NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 341 of 1701

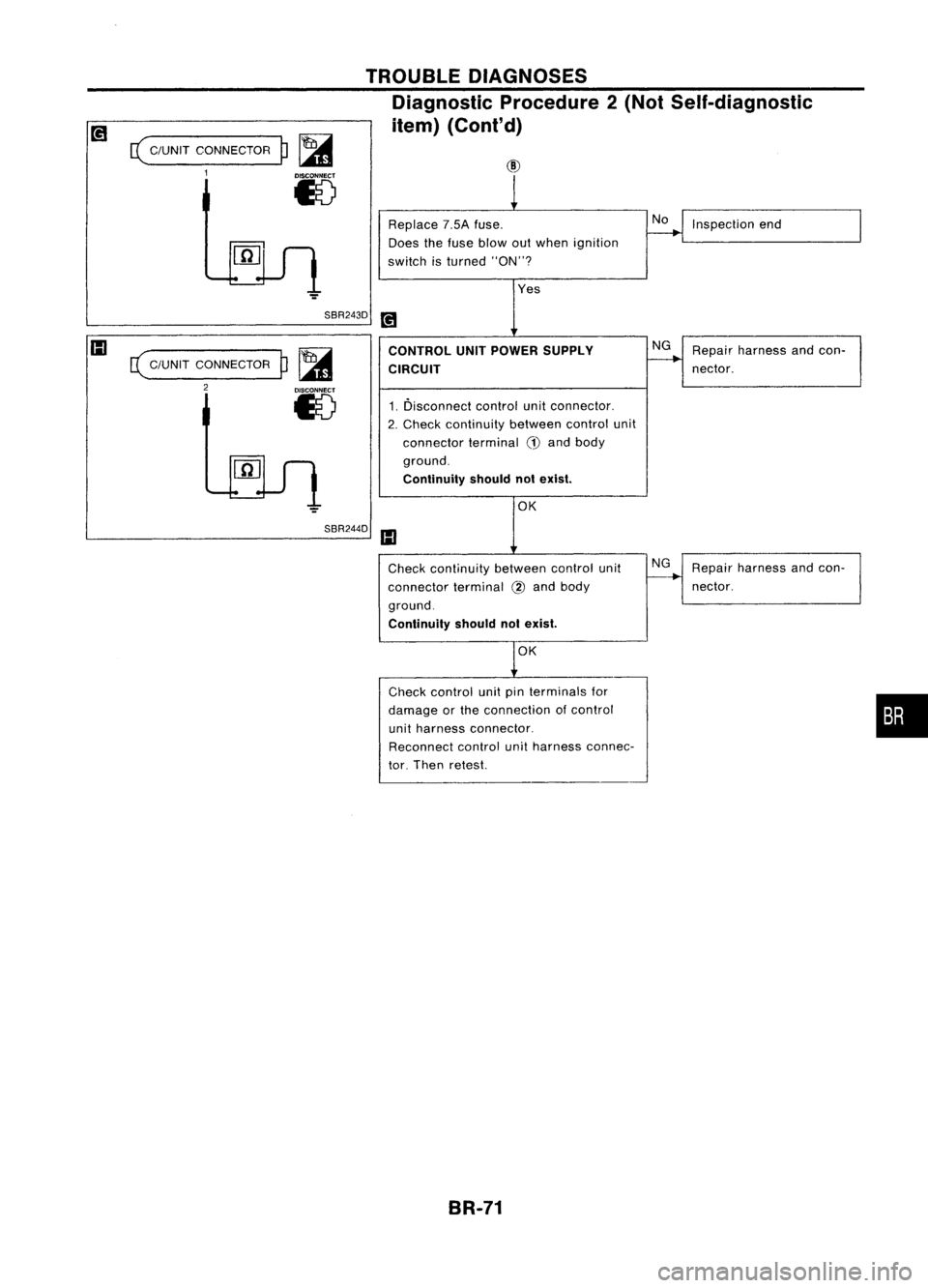

SBR243D

SBR244D

•

1

Replace 7.5Afuse.

~Inspection end

Does thefuse blowout whenignition

switch isturned "ON"?

Yes

[!1 CONTROL UNITPOWER SUPPLY

NG

Repair harness andcon-

---...

CIRCUIT

nector.

1. Disconnect controlunitconnector.

2. Check continuity betweencontrolunit

connector terminal

(D

and body

ground.

Continuity shouldnotexist.

OK

III

Check continuity betweencontrolunit NG

Repair harness andcon-

--+

connector terminal

@

and body nector.

ground.

Continuity shouldnotexist.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

TROUBLE

DIAGNOSES

Diagnostic Procedure2(Not Self-diagnostic

item) (Cont'd)

p~

15

p~

15

c(

C/UNIT CONNECTOR

1

c(

C/UNIT CONNECTOR

2

BR-71

Page 342 of 1701

TROUBLEDIAGNOSES

c(

C/UNIT CONNECTOR

5 .6 25. 26

,33 .34 5354,

(;) ASSactuator

a-pin connector

(ASS actuator side)

P

ASS relay box

2-pin connector

(ASS actuator side)

rO-...@

U!l.LJ

SBR245D

~i8

ASS relay box

2-pin connector

(ASS actuator side)

rO-...@

U!l.LJ

SBR246D Diagnostic

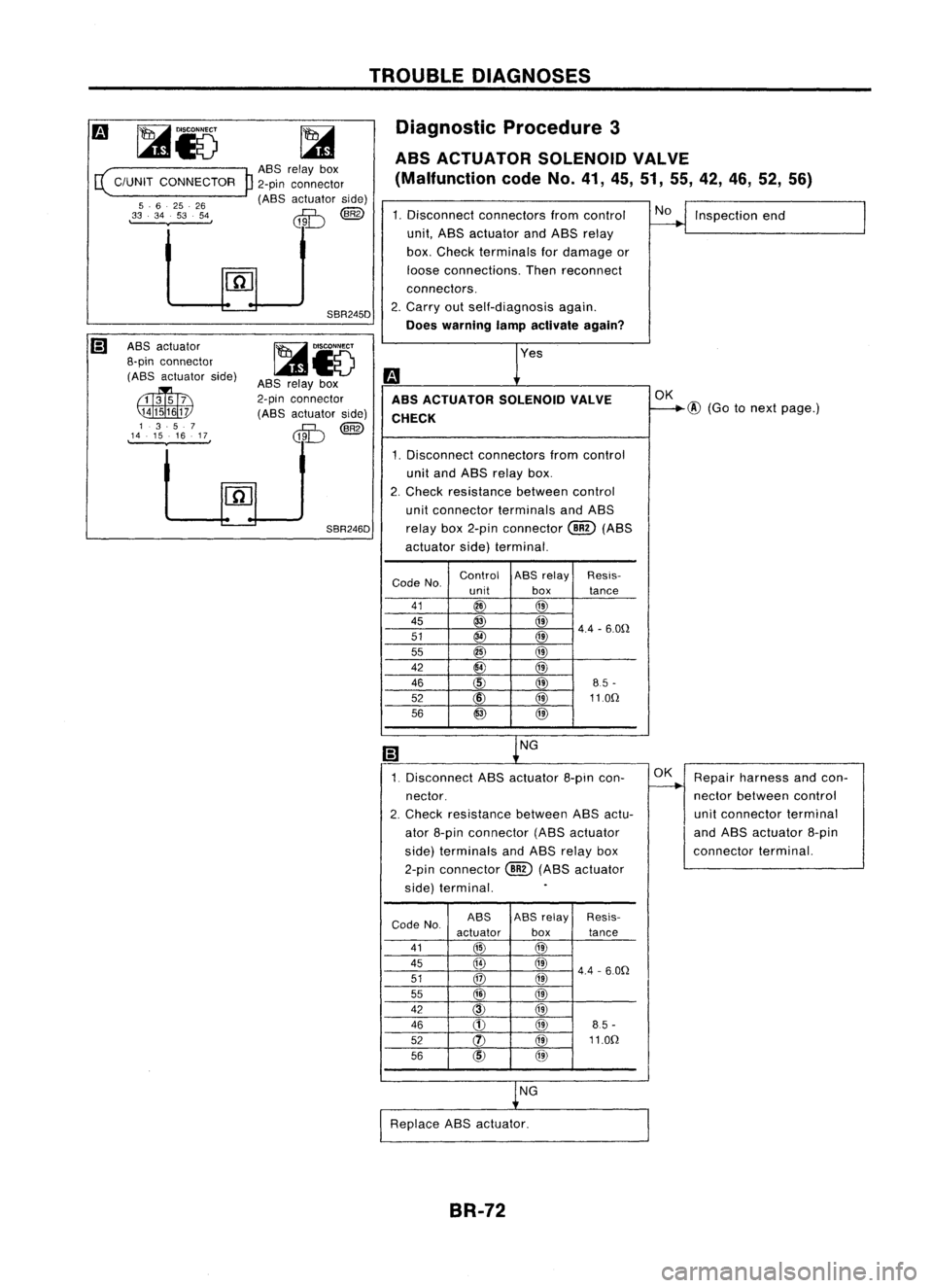

Procedure3

ABS ACTUATOR SOLENOIDVALVE

(Malfunction codeNo.41,45,51, 55,42, 46,52,56)

1. Disconnect connectorsfromcontrol

~Inspection end

unit, ASS actuator andASS relay

box. Check terminals fordamage or

loose connections. Thenreconnect

connectors.

2. Carry outself-diagnosis again.

Does warning lampactivate again?

Yes

m

ABS ACTUATOR SOLENOIDVALVE OK

CHECK

f---+@

(Gotonext page.)

1. Disconnect connectors fromcontrol

unit and ABS relay box.

2. Check resistance betweencontrol

unit connector terminalsandASS

relay box2-pin connector

@

(ABS

actuator side)terminal.

Code No. Control

ASSrelay Resis-

unit boxtance

41

@

@

45

@

@

4.4-6.0n

51

@

@

55

@

@

42

@

@

46

CID

@

85-

52 @ @110n

56

@

@

(;)

NG

1. Disconnect ASSactuator 8-pincon- OK

Repair harness andcon-

nector. ~

nectorbetween control

2. Check

resistance betweenABSactu- unitconnector terminal

ator 8-pin connector (ABSactuator and

ASS actuator 8-pin

side) terminals andASS relay box connector

terminal.

2-pin connector

@)

(ABS actuator

side) terminal.

.

Code No. ASS

ASS

relay Resis-

actuator box

tance

41

@

@

45

@

@)

4.4-6.0n

51

@

@

I

55

@

@

42

@)

@

46

CD

@

85-

52 (J)

@11.0n

56

CID

@

NG

Replace ABSactuator.

BR-72

Page 343 of 1701

TROUBLEDIAGNOSES

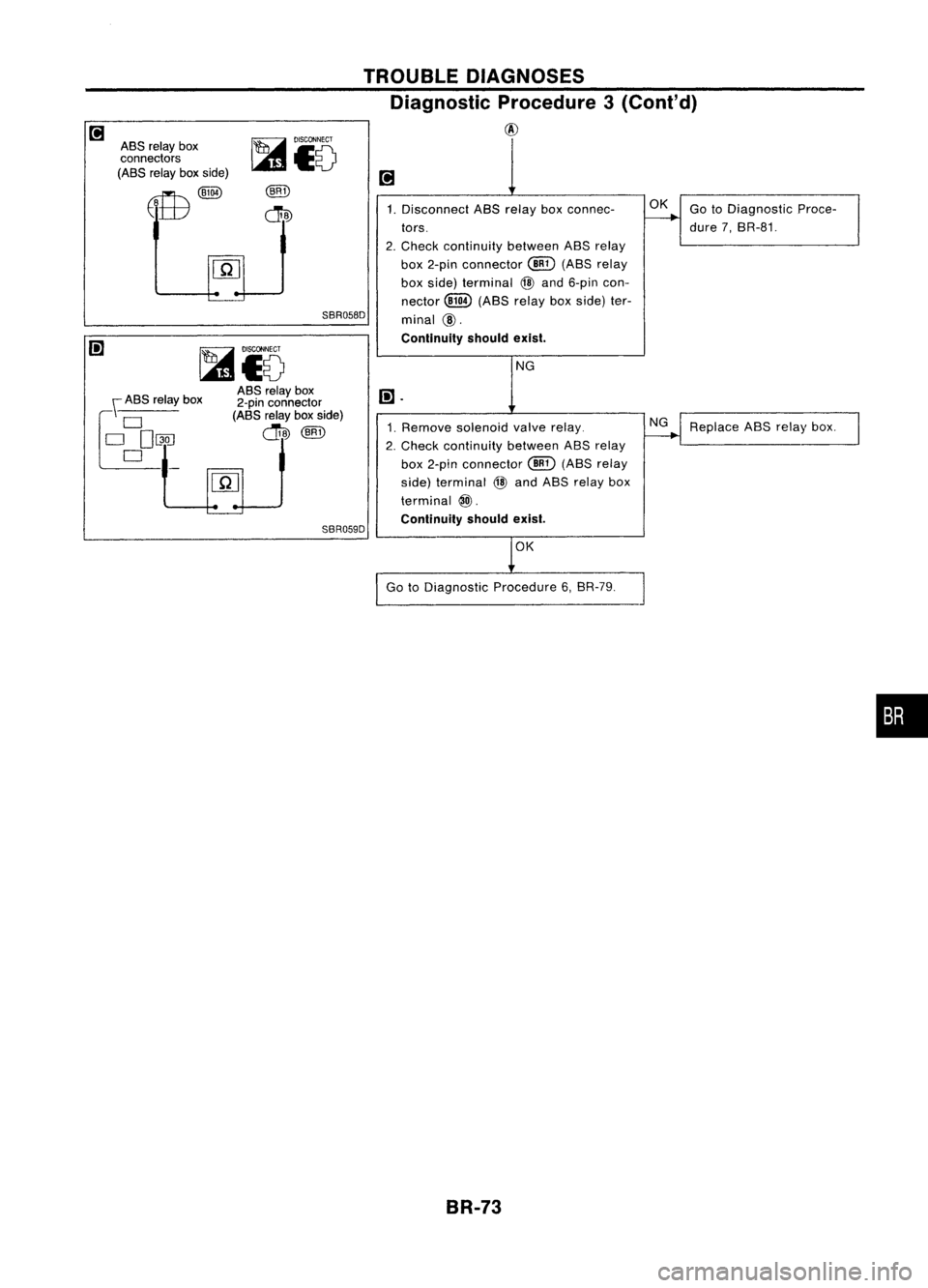

Diagnostic Procedure3(Conl'd)

@

ASS relay box

connectors

(ASS relayboxside)

EffB~

SBR058D1.

Disconnect ASSrelay boxconnec-

tors.

2. Check continuity betweenASSrelay

box 2-pin connector

@D

(ASS relay

box side) terminal @and 6-pin con-

nector

(ASS relayboxside) ter-

minal

@.

Continuity shouldexist. OK

GotoDiagnostic Proce-

dure?, SR-81.

NG

I-

ASS relay box

~~D~ ASS

relay box

2-pin connector

(ASS relayboxside)

Uw@

SBR059D 1.

Remove solenoid valverelay.

2. Check continuity betweenASSrelay

box 2-pin connector

@D

(ASS relay

side) terminal

@

and ASS relay box

terminal

@.

Continuity shouldexist.

OK

Go toDiagnostic Procedure6,BR-79.

BR-73

NG

Replace ASSrelay box.

•

Page 344 of 1701

TROUBLEDIAGNOSES

~i5

E(

C/UNITCONNECTOR

P

,14.9.11 .12, ,15.10.38.13,

SBR247DDiagnostic

Procedure4

WHEEL SENSOR ORROTOR

(Malfunction codeNo.21,22,25,26,31, 32,35, 36or18)

1. Disconnect connectors fromcontrol

~Inspection end

I

unit and wheel sensor ofmalfunction

code No.Check terminals fordam-

age orloose connections. Then

reconnect connectors.

2. Carry outself-diagnosis again.

Does warning lampactivate again?

Yes

m

WHEEL SENSOR ELECTRICAL CHECK

OK

~@

(Seenextpage.)

1. Disconnect controlunitconnector.

2. Check resistance betweencontrol

unit connector terminals.

Code No.21or22 (Front RHwheel)

Terminals

@

and @

Code No.25or26 (Front LHwheel)

Terminals

@

and

@

Code No.31or32 (Rear RHwheel)

Terminals

@

and

@

Code No.35or36 (Rear LHwheel)

Terminals

@

and

@

Resistance: 0.8•1.2 kD

NG

Note Note

CHECK WHEELSENSOR.

~Replace wheelsensor.

I

Refer toWHEEL SENSOR inElectrical

Components Inspection,SR-85.

OK

Note

Note:

Wheel position should

Repair harness andconnectors

be

distinguished by

between controlunitconn'ector and

code

No.

exceplcode

wheel sensor connector.

No.

18(sensor rotor).

BR-74

Page 345 of 1701

Note

Note Clean sensor fixing

portion, orreplace sen-

sor.

NG

OK

OK

Check clearance betweensensorand

rotor.

Clearance: Front0.1 -1.1

mm

(0.004 .0.043 in)

Rear 0.1 -1.1 mm

(0.004 -0.043 in)

WHEEL

SENSOR MECHANICAL CHECK

NGAdjust tirepressure or

replace tire(s).

Check forinflation pressure, wearand

size ofeach tire.

Note

Note Check wheelbearing axialendplay.

m

"Note

TROUBLE

DIAGNOSES

Diagnostic Procedure4(Conl'd)

@

SBR069C

\

\ Rotor

\\ Sensor

)6

Feeler gauge

)I

OK

Note Check sensor rotorforteeth damage.

NG

Note

Replace sensorrotor.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

Note:

Wheel position should •••

be distinguished by

code

No.except code

No. 18(sensor rotor).

BR-75

Page 346 of 1701

m

ASS relay box2-pin

[it

DISCONNECT

connector

@

IJIJ

~c:\

(body side)

";V

rn

TROUBLE

DIAGNOSES

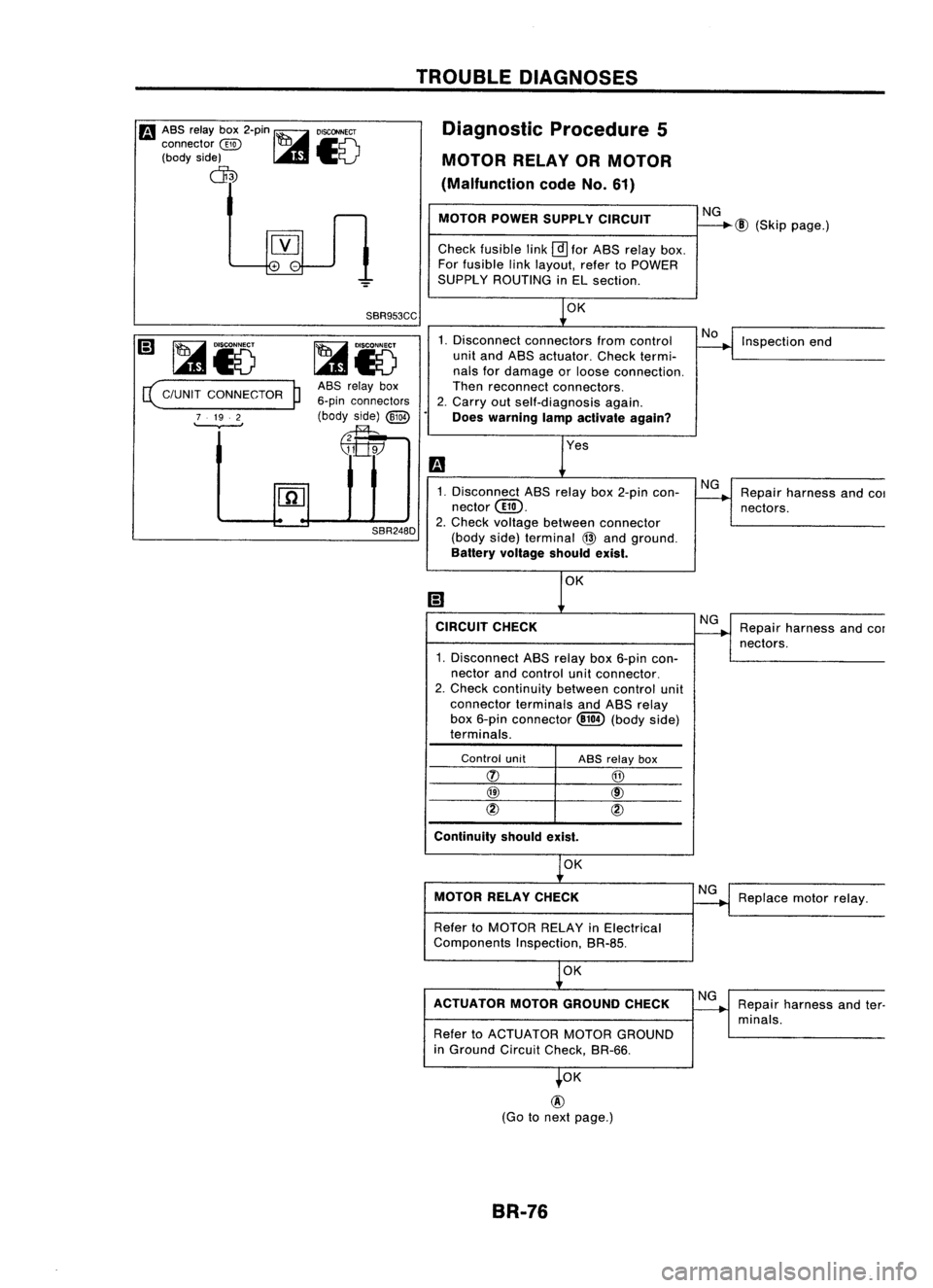

Diagnostic Procedure5

MOTOR RELAYORMOTOR

(Malfunction codeNo.61)

MOTOR POWERSUPPLY CIRCUIT

Check fusible link

@]

for ABS relay box.

For fusible linklayout, refertoPOWER

SUPPLY ROUTING inEL section.

NG

@

(Skip page.)

~iv

c(

C/UNIT CONNECTOR

P

7 19. 2

,

SBR953CC

~iV

ASS relay box

6-pin connectors

(body side)

@29

~

SBR248D OK

1. Disconnect connectors fromcontrol

unit and ABS actuator. Checktermi-

nals fordamage orloose connection.

Then reconnect connectors.

2. Carry outself-diagnosis again.

Does warning lampactivate again?

Yes

1. Disconnect ABSrelay box2-pin con-

nector@.

2. Check voltage between connector

(body side)terminal

@

and ground.

Battery voltage shouldexist.

CIRCUIT CHECK

1. Disconnect ABSrelay box6-pin con-

nector andcontrol unitconnector.

2. Check continuity betweencontrolunit

connector terminalsandABS relay

box 6-pin connector ~(body side)

terminals.

No

NG

NG

Inspection

end

Repair harness and

COI

nectors.

Repair harness andcor

nectors.

Control unit

Continuity shouldexist.

ASS

relay box

@

@

cID

OK

MOTOR RELAYCHECK

Refer toMOTOR RELAYinElectrical

Components Inspection,BR-8S.

OK

ACTUATOR MOTORGROUND CHECK

Refer toACTUATOR MOTORGROUND

in Ground CircuitCheck, BR-66.

OK

@

(Go tonext page.)

BR-76 NG

NG

Replace

motorrelay.

Repair harness andter-

minals.

Page 347 of 1701

TROUBLEDIAGNOSES

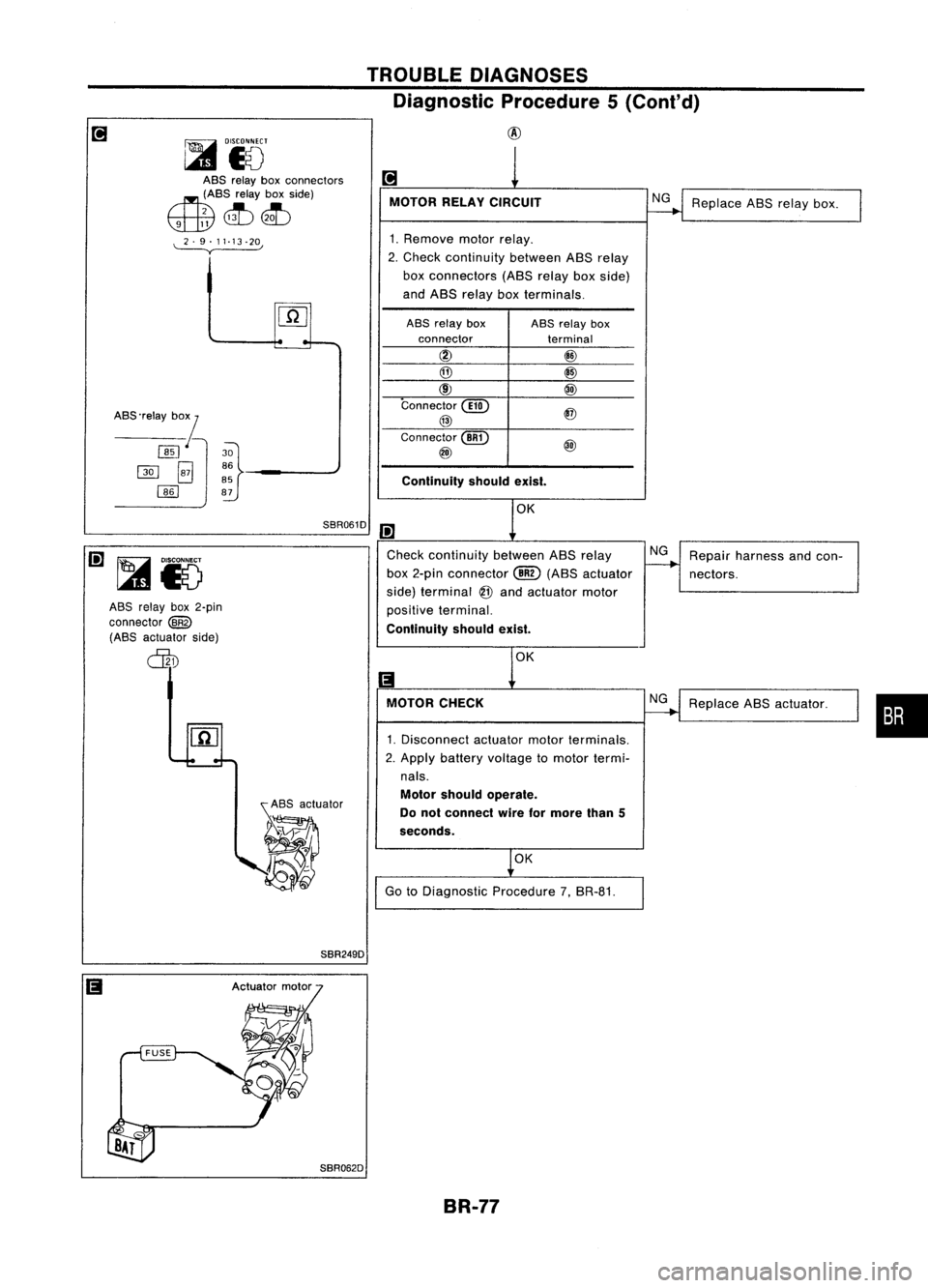

Diagnostic Procedure5(Cont'd)

@

[:tI

°15

T

ASS relay boxconnectors

~(ASS relayboxside)

2~~

9 11~~

~ MOTOR

RELAYCIRCUIT

1. Remove motorrelay.

2. Check continuity betweenASSrelay

box connectors (ASSrelayboxside)

and ASS relay boxterminals. NG

Replace ASSrelay box.

OK

Continuity

shouldexist.

ASS

'relay bOf

[ill

[ill

EJ

WJ

~

86

85

87

ASS

relay box

connector

@

@

@

Connector@

@

Connector@

@

ASS

relay box

terminal

@

@

@

@

SBR061D Ii]

Check continuity betweenASSrelay

box 2-pin connector

@

(ASS actuator

side) terminal @and actuator motor

positive terminal.

Continuity shouldexist.

•

Repair

harness andcon-

nectors.

Replace ASSactuator.

NG

NG

OK

1.

Disconnect actuatormotorterminals.

2. Apply battery voltage tomotor termi-

nals.

Motor should operate.

Do not connect wireformore than5

seconds.

Go toDiagnostic Procedure7,SR-81.

131

MOTOR CHECK

ASS

relay box2-pin

connector

@iY

(ASS actuator side)

do

SBR249DBR-77

Page 348 of 1701

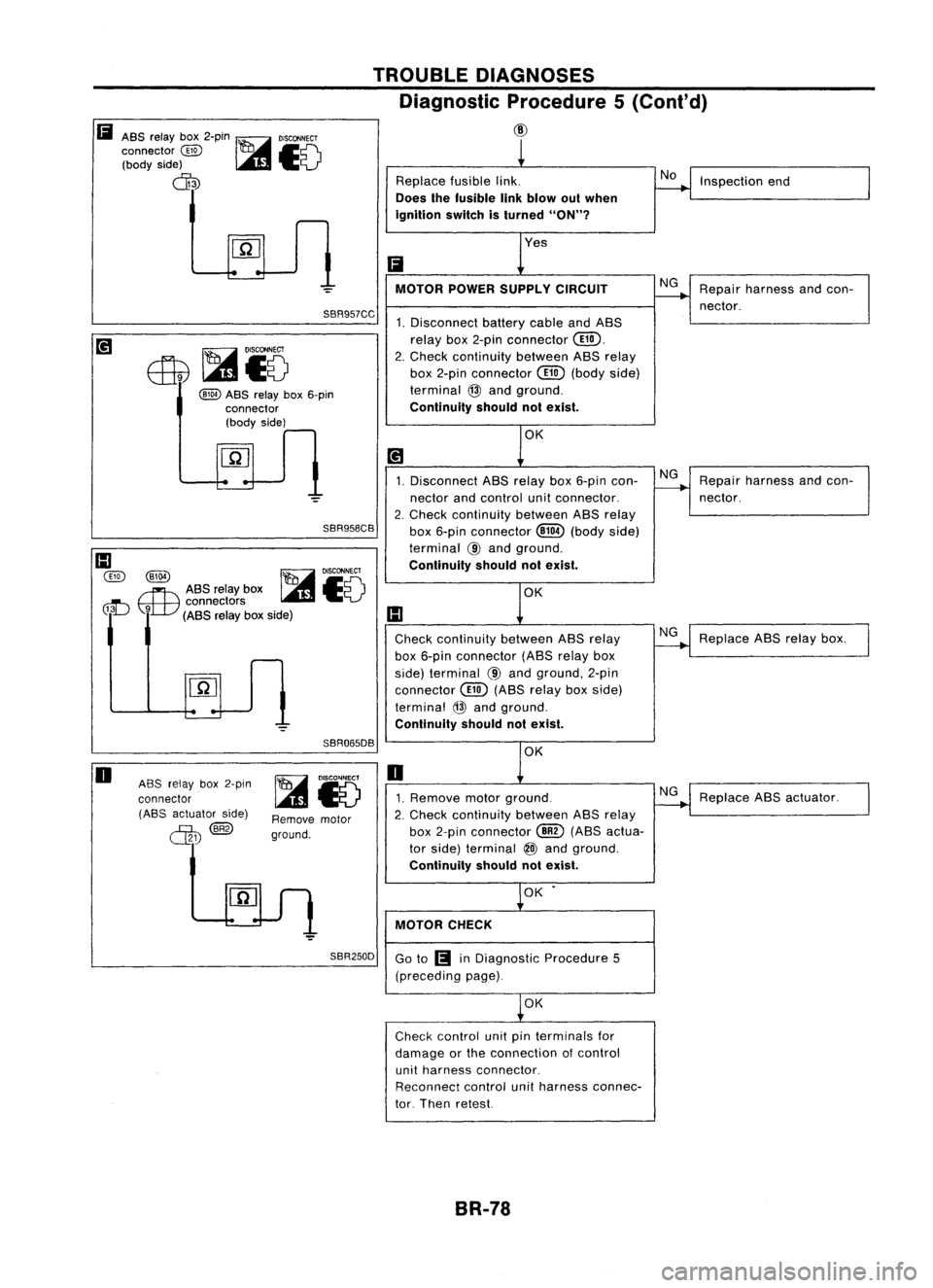

TROUBLEDIAGNOSES

Diagnostic Procedure5(Conl'd)

CID

Ii

ASS relay box2-pin ~

DISCONNECT

connector

@

=

1c0,

(body side)

V

cD

SBR957CC

@)

ASS relay box6-pin

connector (body side)

SBR958CB

III

@

@El ~

DISCONNECT

rrt\

ASSrelay box

~c;"1

\J.tV

connectors

-';;V

0U

9

(ASSrelayboxside) Replace

fusiblelink.

Does thefusible linkblowout when

ignition switchisturned

"ON"?

Ii

MOTOR POWERSUPPLVCIRCUIT

1. Disconnect batterycableandASS

relay box2-pin connector

@.

2. Check continuity betweenASSrelay

box 2-pin connector

@

(body side)

terminal @and ground.

Continuity shouldnotexist.

1. Disconnect ASSrelay box6-pin con-

nector andcontrol unitconnector.

2. Check continUity betweenASSrelay

box 6-pin connector @E)(body side)

terminal

@

and ground.

Continuity shouldnotexist.

OK

Check continuity betweenASSrelay

box 6-pin connector (ABSrelaybox

side) terminal @and ground, 2-pin

connector

@

(ASS relay boxside)

terminal @and ground.

Continuity shouldnotexist. No

NG

NG

NG

Inspection

end

Repair harness andcon-

nector.

Repair harness andcon-

nector.

Replace ASSrelay box.

J

o

ASSrelay box2-pin

connector (ASS actuator side)

~@

L1J.1J

SBR065DB

Remove motor

ground. OK

o

1. Remove motorground.

2. Check continuity betweenASSrelay

box 2-pin connector

@)

(ASS actua-

tor side) terminal

@)

and ground.

Continuity shouldnotexist. NG

Replace ASSactuator.

OK

MOTOR CHECK

SBR250D Goto

n!II

inDiagnostic Procedure5

(preceding page).

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

BR-78

Page 349 of 1701

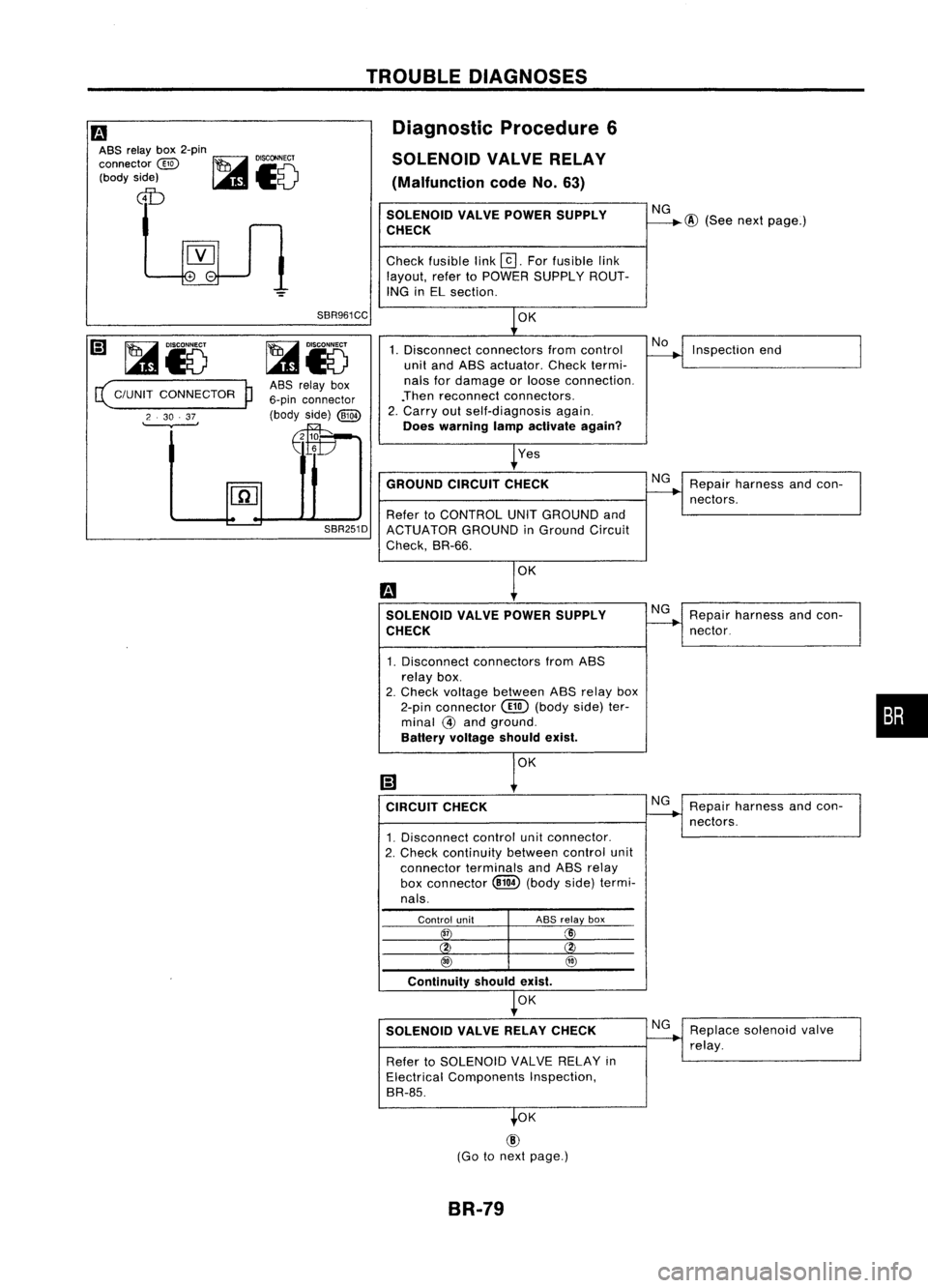

Fa

ASS relay box2-pin

DISCONNECT

connector

@~~~

(body side)

I..lI&I

~V

ctD

TROUBLE

DIAGNOSES

Diagnostic Procedure6

SOLENOID VALVERELAY

(Malfunction codeNo.63)

SOLENOID VALVEPOWER SUPPLY

CHECK

Check fusible link

@].

Forfusible link

layout, refertoPOWER SUPPLY ROUT-

ING inEL section.

NG

@

(See nextpage.)

~Io

( C/UNIT CONNECTOR

P

2 .30 .37

.

SBR961CC

ASS relay box

6-pin connector

(body side)

@W

Efe

OK

1. Disconnect connectors fromcontrol

unit andASS actuator. Checktermi-

nals fordamage orloose connection.

.Then reconnect connectors.

2. Carry outself-diagnosis again.

Does warning lampactivate again?

Yes

No

Inspection end

GROUND CIRCUITCHECK

Refer toCONTROL UNITGROUND and

SBR251D

ACTUATOR GROUNDinGround Circuit

Check, SR-66.

OK

SOLENOID VALVEPOWER SUPPLY

CHECK

1. Disconnect connectors fromASS

relay box.

2. Check voltage between ASSrelay box

2-pin connector

@

(body side)ter-

minal

@

and ground.

Battery voltage shouldexist.

CIRCUIT CHECK

1. Disconnect controlunitconnector.

2. Check continuity betweencontrolunit

connector terminalsandASS relay

box connector

@ill

(body side)termi-

nals. Repair

harness andcon-

nectors.

Repair harness andcon-

nector.

Repair harness andcon-

nectors.

•

Control unit

3T

ABS

relay box

Xi

@ @

Continuity shouldexist.

OK

SOLENOID VALVERELAY CHECK

Refer toSOLENOID VALVERELAY in

Electrical Components Inspection,

SR-85.

OK

@

(Go tonext page.)

BR-79

Replace

solenoid valve

relay.

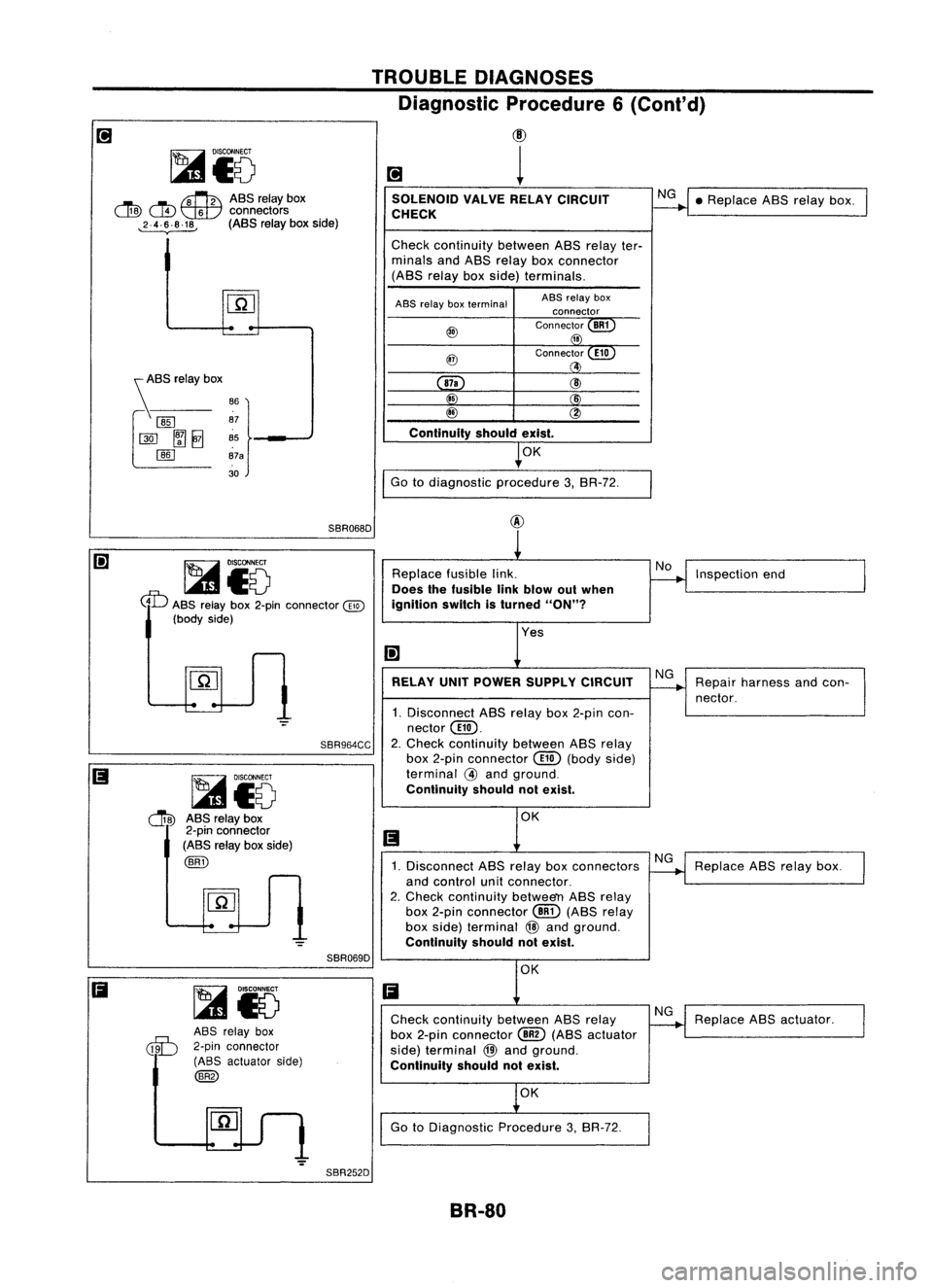

Page 350 of 1701

~i5

TROUBLE

DIAGNOSES

Diagnostic Procedure6

(Co nt'd)

(!)

1

~ ASSrelaybox

LI!ID

c:!D~

connectors

,2.4.~.8.18,

(ASSrelayboxside)

SOLENOID

VALVERELAY CIRCUIT

CHECK

NG

•Replace ASSrelay box.

Check continuity betweenASSrelay ter-

minals andASS relay boxconnector

(ASS relayboxside) terminals.

~SS relaybox

~

:~

}

[]QJ ~~

85

00

87a

30

ABS

relay boxterminal

87a

85

@

Continuity shouldexist.

OK

I

Go todiagnostic procedure3,SR-72.

SBR068D

I;]

~i5

Replace

fusiblelink. No

Inspection end

Does thefusible linkblowout when

GD

ASSrelay box2-pin connector

@

Ignition switchisturned

"ON"?

(body side)

Yes

I;]

[Q]

RELAYUNIT POWER SUPPLY CIRCUIT

NG

Repair harness andcon-

nector.

1. Disconnect ASSrelay box2-pin con-

-=-

nector@.

SBR964CC

2.

Check continuity betweenASSrelay

box 2-pin connector @(body side)

~i5

terminal

@

and ground.

Continuity shouldnotexist.

c1!D

ASS

relay box

OK

2-pin connector

Ii

(ASS relayboxside)

@ED

1.Disconnect ASSrelay boxconnectors NG

Replace ASSrelay box.

and control unitconnector.

2. Check continuity betwee"llASSrelay

box 2-pin connector

@

(ASS relay

box side) terminal

@

and ground.

-=-

Continuity

shouldnotexist.

SBR069D OK

Ii

~io

Ii

Check continuity betweenASSrelay NG

Replace ASSactuator.

@[)

ABS

relay box

box2-pin connector

@

(ASS actuator

2-pin connector

side)terminal

@

and ground.

(ABS actuator side)

Continuityshouldnotexist.

@

OK

Go toDiagnostic Procedure3,SR-72.

':"

SBR252D

BR-80