panel NISSAN ALMERA N15 1995 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 326 of 1701

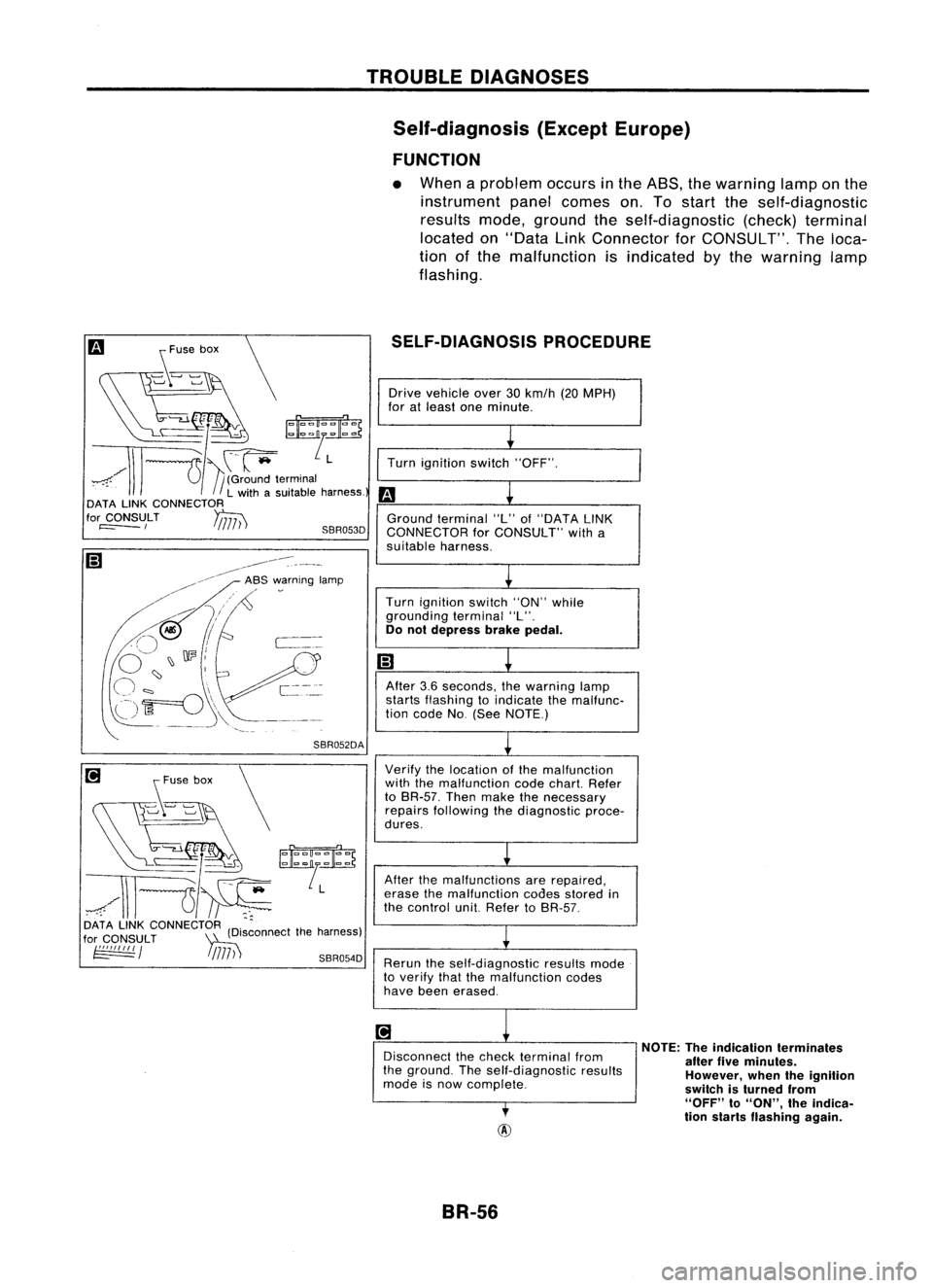

TROUBLEDIAGNOSES

Self-diagnosis (ExceptEurope)

FUNCTION

• When aproblem occursinthe ASS, thewarning lamponthe

instrument panelcomes on.Tostart theself-diagnostic

results mode,ground theself-diagnostic (check)terminal

located on"Data LinkConnector forCONSULT". Theloca-

tion ofthe malfunction isindicated bythe warning lamp

flashing.

SELF-DIAGNOSIS PROCEDURE

[i

s~'~" \

~/''':~~

~/\\l---u~

DATA LINKCONNECTOR (D'.ctthe harness)

for

CONSULT

~Isconne

~ / !

/717) ')

SBR054D

Drive

vehicle over30km/h (20MPH)

for atleast oneminute.

~

Turn ignition switch"OFF".

m

L

Ground terminal "L"of"DATA LINK

CONNECTOR forCONSULT" witha

suitable harness.

L

Turn ignition switch"ON"while

grounding terminal"L".

Do not depress brakepedal.

m

~

After 3.6seconds, thewarning lamp

starts flashing toindicate themalfunc-

tion code No(See NOTE.)

~

Verify thelocation ofthe malfunction

with themalfunction codechart. Refer

to BR-57. Thenmake thenecessary

repairs following thediagnostic proce-

dures.

L

After themalfunctions arerepaired,

erase themalfunction codesstored in

the control unit.Refer toBR-57.

~

Rerun theself-diagnostic resultsmode

to verify thatthemalfunction codes

have been erased.

~

1

Disconnect thecheck terminal from

the ground. Theself-diagnostic results

mode isnow complete.

,

NOTE:

Theindication terminates

after fiveminutes.

However, whentheignition

switch isturned from

"OFF"

to

"ON",

theindica-

tion starts flashing again.

BR-56

Page 363 of 1701

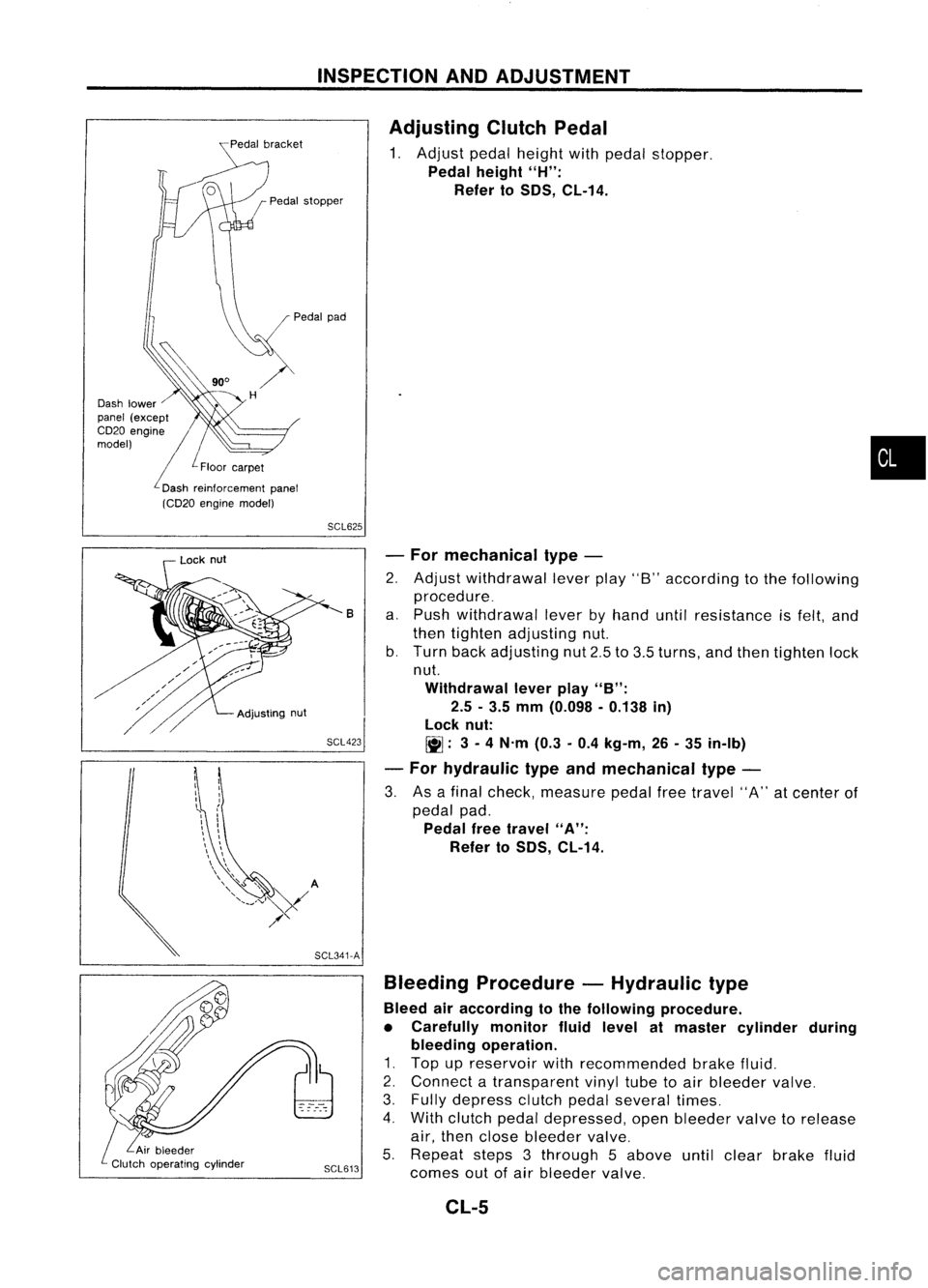

INSPECTIONANDADJUSTMENT

Pedal stopper

Dash lower

panel (except

CD20 engine //

model)

/L

Floor car-pet

L

Dash reinforcement panel

(CD20 engine model)

Adjusting

ClutchPedal

1. Adjust pedalheight withpedal stopper.

Pedal height

"H":

Refer to

50S,

CL-14.

•

SCL625

SCL423 -

For mechanical type-

2. Adjust withdrawal leverplay"8"according tothe following

procedure_

a. Push withdrawal leverbyhand untilresistance isfelt, and

then tighten adjusting nut.

b. Turn backadjusting nut2.5to3.5 turns, andthen tighten lock

nut.

Withdrawal leverplay

"B":

2.5 -3.5 mm (0.098 -0.138 in)

lock nut:

~: 3-

4 N'm (0.3-0.4 kg-m, 26-35 in-Ib)

- For hydraulic typeandmechanical type-

3. Asafinal check, measure pedalfreetravel "A"atcenter of

pedal pad.

Pedal freetravel

"A":

Refer to

50S,

CL-14.

B

Bleeding Procedure -Hydraulic type

Bleed airaccording tothe following procedure.

• Carefully monitorfluidlevel atmaster cylinder during

bleeding operation.

1. Top upreservoir withrecommended brakefluid.

2. Connect atransparent vinyltubetoair bleeder valve.

3. Fully depress clutchpedalseveral times.

4. With clutch pedaldepressed, openbleeder valvetorelease

air, then close bleeder valve.

5. Repeat steps3through 5above untilclear brake fluid

SCL613

comesoutofair bleeder valve.

SCL341-A

Adjusting

nut

Lock

nut

CL-5

Page 372 of 1701

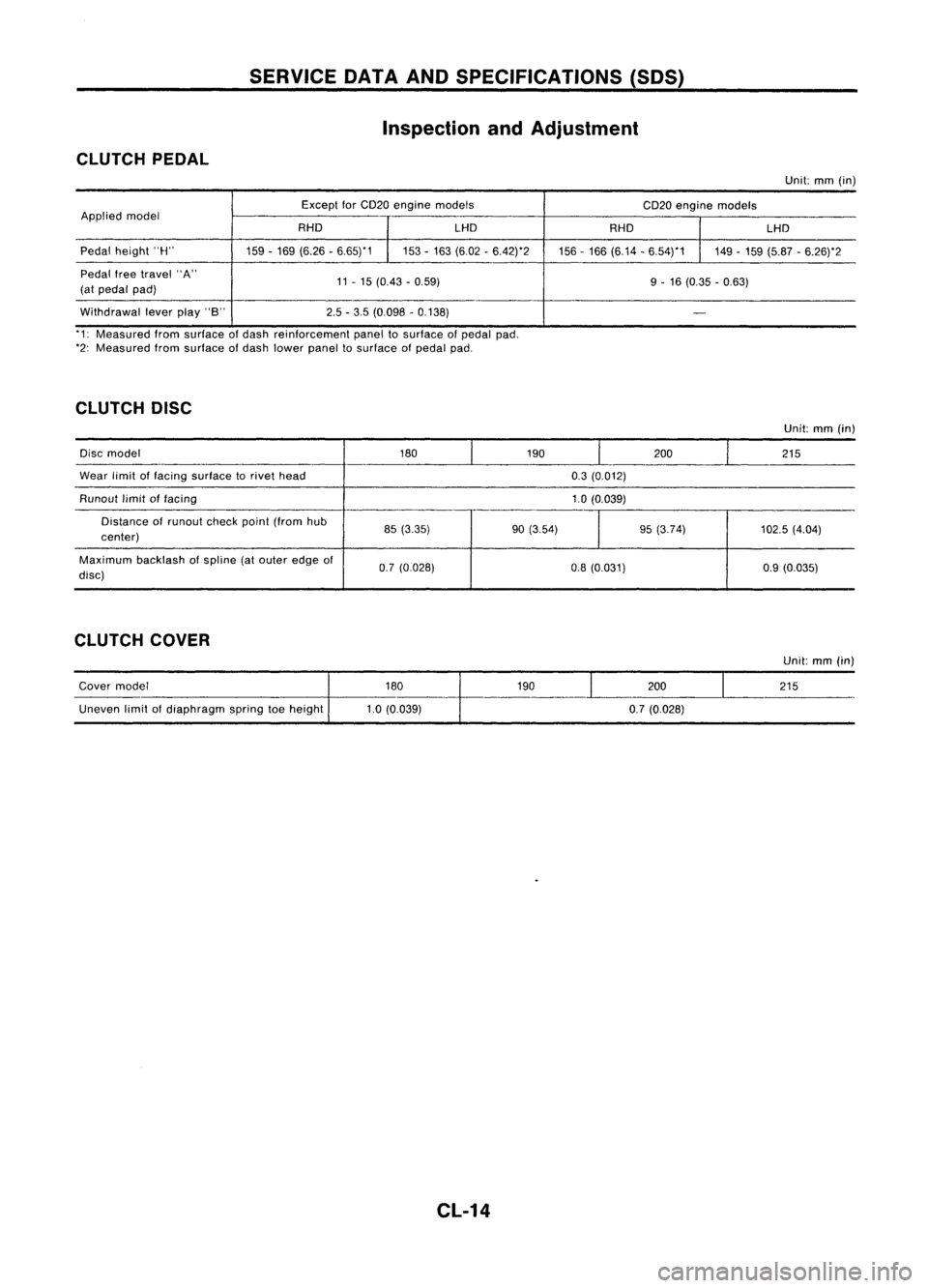

SERVICEDATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment

CLUTCH PEDAL

Unit:mm(in)

Except forCD20 engine models

CD20engine models

Applied model

RHOLHD

RHO LHD

Pedal height "H"

159-169 (6.26 -6.65)'1 153-163 (6.02 -6.42)*2 156-166 (6.14 -6.54)'1

149-159 (5.87 -6.26)'2

Pedal freetravel "A"

11-15 (0.43 -0.59)

9-16 (0.35 -0.63)

(at pedal pad)

Withdrawal leverplay"8" 2.5-3.5 (0.098 -0.138)

-

'1: Measured fromsurface ofdash reinforcement paneltosurface ofpedal pad.

'2: Measured fromsurface ofdash lower paneltosurface ofpedal pad.

CLUTCH DISC

Unit:mm(in)

Disc model

180190

I

200

215

Wear limitoffacing surface torivet head

0.3(0.012)

Runout limitoffacing 1.0(0.039)

Distance ofrunout checkpoint(from hub

85(3.35) 90(3.54)

I

95

(3.74) 102.5(4.04)

center)

Maximum backlashofspline (atouter edgeof

0.7(0.028) 0.8(0.031)

0.9(0.035)

disc)

CLUTCH COVER

Cover model

Uneven limitofdiaphragm springtoeheight 180

1.0 (0.039)

CL-14 190

I

200

0.7 (0.028)

I

Unit:

mm(in)

215

Page 376 of 1701

PRECAUTIONS

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists ofan

air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lampand

spiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis

Service Manual.

WARNING: • Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS.

EL-4

Page 637 of 1701

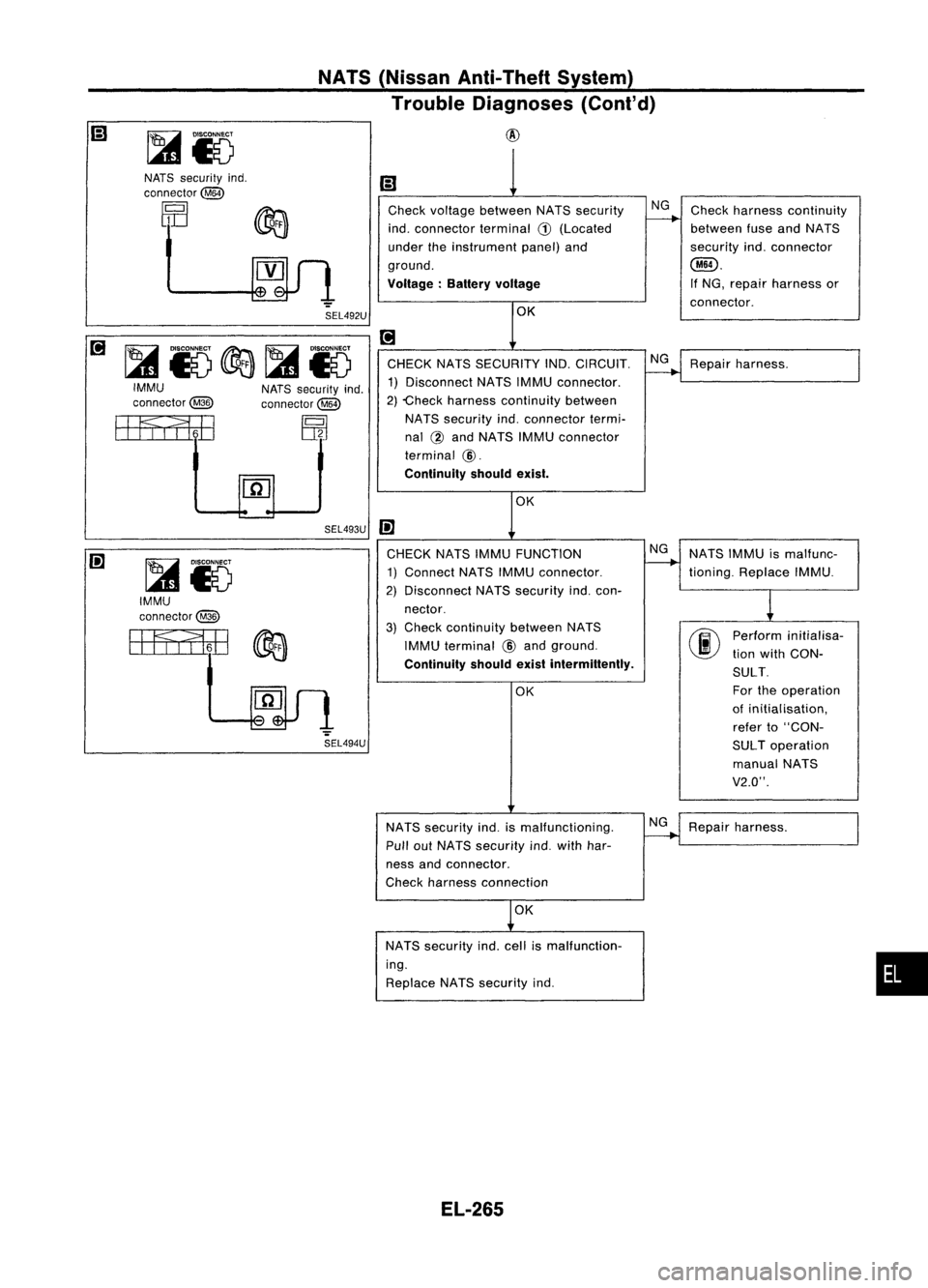

NATS(Nissan Anti-Theft System)

Trouble Diagnoses (Cont'd)

@

•

Ii)

Check voltage between NATSsecurity NG

Check harness continuity

indo connector terminal

G)

(Located

f------+

between fuseandNATS

under theinstrument panel)and securityindoconnector

ground.

@).

Voltage: Batteryvoltage

If

NG, repair harness or

connector .

OK

[!]

CHECK NATSSECURITY IND.CIRCUIT.

~Repair harness.

1) Disconnect NATSIMMU connector.

2) -Check harness continuity between

NATS security indoconnector termi-

nal @and NATS IMMUconnector

terminal

@.

Continuity shouldexist.

OK

IE

CHECK NATSIMMU FUNCTION NG

NATSIMMU ismalfunc-

1) Connect NATSIMMU connector.

-+

tioning. Replace IMMU.

2) Disconnect NATSsecurity indocon-

1

nector.

3)

Check

continuity betweenNATS

00

Perform

initialisa-

IMMU terminal

@

and ground.

tionwith CON-

Continuity shouldexistintermittently.

SULT.

OK For

theoperation

of initialisation,

refer to"CON-

SUL Toperation

manual NATS

V2.0".

NATS security indoismalfunctioning.

~Repair harness.

Pull outNATS security indowith har-

ness andconnector.

Check harness connection

OK

NATS security indocell ismalfunction-

ing.

Replace NATSsecurity indo

SEL494U

NATS

security indo

connector@

rQl

1 ~

DIJ ~

.".

SEL492U

[!]

~15c&a~15IMMU

NATSsecurity indo

connector@ connector~

EEFf,l1iE

~

[ID

SEL493U

IE

~15

IMMU

connector@

EEFfI1iili

~

EL-265

Page 726 of 1701

PRECAUTIONSANDPREPARATION

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer. •

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment ~nany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag", usedalong withaseat belt, helps toreduce therisk or

severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists ofan

air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING: • Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

EC-7

Page 742 of 1701

ENGINEANDEMISSION BASICCONTROL SYSTEMDESCRIPTION

System Chart

I

Camshaft positionsensor

'1

Fuel

injection

&

mixture

ratio control Injectors

Knock sensor

Distributorignitionsystem Powertransistor

Mass airflow sensor

Engine coolant temperature

sensor

Ignition switch Idle

aircontrol system

Fuel pump control

*4

IACV-AAC valve(WithFICD

solenoid valve)

Fuel pump relay

•

'5

Throttle

positionsensor

Neutral positionllnhibitor

switch

Air conditioner switch ECM

(ECCS

control

module)

2

Oxygen sensormonitor

&

On-board diagnostic system

5

Torque converter clutchcan-

cel solenoid valvecontrol

(A/T models) Malfunction

indicatorlamp

(On theinstrument panel)

Torque converter clutchsole-

noid valve

VTC solenoid valve

*6

Air

conditioner relays

Cooling

fanrelay

EVAP canister purgecontrol

solenoid valve

Cooling

fancontrol

Air conditioner cutcontrol

during acceleration

Valve timing control

EVAP canister purgecontrol

7

6

Power

steering oilpressure

switch Battery

voltage

Intake airtemperature sensor

*3

I

Vehicle speedsensor

*2

I

Oxygen sensor

8

'8

Electrical load

• Rear defogger switch

• Lighting switch EGR

&

EVAP canister purge

control EGR

valve

&

EVAP canister

purge control solenoid valve

*1: Except forEurope andIsrael

*2: Heated oxygen sensor(ForEurope andIsrael, andAustralia A/Tmodels)

Oxygen sensor(Except forEurope andIsrael, andAustralia A/Tmodels)

*3: For Australia

*4: IACV-AAC valveandIACV-FICD solenoidvalve(ForEurope andIsrael)

IACV-AAC valve(withFICDsolenoid valve)(Except forEurope andIsrael)

'5: Except forEurope

*6: GA16DE exceptforEurope andIsrael

*7: GA16DE MITmodels exceptforEurope, IsraelandAustralia

*8: For Europe andIsrael andAustralia, andGA15DE MITmodels

EC-23

Page 759 of 1701

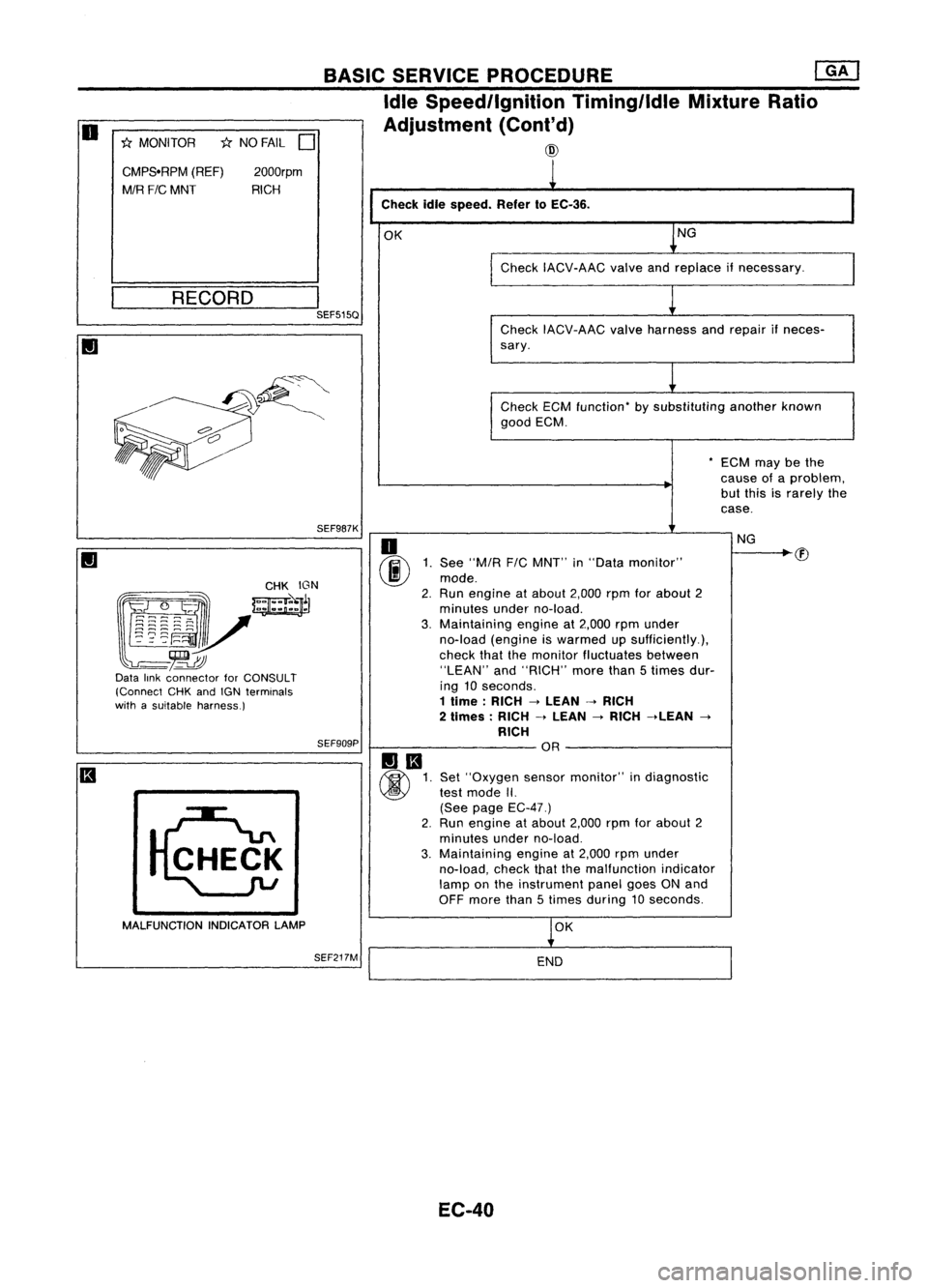

o

1:<

MONITOR

1<

NO FAIL

0

BASIC

SERVICE PROCEDURE

@KJ

Idle Speedllgnition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

CMPS.RPM (REF)

MIR

F/C

MNT 2000rpm

RICH

Checkidlespeed. Refer10EC-36.

OK NG

Check IACV-AAC valveandreplace ifnecessary.

__ R_E_C_O_R_D __

I

SEF515Q

CheckIACV-AAC valveharness andrepair ifneces-

sary.

Check ECMfunction- bysubstituting anotherknown

good ECM.

-ECM maybethe

cause ofaproblem,

but this israrely the

case.

SEF987K

(g~~~:: _

mJ

~~r

l~~~~V

-~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness.)

SEF909P

MALFUNCTION INDICATORLAMP

SEF217M

o

(ij\E

1.See "MIA

F/C

MNT" in"Data monitor"

~ mode.

2. Run engine atabout 2,000rpmforabout 2

minutes underno-load.

3. Maintaining engineat2,000 rpmunder

no-load (engine iswarmed upsufficiently.),

check thatthemonitor fluctuates between

"LEAN" and"RICH" morethan5times dur-

ing 10seconds.

1 lime: RICH->LEAN ->RICH

2 limes: RICH->LEAN

->

RICH ->LEAN

->

RICH OR

Set "Oxygen sensormonitor" indiagnostic

test mode II.

(See page EC-47.)

2. Run engine atabout 2,000rpmforabout 2

minutes underno-load.

3. Maintaining engineat2,000 rpmunder

no-load, checkthatthemalfunction indicator

lamp onthe instrument panelgoesONand

OFF more than5times during 10seconds.

OK

END

EC-40 NG

Page 761 of 1701

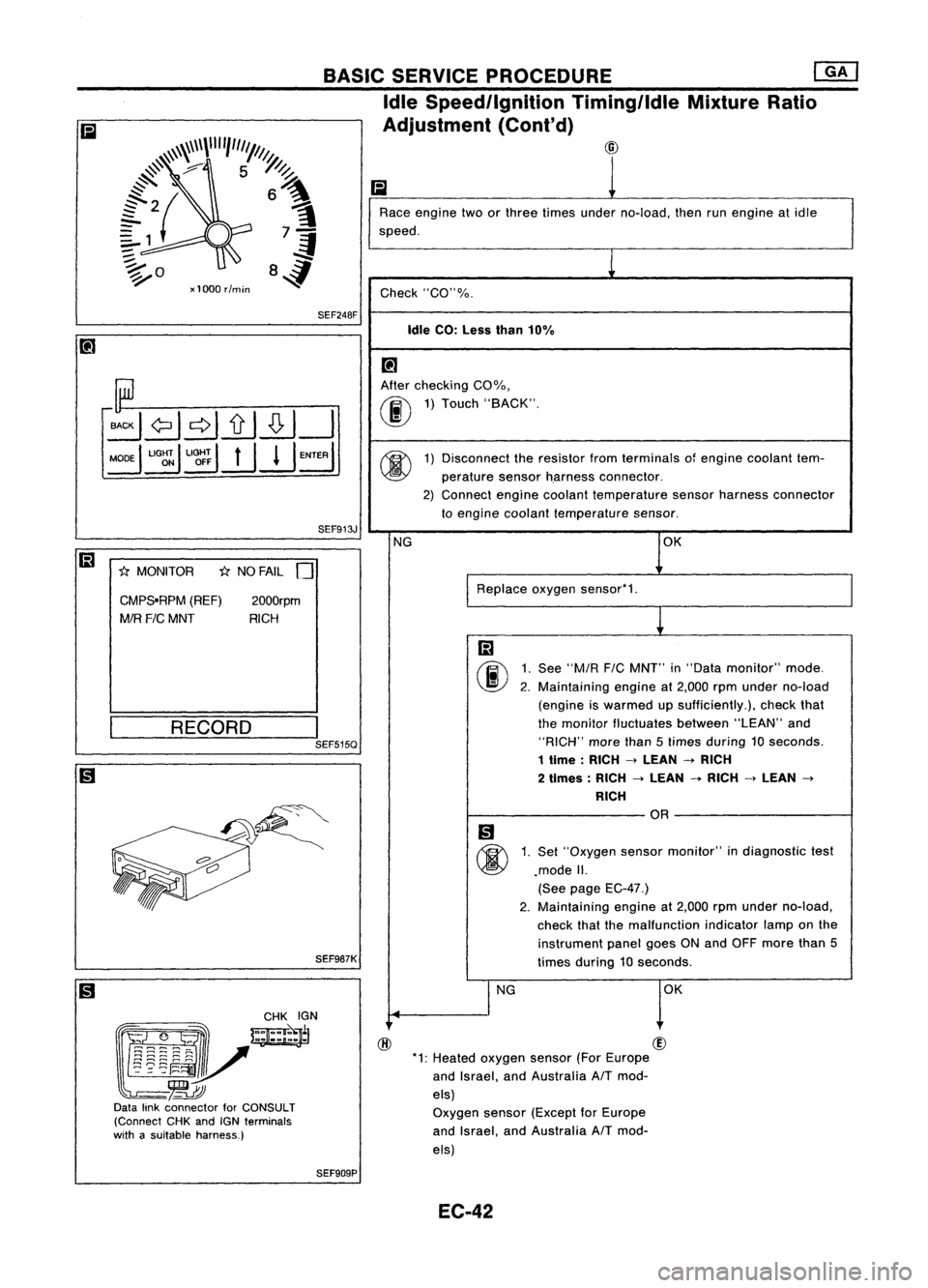

@@

'1: Heated oxygen sensor(ForEurope

and Israel, andAustralia AITmod-

els) Oxygen sensor(Except forEurope

and Israel, andAustralia AITmod-

els)

Ii

1

Race engine twoorthree times under no-load, thenrunengine atidle

speed.

1

Check "CO"%.

Idle CO:Less than10%

[!J

After checking COOJo,

00

1)

Touch "BACK".

@

1)

Disconnect theresistor fromterminals ofengine coolant tem-

perature sensorh.arness connector.

2) Connect enginecoolant temperature sensorharness connector

to engine coolant temperature sensor.

NG OK

Replace oxygensensor'1.

m

00

1.

See

"M/R

FIC

MNT" in"Data monitor" mode.

2. Maintaining engineat2,000 rpmunder no-load

(engine iswarmed upsufficiently.), checkthat

the monitor fluctuates between"LEAN"and

"RICH" morethan5times during 10seconds.

1 time :RICH

->

LEAN

->

RICH

2 times: RICH

->

LEAN

-+

RICH

->

LEAN

->

RICH

OR

Ii)

@

1.

Set "Oxygen sensormonitor" indiagnostic test

.mode II.

(See page EC-47.)

2. Maintaining

engineat2,000 rpmunder no-load,

check thatthemalfunction indicatorlamponthe

instrument panelgoesONand OFF more than5

times during 10seconds.

I

NG OK

SEF913J

2000rpm

RICH

1;:(

NO FAIL

0

SEF248F

CMPS.RPM (REF)

MIR

FIC

MNT

1;:(

MONITOR

BASIC

SERVICE PROCEDURE ~

Idle Speed/Ignition TiminglldleMixtureRatio

Adjustment (Cont'd)

~\\~\\\\""1"'1///1.

@

#'

7 5~

~ ~

{2{ 6~

?1 7-=1

:;::. .;f

~o 84

xl000 rlmin

SEF987K

(gJ~

~~~~N

l~~i~V-=~

-~

Data linkconnector forCONSULT

(Connect CHKandIGNterminals

with asuitable harness.)

__

R_E_C_O_R_D __

I

SEF515Q

SEF909P EC-42

Page 765 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION @KJ

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE I-BULB CHECK

In this mode, theMALFUNCTION INDICATORLAMPonthe instrument panelshould stayON.Ifitremains

OFF, check thebulb. Refer toEL section ("WARNING LAMPSANDCHIME") orsee EC-223.

DIAGNOSTIC TESTMODE I-MALFUNCTION WARNING

MALFUNCTION INDICATORLAMP

ON

OFF Condition

Engine coolant temperature sensorcircuitmalfunction oroverheating isdetected, or

the ECM's CPUismalfunctioning.

No malfunction.

• These Diagnostic TroubleCodeNumbers areclarified inDiagnostic TestMode II(SELF-DIAGNOS-

TIC RESULTS).

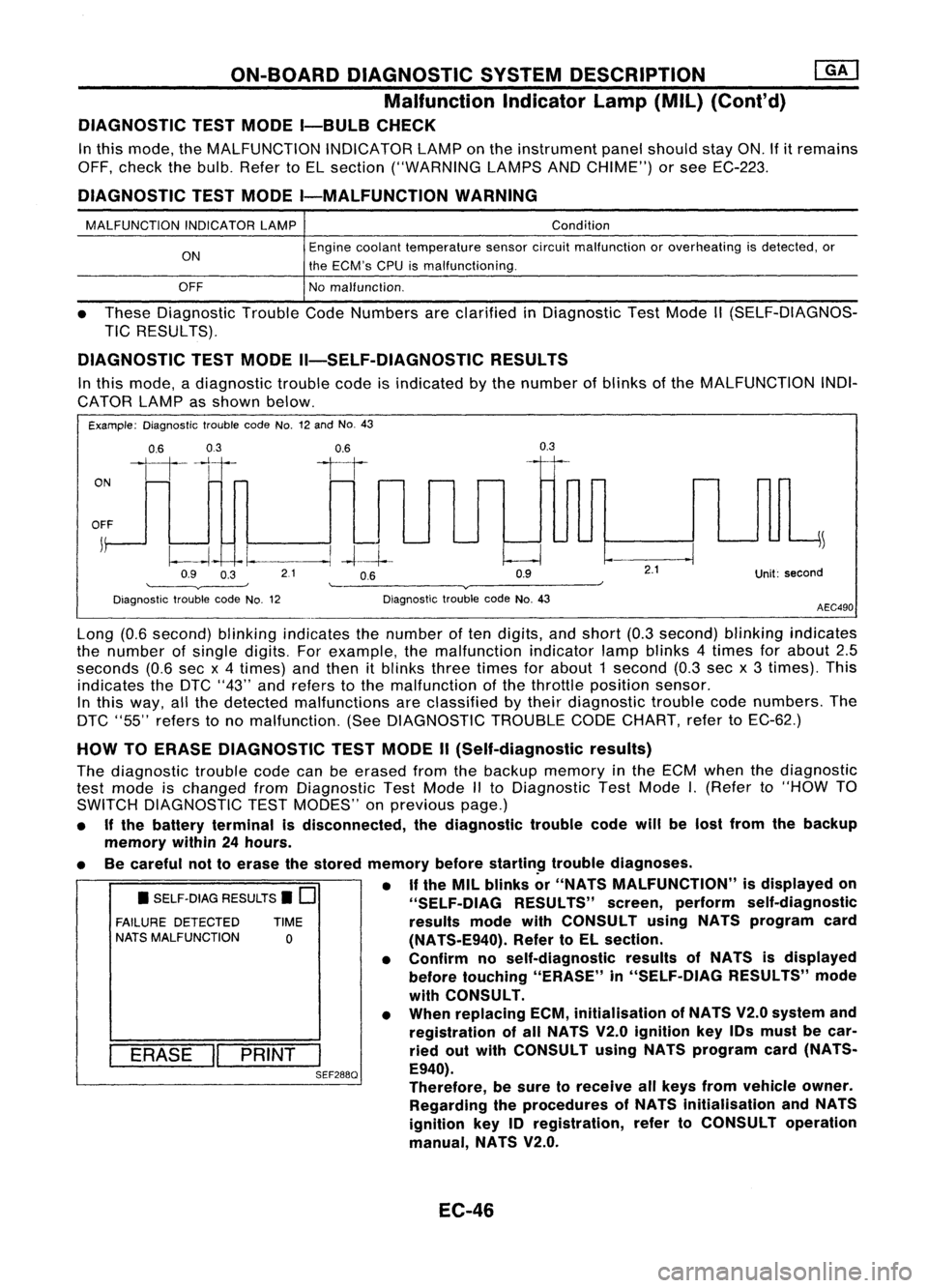

DIAGNOSTIC TESTMODE II-SELF-DIAGNOSTIC RESULTS

In this mode, adiagnostic troublecodeisindicated bythe number ofblinks ofthe MALFUNCTION INDI-

CATOR LAMPasshown below.

Example: Diagnostic troublecodeNo.12and No.43

ON

0.6

03

111-'1

0.6

II

0.3

OFF

j

~

~~ -I.

--.1

-4--1--

Q9 O~ 21 OB Q9

'--------v----' '--------v------~

Diagnostic troublecodeNo.12 DiagnostictroublecodeNo.43

2.1

Unit:second

AEC490

• SELF-DIAG RESULTS.

0

FAILURE DETECTED TIME

NATS MALFUNCTION

0

I

ERASE

II

PRINT

I

SEF288Q

Long

(0.6second) blinkingindicates thenumber often digits, andshort (0.3second) blinkingindicates

the number ofsingle digits. Forexample, themalfunction indicatorlampblinks 4times forabout 2.5

seconds (0.6secx4 times) andthen itblinks threetimes forabout 1second (0.3secx3 times). This

indicates theDTC "43" andrefers tothe malfunction ofthe throttle position sensor.

In this way, allthe detected malfunctions areclassified bytheir diagnostic troublecodenumbers. The

DTC "55" refers tono malfunction. (SeeDIAGNOSTIC TROUBLECODECHART, refertoEC-62.)

HOW TOERASE DIAGNOSTIC TESTMODE II(Self-diagnostic results)

The diagnostic troublecodecanbeerased fromthebackup memory inthe ECM when thediagnostic

test mode ischanged fromDiagnostic TestMode IIto Diagnostic TestMode

I.

(Refer to"HOW TO

SWITCH DIAGNOSTIC TESTMODES" onprevious page.)

• Ifthe battery terminal isdisconnected, thediagnostic troublecodewillbelost from thebackup

memory within24hours.

• Becareful nottoerase thestored memory before

startin~

troublediagnoses.

• If

the MIL blinks or"NATS MALFUNCTION" isdisplayed on

"SELF-OIAG RESULTS"screen,perform self-diagnostic

results modewithCONSULT usingNATS program card

(NATS-E940). RefertoEL section.

• Confirm noself-diagnostic resultsofNATS isdisplayed

before touching "ERASE" in"SELF-DIAG RESULTS"mode

with CONSULT.

• When replacing ECM,initialisation ofNATS V2.0system and

registration ofall NATS V2.0ignition key10smust becar-

ried outwith CONSULT usingNATS program card(NATS-

E940).

Therefore, besure toreceive allkeys from vehicle owner.

Regarding theprocedures ofNATS initialisation andNATS

ignition key10registration, refertoCONSULT operation

manual, NATS V2.0.

EC-46