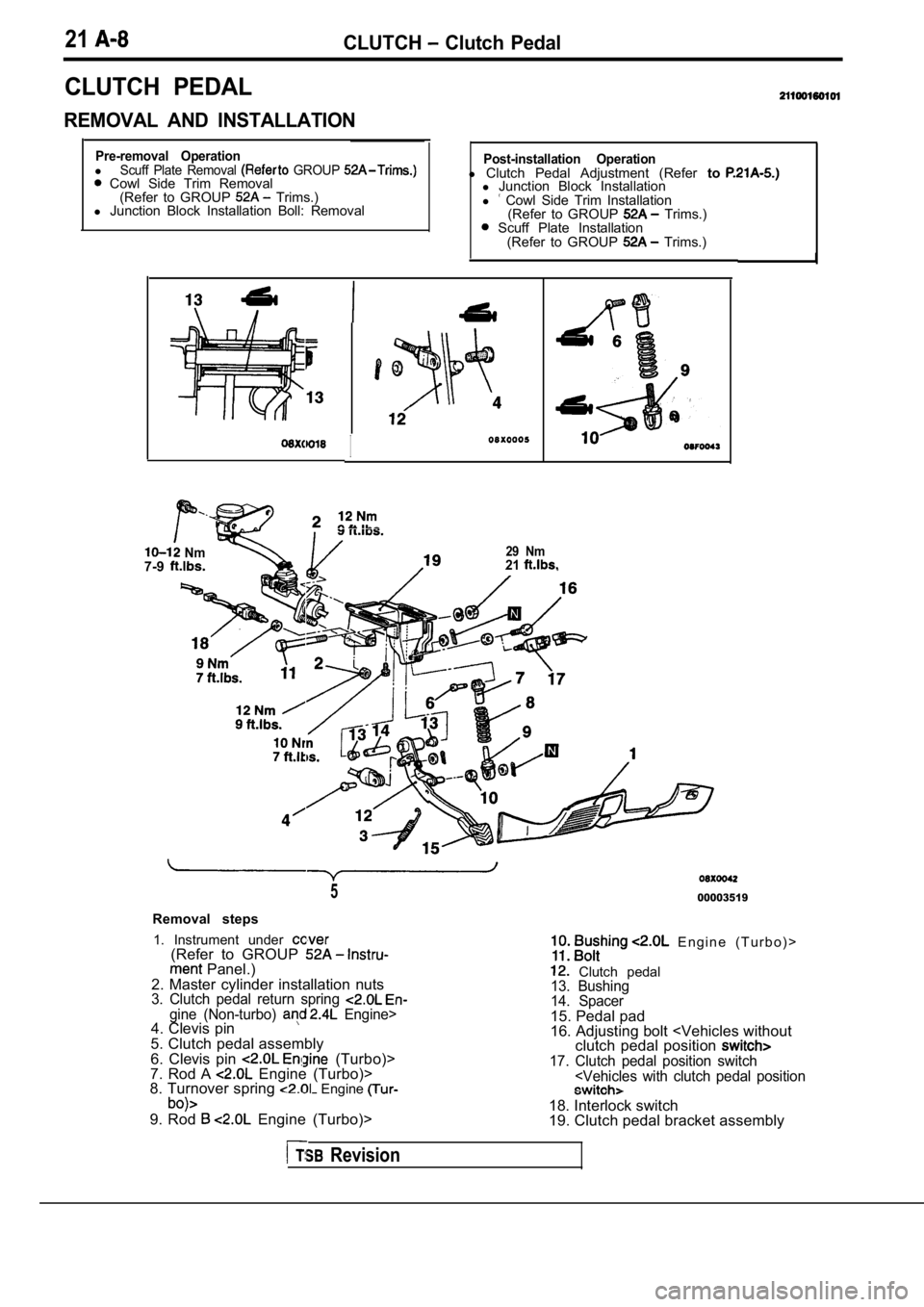

21CLUTCH Clutch Pedal

CLUTCH PEDAL

REMOVAL AND INSTALLATION

Pre-removal OperationlScuff Plate Removal GROUP Cowl Side Trim Removal(Refer to GROUP Trims.)

l Junction Block Installation Boll: Removal

Post-installation Operationl Clutch Pedal Adjustment (Refer tol Junction Block Installation

l Cowl Side Trim Installation (Refer to GROUP Trims.) Scuff Plate Installation

(Refer to GROUP Trims.)

I

I

Nm7-929 Nm21

5

Removal steps

1. Instrument under

(Refer to GROUP Panel.)

2. Master cylinder installation nuts

3. Clutch pedal return spring gine (Non-turbo) Engine>4. Clevis pin

5. Clutch pedal assembly

6. Clevis pin

(Turbo)>

7. Rod A Engine (Turbo)>

8. Turnover spring Engine

9. Rod Engine (Turbo)>

Revision

00003519

E n g i n e ( T u r b o ) >

Clutch pedal13. Bushing

14. Spacer

15. Pedal pad

16. Adjusting bolt

19. Clutch pedal bracket assembly

Page 839 of 2103

CLUTCH Clutch

INSPECTION

l Check the pedal shaft for, wear.

l Check the clutch

‘for

lCheck the return spring for or

lCheck the turnover spring for

lCheck the pedal pad for damage or wear.

TSBRevision

Page 840 of 2103

CLUTCH Clutch Control

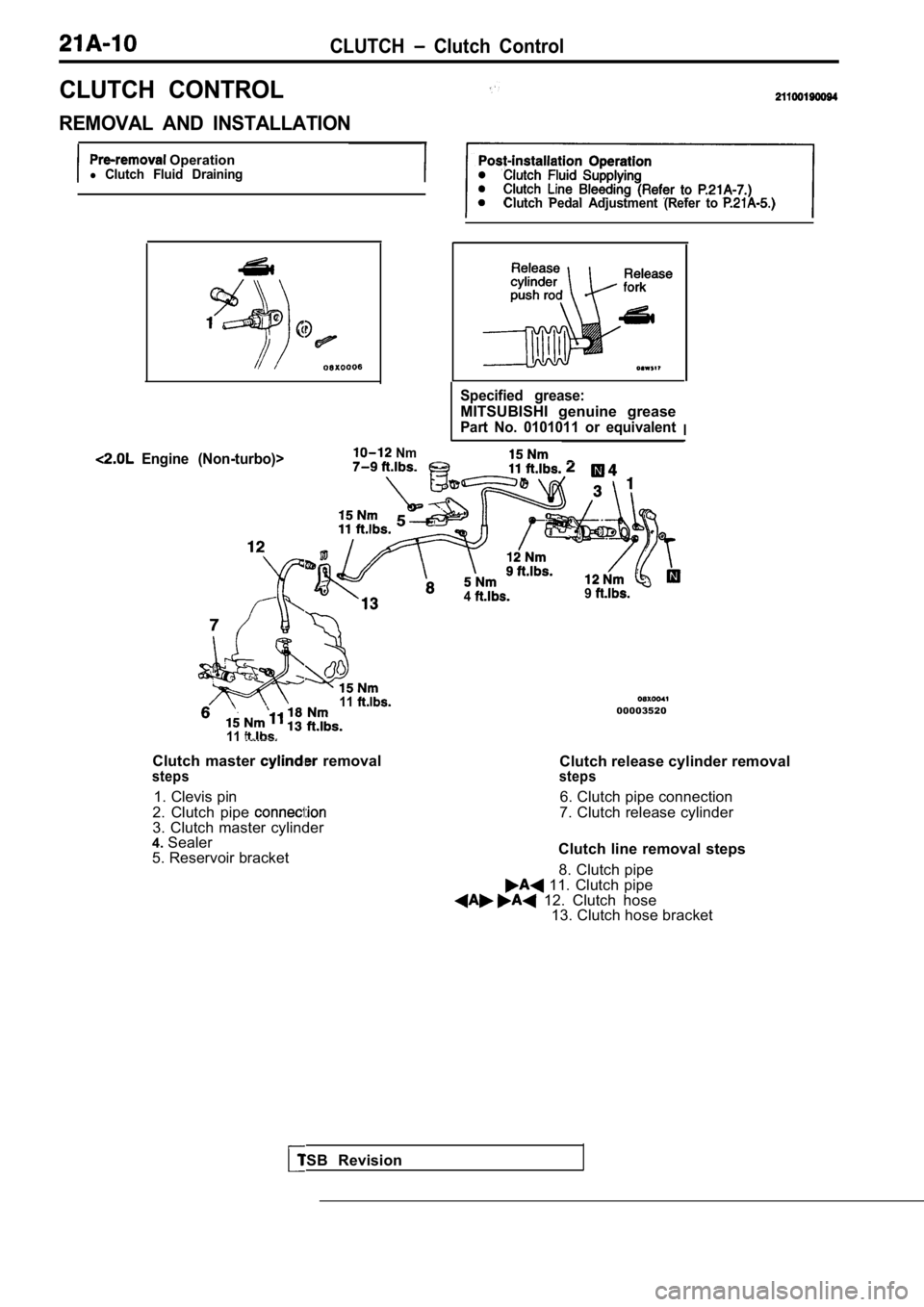

CLUTCH CONTROL

REMOVAL AND INSTALLATION

Operationl Clutch Fluid Draining

Engine (Non-turbo)>

Clutch Pedal Adjustment (Refer to

Specified grease:

MITSUBISHI genuine grease

Part No. 0101011 or equivalentI

Nm

11

11

TSB Revision

Clutch master

removalsteps

1. Clevis pin

2. Clutch pipe

3. Clutch master cylinder

4. Sealer

5. Reservoir bracket

49

00003520

Clutch release cylinder removal

steps

6. Clutch pipe connection

7. Clutch release cylinder

Clutch line removal steps 8. Clutch pipe

11. Clutch pipe 12. Clutch hose 13. Clutch hose bracket