NISSAN ALMERA 2001 Manual Online

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 81 of 2898

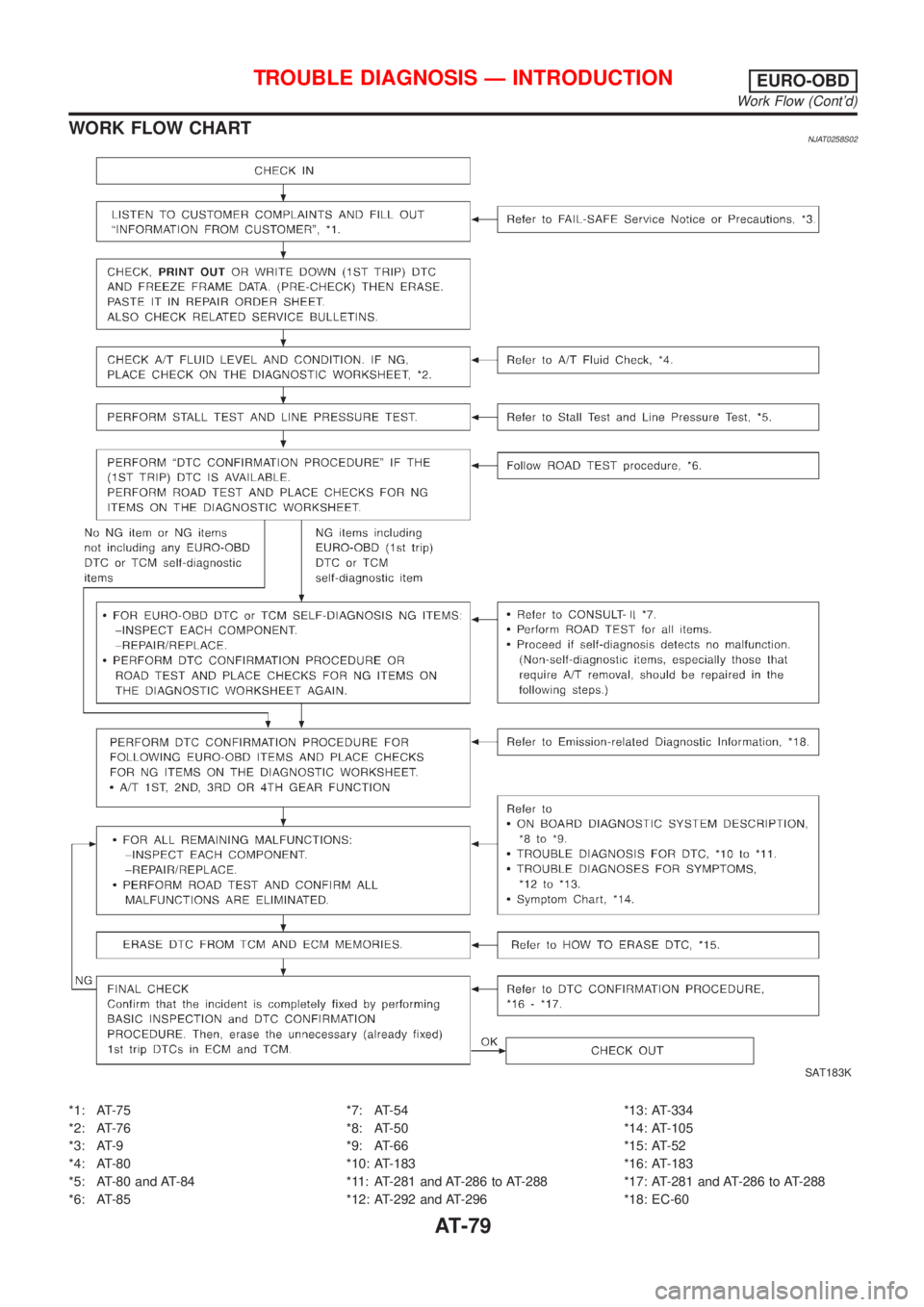

WORK FLOW CHARTNJAT0258S02

SAT183K

*1: AT-75

*2: AT-76

*3: AT-9

*4: AT-80

*5: AT-80 and AT-84

*6: AT-85*7: AT-54

*8: AT-50

*9: AT-66

*10: AT-183

*11: AT-281 and AT-286 to AT-288

*12: AT-292 and AT-296*13: AT-334

*14: AT-105

*15: AT-52

*16: AT-183

*17: AT-281 and AT-286 to AT-288

*18: EC-60

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Work Flow (Cont'd)

AT-79

Page 82 of 2898

SAT767B

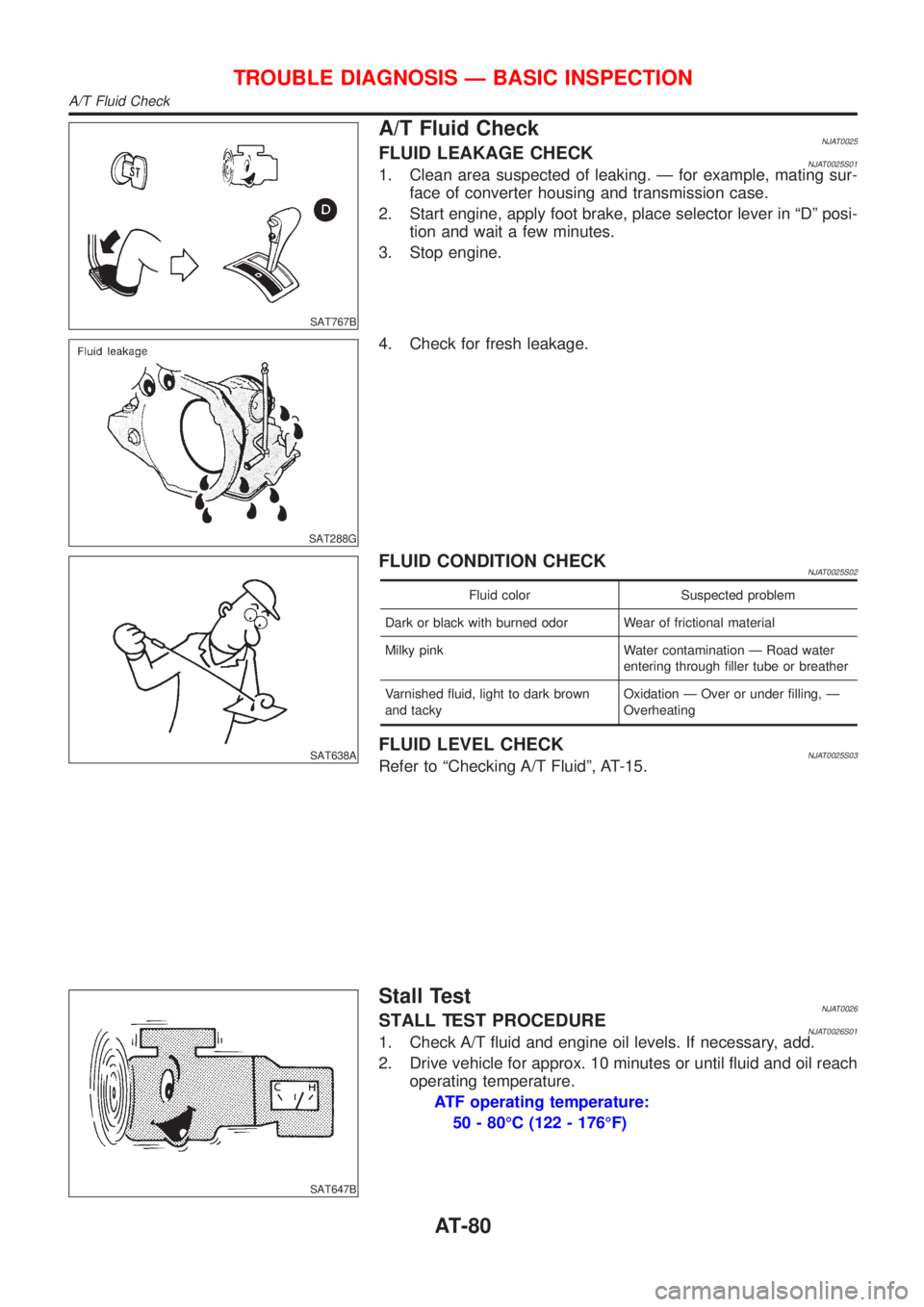

A/T Fluid CheckNJAT0025FLUID LEAKAGE CHECKNJAT0025S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

SAT288G

4. Check for fresh leakage.

SAT638A

FLUID CONDITION CHECKNJAT0025S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNJAT0025S03Refer to ªChecking A/T Fluidº, AT-15.

SAT647B

Stall TestNJAT0026STALL TEST PROCEDURENJAT0026S011. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

A/T Fluid Check

AT-80

Page 83 of 2898

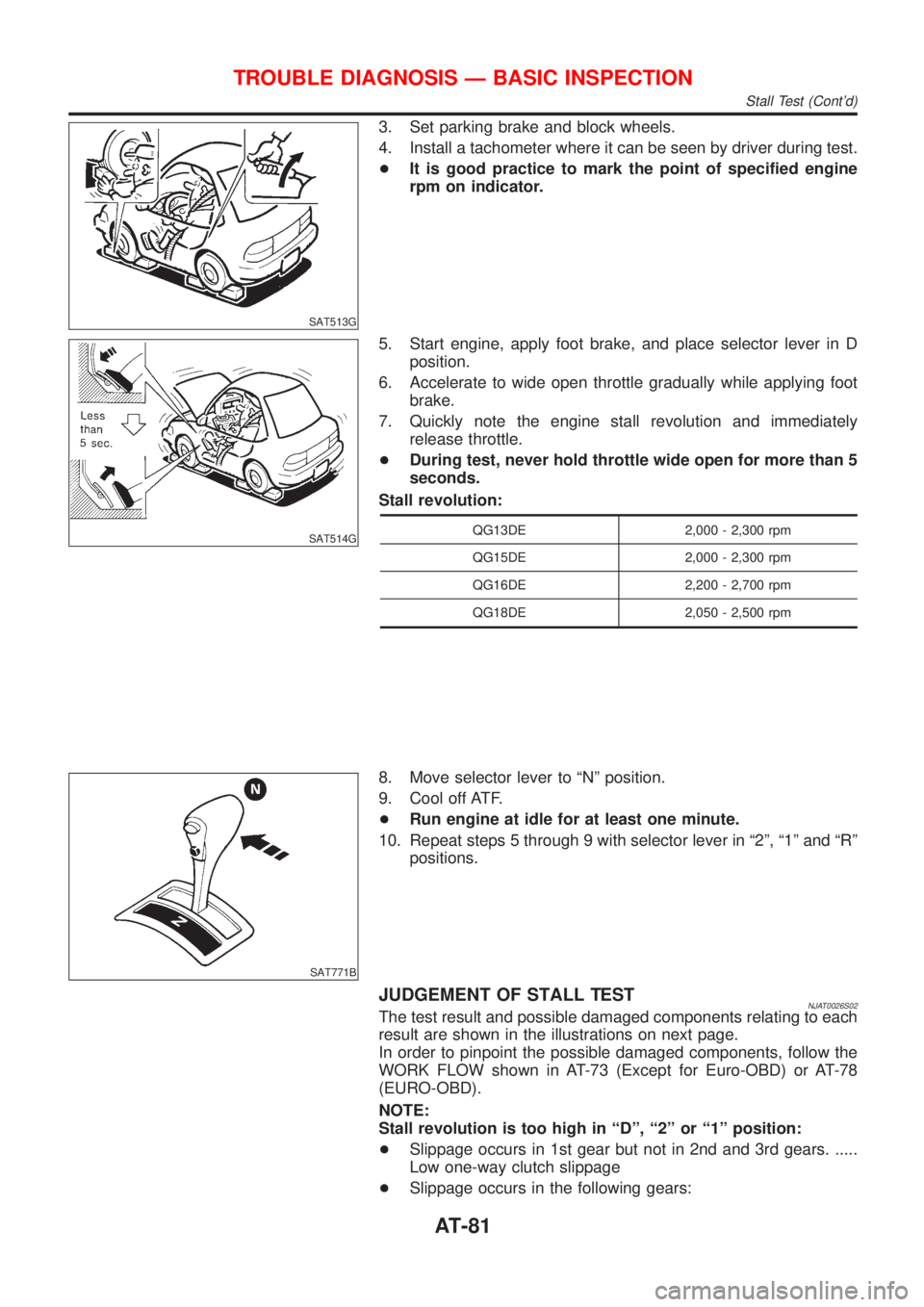

SAT513G

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

+It is good practice to mark the point of specified engine

rpm on indicator.

SAT514G

5. Start engine, apply foot brake, and place selector lever in D

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

+During test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

QG13DE 2,000 - 2,300 rpm

QG15DE 2,000 - 2,300 rpm

QG16DE 2,200 - 2,700 rpm

QG18DE 2,050 - 2,500 rpm

SAT771B

8. Move selector lever to ªNº position.

9. Cool off ATF.

+Run engine at idle for at least one minute.

10. Repeat steps 5 through 9 with selector lever in ª2º, ª1º and ªRº

positions.

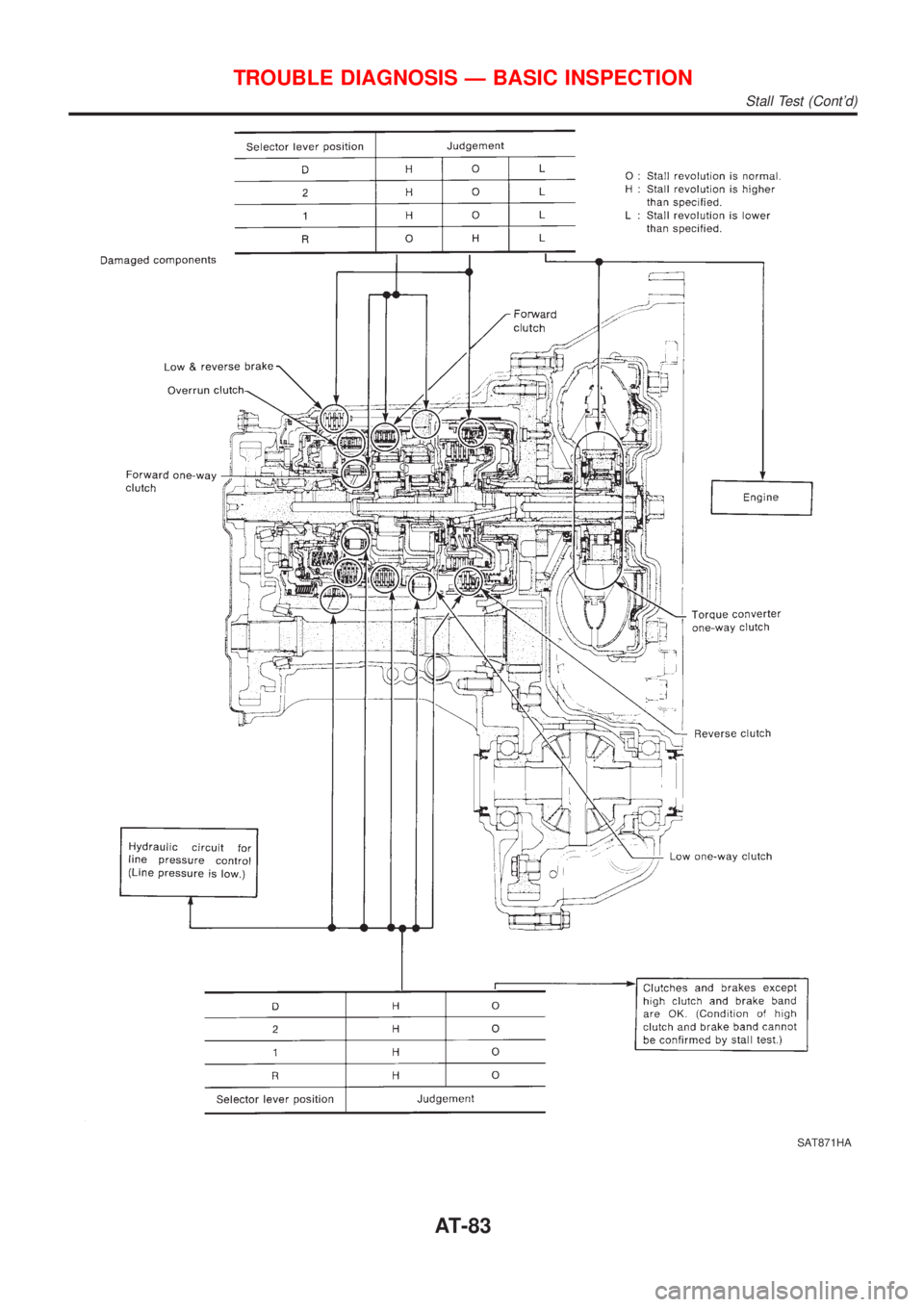

JUDGEMENT OF STALL TESTNJAT0026S02The test result and possible damaged components relating to each

result are shown in the illustrations on next page.

In order to pinpoint the possible damaged components, follow the

WORK FLOW shown in AT-73 (Except for Euro-OBD) or AT-78

(EURO-OBD).

NOTE:

Stall revolution is too high in ªDº, ª2º or ª1º position:

+Slippage occurs in 1st gear but not in 2nd and 3rd gears. .....

Low one-way clutch slippage

+Slippage occurs in the following gears:

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-81

Page 84 of 2898

1st through 3rd gears in ªDº position and engine brake func-

tions with overdrive control switch set to ªOFFº.

1st and 2nd gears in ª2º position and engine brake functions

with accelerator pedal released (fully closed throttle). ..... For-

ward clutch or forward one-way clutch slippage

Stall revolution is too high in R position:

+Engine brake does not function in ª1º position. ..... Low &

reverse brake slippage

+Engine brake functions in ª1º position. ..... Reverse clutch slip-

page

Stall revolution within specifications:

+Vehicle does not achieve speed of more than 80 km/h (50

MPH). ..... One-way clutch seizure in torque converter housing

CAUTION:

Be careful since automatic fluid temperature increases abnor-

mally.

+Slippage occurs in 3rd and 4th gears in ªDº position. ..... High

clutch slippage

+Slippage occurs in 2nd and 4th gear in ªDº position. ..... Brake

band slippage

+Engine brake does not function in 2nd and 3rd gears in ªDº

position, 2nd gear in ª2º position, and 1st gear in ª1º position

with overdrive control switch set to ªOFFº.

Stall revolution less than specifications:

+Poor acceleration during starts. ..... One-way clutch seizure in

torque converter

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-82

Page 85 of 2898

SAT871HA

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-83

Page 86 of 2898

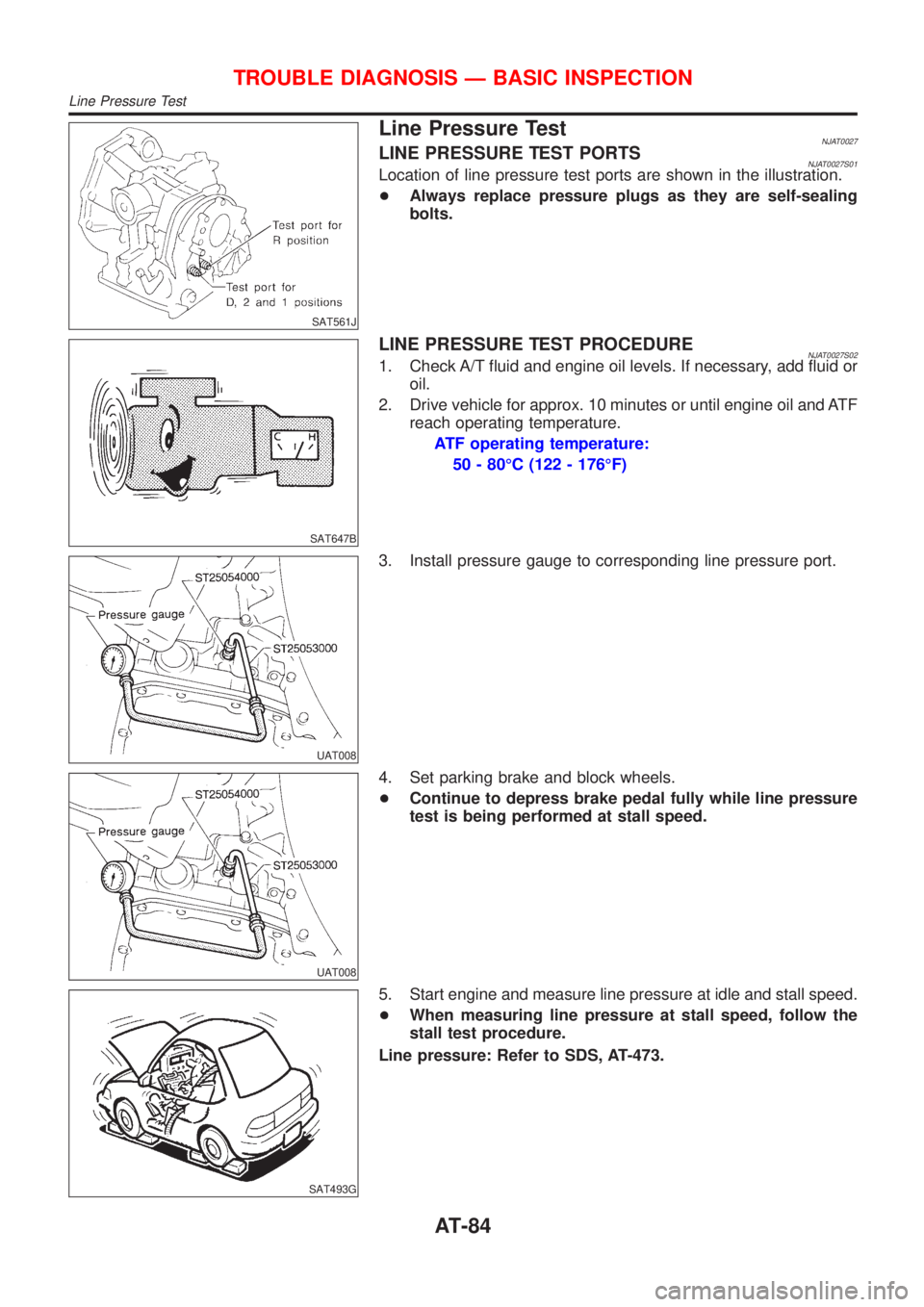

SAT561J

Line Pressure TestNJAT0027LINE PRESSURE TEST PORTSNJAT0027S01Location of line pressure test ports are shown in the illustration.

+Always replace pressure plugs as they are self-sealing

bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENJAT0027S021. Check A/T fluid and engine oil levels. If necessary, add fluid or

oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and ATF

reach operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

UAT008

3. Install pressure gauge to corresponding line pressure port.

UAT008

4. Set parking brake and block wheels.

+Continue to depress brake pedal fully while line pressure

test is being performed at stall speed.

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

+When measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer to SDS, AT-473.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test

AT-84

Page 87 of 2898

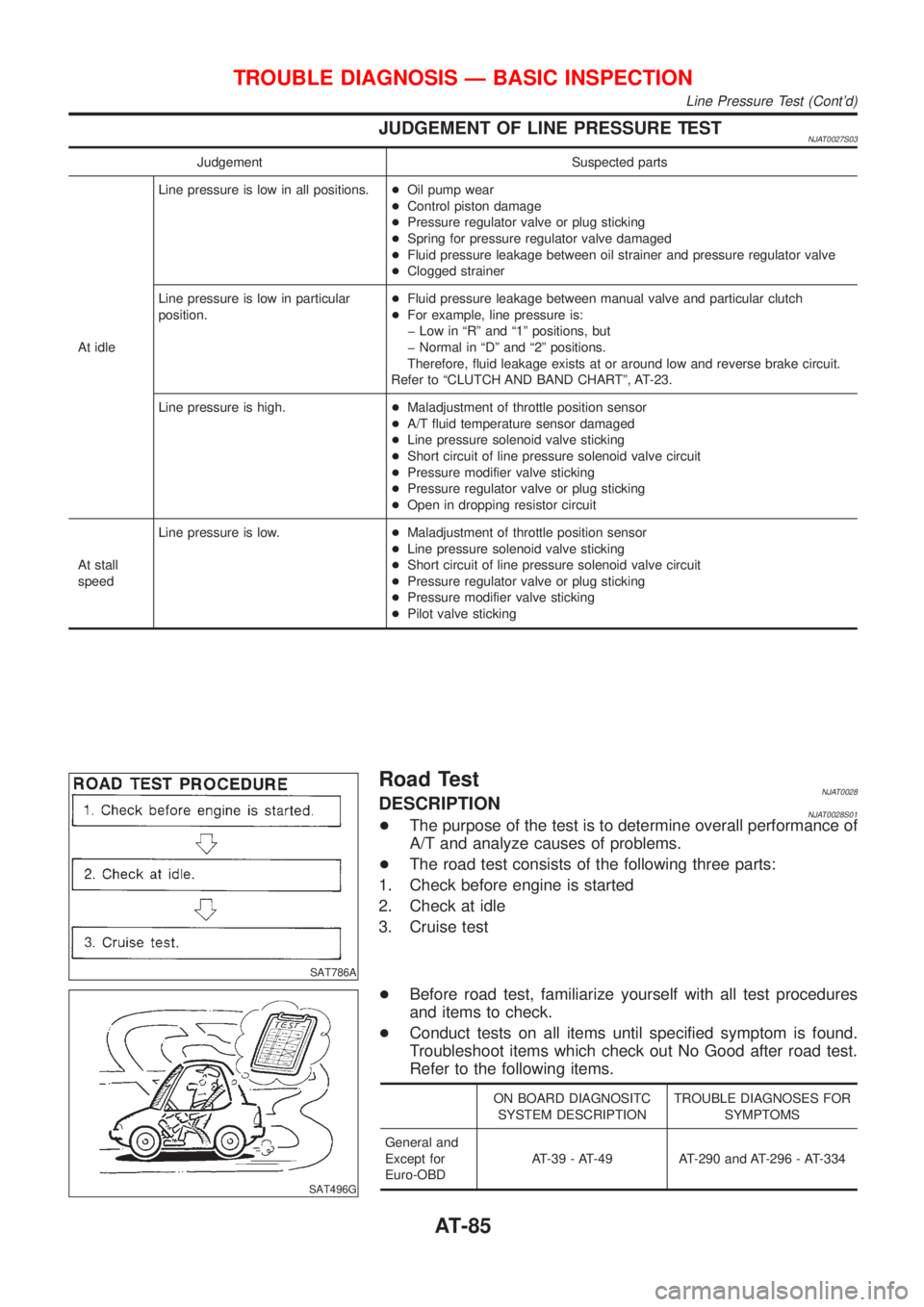

JUDGEMENT OF LINE PRESSURE TESTNJAT0027S03

Judgement Suspected parts

At idleLine pressure is low in all positions.+Oil pump wear

+Control piston damage

+Pressure regulator valve or plug sticking

+Spring for pressure regulator valve damaged

+Fluid pressure leakage between oil strainer and pressure regulator valve

+Clogged strainer

Line pressure is low in particular

position.+Fluid pressure leakage between manual valve and particular clutch

+For example, line pressure is:

þ Low in ªRº and ª1º positions, but

þ Normal in ªDº and ª2º positions.

Therefore, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-23.

Line pressure is high.+Maladjustment of throttle position sensor

+A/T fluid temperature sensor damaged

+Line pressure solenoid valve sticking

+Short circuit of line pressure solenoid valve circuit

+Pressure modifier valve sticking

+Pressure regulator valve or plug sticking

+Open in dropping resistor circuit

At stall

speedLine pressure is low.+Maladjustment of throttle position sensor

+Line pressure solenoid valve sticking

+Short circuit of line pressure solenoid valve circuit

+Pressure regulator valve or plug sticking

+Pressure modifier valve sticking

+Pilot valve sticking

SAT786A

Road TestNJAT0028DESCRIPTIONNJAT0028S01+The purpose of the test is to determine overall performance of

A/T and analyze causes of problems.

+The road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

SAT496G

+Before road test, familiarize yourself with all test procedures

and items to check.

+Conduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to the following items.

ON BOARD DIAGNOSITC

SYSTEM DESCRIPTIONTROUBLE DIAGNOSES FOR

SYMPTOMS

General and

Except for

Euro-OBDAT-39 - AT-49 AT-290 and AT-296 - AT-334

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-85

Page 88 of 2898

ON BOARD DIAGNOSITC

SYSTEM DESCRIPTIONTROUBLE DIAGNOSES FOR

SYMPTOMS

EURO-OBD AT-50 - AT-66 AT-292 and AT-296 - AT-334

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-86

Page 89 of 2898

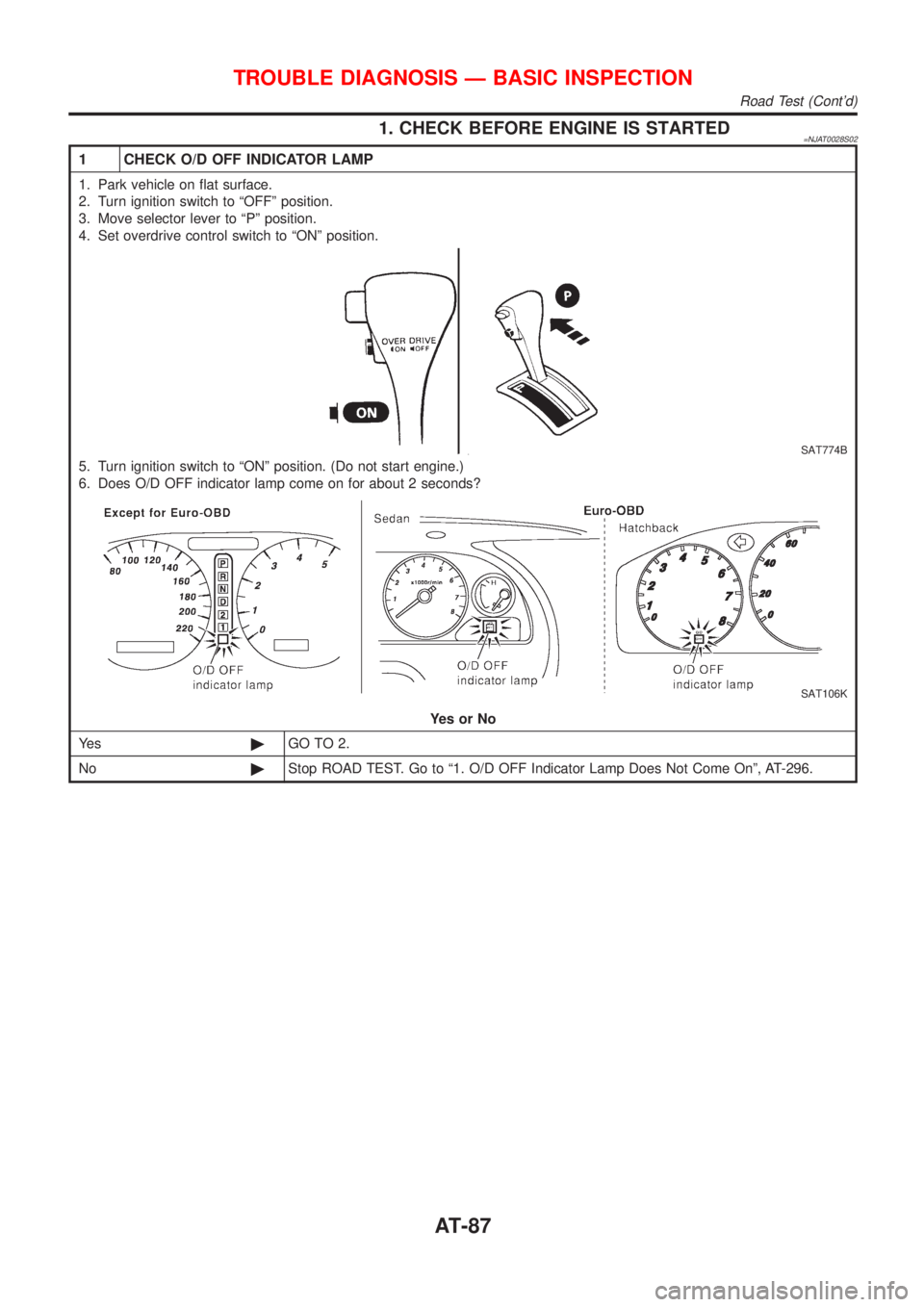

1. CHECK BEFORE ENGINE IS STARTED=NJAT0028S02

1 CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Turn ignition switch to ªOFFº position.

3. Move selector lever to ªPº position.

4. Set overdrive control switch to ªONº position.

SAT774B

5. Turn ignition switch to ªONº position. (Do not start engine.)

6. Does O/D OFF indicator lamp come on for about 2 seconds?

SAT106K

YesorNo

Ye s©GO TO 2.

No©Stop ROAD TEST. Go to ª1. O/D OFF Indicator Lamp Does Not Come Onº, AT-296.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-87

Page 90 of 2898

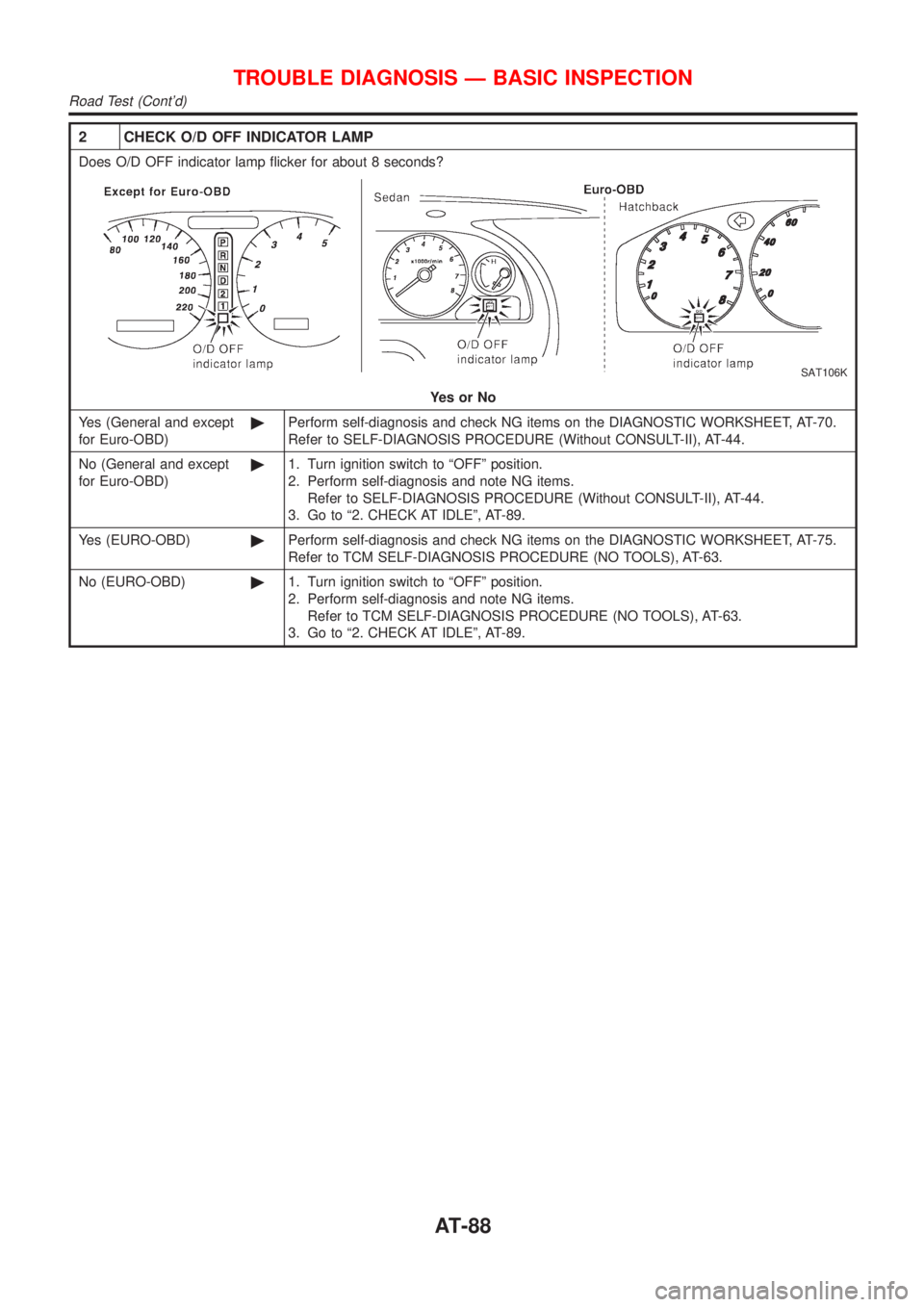

2 CHECK O/D OFF INDICATOR LAMP

Does O/D OFF indicator lamp flicker for about 8 seconds?

SAT106K

YesorNo

Yes (General and except

for Euro-OBD)©Perform self-diagnosis and check NG items on the DIAGNOSTIC WORKSHEET, AT-70.

Refer to SELF-DIAGNOSIS PROCEDURE (Without CONSULT-II), AT-44.

No (General and except

for Euro-OBD)©1. Turn ignition switch to ªOFFº position.

2. Perform self-diagnosis and note NG items.

Refer to SELF-DIAGNOSIS PROCEDURE (Without CONSULT-II), AT-44.

3. Go to ª2. CHECK AT IDLEº, AT-89.

Yes (EURO-OBD)©Perform self-diagnosis and check NG items on the DIAGNOSTIC WORKSHEET, AT-75.

Refer to TCM SELF-DIAGNOSIS PROCEDURE (NO TOOLS), AT-63.

No (EURO-OBD)©1. Turn ignition switch to ªOFFº position.

2. Perform self-diagnosis and note NG items.

Refer to TCM SELF-DIAGNOSIS PROCEDURE (NO TOOLS), AT-63.

3. Go to ª2. CHECK AT IDLEº, AT-89.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-88