MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: fuel filter, flat tire, lock, tire pressure reset, key battery, steering wheel adjustment, brake pads

Page 981 of 2103

MANUAL TRANSAXLE

blockerassemblyI

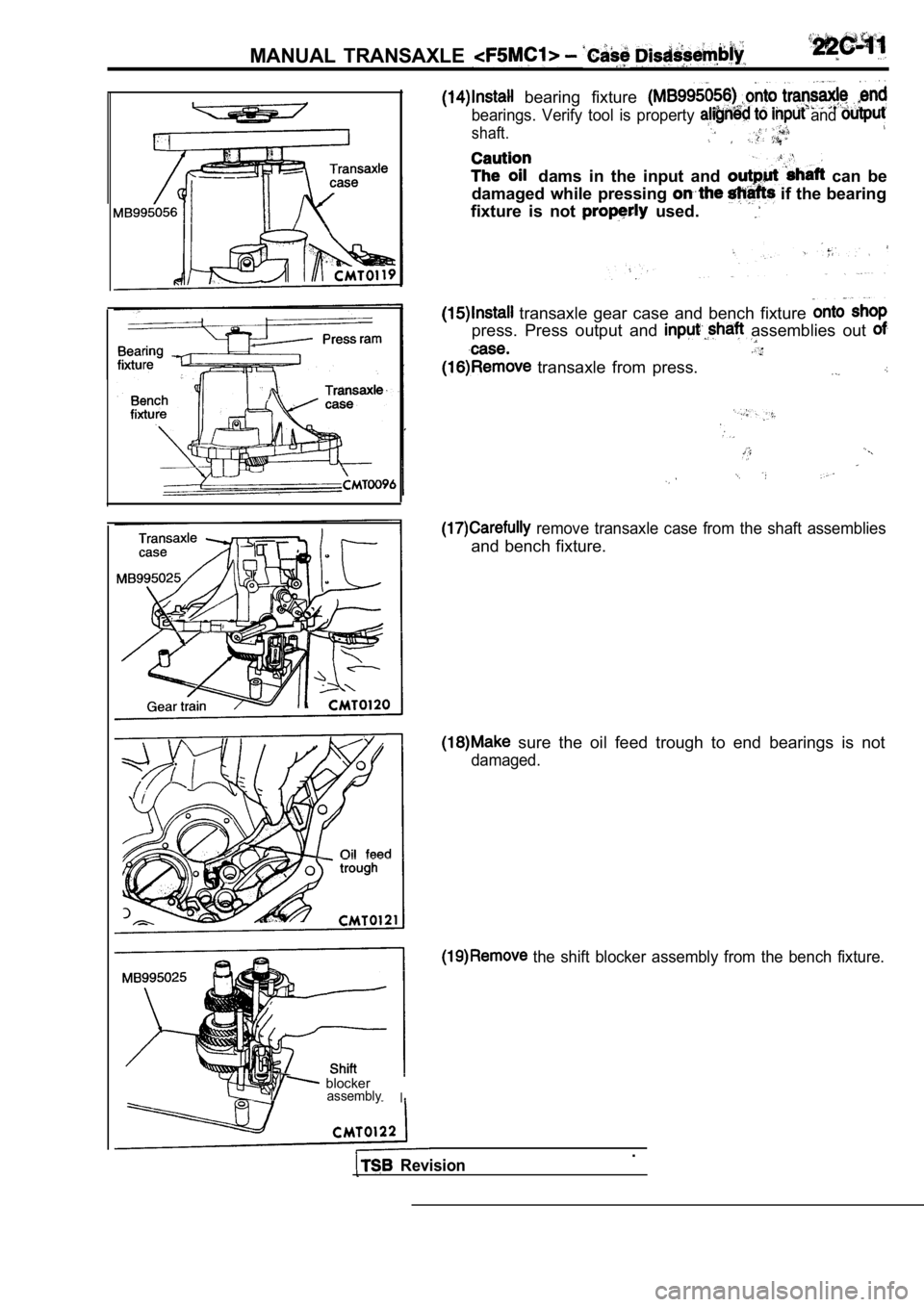

bearing fixture

bearings. Verify tool is property and

shaft.

dams in the input and can be

damaged while pressing

if the bearing

fixture is not

used.

transaxle gear case and bench fixture

press. Press output and assemblies out

transaxle from press.

remove transaxle case from the shaft assemblies

and bench fixture.

sure the oil feed trough to end bearings is not

damaged.

the shift blocker assembly from the bench fixture.

Revision.

Page 982 of 2103

MANUAL TRANSAXLE Case Disassembly

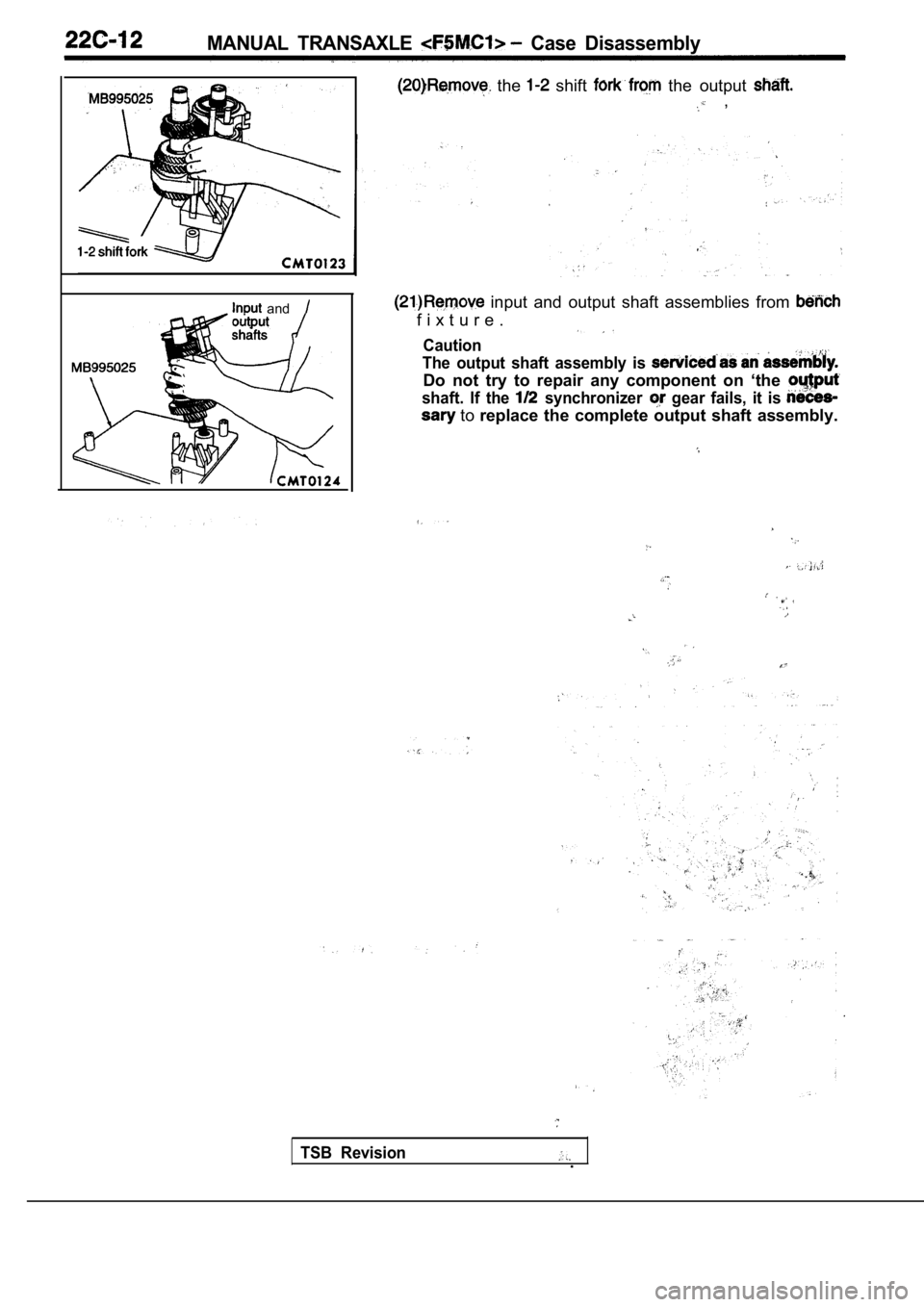

and

the shift the output ,

input and output shaft assemblies from

f i x t u r e .

Caution

The output shaft assembly is

Do not try to repair any component on ‘the

shaft. If the synchronizer gear fails, it is

to replace the complete output shaft assembly.

TSB Revision.

Page 983 of 2103

M A N U A L T R A N S A X L E

speed

speed

Sleeve speed

gearStop ring gear

Caged

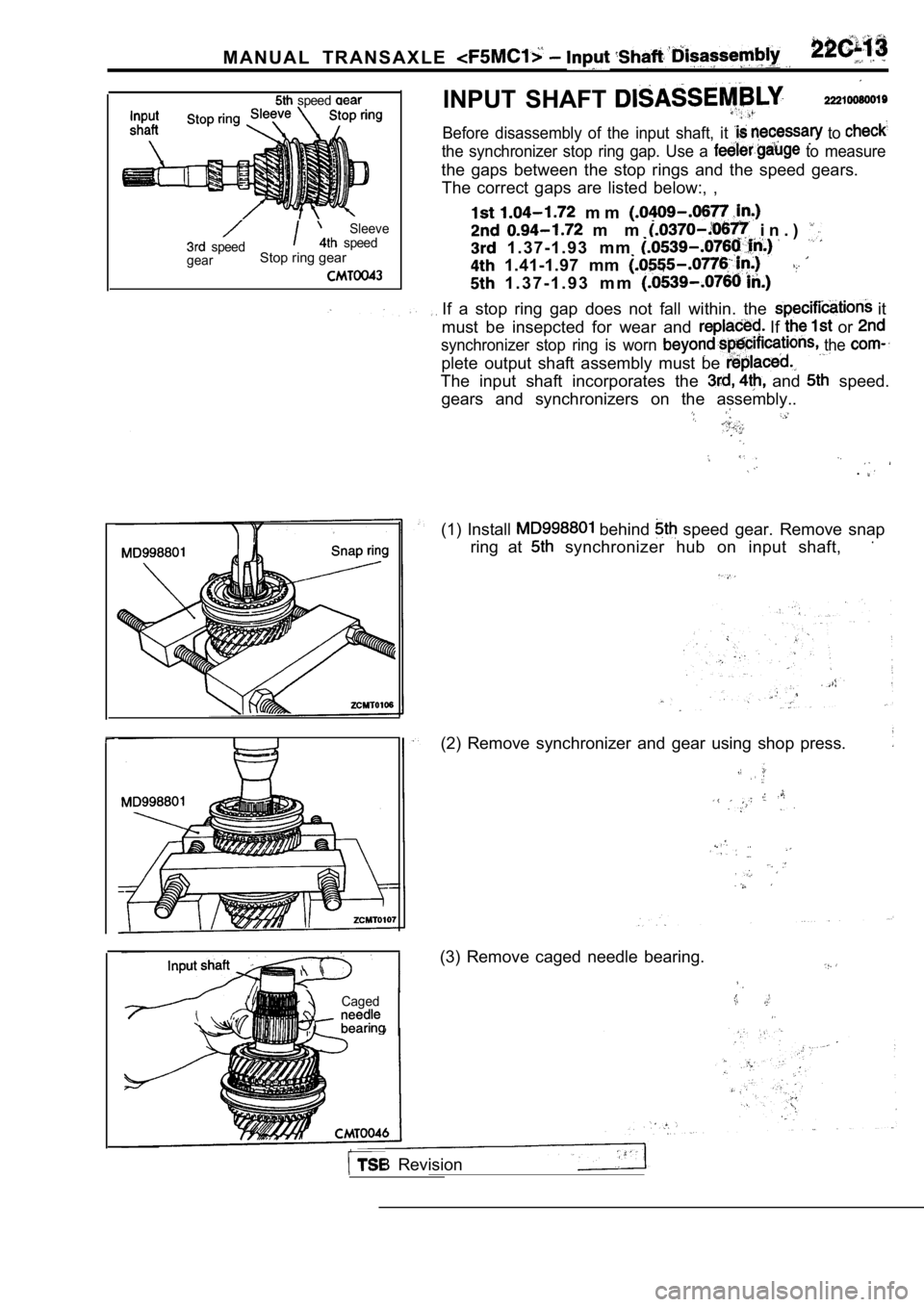

INPUT SHAFT

Before disassembly of the input shaft, it to

the synchronizer stop ring gap. Use a to measure

the gaps between the stop rings and the speed gears .

The correct gaps are listed below:, ,

m m

m m i n . )

1 . 3 7 - 1 . 9 3 m m

1.41-1.97 mm

1 . 3 7 - 1 . 9 3 m m

If a stop ring gap does not fall within. the it

must be insepcted for wear and

If or

synchronizer stop ring is worn the

plete output shaft assembly must be

The input shaft incorporates the and speed.

gears and synchronizers on the assembly..

.

(1) Install behind speed gear. Remove snap

ring at

synchronizer hub on input shaft,

(2) Remove synchronizer and gear using shop press.

(3) Remove caged needle bearing.

TSB Revision

Page 984 of 2103

MANUAL TRANSAXLE Shaft Disassembly

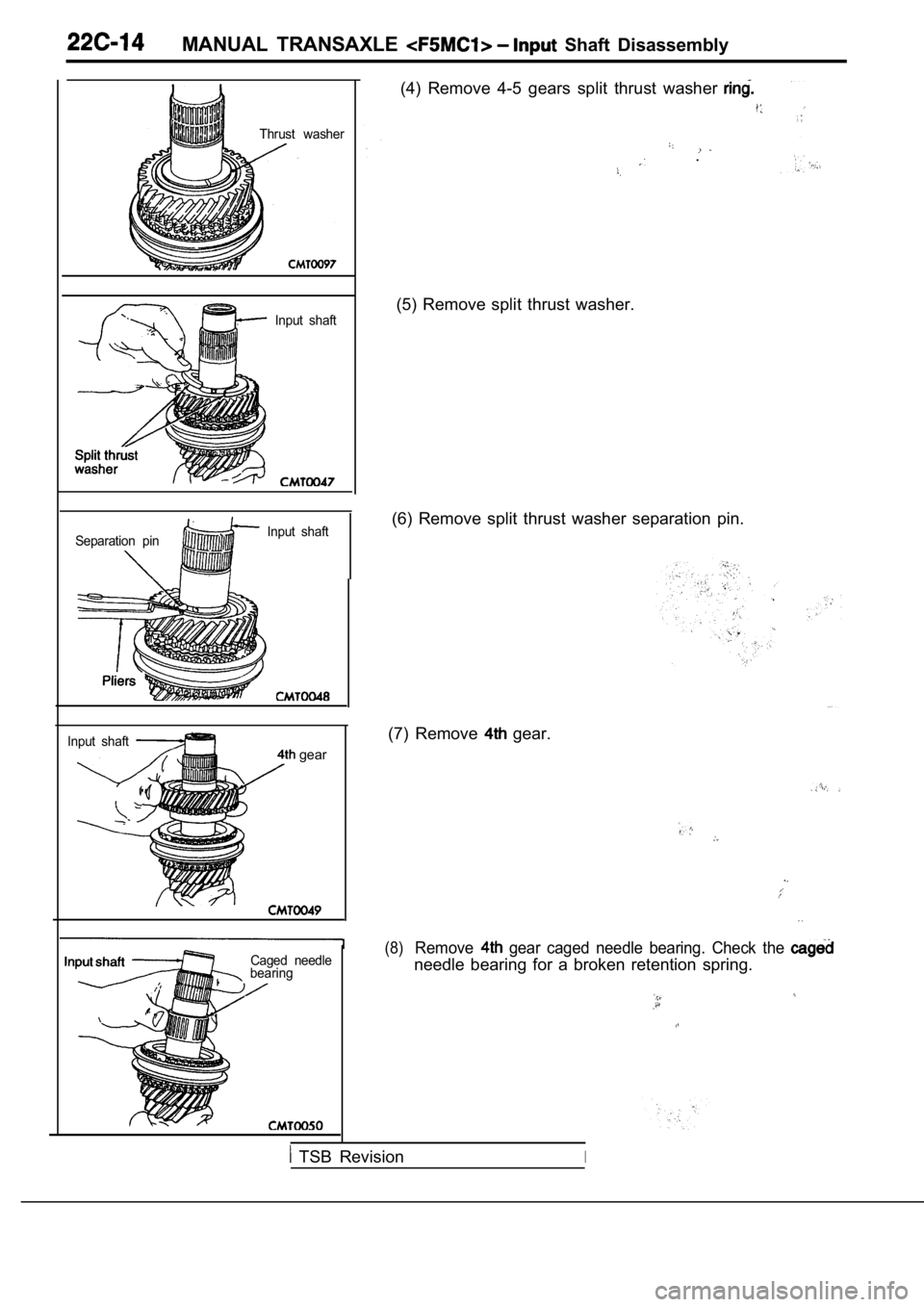

Thrust washerInput shaft

Separation pinInput shaft

Input shaft

gear

Caged needle

bearing

(4) Remove 4-5 gears split thrust washer

.

(5) Remove split thrust washer.

(6) Remove split thrust washer separation pin.

(7) Remove

gear.

(8)Remove gear caged needle bearing. Check the

needle bearing for a broken retention spring.

TSB RevisionI

Page 985 of 2103

MANUAL TRANSAXLE

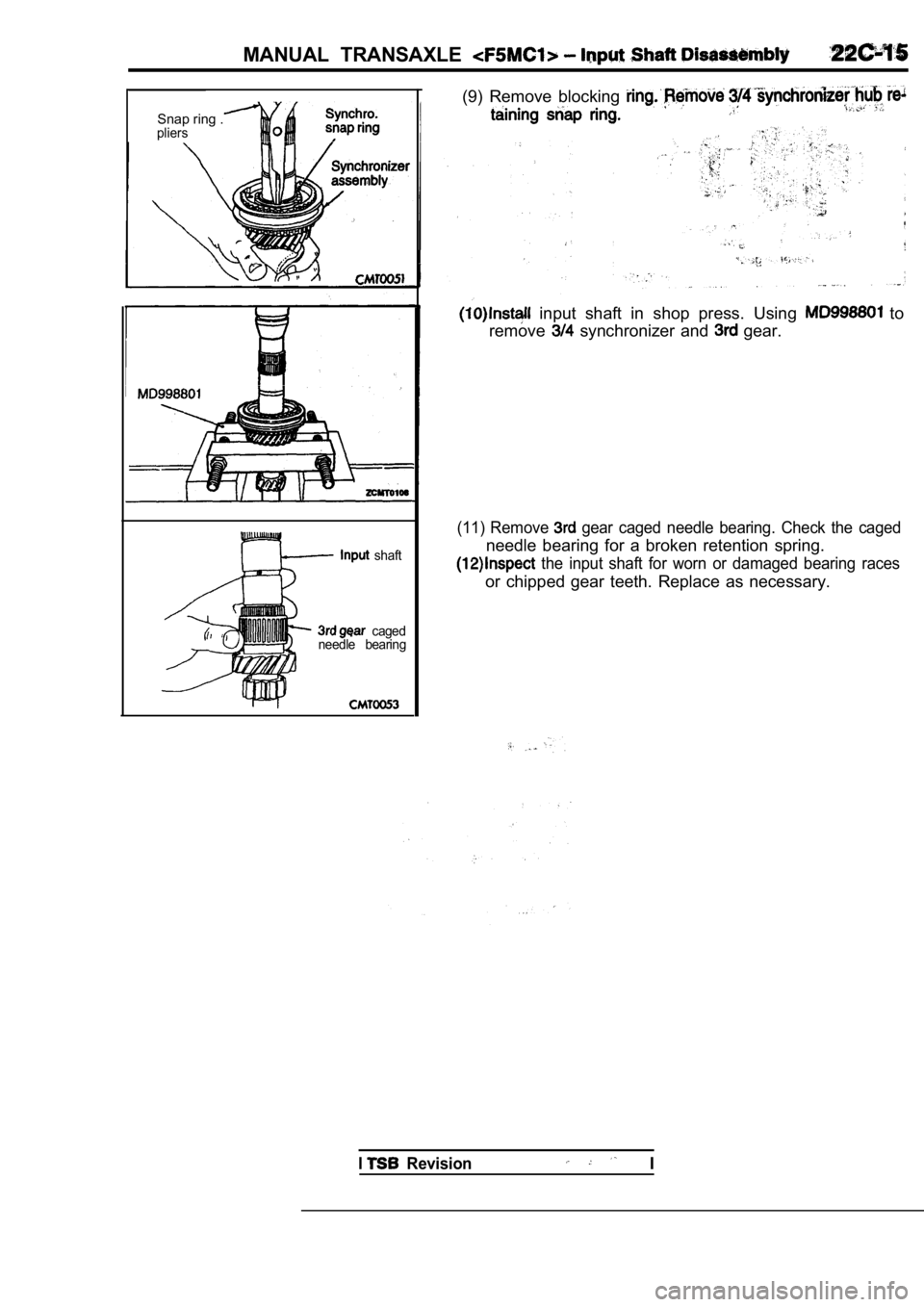

Snap ring .pliers

shaft

caged

needle bearing

(9) Remove blocking

input shaft in shop press. Using to

remove

synchronizer and gear.

(11) Remove gear caged needle bearing. Check the caged

needle bearing for a broken retention spring.

the input shaft for worn or damaged bearing races

or chipped gear teeth. Replace as necessary.

I Revision I

Page 986 of 2103

Output Disassembly/

MANUAL TRANSAXLE

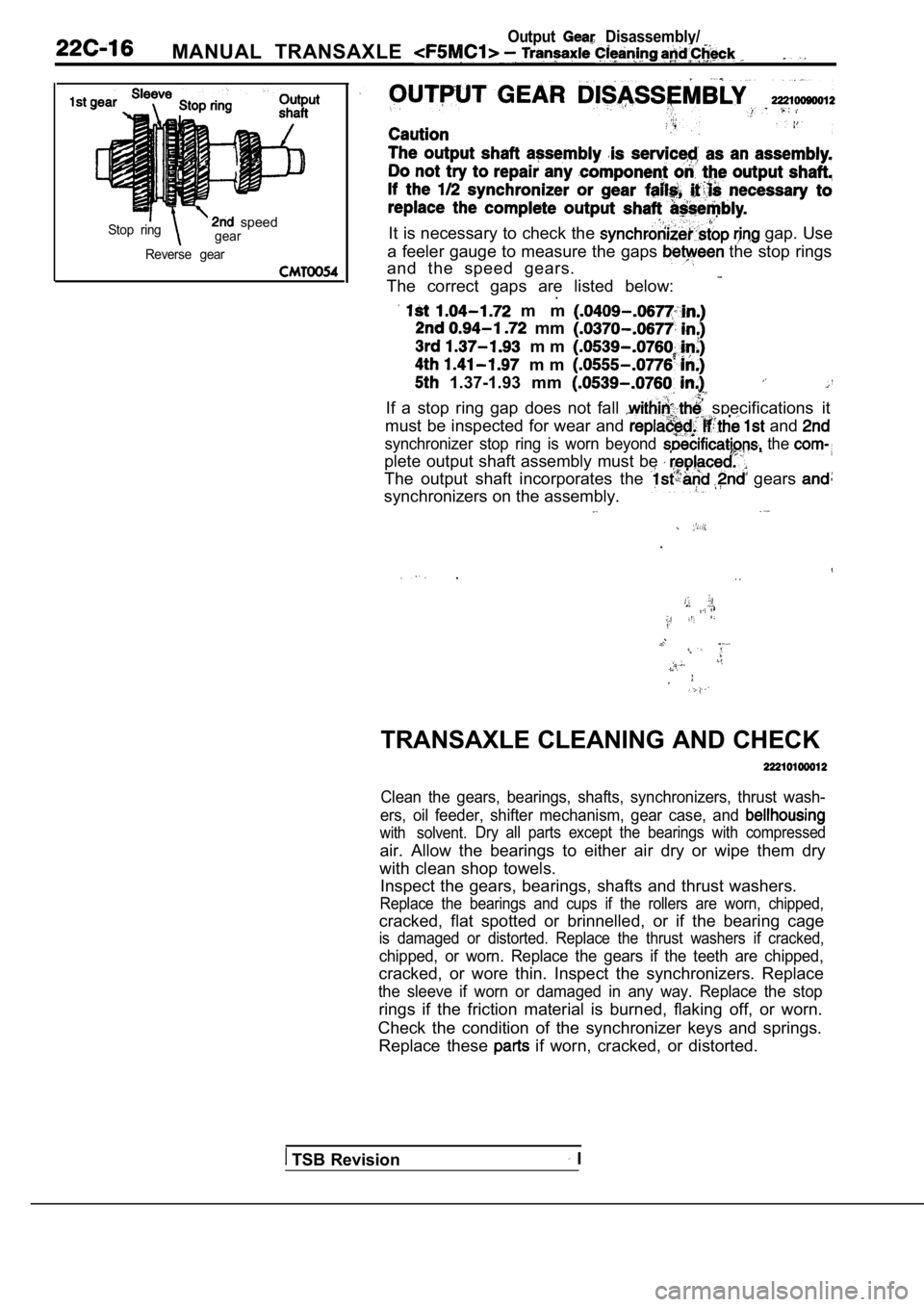

Stop ring speedgear

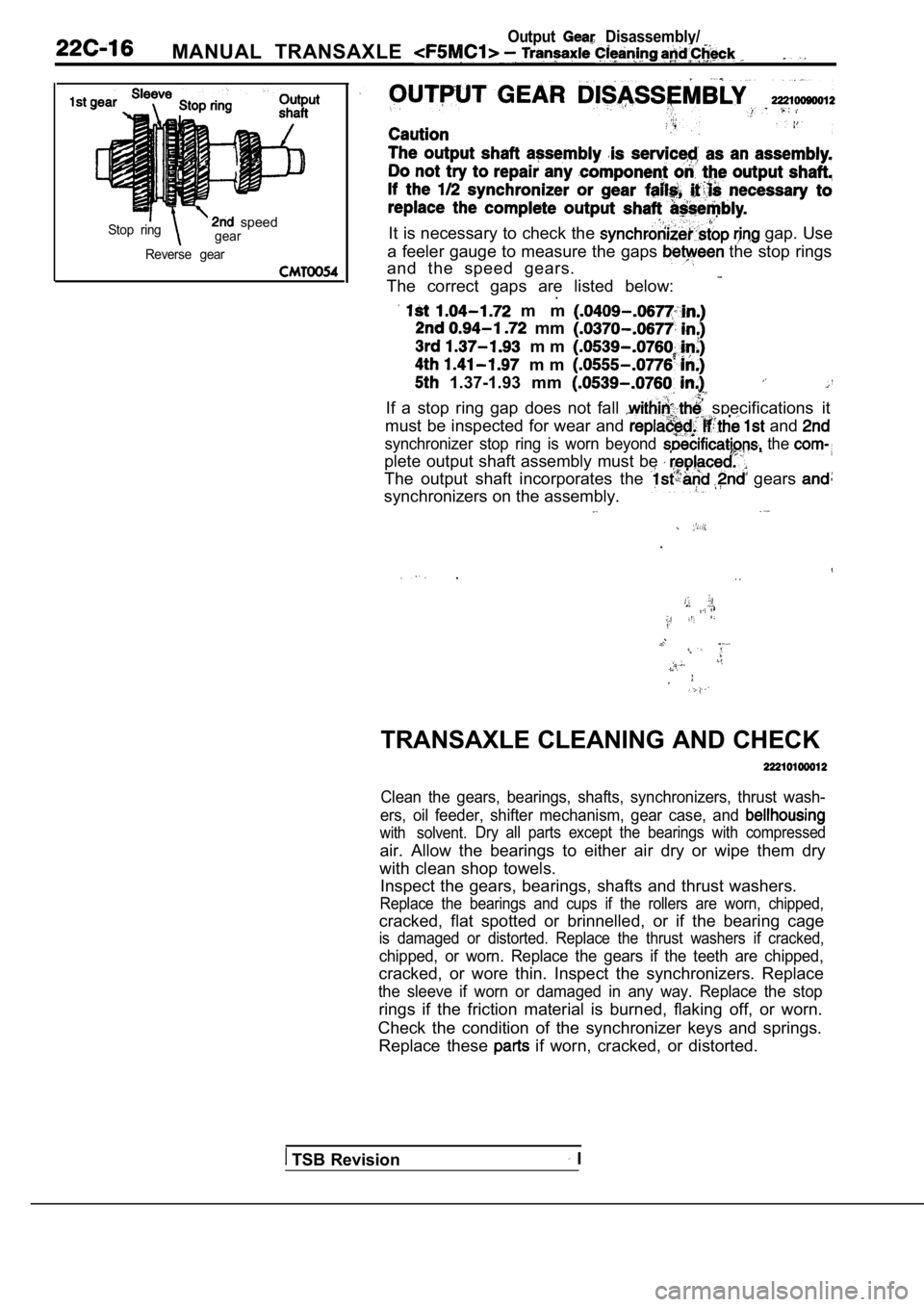

Reverse gearIt is necessary to check the gap. Use

a feeler gauge to measure the gaps

the stop rings

and the speed gears.

The correct gaps are listed below:

.

m m

mm

m m

m m

1.37-1.93 mm .If a stop ring gap does not fall specifications it

must be inspected for wear and

and

synchronizer stop ring is worn beyond the

plete output shaft assembly must be

The output shaft incorporates the gears

synchronizers on the assembly.

.

.. .

TRANSAXLE CLEANING AND CHECK

Clean the gears, bearings, shafts, synchronizers, t hrust wash-

ers, oil feeder, shifter mechanism, gear case, and

with solvent. Dry all parts except the bearings with compressed

air. Allow the bearings to either air dry or wipe t

hem dry

with clean shop towels. Inspect the gears, bearings, shafts and thrust wash ers.

Replace the bearings and cups if the rollers are wo rn, chipped,

cracked, flat spotted or brinnelled, or if the bearing cage

is damaged or distorted. Replace the thrust washers if cracked,

chipped, or worn. Replace the gears if the teeth are chipped,

cracked, or wore thin. Inspect the synchronizers. R eplace

the sleeve if worn or damaged in any way. Replace t he stop

rings if the friction material is burned, flaking off, or worn.

Check the condition of the synchronizer keys and sp rings.

Replace these

if worn, cracked, or distorted.

TSB Revision I

Page 987 of 2103

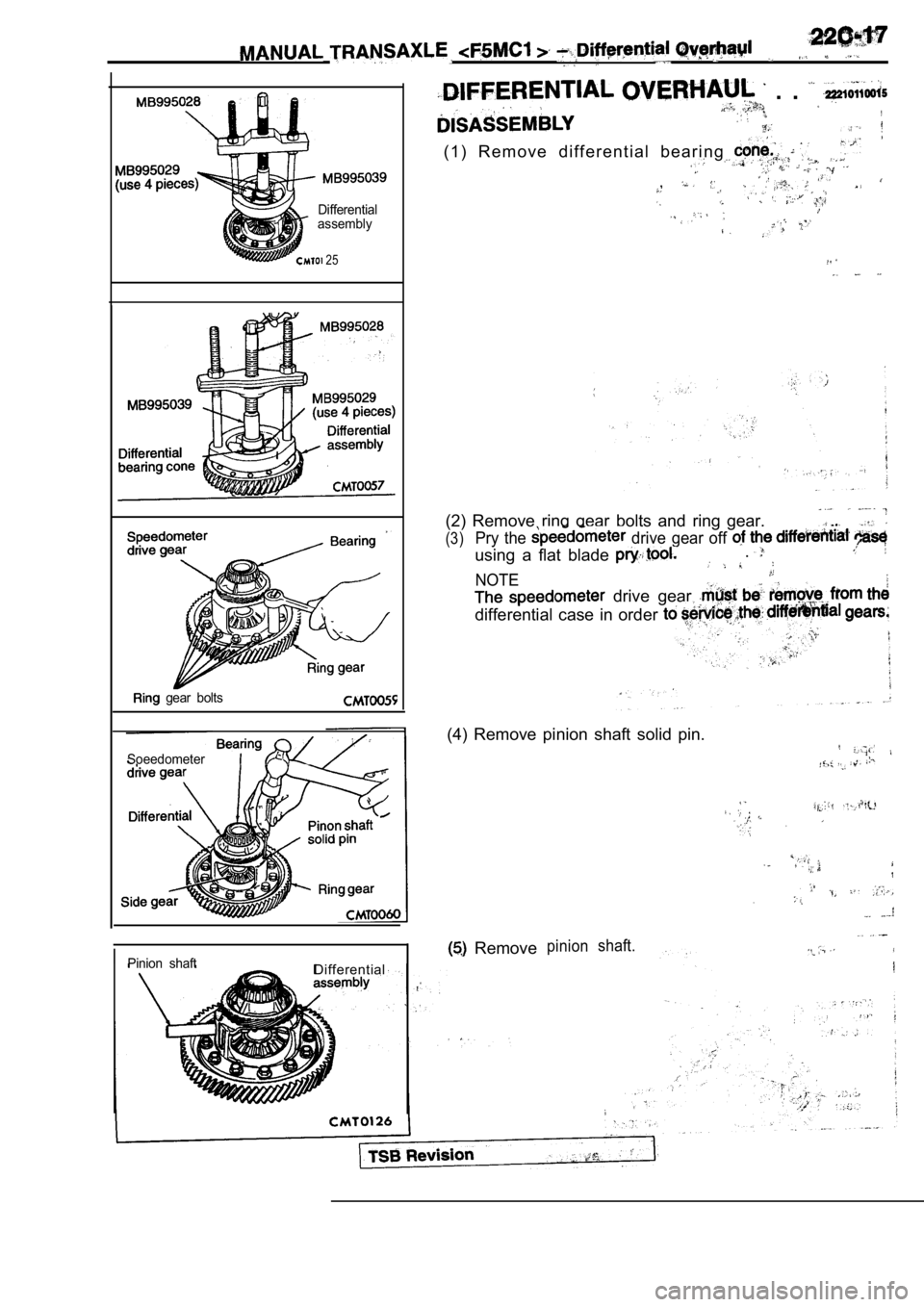

Differentialassembly

25

gear bolts

Soeedometer

Pinion shaftDifferential

. . ,

( 1 ) R e m o v e d i f f e r e n t i a l b e a r i n g ,,

(2) Remove ring gear bolts and ring gear.

(3)Pry the drive gear off

using a flat blade .

NOTE

drive gear

differential case in order

(4) Remove pinion shaft solid pin.

,

.,

Removepinionshaft.

Page 988 of 2103

MANUAL TRANSAXLE

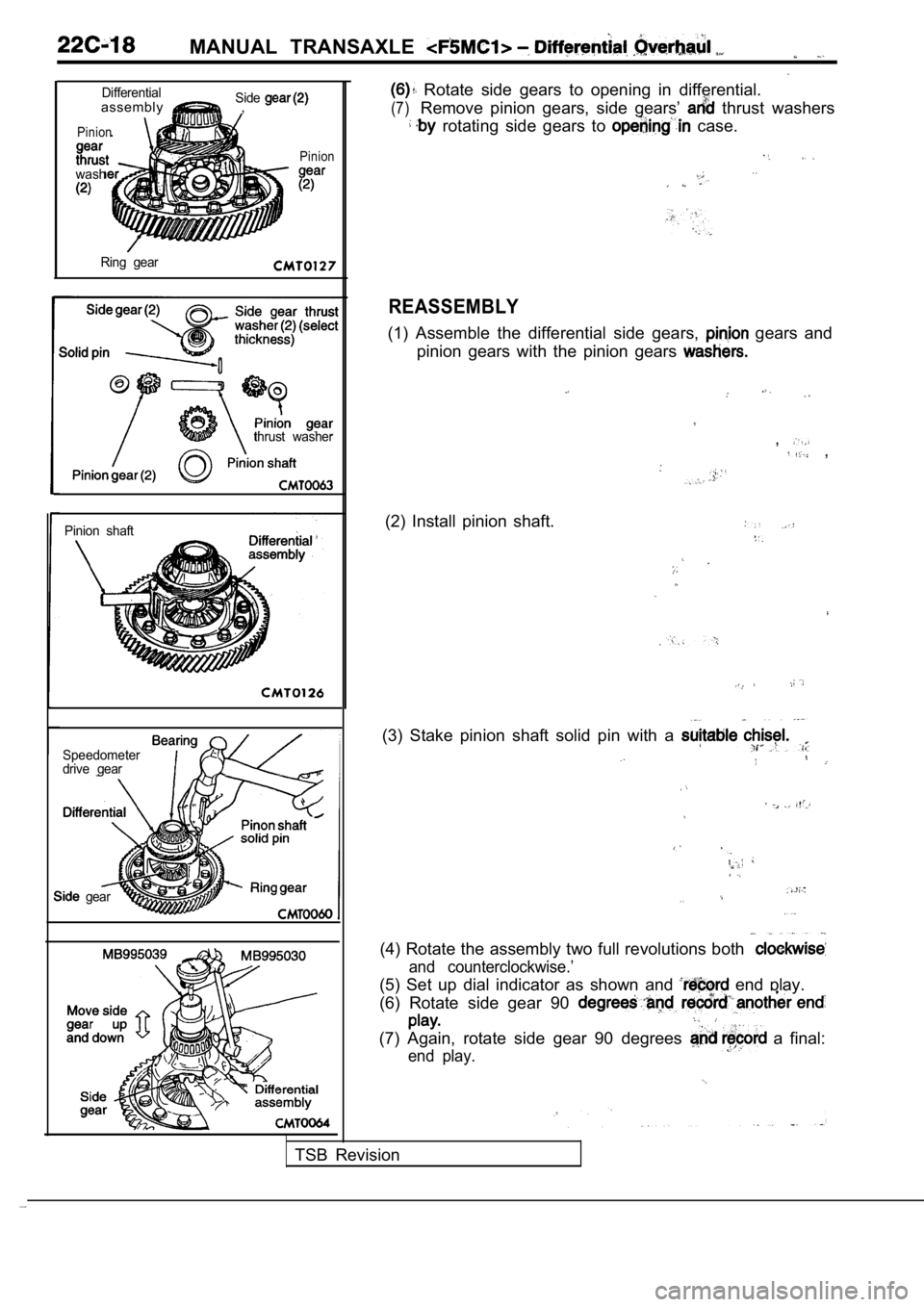

DifferentialassemblySide,

Pinion

wash

Pinion

Ring gear

thrust washer

Pinion shaft

Speedometer

drive gear

gear

Rotate side gears to opening in differential.

(7)Remove pinion gears, side gears’ thrust washers

rotating side gears to case.

. .

REASSEMBLY

(1) Assemble the differential side gears, gears and

pinion gears with the pinion gears

, ,

(2) Install pinion shaft.

(3) Stake pinion shaft solid pin with a

. .

(4) Rotate the assembly two full revolutions both

and counterclockwise.’

(5) Set up dial indicator as shown and end play.

(6) Rotate side gear 90

(7) Again, rotate side gear 90 degrees a final:

end play.

TSB Revision

Page 989 of 2103

MANUAL TRANSAXLE . .

Move sideg e a r u pand down

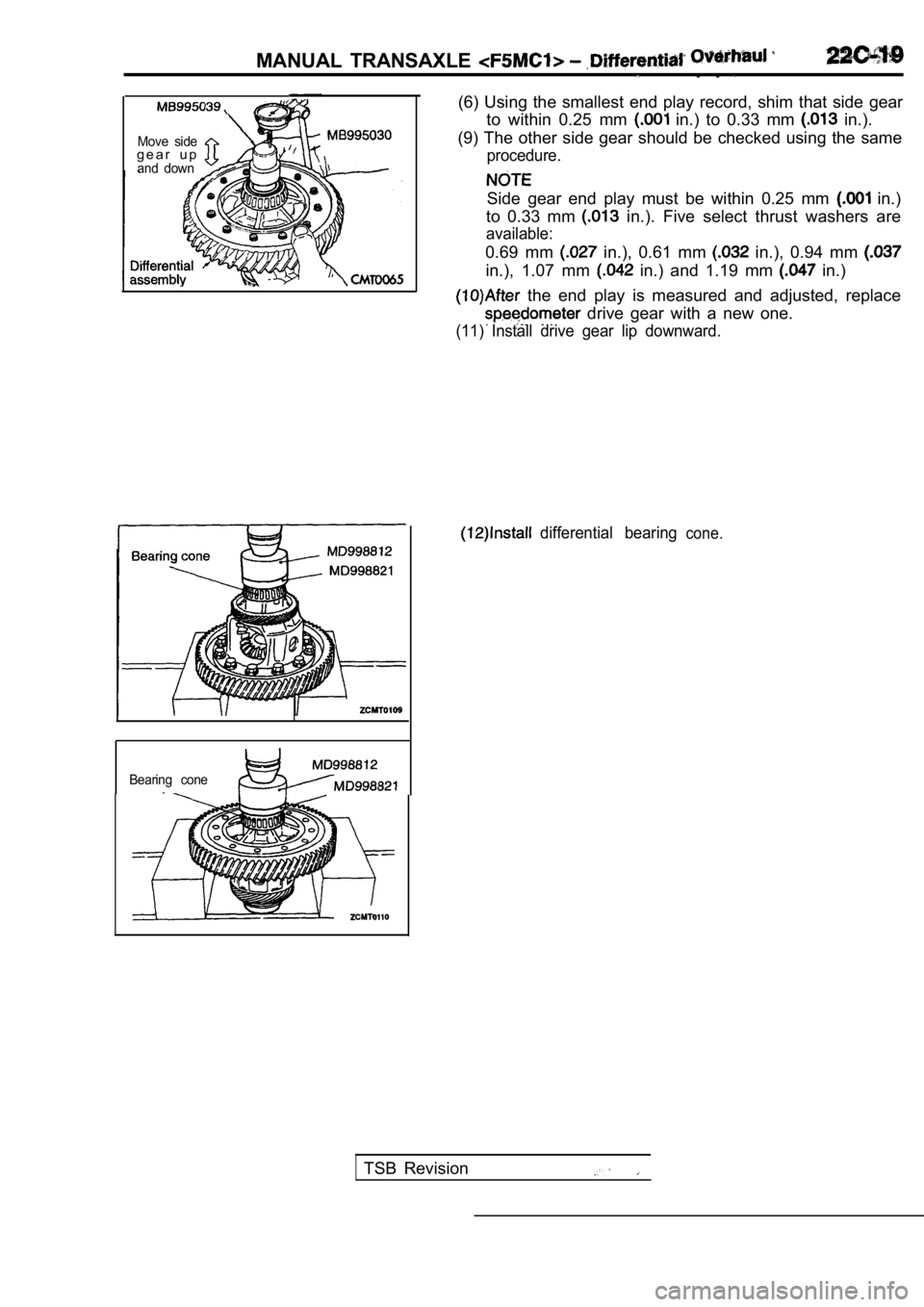

Bearing cone.(6) Using the smallest end play record, shim that s

ide gear

to within 0.25 mm

in.) to 0.33 mm in.).

(9) The other side gear should be checked using the same

procedure.

Side gear end play must be within 0.25 mm in.)

to 0.33 mm

in.). Five select thrust washers are

available:

0.69 mm in.), 0.61 mm in.), 0.94 mm

in.), 1.07 mm in.) and 1.19 mm in.)

the end play is measured and adjusted, replace

drive gear with a new one.

(11) Install drive gear lip downward.

differential bearingcone.

TSB Revision

Page 990 of 2103

MANUAL TRANSAXLE Synchronizer

DISASSEMBLY

Place synchronizer in a clean shop,, towel Wrap. Press

on inner hub. Carefully open up shop. towel and remove

springs, balls, keys, hub, and sleeve.

CLEAN

Do not attempt to clean the blocking rings in solve nt. The

friction material will become contaminated. Place synchronizer

components in a suitable holder and clean with solv ent. Then

let them air, dry.

TSBRevision

Trending: horn, mirror, warning, clock setting, light, ground clearance, spare tire