NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: width, engine overheat, battery capacity, oil pressure, transmission, wheel bolt torque, maintenance schedule

Page 431 of 2898

NAT047

7. Remove idler gear bearing outer race from transmission case.

NAT048

8. Press out reduction pinion gear bearing from reduction pinion

gear.

SAT651D

9. Remove reduction pinion gear bearing outer race from trans-

mission case.

SPD715

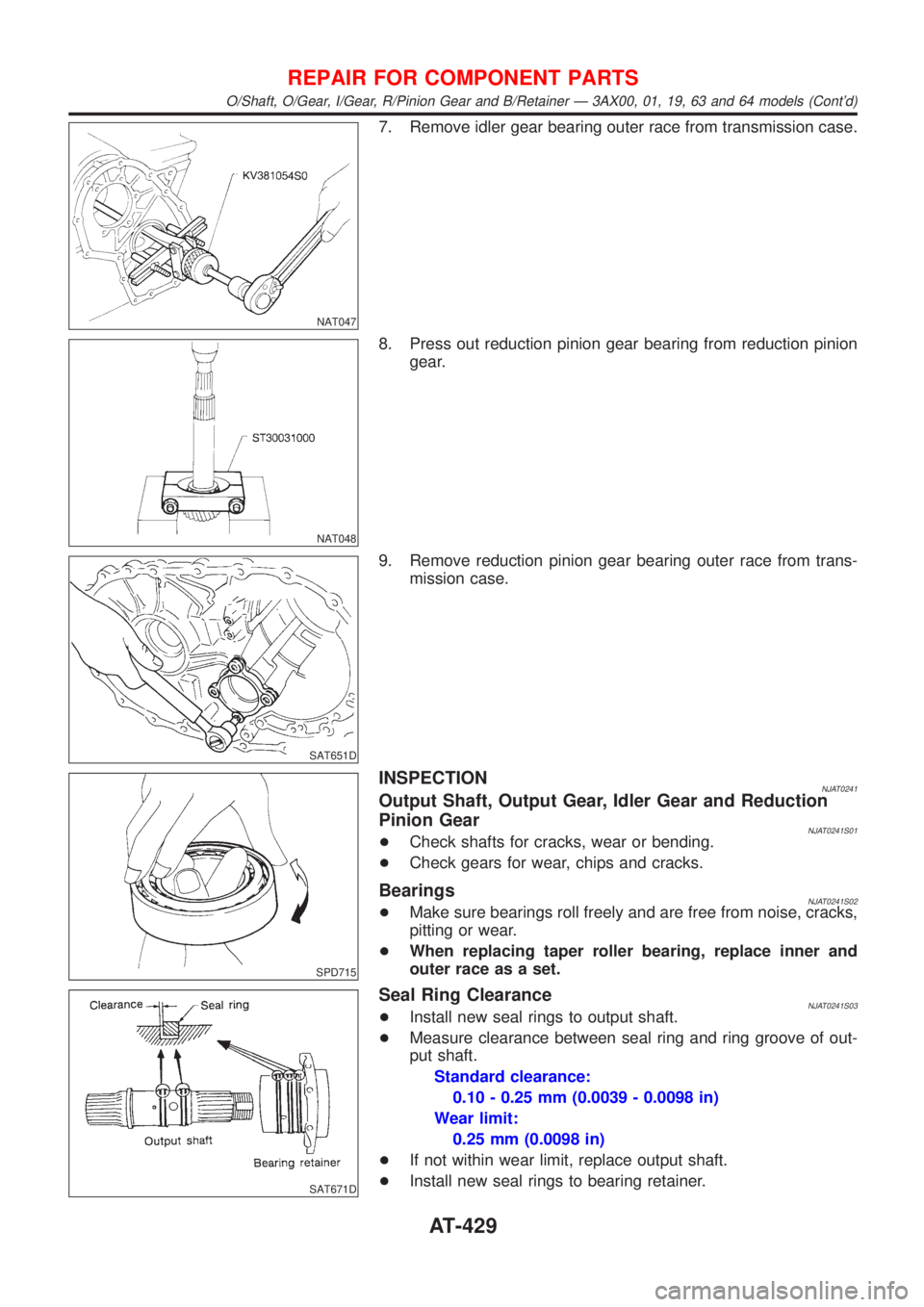

INSPECTIONNJAT0241Output Shaft, Output Gear, Idler Gear and Reduction

Pinion Gear

NJAT0241S01+Check shafts for cracks, wear or bending.

+Check gears for wear, chips and cracks.

BearingsNJAT0241S02+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing taper roller bearing, replace inner and

outer race as a set.

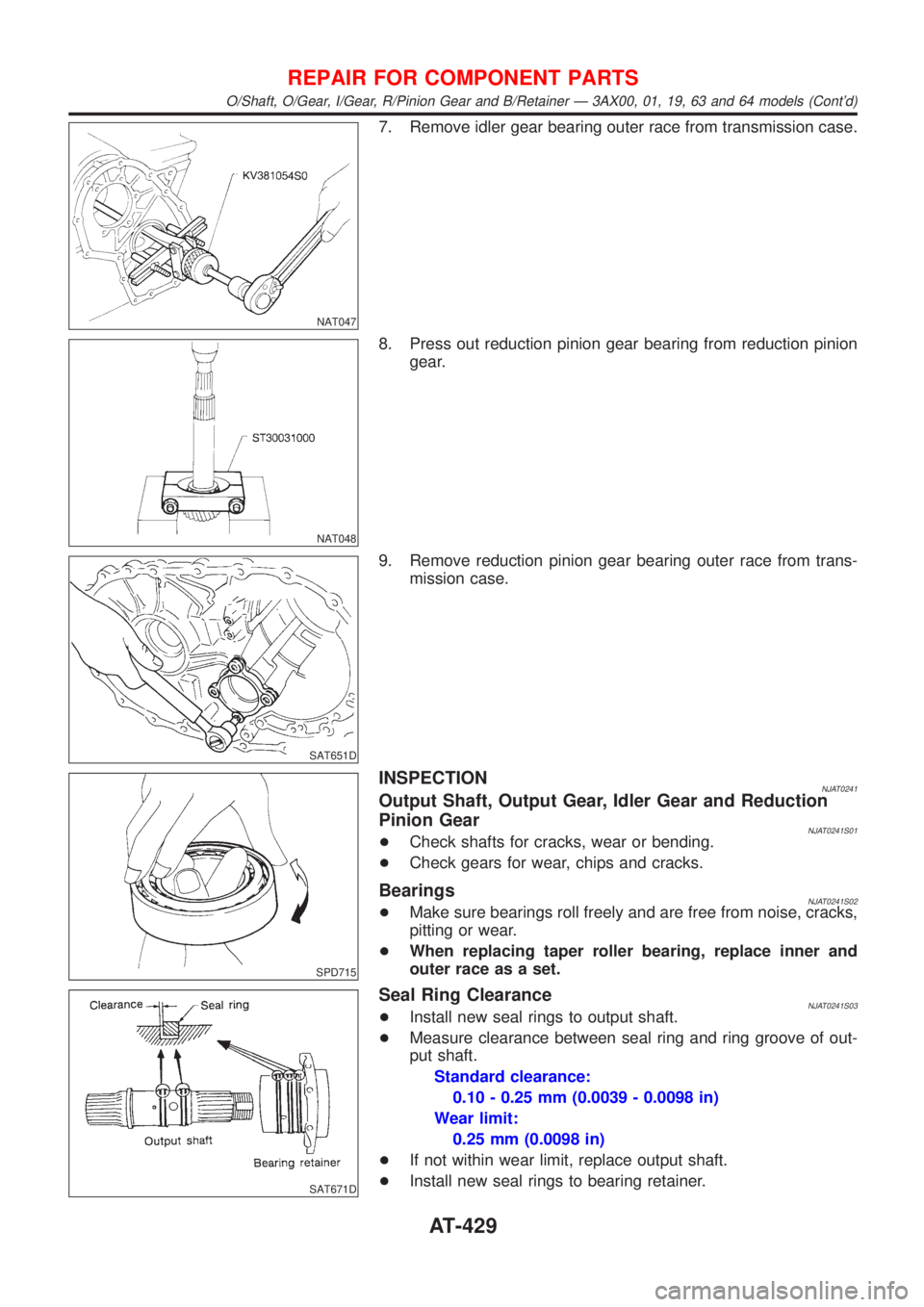

SAT671D

Seal Ring ClearanceNJAT0241S03+Install new seal rings to output shaft.

+Measure clearance between seal ring and ring groove of out-

put shaft.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Wear limit:

0.25 mm (0.0098 in)

+If not within wear limit, replace output shaft.

+Install new seal rings to bearing retainer.

REPAIR FOR COMPONENT PARTS

O/Shaft, O/Gear, I/Gear, R/Pinion Gear and B/Retainer Ð 3AX00, 01, 19, 63 and 64 models (Cont'd)

AT-429

Page 432 of 2898

+Measure clearance between seal ring and ring groove of bear-

ing retainer.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Wear limit:

0.25 mm (0.0098 in)

+If not within wear limit, replace bearing retainer.

NAT049

ASSEMBLYNJAT02421. Press reduction pinion gear bearing on reduction pinion gear.

SAT654D

2. Install reduction pinion gear bearing outer race on transmis-

sion case.

SAT655D

3. Press idler gear bearing inner race on idler gear.

NAT051

4. Install idler gear bearing outer race on transmission case.

REPAIR FOR COMPONENT PARTS

O/Shaft, O/Gear, I/Gear, R/Pinion Gear and B/Retainer Ð 3AX00, 01, 19, 63 and 64 models (Cont'd)

AT-430

Page 433 of 2898

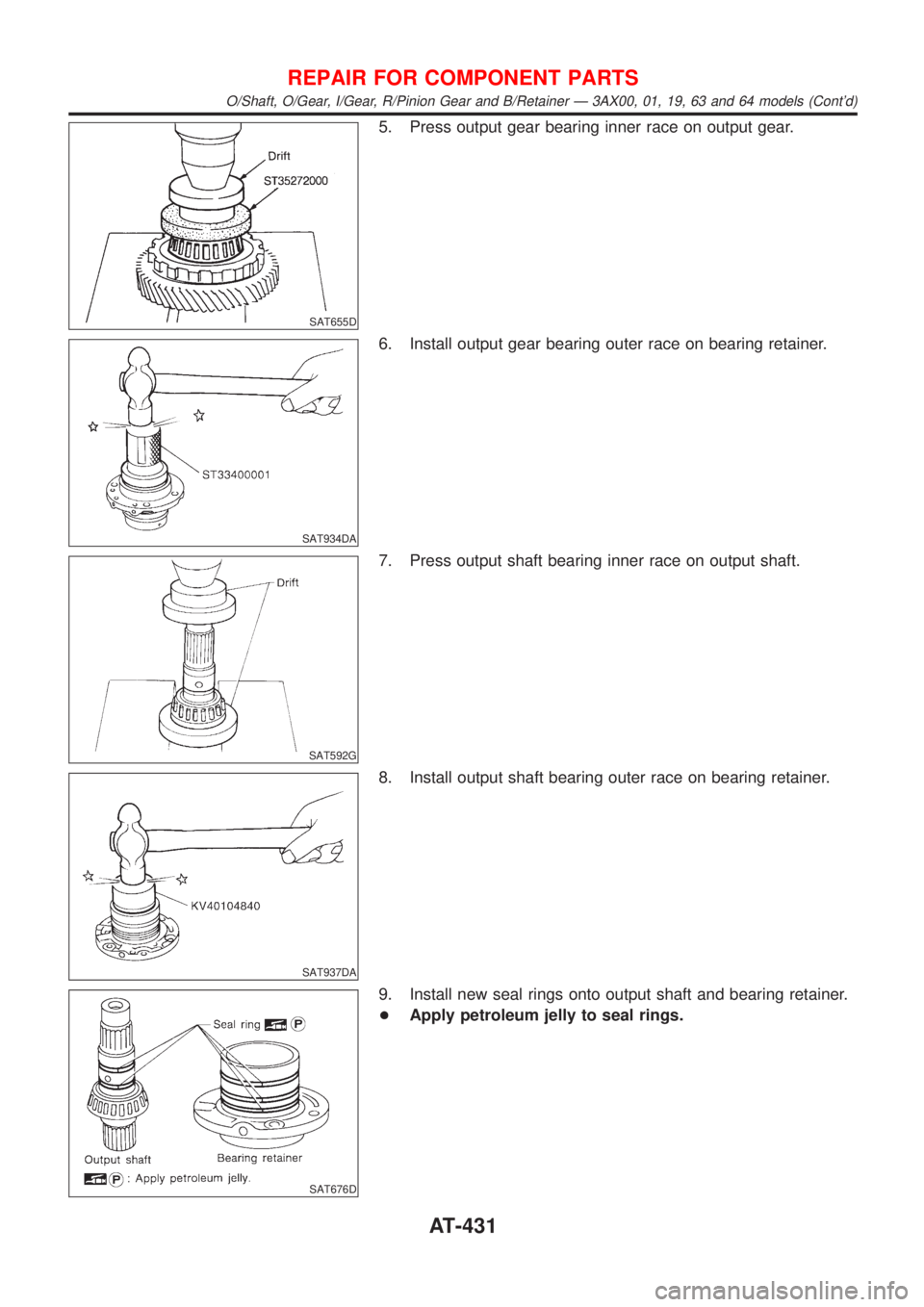

SAT655D

5. Press output gear bearing inner race on output gear.

SAT934DA

6. Install output gear bearing outer race on bearing retainer.

SAT592G

7. Press output shaft bearing inner race on output shaft.

SAT937DA

8. Install output shaft bearing outer race on bearing retainer.

SAT676D

9. Install new seal rings onto output shaft and bearing retainer.

+Apply petroleum jelly to seal rings.

REPAIR FOR COMPONENT PARTS

O/Shaft, O/Gear, I/Gear, R/Pinion Gear and B/Retainer Ð 3AX00, 01, 19, 63 and 64 models (Cont'd)

AT-431

Page 434 of 2898

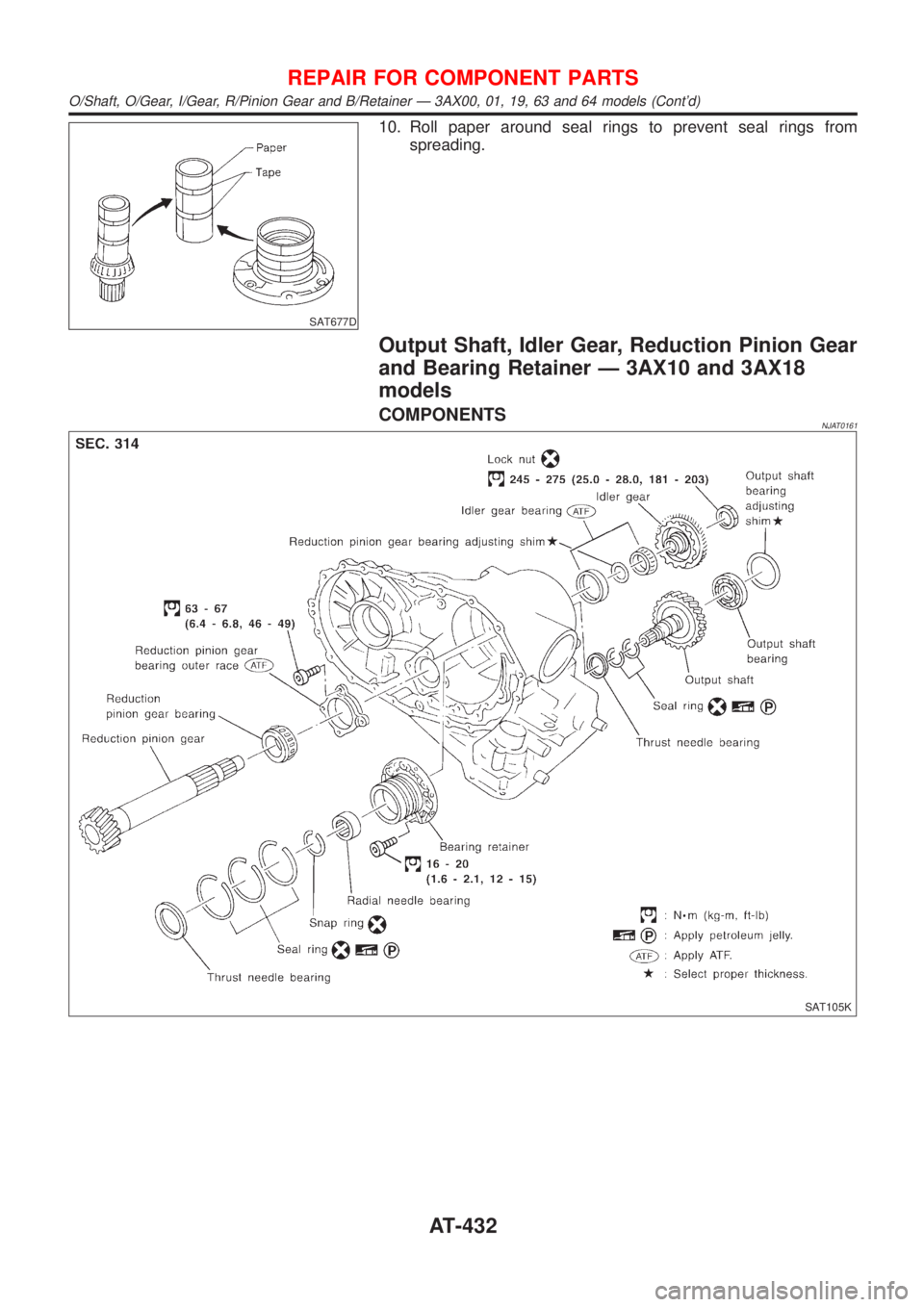

SAT677D

10. Roll paper around seal rings to prevent seal rings from

spreading.

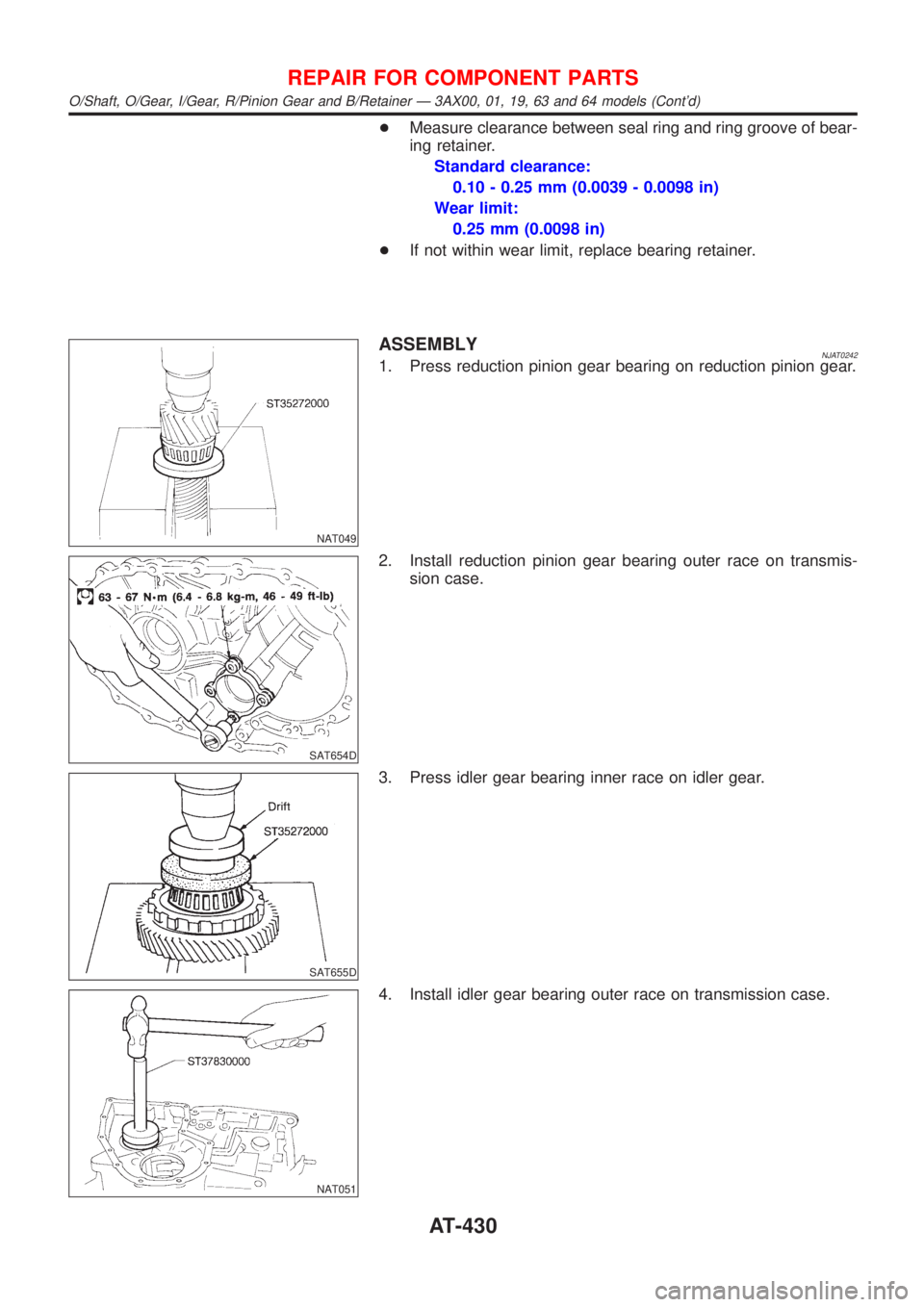

Output Shaft, Idler Gear, Reduction Pinion Gear

and Bearing Retainer Ð 3AX10 and 3AX18

models

COMPONENTSNJAT0161

SAT105K

REPAIR FOR COMPONENT PARTS

O/Shaft, O/Gear, I/Gear, R/Pinion Gear and B/Retainer Ð 3AX00, 01, 19, 63 and 64 models (Cont'd)

AT-432

Page 435 of 2898

SAT644D

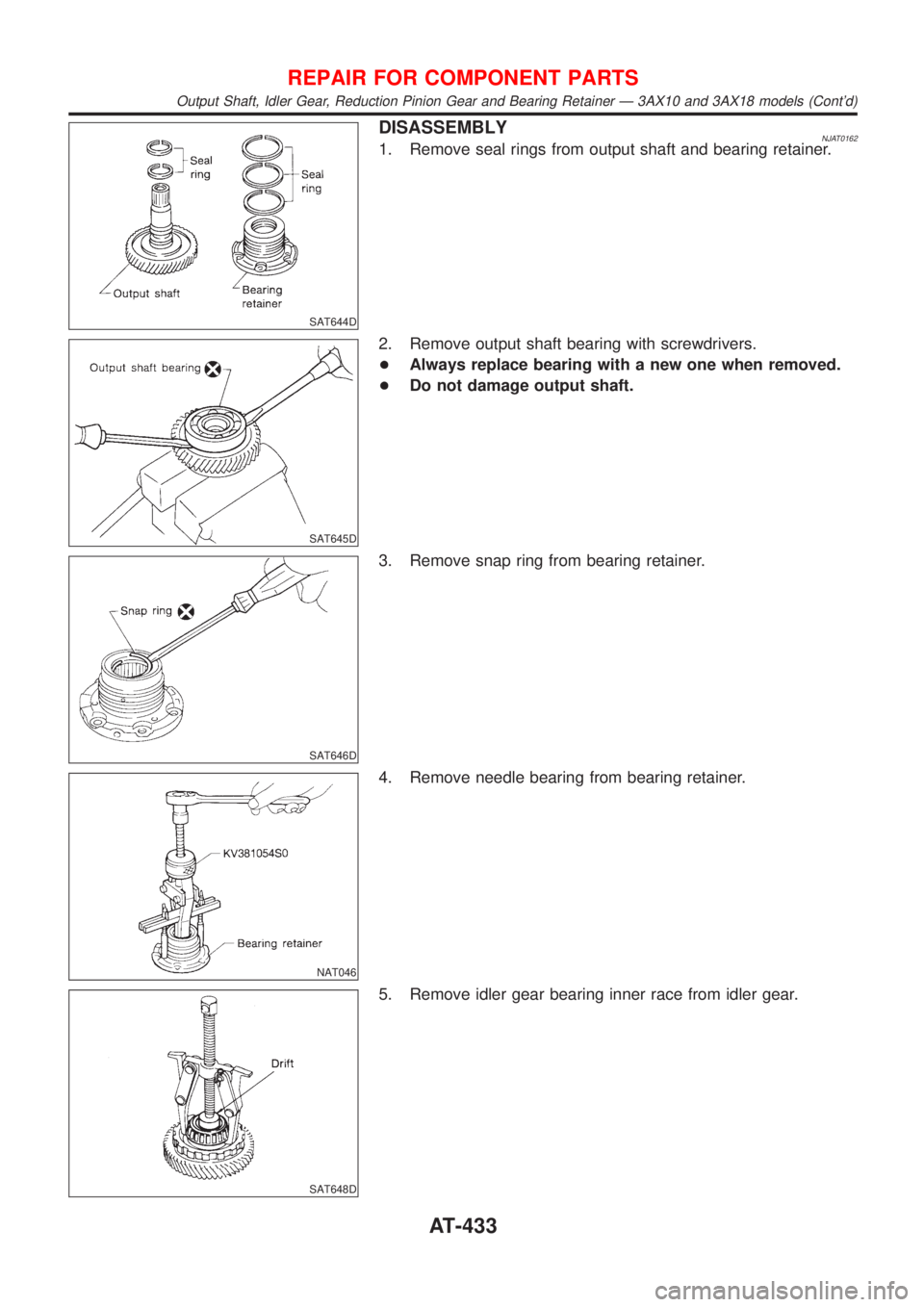

DISASSEMBLYNJAT01621. Remove seal rings from output shaft and bearing retainer.

SAT645D

2. Remove output shaft bearing with screwdrivers.

+Always replace bearing with a new one when removed.

+Do not damage output shaft.

SAT646D

3. Remove snap ring from bearing retainer.

NAT046

4. Remove needle bearing from bearing retainer.

SAT648D

5. Remove idler gear bearing inner race from idler gear.

REPAIR FOR COMPONENT PARTS

Output Shaft, Idler Gear, Reduction Pinion Gear and Bearing Retainer Ð 3AX10 and 3AX18 models (Cont'd)

AT-433

Page 436 of 2898

NAT047

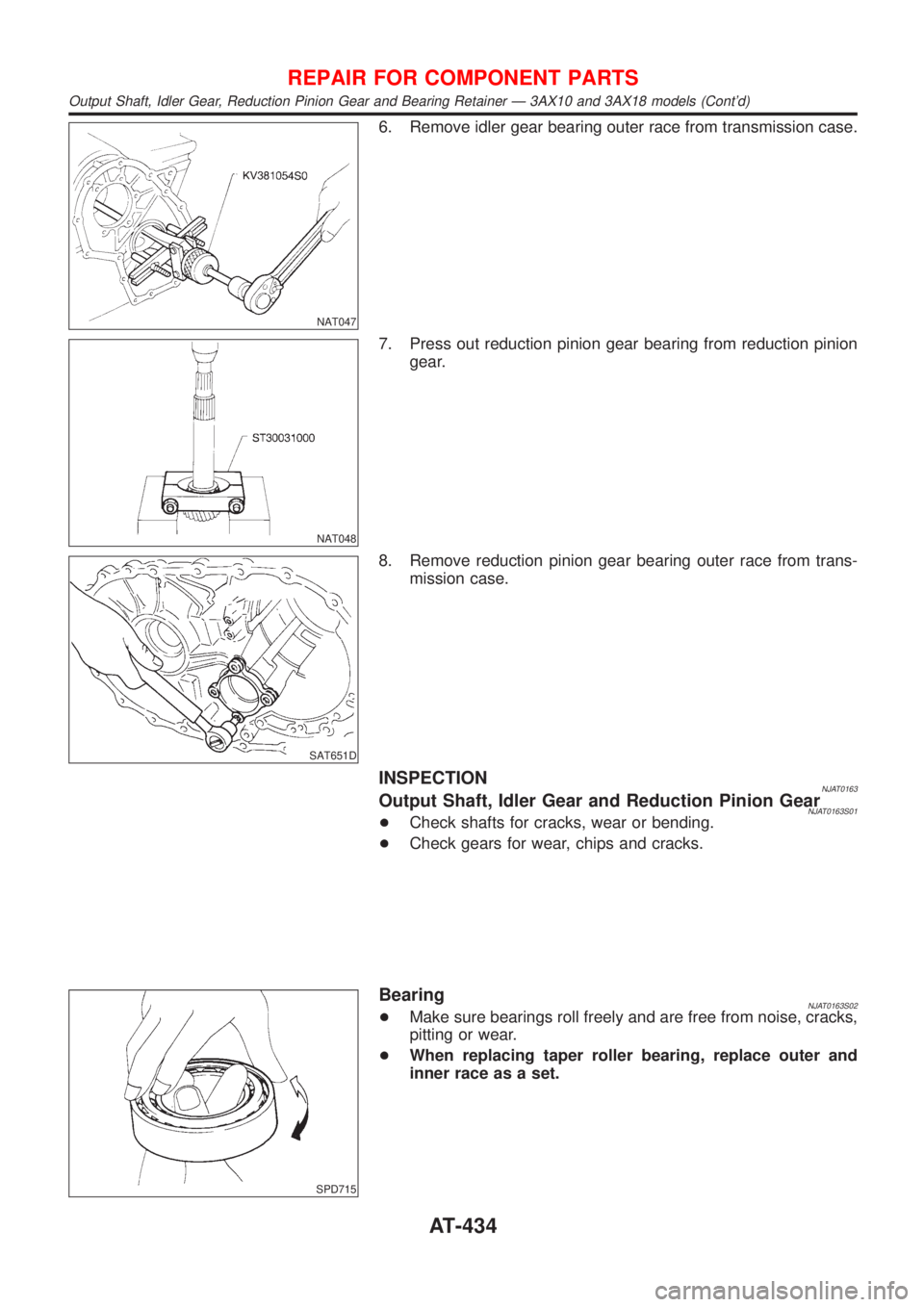

6. Remove idler gear bearing outer race from transmission case.

NAT048

7. Press out reduction pinion gear bearing from reduction pinion

gear.

SAT651D

8. Remove reduction pinion gear bearing outer race from trans-

mission case.

INSPECTIONNJAT0163Output Shaft, Idler Gear and Reduction Pinion GearNJAT0163S01+Check shafts for cracks, wear or bending.

+Check gears for wear, chips and cracks.

SPD715

BearingNJAT0163S02+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing taper roller bearing, replace outer and

inner race as a set.

REPAIR FOR COMPONENT PARTS

Output Shaft, Idler Gear, Reduction Pinion Gear and Bearing Retainer Ð 3AX10 and 3AX18 models (Cont'd)

AT-434

Page 437 of 2898

SAT652D

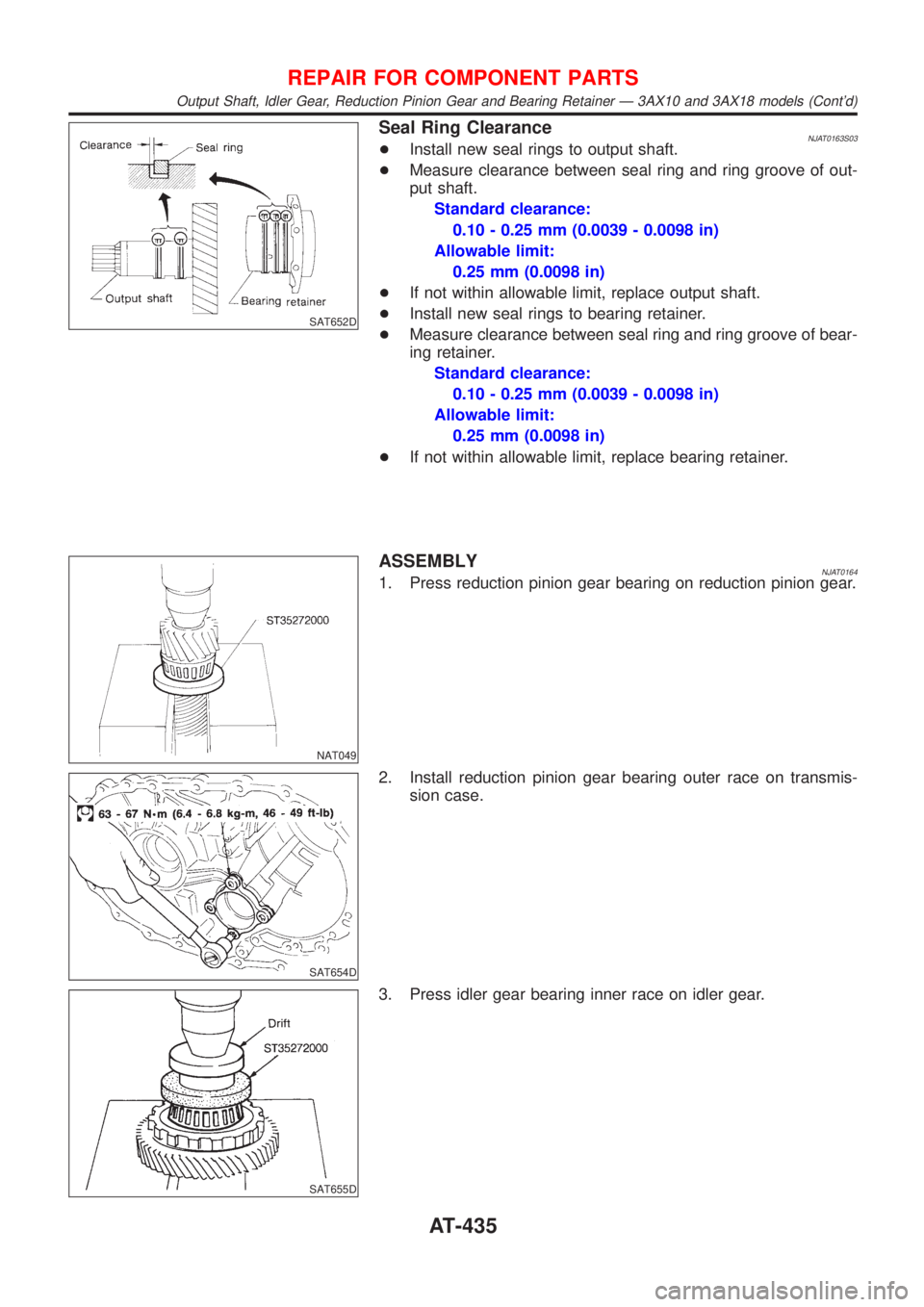

Seal Ring ClearanceNJAT0163S03+Install new seal rings to output shaft.

+Measure clearance between seal ring and ring groove of out-

put shaft.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Allowable limit:

0.25 mm (0.0098 in)

+If not within allowable limit, replace output shaft.

+Install new seal rings to bearing retainer.

+Measure clearance between seal ring and ring groove of bear-

ing retainer.

Standard clearance:

0.10 - 0.25 mm (0.0039 - 0.0098 in)

Allowable limit:

0.25 mm (0.0098 in)

+If not within allowable limit, replace bearing retainer.

NAT049

ASSEMBLYNJAT01641. Press reduction pinion gear bearing on reduction pinion gear.

SAT654D

2. Install reduction pinion gear bearing outer race on transmis-

sion case.

SAT655D

3. Press idler gear bearing inner race on idler gear.

REPAIR FOR COMPONENT PARTS

Output Shaft, Idler Gear, Reduction Pinion Gear and Bearing Retainer Ð 3AX10 and 3AX18 models (Cont'd)

AT-435

Page 438 of 2898

NAT051

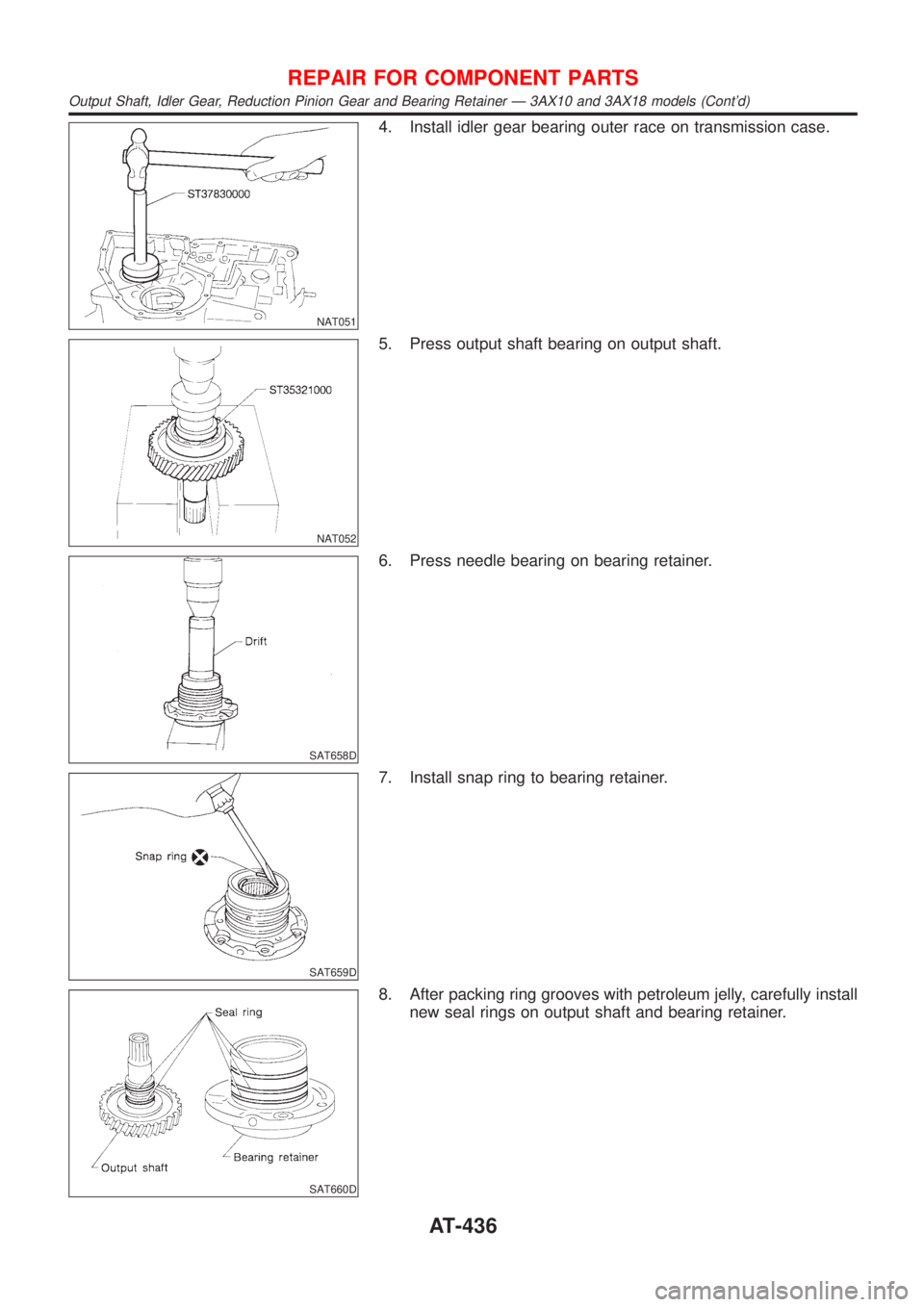

4. Install idler gear bearing outer race on transmission case.

NAT052

5. Press output shaft bearing on output shaft.

SAT658D

6. Press needle bearing on bearing retainer.

SAT659D

7. Install snap ring to bearing retainer.

SAT660D

8. After packing ring grooves with petroleum jelly, carefully install

new seal rings on output shaft and bearing retainer.

REPAIR FOR COMPONENT PARTS

Output Shaft, Idler Gear, Reduction Pinion Gear and Bearing Retainer Ð 3AX10 and 3AX18 models (Cont'd)

AT-436

Page 439 of 2898

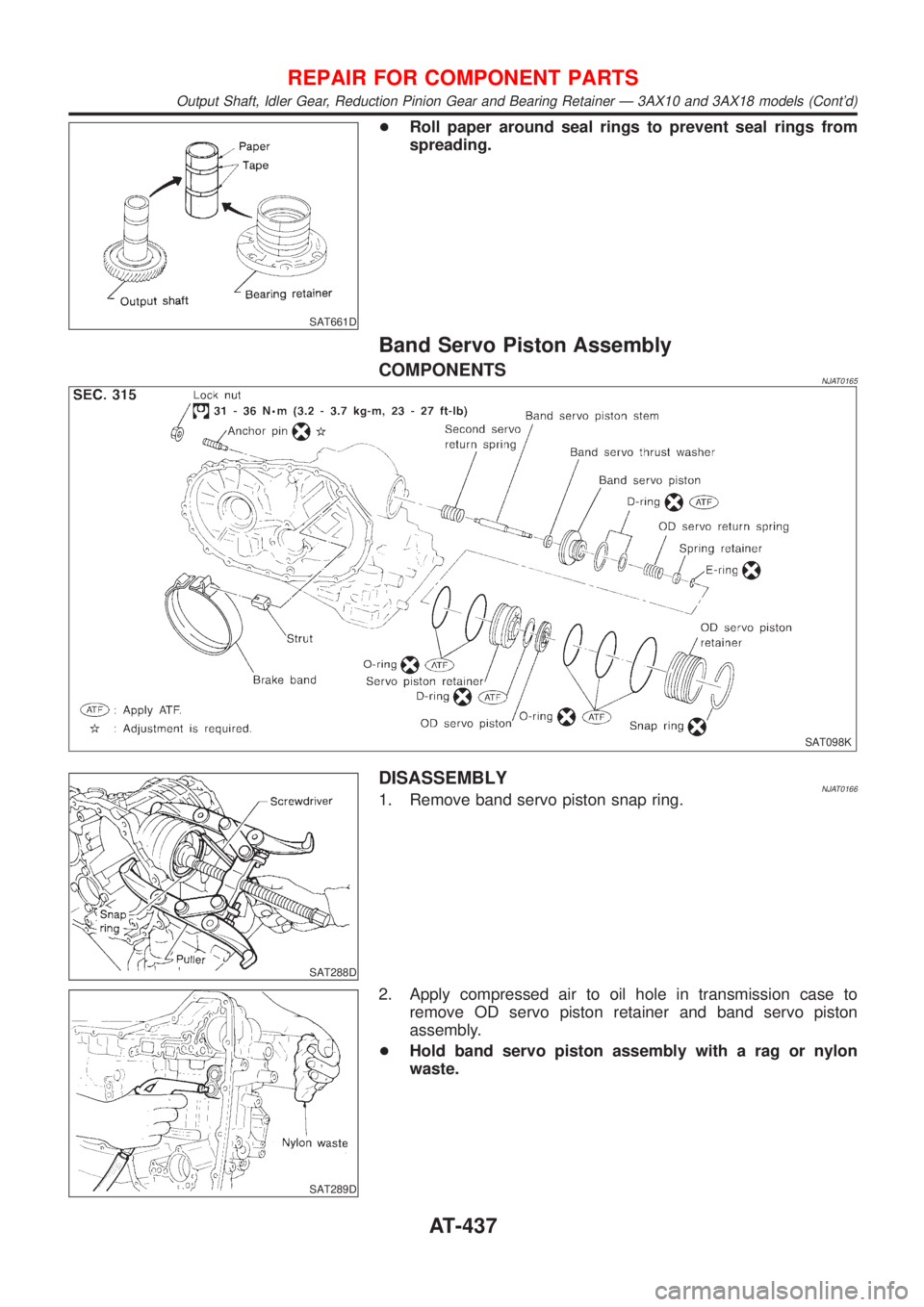

SAT661D

+Roll paper around seal rings to prevent seal rings from

spreading.

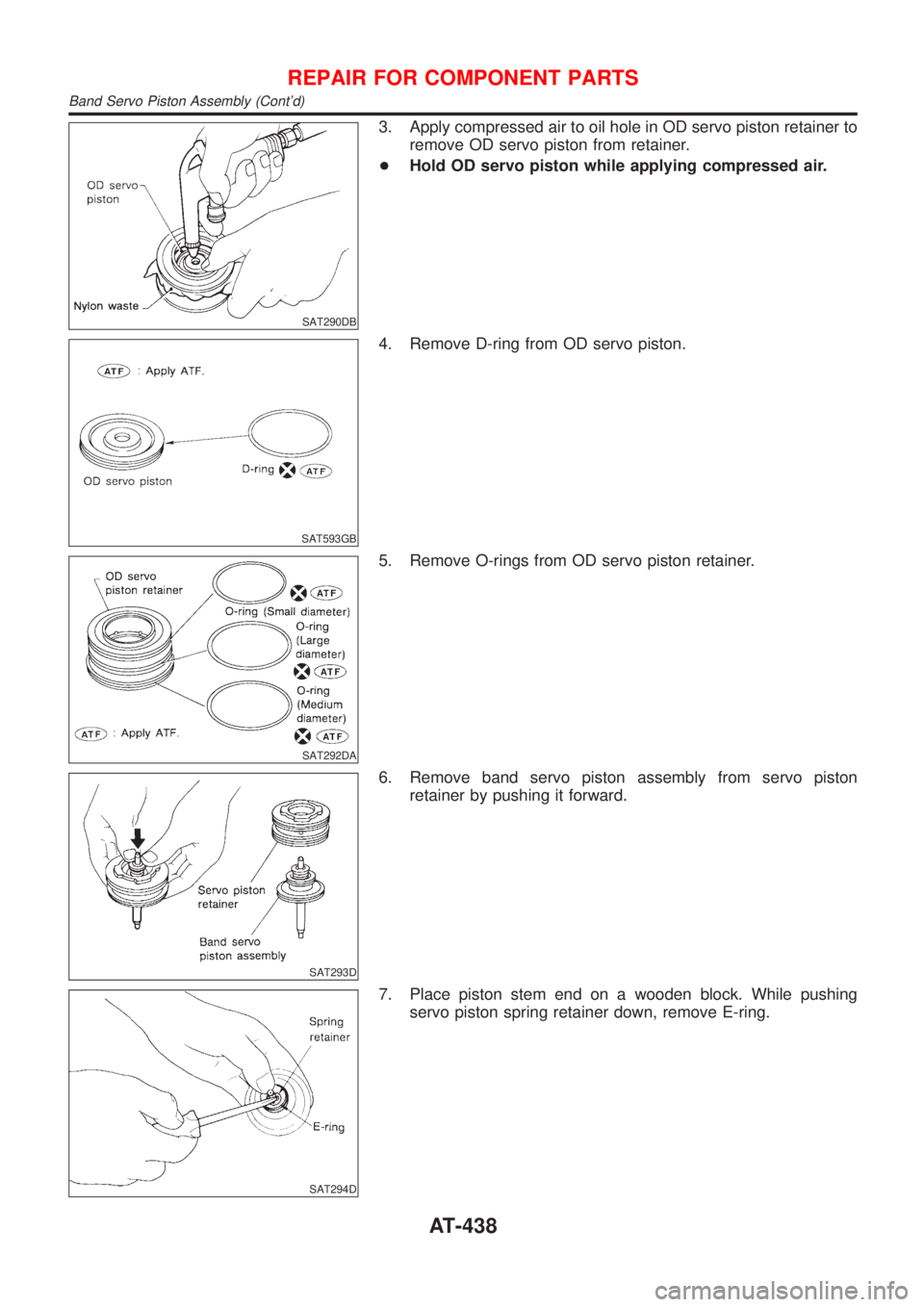

Band Servo Piston Assembly

COMPONENTSNJAT0165

SAT098K

SAT288D

DISASSEMBLYNJAT01661. Remove band servo piston snap ring.

SAT289D

2. Apply compressed air to oil hole in transmission case to

remove OD servo piston retainer and band servo piston

assembly.

+Hold band servo piston assembly with a rag or nylon

waste.

REPAIR FOR COMPONENT PARTS

Output Shaft, Idler Gear, Reduction Pinion Gear and Bearing Retainer Ð 3AX10 and 3AX18 models (Cont'd)

AT-437

Page 440 of 2898

SAT290DB

3. Apply compressed air to oil hole in OD servo piston retainer to

remove OD servo piston from retainer.

+Hold OD servo piston while applying compressed air.

SAT593GB

4. Remove D-ring from OD servo piston.

SAT292DA

5. Remove O-rings from OD servo piston retainer.

SAT293D

6. Remove band servo piston assembly from servo piston

retainer by pushing it forward.

SAT294D

7. Place piston stem end on a wooden block. While pushing

servo piston spring retainer down, remove E-ring.

REPAIR FOR COMPONENT PARTS

Band Servo Piston Assembly (Cont'd)

AT-438

Trending: jump start, warning light, light, ignition, oil viscosity, gas type, tow