MITSUBISHI SPYDER 1990 Service Repair Manual

SPYDER 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57345/w960_57345-0.png

MITSUBISHI SPYDER 1990 Service Repair Manual

Trending: heater, air suspension, alarm, open hood, coolant temperature, jump cable, battery location

Page 921 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle

IDLER GEAR SHAFT BOLT

INSTALLATION

(1)Center the shaft with a Phillips screwdriver [shaft diameter

8 mm in.)] or the like.

(2) Tighten the reverse idler gear shaft bolt to th e specified

torque.

LOCK NUTS FOR INPUT SHAFT

INTERMEDIATE GEAR INSTALLATION,

(1) Install the special tool onto the input shaft.

(2) Screw a bolt [IO mm in.)] into the hole around clutch

housing and attach a handle to the

(3)Shift the transaxle in reverse using control lever and

(4) the lock nut to the specified torque, using

the bolt attached in the above step as a spinner ha ndle

stopper.

(5) Stake the lock nut.

PIN FOR SHIFT FORK

INSTALLATION

TSB Revision

Page 922 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle .

22210033

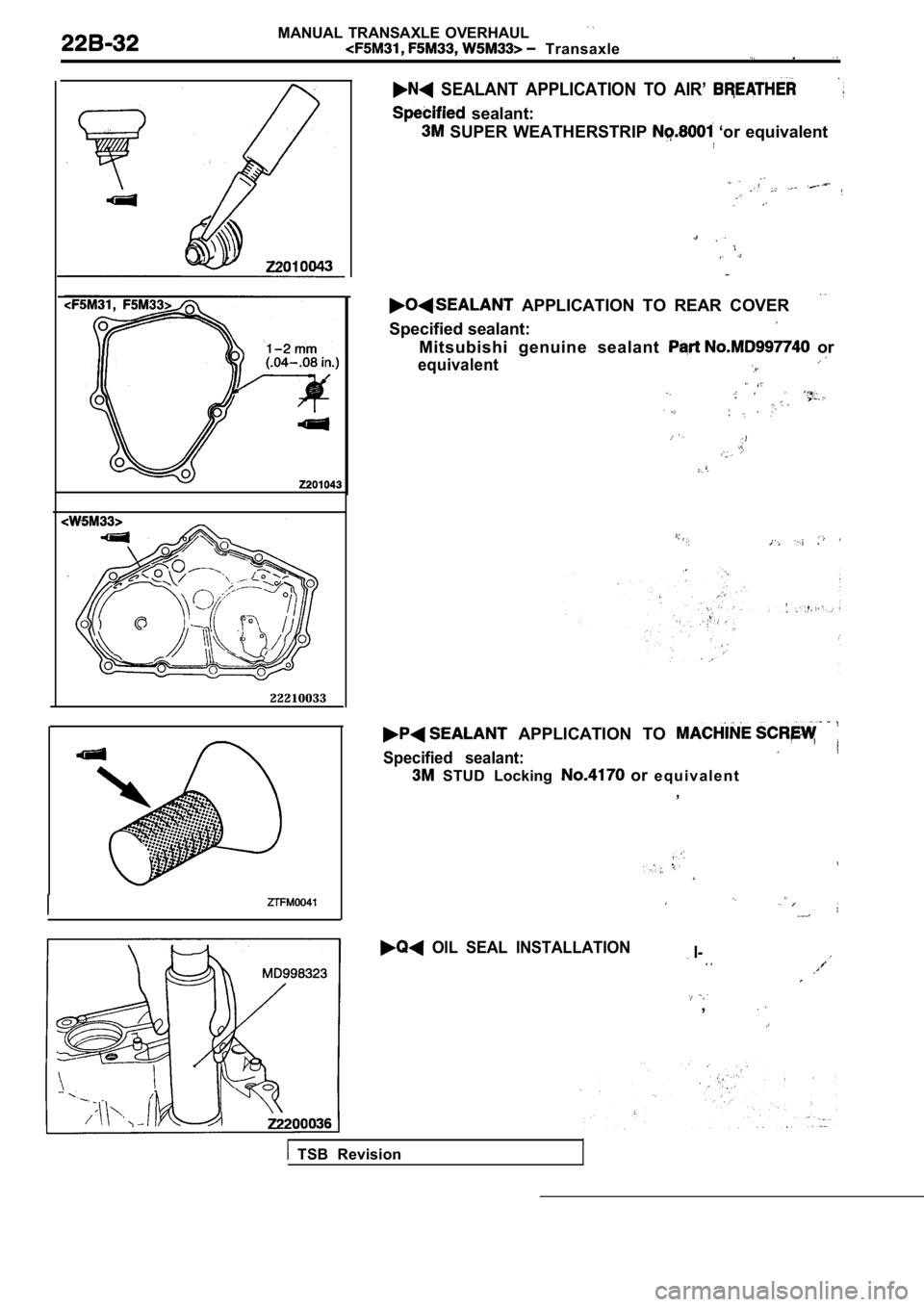

SEALANT APPLICATION TO AIR’

sealant:

SUPER WEATHERSTRIP ‘or equivalent

APPLICATION TO REAR COVER

Specified sealant:

Mitsubishi genuine sealant or

equivalent

APPLICATION TO

Specified sealant:

STUD Locking or e q u i v a l e n t

,

OIL SEAL INSTALLATION I-. .

,

TSB Revision

Page 923 of 2103

MANUAL OVERHAUL

Transaxle

Oil seal

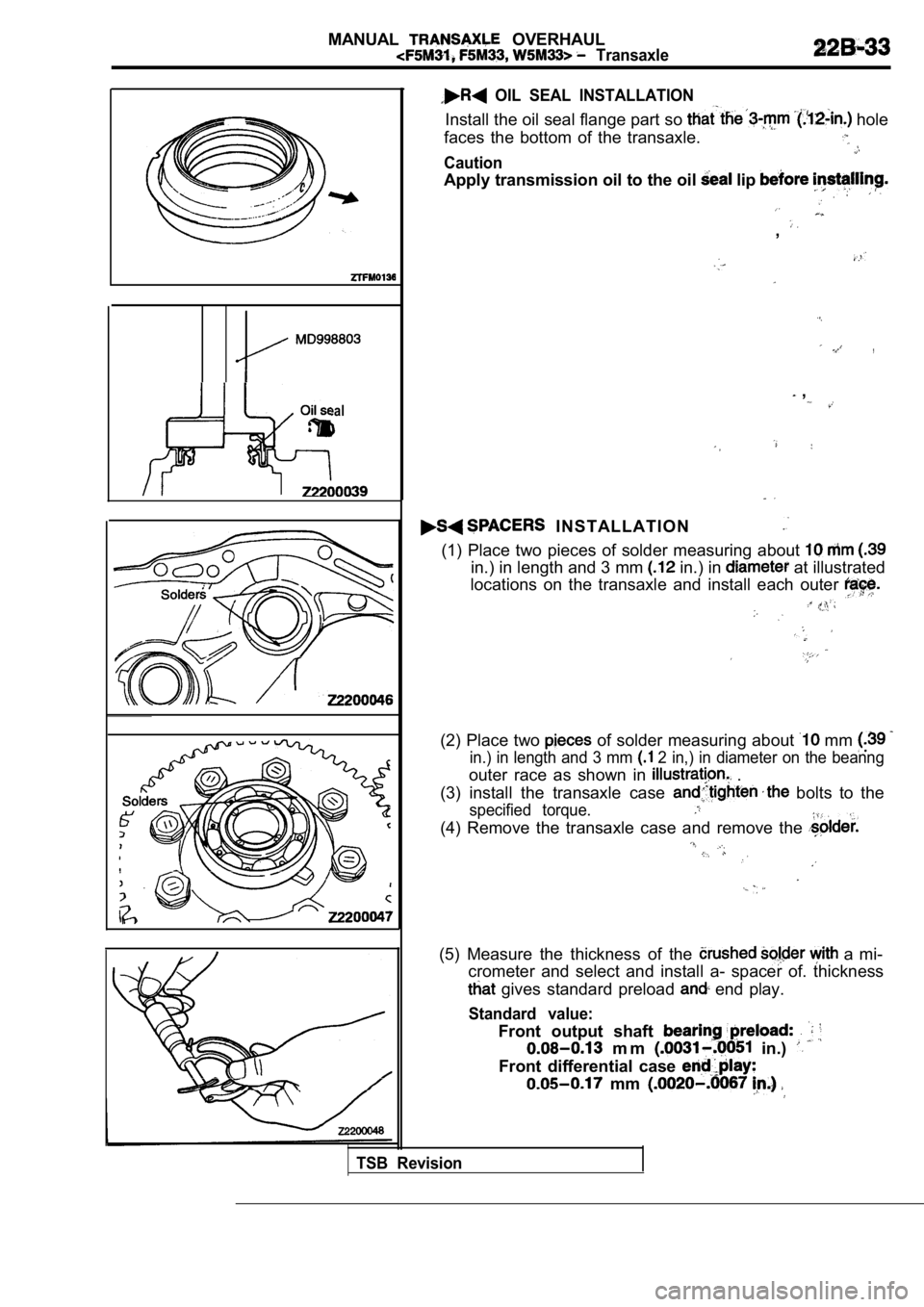

OIL SEAL INSTALLATION

Install the oil seal flange part so hole

faces the bottom of the transaxle.

Caution

Apply transmission oil to the oil lip

,

,

,

I N S T A L L A T I O N

(1) Place two pieces of solder measuring about

in.) in length and 3 mm in.) in at illustrated

locations on the transaxle and install each outer

(2) Place two of solder measuring about mm

in.) in length and 3 mm 2 in,) in diameter on the beanng

outer race as shown in .

(3) install the transaxle case

bolts to the

specified torque.

(4) Remove the transaxle case and remove the

(5) Measure the thickness of the a mi-

crometer and select and install a- spacer of. thick ness

gives standard preload end play.

Standard value:

Front output shaft

m m in.)

Front differential case

mm

TSB Revision

Page 924 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle.,

22200056

0123

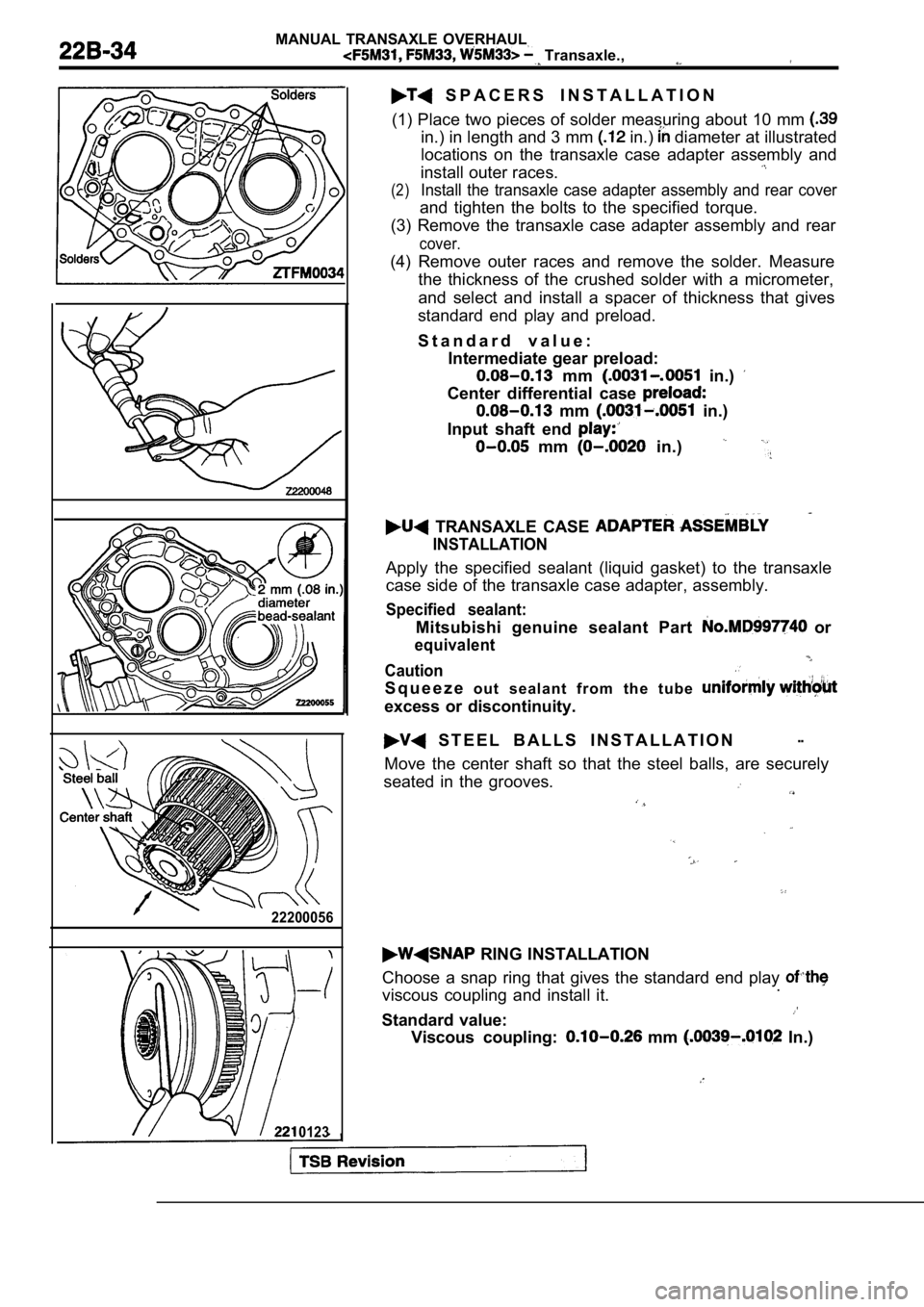

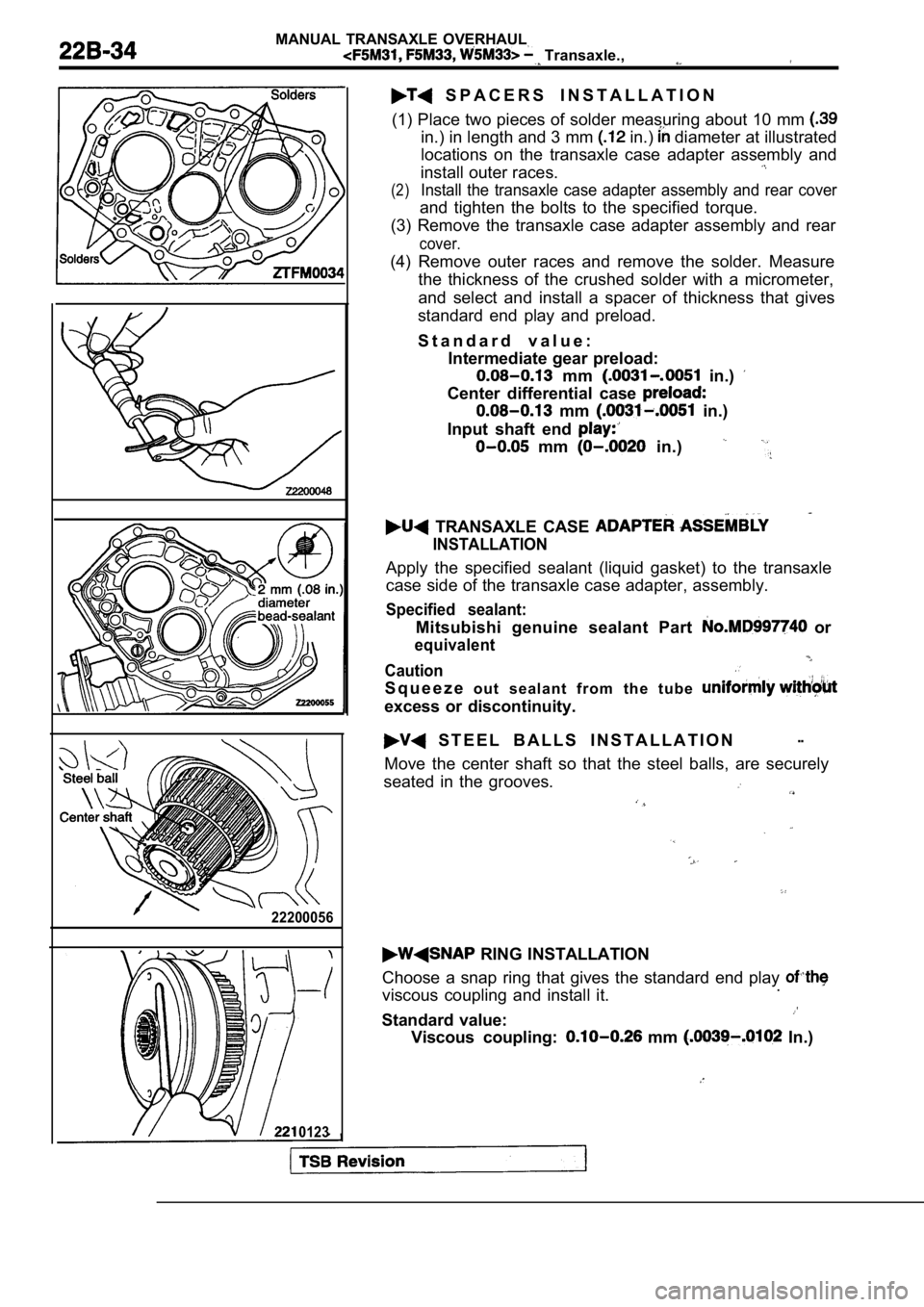

S P A C E R S I N S T A L L A T I O N

(1) Place two pieces of solder measuring about 10 m m

in.) in length and 3 mm in.) diameter at illustrated

locations on the transaxle case adapter assembly an d

install outer races.

(2)Install the transaxle case adapter assembly and rea r cover

and tighten the bolts to the specified torque.

(3) Remove the transaxle case adapter assembly and rear

cover.

(4) Remove outer races and remove the solder. Measu re

the thickness of the crushed solder with a micromet er,

and select and install a spacer of thickness that g ives

standard end play and preload.

S t a n d a r d v a l u e : Intermediate gear preload:

mm in.)

Center differential case

mm in.)

Input shaft end

mm in.)

TRANSAXLE CASE

INSTALLATION

Apply the specified sealant (liquid gasket) to the transaxle

case side of the transaxle case adapter, assembly.

Specified sealant:

Mitsubishi genuine sealant Part or

equivalent

Caution

S q u e e z e o u t s e a l a n t f r o m t h e t u b e

excess or discontinuity.

S T E E L B A L L S I N S T A L L A T I O N--

Move the center shaft so that the steel balls, are securely

seated in the grooves.

RING INSTALLATION

Choose a snap ring that gives the standard end play

viscous coupling and install it..

Standard value:

Viscous coupling: mm In.)

Page 925 of 2103

MANUAL TRANSAXLE OVERHAUL

Transaxle

0

00

0

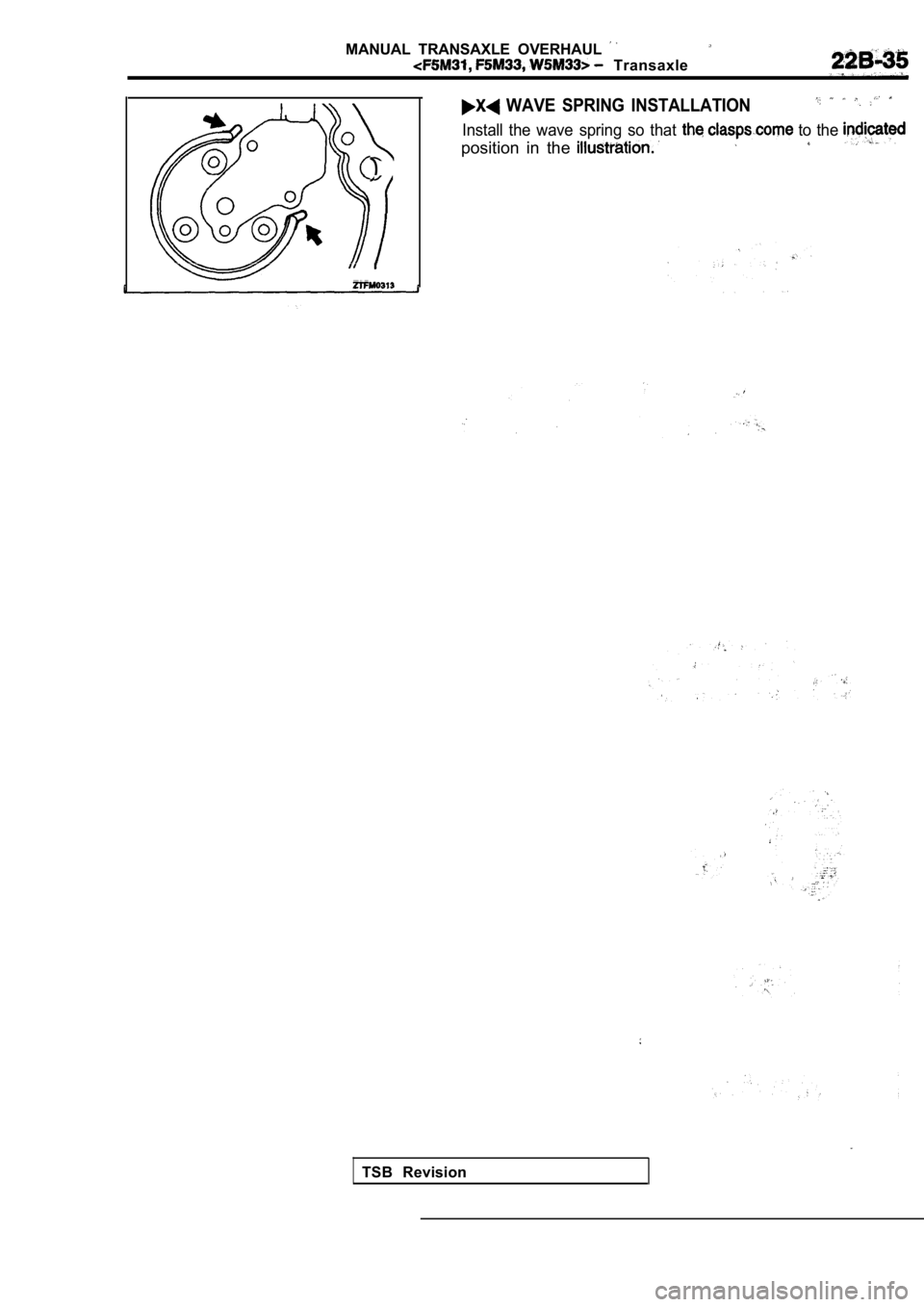

WAVE SPRING INSTALLATION

Install the wave spring so that to the

position in the

TSB Revision

Page 926 of 2103

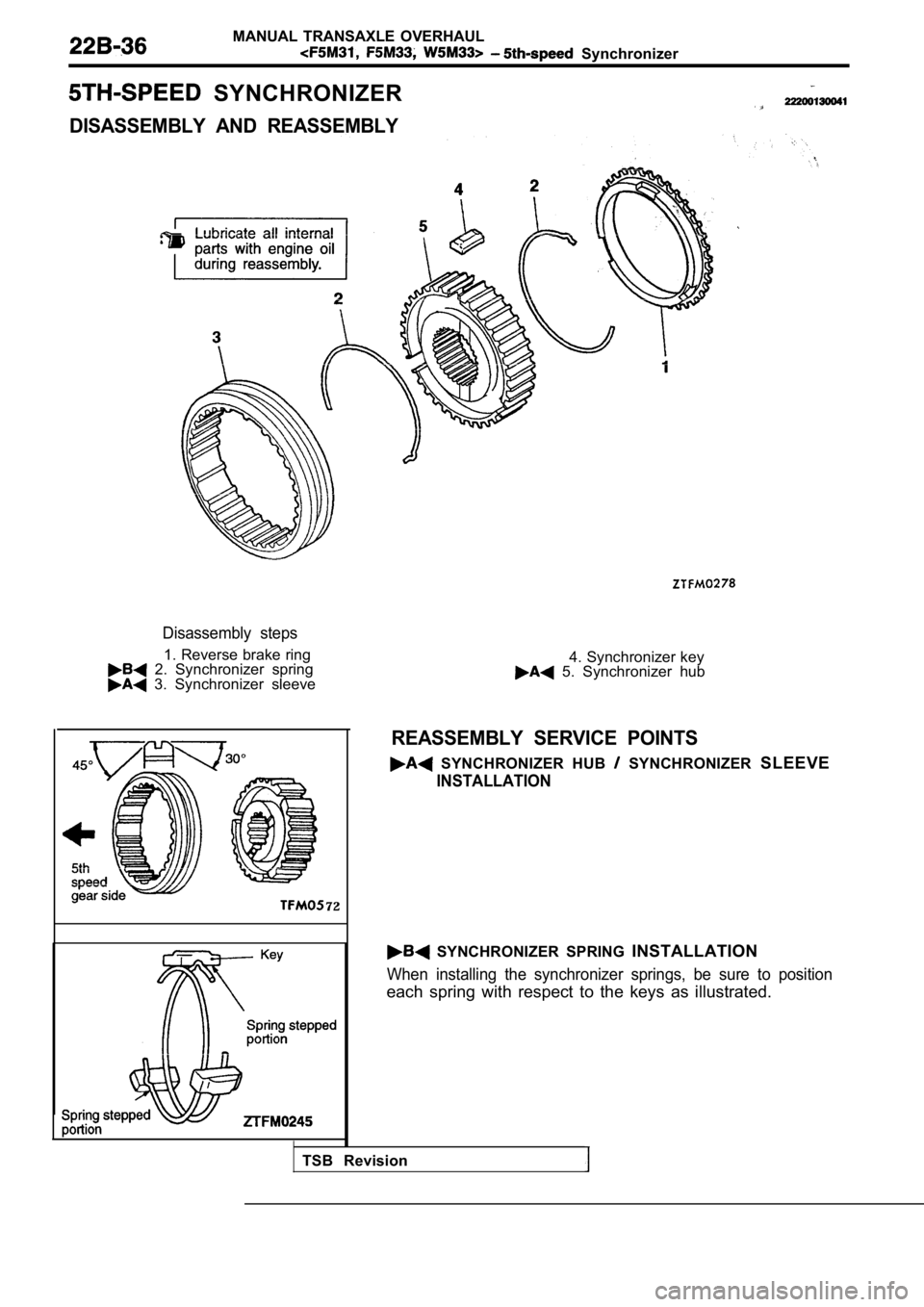

MANUAL TRANSAXLE OVERHAUL

Synchronizer

SYNCHRONIZER

DISASSEMBLY AND REASSEMBLY

Disassembly steps

1. Reverse brake ring 2. Synchronizer spring 3. Synchronizer sleeve

72

4. Synchronizer key 5. Synchronizer hub

REASSEMBLY SERVICE POINTS

SYNCHRONIZER HUB SYNCHRONIZER SLEEVE

INSTALLATION

SYNCHRONIZER SPRING INSTALLATION

When installing the synchronizer springs, be sure t o position

each spring with respect to the keys as illustrated.

TSB Revision

Page 927 of 2103

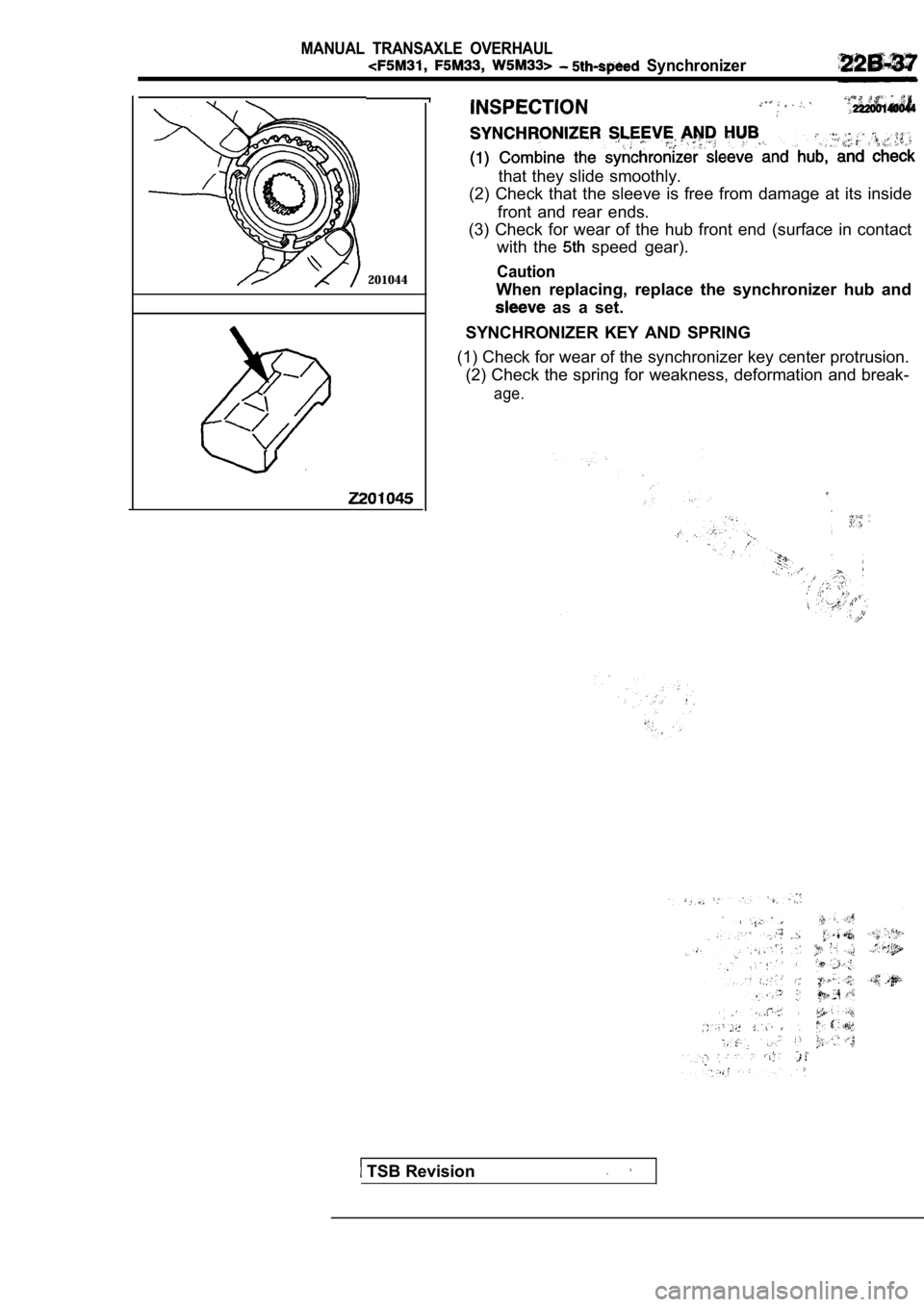

MANUAL TRANSAXLE OVERHAUL

Synchronizer

201044

that they slide smoothly.

(2) Check that the sleeve is free from damage at it s inside

front and rear ends.

(3) Check for wear of the hub front end (surface in contact

with the

speed gear).

Caution

When replacing, replace the synchronizer hub and

as a set.

SYNCHRONIZER KEY AND SPRING

(1) Check for wear of the synchronizer key center p rotrusion.

(2) Check the spring for weakness, deformation and break-

age.

TSB Revision

Page 928 of 2103

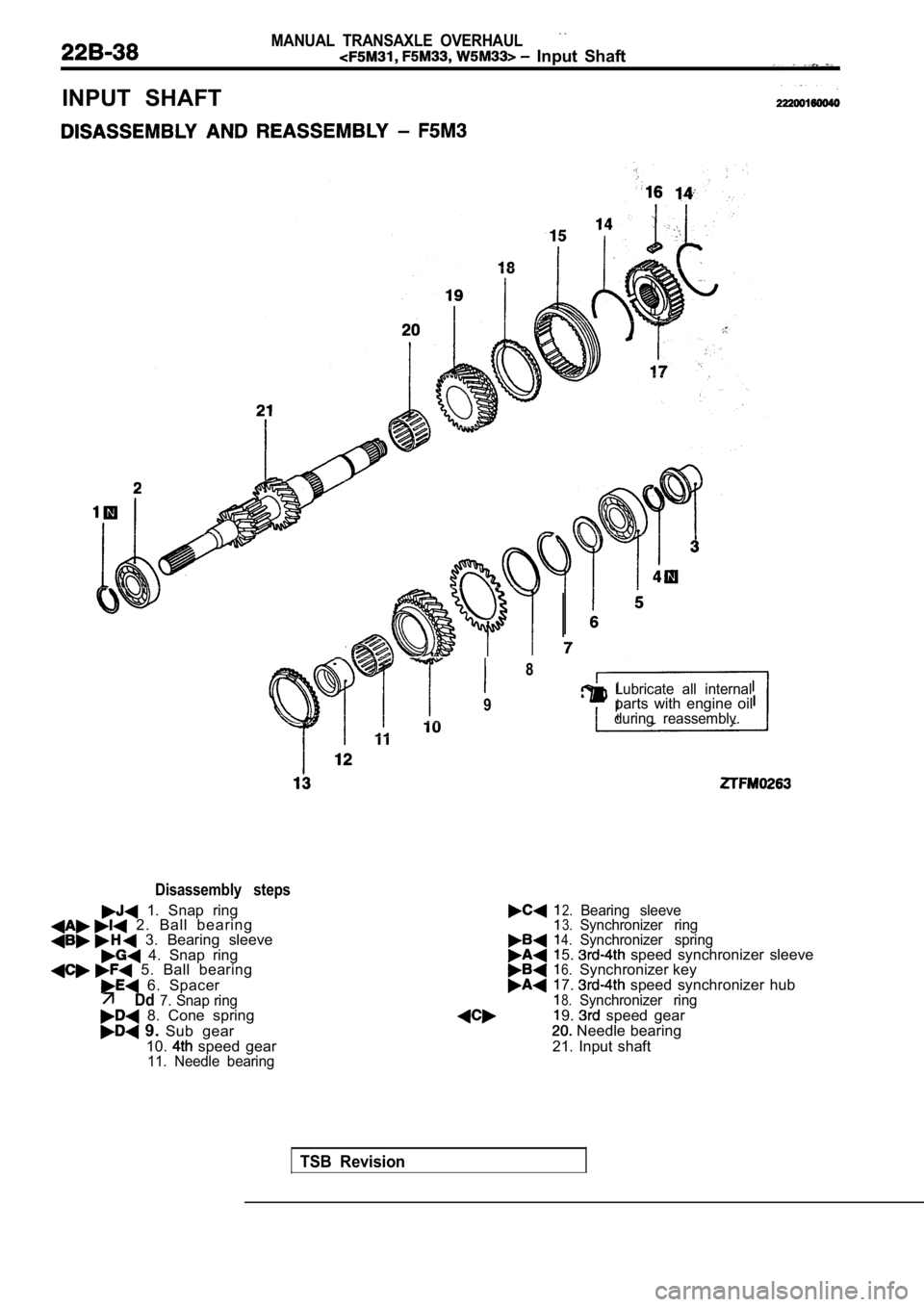

MANUAL TRANSAXLE OVERHAUL

Input Shaft

INPUT SHAFT

Disassembly steps

1. Snap ring 2. Ball bearing 3. Bearing sleeve 4. Snap ring 5. Ball bearing

6. Spacer

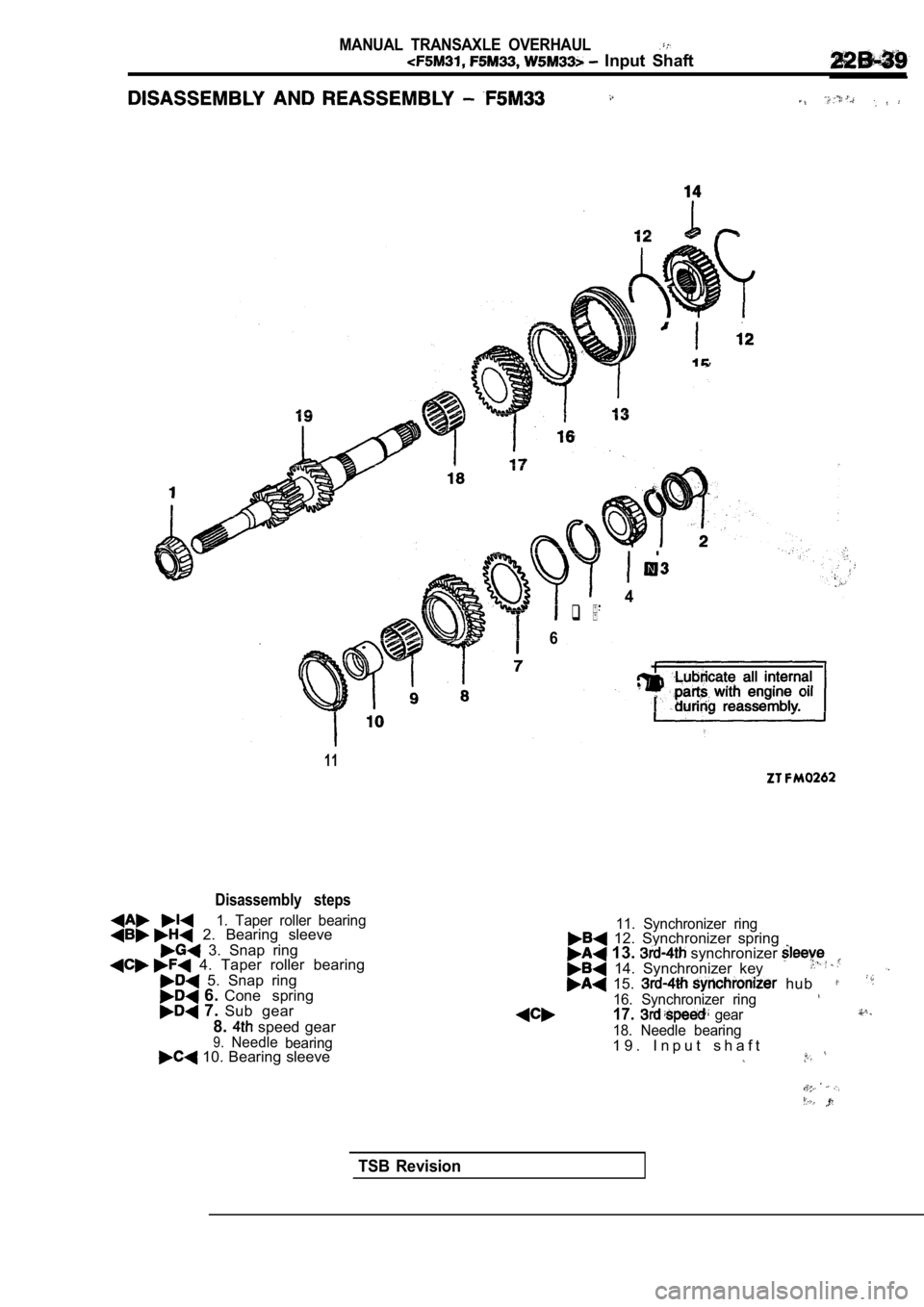

Page 929 of 2103

MANUAL TRANSAXLE OVERHAUL

Input Shaft

4

q 5

6

11

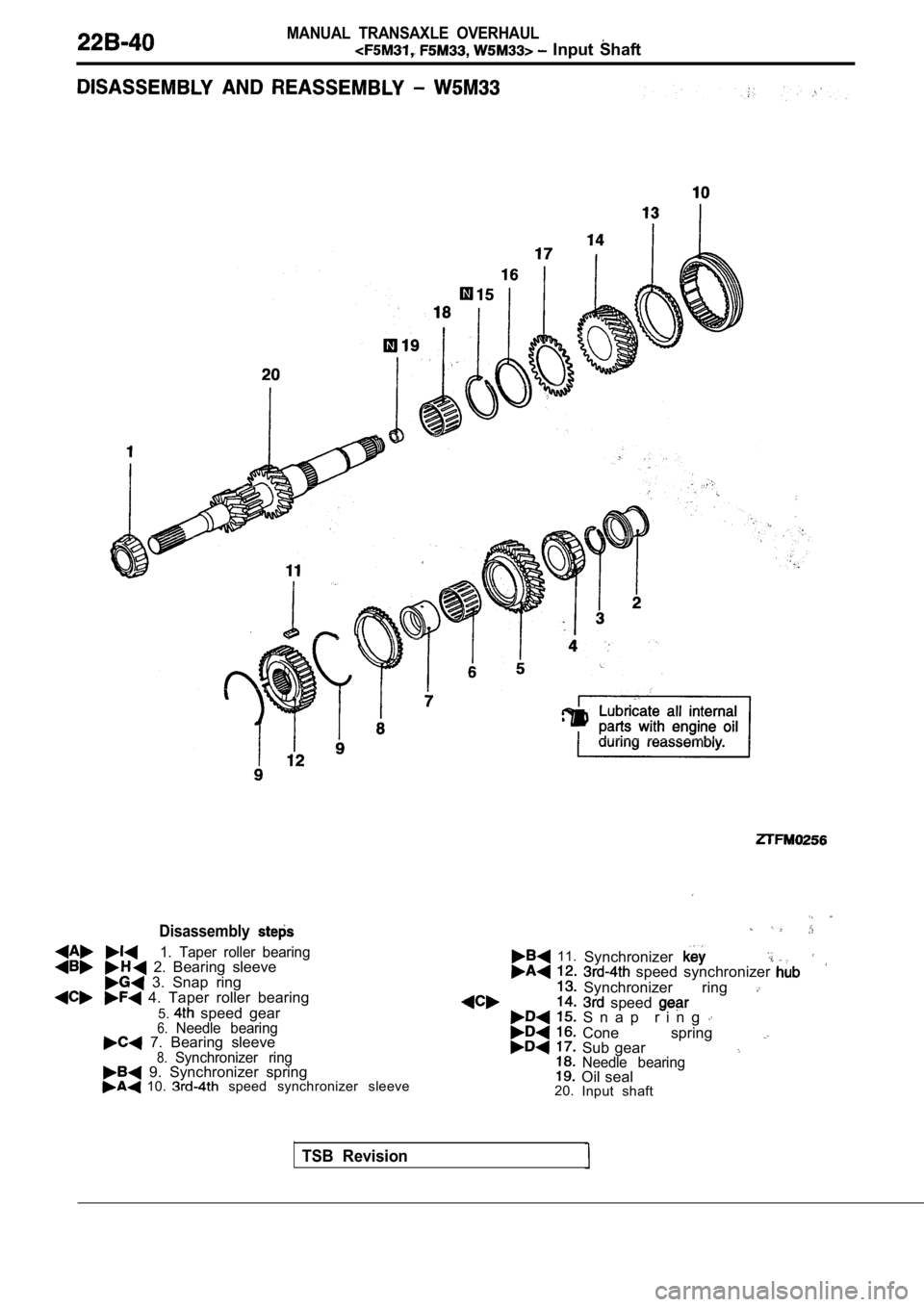

Disassembly steps

1. Taper roller bearing 2. Bearing sleeve

3. Snap ring 4. Taper roller bearing

5. Snap ring 6. Cone spring 7. Sub gear

8.

speed gear9.Needle bearing 10. Bearing sleeve

11. Synchronizer ring 12. Synchronizer spring 13. synchronizer 14. Synchronizer key 15. hub

16. Synchronizer ring17. gear

18. Needle bearing1 9 . I n p u t s h a f t

TSB Revision

Page 930 of 2103

MANUAL TRANSAXLE OVERHAUL. Input Shaft

Disassembly

1. Taper roller bearing 2. Bearing sleeve 3. Snap ring 4. Taper roller bearing5.

speed gear6.Needle bearing 7. Bearing sleeve8.Synchronizer ring 9. Synchronizer spring 10. speed synchronizer sleeve

11.Synchronizer speed synchronizer

Synchronizer ring speed S n a p r i n g

Cone spring Sub gearNeedle bearingOil sealInput shaft

20.

TSB Revision

Trending: dead battery, battery replacement, coolant reservoir, service indicator, change time, height adjustment, change key battery

![MITSUBISHI SPYDER 1990 Service Repair Manual MANUAL TRANSAXLE OVERHAUL

Transaxle

IDLER GEAR SHAFT BOLT

INSTALLATION

(1)Center the shaft with a Phillips screwdriver [shaft diameter

8 mm in.)] or the like.

(2) Tighten the re MITSUBISHI SPYDER 1990 Service Repair Manual MANUAL TRANSAXLE OVERHAUL

Transaxle

IDLER GEAR SHAFT BOLT

INSTALLATION

(1)Center the shaft with a Phillips screwdriver [shaft diameter

8 mm in.)] or the like.

(2) Tighten the re](/img/19/57345/w960_57345-920.png)