MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: service interval, roof rack, warning lights, compression ratio, fuel pump, fuel fill door release, battery

Page 911 of 2103

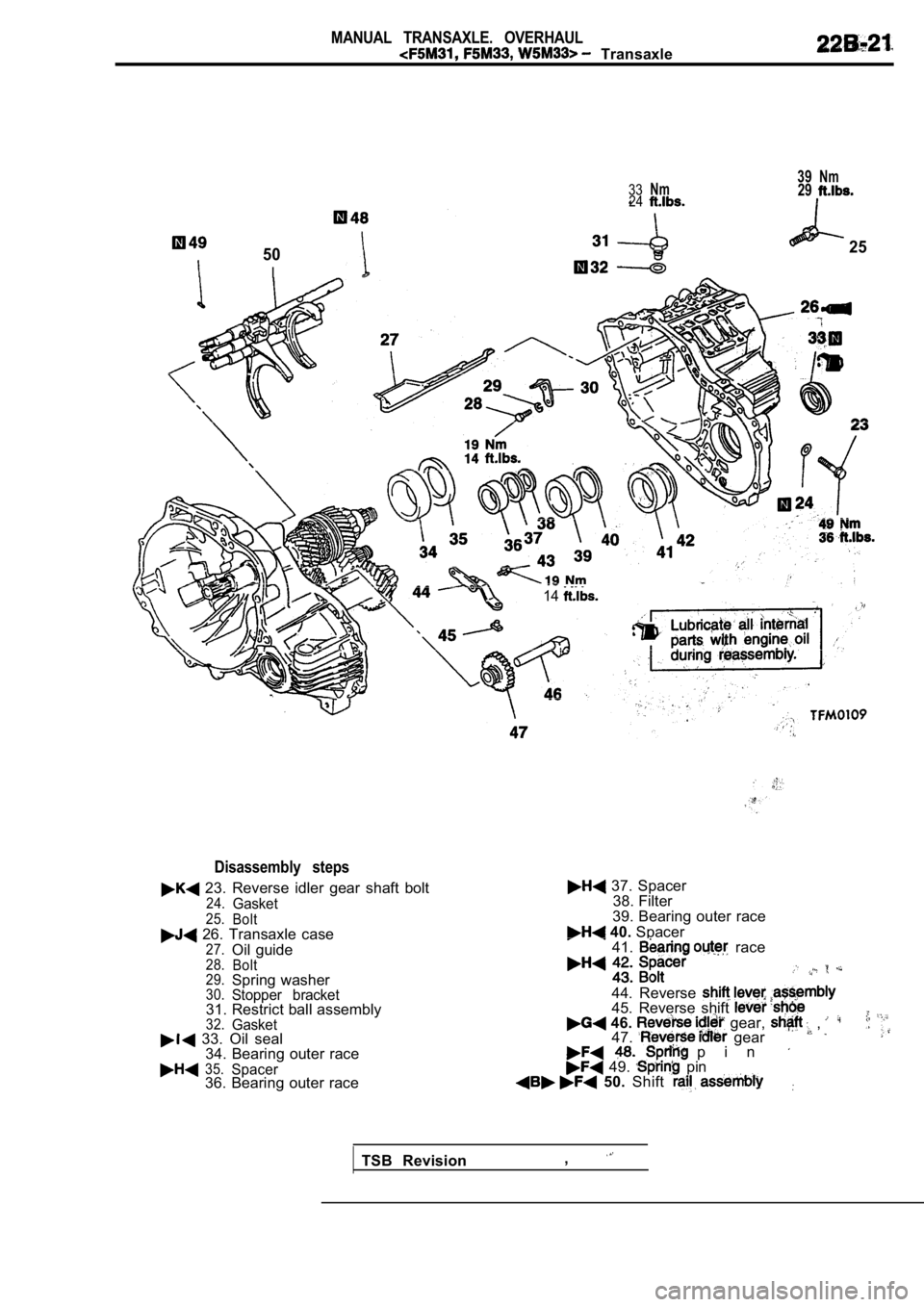

MANUAL TRANSAXLE. OVERHAUL

Transaxle

39Nm33Nm2924

5025

I

Disassembly steps

23. Reverse idler gear shaft bolt24.Gasket25.Bolt 26. Transaxle case27.Oil guide28.Bolt

29.Spring washer30.Stopper bracket31. Restrict ball assembly32.Gasket 33. Oil seal

34. Bearing outer race

35.Spacer36. Bearing outer race

14

37. Spacer

38. Filter

39. Bearing outer race

40. Spacer41. race

44. Reverse 45. Reverse shift 46. gear, , 47. gear p i n 49. pin 50. Shift

TSB Revision,

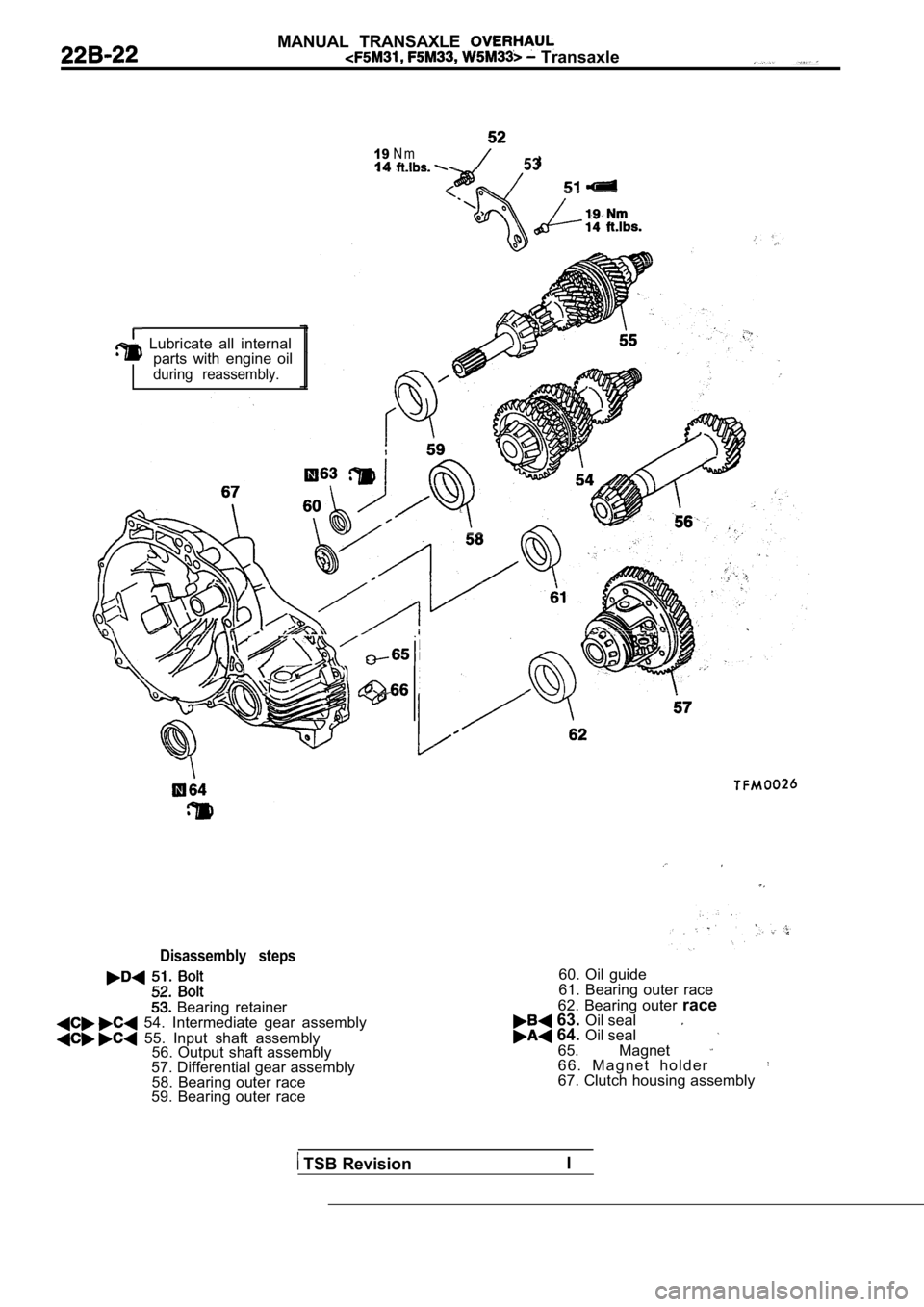

Page 912 of 2103

MANUAL TRANSAXLE Transaxle

19N m1453

Lubricate all internalparts with engine oil

during reassembly.

.

Disassembly steps

Bearing retainer 54. Intermediate gear assembly

55. Input shaft assembly 56. Output shaft assembly

57. Differential gear assembly 58. Bearing outer race

59. Bearing outer race 60. Oil guide

61. Bearing outer race

62. Bearing outer race

63. Oil seal 64. Oil seal65. Magnet 6 6 . M a g n e t h o l d e r67. Clutch housing assembly

TSB Revision I

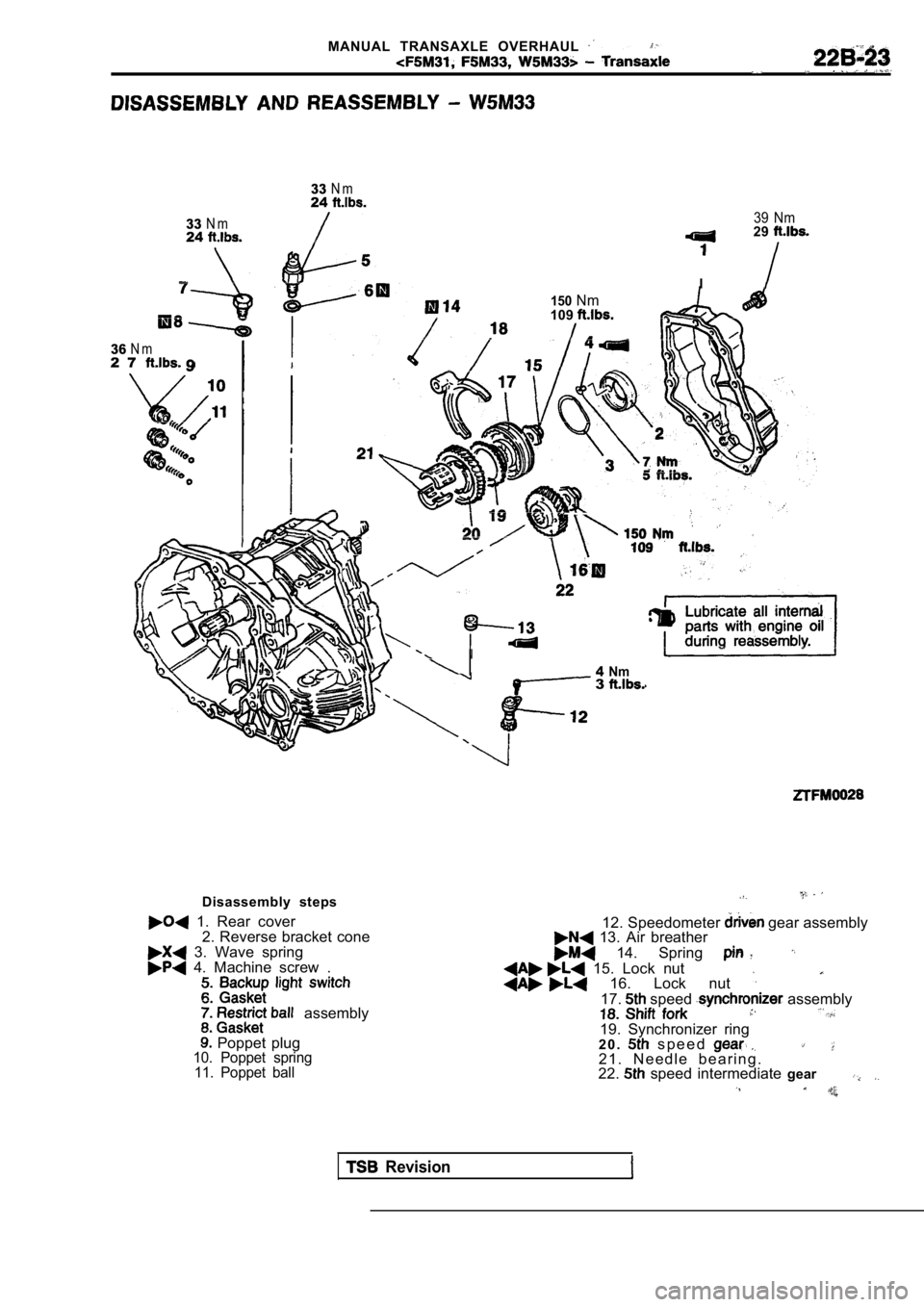

Page 913 of 2103

MANUAL TRANSAXLE OVERHAUL

33N m24

33N m24

36N m2 7

39 Nm29

I

150Nm109

4Nm 3

Disassembly steps

1. Rear cover2. Reverse bracket cone

3. Wave spring 4. Machine screw .

assembly

Poppet plug10. Poppet spring11. Poppet ball

12. Speedometer gear assembly 13. Air breather

14. Spring

15. Lock nut 16. Lock nut

17. speed assembly

19. Synchronizer ring

2 0 . s p e e d 2 1 . N e e d l e b e a r i n g .

22. speed intermediate gear

Revision

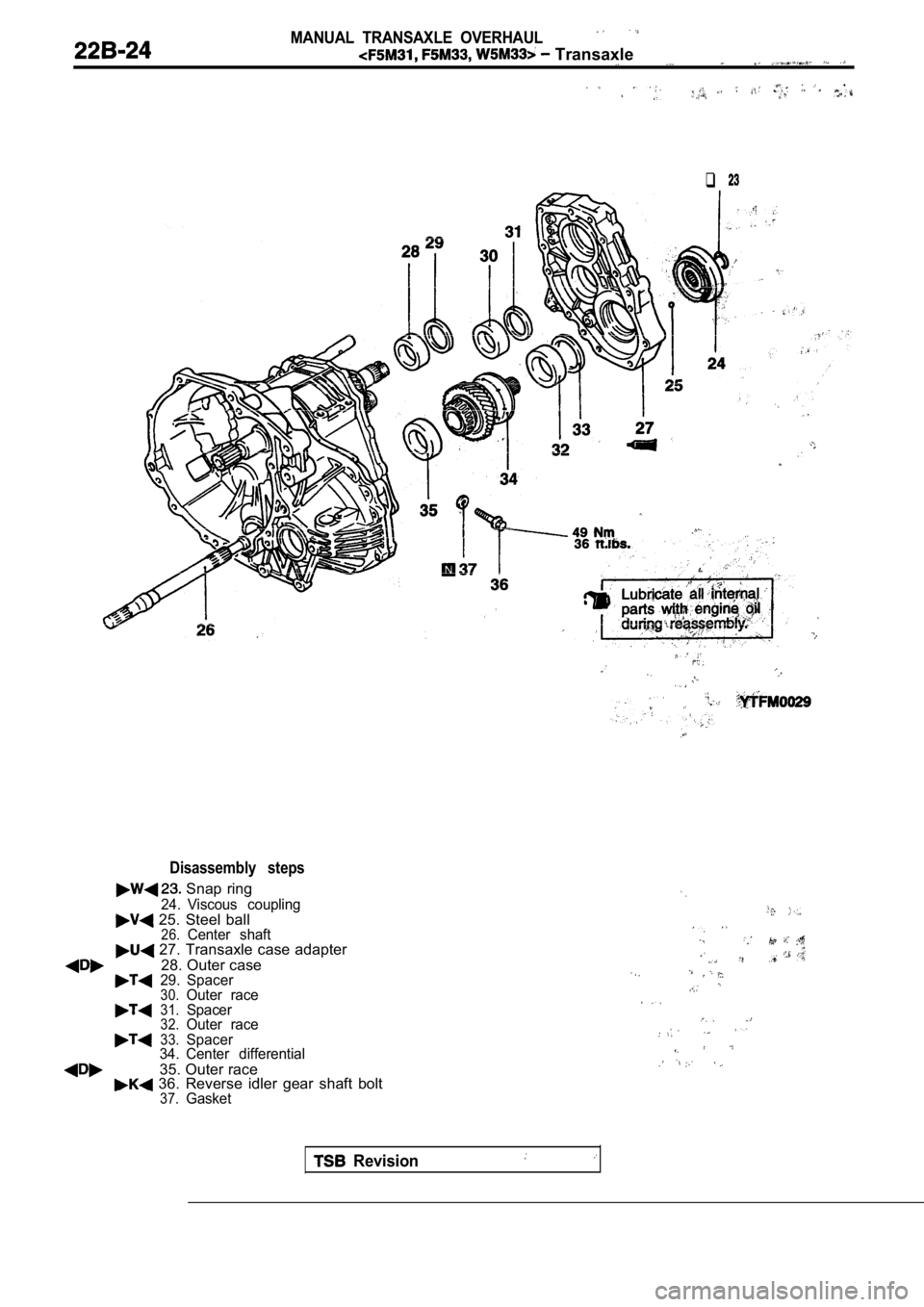

Page 914 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle

q

Disassembly steps

Snap ring

24. Viscous coupling 25. Steel ball26.Center shaft 27. Transaxle case adapter

28. Outer case29. Spacer30.Outer race31.Spacer32.Outer race33.Spacer

34. Center differential

35. Outer race 36. Reverse idler gear shaft bolt37.Gasket

Revision

Page 915 of 2103

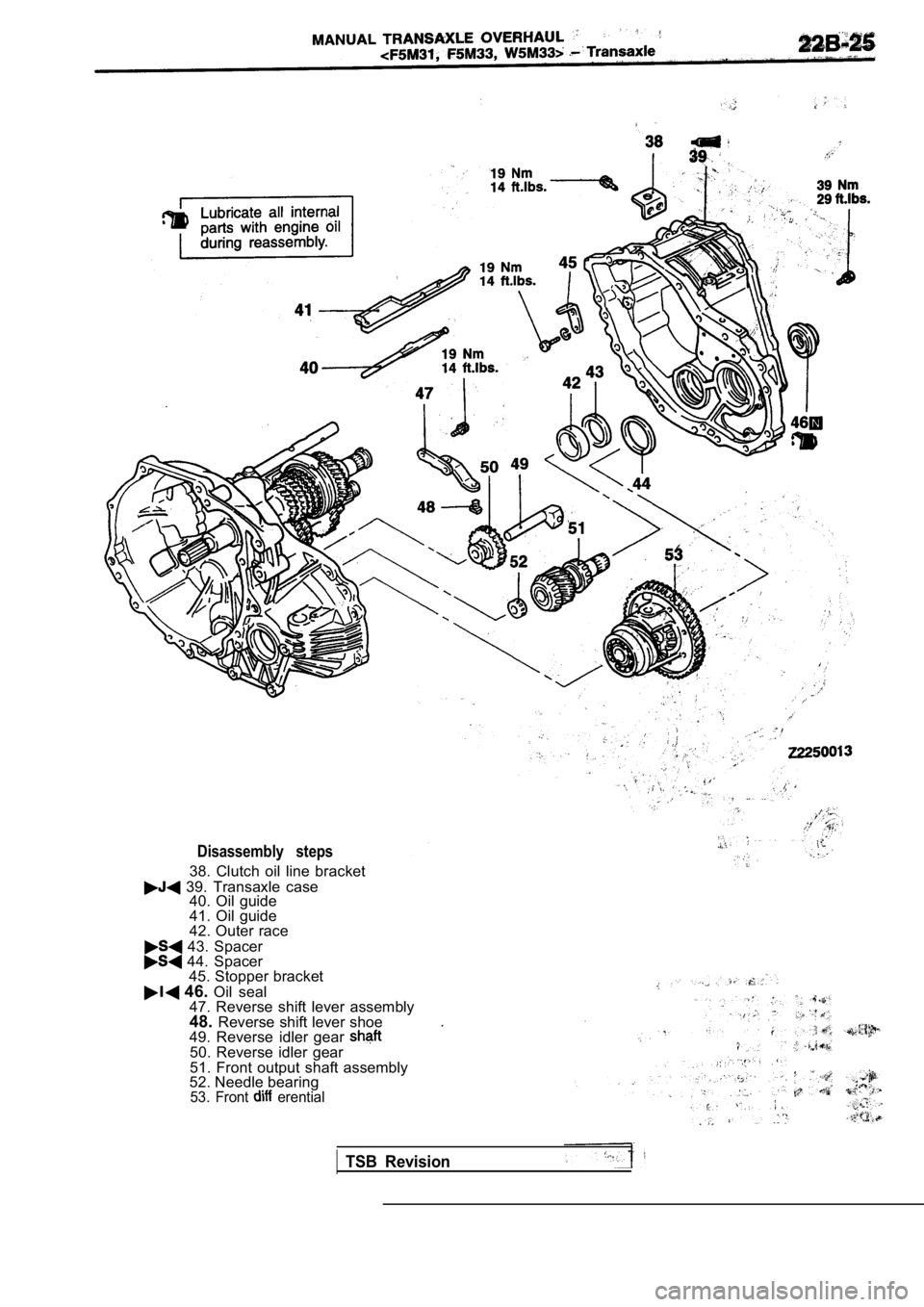

Disassembly steps

38. Clutch oil line bracket

39. Transaxle case40. Oil guide

41. Oil guide

42. Outer race

43. Spacer 44. Spacer

45. Stopper bracket

46. Oil seal

47. Reverse shift lever assembly

48. Reverse shift lever shoe .

49. Reverse idler gear

50. Reverse idler gear

51. Front output shaft assembly

52. Needle bearing

53. Front erential

TSB Revision

Page 916 of 2103

MANUAL TRANSAXLE OVERHAUL

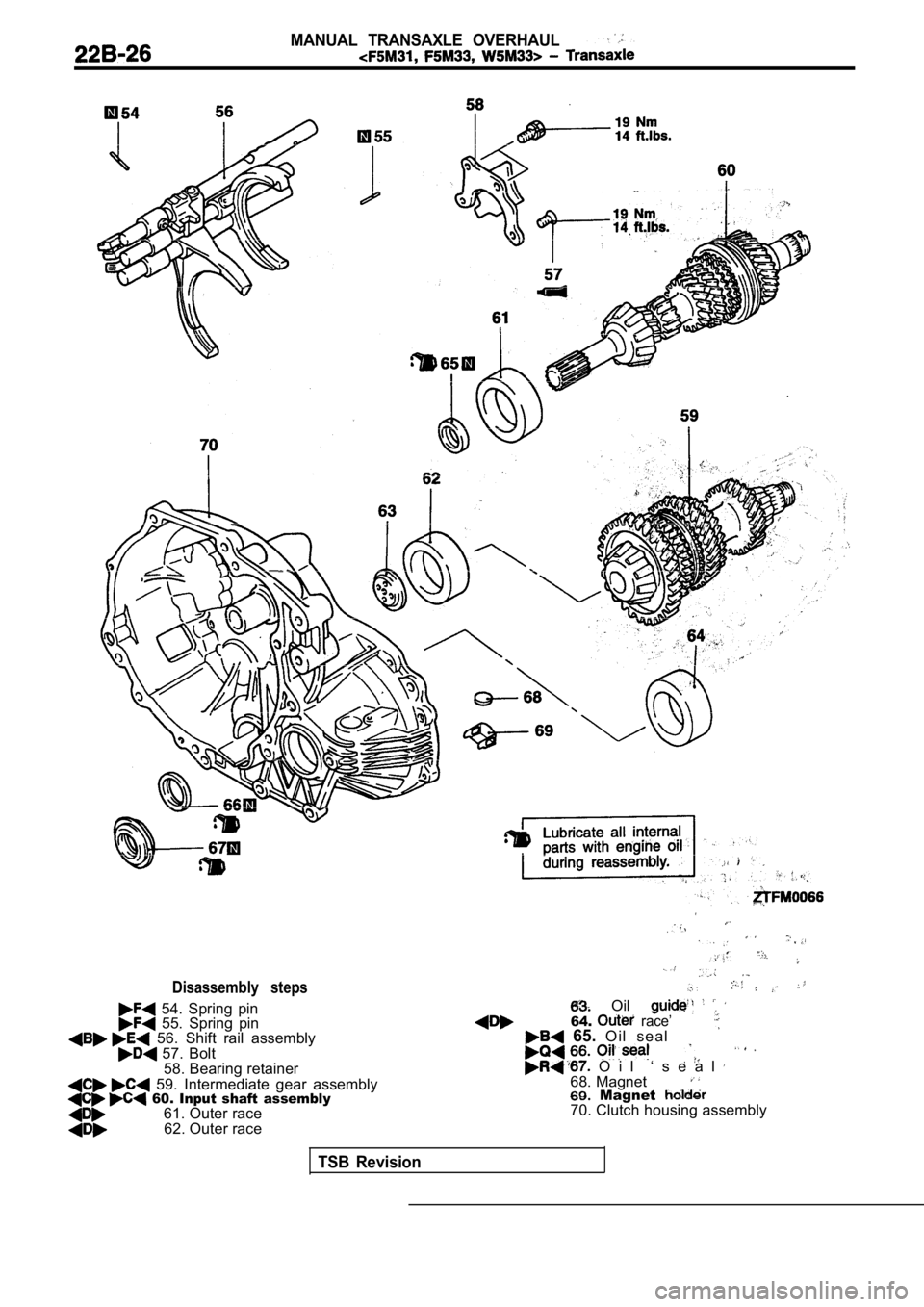

Disassembly steps

54. Spring pin 55. Spring pin 56. Shift rail assembly 57. Bolt58. Bearing retainer

59. Intermediate gear assembly 60. Input shaft assembly61. Outer race62. Outer race

Oil 64. race’ 65. O i l s e a l

O i l ‘ s e a l 68. Magnet Magnet 70. Clutch housing assembly

TSB Revision

Page 917 of 2103

MANUAL TRANSAXLE OVERHAUL Transaxle

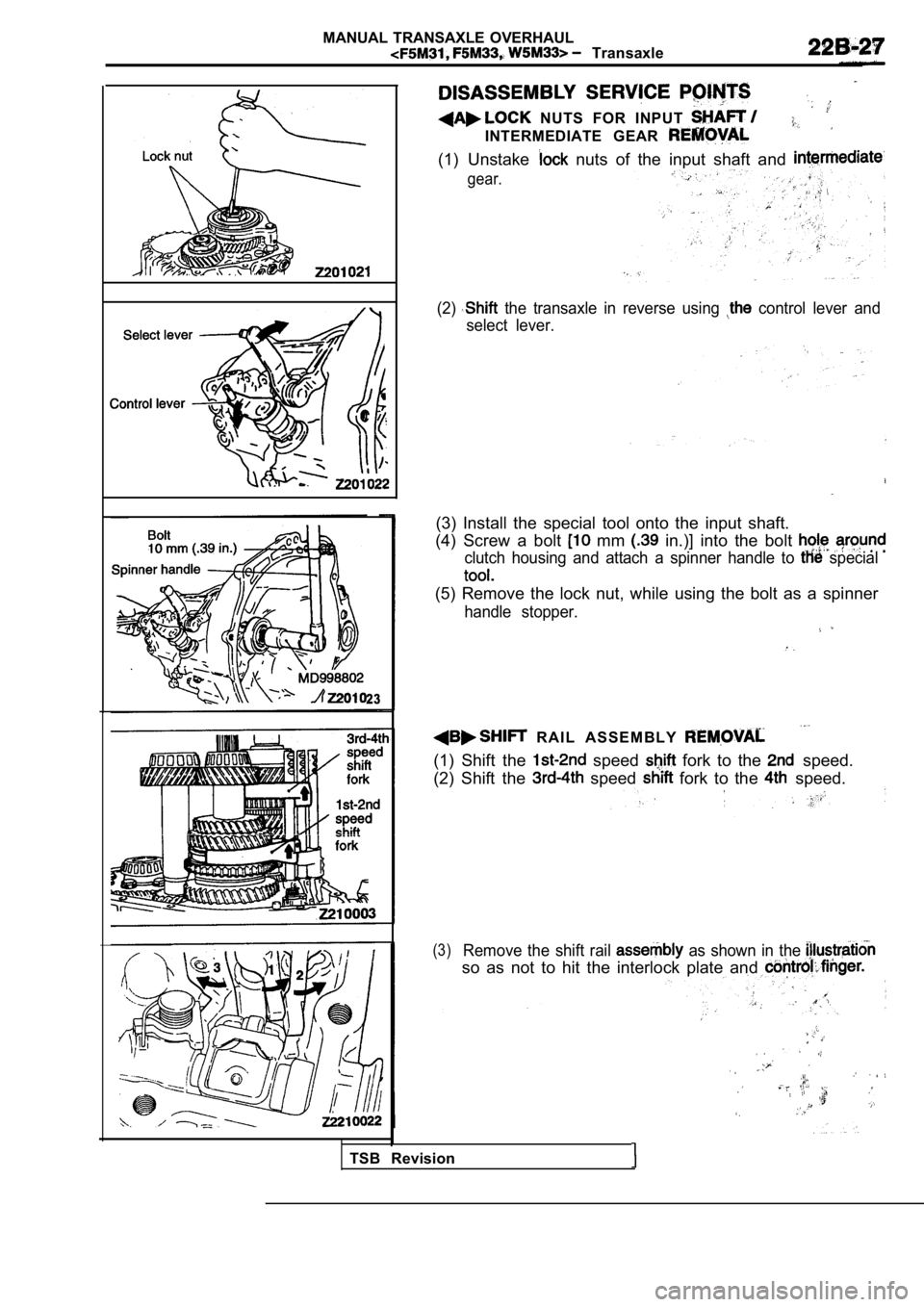

23

NUTS FOR INPUT

INTERMEDIATE GEAR

(1) Unstake nuts of the input shaft and

gear.

(2) the transaxle in reverse using control lever and

select lever.

(3) Install the special tool onto the input shaft.

(4) Screw a bolt

mm in.)] into the bolt

clutch housing and attach a spinner handle to special

(5) Remove the lock nut, while using the bolt as a spinner

handle stopper.

R A I L A S S E M B L Y

(1) Shift the speed fork to the speed.

(2) Shift the

speed fork to the speed.

TSB Revision

(3)Remove the shift rail as shown in the

so as not to hit the interlock plate and

Page 918 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle

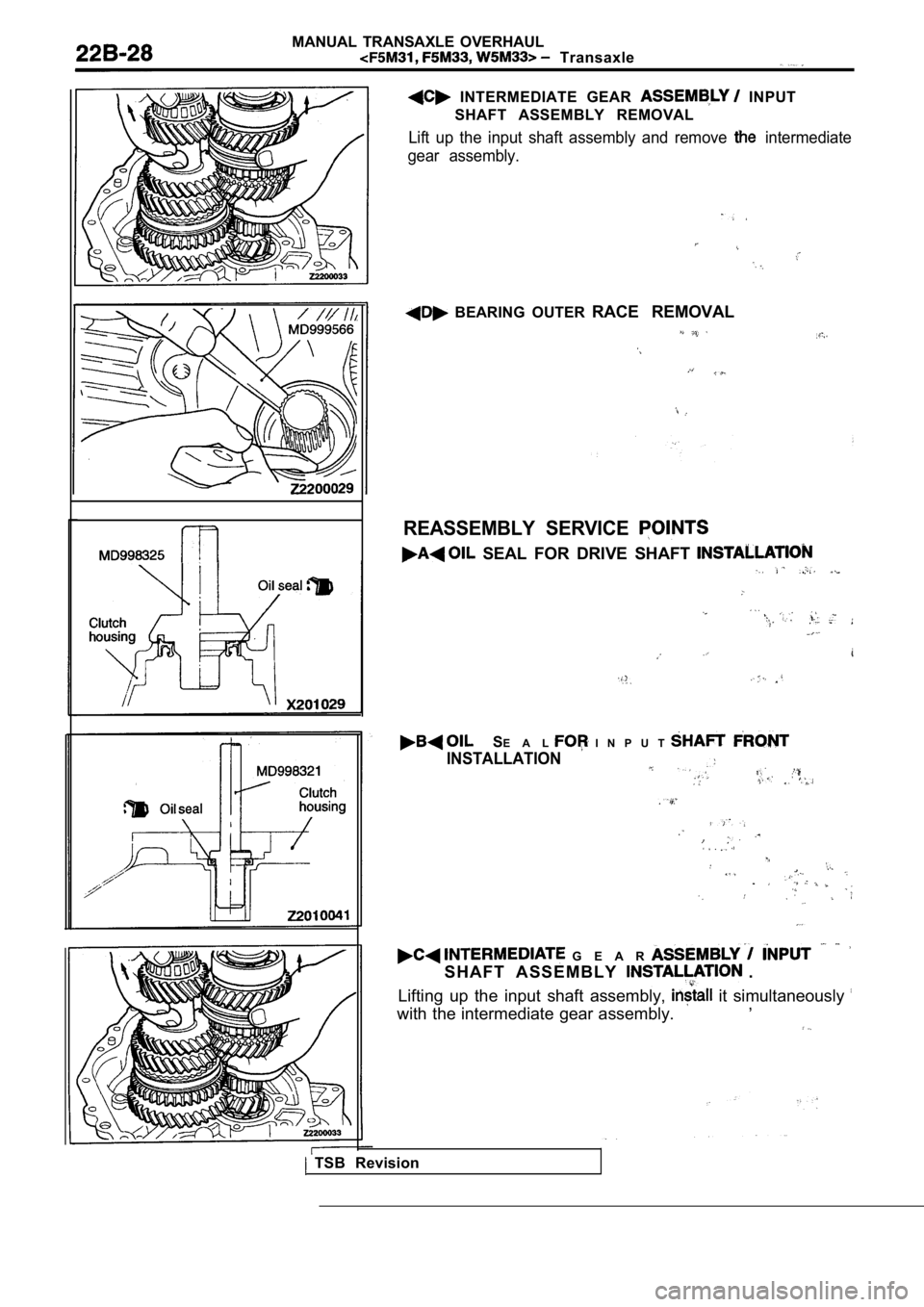

INTERMEDIATE GEAR INPUT

SHAFT ASSEMBLY REMOVAL

Lift up the input shaft assembly and remove intermediate

gear assembly.

BEARING OUTER RACE REMOVAL

REASSEMBLY SERVICE

SEAL FOR DRIVE SHAFT

SE A L I N P U T

INSTALLATION

G E A R

S H A F T A S S E M B L Y .

Lifting up the input shaft assembly,

it simultaneously

with the intermediate gear assembly. ,

TSB Revision

Page 919 of 2103

MANUALTRANSAXLE OVERHAUL

Transaxle

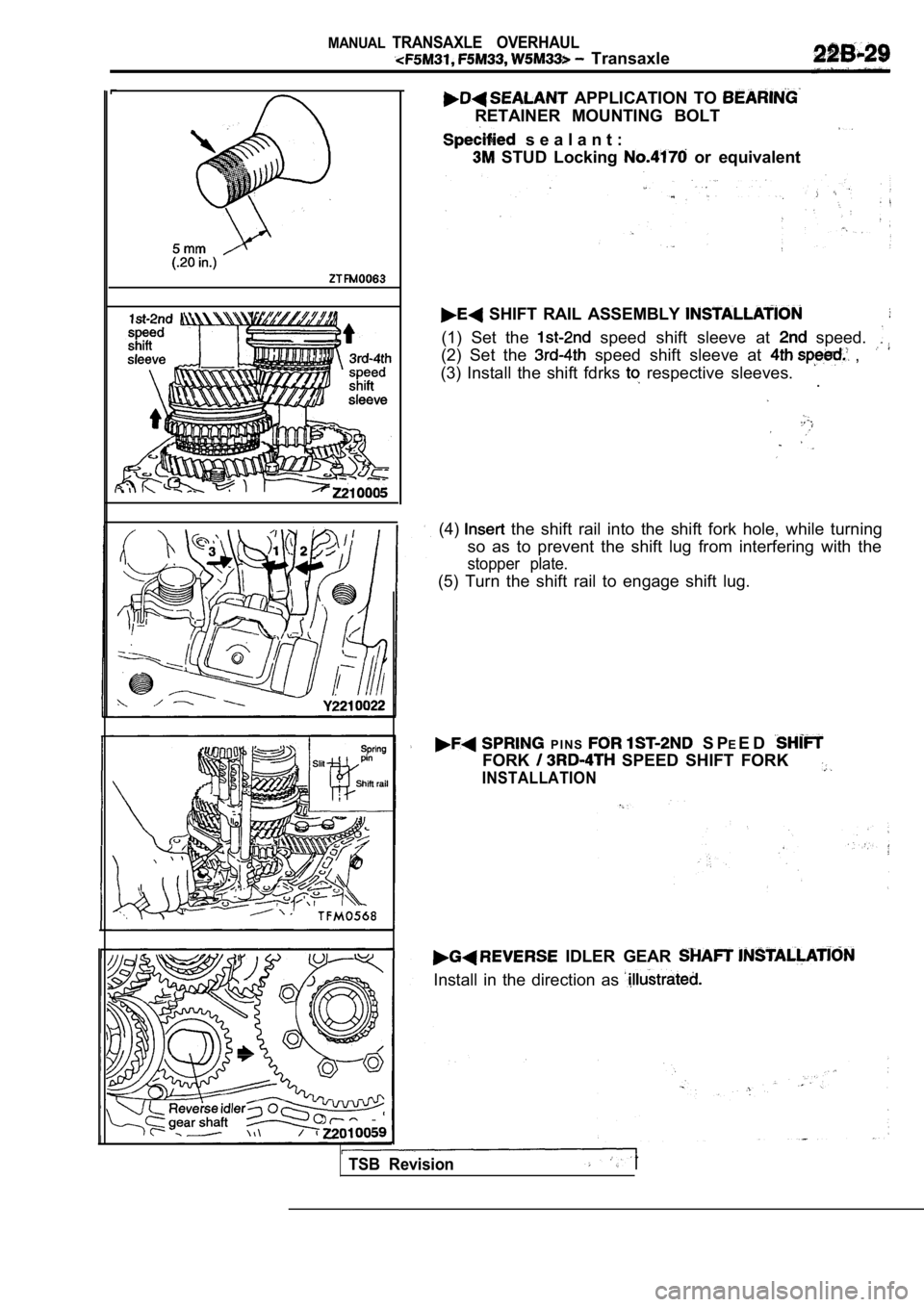

APPLICATION TO

RETAINER MOUNTING BOLT

s e a l a n t :

STUD Locking or equivalent

SHIFT RAIL ASSEMBLY

(1) Set the speed shift sleeve at speed.

(2) Set the speed shift sleeve at ,

(3) Install the shift fdrks

respective sleeves. .

(4) the shift rail into the shift fork hole, while tur ning

so as to prevent the shift lug from interfering wit h the

stopper plate.

(5) Turn the shift rail to engage shift lug.

P I N S S PEE D

FORK SPEED SHIFT FORK

INSTALLATION

IDLER GEAR

Install in the direction as

TSB Revision

Page 920 of 2103

MANUAL Transaxle

SolderSolder

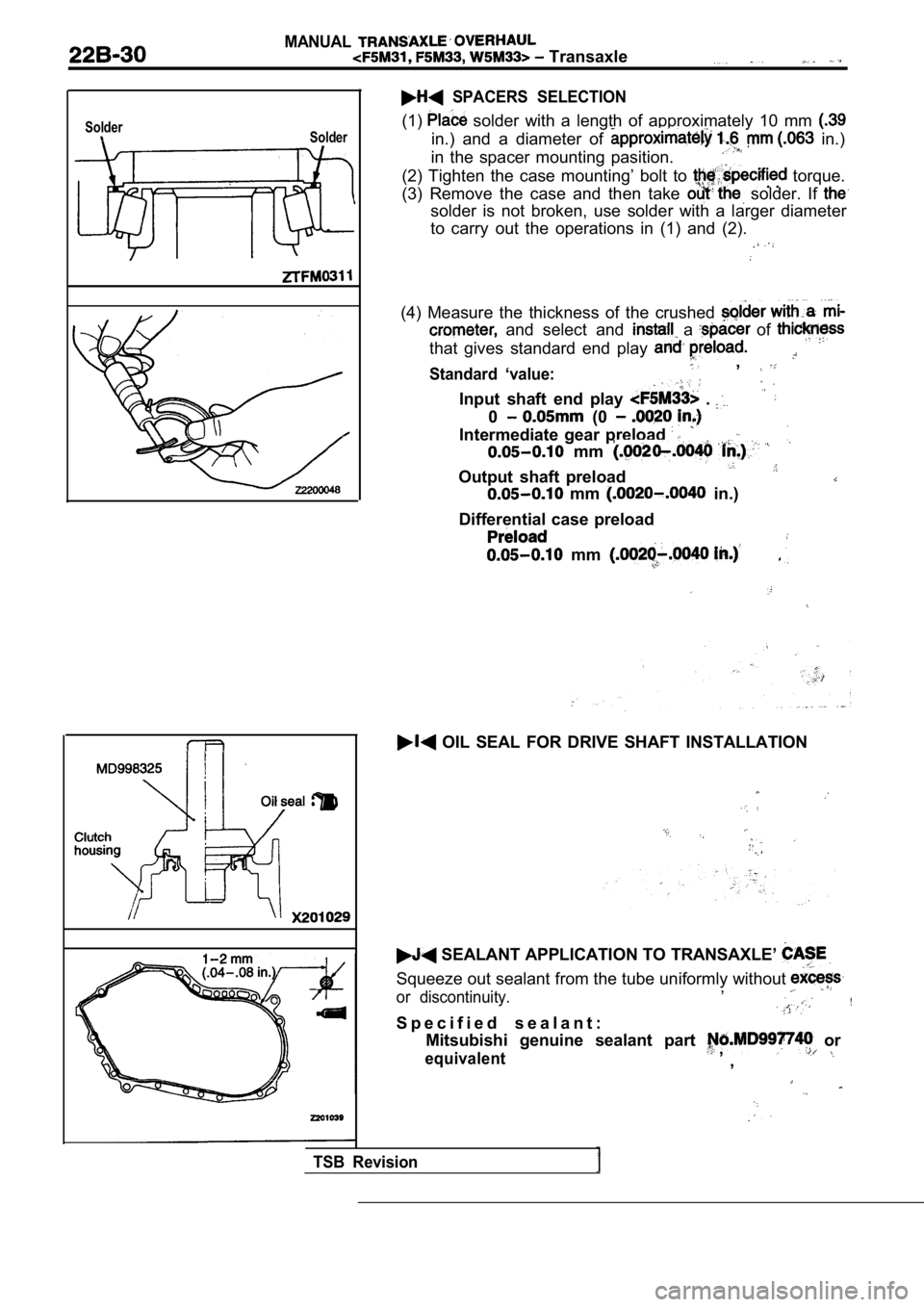

SPACERS SELECTION

(1) solder with a length of approximately 10 mm

in.) and a diameter of in.)

in the spacer mounting pasition.

(2) Tighten the case mounting’ bolt to

torque.

(3) Remove the case and then take

solder. If

solder is not broken, use solder with a larger diam eter

to carry out the operations in (1) and (2).

(4) Measure the thickness of the crushed

and select and a of

that gives standard end play

Standard ‘value: ,

Input shaft end play .

0 (0

Intermediate gear preload

mm

Output shaft preload

mm in.)

Differential case preload

mm

OIL SEAL FOR DRIVE SHAFT INSTALLATION

SEALANT APPLICATION TO TRANSAXLE’

Squeeze out sealant from the tube uniformly without

or discontinuity.,

S p e c i f i e d s e a l a n t :

Mitsubishi genuine sealant part

or

equivalent ,,

TSB Revision

Trending: spare tire, octane, service reset, ECO mode, engine overheat, headlight bulb, airbag