torque NISSAN ALMERA 2001 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 710 of 2898

CLUTCH PEDAL ADJUSTMENTNJCL0006S04Pedal StrokeNJCL0006S04011. Loosen the pedal stopper bolt completely (so there is no con-

tact between pedal and stopper bolt).

2. Adjust pedal stroke to the specified value with the master cyl-

inder push rod.

3. Adjust the pedal stopper bolt until it is just in contact with the

pedal, then tighten the lock nut.

4. Once stroke is set to specification, adjust clutch pedal free

play.

Pedal stroke ªSº.

Refer to ªSDSº, CL-24.

Pedal Free PlayNJCL0006S04021. Adjust pedal free play to the specified value with the master

cylinder push rod.

2. Tighten lock nut of the master cylinder push rod.

+Push on the clutch pedal until resistance is felt, and check the

distance the pedal moves.

Pedal free play ªAº.

Refer to ªSDSº, CL-24.

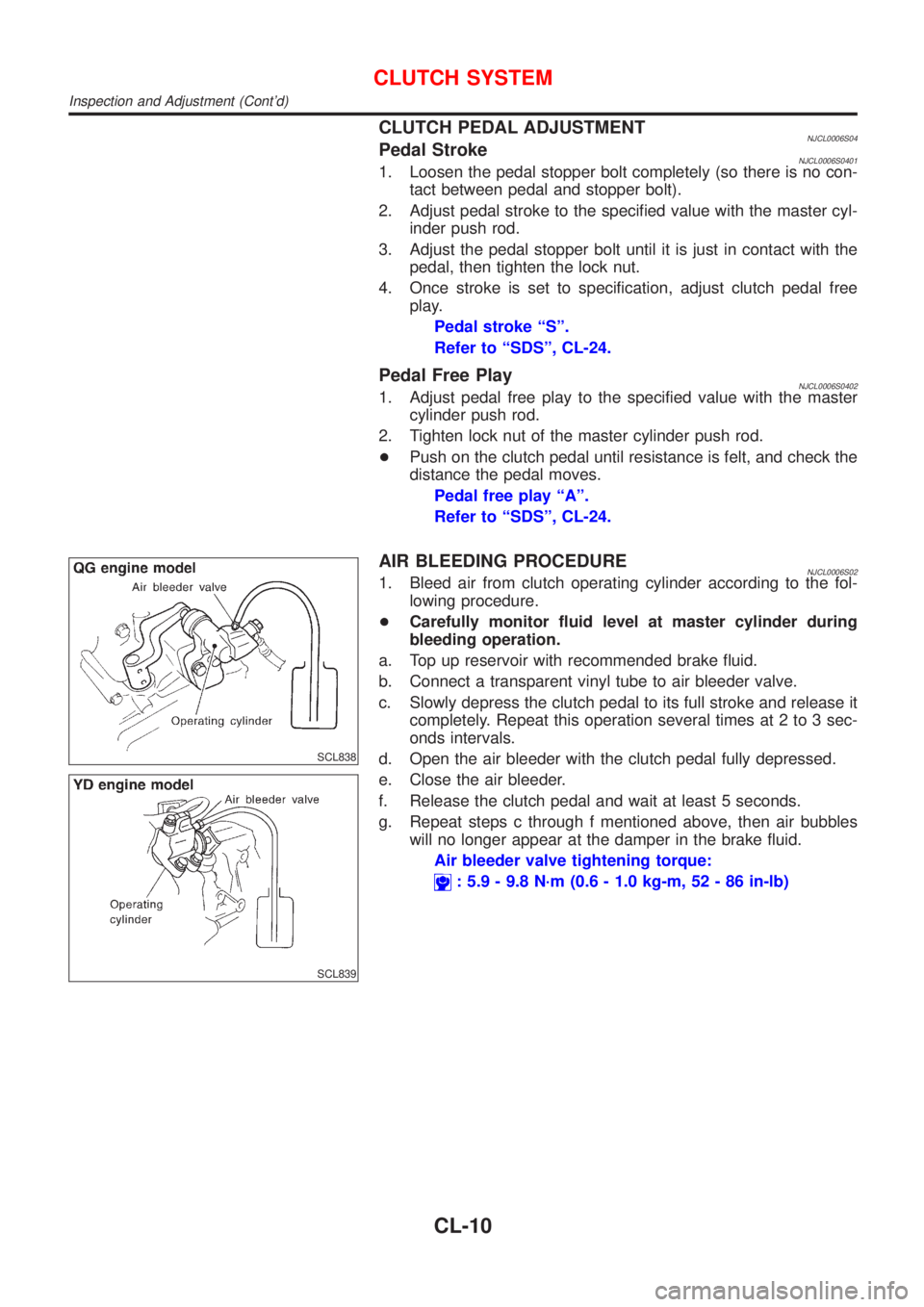

SCL838

SCL839

AIR BLEEDING PROCEDURENJCL0006S021. Bleed air from clutch operating cylinder according to the fol-

lowing procedure.

+Carefully monitor fluid level at master cylinder during

bleeding operation.

a. Top up reservoir with recommended brake fluid.

b. Connect a transparent vinyl tube to air bleeder valve.

c. Slowly depress the clutch pedal to its full stroke and release it

completely. Repeat this operation several times at 2 to 3 sec-

onds intervals.

d. Open the air bleeder with the clutch pedal fully depressed.

e. Close the air bleeder.

f. Release the clutch pedal and wait at least 5 seconds.

g. Repeat steps c through f mentioned above, then air bubbles

will no longer appear at the damper in the brake fluid.

Air bleeder valve tightening torque:

: 5.9 - 9.8 N´m (0.6 - 1.0 kg-m, 52 - 86 in-lb)

CLUTCH SYSTEM

Inspection and Adjustment (Cont'd)

CL-10

Page 712 of 2898

RemovalNJCL00081. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

2. Remove clutch tube using a flare nut wrench.

3. Remove snap pin between clutch pedal and push rod, and

remove clevis pin.

4. Unscrew master cylinder assembly mounting nuts and remove

master cylinder assembly from vehicle.

InstallationNJCL00091. Connect clutch tube to master cylinder assembly, and hand-

tighten flare nut.

2. Install master cylinder assembly to vehicle, and tighten mount-

ing nuts to the specified torque.

: 11 - 14 N´m (1.1 - 1.5 kg-m,8-10ft-lb)

3. Tighten clutch tube flare nut using a flare nut torque wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

4. After installing clevis pin, install snap pin to connect clutch

pedal to push rod.

5. After finishing the operation, bleed air from clutch piping con-

nector and operating cylinder. (Refer to ªAir Bleeding

Procedureº, CL-10.)

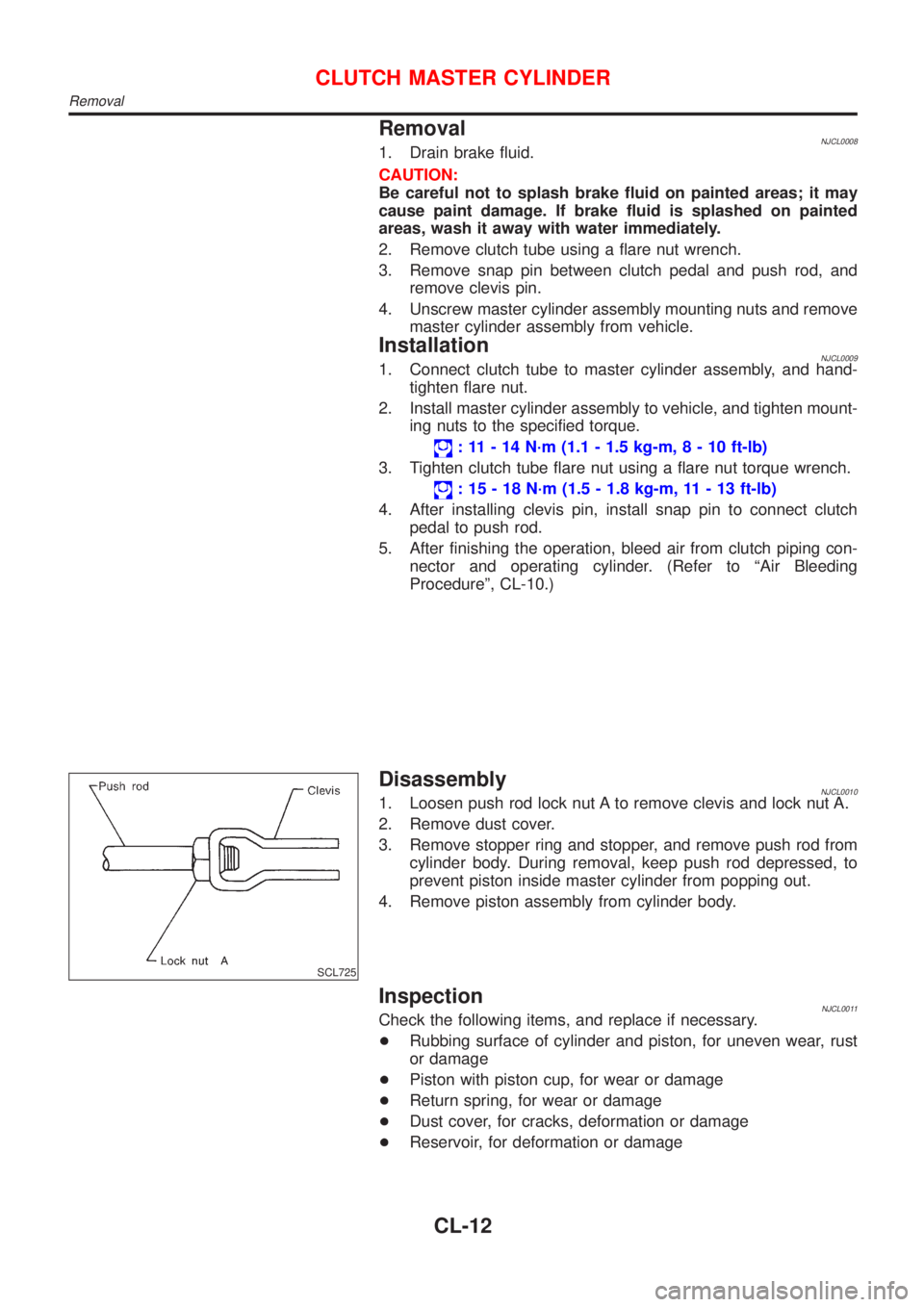

SCL725

DisassemblyNJCL00101. Loosen push rod lock nut A to remove clevis and lock nut A.

2. Remove dust cover.

3. Remove stopper ring and stopper, and remove push rod from

cylinder body. During removal, keep push rod depressed, to

prevent piston inside master cylinder from popping out.

4. Remove piston assembly from cylinder body.

InspectionNJCL0011Check the following items, and replace if necessary.

+Rubbing surface of cylinder and piston, for uneven wear, rust

or damage

+Piston with piston cup, for wear or damage

+Return spring, for wear or damage

+Dust cover, for cracks, deformation or damage

+Reservoir, for deformation or damage

CLUTCH MASTER CYLINDER

Removal

CL-12

Page 713 of 2898

AssemblyNJCL00121. Apply rubber lubricant to the sliding part of piston assembly,

and insert piston assembly.

2. After installing stopper to push rod, install stopper ring while

keeping piston assembly depressed by hand, so that piston

assembly will not pop out.

CAUTION:

Stopper ring cannot be reused. Always use a new stopper ring

for assembly.

3. Install dust cover.

4. Install clevis to push rod, and tighten lock nut A to the speci-

fied torque.

:8-10N´m(0.8 - 1.1 kg-m, 70 - 95 in-lb)

5. Install spring pin using a pin punch.

CLUTCH MASTER CYLINDER

Assembly

CL-13

Page 716 of 2898

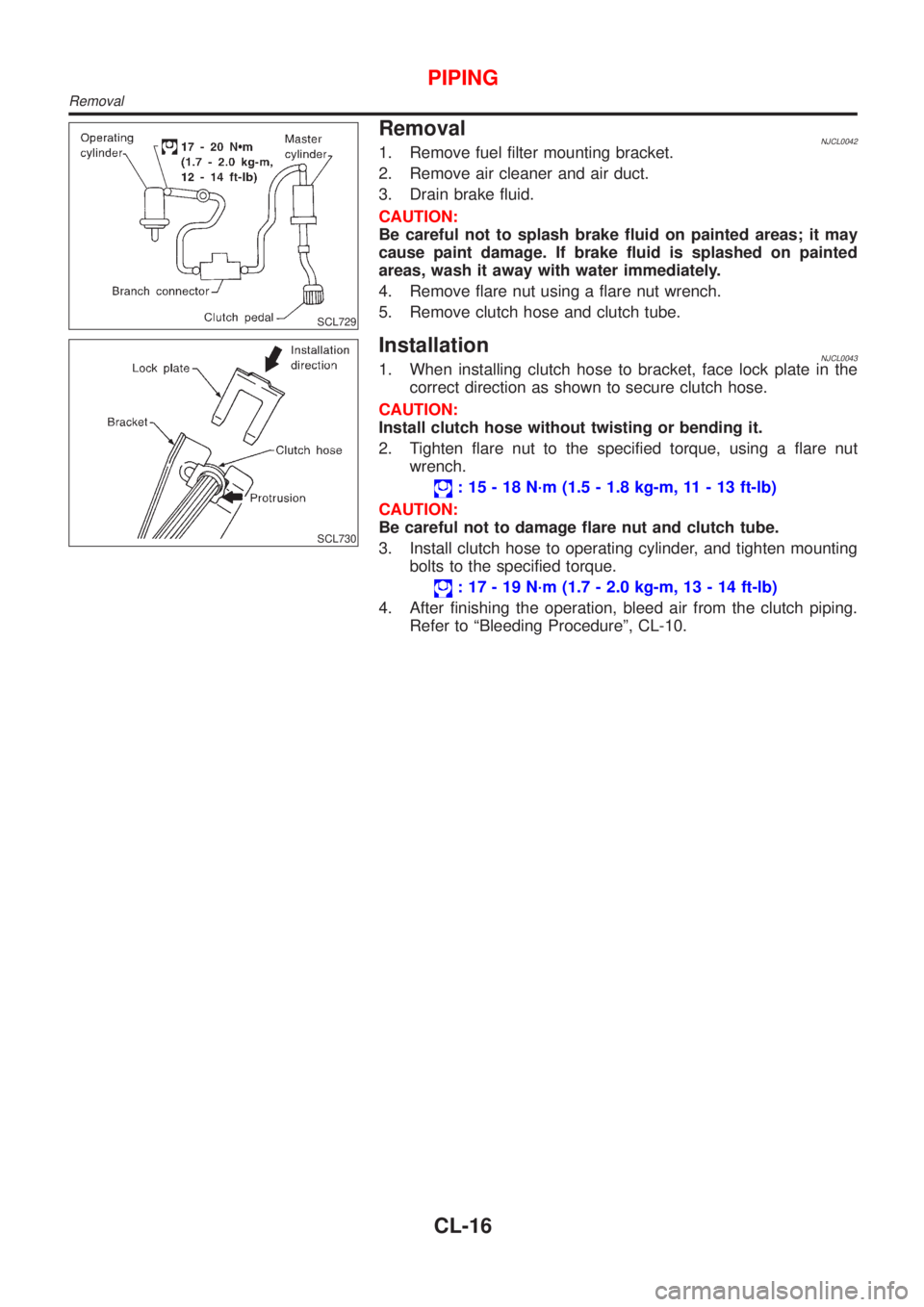

SCL729

RemovalNJCL00421. Remove fuel filter mounting bracket.

2. Remove air cleaner and air duct.

3. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

4. Remove flare nut using a flare nut wrench.

5. Remove clutch hose and clutch tube.

SCL730

InstallationNJCL00431. When installing clutch hose to bracket, face lock plate in the

correct direction as shown to secure clutch hose.

CAUTION:

Install clutch hose without twisting or bending it.

2. Tighten flare nut to the specified torque, using a flare nut

wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

CAUTION:

Be careful not to damage flare nut and clutch tube.

3. Install clutch hose to operating cylinder, and tighten mounting

bolts to the specified torque.

: 17 - 19 N´m (1.7 - 2.0 kg-m, 13 - 14 ft-lb)

4. After finishing the operation, bleed air from the clutch piping.

Refer to ªBleeding Procedureº, CL-10.

PIPING

Removal

CL-16

Page 743 of 2898

SEF605X

+Do not operate fuel pump when there is no fuel in lines.

+Tighten fuel hose clamps to the specified torque.

SEF709Y

+Do not depress accelerator pedal when starting.

+Immediately after starting, do not rev up engine unneces-

sarily.

+Do not rev up engine just prior to shutdown.

SEF708Y

+When installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

1)Keep the antenna as far as possible from the electronic

control units.

2)Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

3)Adjust the antenna and feeder line so that the standing-

wave ratio can be kept smaller.

4)Be sure to ground the radio to vehicle body.

Wiring Diagrams and Trouble DiagnosisNJEC0006When you read Wiring diagrams, refer to the following:

+GI-11, ªHOW TO READ WIRING DIAGRAMSº

+EL-10, ªPOWER SUPPLY ROUTINGº for power distribution

circuit

When you perform trouble diagnosis, refer to the following:

+GI-31, ªHOW TO FOLLOW TEST GROUP IN TROUBLE

DIAGNOSISº

+GI-21, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENTº

PRECAUTIONSQG

Engine Fuel & Emission Control System (Cont'd)

EC-19

Page 764 of 2898

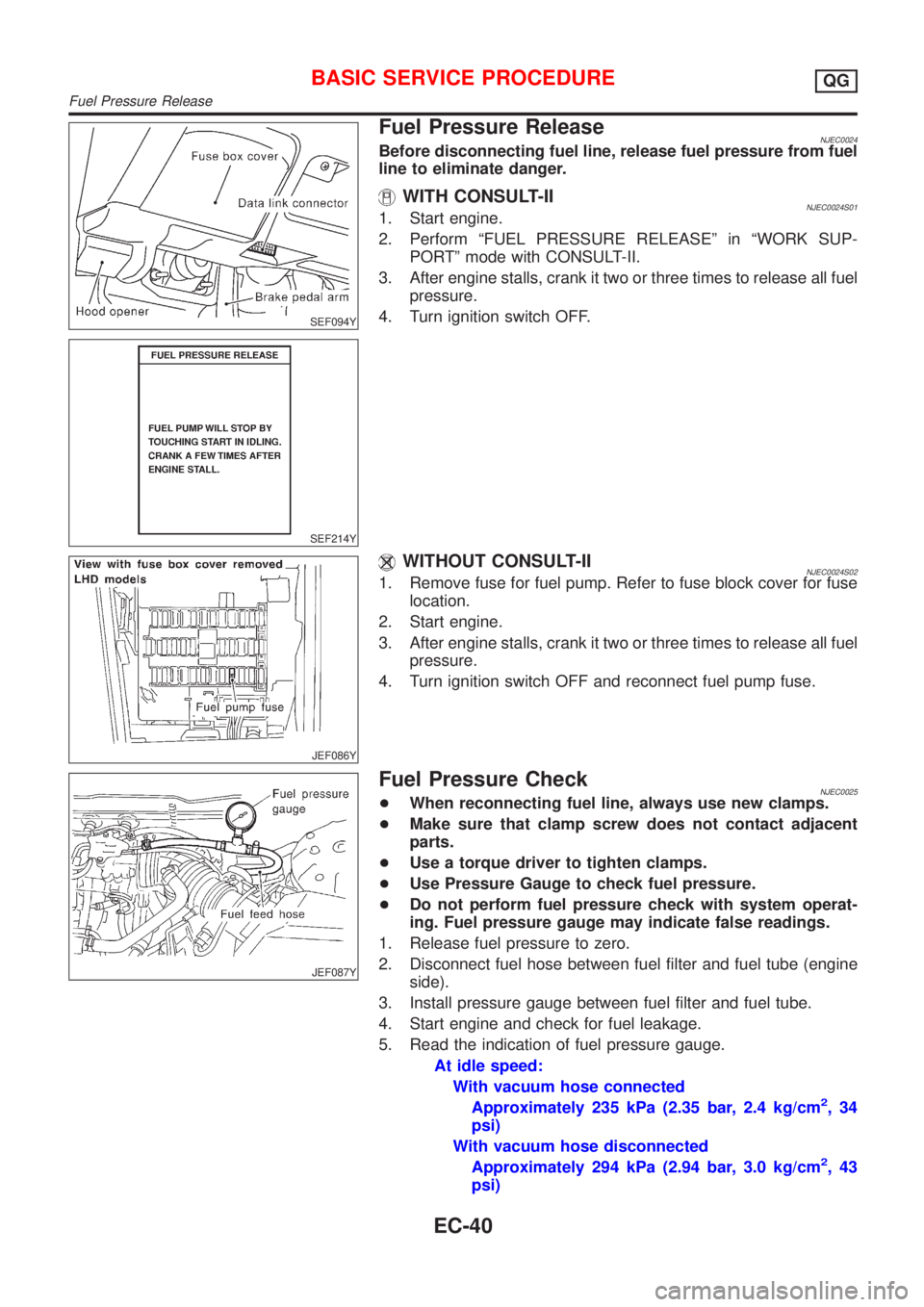

SEF094Y

SEF214Y

Fuel Pressure ReleaseNJEC0024Before disconnecting fuel line, release fuel pressure from fuel

line to eliminate danger.

WITH CONSULT-IINJEC0024S011. Start engine.

2. Perform ªFUEL PRESSURE RELEASEº in ªWORK SUP-

PORTº mode with CONSULT-II.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF.

JEF086Y

WITHOUT CONSULT-IINJEC0024S021. Remove fuse for fuel pump. Refer to fuse block cover for fuse

location.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch OFF and reconnect fuel pump fuse.

JEF087Y

Fuel Pressure CheckNJEC0025+When reconnecting fuel line, always use new clamps.

+Make sure that clamp screw does not contact adjacent

parts.

+Use a torque driver to tighten clamps.

+Use Pressure Gauge to check fuel pressure.

+Do not perform fuel pressure check with system operat-

ing. Fuel pressure gauge may indicate false readings.

1. Release fuel pressure to zero.

2. Disconnect fuel hose between fuel filter and fuel tube (engine

side).

3. Install pressure gauge between fuel filter and fuel tube.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

At idle speed:

With vacuum hose connected

Approximately 235 kPa (2.35 bar, 2.4 kg/cm

2,34

psi)

With vacuum hose disconnected

Approximately 294 kPa (2.94 bar, 3.0 kg/cm

2,43

psi)

BASIC SERVICE PROCEDUREQG

Fuel Pressure Release

EC-40

Page 766 of 2898

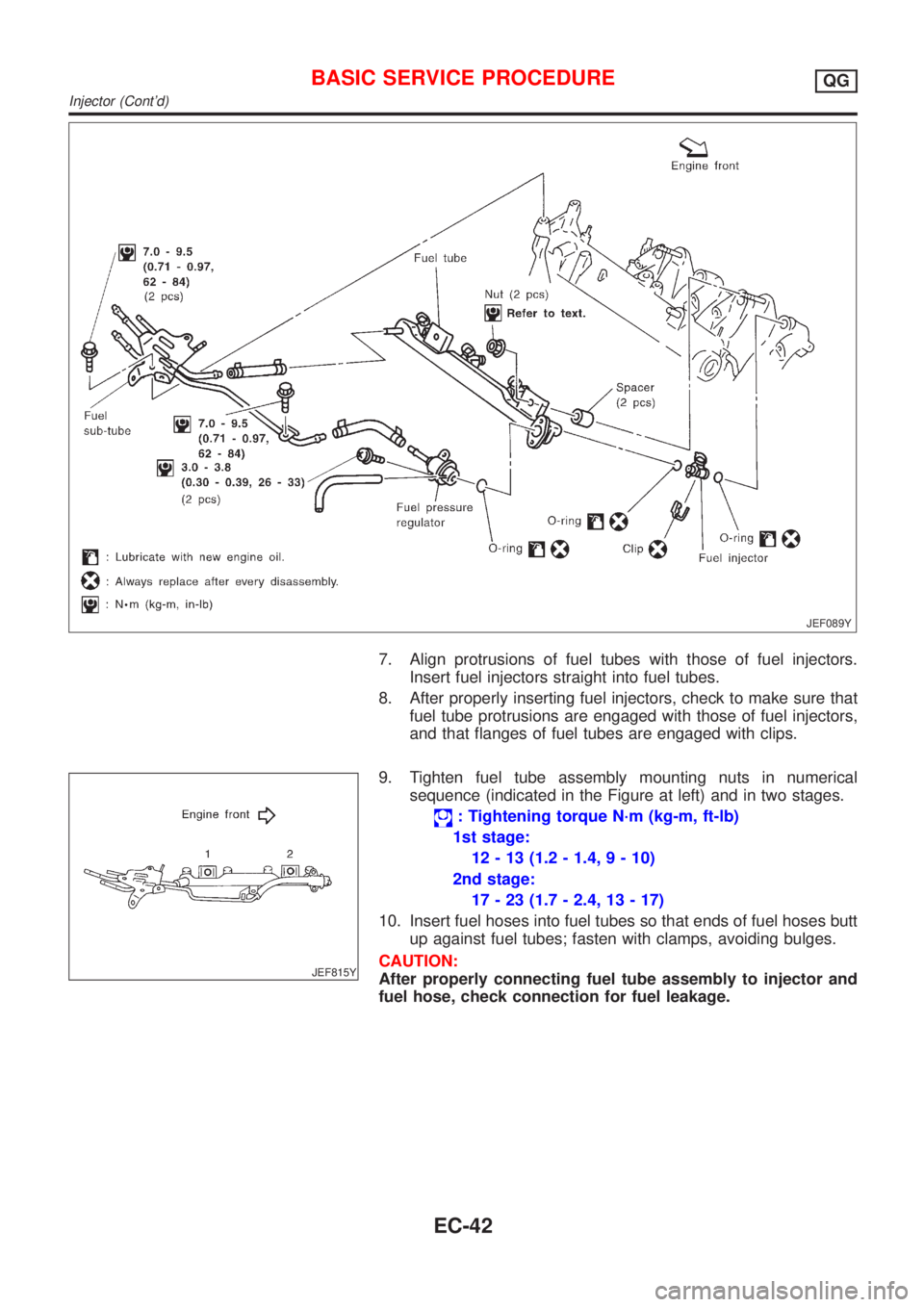

JEF089Y

7. Align protrusions of fuel tubes with those of fuel injectors.

Insert fuel injectors straight into fuel tubes.

8. After properly inserting fuel injectors, check to make sure that

fuel tube protrusions are engaged with those of fuel injectors,

and that flanges of fuel tubes are engaged with clips.

JEF815Y

9. Tighten fuel tube assembly mounting nuts in numerical

sequence (indicated in the Figure at left) and in two stages.

: Tightening torque N´m (kg-m, ft-lb)

1st stage:

12 - 13 (1.2 - 1.4, 9 - 10)

2nd stage:

17 - 23 (1.7 - 2.4, 13 - 17)

10. Insert fuel hoses into fuel tubes so that ends of fuel hoses butt

up against fuel tubes; fasten with clamps, avoiding bulges.

CAUTION:

After properly connecting fuel tube assembly to injector and

fuel hose, check connection for fuel leakage.

BASIC SERVICE PROCEDUREQG

Injector (Cont'd)

EC-42

Page 950 of 2898

7) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-226.

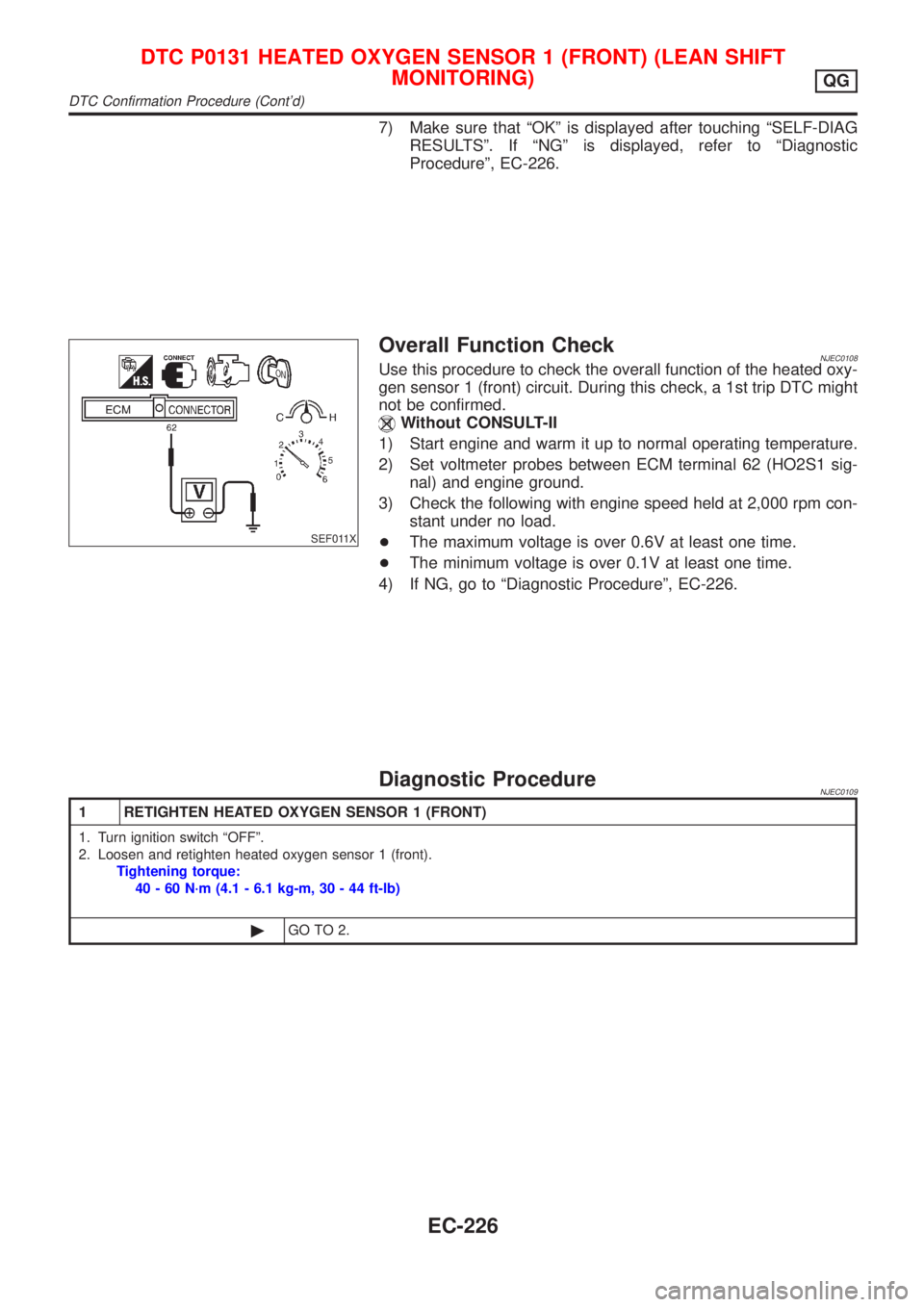

SEF011X

Overall Function CheckNJEC0108Use this procedure to check the overall function of the heated oxy-

gen sensor 1 (front) circuit. During this check, a 1st trip DTC might

not be confirmed.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (HO2S1 sig-

nal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

+The maximum voltage is over 0.6V at least one time.

+The minimum voltage is over 0.1V at least one time.

4) If NG, go to ªDiagnostic Procedureº, EC-226.

Diagnostic ProcedureNJEC0109

1 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

1. Turn ignition switch ªOFFº.

2. Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40 - 60 N´m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 2.

DTC P0131 HEATED OXYGEN SENSOR 1 (FRONT) (LEAN SHIFT

MONITORING)

QG

DTC Confirmation Procedure (Cont'd)

EC-226

Page 956 of 2898

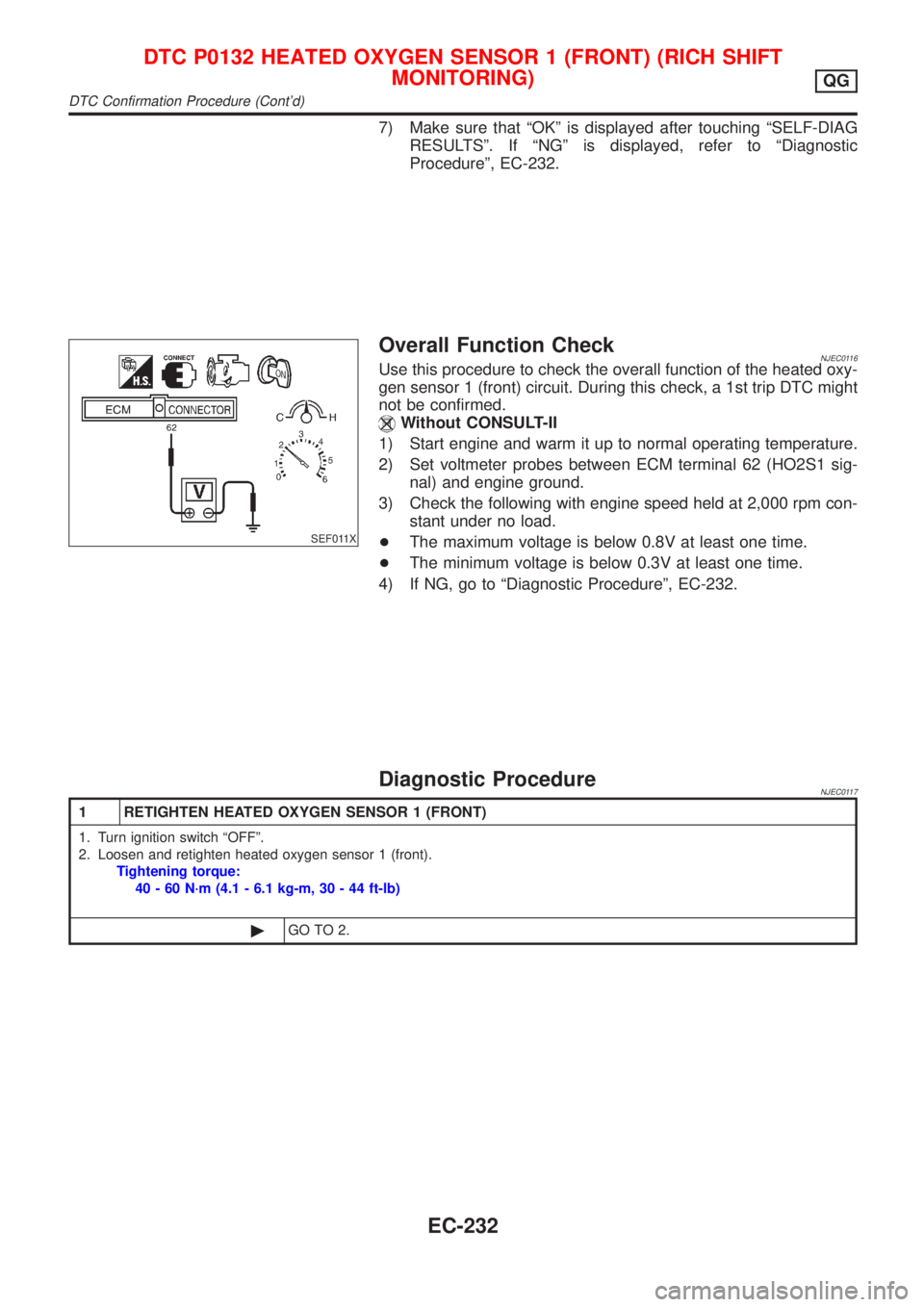

7) Make sure that ªOKº is displayed after touching ªSELF-DIAG

RESULTSº. If ªNGº is displayed, refer to ªDiagnostic

Procedureº, EC-232.

SEF011X

Overall Function CheckNJEC0116Use this procedure to check the overall function of the heated oxy-

gen sensor 1 (front) circuit. During this check, a 1st trip DTC might

not be confirmed.

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (HO2S1 sig-

nal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

+The maximum voltage is below 0.8V at least one time.

+The minimum voltage is below 0.3V at least one time.

4) If NG, go to ªDiagnostic Procedureº, EC-232.

Diagnostic ProcedureNJEC0117

1 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

1. Turn ignition switch ªOFFº.

2. Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40 - 60 N´m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 2.

DTC P0132 HEATED OXYGEN SENSOR 1 (FRONT) (RICH SHIFT

MONITORING)

QG

DTC Confirmation Procedure (Cont'd)

EC-232

Page 965 of 2898

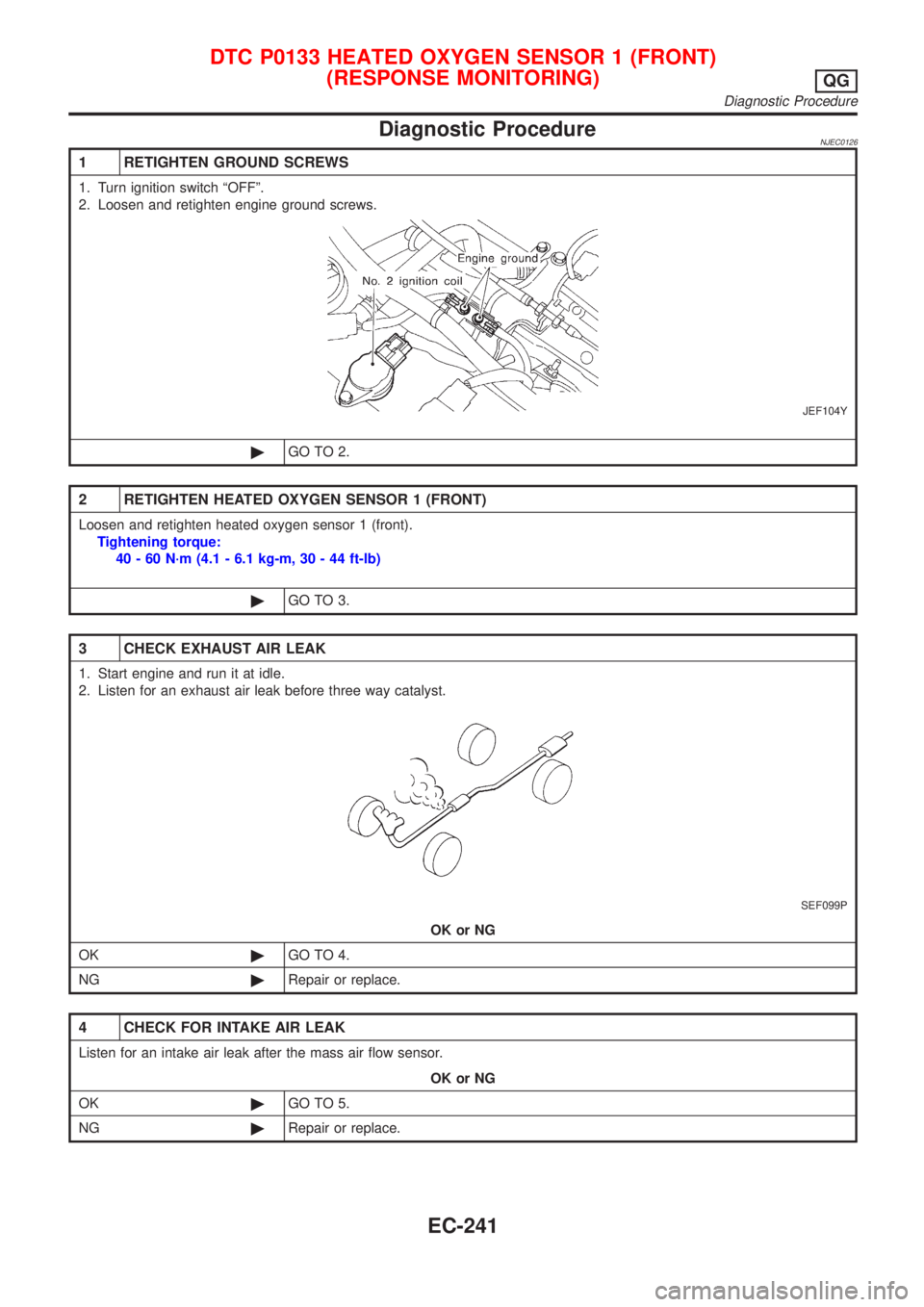

Diagnostic ProcedureNJEC0126

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

©GO TO 2.

2 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten heated oxygen sensor 1 (front).

Tightening torque:

40 - 60 N´m (4.1 - 6.1 kg-m, 30 - 44 ft-lb)

©GO TO 3.

3 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before three way catalyst.

SEF099P

OK or NG

OK©GO TO 4.

NG©Repair or replace.

4 CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 5.

NG©Repair or replace.

DTC P0133 HEATED OXYGEN SENSOR 1 (FRONT)

(RESPONSE MONITORING)

QG

Diagnostic Procedure

EC-241