NISSAN ALMERA N15 1995 Service Manual

Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 351 of 1701

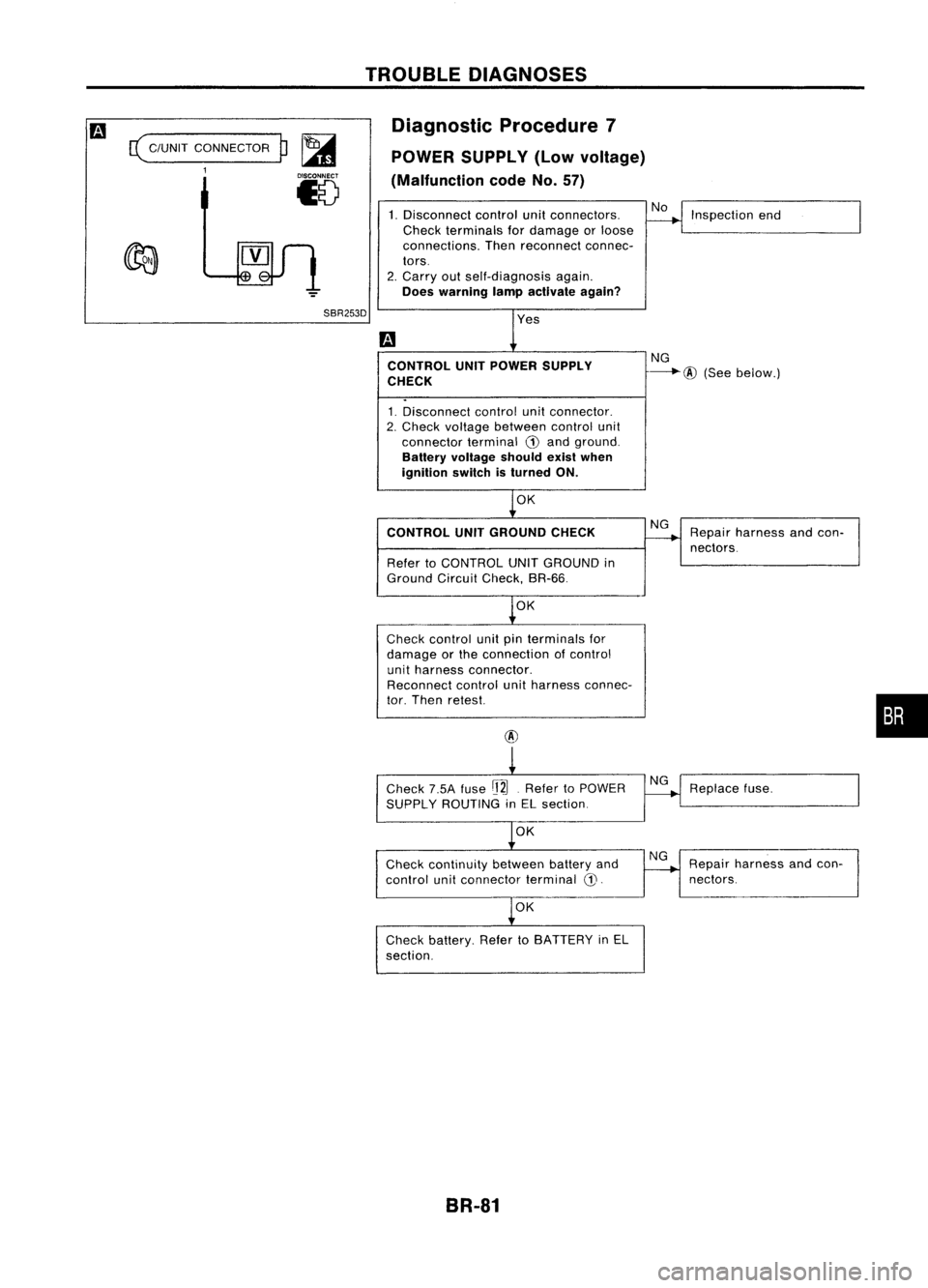

c(

C/UNIT CONNECTOR

1

p~

18

TROUBLE

DIAGNOSES

Diagnostic Procedure7

POWER SUPPLY (Lowvoltage)

(Malfunction codeNo.57)

1. Disconnect controlunitconnectors.

Check terminals fordamage orloose

connections. Thenreconnect connec-

tors.

2. Carry outself-diagnosis again.

Does warning lampactivate again? No

Inspection end

SBR253D CONTROL UNITPOWER SUPPLY

CHECK

1. Disconnect controlunitconnector.

2. Check voltage between controlunit

connector terminalG)and ground.

Battery voltage shouldexistwhen

ignition switchisturned ON.

OK NG

---.-.@

(Seebelow.)

CONTROL UNITGROUND CHECK

Refer toCONTROL UNITGROUND in

Ground CircuitCheck, BR-66.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

@

Check 7.5Afuse

rj2J.

Refer toPOWER

SUPPLY ROUTING inEL section.

OK

Check continuity betweenbatteryand

control unitconnector terminal

CD.

OK

Check battery. RefertoBATTERY inEL

section.

BR-81 NG

NG

NG Repair

harness andcon-

nectors.

Replace fuse.

Repa;, hame" aodcoo-

I

nectors.

•

Page 352 of 1701

TROUBLEDIAGNOSES

Diagnostic Procedure8

CONTROL UNIT

(Malfunction codeNo.71)

Carry outself-diagnosis aftererasing

self-diagnostic results,BR-56.

Does warning lampindicate codeNo.

71 again?

No

Inspect thesystem according tothe

code No. Yes

Replace controlunit.

Brake pedal Diagnostic

Procedure9

SYMPTOM: Pedalvibration andnoise

No

Does thesymptom appearwhenelectri-

SAT797A

calequipment switches(suchashead-

lamp) areoperated?

1.

Apply brake.

2. Start engine.

3. Does thesymptom appearonlywhen

engine isstarted?

No

Yes

Check wheelsensor shieldgrou.nd

secured withcontrol unitmounting bolt.

Refer toBR-41. Yes

Carryoutself-diagnosis.

Refer toBR-53 (Europe)

or BR-56 (Except

Europe).

Go to

Ii1

inDiagnostic

Procedure 11,BR-83.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

Note: ABSmayoperate andcause vibration underanyofthe

following conditions.

• Applying brakegradually whenshifting oroperating clutch.

• Low friction (slippery) road.

• High speed cornering.

• Driving overbumps andpotholes.

• Engine speedisover 5,000 rpmwith vehicle stopped.

BR-82

Page 353 of 1701

TROUBLEDIAGNOSES

Diagnostic Procedure10

SYMPTOM: Longstopping distance

Disconnect ABSrelay box6-pin connec- No

tor and check whether stopping dis-

tance isstill long.

Perform Preliminary Checkandair

bleeding. Go

to

IiJ

inDiagnostic

Procedure 11.SR-83.

Note: Stopping distancemaybelarger thanvehicles without

ABS when roadcondition isslippery.

Diagnostic Procedure11

SYMPTOM: Unexpected pedalaction

m

Check brakepedalstroke. Isstroke

excessively

large?

No

Disconnect ASSrelay box6-pin connec-

tor and check whether brakeiseffec-

SBR540A tive.

Yes

Ensure warning lampremains offwhile

driving.

OK

CHECK WHEEL SENSOR.

1. Check wheelsensor connector for

terminal damageorloose connec-

tion.

2. Perform wheelsensor mechanical

check. Refer to

IiJ

inDiagnostic Procedure

4, BR-75.

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

BR-83

Yes

Perform Preliminary

Check. refertoSR-65.

Perform Preliminary

Check. refertoSR-65.

Carry outself-diagnosis.

Refer toBR-53 (Europe)

or SR-56 (Except

Europe).

Repair.

•

Page 354 of 1701

TROUBLEDIAGNOSES

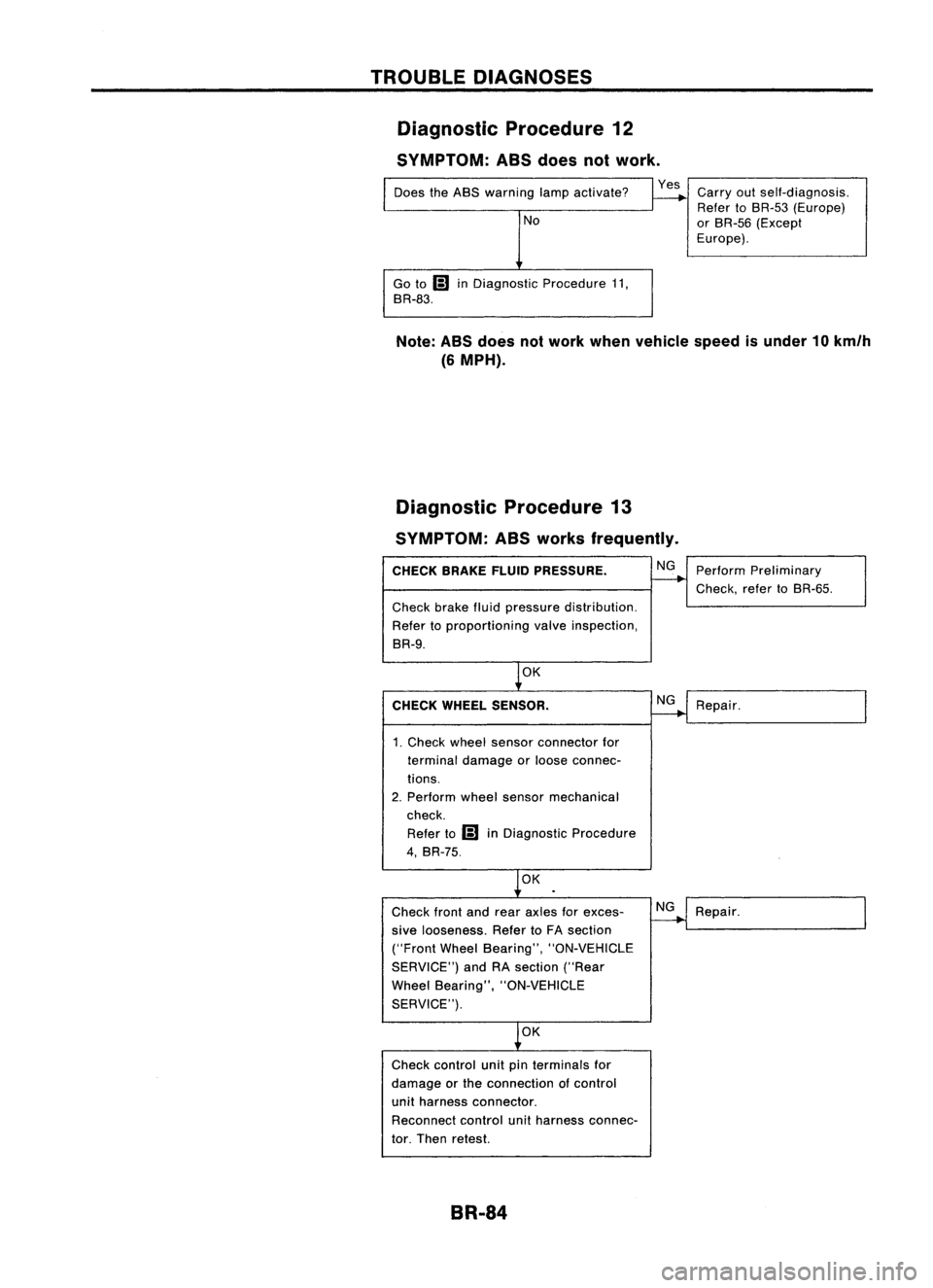

Diagnostic Procedure12

SYMPTOM: ASSdoes notwork.

Does theABS warning lampactivate?

No

Go to

Ii)

inDiagnostic Procedure11,

BR-83.

Yes

Carryoutself-diagnosis.

Refer toBR-53 (Europe)

or BR-55 (Except

Europe).

Note: ABSdoes notwork when vehicle speedisunder 10km/h

(6 MPH).

Diagnostic Procedure13

SYMPTOM: ASSworks frequently.

CHECK BRAKEFLUIDPRESSURE.

Check brakefluidpressure distribution.

Refer toproportioning valveinspection,

BR-9.

OK

CHECK WHEEL SENSOR.

1. Check wheelsensor connector for

terminal damage orloose connec-

tions.

2. Perform wheelsensor mechanical

check.

Refer to

Ii)

inDiagnostic Procedure

4, BR-75.

OK

Check frontandrear axles forexces-

sive looseness. RefertoFA section

("Front WheelBearing", "ON-VEHICLE

SERVICE") andRAsection ("Rear

Wheel Bearing", "ON-VEHICLE

SERVICE").

OK

Check control unitpinterminals for

damage orthe connection ofcontrol

unit harness connector.

Reconnect controlunitharness connec-

tor. Then retest.

BR-84 NG

NG

NG

Perform

Preliminary

Check, refertoBR-55.

Repair.

Repair.

Page 355 of 1701

TROUBLEDIAGNOSES

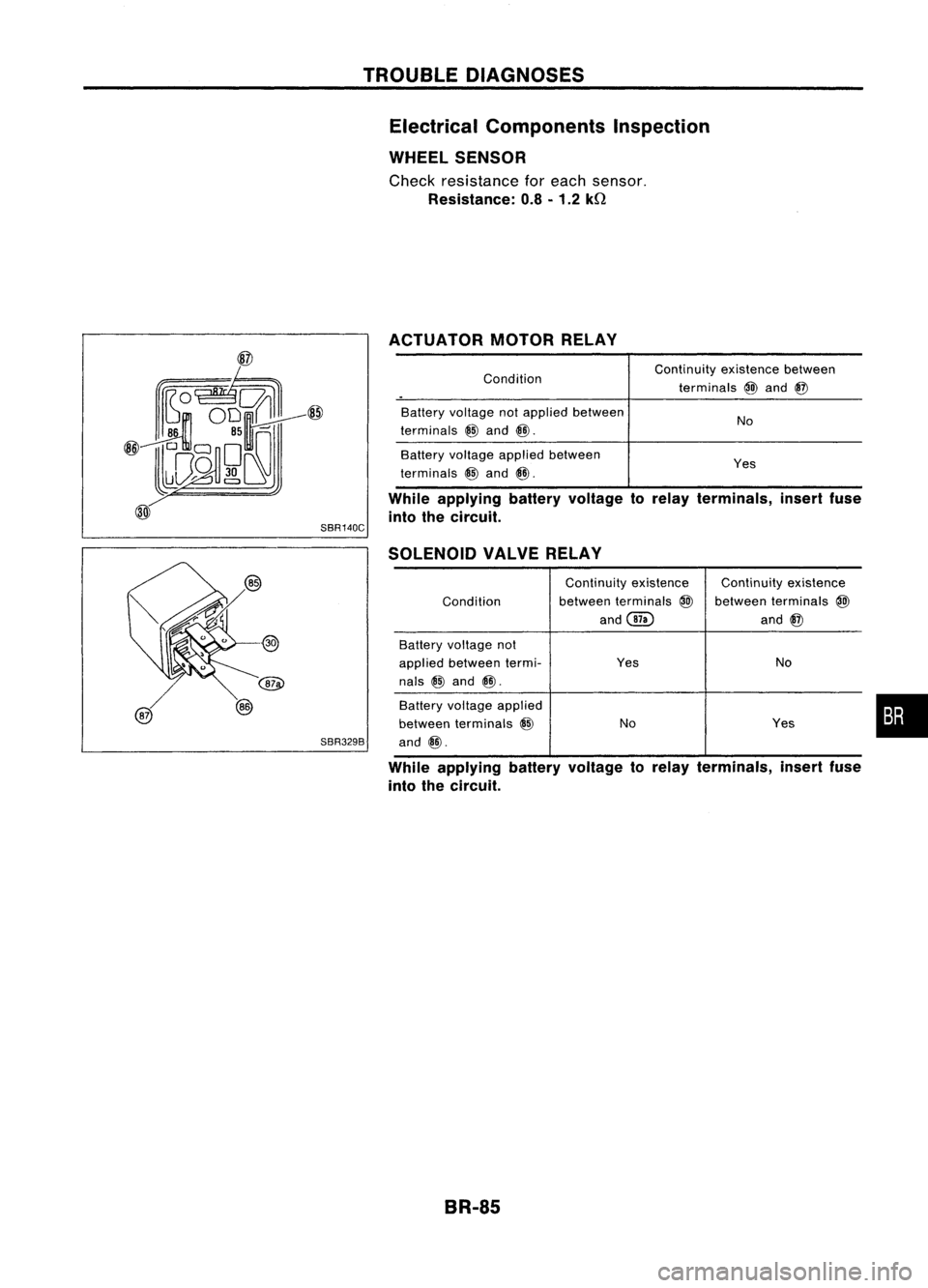

Electrical Components Inspection

WHEEL SENSOR

Check resistance foreach sensor.

Resistance: 0.8-1.2 kQ

ACTUATOR MOTORRELAY

While applying batteryvoltage torelay terminals, insertfuse

into thecircuit.

Condition

Battery voltage notapplied between

terminals

@

and

@.

Battery voltage applied between

terminals

@

and

@.

SBR140C

Continuity

existencebetween

terminals

@

and

@

No

Yes

SBR329B SOLENOID

VALVERELAY

Continuity existence Continuityexistence

Condition between

terminals

@

between terminals

@

and@ and

@

Battery voltage not

applied between termi- Yes

No

nals

@

and

@.

Battery voltage applied

between terminals

@

No Yes

and

@.

While applying batteryvoltage torelay terminals, insertfuse

into thecircuit.

BR-85

•

Page 356 of 1701

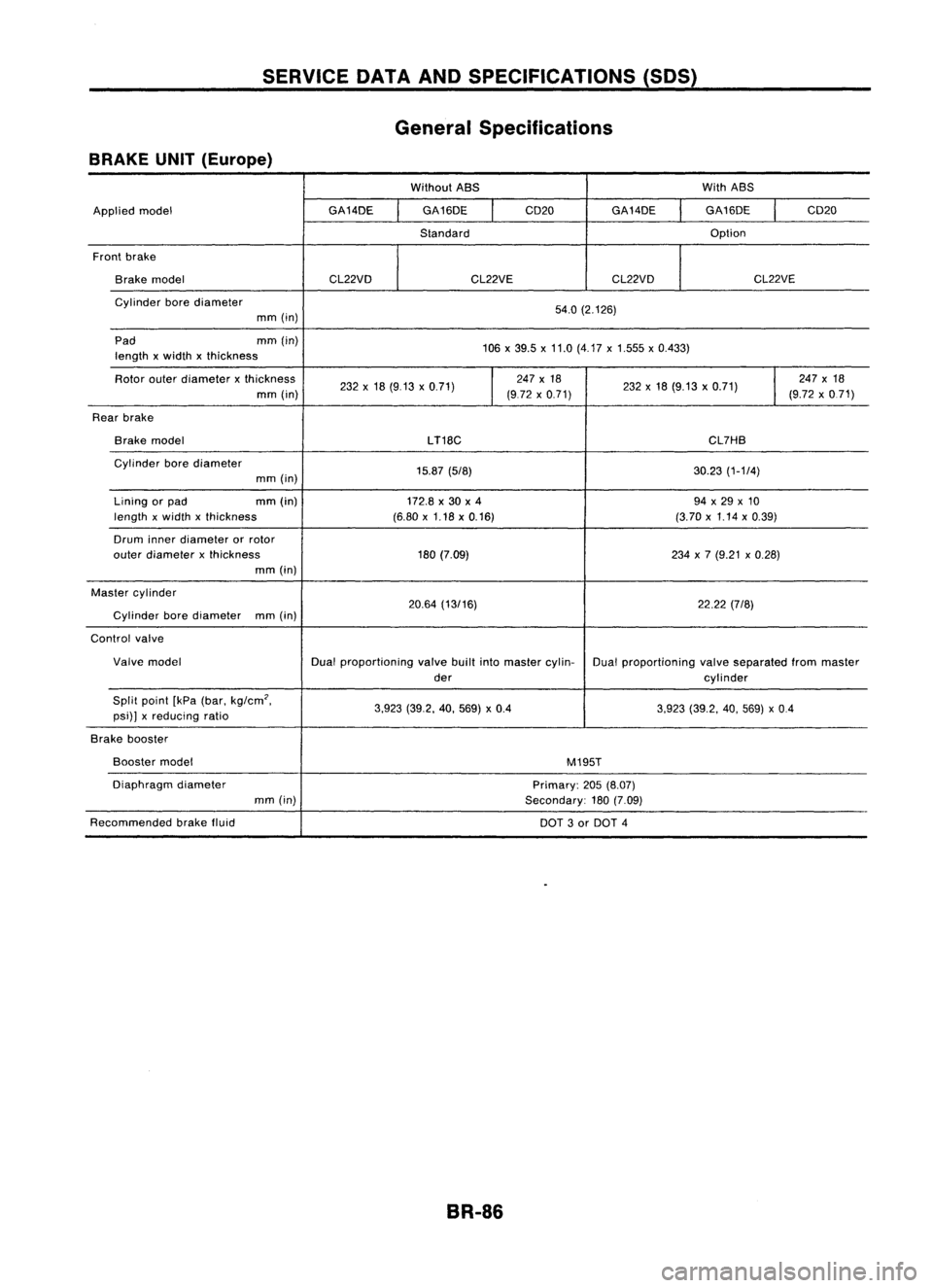

SERVICEDATAANDSPECIFICATIONS (SOS)

General Specifications

BRAKE UNIT(Europe)

WithoutABS WithABS

Applied model GA14DE

GA16DE

I

CD20

GA14DE GA16DE

I

CD20

Standard Option

Front brake

Brake model CL22VDCL22VECL22VD CL22VE

Cylinder borediameter

54.0(2.126)

mm (in)

Pad mm(in)

106x39.5 x11.0 (4.17 x1.555 x0.433)

length xwidth xthickness

Rotor outerdiameter xthickness

232x18 (9.13 x0.71)

I

247

x18

232x18 (9.13 x0.71)

I

247

x18

mm (in) (972x0.71) (9.72x0.71)

Rear brake

Brake model

LT18C CL7HB

Cylinder borediameter

15.87(5/8) 30.23(1-1/4)

mm (in)

Lining orpad mm

(in)

172.8x30 x4 94x29 x10

length xwidth xthickness (6.80x1.18 x0.16) (3.70x1.14 x0.39)

Drum innerdiameter orrotor

outer diameter xthickness 180(7.09) 234x7 (9.21 x0.28)

mm (in)

Master cylinder

20.64(13/16) 22.22(7/8)

Cylinder borediameter

mm(in)

Control valve

Valve model Dualproportioning valvebuiltintomaster cylin-

Dualproportioning valveseparated frommaster

der cylinder

Split point [kPa(bar. kg/cm

2•

3.923(39.2. 40.569) x0.4

3.923(39.2. 40.569) x0.4

psi)] xreducing ratio

Brake booster

Booster model

M195T

Diaphragm diameter

Primary:205(8.07)

mm (in)

Secondary:180(7.09)

Recommended brakefluid

DOT3or DOT 4

BR-86

Page 357 of 1701

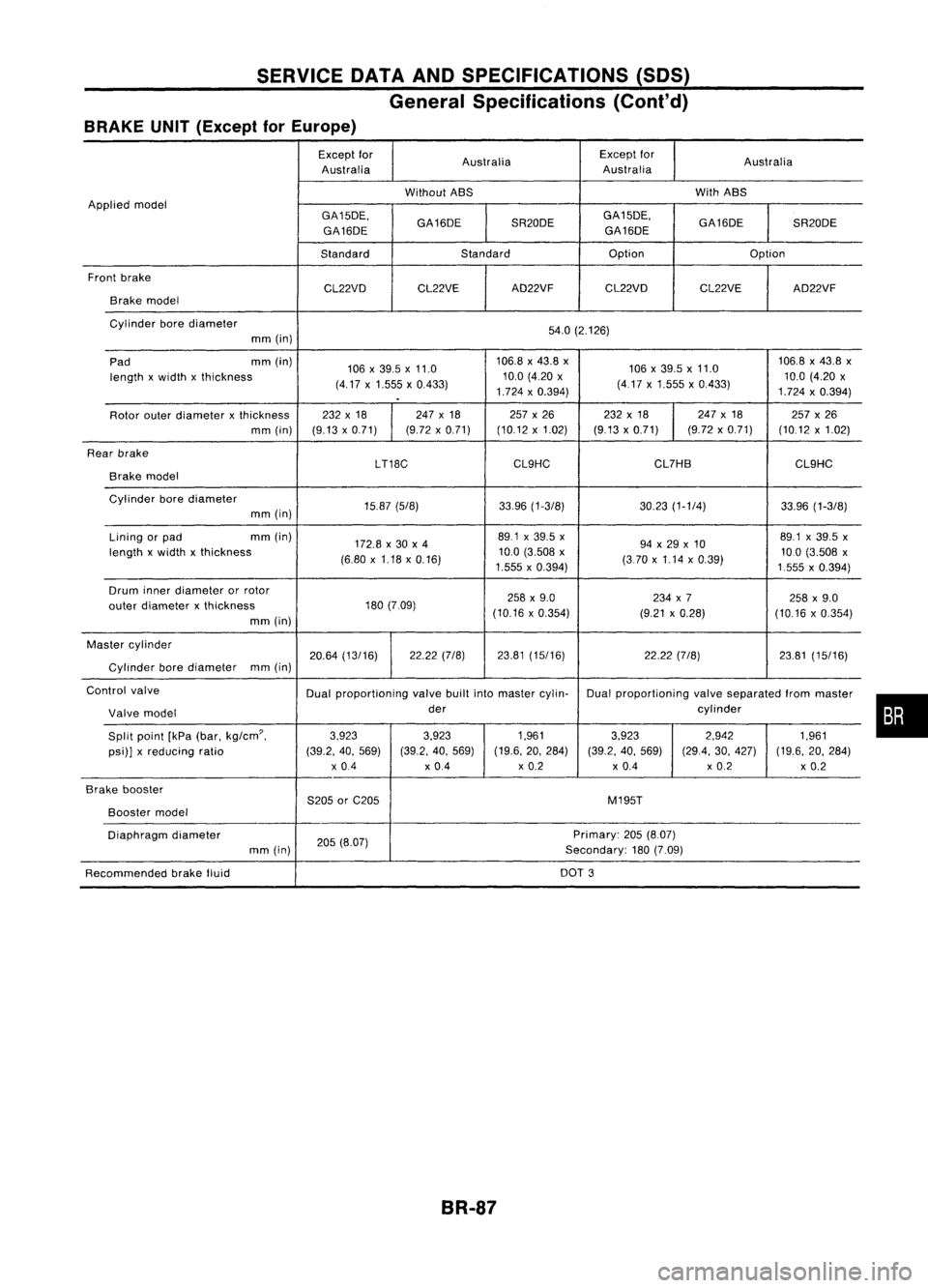

SERVICEDATAANDSPECIFICATIONS (SDS)

General Specifications (Cont'd)

BRAKE UNIT(Except forEurope)

Except for

Australia Except

for

Australia

Australia Australia

Without ABS With

ABS

Applied model

GA15DE.GA16DESR20DEGA15DE.

GA16DESR20DE

GA16DE GA16DE

Standard Standard Option

Option

Front brake

CL22VDCL22VE AD22VF

CL22VD CL22VEAD22VF

Brake model

Cylinder borediameter

54.0(2.126)

mm (in)

Pad mm

(in)

106x39.5 x11.0 106.8

x43.8 x

106x39.5x11.0 106.8

x43.8 x

length xwidth xthickness

(4.17x1.555 x0.433) 10.0

(4.20 x

(417x1.555 x0.433) 10.0

(4.20 x

.

1.724

x0.394)

1.724x0.394)

Rotor outerdiameter xthickness 232

x18 247x18 257x26 232x18 247

x18

257x26

mm (in) (9.13x0.71) (9.72

x0.71) (10.12x1.02) (9.13x0.71) (9.72x0.71) (10.12x1.02)

Rear brake

LT18CCL9HC CL7HB

CL9HC

Brake model

Cylinder borediameter

15.87(5/8) 33.96(1-3/8) 30.23(1-1/4) 33.96(1-3/8)

mm (in)

Lining orpad mm

(in)

172.8x30 x4 89.1

x39.5 x

94x29 x10 89.1

x39.5 x

length xwidth xthickness

(6.80x1.18 x0.16) 10.0

(3.508 x

(370x1.14 x0.39) 10.0

(3.508 x

1.555 x0.394)

1555x0.394)

Drum innerdiameter orrotor

258x9.0 234x7

258x9.0

outer diameter xthickness 180

(7.09)

(10.16x0.354) (9.21x0.28)

(10.16x0.354)

mm (in)

Master cylinder

20.64(13/16) 22.22

(7/8) 23.81(15/16) 22.22(7/8) 23.81(15/16)

Cylinder borediameter mm

(in)

Control valve

Dualproportioning valvebuiltintomaster cylin- Dualproportioning valveseparated frommaster

Valve model der

cylinder

Split point [kPa(bar.

kg/cm'.

3.923

3.923 1.9613.923 2.942

1.961

psi)] xreducing ratio (39.2.40.569) (39.2.40.569) (19.6.

20.284)

(39.2.40.569) (29.4.30.427) (19.6.20.284)

x 0.4 x0.4 x

0.2

x0.4 x

0.2

x0.2

Brake booster

S205orC205 M195T

Booster

model

Diaphragm diameter

205(8.07) Primary:

205(8.07)

mm (in) Secondary:180(7.09)

Recommended brakefluid DOT

3

BR-87

•

Page 358 of 1701

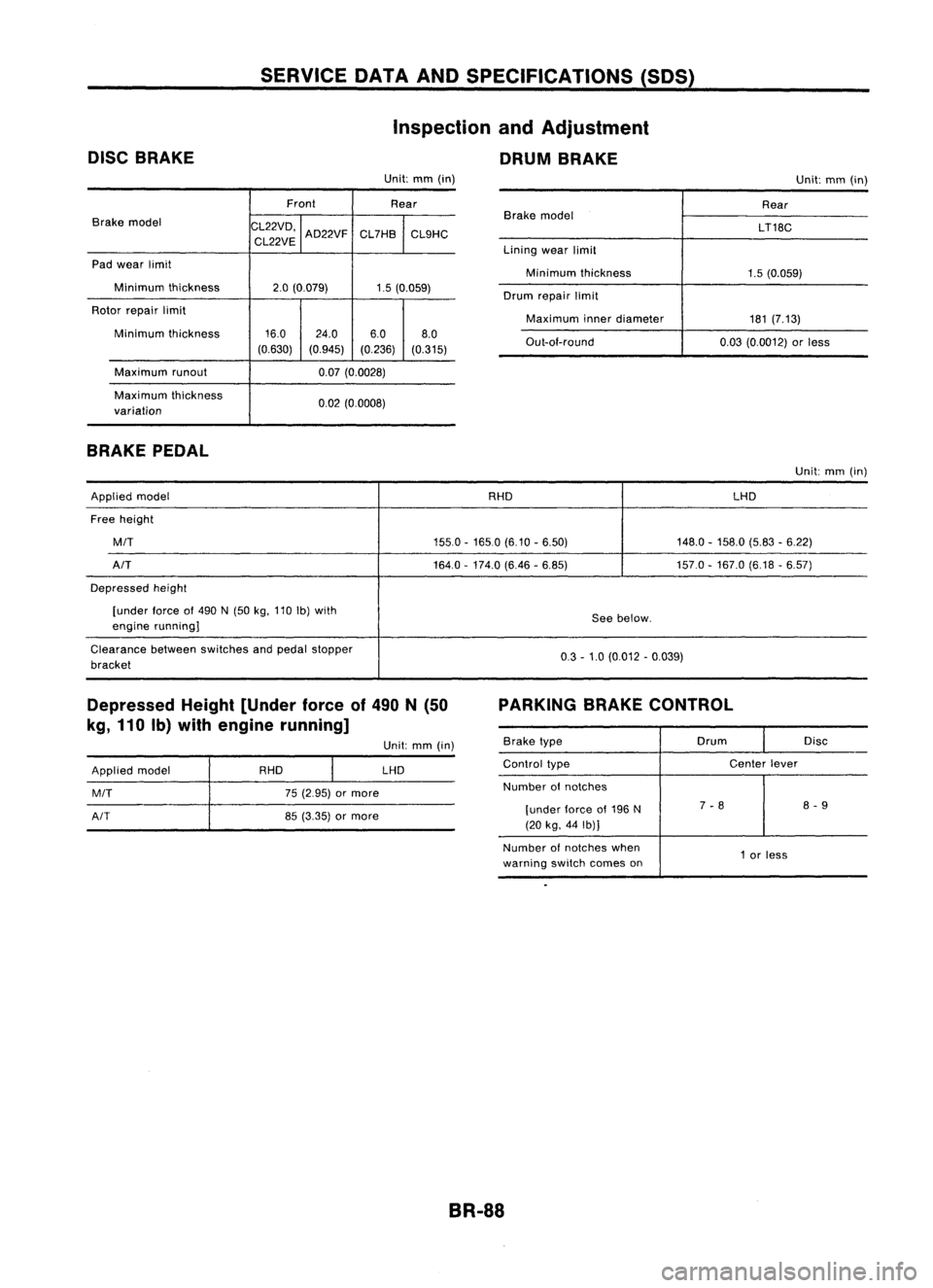

DISCBRAKE SERVICE

DATAANDSPECIFICATIONS (SDS)

Inspection andAdjustment

DRUM BRAKE

Unit: mm(in)

Unit:mm(in)

Front Rear

Brake model

CL22VD,

CL22VE AD22VF

CL7HB

CL9HC

Pad wear limit

Minimum thickness

2.0(0.079) 1.5(0.059)

Rotor repair limit

Minimum thickness 16.0

24.0 6.08.0

(0.630) (0.945) (0.236)(0.315)

Maximum runout 0.07(0.0028)

Maximum thickness

0.02(0.0008)

variation

BRAKE PEDAL

Brake

model

Lining wearlimit

Minimum thickness

Drum repair limit

Maximum innerdiameter

Out-ai-round Rear

LT18C

1.5 (0.059)

181 (7.13)

0.03 (0.0012) orless

Unit: mm(in)

Applied model RHDLHD

Free height

MIT

155.0-1650 (6.10-6.50) 148.0-158.0 (5.83-6.22)

AIT

164.0-174.0 (6.46-6.85) 157.0-167.0 (6.18-6.57)

Depressed height

[under force

01

490 N(50 kg,110 Ib)with

Seebelow.

engine running]

Clearance betweenswitches andpedal stopper

0.3-1.0 (0.012 -0.039)

bracket

Depressed Height[Under forceof490 N(50

kg, 110 Ib)with engine running] PARKING

BRAKECONTROL

Applied model

MIT

AIT

RHD

75(2.95) ormore

85 (3.35) ormore Unit:

mm(in)

LHD

Brake

type Drum

Disc

Control type Center

lever

Number

01

notches

[under lorceof196 N 7

-8 8

-9

(20 kg, 44Ib)]

Number ofnotches when

1or less

warning switchcomes on

BR-88

Page 359 of 1701

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS ANDPREPARATION 2

Precautions 2

Preparation 2

CLUTCH SYSTEM-Hydraulic Type

3

CLUTCH SYSTEM-Mechanical Type 4

INSPECTION ANDADJUSTMENT

5

Adjusting ClutchPedal 5

Bleeding Procedure -Hydraulic type 5

HYDRAULIC CLUTCHCONTROL.. 6

Clutch Master Cylinder 6Operating

Cylinder 7

Clutch Damper 8

CLUTCH RELEASE MECHANiSM 9

CLUTCH DISCANDCLUTCH COVER 11

Clutch Disc 11

Clutch CoverandFlywheel 12

SERVICE DATAANDSPECIFICATIONS (SDS)13

General Specifications 13

Inspection andAdjustment 14

•

Page 360 of 1701

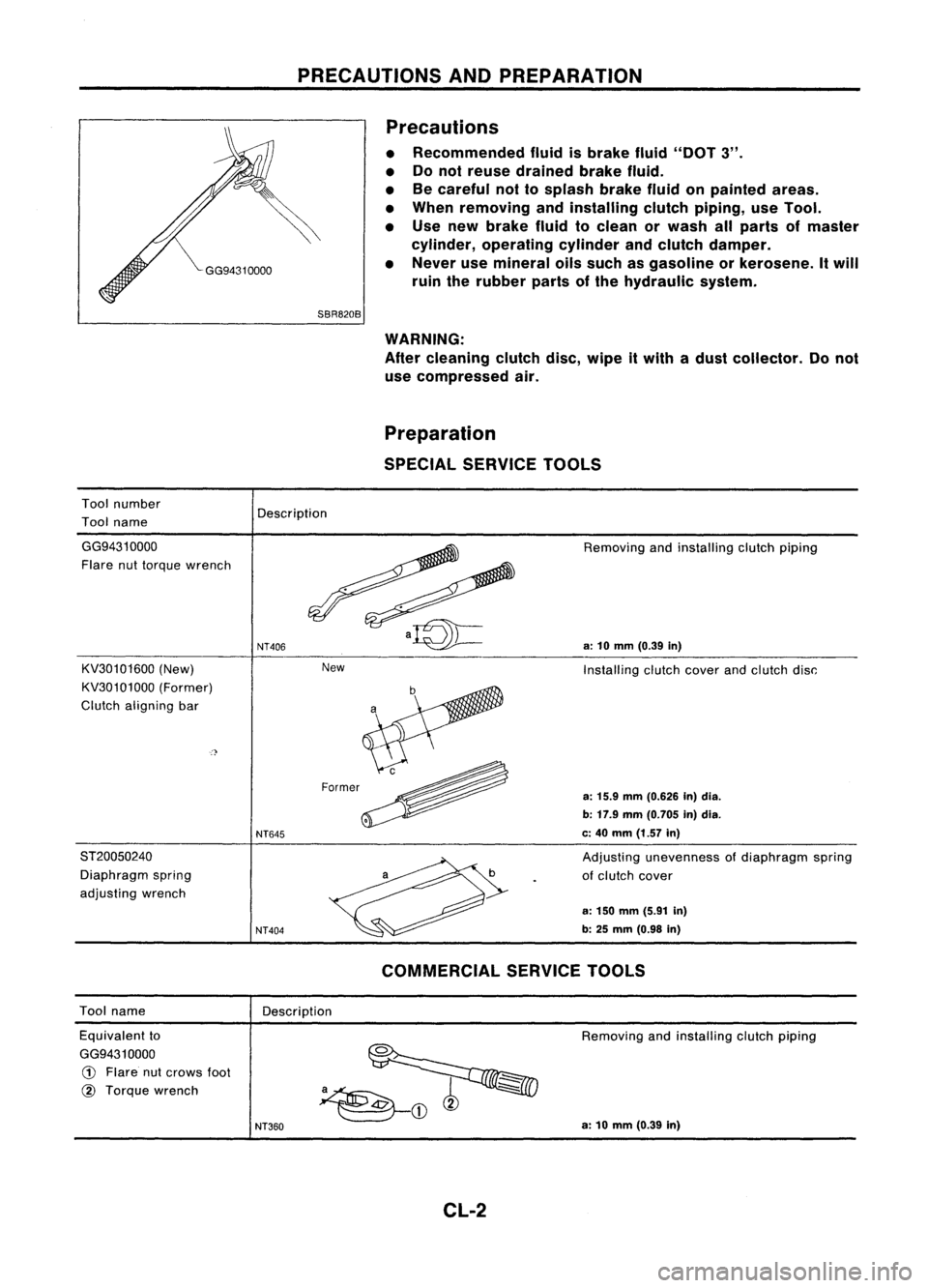

PRECAUTIONSANDPREPARATION

Precautions

• Recommended fluidisbrake fluid"DOT 3".

• Donot reuse drained brakefluid.

• Becareful nottosplash brakefluidonpainted areas.

• When removing andinstalling clutchpiping, useTool.

• Use new brake fluidtoclean orwash allparts ofmaster

cylinder, operating cylinderandclutch damper.

• Never usemineral oilssuch asgasoline orkerosene. Itwill

ruin therubber partsofthe hydraulic system.

Tool number

Tool name

SBR820B

WARNING:

After cleaning clutchdisc,wipe itwith adust collector. Donot

use compressed air.

Preparation

SPECIAL SERVICE TOOLS

Description

New

GG94310000

Flare nuttorque wrench

KV30101600 (New)

KV30101000 (Former)

Clutch aligning bar

ST20050240 Diaphragm spring

adjusting wrench

NT406

NT645

NT404

Removing

andinstalling clutchpiping

a:

10

mm

(0.39

in)

Installing clutchcoverandclutch disc:

a:

15.9

mm

(0.626 In)dia.

b: 17.9 mm(0.705 in)dia.

c: 40 mm (1.57 in)

Adjusting unevenness ofdiaphragm spring

of clutch cover

a: 150 mm (5.91 in)

b: 25

mm

(0.98

in)

Tool name

Description

COMMERCIAL

SERVICETOOLS

Equivalent to

GG9431 0000

CD

Flare nutcrows foot

@

Torque wrench

NT360

Removing

andinstalling clutchpiping

a: 10 mm (0.39 in)

CL-2