sensor NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 829 of 1701

![NISSAN ALMERA N15 1995 Service Manual GA16DE forAustralia TROUBLE

DIAGNOSIS FORDTC13

[]K]

Engine Coolant Temperature Sensor(ECTS)

(Cont'd)

EC-ECTS-01

~ENGINE COOLANT

TEMPERATURE

SENSOR

(ffl)

U:iJ

lbi=ll

BR/Y B

t

-:

-:

Det NISSAN ALMERA N15 1995 Service Manual GA16DE forAustralia TROUBLE

DIAGNOSIS FORDTC13

[]K]

Engine Coolant Temperature Sensor(ECTS)

(Cont'd)

EC-ECTS-01

~ENGINE COOLANT

TEMPERATURE

SENSOR

(ffl)

U:iJ

lbi=ll

BR/Y B

t

-:

-:

Det](/img/5/57349/w960_57349-828.png)

GA16DE forAustralia TROUBLE

DIAGNOSIS FORDTC13

[]K]

Engine Coolant Temperature Sensor(ECTS)

(Cont'd)

EC-ECTS-01

~ENGINE COOLANT

TEMPERATURE

SENSOR

(ffl)

U:iJ

lbi=ll

BR/Y B

t

-:

-:

Detectable

line

for DTC

Non-detectable line forDTC

~

@

GY

BR/Y

IT5TI

TW

B

115"0

I

GND -A

ECM

(ECCS

CONTROL

MODULE)

em

101 102103

107 108109

113 114115 104

105 106

110 HI H2

116 117118

EC-110 HEC065

Page 830 of 1701

•

Replace enginecoolant

temperature sensor.

Check

thefollowing.

• Harness foropen or

short between ECM

and engine coolant

temperature sensor

If NG, repair harness or

connectors.

Check thefollowing.

• Harness foropen or

short between ECM

and engine coolant

temperature sensor

If NG, repair harness or

connectors.

NG

NG

NG

CHECK COMPONENT

(Engine coolanttemperature sensor).

Refer to"COMPONENT INSPECTION"

on next page.INSPECTION

START

m

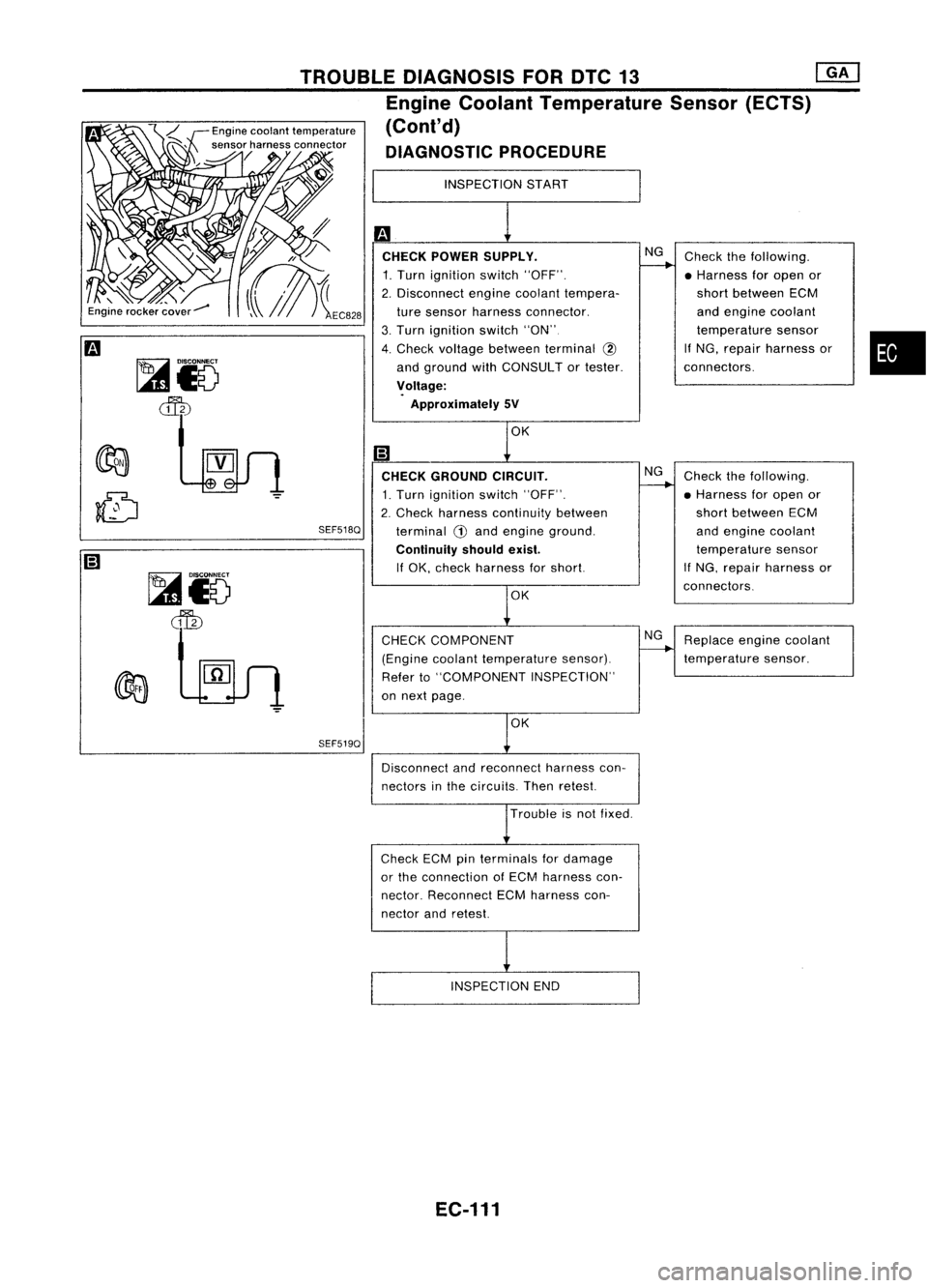

CHECK POWER SUPPLY.

1. Turn ignition switch"OFF".

2. Disconnect enginecoolant tempera-

ture sensor harness connector.

3. Turn ignition switch"ON"

4. Check voltage between terminal @

and ground withCONSULT ortester.

~oltage:

Approximately SV

SEF519Q

Ii)

CHECK GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Check harness continuity between

SEF518Q

terminal

G)

and engine ground.

Continuity shouldexist.

If OK, check harness forshort.

TROUBLE

DIAGNOSIS FORDTC13 ~

Engine Coolant Temperature Sensor(ECTS)

(Cont'd)

DIAGNOSTIC PROCEDURE

Engine

coolant temperature

sensor harness connector

~/

~Io

ten

~Io

~

Disconnectandreconnect harnesscon-

nectors inthe circuits. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

EC-111

Page 831 of 1701

TROUBLEDIAGNOSIS FORDTC13 @KJ

Engine Coolant Temperature Sensor(ECTS)

, '(Cont'd)

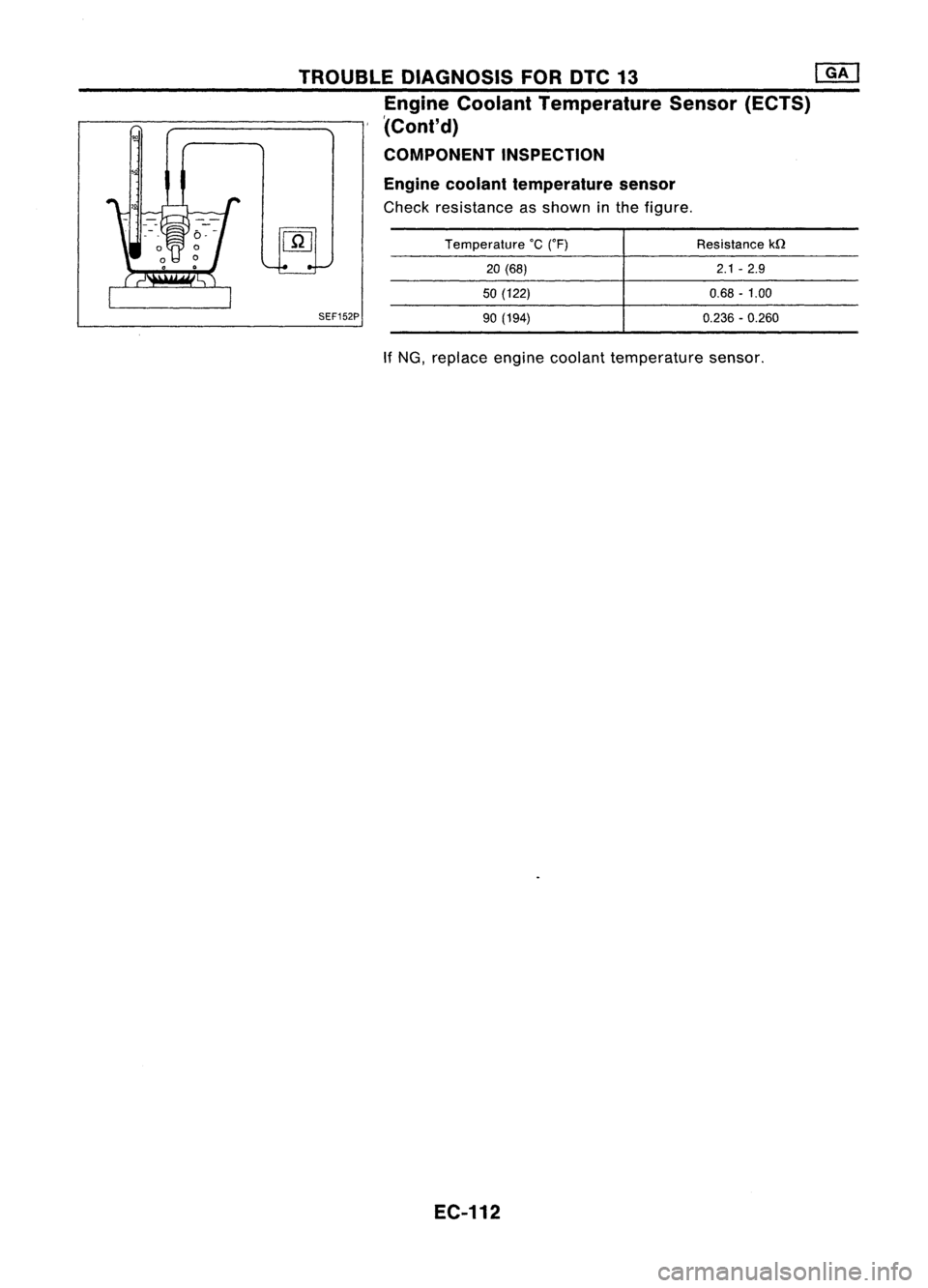

COMPONENT INSPECTION

Engine coolant temperature sensor

Check resistance asshown inthe figure.

SEF152P Temperature

°C

(OF)

20 (68)

50 (122)

90 (194) Resistance

kQ

2.1 -2.9

0.68 -1.00

0.236 -0.260

If

NG, replace enginecoolant temperature sensor.

EC-112

Page 832 of 1701

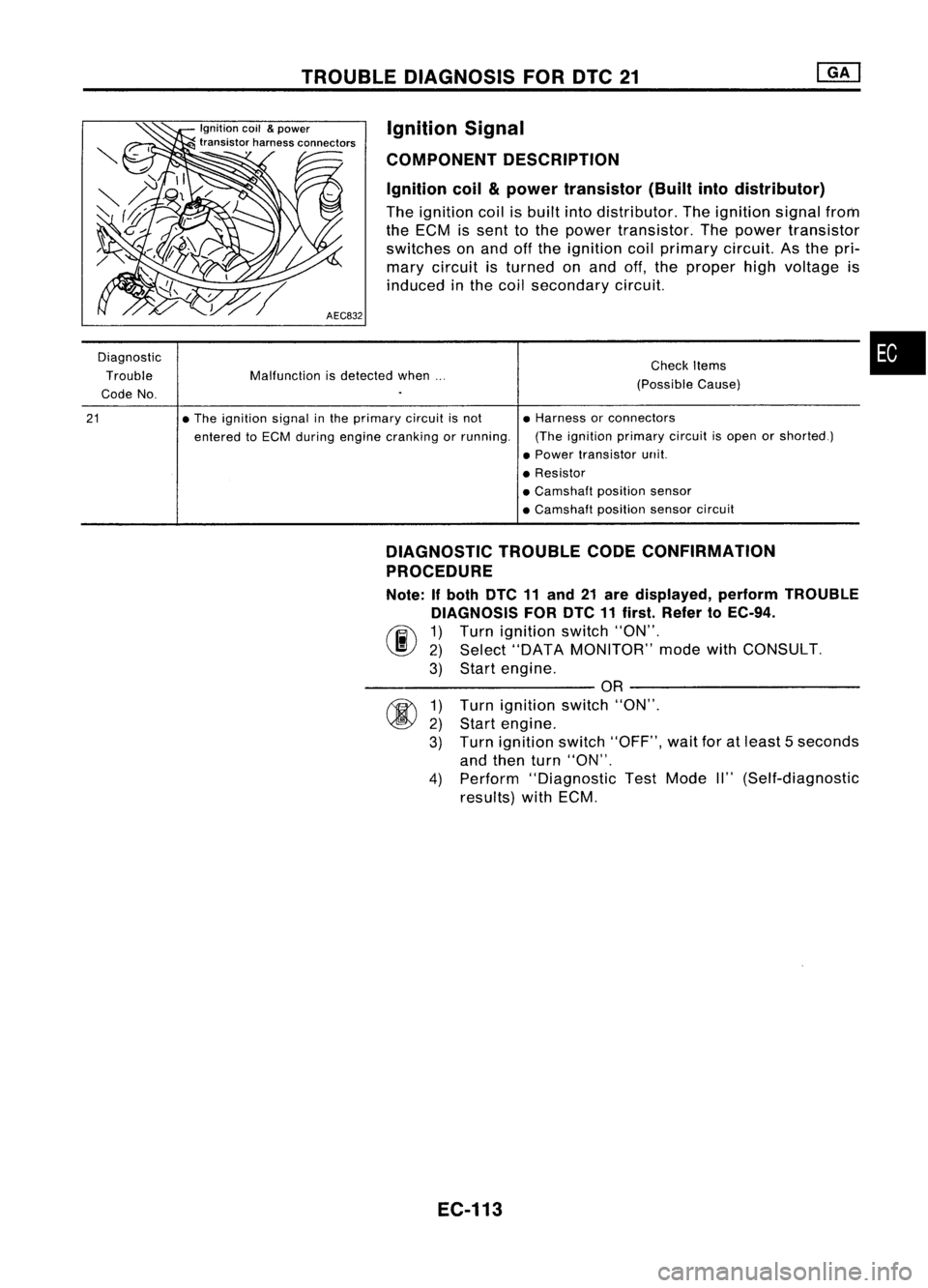

TROUBLEDIAGNOSIS FORDTC21

Malfunction isdetected when...

Diagnostic

Trouble

Code No.

Ignition

coil

&

power

transistor harnessconnectors

AEC832 Ignition

Signal

COMPONENT DESCRIPTION

Ignition coil

&

power transistor (Builtintodistributor)

The ignition coilisbuilt intodistributor. Theignition signalfrom

the ECM issent tothe power transistor. Thepower transistor

switches onand offthe ignition coilprimary circuit.Asthe pri-

mary circuit isturned onand off,the proper highvoltage is

induced inthe coil secondary circuit.

Check Items

(Possible Cause)

•

21

•

The ignition signalinthe primary circuitisnot

entered toECM during engine cranking orrunning. •

Harness orconnectors

(The ignition primary circuitisopen orshorted.)

• Power transistor unit.

• Resistor

• Camshaft positionsensor

• Camshaft positionsensorcircuit

DIAGNOSTIC TROUBLECODECONFIRMATION

PROCEDURE

Note: Ifboth DTC11and 21are displayed, performTROUBLE

DIAGNOSIS FORDTC11first. Refer toEC-94.

(F.i\ 1)Turn ignition switch"ON".

~ 2)Select "DATA MONITOR" modewithCONSULT.

3) Start engine.

----------OR ----------

1) Turn ignition switch"ON".

2) Start engine.

3) Turn ignition switch"OFF", waitforatleast 5seconds

and then turn"ON".

4) Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-113

Page 838 of 1701

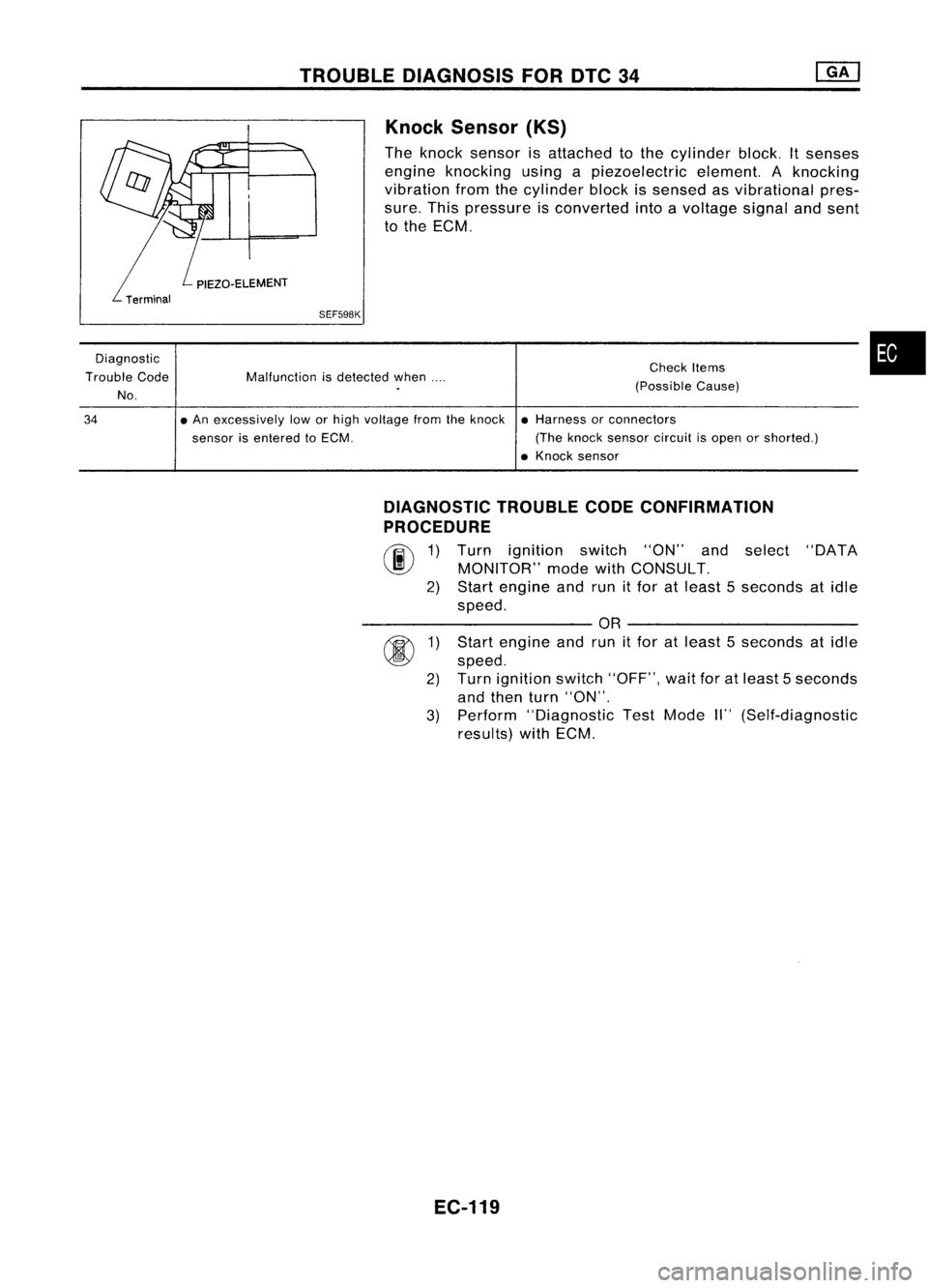

TROUBLEDIAGNOSIS FOROTC34

PIEZO-ELEMENT Malfunction isdetected when....

Diagnostic

Trouble Code

No. SEF598KKnock

Sensor (KS)

The knock sensor isattached tothe cylinder block.Itsenses

engine knocking usingapiezoelectric element.Aknocking

vibration fromthecylinder blockissensed asvibrational pres-

sure. Thispressure isconverted intoavoltage signalandsent

to the ECM.

CheckItems

(Possible Cause)

•

00

1)

2)

3)

34

•An excessively loworhigh voltage fromtheknock •Harness orconnectors

sensor isentered toECM. (Theknock sensor circuitisopen orshorted.)

• Knock sensor

DIAGNOSTIC TROUBLECODECONFIRMATION

PROCEDURE

rif\

1)Turn ignition switch"ON"andselect "DATA

\J!I)

MONITOR" modewithCONSULT.

2) Start engine andrunitfor atleast 5seconds atidle

speed.

---------- OR----------

Start engine andrunitfor atleast 5seconds atidle

speed.

Turn ignition switch"OFF", waitforatleast 5seconds

and then turn"ON".

Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-119

Page 839 of 1701

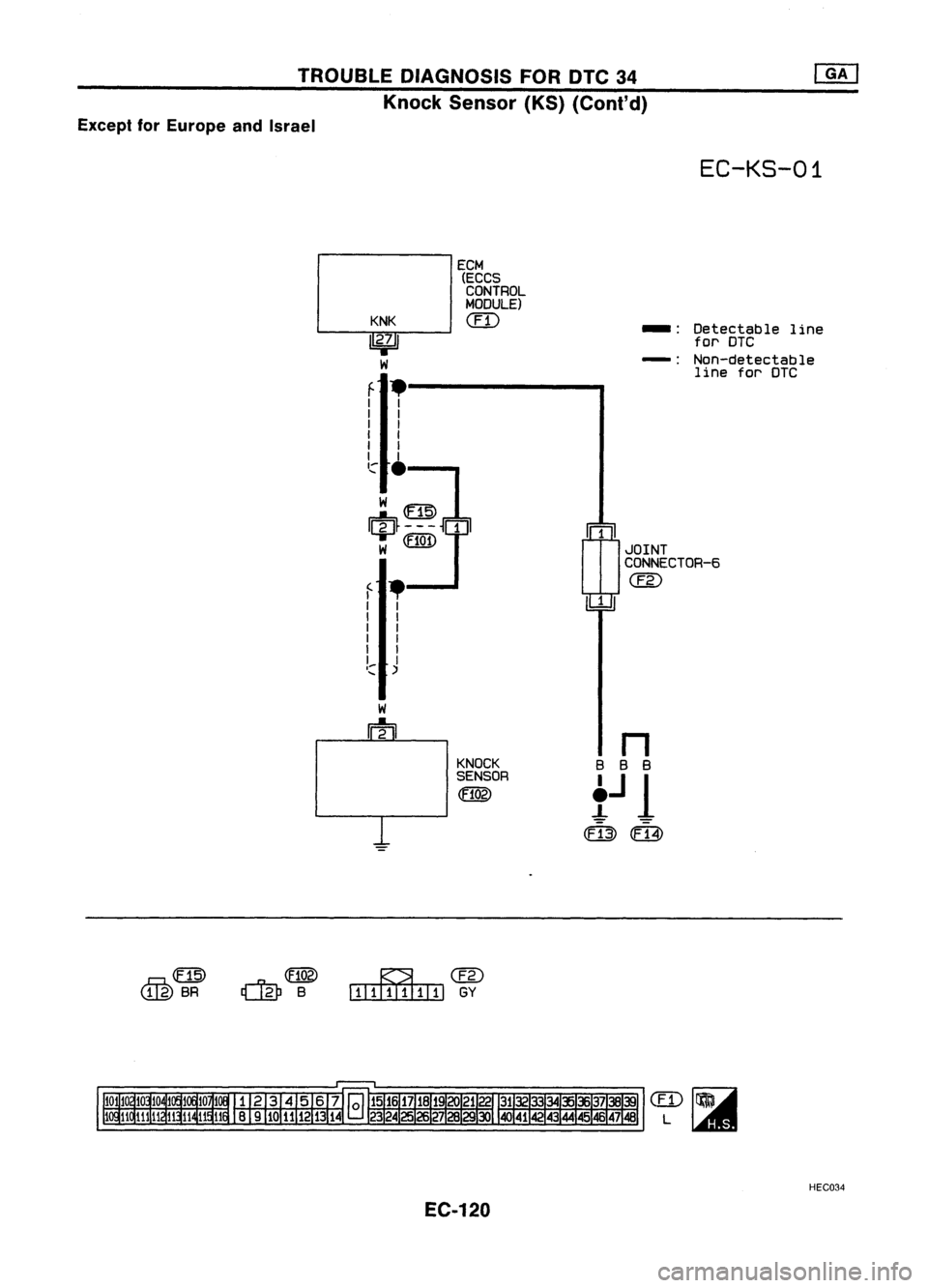

TROUBLEDIAGNOSIS FORDTC34

Knock Sensor (KS)(Cont'd)

Except forEurope andIsrael

EC-KS-01

rn

JOINT

CONNECTOR-6

CW

1

ECM

(ECCS

CONTROL

MODULE)

em

KNK

11

2:

I

w

f .--------.

I I

I I

I I

I I

I I

l~ •

w~

wOO

f •

I I

I I

I I

I I

I I

I I

I': )

-:

Detectable line

for DTC

-: Non-detectable

line forOTC

@g)

BR

~oo

LL.@y B

w

m

KNOCK

SENSOR

~cw

I1IIIITITDII

GY

EC-120 HEC034

Page 840 of 1701

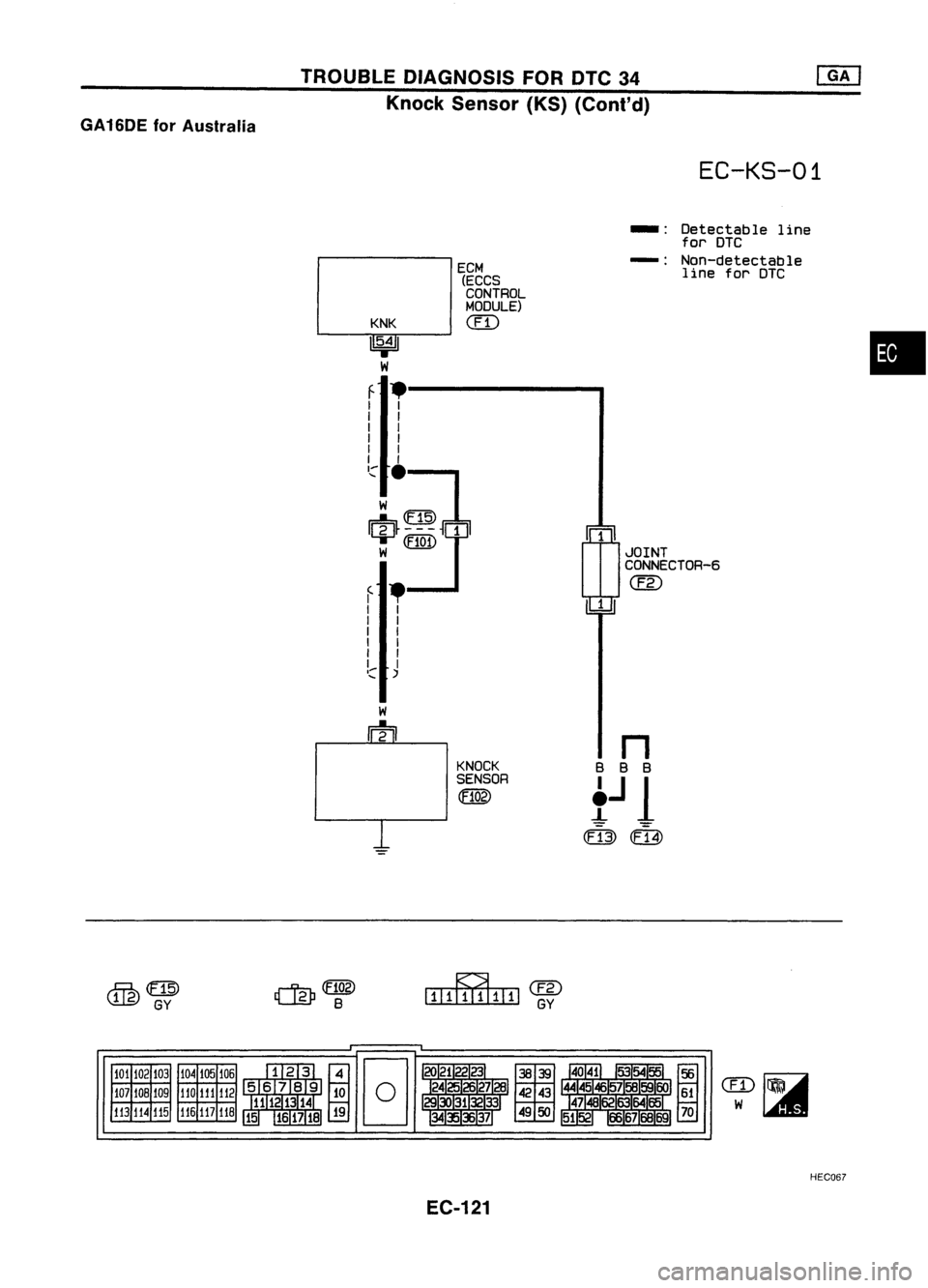

GA16DE forAustralia TROUBLE

DIAGNOSIS FORDTC34

Knock Sensor (KS)(Cont'd)

EC-KS-01

rn

JOINT

CONNECTOR-6

(F2)

1

ECM

(ECCS

CONTROL

MODULE)

em

KNK

1

5•4

1

w

f .------ .....

I I

I I

I I

I I

I I

I I

1':- •

w

w

f •

I I

I I

I I

I I

I I

!.:-

j

-:

Detectable line

for

DTC

-: Non-detectable

line for

DTC

•

fl

\!.1.SJ

GY

w

m

KNOCK

SENSOR

0:102)

~@

rn:IIIITIIIII

GY

101 102103

107 108109

113

114

115

104

105 106

110 111112

116

117

118

HEC067

EC-121

Page 841 of 1701

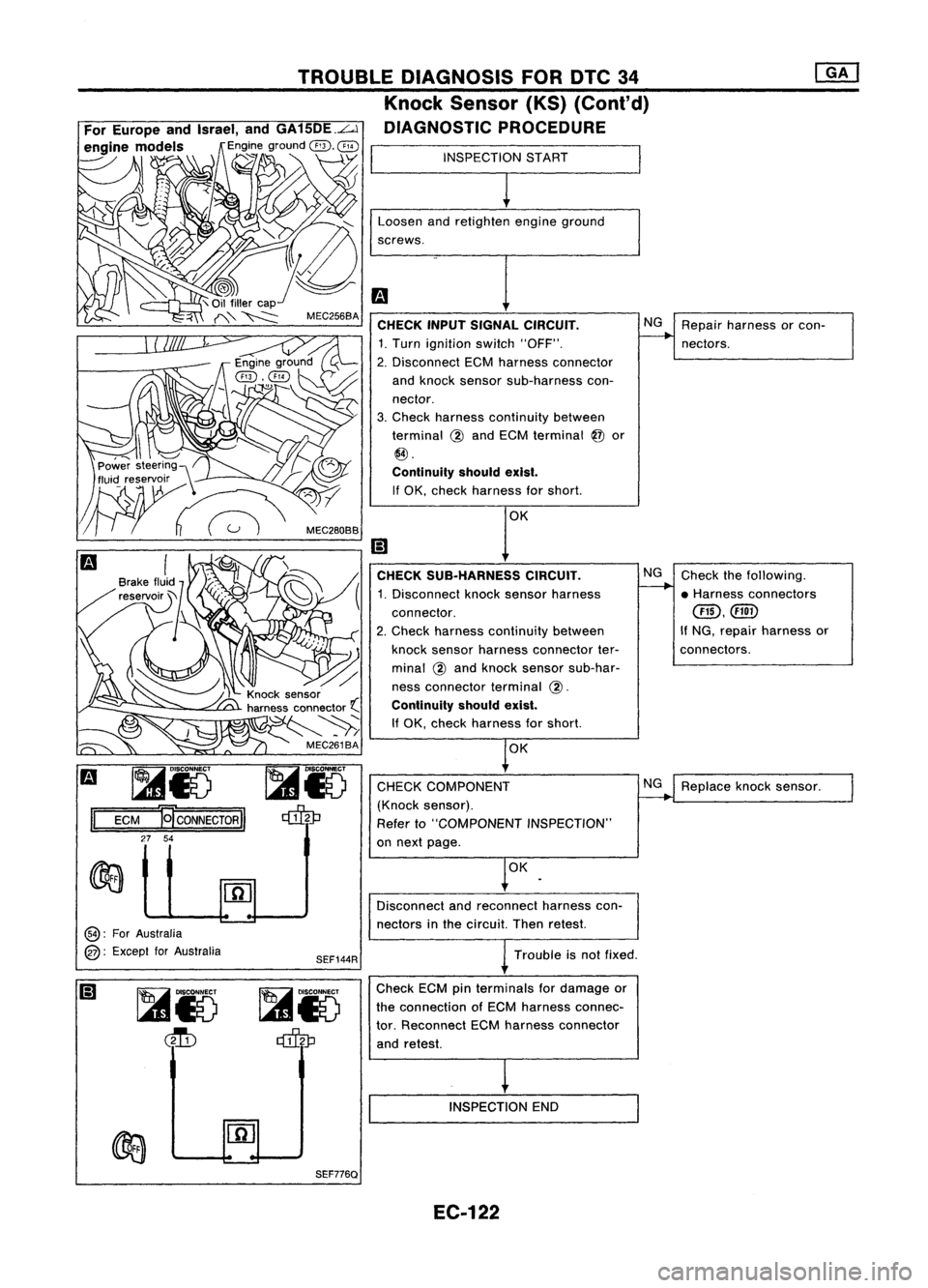

Replaceknocksensor.

NG

NG

Check thefollowing.

• Harness connectors

@,@

If NG, repair harness or

connectors.

r

OK

CHECK

SUB.HARNESS CIRCUIT.

1. Disconnect knocksensor harness

connector.

2. Check harness continuity between

knock sensor harness connector ter-

minal @and knock sensor sub-har-

ness connector terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

CHECK COMPONENT

(Knock sensor).

Refer to"COMPONENT INSPECTION"

on next page.

Loosen

andretighten engineground

screws.

Fa

CHECK INPUTSIGNAL CIRCUIT. NG

Repair harness orcon-

1. Turn ignition switch"OFF".

--.

nectors.

2. Disconnect ECMharness connector

and knock sensor sub-harness con-

nector.

3. Check harness continuity between

terminal @and ECM terminal

@

or

@.

Continuity shouldexist.

If OK, check harness forshort.

TROUBLE

DIAGNOSIS FORDTC34

Knock Sensor (KS)(Conl'd)

DIAGNOSTIC PROCEDURE

For Europe andIsrael, andGA15DE.L..l

en~ine m\~~:e?, Is

Eng~eground

@'~@)

1 _

- \.Y

INSPECTIONSTART

J--

Fa

~i5

II

ECM

]9'CONNECTORII

27 54

,~\

C-/

Power steerin9\'

fluid reservoir /'\ /-:

.~~ :,c"",

OK

@:

ForAustralia

@:

Except forAustralia

SEF144RDisconnect

andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage or

the connection ofECM harness connec-

tor. Reconnect ECMharness connector

and retest.

INSPECTION END

SEF776Q EC.122

Page 842 of 1701

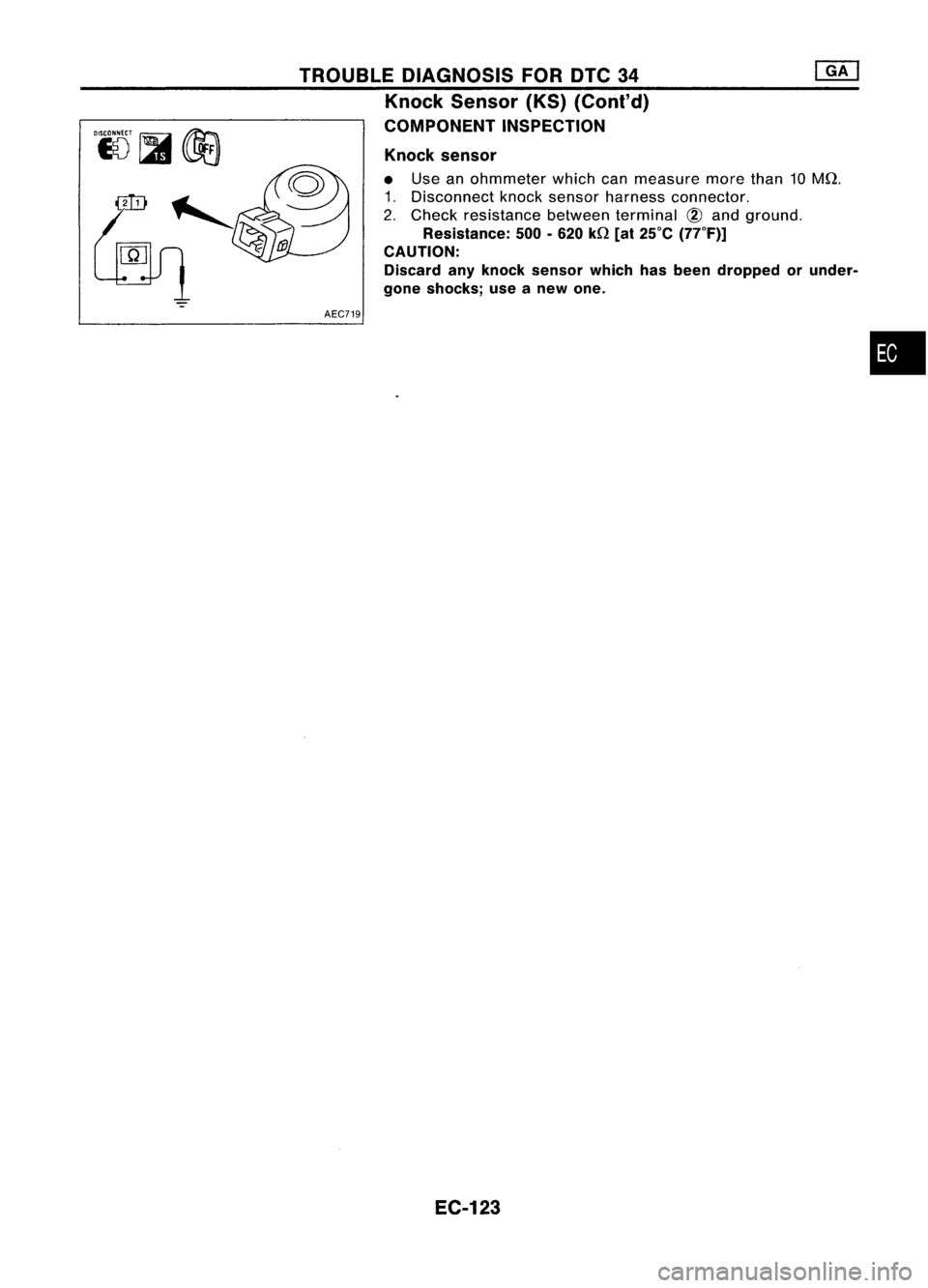

TROUBLEDIAGNOSIS FOROTC34

Knock Sensor (KS)(ConI' d)

COMPONENT INSPECTION

Knock sensor

• Use anohmmeter whichcanmeasure morethan10MQ.

1. Disconnect knocksensor harness connector.

2. Check resistance betweenterminal

@

and ground.

Resistance: 500-620 kQ[at25°C (77°F)]

CAUTION:

Discard anyknock sensor whichhasbeen dropped orunder-

gone shocks; useanew one.

AEC719

EC-123

•

Page 843 of 1701

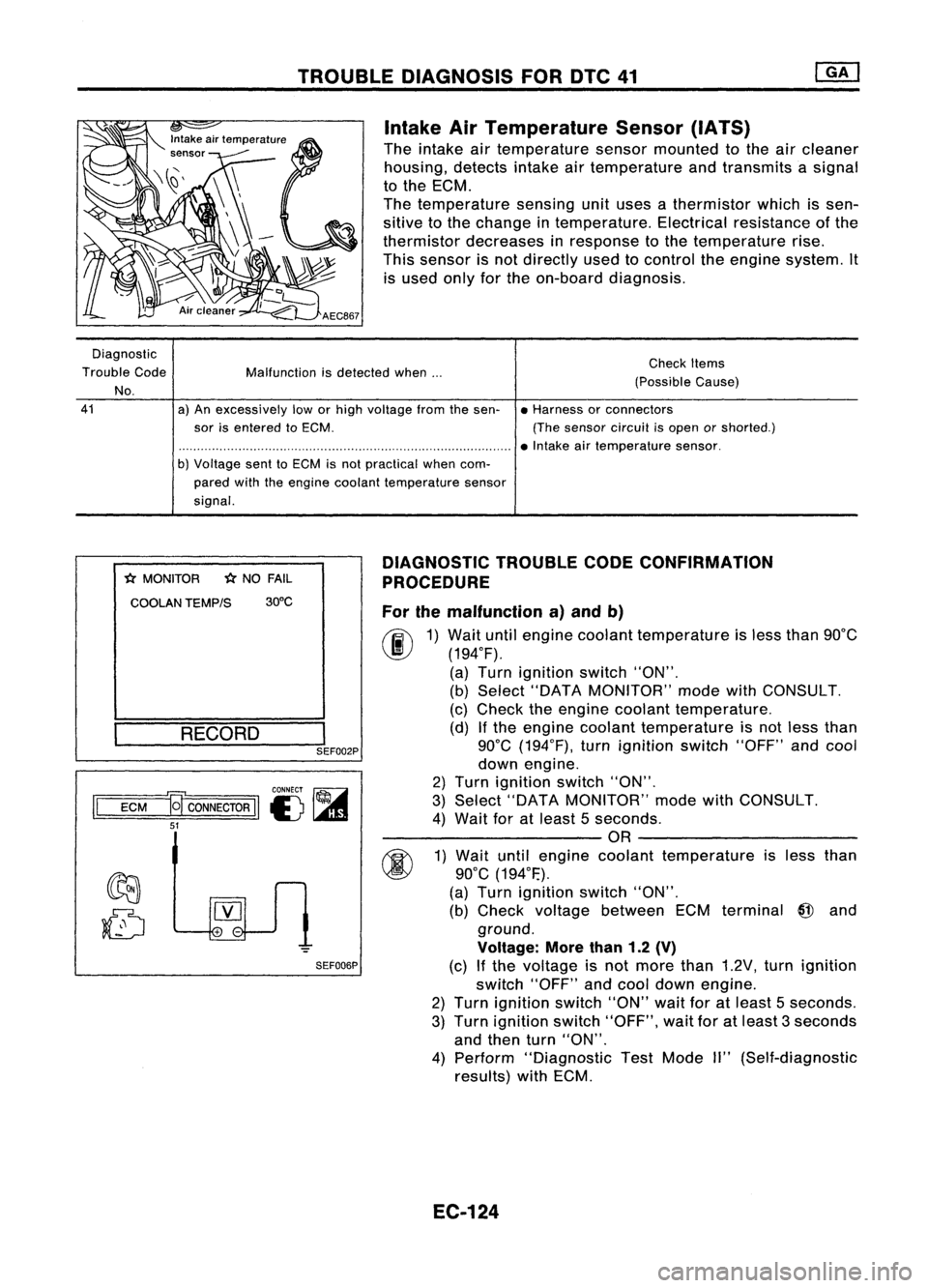

TROUBLEDIAGNOSIS FOROTC41

Intake AirTemperature Sensor(IATS)

The intake airtemperature sensormounted tothe aircleaner

housing, detectsintakeairtemperature andtransmits asignal

to the ECM.

The temperature sensingunituses athermistor whichissen-

sitive tothe change intemperature. Electricalresistance ofthe

thermistor decreases inresponse tothe temperature rise.

This sensor isnot directly usedtocontrol theengine system. It

is used onlyforthe on-board diagnosis.

Diagnostic

Trouble Code

No.

41

Malfunction

isdetected when...

a) An excessively loworhigh voltage fromthesen-

sor isentered toECM.

b) Voltage senttoECM isnot practical whencom-

pared withtheengine coolant temperature sensor

signal. Check

Items

(Possible Cause)

• Harness orconnectors

(The sensor circuitisopen orshorted.)

• Intake airtemperature sensor.

*

MONITOR

*

NO FAIL

COOLAN TEMP/S 30°C

RECORD

I

SEF002P

CONNECT ~

II

ECM

a

CONNECTOR

II

I) ~

51

SEF006PDIAGNOSTIC

TROUBLECODECONFIRMATION

PROCEDURE

For themalfunction a)and b)

fF.I\

1)Wait untilengine coolant temperature isless than 90°C

~ (194°F).

(a) Turn ignition switch"ON".

(b) Select "DATA MONITOR" modewithCONSULT.

(c) Check theengine coolant temperature.

(d) Ifthe engine coolant temperature isnot less than

90°C (194°F), turnignition switch"OFF"andcool

down engine.

2) Turn ignition switch"ON".

3) Select "DATA MONITOR" modewithCONSULT.

4) Wait foratleast 5seconds.

---------OR ---------

~ 1)Wait untilengine coolant temperature isless than

~ 90°C(194°F.).

(a) Turn ignition switch"ON".

(b) Check voltage between ECMterminal

@

and

ground.

Voltage: Morethan1.2(V)

(c) Ifthe voltage isnot more than1.2V, turnignition

switch "OFF"andcool down engine.

2) Turn ignition switch"ON"waitforatleast 5seconds.

3) Turn ignition switch"OFF", waitforatleast 3seconds

and then turn"ON".

4) Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-124