panel NISSAN ALMERA N15 1995 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 783 of 1701

TROUBLEDIAGNOSIS -General Description

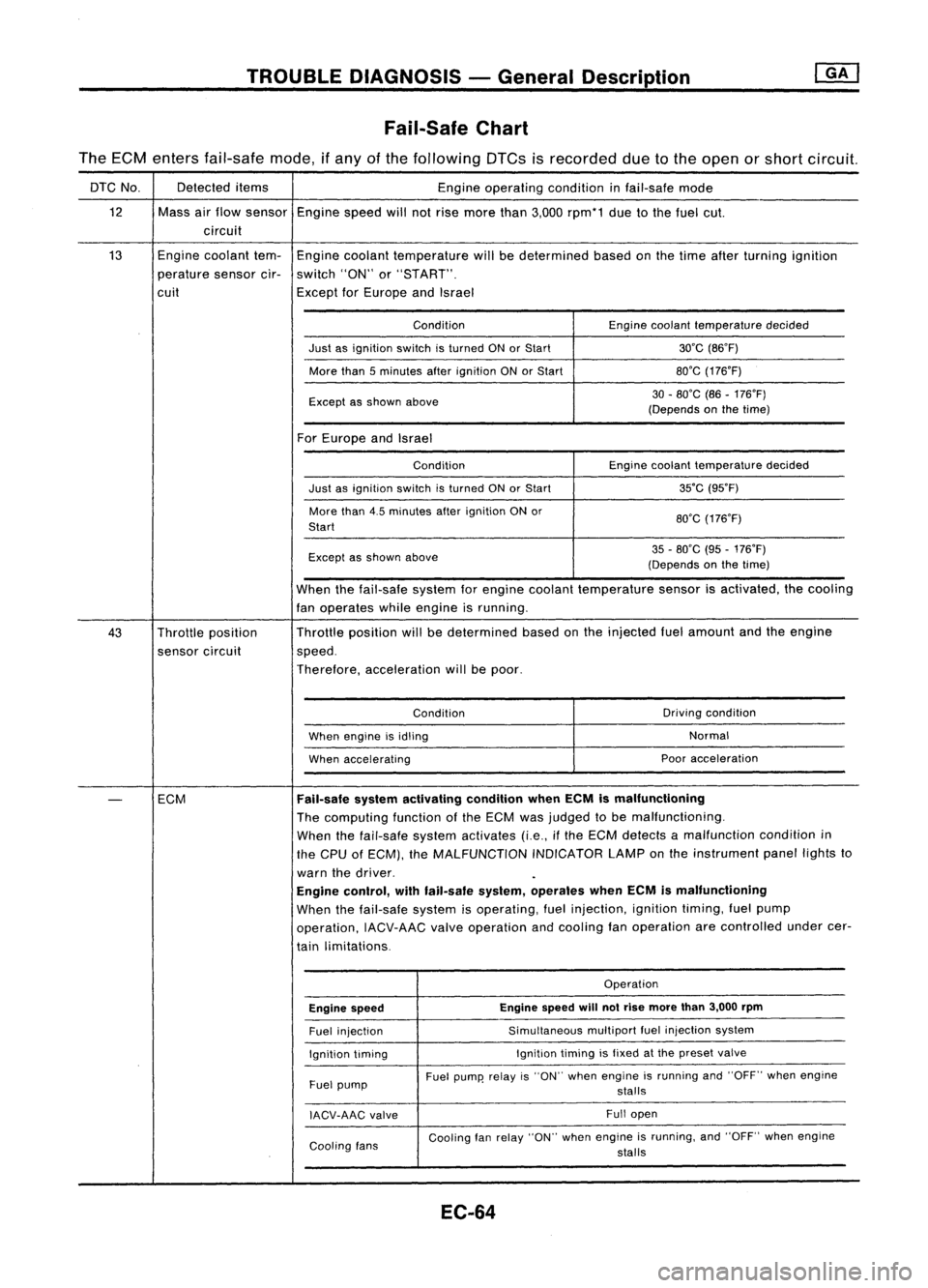

Fail-Safe Chart

The ECM enters fail-safe mode,ifany ofthe following DTCsisrecorded duetothe open orshort circuit.

DTC No. Detected

items

Engineoperating conditioninfail-safe mode

12 Massairflow sensor

Enginespeedwillnotrise more than3,000 rpm*1 duetothe fuel cut.

circuit

13 Engine

coolant tem-

Engine coolant temperature willbedetermined basedonthe time after turning ignition

perature sensorcir-switch "ON"or"START".

cuit ExceptforEurope andIsrael

Condition Enginecoolant temperature decided

Just asignition switchisturned ONorStart 30'C(B6'F)

More than5minutes afterignition ONorStart BO'G

(176'F)

Except asshown above 30

-BO'C (B6-176'F)

(Depends onthe time)

For Europe andIsrael

Condition Enginecoolant temperature decided

Just asignition switchisturned ONorStart 35'C

(95'F)

More than4.5minutes afterignition ONor

BO'G(176'F)

Start

Except asshown above 35

-BO'C (95-176'F)

(Depends onthe time)

When thefail-safe systemforengine coolant temperature sensorisactivated, thecooling

fan operates whileengine isrunning.

43 Throttle position Throttle

position willbedetermined basedonthe injected fuelamount andtheengine

sensor circuit speed.

Therefore, acceleration willbepoor.

Condition Driving

condition

When engine isidling Normal

When accelerating Poor

acceleration

-

ECM

Fail-safe

systemactivating conditionwhenECMismalfunctioning

The computing functionofthe ECM wasjudged tobe malfunctioning.

When thefail-safe systemactivates (i.e.,ifthe ECM detects amalfunction conditionin

the CPU ofECM), theMALFUNCTION INDICATORLAMPonthe instrument panellightsto

warn thedriver.

Engine control, withfail-safe system,operates whenECMismalfunctioning

When thefail-safe systemisoperating, fuelinjection, ignitiontiming,fuelpump

operation, IACV-AACvalveoperation andcooling fanoperation arecontrolled undercer-

tain limitations.

Operation

Engine speed Engine

speed

will

notrise more than3,000 rpm

Fuel injection Simultaneous

multipartfuelinjection system

Ignition timing Ignition

timingisfixed atthe preset valve

Fuel pump Fuel

pump' relayis"ON" when engine isrunning and"OFF" whenengine

stalls

IACV-AAG valve Full

open

Cooling fans Cooling

fanrelay "ON" whenengine isrunning, and"OFF" whenengine

stalls

EC-64

Page 797 of 1701

TROUBLEDIAGNOSES -General Description

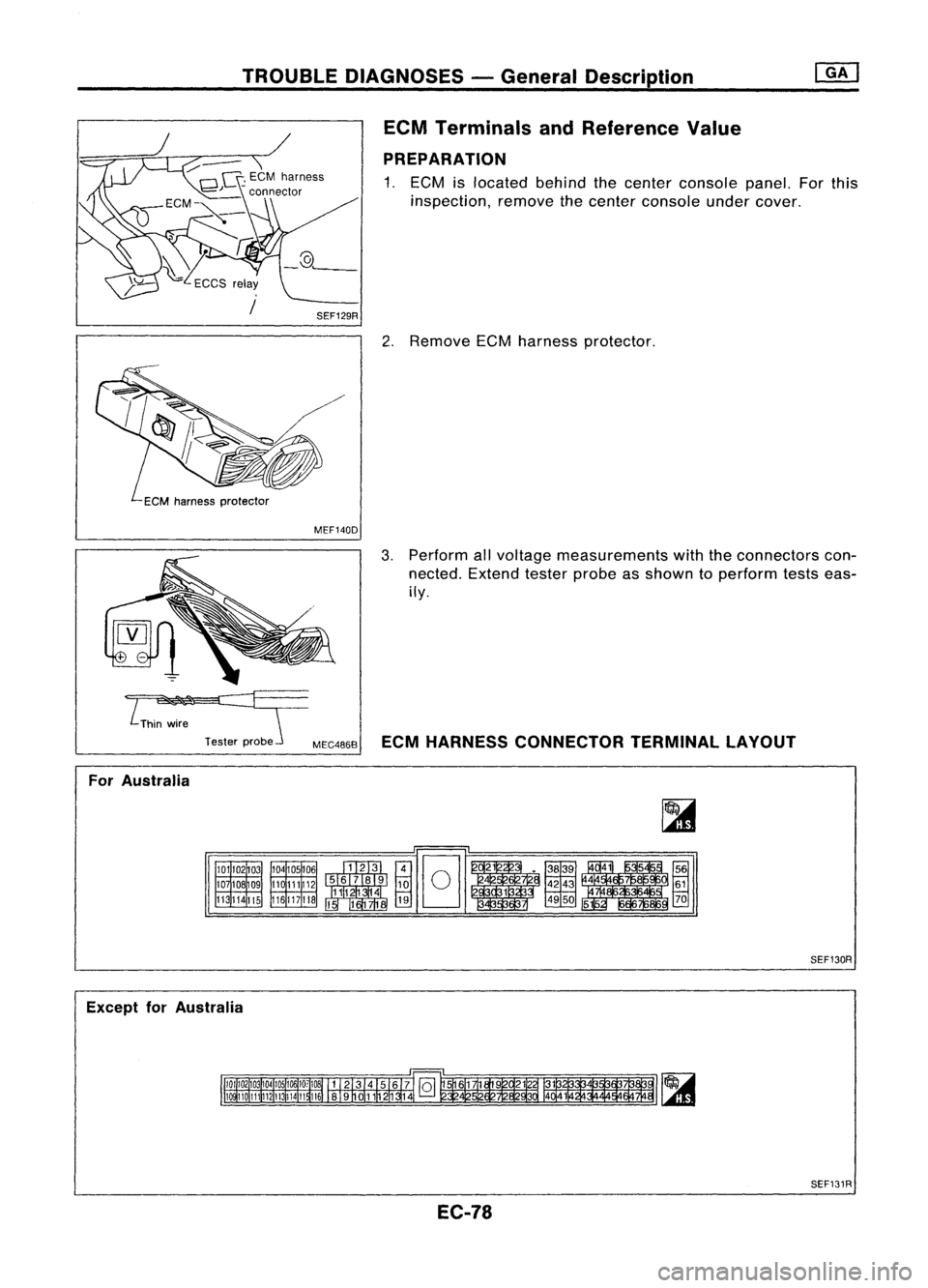

ECM Terminals andReference Value

PREPARATION

1. ECM islocated behindthecenter console panel.Forthis

inspection, removethecenter console undercover.

2. Remove ECMharness protector.

MEF140D

3.Perform allvoltage measurements withtheconnectors con-

nected. Extendtesterprobeasshown toperform testseas-

ily.

~~

Testerprobe

MEC4868ECMHARNESS CONNECTOR TERMINALLAYOUT

For Australia

101102

03

107

lOB

09

113 114

115

Except forAustralia

104

105106

110 111112

116 117

lIB

~

~1~9

@]8

1 .~~~~.41

i

i5~

3 1 4950 70

51

SEF130R

SEF131R

EC-78

Page 910 of 1701

2:

1

:>

Q)

Ol

~

0

>

::;

c.

::;

0

,,"--

0

-

Rich- Idealratio _

Lean

Mixlure ratio

SEF288D

•

Zirconia

tube SEF406H

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

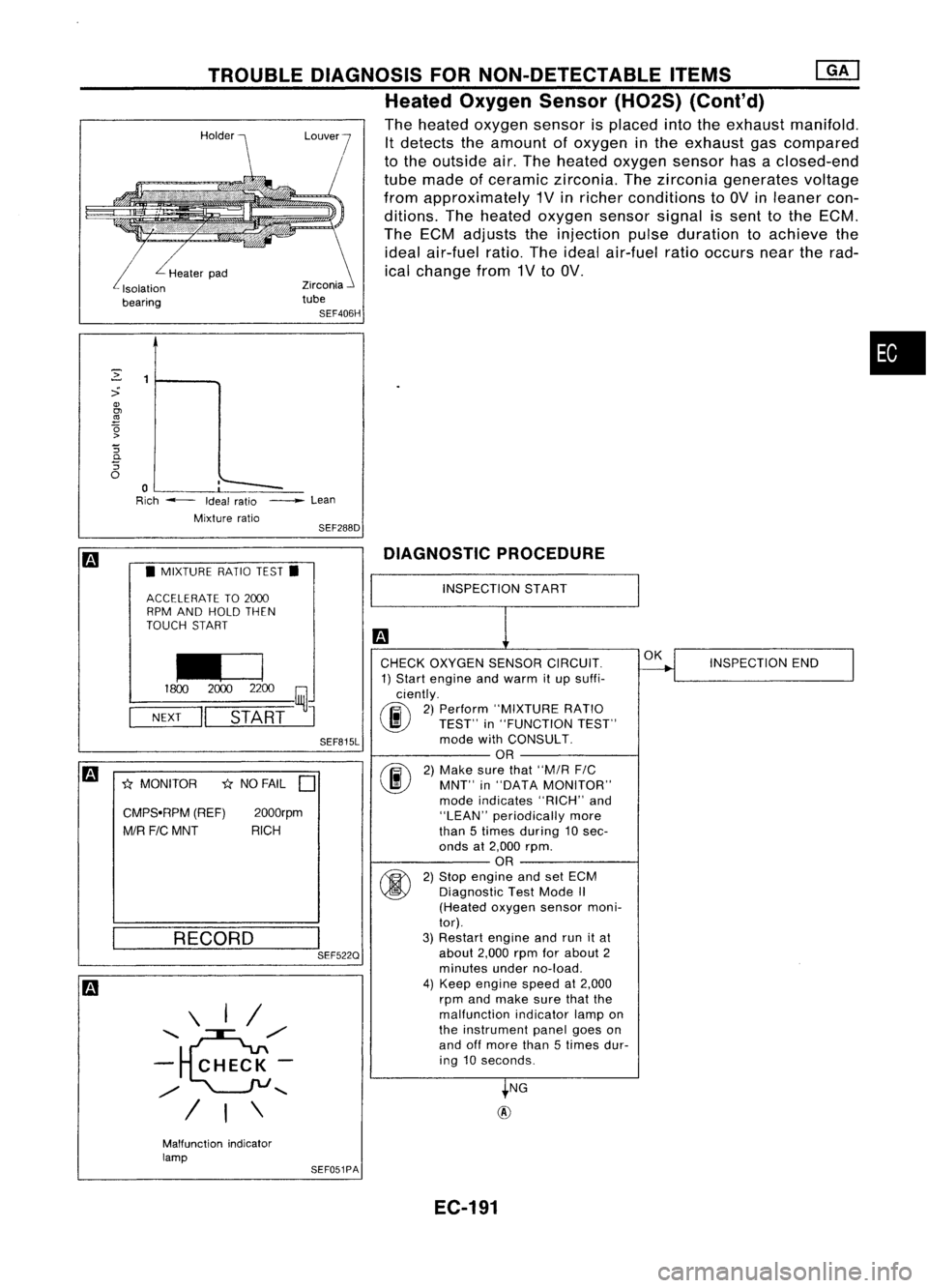

Heated Oxygen Sensor(H02S)(Cont'd)

The heated oxygen sensorisplaced intotheexhaust manifold.

It detects theamount ofoxygen inthe exhaust gascompared

to the outside air.The heated oxygen sensorhasaclosed-end

tube made ofceramic zirconia. Thezirconia generates voltage

from approximately 1Vinricher conditions to

av

inleaner con-

ditions. Theheated oxygen sensorsignalissent tothe ECM.

The ECM adjusts theinjection pulseduration toachieve the

ideal air-fuel ratio.Theideal air-fuel ratiooccurs neartherad-

ical change from1Vto

av.

L

Healerpad

Isolalion

bearing

m

•MIXTURE RATIOTEST.

ACCELERATE TO2000

RPM AND HOLD THEN

TOUCH START

I£J

1800

20002200

~J

NEXT

II

START

SEF815L

m

*

MONITOR

*

NO FAIL

D

CMPS.RPM (REF)2000rpm

MIR FICMNT RICH

DIAGNOSTIC

PROCEDURE

RECORD

\ I/

........ e",/

- CHECK-

",/

........

/ I\

I

SEF522Q

INSPECTION

START

CHECK OXYGEN SENSORCIRCUIT.

1) Start engine andwarm itup suffi-

ciently.

(F.i\

2)Perform "MIXTURE RATIO

~ TEST"in"FUNCTION TEST"

mode withCONSULT.

OR

(F.i\

2)Make surethat"M/R

FIC

~ MNT"in"DATA MONITOR"

mode indicates "RICH"and

"LEAN" periodically more

than 5times during 10 sec-

onds at2,000 rpm.

OR

fti>\

2)Stop engine andsetECM

~ Diagnostic TestMode

/I

(Heated oxygensensormoni-

tor).

3) Restart engineandrunitat

about 2,000rpmforabout 2

minutes underno-load.

4) Keep engine speedat2,000

rpm andmake surethatthe

malfunction indicatorlampon

the instrument panelgoeson

and offmore than5times dur-

ing 10seconds.

NG

@

OK

INSPECTION END

Malfunction indicator

lamp SEF051PA

EC-191

Page 915 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

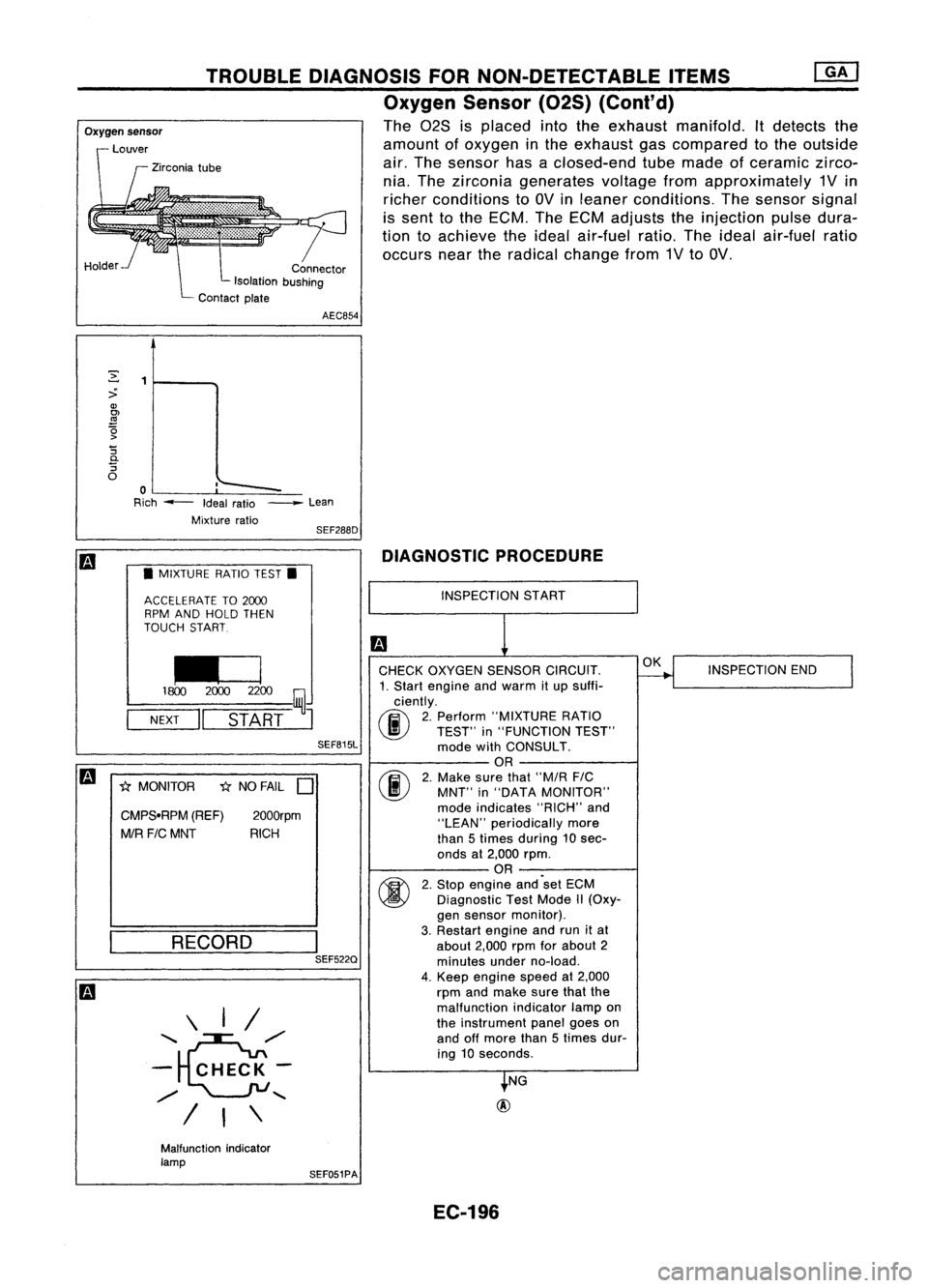

Oxygen Sensor(02S)(Cont'd)

The 028 isplaced intotheexhaust manifold. Itdetects the

amount ofoxygen inthe exhaust gascompared tothe outside

air. The sensor hasaclosed-end tubemade ofceramic zirco-

nia. The zirconia generates voltagefromapproximately 1Vin

richer conditions toOV inleaner conditions. Thesensor signal

is sent tothe ECM. TheECM adjusts theinjection pulsedura-

tion toachieve theideal air-fuel ratio.Theideal air-fuel ratio

occurs neartheradical change from1VtoOV.

r

Connector

Isolation bushing

Contact plate

Oxygen

sensor

Louver

Zirconia tube

Holder AEC854

,'--

~

:>

Q)

OJ

.!!1

~ '5

0-

'5

o

o

Rich --- Idealratio

Mixture ratio_

Lean

SEF288D

m

•MIXTURE RATIOTEST.

ACCELERATE TO2CXXJ

RPM AND HOLD THEN

TOUCH START

~

1800 2CXXJ2200

~J

NEXT

II

START

SEF815L

m

1;{MONITOR 1;{NO FAIL

D

CMPS.RPM (REF)

2000rpm

MIR FICMNT RICH

RECORD \ I/

'~/'

- CHECK-

/

"-

I

I\

I

SEF522Q DIAGNOSTIC

PROCEDURE

INSPECTION START

CHECK OXYGEN SENSORCIRCUIT.

1. Start engine andwarm itup suffi-

ciently.

(F.i\

2.Perform "MIXTURE RATIO

~ TEST"in"FUNCTION TEST"

mode withCONSULT.

OR

(F.i\

2.Make surethat"M/R FIC

\..!!J

MNT"in"DATA MONITOR"

mode indicates "RICH"and

"LEAN" periodically more

than 5times during 10sec-

onds at2,000 rpm.

OR

~ 2.Stop engine and'set ECM

~ Diagnostic TestMode II(Oxy-

gen sensor monitor).

3. Restart engineandrunitat

about 2,000rpmforabout 2

minutes underno-load.

4. Keep engine speedat2,000

rpm andmake surethatthe

malfunction indicatorlampon

the instrument panelgoeson

and offmore than5times dur-

ing 10seconds.

NG

@

OK

INSPECTION END

Malfunction indicator

lamp SEF051PA

EC-196

Page 951 of 1701

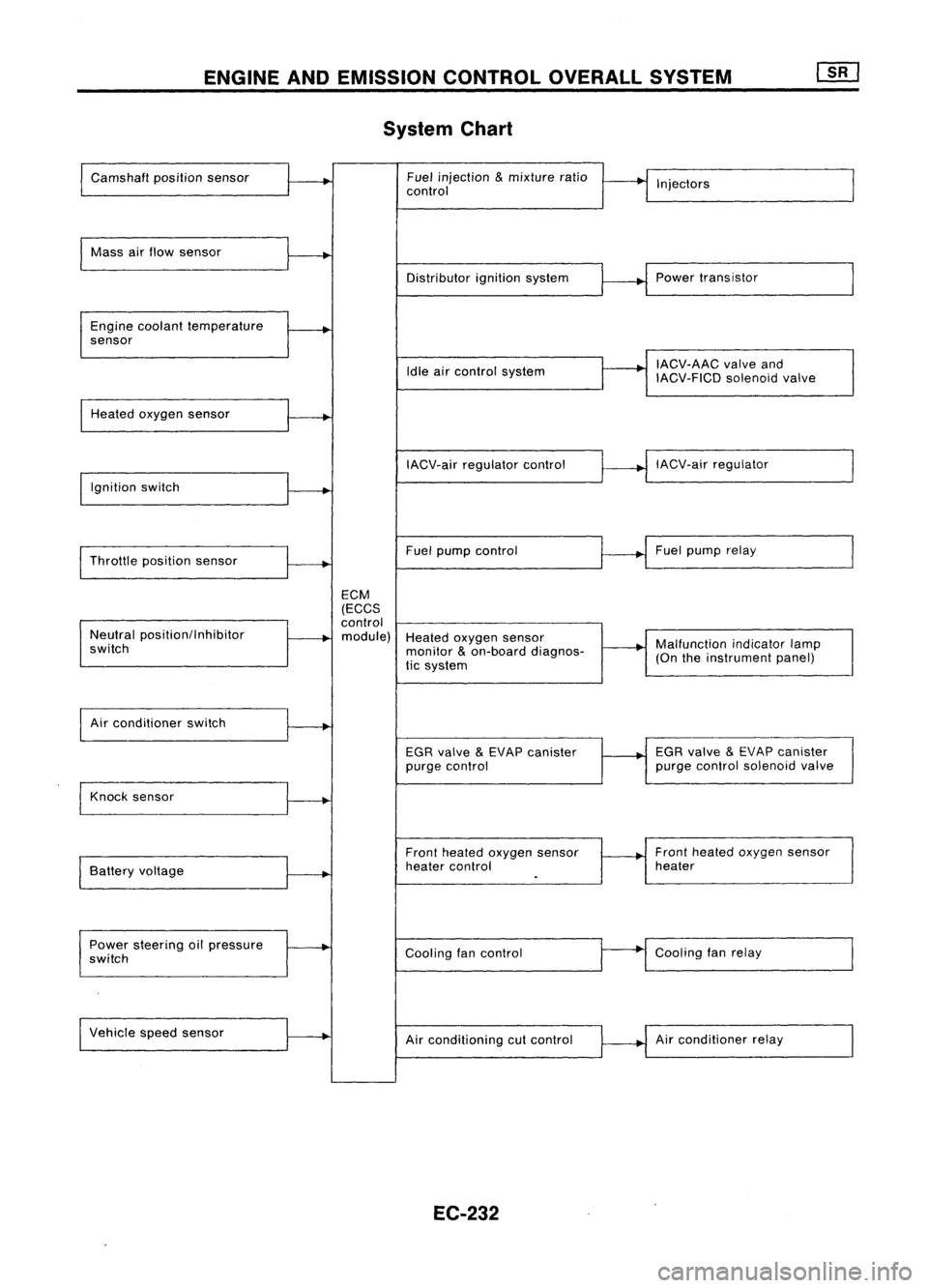

ENGINEANDEMISSION CONTROLOVERALLSYSTEM

System Chart

Camshaft positionsensor Fuel

injection

&

mixture ratio

•

I

I

control Injectors

Mass airflow sensor

I

Distributorignitionsystem

r

~1

Power transistor

Engine coolant temperature

.

sensor

I

IACV-AAC valveand

Idle aircontrol system

IACV-FICDsolenoidvalve

Heated oxygen sensor

I

IACV-airregulator control

~--..j

IACV-air regulator

I

Ignition switch

I

I

Throttle position sensor

~-+

Fuel

pump control Fuel

pump relay

ECM

(ECCS

control

Neutral position/Inhibitor

.

module) Heatedoxygen sensor

switch monitor

&

on-board diagnos-

~-+

Malfunction

indicatorlamp

tic system (On

theinstrument panel)

I

Air conditioner switch

t~

EGRvalve

&

EVAP canister

1---+

EGR

valve

&

EVAP canister

purge control purge

control solenoid valve

Knock sensor

.....

Frontheated oxygen sensor Front

heated oxygen sensor

Battery voltage

.

heater

control heater

I

.

Power steering oilpressure

~

Coolingfancontrol

--

Cooling

fanrelay

switch

Vehicle speedsensor

.....

Airconditioning cutcontrol Air

conditioner relay

EC-232

Page 971 of 1701

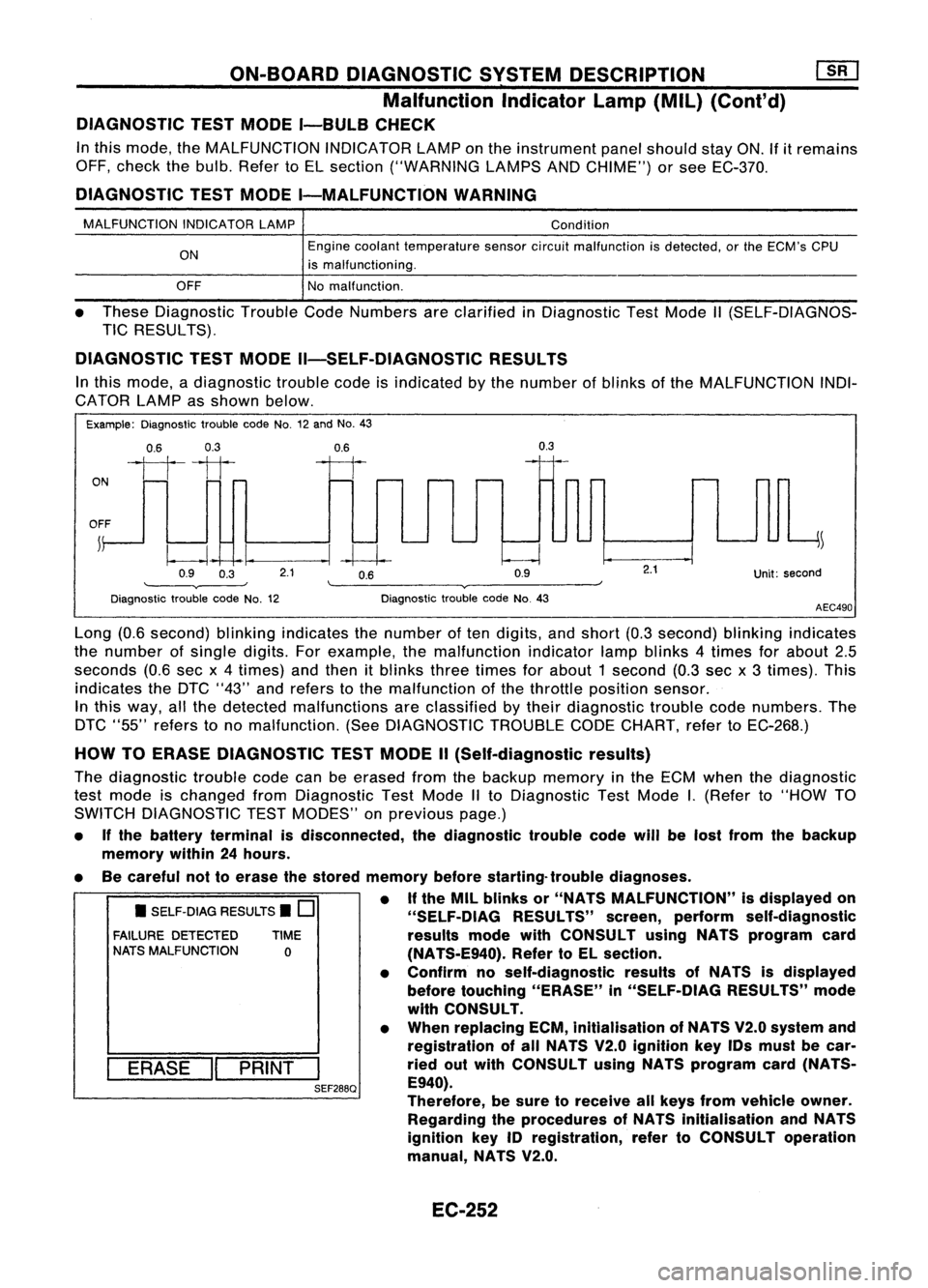

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION ~

Malfunction IndicatorLamp(MIL)(Cont'd)

DIAGNOSTIC TESTMODE I-BULB CHECK

In this mode, theMALFUNCTION INDICATORLAMPonthe instrument panelshould stayON.If

it

remains

OFF, check thebulb. Refer toEL section ("WARNING LAMPSANDCHIME") orsee EC-370.

DIAGNOSTIC TESTMODE I-MALFUNCTION WARNING

MALFUNCTION INDICATORLAMP

ON

OFF Condition

Engine coolant temperature sensorcircuitmalfunction isdetected, orthe ECM's CPU

is malfunctioning.

No malfunction.

• These Diagnostic TroubleCodeNumbers areclarified inDiagnostic TestMode II(SELF-DIAGNOS-

TIC RESULTS).

DIAGNOSTIC TESTMODE II-SELF-DIAGNOSTIC RESULTS

In this mode, adiagnostic troublecodeisindicated bythe number ofblinks ofthe MALFUNCTION INDI-

CATOR LAMPasshown below.

Example: Diagnostic troublecodeNo.12and No.43

0.6 0.3

ON

1111

OFF ~

0.9 0.3

0.6

--I~

2.1 0.6

0.9

0.3

Unit:second

Diagnostic troublecodeNo.12 Diagnostic

troublecodeNo.43

AEC490

• SELF-DIAG RESULTS.

0

FAILURE DETECTED TIME

NATS MALFUNCTION

0

I

ERASE

II

PRINT

I

SEF288Q

Long

(0.6second) blinkingindicates thenumber often digits, andshort (0.3second) blinkingindicates

the number ofsingle digits.Forexample, themalfunction indicatorlampblinks 4times forabout 2.5

seconds (0.6secx4times) andthen itblinks threetimes forabout 1second (0.3sec x3 times). This

indicates theDTC "43" andrefers tothe malfunction ofthe throttle position sensor.

In this way, allthe detected malfunctions areclassified bytheir diagnostic troublecodenumbers. The

DTC "55" refers tono malfunction. (SeeDIAGNOSTIC TROUBLECODECHART, refertoEC-268.)

HOW TOERASE DIAGNOSTIC TESTMODE II(Self-diagnostic results)

The diagnostic troublecodecanbeerased fromthebackup memory inthe ECM when thediagnostic

test mode ischanged fromDiagnostic TestMode IIto Diagnostic TestMode

I.

(Refer to"HOW TO

SWITCH DIAGNOSTIC TESTMODES" onprevious page.)

• Ifthe battery terminal isdisconnected, thediagnostic troublecodewillbelost from thebackup

memory within24hours.

• Becareful nottoerase thestored memory beforestarting- troublediagnoses.

• Ifthe MIL blinks or"NATS MALFUNCTION" isdisplayed on

"SELF-OIAG RESULTS"screen,perform self-diagnostic

results modewithCONSULT usingNATS program card

(NA TS-E940). RefertoEL section.

• Confirm noself-diagnostic resultsofNATS isdisplayed

before touching "ERASE" in"SELF-DiAG RESULTS"mode

with CONSULT.

• When replacing ECM,inltialisation ofNATS V2.0system and

registration ofall NATS V2.0 Ignition keyIDsmust becar-

ried outwith CONSULT usingNATS program card(NATS-

E940).

Therefore, besure toreceive allkeys from vehicle owner.

Regarding theprocedures ofNATS initialisation andNATS

ignition key

10

registration, refertoCONSULT operation

manual, NATS V2.0.

EC-252

Page 989 of 1701

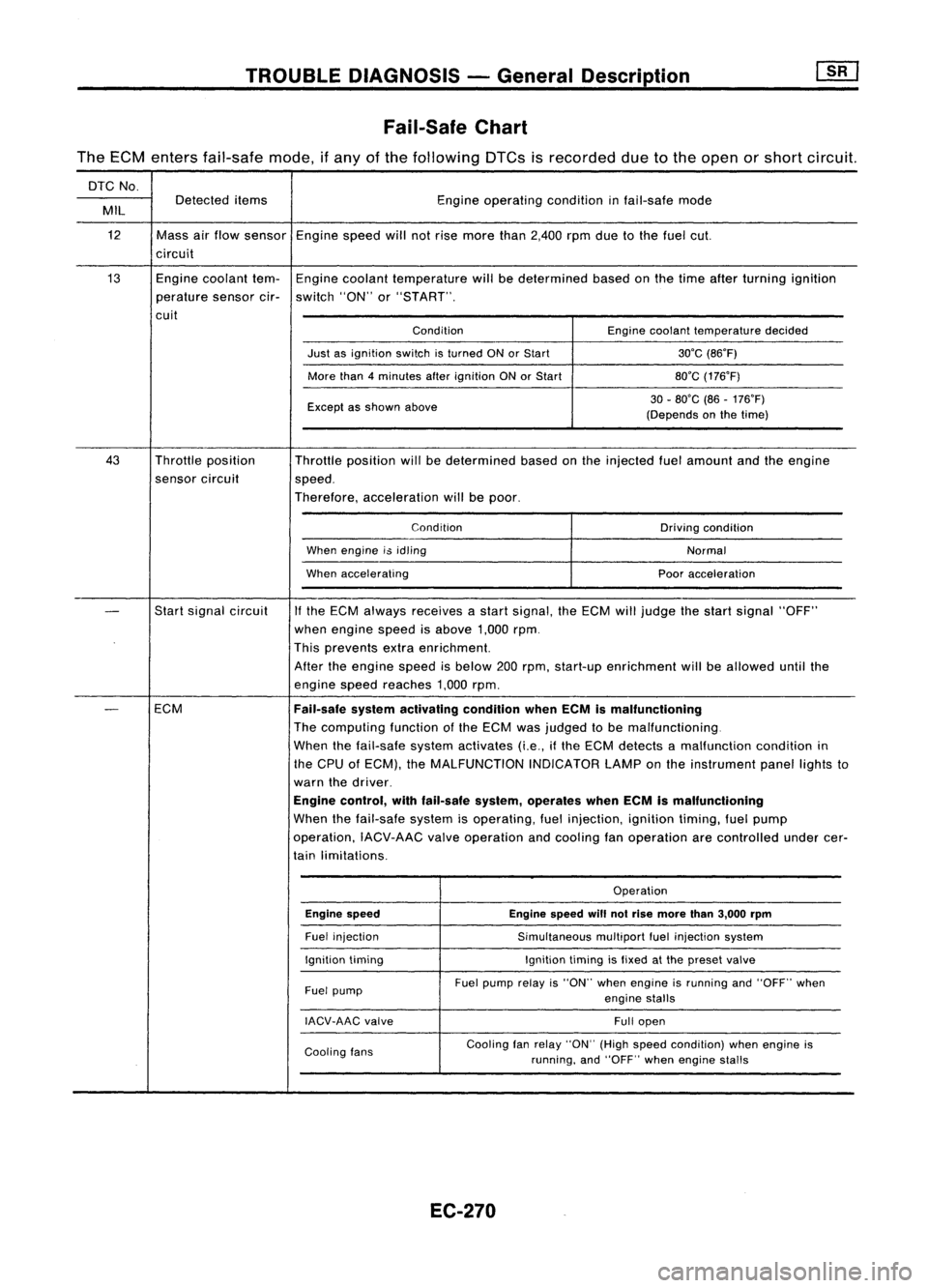

TROUBLEDIAGNOSIS -General Description

Fail-Safe Chart

The ECM enters fail-safe mode,ifany ofthe following DTCsisrecorded duetothe open orshort circuit.

DTC No.

Detected items Engineoperating conditioninfail-safe mode

MIL

12 Massairflow sensor Enginespeedwillnotrise more than2,400 rpmduetothe fuel cut.

circuit

13 Enginecoolant tem-Engine coolant temperature willbedetermined basedonthe time after turning ignition

perature sensorcir-switch "ON"or"START".

cuit ConditionEnginecoolant temperature decided

Just asignition switchisturned ONorStart 30'C(86'F)

More than4minutes afterignition ONorStart 80'C(176'F)

Except asshown above 30

-80'C (86-176'F)

(Depends onthe time)

43 Throttle position

Throttleposition willbedetermined basedonthe injected fuelamount andtheengine

sensor circuit

speed.

Therefore, acceleration willbepoor.

Condition Drivingcondition

When engine i$idling

Normal

When accelerating Pooracceleration

-

Start

signal circuit

If

the ECM always receives astart signal, theECM willjudge thestart signal "OFF"

when engine speedisabove 1,000rpm.

This prevents extraenrichment.

After theengine speedisbelow 200rpm, start-up enrichment willbeallowed untilthe

engine speedreaches 1,000rpm.

-

ECM

Fail-safesystemactivating conditionwhenECMismalfunctioning

The computing functionofthe ECM wasjudged tobe malfunctioning.

When thefail-safe systemactivates (i.e.,ifthe ECM detects amalfunction conditionin

the CPU ofECM), theMALFUNCTION INDICATORLAMPonthe instrument panellightsto

warn thedriver.

Engine control, withfail-safe system,operates whenECMismalfunctioning

When thefail-safe systemisoperating, fuelinjection, ignitiontiming,fuelpump

operation, IACV-AACvalveoperation andcooling fanoperation arecontrolled undercer-

tain limitations.

Operation

Engine speed Enginespeedwillnotrise more than3,000 rpm

Fuel injection

Simultaneousmultiportfuelinjection system

Ignition timing Ignitiontimingisfixed atthe preset valve

Fuel pump Fuel

pump relayis"ON" whenengine isrunning and"OFF" when

engine stalls

IACV-AAC valve

Fullopen

Cooling fans Cooling

fanrelay "ON" (Highspeed condition) whenengine is

running, and"OFF" whenengine stalls

EC-270

Page 1000 of 1701

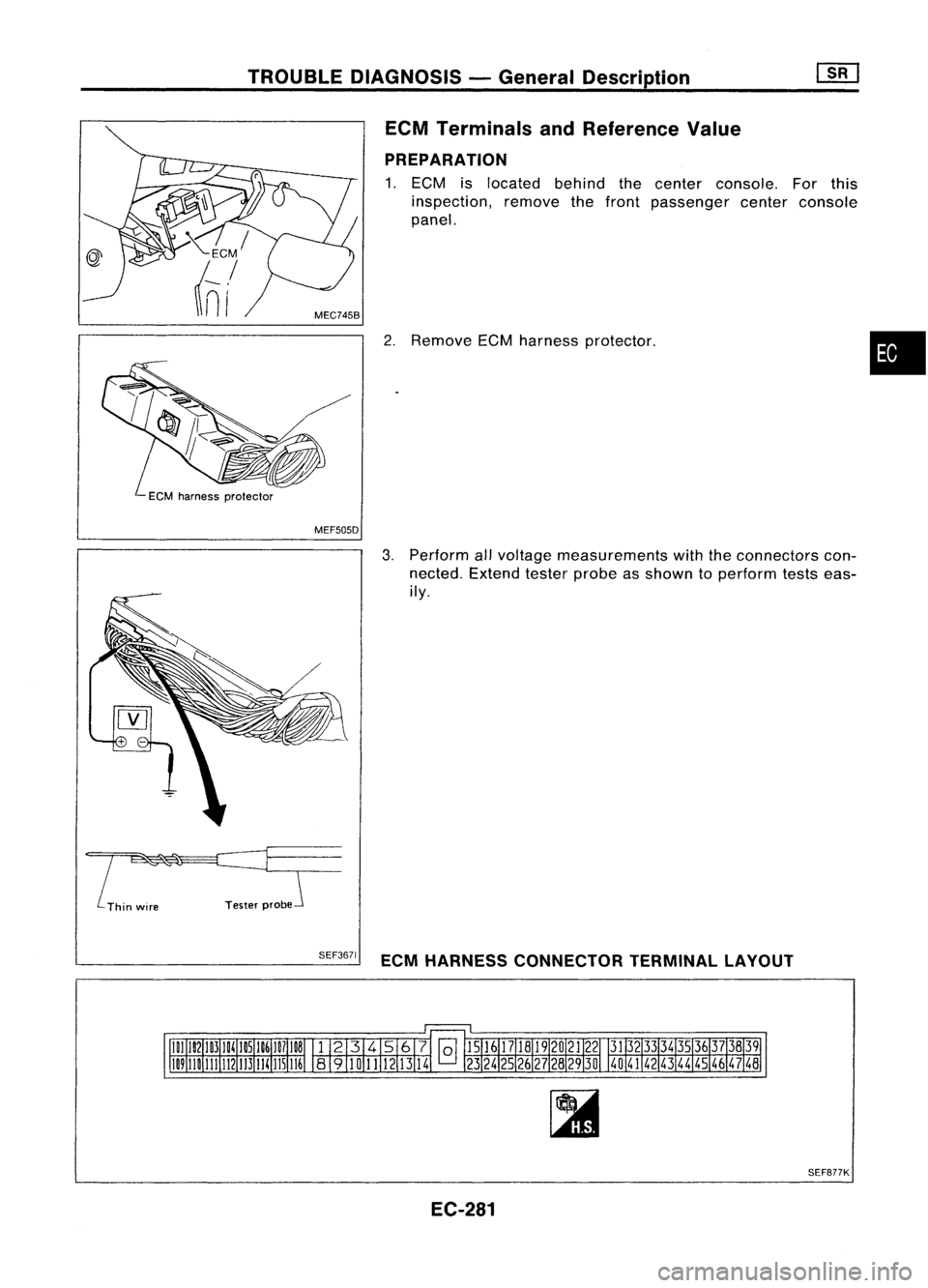

TROUBLEDIAGNOSIS -General Description

ECM Terminals andReference Value

PREPARATION

1. ECM islocated behindthecenter console. Forthis

inspection, removethefront passenger centerconsole

panel.

2. Remove ECMharness protector.

•

MEF505D

!~

Thin wire TesterprobeJ

SEF3671

3.

Perform allvoltage measurements withtheconnectors con-

nected. Extendtesterprobeasshown toperform testseas-

ily.

ECM HARNESS CONNECTOR TERMINALLAYOUT

EC-281 SEF877K

Page 1083 of 1701

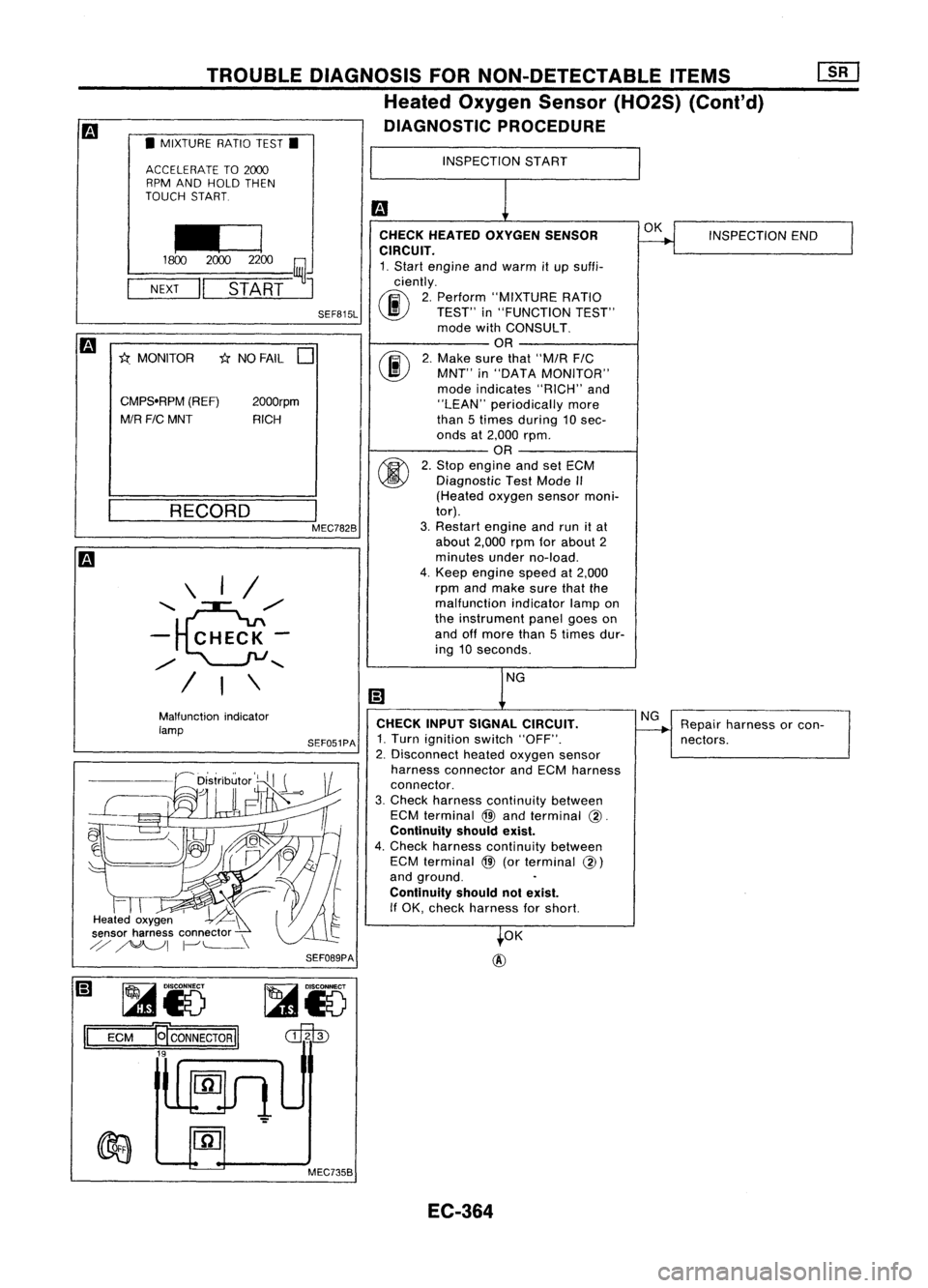

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Heated Oxygen Sensor(H02S)(Cont'd)

DIAGNOSTIC PROCEDURE

• MIXTURE RATIOTEST.

ACCELERATE TO2000

RPM AND HOLD THEN

TOUCH START.

INSPECTION

START

*

NO FAIL

0

II=]

1800 20002200

ij

NEXT

II

START

J

RECORD \ I/

'~/'

- CHECK-

/

......

/ I\

INSPECTION

END

OK

NG

CHECK

HEATED OXYGEN SENSOR

CIRCUIT.

1. Start engine andwarm itup suffi-

ciently.

rF.i\

2.Perform "MIXTURE RATIO

\J!J

TEST"in"FUNCTION TEST"

mode withCONSULT.

OR

rF.i\

2.Make surethat"M/R FIC

\J!J

MNT"in"DATA MONITOR"

mode indicates "RICH"and

"LEAN" periodically more

than 5times during 10 sec-

onds at2,000 rpm.

OR

~ 2.Stop engine andsetECM

~ Diagnostic TestMode II

(Heated oxygensensormoni-

tor).

3. Restart engineandrunitat

about 2,000rpmforabout 2

minutes underno-load.

4. Keep engine speedat2,000

rpm andmake surethatthe

malfunction indicatorlampon

the instrument panelgoeson

and offmore than5times dur-

ing 10seconds.

SEF815L

I

MEC782B

2000rpm

RICH

CMPSoRPM

(REF)

M/R FICMNT

*.

MONITOR

Repairharness orcon-

nectors.

NG

OK

@

SEF089PA

Malfunction

indicator

lamp

~

Heated oxygen '~~

sensor harness connector \

ij

~I 1-''--\

CHECK

INPUTSIGNAL CIRCUIT.

SEF051PA

1.Turn ignition switch"OFF".

'-------------------' 2.Disconnect heatedoxygen sensor

harness connector andECM harness

connector.

3. Check harness continuity between

ECM terminal

@

and terminal

@.

Continuity shouldexist.

4. Check harness continuity between

ECM terminal

@

(orterminal

@)

and ground.

Continuity shouldnotexist.

if OK, check harness forshort.

II

~i5

ECM

-er

CONNECTOR

II

19

~i5

~

MEC735B EC-364

Page 1106 of 1701

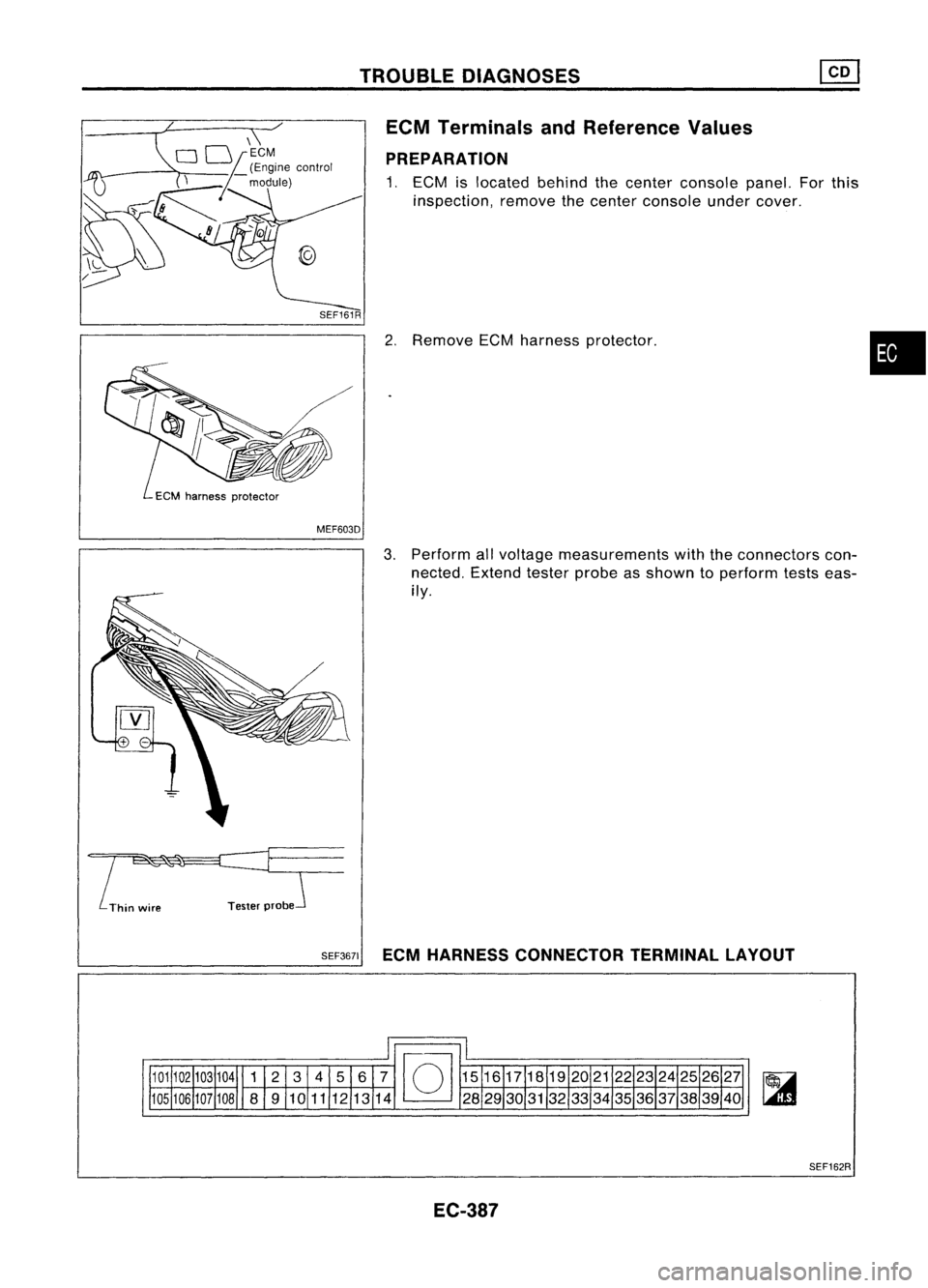

TROUBLEDIAGNOSES

ECM Terminals andReference Values

PREPARATION

1. ECM islocated behindthecenter console panel.Forthis

inspection, removethecenter console undercover.

2. Remove ECMharness protector.

•

MEF603D

!~

Thin wire TesterprobeJ 3.

Perform allvoltage measurements withtheconnectors con-

nected. Extendtesterprobeasshown toperform testseas-

ily.

SEF3671 ECMHARNESS CONNECTOR TERMINALLAYOUT

SEF162R

EC-387