NISSAN 300ZX 1984 Z31 Electrical System Owners Manual

300ZX 1984 Z31

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/567/w960_567-0.png

NISSAN 300ZX 1984 Z31 Electrical System Owners Manual

Trending: battery location, AUX, oil temperature, seat, weight, theft, Throttle

Page 91 of 116

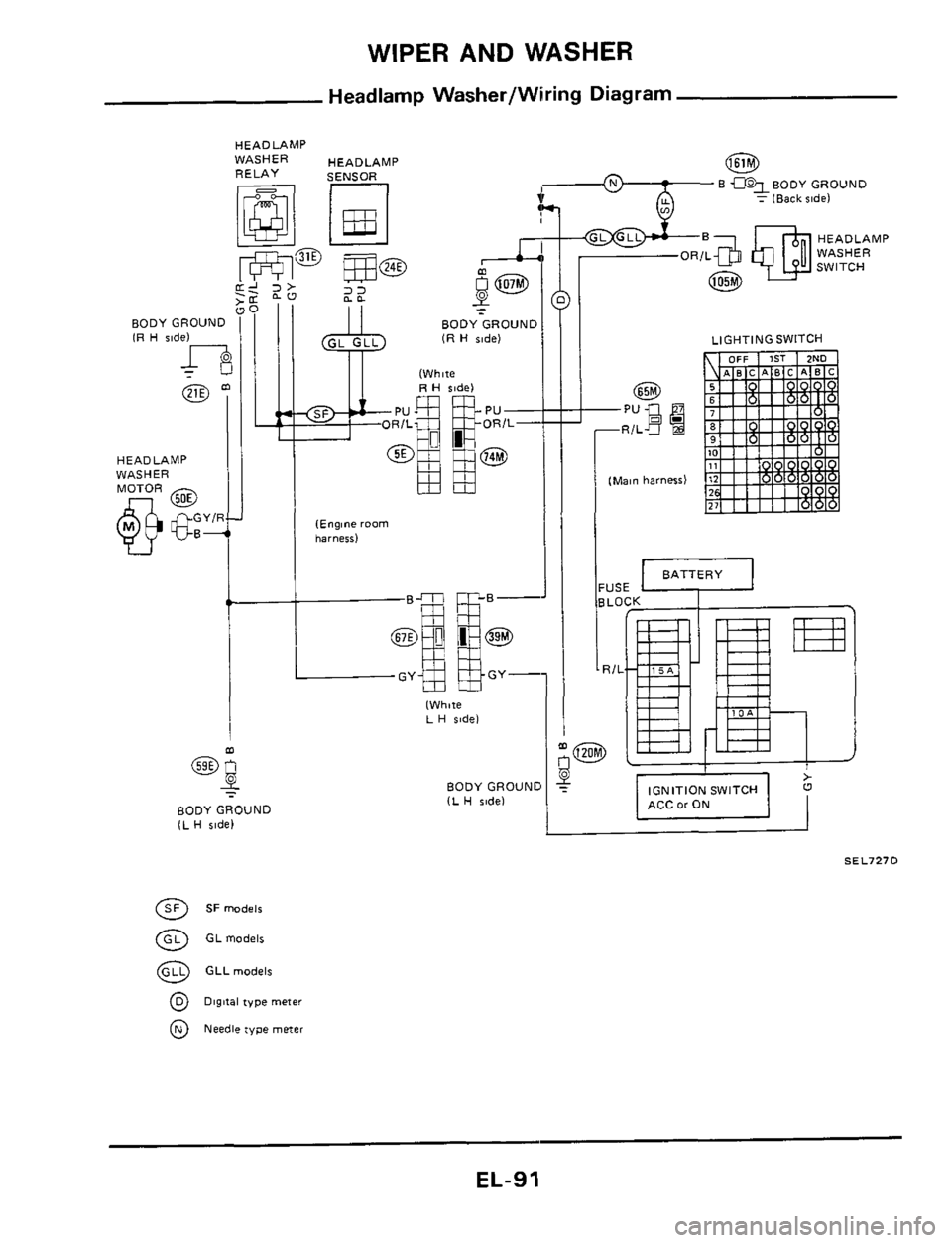

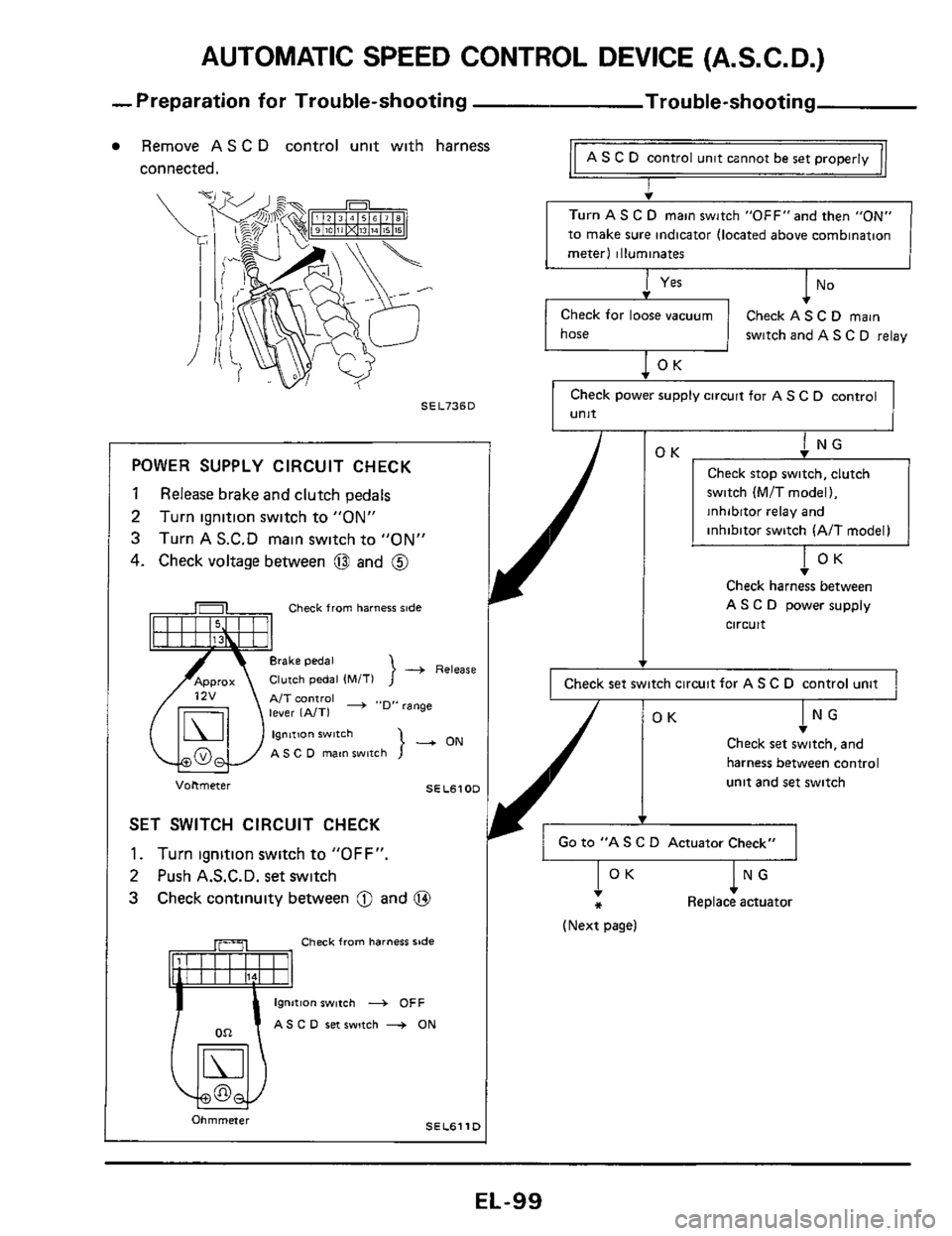

WIPER AND WASHER

Headlamp Washer/Wiring Diagram

HEADLAMP

RELAY

WASHER HEADLAMP @

: (Back ride)

HEADLAMP

WASHER

SWITCH

7

- 22 I1 BODY GROUND IR H ride)

HEADLAMP

WASHER

BODYGROUND (L H $#de)

@ GLmodelr

@ GLLrnodelr

@ Digital type meter

@ Needle type meiei

BODY GROl (R H ride)

II fWhw

(Engine room harnerr)

I LIGHTING SWITCH

J

(Main harness)

USE

7/1

w

II

IGNITION SWITCH I ACC or ON

I I

SEL727D

EL-91

Page 92 of 116

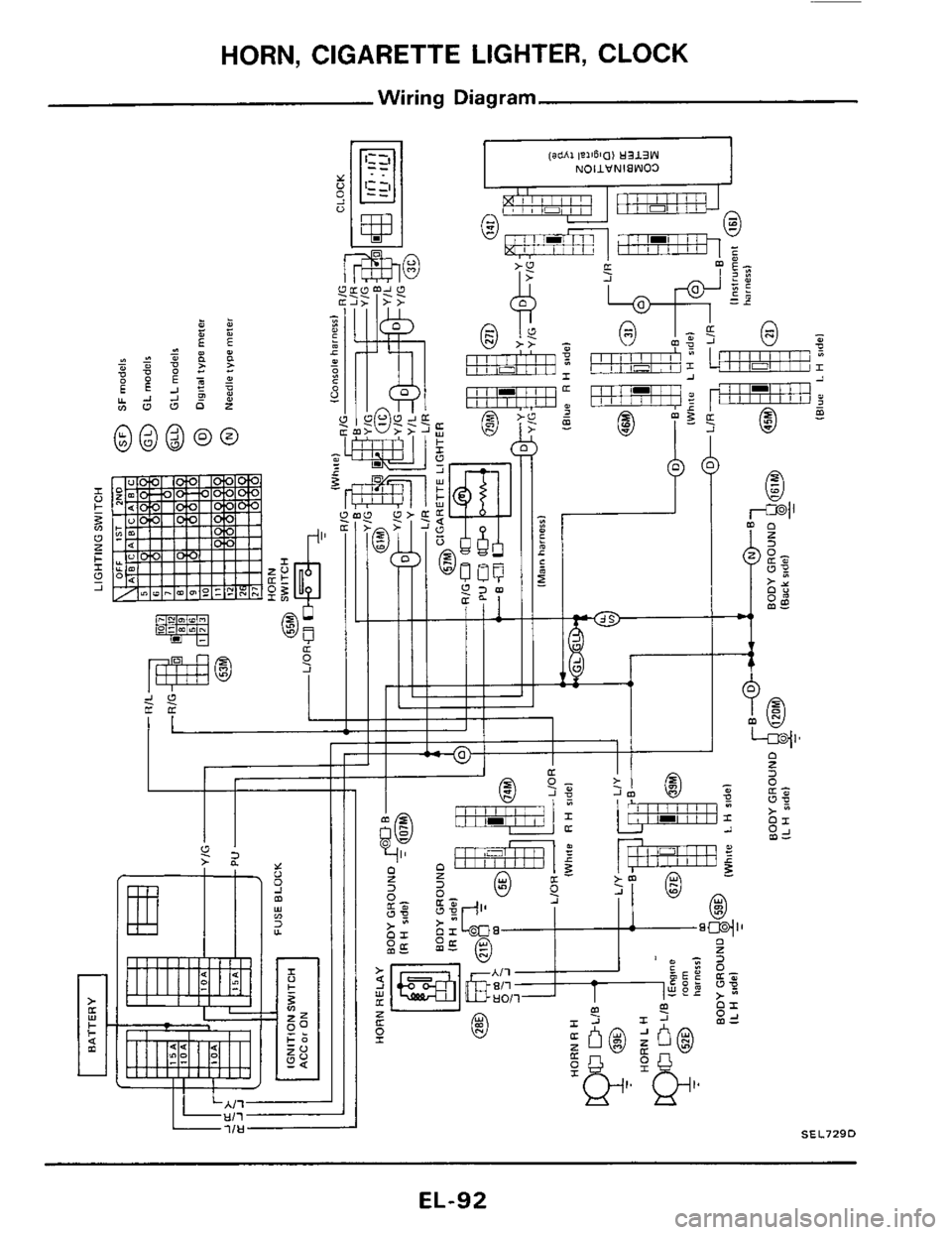

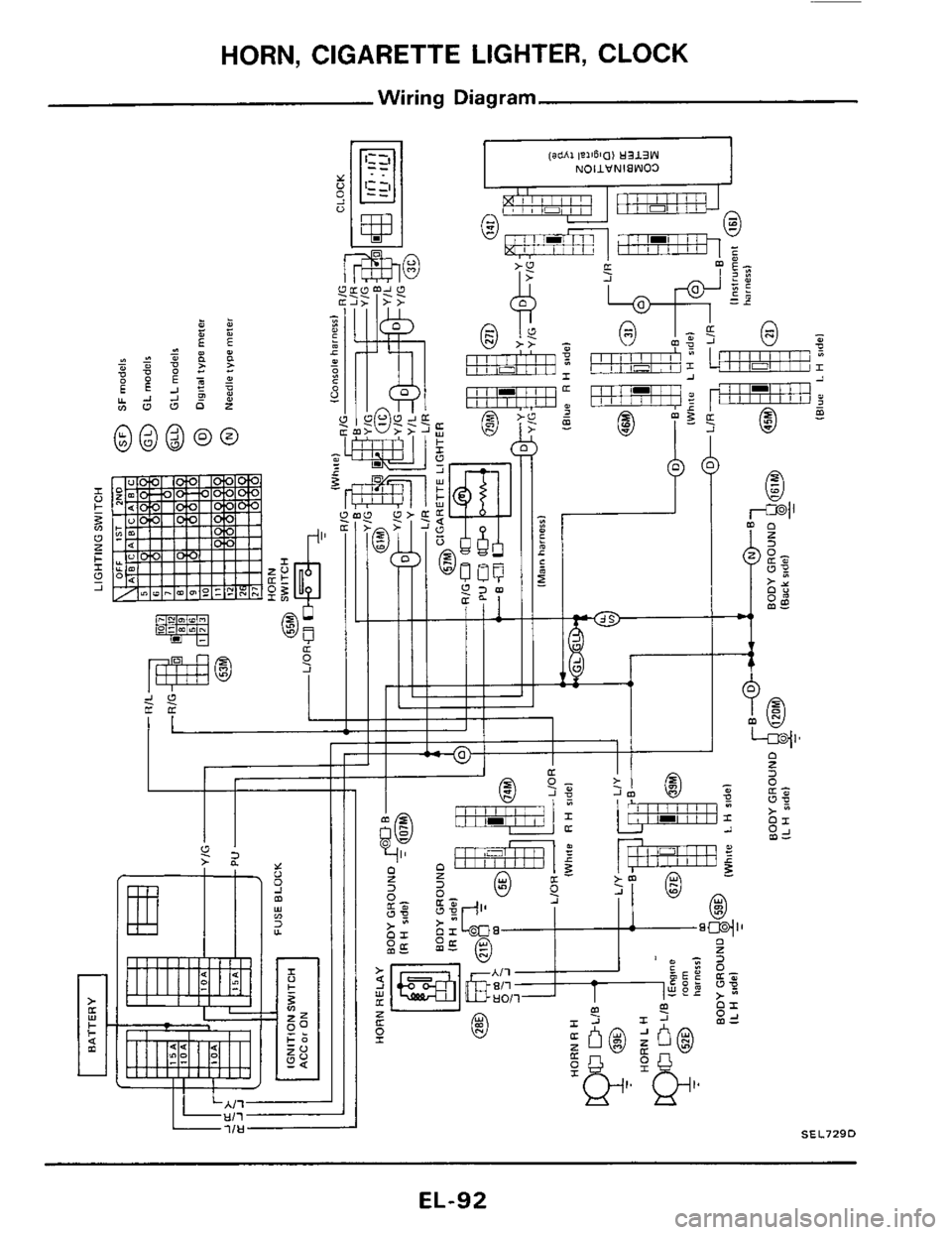

HORN, CIGARETTE LIGHTER, CLOCK

Wiring Diagram

SEL729D

EL-92

Page 93 of 116

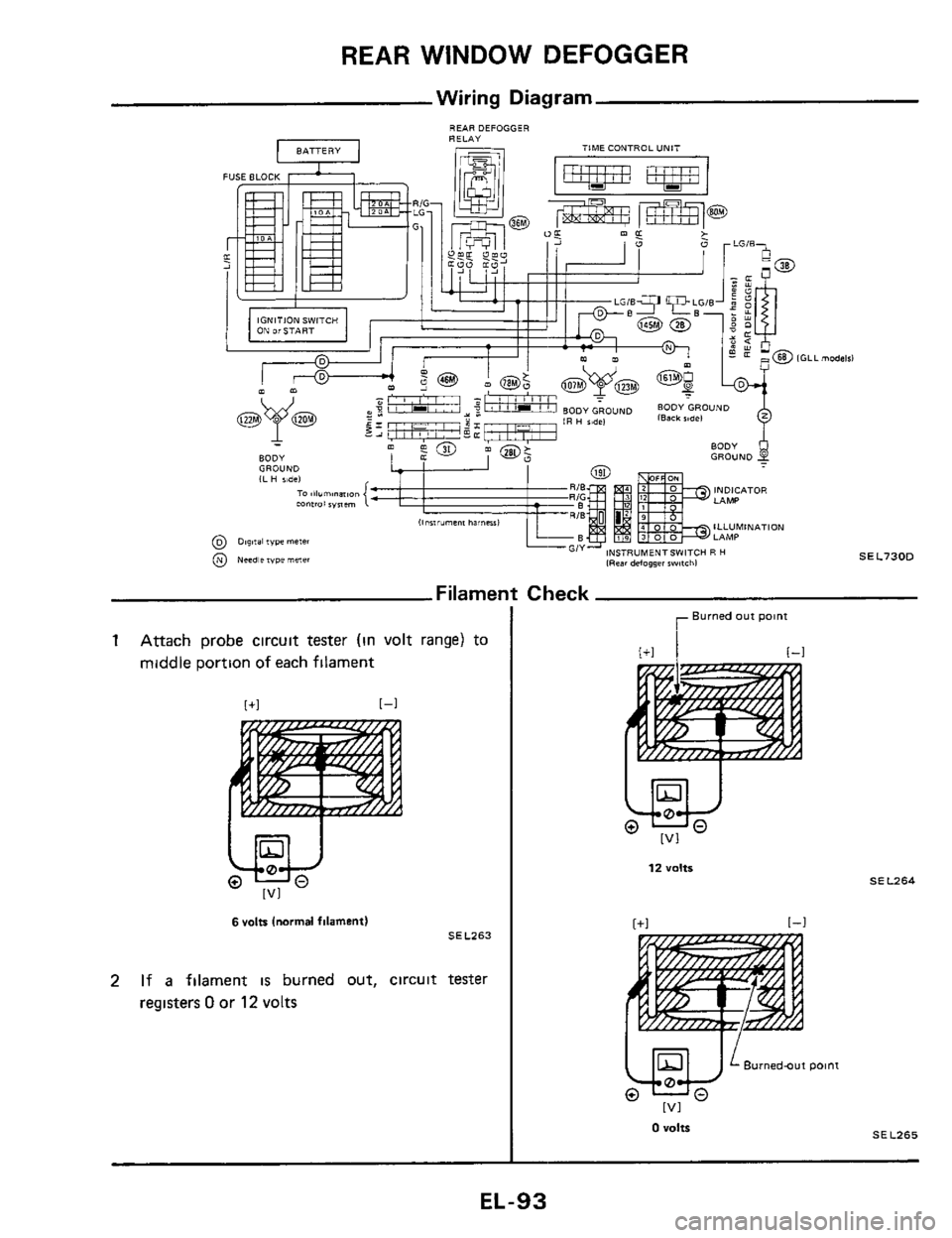

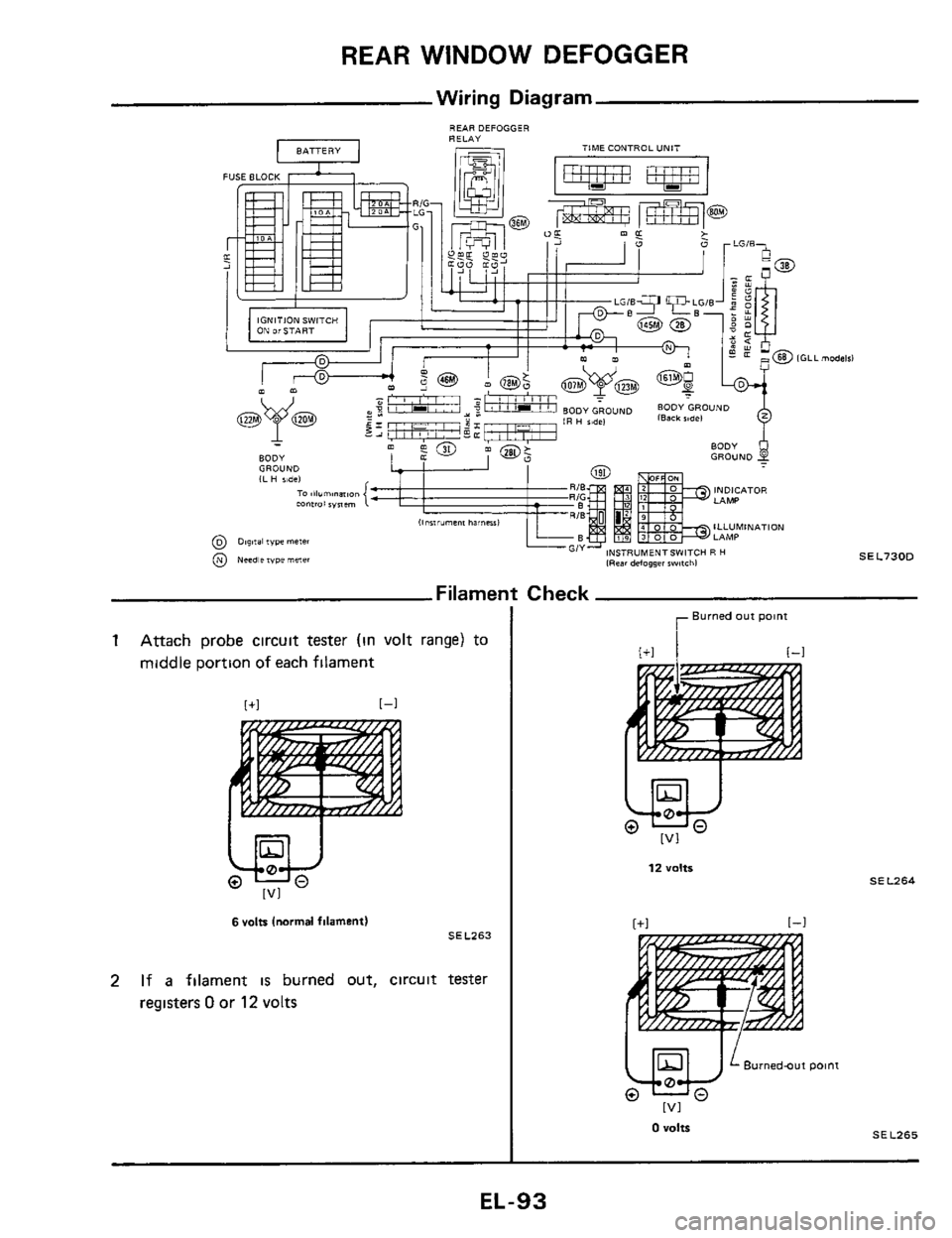

REAR WINDOW DEFOGGER

Wiring Diagram

REARDEFOGGER

.L modald

SEL730D

Filament Check

1 Attach probe circuit tester (in volt range) to

middle Dortion

of each filament

l+l [-I

6 volts inormal filament) SEL263

2 If a filament is burned out, circuit tester

registers 0 or 12 volts

Burned out point

i+l i (-1 .. .

12 Volts SEL264

r+i I-]

SEL265 0 volts

EL-93

Page 94 of 116

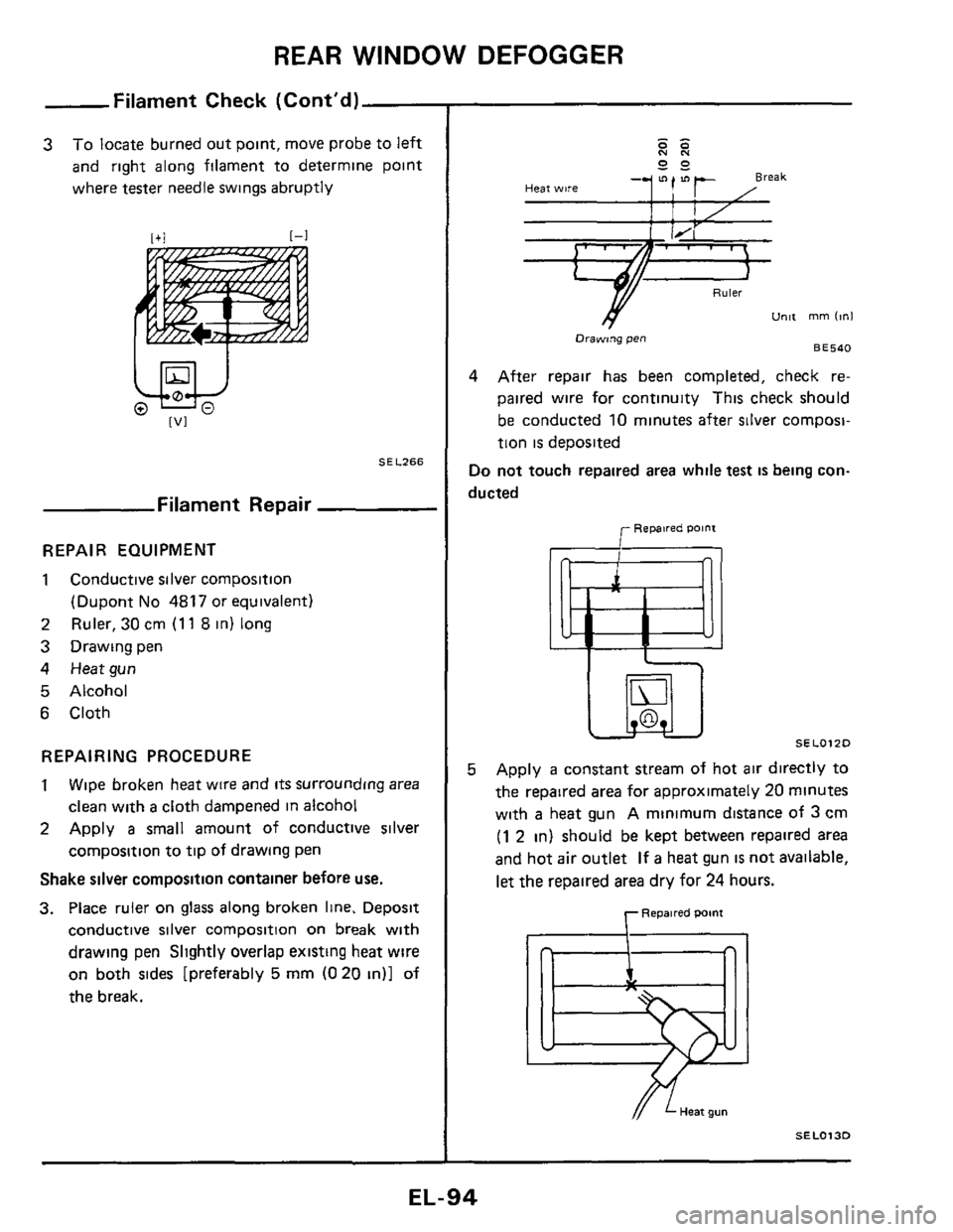

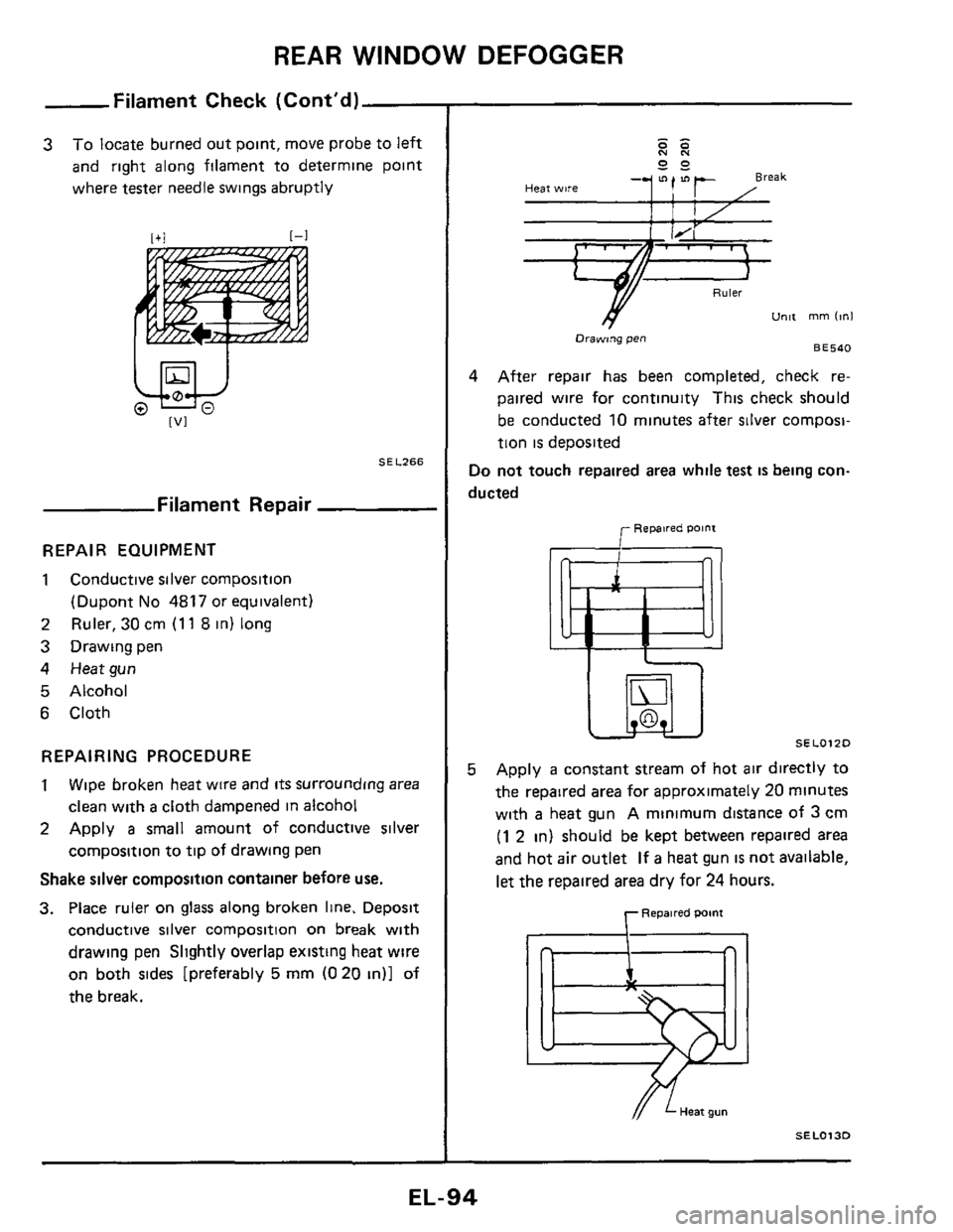

REAR WINDOW DEFOGGER

Filament Check (Cont'd)

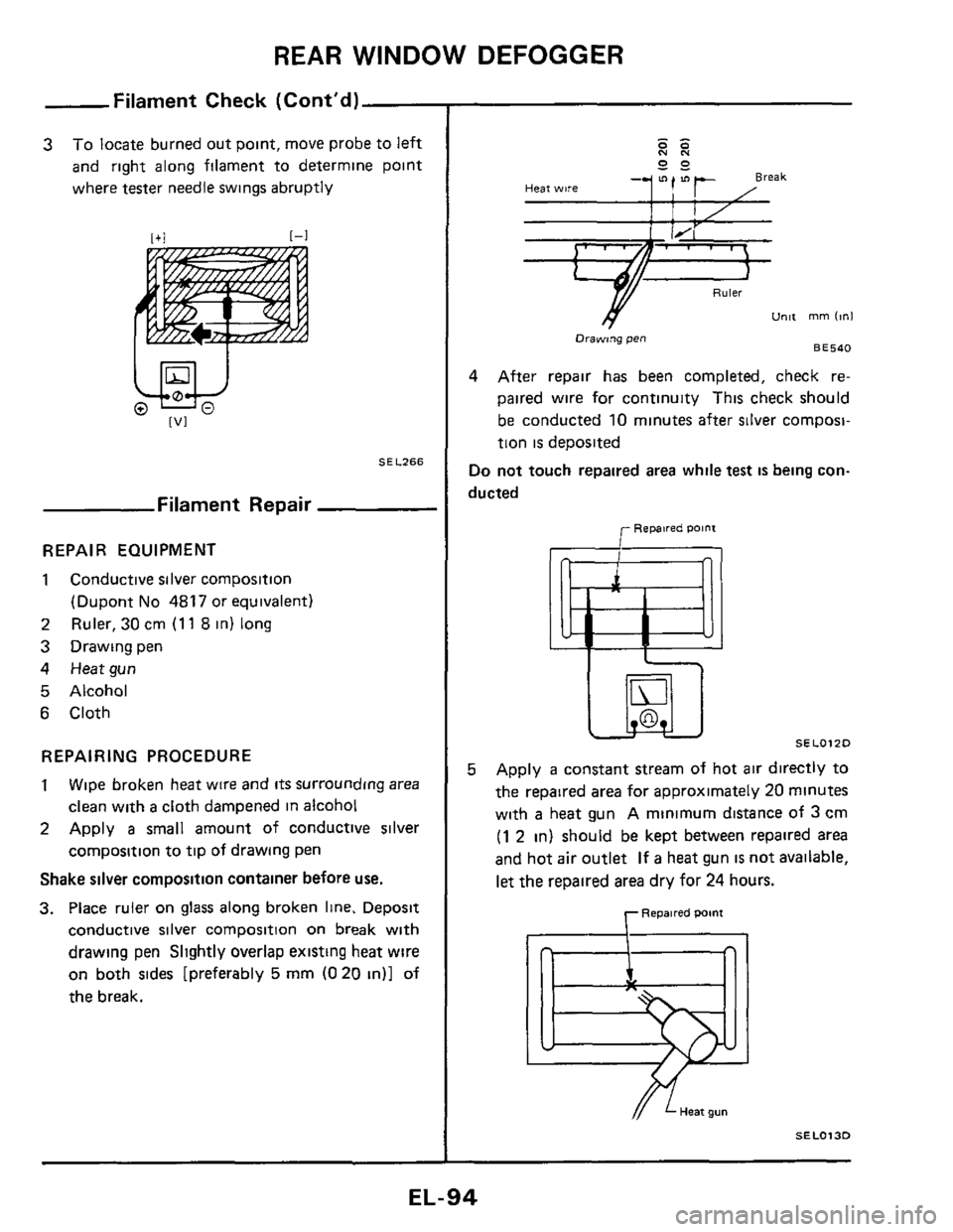

3 To locate burned out point, move probe to left

and right along filament to determine point

where

tester needle swings abruptly

/AI 1-1

SEL266

Filament Repair

REPAIR EQUIPMENT

1 Conductive silver composition

(Dupont No 4817 or equivalent)

2 Ruler, 30 cm (1 1 8 in) long

3 Drawingpen

4 Heatgun

5 Alcohol

6 Cloth

REPAIRING PROCEDURE

1 Wipe broken heat wire and its surrounding area

clean with

a cloth dampened in alcohol

2 Apply a small amount of conductive silver

composition to tip of drawing pen

Shake silver composition container before use.

3. Place ruler on glass along broken line. Deposit

conductive silver composition on break with

drawing pen Slightly overlap existing heat wire

on both sides [preferably 5 mm (020 in)] of

the break.

Funit Drawmg pen Ruler mm (In]

BE540

4 After repair has been completed, check re-

paired wire for continuity This check should

be conducted

10 minutes after silver composi-

tion

is deposited

Do not touch repaired area while test is being con-

ducted

r point

SEL0120

5 Apply a constant stream of hot air directly to

the repaired area for approximately

20 minutes

with

a heat gun A minimum distance of 3 cm

(1 2 in) should be kept between repaired area

and hot

air outlet If a heat gun is not available,

let the repaired area dry for 24 hours.

Repaired Point

Heat gun

SEL0130

EL-94

Page 95 of 116

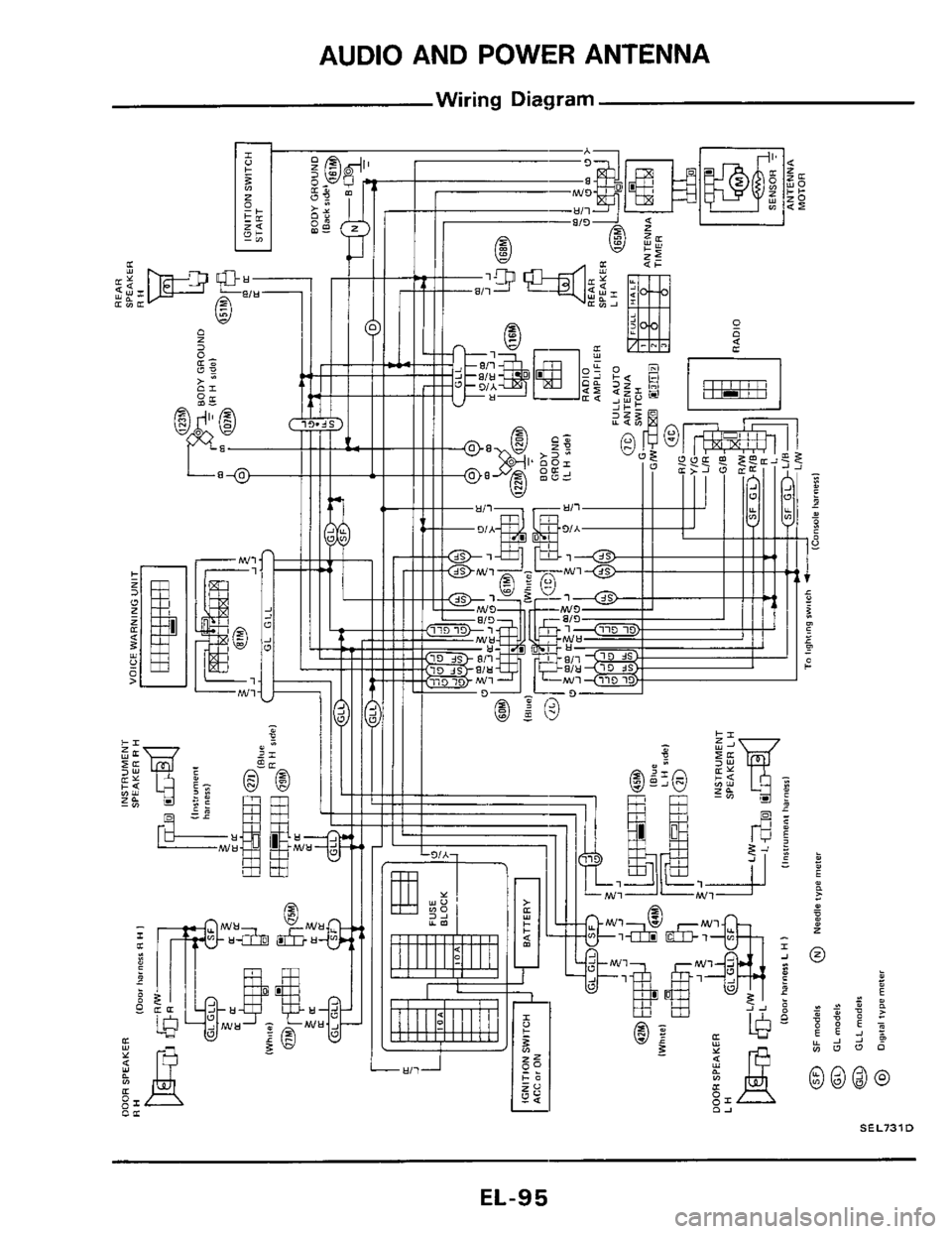

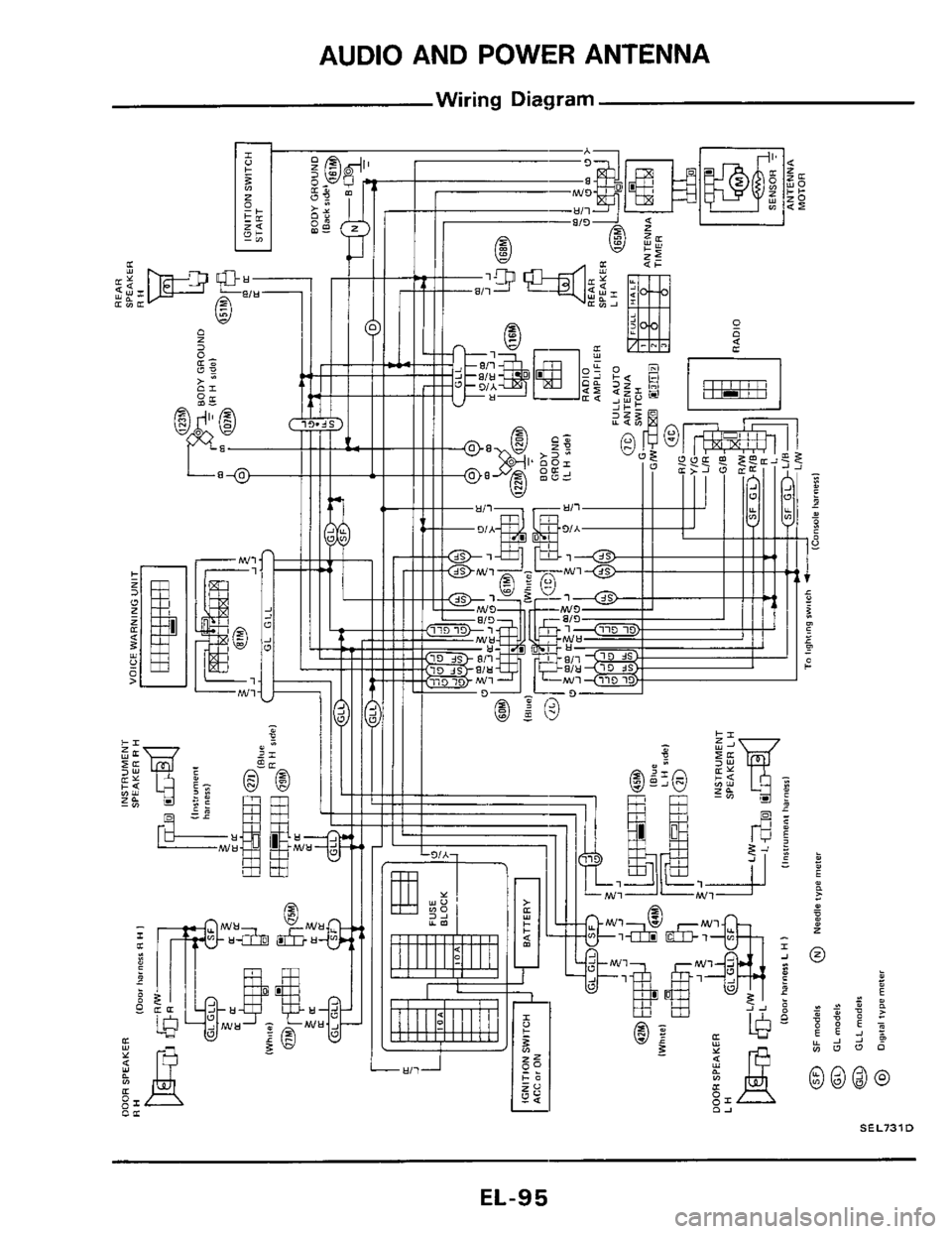

AUDIO AND POWER ANTENNA

Wiring Diagram

SEL731 ID

EL-95

Page 96 of 116

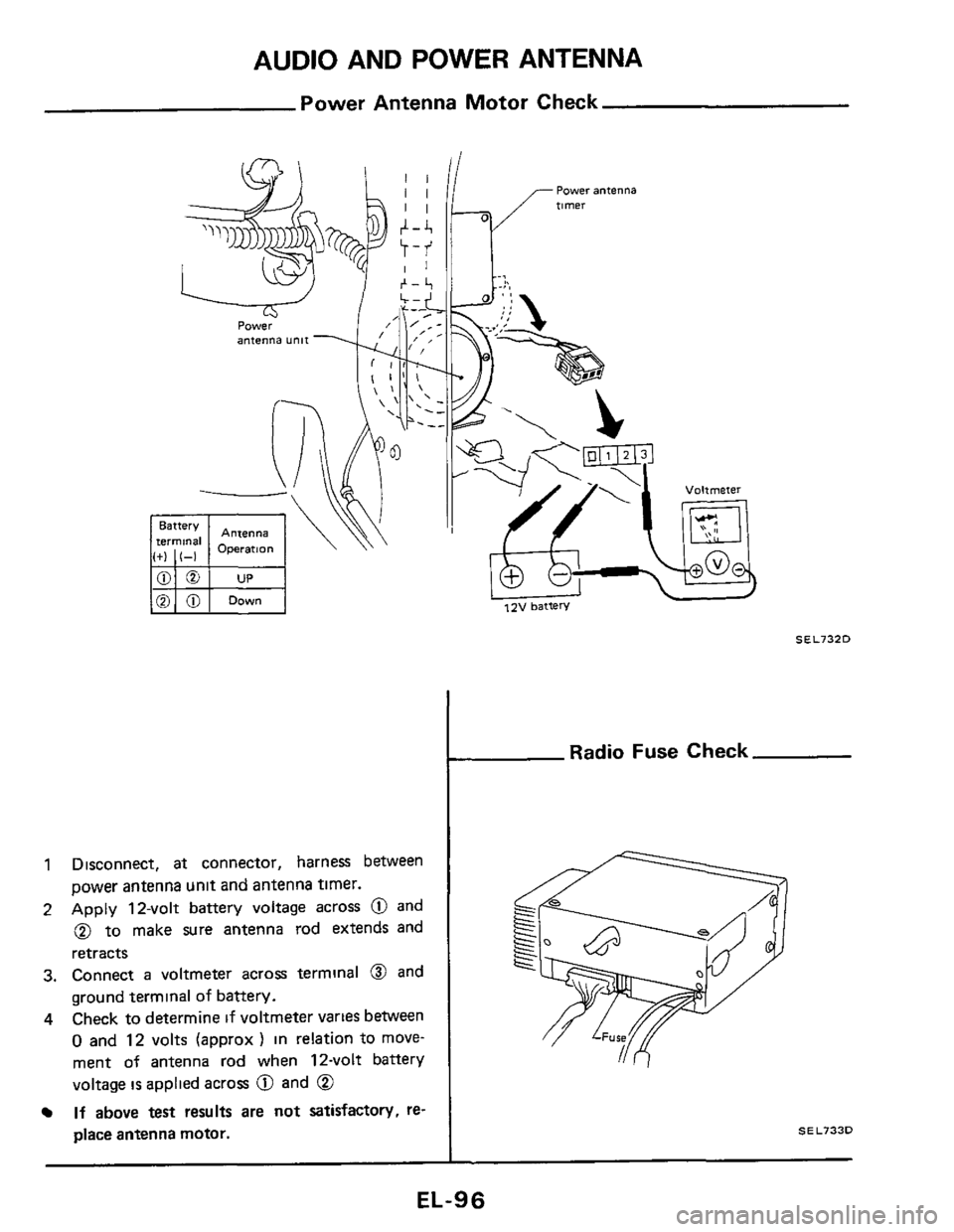

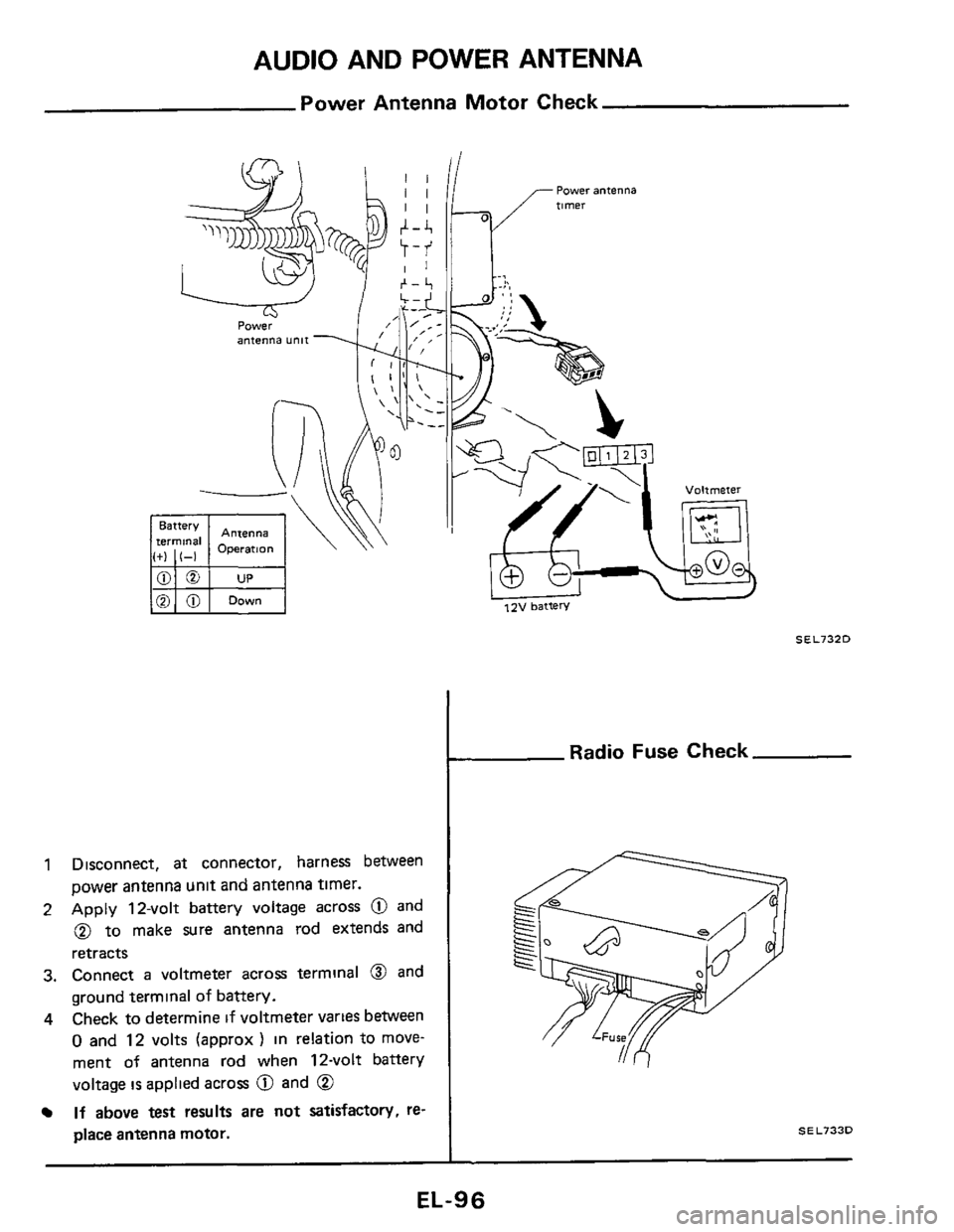

AUDIO AND POWER ANTENNA

Power Antenna Motor Check

1 Disconnect, at connector, harness between

power antenna unit and antenna timer.

2 Apply 12-volt battery voltage across @ and

@ to make Sure antenna rod extends and

retracts

3. Connect a voltmeter across terminal 0 and

ground terminal

of battery.

4 Check to determine if voltmeter varies between

0 and 12 volts (approx ) in relation to move-

ment

of antenna rod when 12-volt battery

voltage

IS applied across @ and @

If above test results are not satisfactory, re-

place antenna

motor.

SEL732D

Radio Fuse Check

SEL733D

EL-96

Page 97 of 116

Page 98 of 116

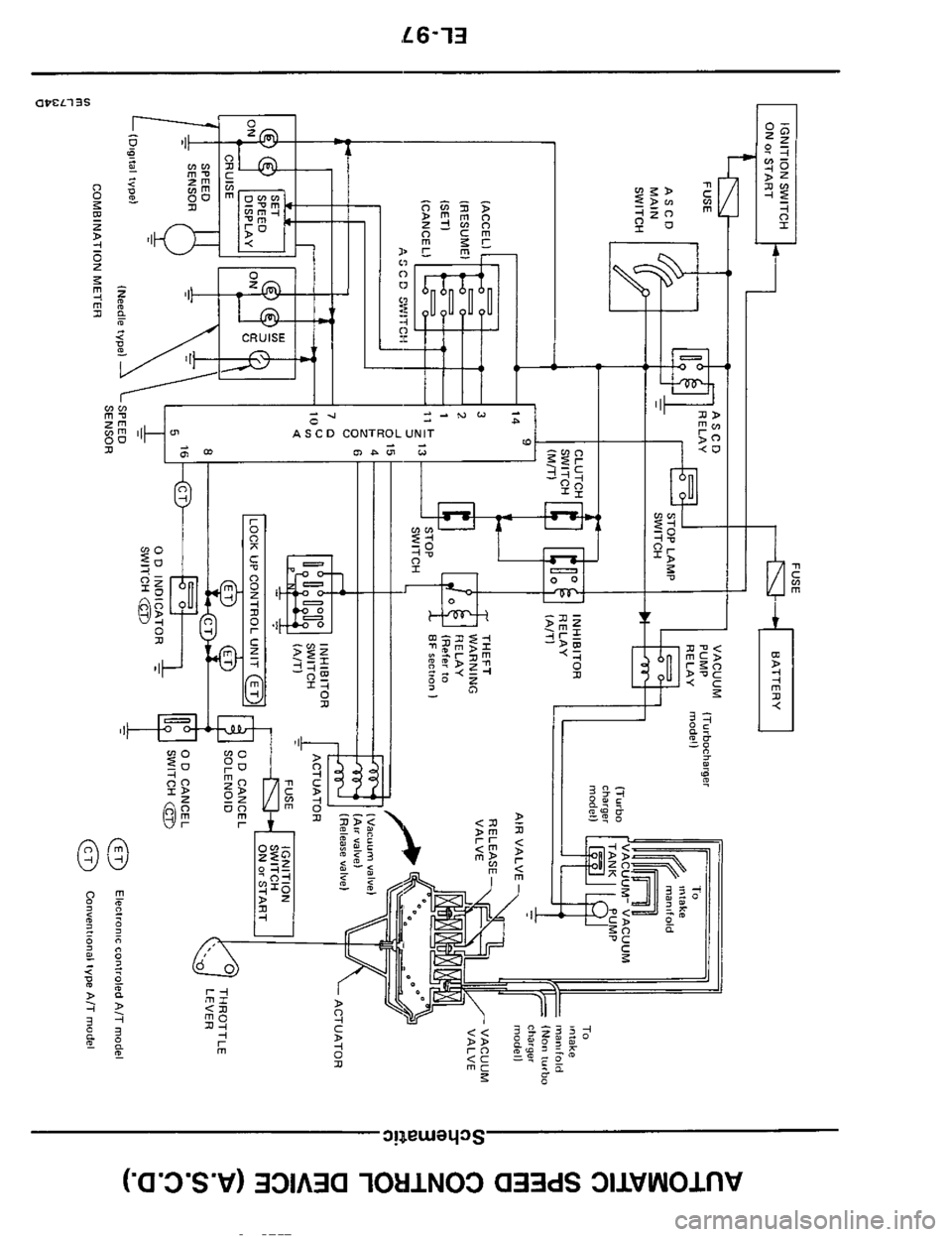

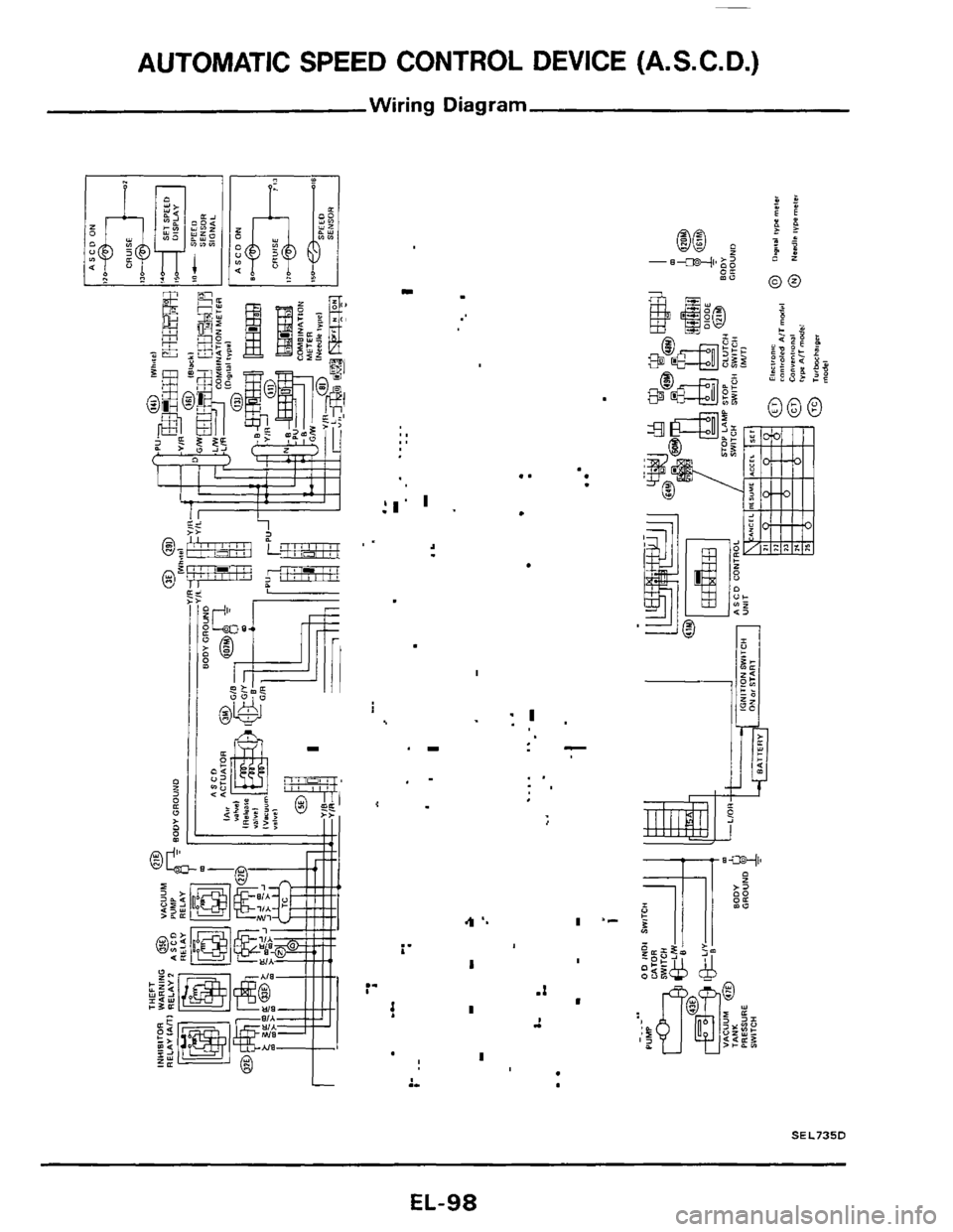

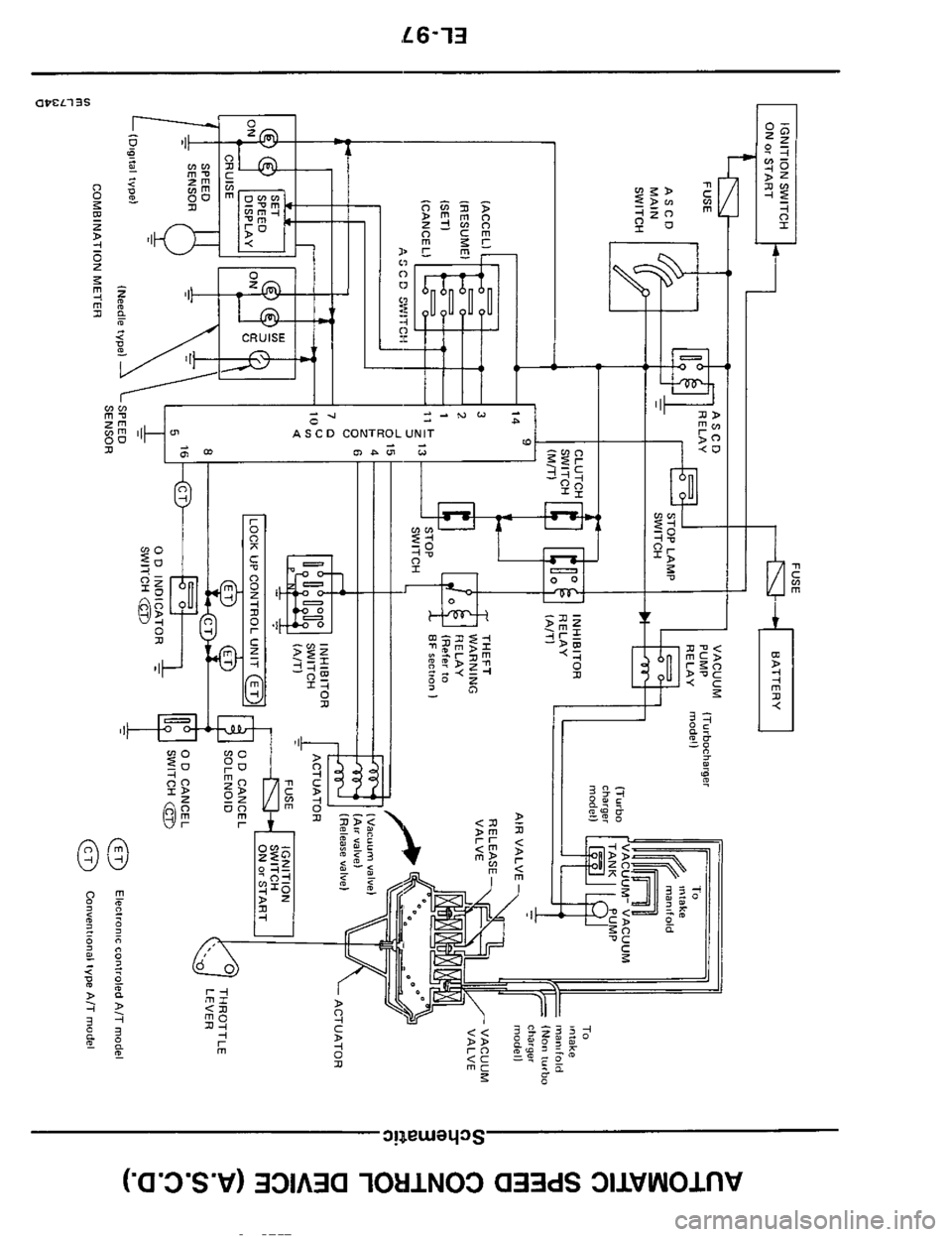

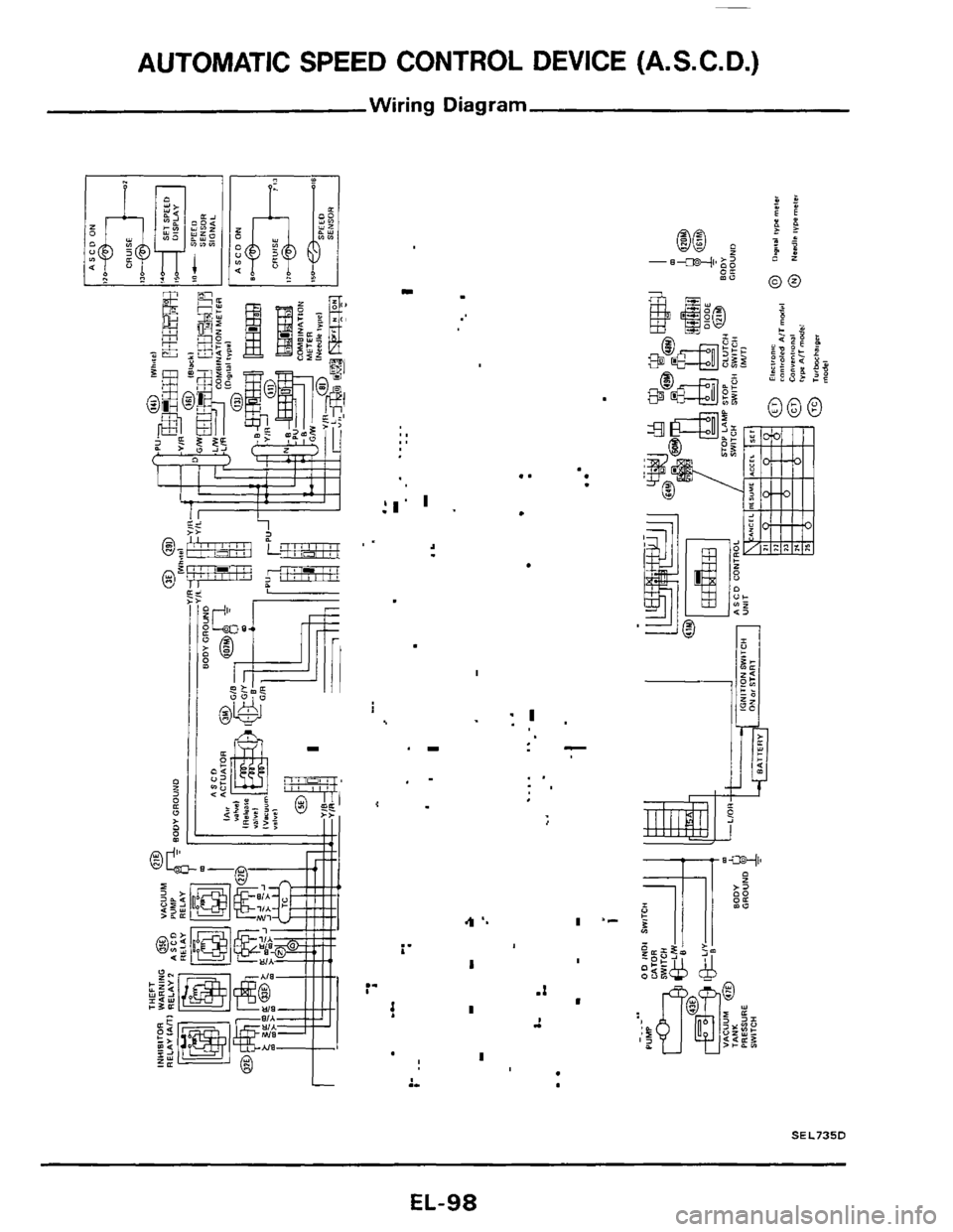

AUTOMATIC SPEED CONTROL DEVICE (A. S. C. D.)

Wiring Diagram

L

.I .. I .-

i' I

:- .I

I I

- !

I

.-

SEL735D

EL-98

Page 99 of 116

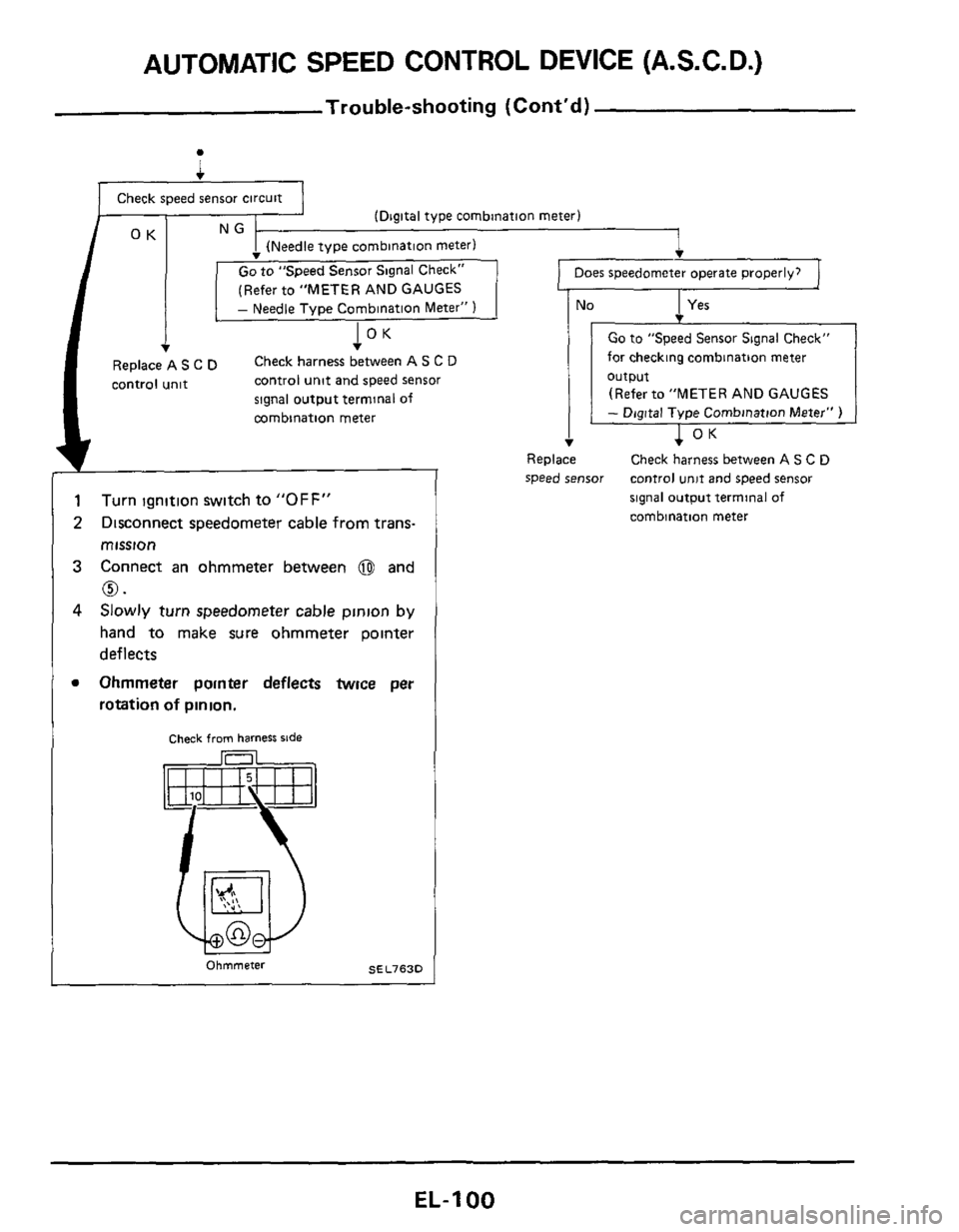

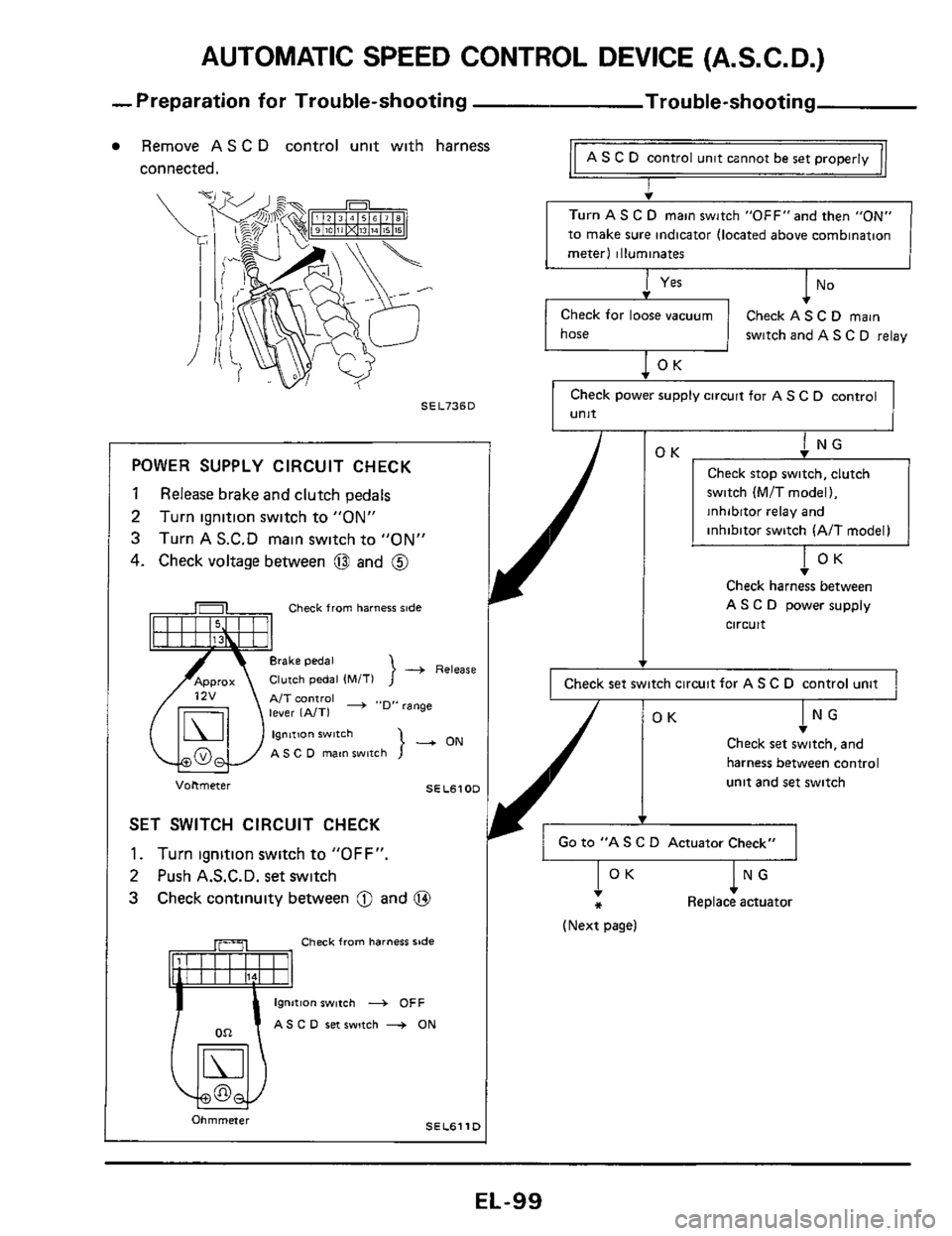

AUTOMATIC SPEED CONTROL DEVICE (A.S.C.D.)

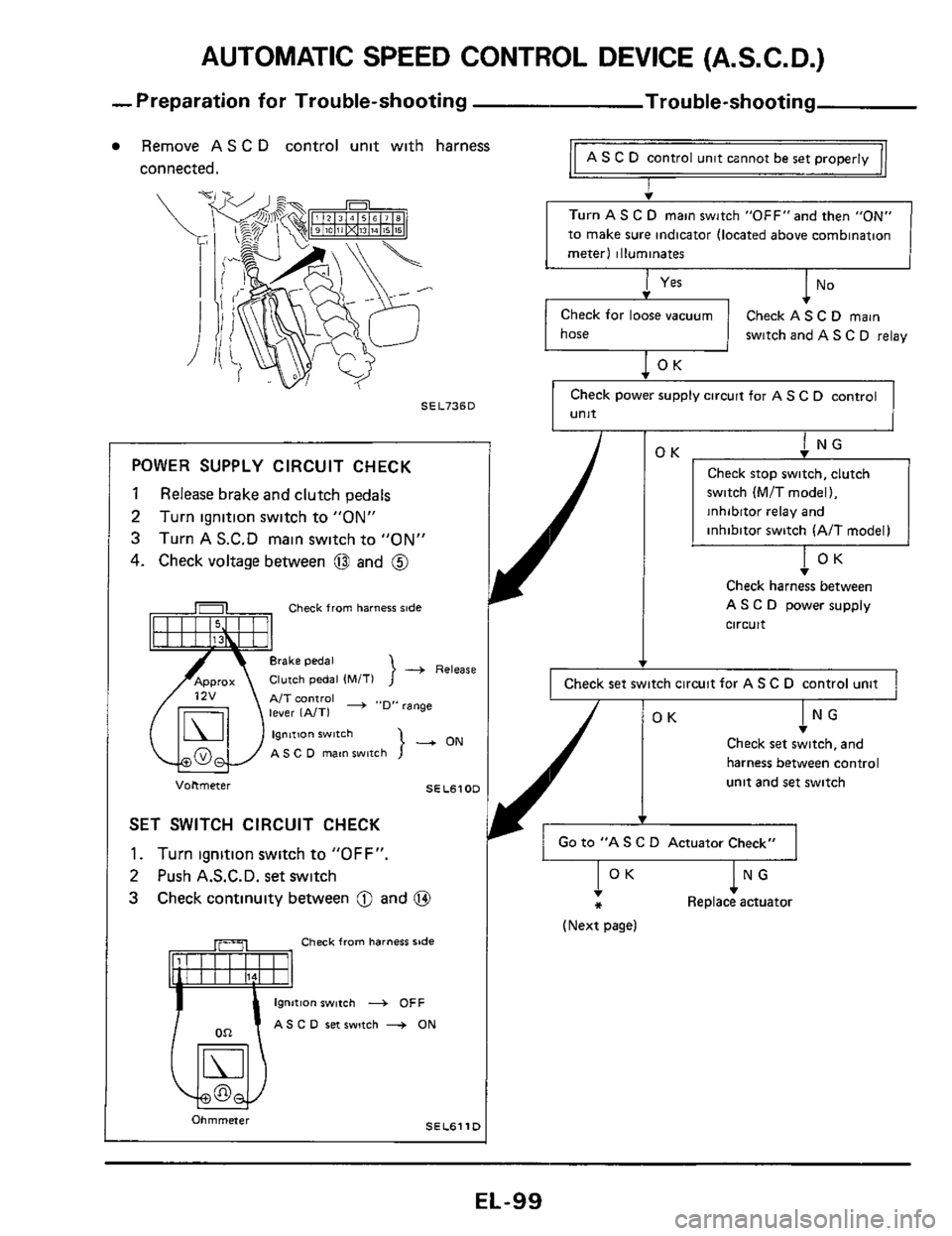

-Preparation for Trouble-shooting Trouble-shooting

Remove AS C D control unit with harness AS C D control unit cznnot be set properly connected. I

Turn AS C D main switch "0FF"and then "ON"

to make sure indicator (located above combination

meter1 illuminates

Check for loose vacuum Check AS C D main

[-I switch and AS C D relay

Check power supply circuit for

A S C D control

unit SEL736D

Check stop switch. clutch

switch (MIT model).

inhibitor relay and

inhibitor switch (AIT model) POWER SUPPLY CIRCUIT CHECK

1 Release brake and clutch pedals

2 Turn ignition switch to "ON"

3 Turn A S.C.D main switch to "ON"

4. Check voltage between 0 and @ v Check harness between

AS C D power supply Check from harness side

-+ Release

A/T control -+ ..D" range

AS C D main wnch }-ON IOK Checksets:and

harness between control

unit and

set switch Voltmeter SELSlOD

SET SWITCH CIRCUIT CHECK

1. Turn ignition switch to "OFF". Go to "A S C D Actuator Check" -

2 Push A.S.C.D. set switch

3 Check continuity between 0 and @

Check from harness side

tion switch 4 OFF

C 0 ret switch + ON

SELBllD Ohmmeter

I

circuit

I Check set switch circuit for AS C D control unit 1

lNG Replace actuator !OK *

(Next page)

EL-99

Page 100 of 116

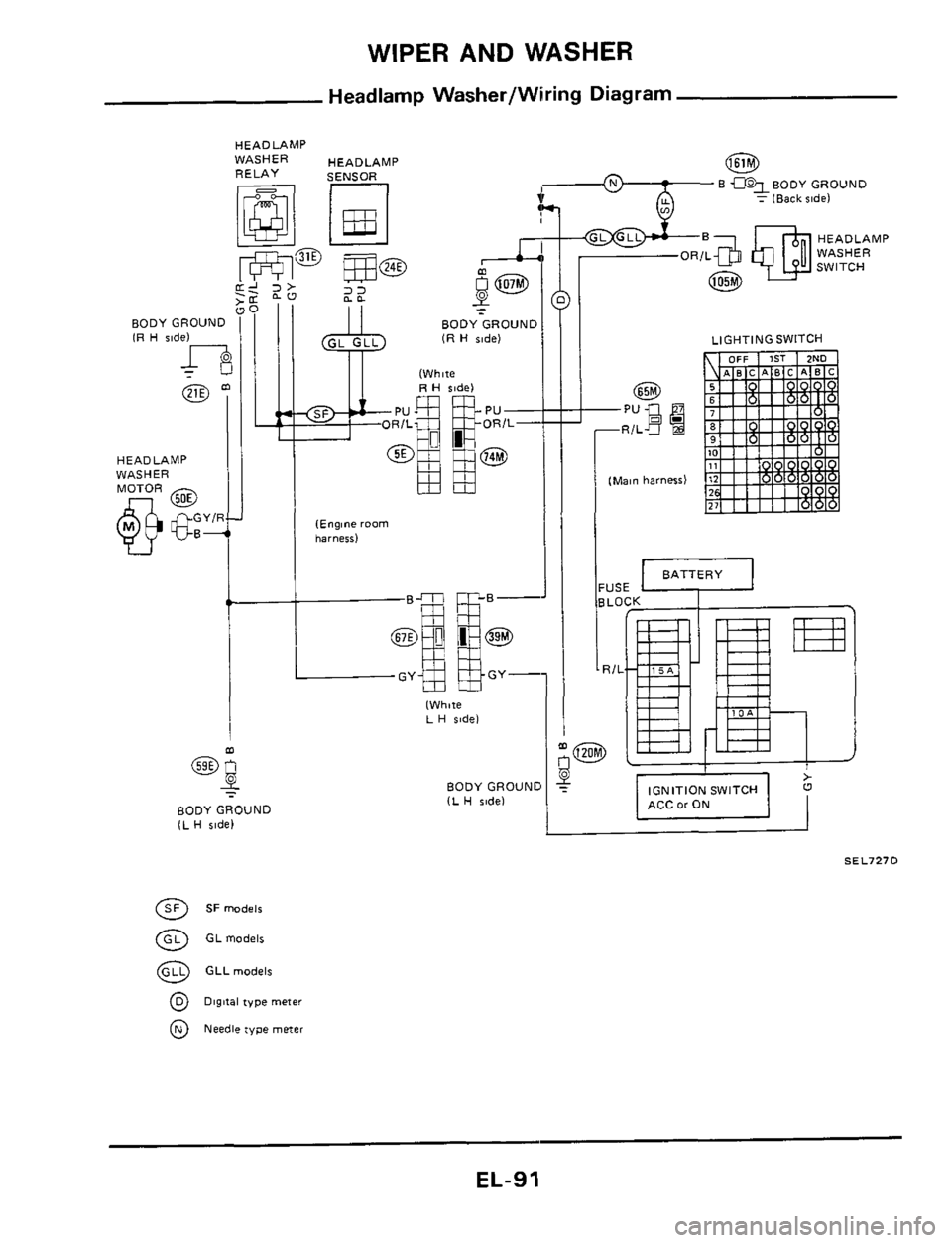

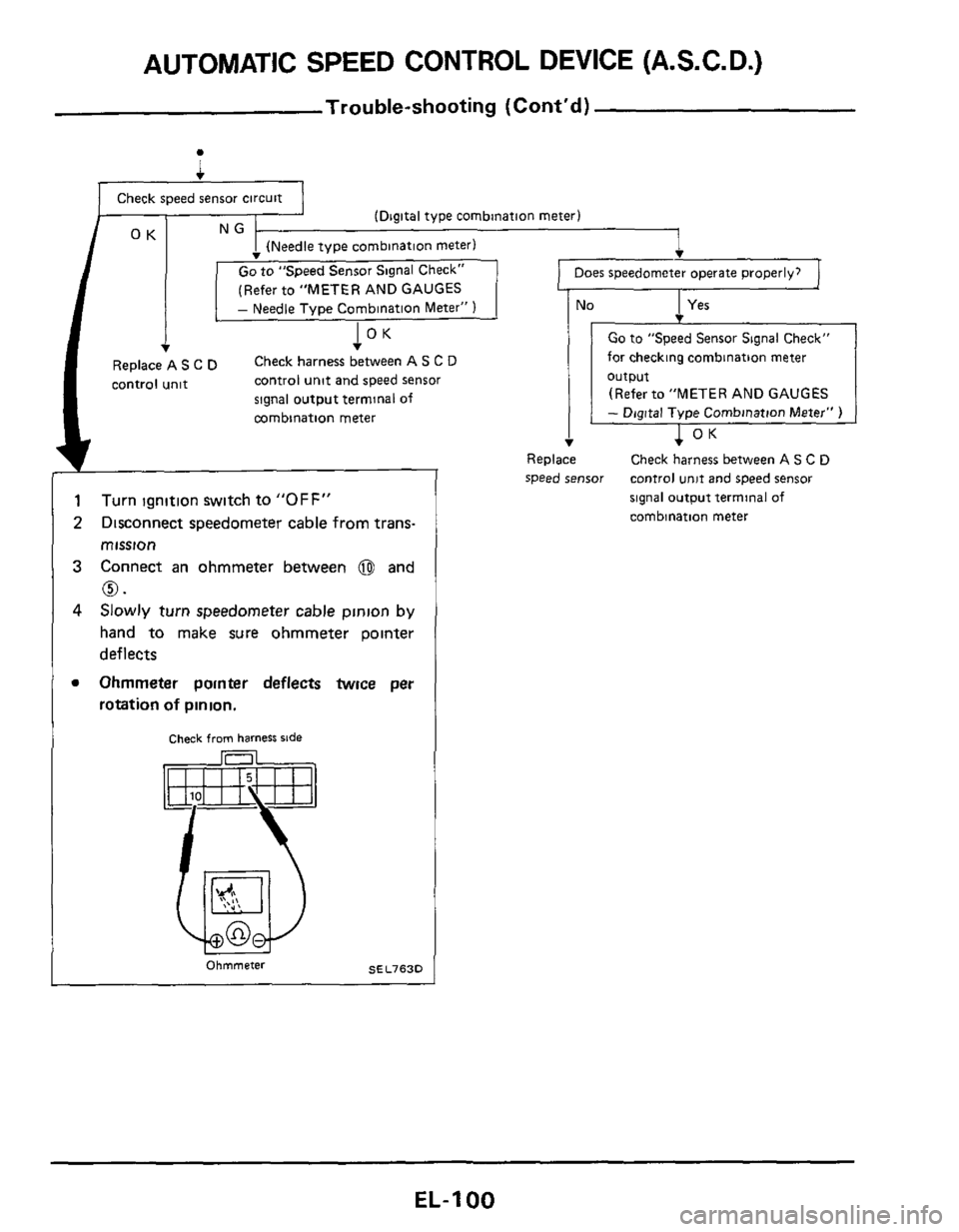

AUTOMATIC SPEED CONTROL DEVICE (A.S.C. D.)

Trouble-shooting (Cont'd)

Turn ignition switch to "OFF"

Disconnect speedometer cable from trans-

mission

Connect an ohmmeter between

@ and

Slowly turn speedometer cable pinion by

hand to make

sure ohmmeter pointer

deflects

Ohmmeter pointer deflects twice per

rotation

of pinion.

0.

Check from harness side

Ohmmeter SEL7630

i

Check speed sensor circuit

(Digital type combination meter) -

(Refer to "METER AND GAUGES

- Needle Type Combination Meter"

~~~l~~~ AS c D

control unit

Check harness between A S C D

control unit and speed sensor

signal output terminal

of

combination meter

Does speedometer operate properly?

Go to "Speed Sensor Signal Check"

for checking combination meter

(Refer to "METER AND GAUGES

- Digital Type Combination Meter" )

Replace

speed sensor Check harness between AS C D

control unit and speed sensor

signal output terminal of

combination meter

EL-I 00

Trending: Relays, Window, air, brake light, Pump, tires, EL-76