MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: width, fuel type, service interval, oil level, radio, belt, bulb

Page 941 of 2103

MANUAL TRANSAXLE OVERHAUL

bear

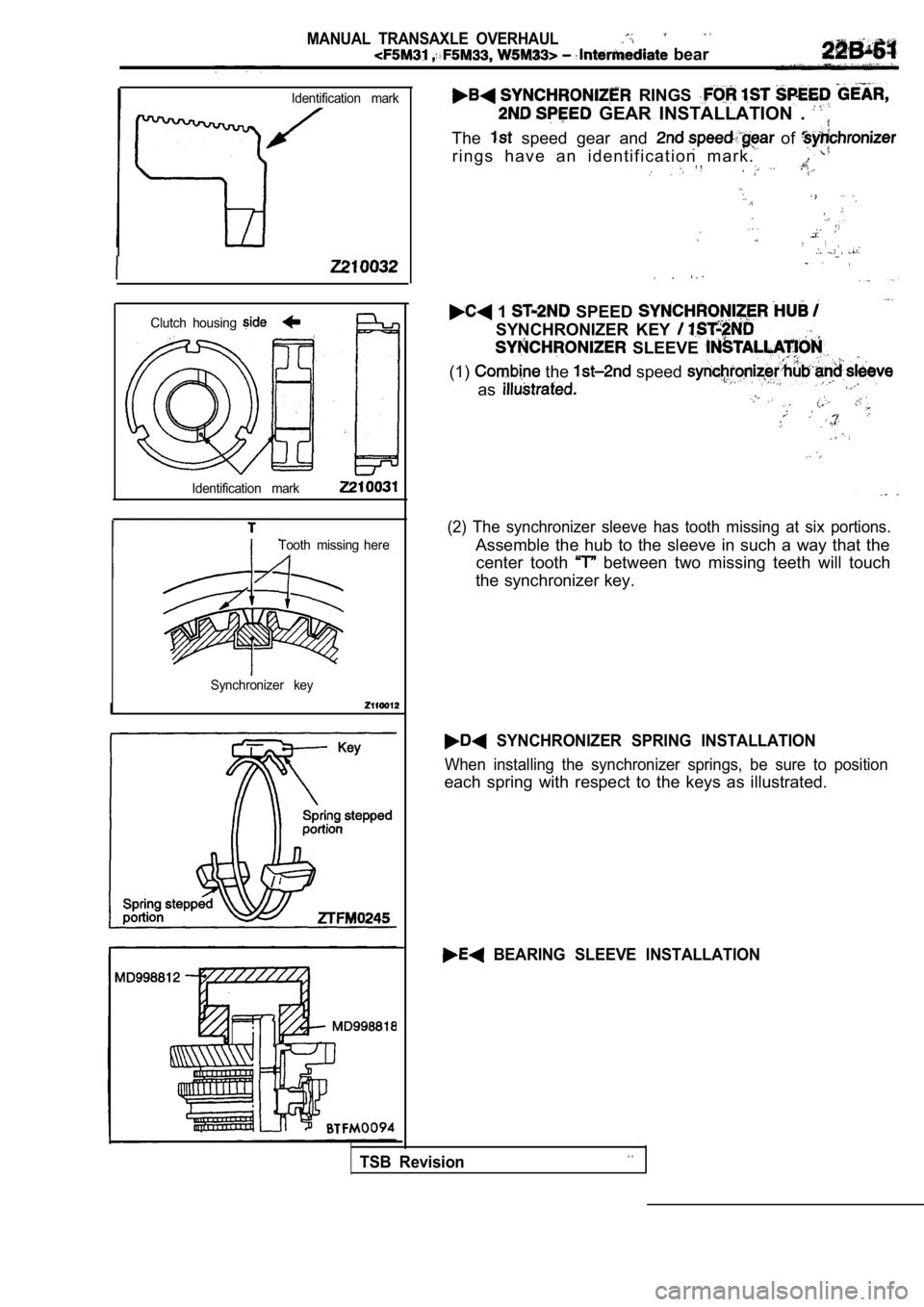

Identification mark RINGS

GEAR INSTALLATION .

The speed gear and of

r i n g s h a v e a n i d e n t i f i c a t i o n m a r k .

Clutch housing

Identification markTooth missing here

Synchronizer key

1 SPEED

SYNCHRONIZER KEY

SLEEVE

(1) the speed

as

(2) The synchronizer sleeve has tooth missing at si x portions.

Assemble the hub to the sleeve in such a way that t he

center tooth

between two missing teeth will touch

the synchronizer key.

SYNCHRONIZER SPRING INSTALLATION

When installing the synchronizer springs, be sure t o position

each spring with respect to the keys as illustrated.

BEARING SLEEVE INSTALLATION

TSB Revision

. .

Page 942 of 2103

MANUAL TRANSAXLE OVERHAUL

Intermediate Gear.

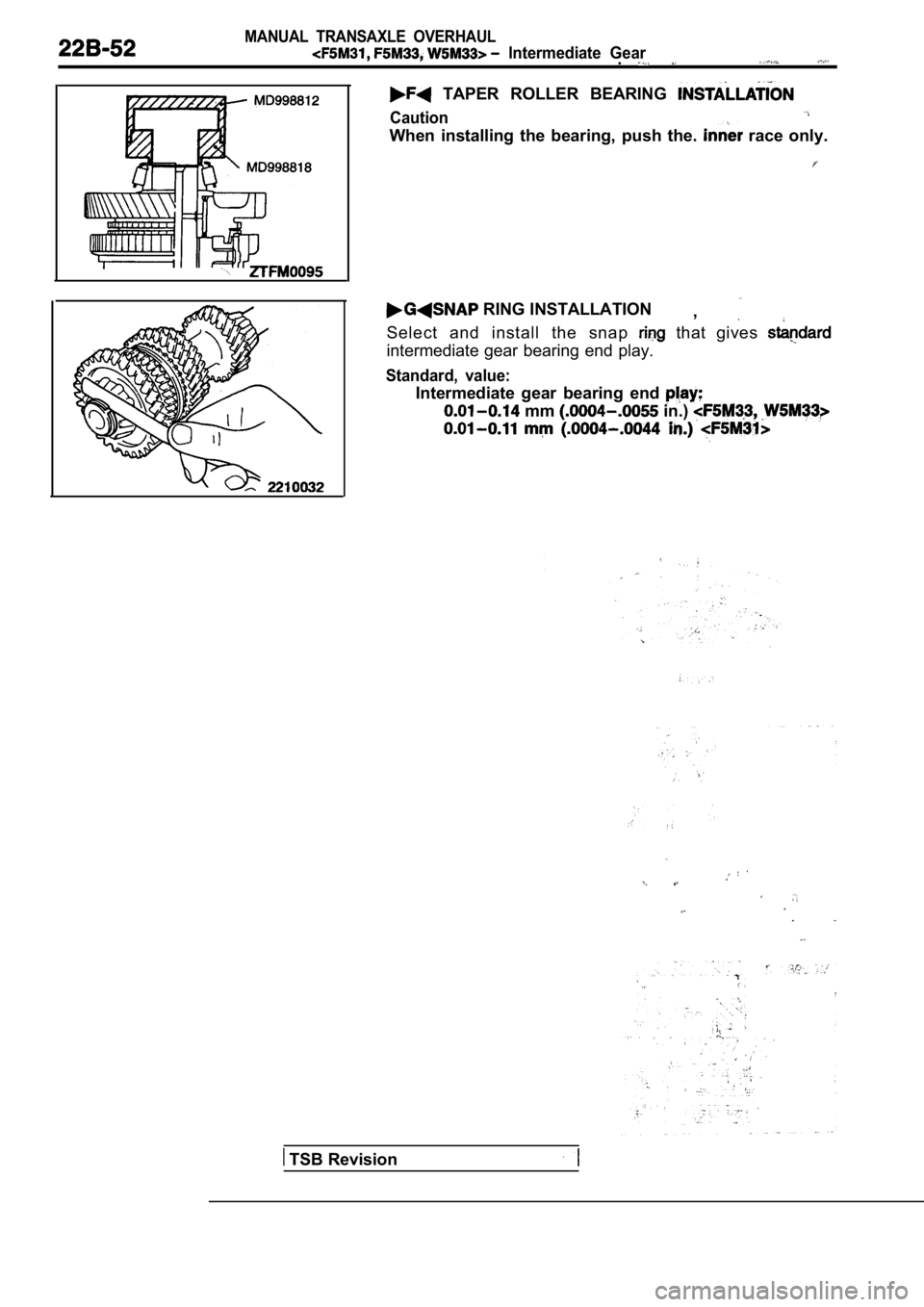

TAPER ROLLER BEARING

Caution

When installing the bearing, push the. race only.

RING INSTALLATION,

Select and install the snap that gives

intermediate gear bearing end play.

Standard, value:

Intermediate gear bearing end

mm in.)

TSB Revision

Page 943 of 2103

MANUAL TRANSAXLE OVERHAUL

Gear

ring

201051

Gear2110009

and wear

Scratches and damage

and wear

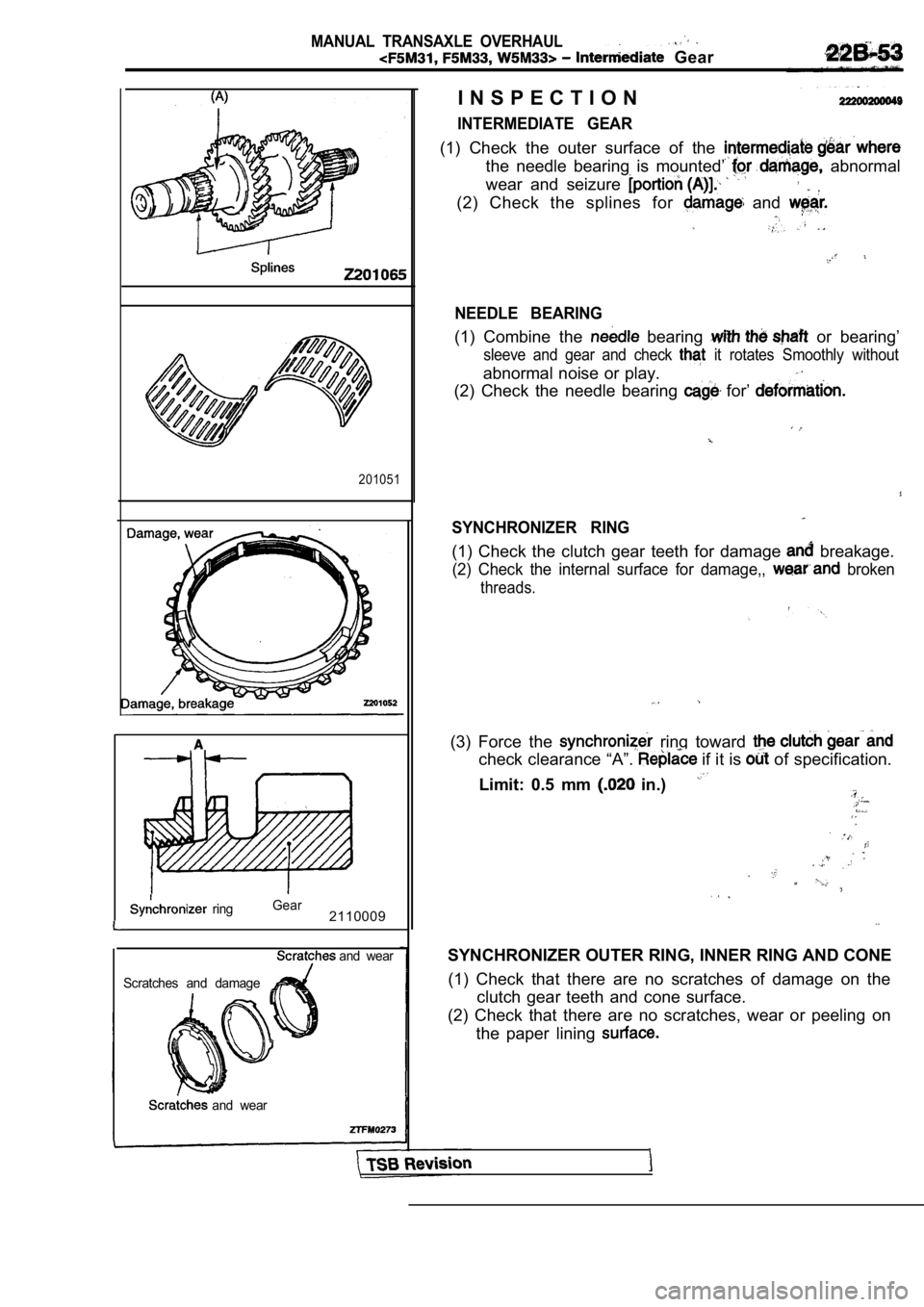

I N S P E C T I O N

INTERMEDIATE GEAR

(1) Check the outer surface of the

the needle bearing is mounted’ abnormal

wear and seizure

(2) Check the splines for and

NEEDLE BEARING

(1) Combine the bearing or bearing’

sleeve and gear and check it rotates Smoothly without

abnormal noise or play.

(2) Check the needle bearing for’

SYNCHRONIZER RING

(1) Check the clutch gear teeth for damage breakage.

(2) Check the internal surface for damage,, broken

threads.

(3) Force the ring toward

check clearance “A”. if it is of specification.

Limit: 0.5 mm

in.)

SYNCHRONIZER OUTER RING, INNER RING AND CONE (1) Check that there are no scratches of damage on the

clutch gear teeth and cone surface.

(2) Check that there are no scratches, wear or peel ing on

the paper lining

Page 944 of 2103

MANUAL TRANSAXLE OVERHAUL

Intermediate Gear

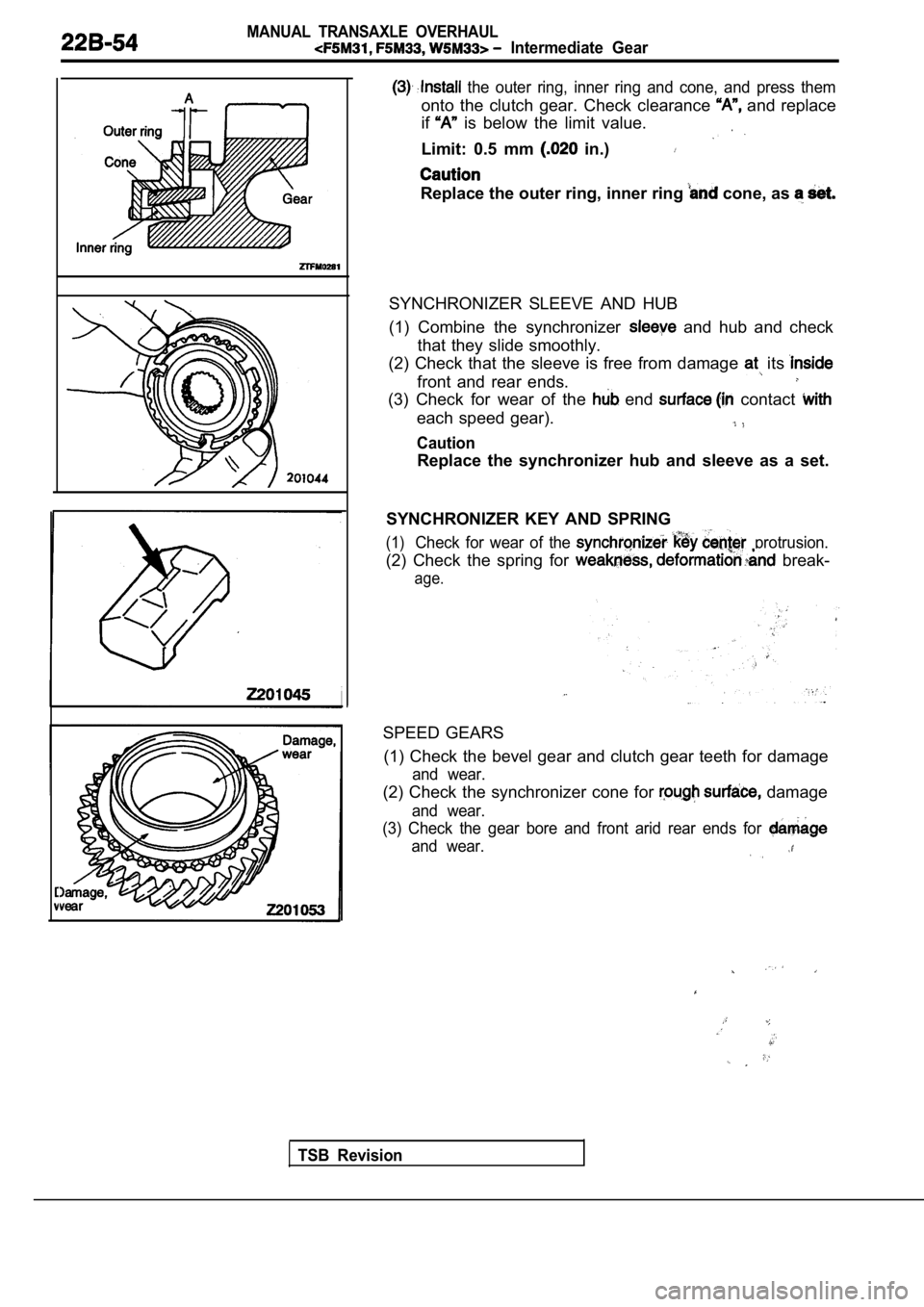

the outer ring, inner ring and cone, and press them

onto the clutch gear. Check clearance and replace

if

is below the limit value..

Limit: 0.5 mm in.)

Replace the outer ring, inner ring cone, as

TSB Revision

SYNCHRONIZER SLEEVE AND HUB

(1) Combine the synchronizer

and hub and check

that they slide smoothly.

(2) Check that the sleeve is free from damage

its

front and rear ends.

(3) Check for wear of the end contact

each speed gear).

Caution

Replace the synchronizer hub and sleeve as a set.

SYNCHRONIZER KEY AND SPRING

(1)Check for wear of the protrusion.

(2) Check the spring for break-

age.

SPEED GEARS (1) Check the bevel gear and clutch gear teeth for damage

and wear.

(2) Check the synchronizer cone for damage

and wear.

(3) Check the gear bore and front arid rear ends fo r

and wear.

Page 945 of 2103

MANUAL TRANSAXLE OVERHAUL

Output Shaft

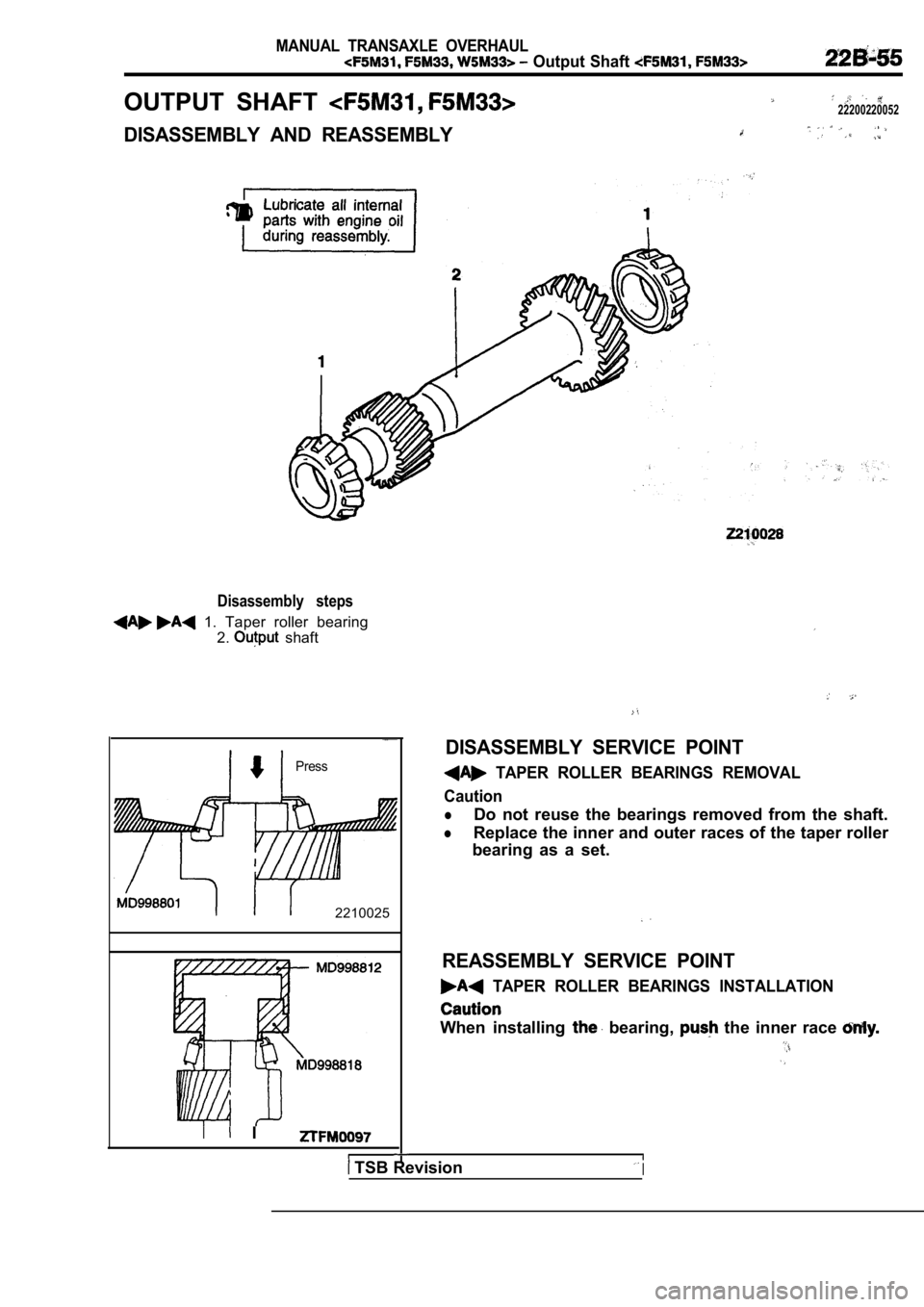

OUTPUT SHAFT 22200220052

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Taper roller bearing2.

shaft

Press

2210025

I I

DISASSEMBLY SERVICE POINT

TAPER ROLLER BEARINGS REMOVAL

Caution

lDo not reuse the bearings removed from the shaft.

lReplace the inner and outer races of the taper roll er

bearing as a set.

REASSEMBLY SERVICE POINT

TAPER ROLLER BEARINGS INSTALLATION

When installing bearing, the inner race

TSB RevisionI

Page 946 of 2103

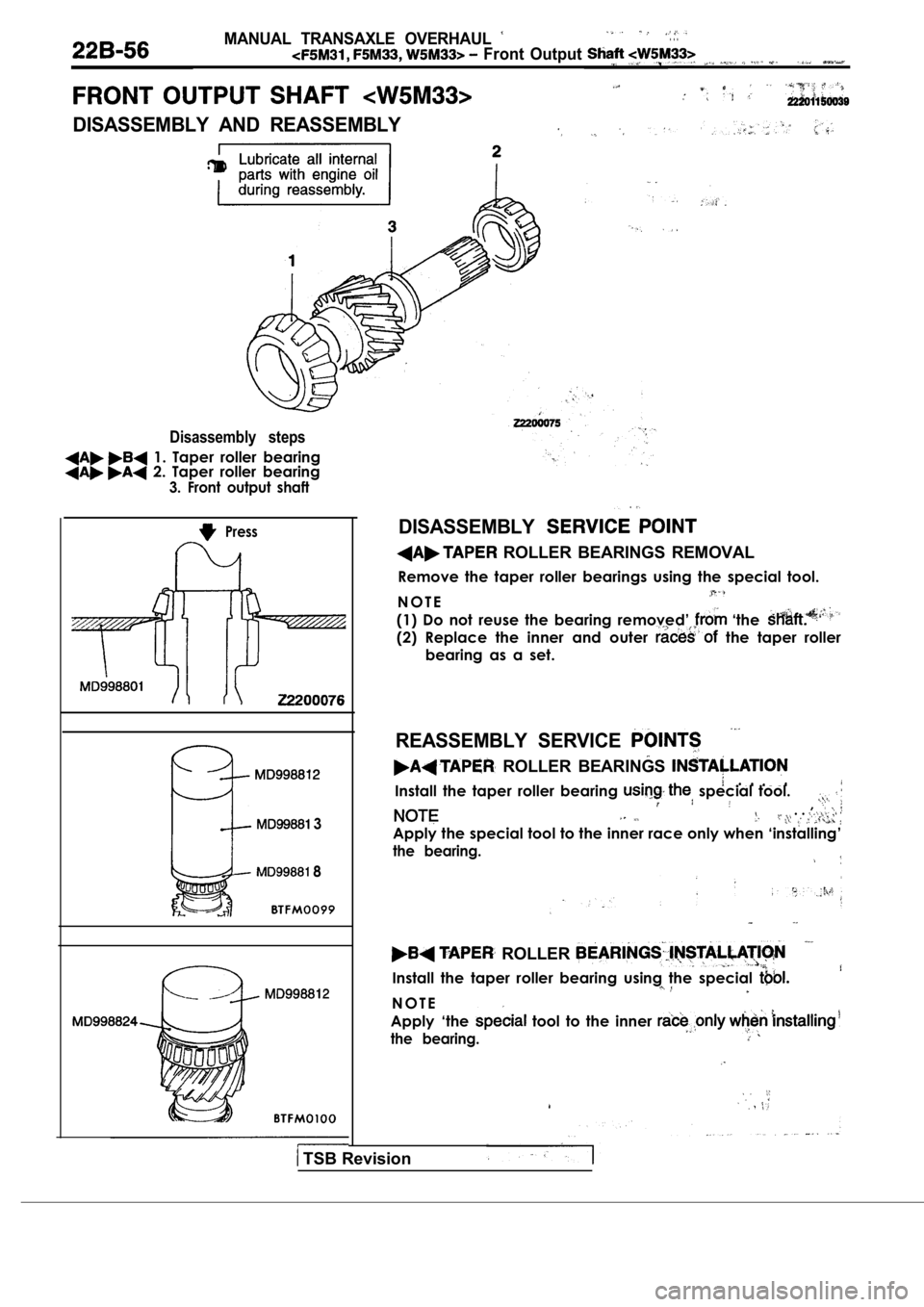

MANUAL TRANSAXLE OVERHAUL . . .

Front Output ,__

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Taper roller bearing 2. Taper roller bearing

3. Front output shaft

Press

3

8

DISASSEMBLY

ROLLER BEARINGS REMOVAL

Remove the taper roller bearings using the special tool.

N O T E

(1) Do not reuse the bearing removed’ ‘the

(2) Replace the inner and outer the taper roller

bearing as a set.

REASSEMBLY SERVICE

ROLLER BEARINGS

Install the taper roller bearing special tool.,. .

Apply the special tool to the inner race only when ‘installing’

the bearing.

ROLLER

Install the taper roller bearing using the special

N O T E

Apply ‘the

tool to the inner

the bearing.

TSB Revision

Page 947 of 2103

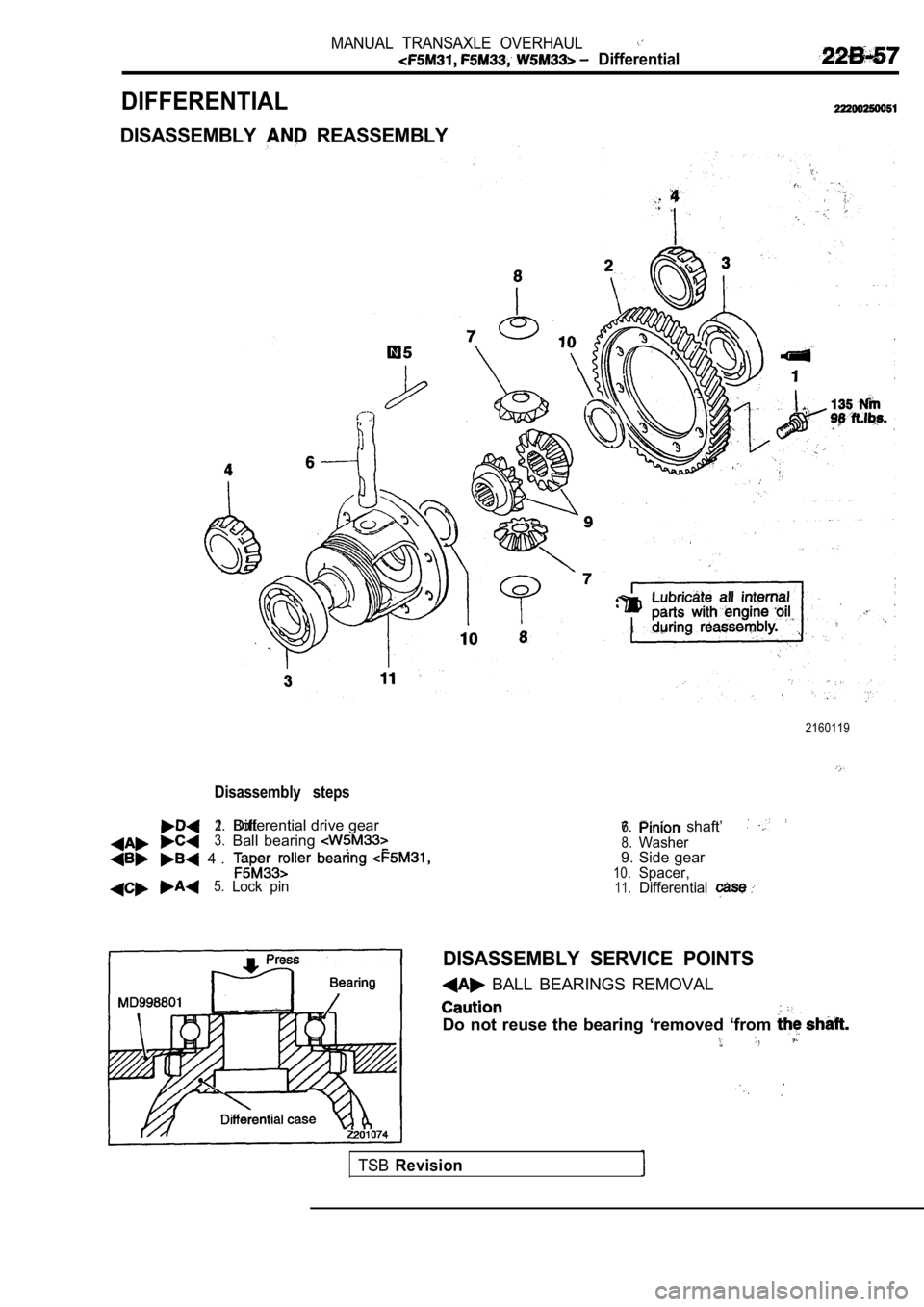

MANUAL TRANSAXLE OVERHAUL

Differential

DIFFERENTIAL

DISASSEMBLY REASSEMBLY

2160119

Disassembly steps

1.Bolt2.Differential drive gear3.Ball bearing

4 .

5.Lock pin

6.Pinion shaft’7.

8.Washer9. Side gear10.Spacer,11.Differential

Do not reuse the bearing ‘removed ‘from

DISASSEMBLY SERVICE POINTS

BALL BEARINGS REMOVAL

TSBRevision

Page 948 of 2103

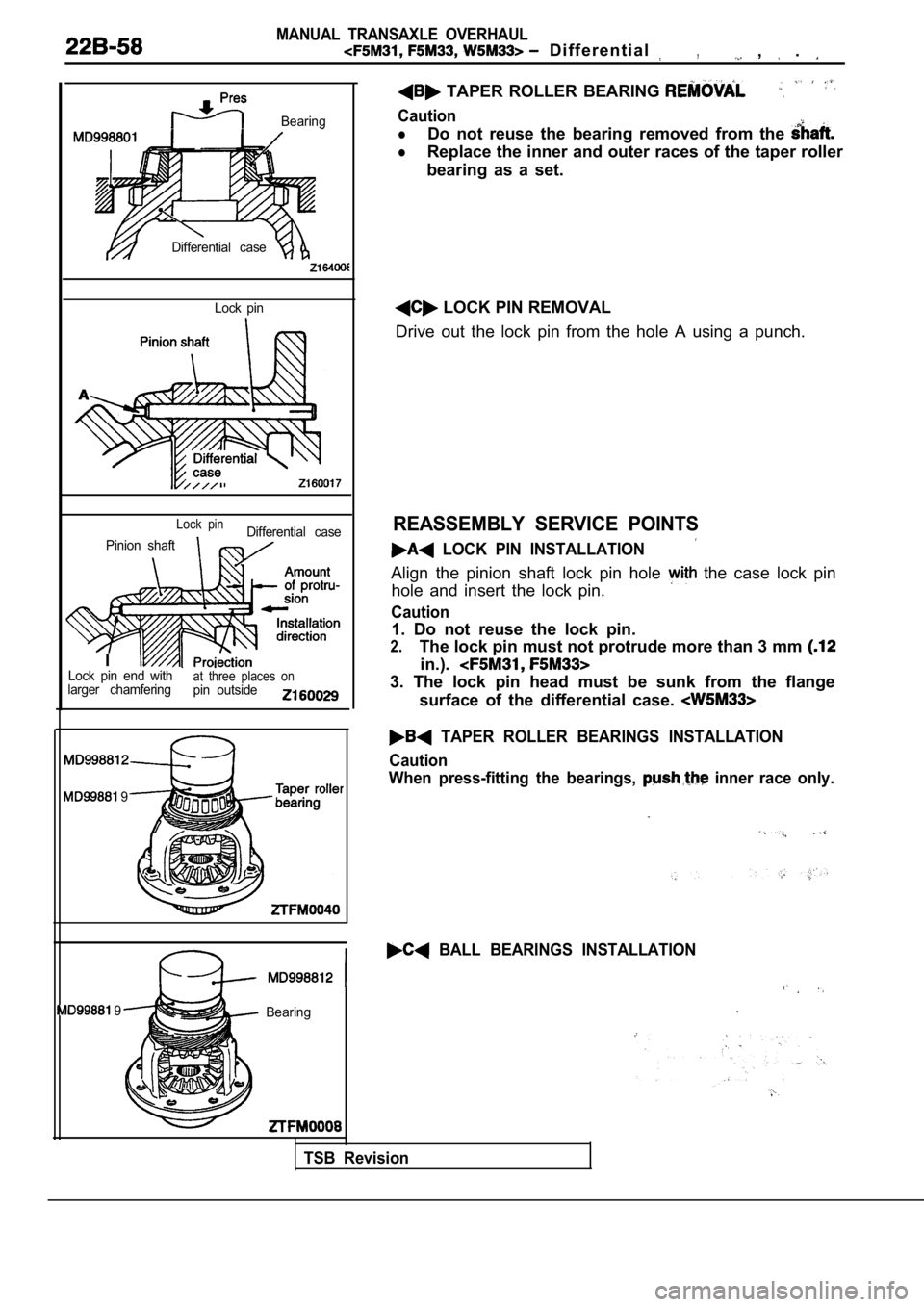

MANUAL TRANSAXLE OVERHAUL

D i f f e r e n t i a l , , .

Bearing

Differential case Lock pin

Lock pinDifferential case

Pinion shaft

ILock pin end with

larger chamferingat three places onpin outside

9

9 Bearing

TAPER ROLLER BEARING

Caution

lDo not reuse the bearing removed from the

lReplace the inner and outer races of the taper roll er

bearing as a set.

LOCK PIN REMOVAL

Drive out the lock pin from the hole A using a punc h.

REASSEMBLY SERVICE POINTS

LOCK PIN INSTALLATION

Align the pinion shaft lock pin hole the case lock pin

hole and insert the lock pin.

Caution

1. Do not reuse the lock pin.

2.The lock pin must not protrude more than 3 mm

in.).

3. The lock pin head must be sunk from the flange

surface of the differential case.

TAPER ROLLER BEARINGS INSTALLATION

Caution

When press-fitting the bearings,

inner race only.

BALL BEARINGS INSTALLATION

TSB Revision

Page 949 of 2103

MANUAL TRANSAXLE OVERHAUL Differential

160030I

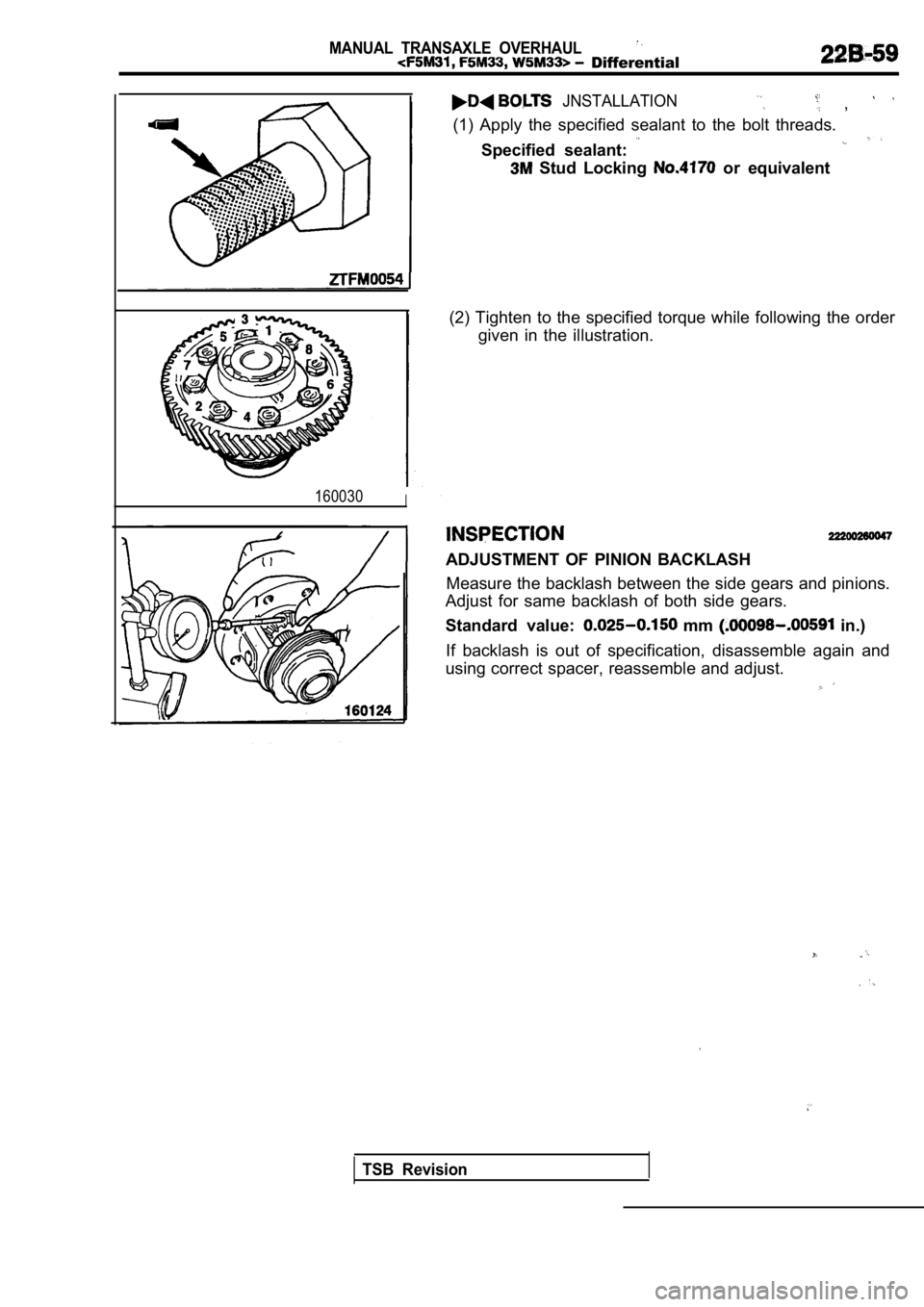

JNSTALLATION ,

(1) Apply the specified sealant to the bolt threads.

Specified sealant:

Stud Locking or equivalent

(2) Tighten to the specified torque while following the order

given in the illustration.

ADJUSTMENT OF PINION BACKLASH

Measure the backlash between the side gears and pin ions.

Adjust for same backlash of both side gears.

Standard value:

mm in.)

If backlash is out of specification, disassemble ag ain and

using correct spacer, reassemble and adjust.

TSB Revision

Page 950 of 2103

MANUAL TRANSAXLE OVERHAULCenter Differential ,

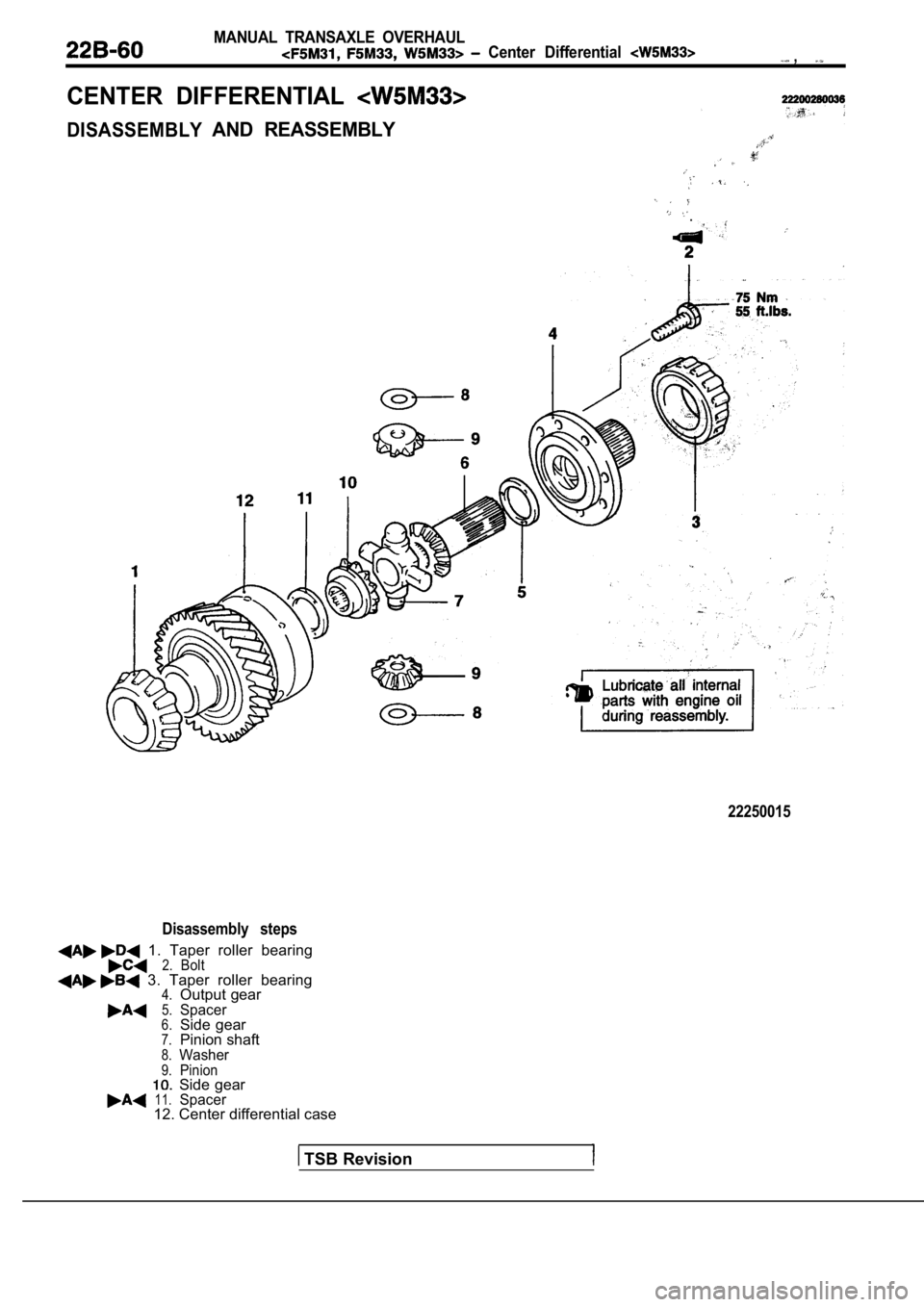

CENTER DIFFERENTIAL

DISASSEMBLYAND REASSEMBLY

,

22250015

Disassembly steps

1. Taper roller bearing2.Bolt 3. Taper roller bearing4.Output gear5.Spacer6.Side gear7.Pinion shaft8.Washer9.PinionSide gear11.Spacer12. Center differential case

TSB Revision

Trending: steering wheel, oil level, fog light, tires, brake light, oil capacities, length